Abstract

Solid-state electric double-layer capacitors (EDLCs) based on corn starch biodegradable polymer electrolytes are fabricated. Silica is added into the corn starch polymer electrolytes to improve the ionic conductivity and capacitance of the EDLCs. The ionic conductivity as a function of temperature obeys the Arrhenius equation indicating ionic hopping mechanism in the polymer electrolytes. Linear sweep voltammetry shows that the prepared corn starch-based biopolymer electrolyte is stable in the range from −2.5 to 2.5 V. Electrical capacitance performances of these capacitors are studied by cyclic voltammetry, galvanostatic charge–discharge, and AC impedance spectroscopy. The discharge characteristics have been found to be almost linear, which confirms the capacitive behavior of the EDLC cell. The fabricated EDLC cells perform good cyclability up to 500 cycles with more than 90 % of coulombic efficiency.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodegradable materials have captured much interest in view of their applications in industrial and biomedical sectors [1, 2]. Employment of biodegradable polymers from renewable sources can reduce environmental problems and at the same time reduce the usage of synthetic polymers. The effort to promote green materials in polymer electrolytes has been widely supported by scientists worldwide. The carbonaceous material from natural resources shows good potential to be used as electrode in EDLC application as reported by Arof and co-workers [3]. Li and co-workers reported that starch-derived activated carbon electrodes showed promising results for EDLCs [4]. According to Kumar and Brat, there is a trend towards the production of degradable polymers and the use of natural polymer blends in electrochemical devices [5].

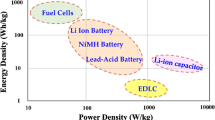

Electric double-layer capacitors (EDLCs) are assembled in this present work because of their attractive properties. EDLCs have attracted numerous interests as alternative energy storage systems compared with conventional capacitors and secondary batteries. EDLCs have been widely used because of their advantages such as large capacitance, free of maintenance, toxic-free, higher specific power, and longer cycle life compared with batteries [6–8]. In addition, EDLCs have been widely used as memory back-up devices in many fields of electric equipment. EDLCs with liquid electrolyte have many disadvantages such as being leak-prone, self-discharging, corrosive, and bulky. Therefore, solid or gel polymer electrolytes have been attracting numerous attentions as they can overcome the leakage and safety issues [9]. Therefore, fabricating solid-state EDLC using solid polymer electrolytes is an alternative approach to improve the safety performance of EDLC.

However, the ionic conductivity of polymer-salt based solid-state electrolytes is low and is not applicable in any electrochemical device. Therefore, there are several ways to enhance the ionic conductivity of polymer electrolytes such as mixed-salt system, addition of plasticizers and ionic liquids, doping of fillers, and polymer blending. The method of dispersion of fillers is selected because they can increase cationic diffusivity by altering the transport properties in polymer electrolyte, improve the physical properties of polymer electrolytes, and increase the mechanical strength of polymer electrolytes [10–12]. In addition, they enhance the thermal stability of polymer matrix, increase interfacial stability between electrode and electrolyte, and improve the long-term electrochemical stability [11, 13, 14]. Addition of filler into the polymer electrolyte results in the formation of composite polymer electrolytes.

Corn starch-based composite polymer electrolytes are prepared and studied in this present work. The effect of adding nano-sized silica (SiO2) onto biopolymer electrolytes based on corn starch and lithium perchlorate (LiClO4) is investigated in this study. Corn starch is chosen due to its low cost, renewable nature, and good mechanical properties [15]. It is a semi-crystalline polymer composing of a mixture of linear amylase and branched amylopectin polysaccharide chain [16]. Lithium perchlorate exhibits lesser electronegativity compared with other fluoro-type lithium salts. Moreover, LiClO4 is chosen due to its good conductivity and ease of complex formation in the preparation of solid polymer electrolytes [17]. The performances of the fabricated EDLC cells have been evaluated by impedance spectroscopy, linear sweep voltammetry, cyclic voltammetry, and galvanostatic charge–discharge techniques. To date, there is no literature reporting the EDLC fabrication using corn starch–LiClO4–SiO2.

