Abstract

Polymer electrolyte membranes, comprising of poly(methyl methacrylate) (PMMA), lithium tetraborate (Li2B4O7) as salt and dibutyl phthalate (DBP) as plasticizer were prepared using a solution casting method. The incorporation of DBP enhanced the ionic conductivity of the polymer electrolyte. The polymer electrolyte containing 70 wt.% of poly(methyl methacrylate)–lithium tetraborate and 30 wt.% of DBP presents the highest ionic conductivity of 1.58 × 10−7 S/cm. The temperature dependence of ionic conductivity study showed that these polymer electrolytes obey Vogel–Tamman–Fulcher (VTF) type behaviour. Thermogravimetric analysis (TGA) was employed to analyse the thermal stability of the polymer electrolytes. Fourier transform infrared (FTIR) studies confirmed the complexation between poly(methyl methacrylate), lithium tetraborate and DBP.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Interest in polymer electrolytes has been sustained since the development of complexes of alkali metal ions with poly(ethylene oxide) (PEO) by Fenton et al. [1]. Solid polymer electrolytes have been extensively studied for applications in high-energy density batteries, gas sensors, electrochemical devices, electrochromic displays, fuel cells, supercapacitors, etc. A polymer electrolyte can be used as both electrolyte and the separator between the electrodes in solid state rechargeable lithium batteries [2–5].

Polymer electrolytes must fulfill numerous requirements such as ionic conductivity, electrochemical stability, compatibility, thermal stability, mechanical stability and availability in order to function as both a separator and electrolyte [6]. The main aim of most research is focused on the enhancement of ionic conductivity. Various investigations have been performed, by blending of polymers, cross-linking, insertion of ceramic fillers and plasticization in order to enhance the ionic conductivity [7–10]. Plasticization was an effective way to improve the ionic conductivity [11]. In order for a plasticizer to enhance ionic conductivity, high dielectric constant to dissociate ions and low viscosity to facilitate the ion transport are essential. Examples of plasticizers that exhibit these properties are dibuthyl phthalate (DBP), propylene carbonate (PC), ethylene carbonate (EC) and diocthyl adipate (DOA) [12].

The crystallinity of PMMA is low compared with other polymers like PEO and PVC. In addition, PMMA-based polymer electrolytes have better interfacial properties towards the lithium electrodes [13]. Pure PMMA is an insulator with a conductivity range from 10−10 to 10−12 S/cm. Adding plasticizers to PMMA will affect the overall ionic conductivity through crystalline complex formation, intramolecular cross-linking of the polymer chains and the degree of salt dissociation [14–16].

In this study, plasticized polymer electrolytes composed of PMMA as the host polymer, Li2B4O7 as the salt and DBP, as the plasticizer were prepared. The high molecular weight polymer and the range of plasticizer concentrations were selected to produce a polymer–salt–plasticizer system. The conductivity of polymer salt complexes exhibits a maximum at a given concentration, which depends on several factors. Among the most discussed factors is the effect on simultaneously increasing the plasticizer concentration on the conductivity and reduced mobility of the ions in the amorphous phase [17]. The properties and characteristics of the polymer complexes are studied by Fourier transform infrared (FTIR), Impedance spectroscopy and thermogravimetric analysis (TGA).

Experimental

PMMA with an average molecular weight of 35,000, was obtained from Acros Organic, lithium tetraborate (Li2B4O7), dibutyl phthalate (DBP) was obtained from Aldrich and tetrahyrofuran (THF) was obtained from J.T. Baker.

Prior to the preparation of the polymer electrolytes, Li2B4O7 was dried at 120 °C for 24 h to eliminate any trace amounts of water in the material. Different ratio compositions of polymer thin film were prepared by solution casting method. The designations of polymer electrolytes are as listed in Table 1. The PMMA, Li2B4O7 and DBP were dissolved in THF and stirred for 24 h to make a homogeneous solution. The solution was cast in a Petri dish and allowed to evaporate slowly inside a dessicator. This procedure yields free standing and mechanically stable films. The thickness of the films was then measured with a micrometer screw gauge.