Experimental

Nanocomposite polymer electrolyte preparation

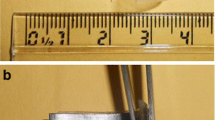

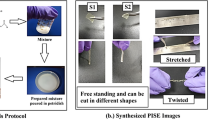

Corn starch with a linear formula of C6H10O5 was obtained from Sigma-Aldrich. Lithium perchlorate salt, LiClO4, with 99.99 % purity and less than 100 ppm total metallic purities was obtained from Aldrich. Fumed silica (SiO2) with 7 nm particle size was obtained from J.T. Baker. The nanocomposite polymer electrolyte films were prepared by solution-casting technique with distilled water as solvent [18]. The ratio of polymer to salt used is 60:40 as this is the polymer electrolyte ratio that achieved the highest ionic conductivity as reported in our published work [19]. Appropriate amounts of corn starch and LiClO4 are initially dissolved in 20 ml of distilled water. 4 wt.% of silica is then added into polymer–salt solution. The mixture was then stirred for 24 h to ensure homogeneity and complete dissolution. The mixture was cast in a Petri dish and allowed to evaporate slowly inside an oven to produce free-standing nanocomposite polymer electrolyte films. This procedure yields mechanically stable and free-standing films.

Nanocomposite polymer electrolyte characterization

Impedance measurements

The impedance of the prepared films was measured using the HIOKI 3531 Z HI-TESTER in the frequency range of 50 Hz–5 MHz from 25 °C to 70 °C. The films were sandwiched between two stainless-steel blocking electrodes. A micrometer screw gauge measured the thickness of the film. The ionic conductivity, σ, was measured using the equation below:

where l is thickness of film, R b is bulk resistance obtained from nyquist plot, and A is area of the film.

Linear sweep voltammetry

Linear sweep voltammetry (LSV) is used to determine the electrochemical stability window of the electrolyte. The CH-Instrument Model 600D electrochemical analyzer was used. The electrolytes were sandwiched between two stainless steel electrodes, and the measurements were performed from −4 to 4 V at a scan rate of 10 mVs−1.

EDLC preparation

The electrodes for EDLC were prepared by mixing a ratio of 8:1:1 of activated carbon (BP20) (purchased from SANWA Components, Inc), carbon black (Super P), poly(vinylidine fluoride) (PVdF) in N-methylpyrrolidone (NMP) solvents. The mixture was allowed to stir until homogeneous slurry was obtained. The slurry was doctor-bladed on aluminum foil current collectors. Carbon cloth electrodes are eventually produced. EDLC was then constructed by sandwiching the polymer electrolyte film between two activated carbon cloth electrodes. The constructed EDLC cells were pressed under 200 mbar pressure to ensure good contact between electrode and polymer electrolyte.

EDLC characterization

The performances of the EDLC cells were tested using cyclic voltammetry (CV) measurements, galvanostatic charge–discharge studies (GCD), and low-frequency electrochemical impedance measurements (EIS). CV was carried out using Autolab PGSTAT12 potentiostat–galvanostat from 0 to 1 V at 10 mVs−1. Galvonostatic charging–discharging tests were performed in the voltage range between 0 and 1 V at a constant current of 0.5 mA by using Neware battery cycler. Low-frequency impedance measurements were carried out using the HIOKI 3532 Z HI-TESTER in the frequency range from 10 mHz to 100 kHz at room temperature.