FTIR studies were carried out using Perkin-Elmer FTIR Spectrophotometer Spectrum RX1. It was recorded in the range of 4,000 and 400 cm−1, with a resolution of 4 cm−1. Two stainless steel electrodes with a surface area of 2.50 cm2 were used for conductivity measurements. A thin layer of a sample film was inserted between them. A HIOKI 3532-50 LCR Hi-Tester was used for impedance spectra measurements between the frequency ranges of 50 Hz and 1 MHz. The conductivity dependent temperature was obtained at temperature range of 303–373 K. Thermal stability of polymer films was determined by using a Mettler Toledo analyzer that consisted of TGA/SDTA851e main unit and STARe software. The temperature profile carried out was in the range of 30–400 °C with a 10 °C/min heating rate. Inert nitrogen gas was used in the analysis with a rate of 10 ml/min.

Results and discussion

Impedance studies

Conductivity studies

The graph of logarithmic conductivity against various percentage of plasticizer content is shown in Fig. 1. The conductivity of PMMA–Li2B4O7 solid polymer electrolyte is found to increase as DBP is added until a conductivity of 1.58 × 10−7 S cm−1 is obtained at 30 wt.% DBP. This is the highest conductivity achieved. Further addition of DBP reduces the conductivity.

The ionic conductivity enhancement of the plasticized polymer electrolyte is explained as follows: a fraction of Li+ ions detaches itself from the PMMA and attaches to DBP which results in the weakening of the dipole–ion interaction. This structural change in the electrolyte causes a substantial decoupling of the Li+ motion from that of the polymer chain. These electrolytes are believed to have structures in which the lithium salt is complexed to both the polymer, through its electron donor group, and the plasticizer solvent [18].

The ionic conductivity value depends upon the viscosity value of the plasticizer used. The low viscosity of DBP (η = 16.45 cP) causes a greater mobility to the ions. The mobility of the system increases with the increase in plasticizer content, which in turn increases the conductivity of the polymer electrolyte. However, the conductivity values were found to decrease after SPE7. This phenomenon was due to the formation of linkages between the plasticizer itself, thus causing it to crystallize, resulting in the decrease in conductivity [19–21].

Conductivity–frequency dependence

The conductivity of the PMMA–Li2B4O7–DBP salt polymer electrolytes was analysed with respect to the frequency. The logarithmic conductivity against logarithmic frequency for SPE7 between 303 K and 373 K is shown in Fig. 2. The figure shows that the conductivity of the samples increase with increasing frequency and temperature. The low frequency dispersion may be due to the interfacial impedance or space charge polarization [22]. As the frequency decreases, more and more charge accumulation occurs at the electrode and electrolyte interface, which leads to a decrease in the number of mobile ions and eventually to a drop in conductivity at low frequency. In the high frequency region, the mobility of charge carriers is high and hence the conductivity increases with frequency [7].

Temperature-dependent conductivity studies

The temperature dependent conductivity of SPE7 was investigated at the temperature range of 303–373 K. The conductivity of the plasticized polymer electrolyte increased gradually with temperature due to the increase of ionic mobility in the polymer electrolyte as shown in Fig. 3. This is because when the temperature increases, small spaces are created by pushing the polymer segment against the hydrostatic pressure applied by the neighboring atoms as the result of vibrational energy. Hence, free volume is produced and enables the ions, solvated molecules, or polymer segments to move through the resulting conductivity. The overall mobility of ion and polymer is influenced by the free volume around the polymer chain. Thus, increase in free volume due to the increase in temperature causes the increase in conductivity since it also increases the ion mobility and segmental mobility [7].