Results and discussion

Ionic conductivity studies

The ionic conductivity behavior was investigated by impedance spectroscopy. Table 1 shows the composition of biopolymer electrolytes in the system. Addition of 4 wt.% silica into the system increases the ionic conductivity of the biopolymer electrolyte significantly. The ionic conductivity is increased about two orders of magnitude from 1.55 × 10−6 S cm−1 to 1.23 × 10−4 S cm−1 at ambient temperature. Incorporation of silica promotes the salt dissociation and weakens the Li+/polymer bond [20]. It is believed that the charged nature of the surface of fumed silica facilitates the dissociation of aggregate ions and salt into free-moving ions. As a result, the ionic conductivity of biopolymer electrolytes is improved abruptly. Other than that, silica acts as a solid plasticizer that can soften the polymer backbone of the polysaccharide chain of the corn starch. Therefore, an increase in ionic conductivity is observed upon addition of silica. Figure 1 shows a comparative Arrhenius plot of the ionic conductivity in the temperature range between 25 °C and 70 °C. The linear variation in temperature-dependent ionic conductivity is suggestive of an Arrhenius-type thermally activated process. The theory infers that the ionic conductivity increases with increasing temperature because of ion hopping mechanism [21]. Activation energy, E a , was calculated using the slope obtained by linear fitting the curves from log σ versus 103/T graph. This is based on the Arrhenius rule as shown below:

where σ 0 is the pre-exponential factor, E a is the activation energy, k is the Boltzmann constant, and T is absolute temperature. The calculated activation energy for Si-0 and Si-4 is 0.64 and 0.25 eV, respectively. The higher activation energy value signifies more energy is required to promote the dissociation of Li+/polymer bond in silica-free sample.

LSV results

Linear sweep voltammetry is carried out to show the electrochemical stability window of the corn starch-based biopolymer electrolytes. The electrochemical stability window is used to determine the working voltage of EDLC. Figure 2 portrays the LSV responses of Si-0 and Si-4. From the voltammogram shown in Fig. 2, the stability window was −2.5 and 2.5 V for both Si-0 and Si-4 as observed in anodic and cathodic cycles, respectively. It can be observed that there are no appreciable current flows in the biopolymer electrolytes in the range of −2.5 to 2.5 V. Thus, both these biopolymer electrolytes are stable up to 2.5 V for EDLC cell analysis.

Performance studies of EDLCs

The capacitance of the assembled EDLCs is determined by

-

1.

Cyclic voltammetry (CV)

-

2.

Galvanostatic charge-discharge (CGD)

-

3.

EIS at low frequency

The results obtained from these three studies are tabulated and compared in Table 2. Figure 3 depicts the cyclic voltammograms for the capacitors with Si-0 and Si-4 and room temperature. The observed behavior approaches a rectangular shape where no redox peaks are observed. This can be attributed to the formation of a homogenous and ideally polarizable double layer formed at the interface [22]. The slow scan rate voltammograms exhibited almost perfect horizontal plateau indicating ion diffusion occurs at a fairly constant rate with minor impact from ohmic resistance [23]. The CV curves discrepancy from a box-like shape is assigned to the internal resistance and carbon porosity, which produces a current dependence of potential [24, 25]. The specific capacitance of single electrode in EDLC is calculated according to equation below [3]:

where C sp is specific capacitance (farads), i is average current (amps), s is scan rate (volts per second), and m is the weight (grams) of electrode. Si-4 depicts higher current peak compared with Si-0, which eventually shows higher calculated capacitance value as in Fig. 3. The specific capacitance of EDLC containing silica-free polymer electrolyte is 5.42 Fg−1. The specific capacitance of EDLC consisting of silica-based polymer electrolyte is increased about 61 % to 8.71 Fg−1. The increase in specific capacitance is because of higher ionic conductivity of silica-doped polymer electrolyte. Silica can promote the ion dissociation and soften the polymer backbone as aforementioned in ionic conductivity studies. Therefore, more mobile ions can be transported from electrolyte towards electrode with high ionic mobility.

The charge–discharge characteristics of the EDLC cells are evaluated galvanostatically. Figure 4 shows the charge–discharge profile of EDLC cells containing Si-0 and Si-4 at constant current of 0.5 mA in the range of 0 and 1 V. The discharge characteristics have been found to be almost linear, which confirms the capacitive behavior of the EDLC cell. The initial jump/drop in the voltage while charging and discharging each cell has been observed, which is due to ohmic resistance (R t), referred to as equivalent series resistance (ESR) of the cells. ESR of EDLC can be calculated from the voltage drop or IR drop during the discharging process as shown by the equation:

Here, IR drop is the voltage drop upon discharge while i is the discharge current.

The time required for charge or discharge for the two capacitors was nearly identical. This reflects similar ultimate charge-storage capacities. The capacitance of an EDLC cell is deduced from the discharge curve using the equation below [26]:

where C sp is the specific capacitance of cell (farads per gram), I is the applied current (amps), m is the average mass of electrode materials (including the binder and carbon black), dV represents the potential change of a discharging process excluding the internal resistance drop occurring at the beginning of the cell discharge, and dt is the time interval of discharging process. The dV/dt is determined from the slope of the discharge curve. The energy stored in a capacitor is calculated as follows [27]:

where C is the specific capacitance and V is the working voltage. The power density (P) is calculated as below:

where V is the working voltage and ESR is equivalent series resistance. Calculated results are presented in Table 2. Si-0-based EDLC illustrates specific capacitance of 7.09 Fg−1, energy density of 0.668 W h kg−1 and power density of 106.9 W kg−1. On the other hand, EDLC based on Si-4 depicts specific capacitance of 9.83 Fg−1, energy density of 0.902 W h kg−1 and power density of 135 W kg−1. EDLC containing Si-4 shows higher specific capacitance, energy density, and power density obtained from charge–discharge test compared to that of Si-0. EDLC containing the nano-sized SiO2-added polymer electrolyte has higher capacitance, energy density, and power density mainly due to the higher ionic conductivity of the nanocomposite polymer electrolyte in comparison to SiO2-free polymer electrolyte. The ion adsorption at the electrode–electrolyte interface is favorable in the nanocomposite polymer electrolyte.

Long cycling test is performed to evaluate cycle durability. Here, we summarize the dependence of coulombic efficiency on cycle number. Coulombic efficiency (η) is calculated as below [28]:

where t d and t c are the times for discharging and charging of EDLC in each cycle, respectively. Figure 5 indicates the model cells containing Si-0 and Si-4. Both cells maintain their coulombic efficiency at ~90 % throughout 500 cycles because of good interfacial contacts between electrode and both electrolytes. We suggest that the EDLC cells are stable under these charge–discharge conditions as the cells show reduced voltage drops in the first 100 cycles and then maintain its stability up to 500 cycles.

Complex impedance spectra for both fabricated Si-0- and Si-4-based EDLC cells are shown in Fig. 6. Impedance spectroscopy enables the evaluation of various parameters associated with the bulk properties of electrolytes and electrode–electrolyte interactions. The Nyquist plots of the impedance spectra analyses show a semicircle nature at high-frequency region (100 kHz–1 Hz) and a line inclined to the real axis in the low-frequency region (1 Hz–10 mHz). The specific capacitance for EDLCs from impedance spectra can be calculated by using the following relationship [28]:

where Z″ is the imaginary impedance (Ω) and f is the frequency (hertz). The specific capacitance of EDLC-based Si-4 polymer electrolyte is expected to be higher than Si-0 polymer electrolyte. The specific capacitance obtained from EIS for EDLC comprising Si-0 and Si-4 are 5.59 and 9.88 Fg−1, respectively. The results obtained from this study are comparable with the findings in CV and GCD studies.