When the ion transport is dominated by the mobility of the solvent molecules the conductivity will correlate with Vogel–Tamman–Fulcher (VTF) equation:

where A is the pre-exponential factor, B is the pseudo-activation energy for conduction, k is the Boltzmann constant and T 0 is the equilibrium glass transition. The temperature-dependent conductivity can be fitted with VTF equation very well as shown in Fig. 3. The VTF equation describes transport properties in a viscous matrix. It suggests that the ion moves through the plasticizer-rich phase [23]. In conclusion, the increase in temperature will affect the ion mobility and segmental mobility in the system. This assists ion transport and virtually compensates for the retarding effect of the ion cloud and causes a higher conductivity [24].

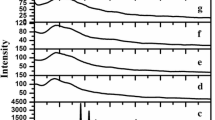

TGA analysis

The significant weight loss which begins at temperature above 100 °C is due to crystallization [25] (Fig. 4). The second weight loss is caused by the decomposition of the polymer electrolyte. The first and second decomposition temperature and the weight loss at the first decomposition temperature for SPE3, SPE5, SPE7 and SPE9 are listed in Table 2.

The results indicate that as plasticizer content increases, the weight loss at first decomposition temperature of the polymer films also increases. The stability of the polymer films with higher plasticizer content decreases due to the decline of T g. This, as a result, softens the polymer backbone and causes increase in its segmental motion which allows easier flow for ions through the material when there is an applied electric field [26, 27]. High thermal stability of the polymer films will restrict the movement of ions, hence when plasticizer content of the polymer films increases, the thermal stability of the polymer films decreases.

From TGA analyses, the least stable polymer film is found to be SPE7 with a weight loss at first decomposition of 48.31%. The ionic conductivity is maximum for SPE7 as evident from the fact that in the least stable polymer film, there is no restriction for ion movement, hence giving rise to high ionic conductivity [24].

FTIR studies

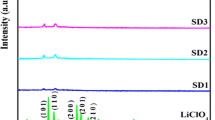

FTIR spectroscopy is a powerful tool for identifying the nature bonding and different functional groups present in a sample by monitoring the vibrational energy levels of molecules, which are essentially the fingerprint of different molecules [28]. The FTIR spectra of pure PMMA, lithium tetraborate (Li2B4O7) and DBP are shown in Fig. 5a, b and c, respectively.

From FTIR spectra in Fig. 5a, C–H stretching mode can be observed at 2,988 cm−1, C=O asymmetric stretching mode at 1,736 cm−1, and CH3 stretching mode at 1,462 and 1,077 cm−1 are assigned to O–CH3 stretching vibrations in pure PMMA [29]. Figure 5b shows that the absorption peaks at 1,376 and 1,246 cm−1 are allocated to B–O (B) stretching vibration of BO3 triangle in Li2B4O7. The absorption peaks at 1,116, 1,030, 898, 819 and 706 cm−1 are given to B–O (B) stretching vibration of BO4 tetrahedral and the absorption peaks at 651, 565, 503 and 447 cm−1 are assigned to O-B-O deforming vibration of BO4 tetrahedral in Li2B4O7 [29]. Figure 5c illustrates the spectrum of DBP. C–H stretching mode can be observed at 2,946 and 2879 cm−1, C=O asymmetric stretching mode at 1730 cm−1, C=C stretching mode at 1600 cm−1, CH3 stretching mode at 1,462, 1,121 and 1,067 cm−1 are assigned to O–CH3 stretching vibrations in pure DBP.

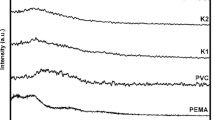

Complexation may shift the polymer cage peak frequencies. FTIR would be sensitive both in situations where complexation has occurred in crystalline or amorphous phase [30]. The characteristic peaks of pure PMMA at 2,988, 1,736 and 1,077 cm−1 are shifted to 2,980, 1,734 and 1,076 cm−1 for SPE1, 2,974, 1,732 and 1,068 cm−1 for SPE5 and 2,974, 1,734 and 1,068 cm−1 for SPE7, respectively, in Fig. 6. The cause of these peaks shifting is due to the complexation occurring between PMMA and Li2B4O7.

In addition, some new peaks at 2,201 and 1,967 cm−1 are also observed which are not present in the pure PMMA and Li2B4O7 spectrum. The changes in position of some PMMA-related peaks along with the appearance of some new peaks show that complexation had taken place [28].

The FTIR spectra of the samples containing DBP (SPE5 and SPE7) in the polymer–salt complexes are similar to that of the unplasticized polymer–salt complexes (SPE1). However, the C=O bands in DBP (1,730 cm−1) seem to have overlapped and broadened. The broadening of the C=O band in the plasticized polymer salt complexes indicated that the plasticizer just interacts physically with the polymer and salt. No chemical reaction occurred between the plasticizer and polymer or between the plasticizer and the salt [28].

Conclusion

The composition and temperature dependence of conductivity and electrical relaxation behaviour of the films have been examined. The highest conducting sample was SPE7 with a conductivity of 1.58 × 10−7 Scm−1. The plasticizer acts as a conductivity enhancer by reducing the T g of the polymer complexes and increasing the segmental motion of the polymer chain. Temperature dependence studies indicate that the ion conduction follows the VTF rule in which the ion transport in polymer electrolytes is correlated with polymer segmental motion. In addition, FTIR studies confirm the interaction between pure PMMA, Li2B4O7 and DBP. TGA studies showed that sample SPE7 is the most unstable polymer film with a weight loss of 48.31%. The stability of the polymer films will influence the conductivity of the polymer films by affecting the movement of ions.

References

Fenton DE, Parker JM, Wright PV (1973) Complexes of alkali metal ions with poly(ethylene oxide). Polymer 14:589

Armand MB, Chabagano JM, Duclot M (1979) In: Vashista P, Mundy JN, Shenoy GK (eds) Fast ion transport in solids. North-Holland, Amsterdam, p 131

Ramesh S, Yuen TF, Shen CJ (2008) Conductivity and FTIR studies on PEO–LiX [X: CF3SO3 −, SO4 2−] polymer electrolytes. Spectrochim Acta Part A 69:670–675

Ramesh S, Chai MF (2007) Conductivity, dielectric behavior and FTIR studies of high molecular weight poly(vinylchloride)–lithium triflate polymer electrolytes. Mater Sci Eng B 139:240–245

Ramesh S, Tan W, Arof AK (2007) Investigation of mechanical properties of polyvinyl chloride–polyethylene oxide (PVC–PEO) based polymer electrolytes for lithium polymer cells. Eur Polym J 43:1963–1968

Gray FM (1997) Polymer electrolytes. The Royal Society of Chemistry, Cambridge

Rajendran S, Sivakumar M, Subadevi R (2004) Investigations on the effect of various plasticizers in PVA-PMMA solid polymer blend electrolytes. Mater Lett 58:641–649

Xiao Q, Wang X, Li W, Li Z, Zhang T, Zhang H (2009) Macroporous polymer electrolytes based on PVDF/PEO-b-PMMA block copolymer blends for rechargeable lithium ion battery. J Membr Sci 334:117–122

Krejza O, Velicka J, Sedlarikova M, Vondrak J (2008) The presence of nanostructured Al2O3 in PMMA-based gel electrolytes. J Power Sources 178:774–778

Ramesh S, Arof AK (2009) A study incorporating nano-sized silica into PVC blend based polymer electrolytes for lithium batteries. J Mater Sci 44:6404–6407

Ramesh L, Yi J (2009) Structural, thermal and conductivity studies of high molecular weight poly(vinylchloride)-lithium triflate polymer electrolyte plasticized by dibutyl phthalate. Ionics 15:725–730

Weili L, Yuan M, Yang M (2006) Dual-phase polymer electrolyte with enhanced phase compatibility based on Poly(MMA-g-PVC)/PMMA. Eur Polym J 42:1396–1402