The linearly rising pattern (or spike) in the impedance plot reveals the ion adsorption at the electrode–electrolyte boundary and hence indicates the capacitive behavior of EDLC. This linear steep rising curve with the phase angle of ~45° indicates the presence of Warburg impedance (W o) in the equivalent circuit as shown in Fig. 6. The Warburg resistance is related to the ion diffusion into the porous carbon. This linearly rising pattern denotes the ion adsorption at the surface between carbon-based electrode and polymer electrolyte and leads to the electrical double layer formation. This pattern further proves the capacitive behavior of the EDLC represented by the constant phase element of capacitor (CPE) in the Randles equivalent circuit. The spike is then followed by a semicircle in the high frequency range that reflects the bulk properties of the electrolytes and the charge transfer process at the electrode–electrolyte interface of the newly assembled EDLC. Bulk resistance, R b, and charge transfer resistance, R ct, can be determined by plotting a locus of the semicircle intercepting the real axis at R s and R s + R ct in the Nyquist plot. We found that the impedance plots do not start at the origin point. This phenomenon is suggestive of the presence of a bulk resistance (R b ) as displayed in the equivalent circuit of the cell. This resistance originates from the bulk resistance of polymer electrolyte, series resistance (R s ) of connector, and internal resistance of electrode (R i ) for the ion diffusion as well as ohmic loss of the cell. The semicircle consists of a capacitor and a resistor in parallel form as depicted in the equivalent circuit. The capacitor is represented by the capacitance of double layer (C dl ). The C dl comes from the formation of electrical double layer at electrode–electrolyte due to the ion accumulation between electrode and electrolyte when the ions are diffused in the electrolyte and adsorbed into the porous carbon electrode. The resistance is known as charge transfer resistance (R ct ) of ion transport from electrolyte to the porous carbon, which is one of the bulk behaviors of electrode–electrolyte interface to form the ion adsorption (Wang et al. 2014). This resistance of ion diffusion is the minimum energy required to form the electrical double layer at the electrode–electrolyte boundary. The mobile charge carriers must overcome this resistance in order to perform the ion diffusion and accumulation onto the pores of the carbon electrode. The values of R b and R ct for both cells are summarized in Table 3. Si-4 shows lower value of R b and R ct compared with Si-0. Therefore, we imply that addition of silica can decrease both resistances of the devices. As a result, the capacitance of the EDLC containing Si-4 is higher than that of Si-0.

Shukur and co-workers also use corn starch-based biopolymer electrolytes to prepare EDLC. Higher specific capacitance of 33 Fg−1 was observed because the corn starch-based polymer electrolyte is plasticized by glycerol [29]. A similar observation is also obtained in our published work using corn starch-based polymer electrolytes which are embedded with ionic liquids [30]. The ionic liquid-added polymer electrolyte-based EDLCs portray the specific capacitance of 36–43 Fg−1 in this study. Plasticization and addition of ionic liquids on the polymer electrolyte could produce sticky behavior of the polymer electrolytes. Therefore, the interfacial contact between electrode and electrolyte is excellent in both works. Hence, higher capacitance is observed in these two studies compared with the present work which has poor contact at the electrode–electrolyte boundary. Although the specific capacitance obtained in this work is much lower than other existing biopolymer electrolytes, it exhibits higher capacitance than studies using non-biodegradable polymer as host polymer. EDLC fabricated using ionic liquid–based poly(ethylene oxide) polymer electrolytes and multi-walled carbon nanotubes electrodes shows specific capacitance of 2.6–3 Fg−1 which is almost two times lower than our current work [31].

Conclusion

Solid-state polymeric capacitors were successfully assembled using corn starch–LiClO4–SiO2 as biodegradable polymer electrolyte. Addition of silica into the system improves the ionic conductivity of polymer electrolytes and capacitance of EDLC. Capacitance of the EDLC device is dependent on the ionic conductivity of the polymer electrolyte and all the resistances of the cell. High ionic conductivity of polymer electrolyte and low internal resistances of the EDLC enhance the capacity of the cell. LSV confirms that the biopolymer electrolyte prepared is stable in the range from −2.5 to 2.5 V. The EDLC cells with Si-0 and Si-4 exhibit a specific capacitance calculated from different methods in the range of 5.4 to 7.1 and 8.7 to 9.9 F g−1, respectively. The experimental data also indicate that the EDLC prepared has rather stable and good cycle-life characteristics up to 500 cycles. In view of that, it can be concluded that biodegradable polymer electrolyte is a promising material for solid-state capacitors.