Appetecchi GB, Croce F, Scrosati B (1995) Kinetics and stability of the lithium electrode in poly(methylmethacrylate)-based gel electrolytes. Electrochim Acta 40:991–997

Pitawala HMJC, Dissanayake MAKL, Seneviratne VA (2007) Combined effect of Al2O3 nano-fillers and EC plasticizer on ionic conductivity enhancement in the solid polymer electrolyte (PEO)9LiTf. Solid State Ionics 178:885–888

Sekhon SS, Agnihotry SA, Pradeep P (1999) PMMA based gel electrolyte for EC smart windows. Electrochim Acta 44:3121–3122

Rhoo HJ, Kim HT, Park JK, Hwang TS (1997) Ionic conduction in plasticized PVC/PMMA blend polymer electrolytes. Electrochim Acta 42:1571–1579

Ali AMM, Mohamed NS, Arof AK (1998) Polyethylene oxide (PEO)–ammonium sulfate ((NH4)2SO4) complexes and electrochemical cell performance. J Power Sources 74:135–141

Abraham KM, Alamgir M (1994) Room temperature polymer electrolytes and batteries based on them. Solid State Ionics 70/71:20–26

Gorecki M, Andreani R, Berthier C, Armand MB, Mali M, Roos J, Brinkmann D (1986) NMR, DSC, and conductivity study of a poly(ethylene oxide) complex electrolyte: PEO(LiClO4)x. Solid State Ionics 18:295–299

Ali AMM, Yahya MZA, Bahron H, Subban RHY, Harun MK, Atan I (2007) Impedance studies on plasticized PMMA-LiX [X: CF3SO3 −, N(CF3SO2)2−] polymer electrolytes. Mater Lett 61:2026–2029

Cha EH, Macfarlane DR, Forsyth M, Lee CW (2004) Ionic conductivity studies of polymeric electrolytes containing lithium salt with plasticizer. Electrochim Acta 50:335–338

Gogulamurali N, Suthanthiraraj SA, Maruthamuthu P (1992) In: Chowdari BVR, Chandra S, Singh S, Srivastava PC (eds) Solid state ionics materials and applications. World Scientific, Singapore, p 373

Uma T, Mahalingam T, Stimming U (2003) Mixed phase solid polymer electrolytes based on poly(methylmethacrylate) systems. Mater Chem Phys 82:478–483

Uma T, Mahalingam T, Stimming U (2005) Solid polymer electrolytes based on poly(vinylchloride)–lithium sulfate. Mater Chem Phys 90:239–244

Ramesh S, Arof AK (2001) Structural, thermal and electrochemical cell characteristics of poly (vinyl chloride) based polymer electrolytes. J Power Sources 99:41–47

Qian X, Gu N, Cheng Z, Yang X, Wang E, Dong S (2002) Plasticizer effect on the ionic conductivity of PEO-based polymer electrolyte. Mater Chem Phys 74:98–103

Stephan AM, Kumar SG, Renganathan NG, Kulandainathan MA (2005) Characterization of poly(vinylidene fluoride–hexafluoropropylene) (PVdF–HFP) electrolytes complexed with different lithium salts. Eur Polym J 41:15–21

Ramesh S, Leen KH, Kumutha K, Arof AK (2007) FTIR studies of PVC/PMMA blend based polymer electrolytes. Spectrochim Acta Part A 66:1237–1242

Farmer VC (1974) The infrared spectra of minerals. Mineralogical Society, London

Rajendran S, Uma T (2000) Effect of ZrO2 on conductivity of PVC–LiBF4–DBP polymer electrolytes. Mater Lett 44:208–214

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramesh, S., Chao, L.Z. Investigation of dibutyl phthalate as plasticizer on poly(methyl methacrylate)–lithium tetraborate based polymer electrolytes. Ionics 17, 29–34 (2011). https://doi.org/10.1007/s11581-010-0481-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-010-0481-7