References

Tian HY, Tang ZH, Zhuang XL, Chen XS, Jing XB (2012) Prog Polym Sci 37:237

Vroman I, Tighzert L (2009) Materials 2:307

Arof AK, Kufian MZ, Syukur MF, Aziz MF, Abdelrahman AE, Majid SR (2012) Electrochim Acta 74:39

Li Q-Y, Wang H-Q, Dai Q-F, Yang J-H, Zhong Y-L (2008) Solid State Ionics 179:269

Kumar MS, Bhat DK (2009) Phys B 404:11143

Burke A (2000) J Power Sources 91:37

Kotz R, Carlen M (2000) Electrochim Acta 45:2483

Yukari K, Takash S, Mitsuyoshi K, Junji T, Atsushi O (1996) J Power Sources 60:219

Stephen AM (2006) Eur Polym J 42:21

Samir MASA, Alloin F, Sanchez J–Y, Dufresne A (2005) Polímeros-Ciênc Tecnol 15:109

Krawiec W, Scanlon LG Jr, Fellner JP, Vaia RA, Vasudevan S, Giannelis EP (1995) J Power Sources 54:310

Hammami R, Ahamed Z, Charradi K, Beji Z, Assaker IB, Naceur JB, Auvity B, Squadrito G, Chtourou R (2013) Int J Hydrogen Energy 38:11583

Kim KM, Park N–G, Ryu KS, Chang KS (2002) Polym 43:3951

Jian–hua T, Peng–fei G, Zhi–yuan Z, Wen–hui L, Zhong–qiang S (2008) Int J Hydrogen Energy 33:5686

Xu XY, Kim KM, Hana MA, Nag D (2005) Ind Crop Prod 21:185

Pawlicka A, Sabadini AC, Raphael E, Dragunski DC (2008) Mol Cryst Liq Cryst 485:56

Yeow ML, Liu Y, Li K (2005) J Membrane Sci 258:16

Teoh KH, Ramesh S, Arof AK (2012) J Solid State Electrochem 16:3165

Teoh KH, Lim C-S, Ramesh S (2014) Measurement 48:87

Wang X-L, Fan L-Z, Xu Z-H, Lin Y-H, Nan C-W (2008) Solid State Ionics 179:1310

Gray FM (1997) Polymer Electrolytes. Royal Society of Chemistry, Cambridge, UK

Ganesh B, Kalpana D, Renganathan NG (2008) Ionics 14:339

Tien C-P, Liang W-J, Kuo P-L, Teng H-S (2008) Electrochim Acta 53:4505

Niu JJ, Pell WG, Brian E (2006) J Power Sources 156:725

Frackowiak E, Béguin F (2001) Carbon 39:937

Amitha FE, Reddy ALM, Ramaprabhu S (2009) J Nanoparticle Res 11:725

Yu H, Wu J, Fan L, Lin Y, Xu K, Tang Z, Cheng C, Tang S, Lin J, Huang M, Lan Z (2012) J Power Sources 198:402

Mitra S, Shukla AK, Sampath S (2001) J Power Sources 101:213

Shukur MF, Ithnin R, Kadir MFZ (2014) Electrochim Acta 136:204

Liew C-W, Ramesh S (2014) Mater 7:4019

Pandey GP, Kumar Y, Hashmi SA (2011) Solid State Ionics 190:93–98

Acknowledgments

This work was supported by the Fundamental Research Grant Scheme (FRGS) from Ministry of Higher Education, Malaysia (FP024-2013A), and University Malaya Research Grant (UMRG: RG276-14AFR and RP025A-14AFR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teoh, K.H., Lim, CS., Liew, CW. et al. Electric double-layer capacitors with corn starch-based biopolymer electrolytes incorporating silica as filler. Ionics 21, 2061–2068 (2015). https://doi.org/10.1007/s11581-014-1359-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-014-1359-x