Abstract

Electrochemical impedance spectroscopy (EIS) was employed to study electrochemical behaviors during Li-ion insertion into rice husk carbon. The impedance spectra consist of two depressed semicircles in the high and middle range frequency and an incline line at low frequency. The impedance spectra, obtained in the potential range 2.0 to 0.005 V were analyzed with an equivalent circuit model. Kinetic parameters such as the charge-transfer resistance and surface film resistance were evaluated and discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of lithium-ion batteries are based on intercalation and de-intercalation of lithium ion into and from host materials [1–4], which is one of the most important areas of modern electrochemistry. Graphitized carbons including natural graphite have been extensively studied for use as anode material for lithium-ion batteries [5–7]. The intense search for alternative anode materials capable of intercalating larger amounts of lithium has led to the synthesis of many unique disordered carbon materials. A variety of mineral, agricultural, and polymeric sources were employed for preparing new and improved disordered carbon materials [4, 8, 9]. Disordered carbon derived from rice husk, a major by-product in the rice milling industry, was reported as a potential carbon anode material for lithium-ion batteries [10].

The characteristics of lithium intercalation into carbon anodes can be greatly affected by the kinetics of intercalation. The electrochemical kinetics for carbons as the anode is essential to help further improve the high rate charge–discharge performance of secondary lithium ion batteries. Kinetic studies on the lithium intercalation reaction have been carried out using several electrochemical techniques [11] such as the potentiostatic intermittent titration technique (PITT), the galvanostatic intermittent titration technique (GITT), cyclic voltammetry (CV), and electrochemical impedance spectroscopy (EIS). Among the various techniques above, EIS is a powerful tool to analyze electrochemical Li+ intercalation into carbonaceous materials.

The ion insertion mechanism involves a series of complex phenomena including Li+ ion diffusion in the electrolyte, migration through the carbon electrode passivation film, charge transfer at the carbon surface, and diffusion in the carbon host. EIS is a powerful technique that allows us to separate most of these phenomena due to differences in their time constant. In this work, we present electrochemical lithium intercalation into rice husk carbon studied by EIS. The spectra obtained were analyzed using an equivalent circuit, and the variations of electrochemical parameters with electrode potential, such as the charge-transfer resistance and the surface layer resistance, were evaluated and discussed.

Experimental

The detail preparation procedure of rice husk carbon was reported in a previous paper [9]. The electrode was prepared by spreading a mixture of rice husk carbon and ethylene propylene diene monomer (EPDM) in cyclohexane onto copper foil and dried in oven overnight at 100 °C. The electrolyte 1 M LiPF6 in ethylene carbonate (EC) + dimethyl carbonate (DMC) (1:1 in volume, lithium battery grade) was used as received from Mitsubishi Chemical. A Li foil of 1 cm2 served both as the reference and the counter electrodes.

Electrochemical impedance measurement was performed using a Solartron SI 1260 impedance/gain phase analyzer coupled with Solartron SI 1287 electrochemical interface. Impedance spectra were potentiostatically measured by applying an AC voltage of 10 mV amplitude over the frequency range 100 kHz to 1 mHz after the electrode has attained an equilibrium at each potential. Cell impedance was potentiostatically measured after the cell had been cycled to a potential at 0.01 mA/cm2. The impedance data obtained were analyzed and simulated with equivalent circuit using Zview™ program (Scribner)

Results and discussion

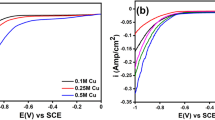

The impedance of Li/carbon cells consists of the impedance of electrolyte, electrode, and passive film formed on the electrodes. Cells were stored for 24 h at open circuit (OCV) to stabilize the passive film growth on the surface of the lithium electrodes, to minimize the effect of the lithium counter electrode on the cell impedance. Figure 1a shows impedance spectrum obtained from rice husk carbon electrode at open circuit potential recorded before the intercalation process. It exhibits the typical impedance spectrum character of a blocking electrode, indicating that no intercalation reaction occurs at this potential as suggested by Funabiki et al. [12].

The results of impedance spectra measured at a variety of potentials between OCV and 0.005 V were plotted in Fig. 1. At potential lower than 1.0 V (as shown in Fig. 1b), two depressed semicircles and a spike appeared. Because the surface films on the carbon electrode and graphite are very similar [13], the first semicircle in the high frequency region was generally assigned to Li-ion migration through the surface films formed on the carbon. When a rice husk carbon is electrochemically charged with Li+ in the electrolyte, the intercalation reaction is accompanied by an irreversible process in which solution components are reduced on the carbon surface to form surface films. The second semicircle at the middle frequency region is accordingly ascribed to Li-ion transfer across the interface between the surface films and the carbon. While the spike at very low frequency part reflects Li-ion diffusion in the carbon and also an accumulation of lithium into the carbon, as suggested by Gnanaraj et al. [14], the process of lithium ions in carbon is considerably slower than that in an electrolyte solution [15].

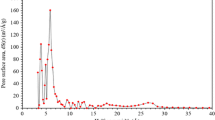

The measured impedance data for the entire frequency range was analyzed using an equivalent circuit shown in Fig. 2 to understand the electrochemical process during lithium intercalation. In the equivalent circuit, R e represents the total resistance of electrolyte, electrode, and separator. CPEf and R f are the capacitance and resistance, respectively, of the surface film formed on the electrode. R ct and CPEdl are the charge-transfer resistance and the double-layer capacitance, respectively, and Z w is the Warburg impedance related to the diffusion of lithium ions into the bulk electrode. In the present work, the use of a constant phase element (CPE) instead of a capacitance, C, represents the non-ideal behavior of composite electrode such as porosity of the carbon and roughness of the surface.

Equivalent circuit used for analysis of impedance spectra obtained as shown in Fig. 1

Figure 3 shows the dependence of R f and R ct on cell potentials for the first Li-ion insertion. Both resistances related to the high and middle frequency semicircles tend to decrease as Li-ion insertion into the rice husk carbon proceeds. This behavior is in agreement with the results on Li insertion into disordered carbon reported by Gnanaraj et al. [14]. The decrease of charge transfer resistance with lowering potential as more lithium ions intercalate into the carbon can be rationalized in terms of Butler–Volmer type kinetics. The dependence of R f with potential indicates the formation of highly conductive surface films, which result in a decrease of R f. This may be due to some reversible changes in the surface films, which lowered their resistivity, as Li insertion proceeds.

Conclusion

EIS technique has been used to study the kinetic properties of a rice husk carbon during Li-ion insertion. Impedance spectra were measured in a wide range of potential from OCV to 0.005 V, and analysis was carried out on the three regions of frequency, high-, middle-, and low-frequency range. Formation of surface films is clearly reflected by the impedance spectra of a high frequency semicircle with typical resistance and capacitance parameters of Li-ion-conducting surface layers.

References

Armand M, Murphy DW (1980) In: Broadhead S, Steels BDH (eds) Materials for advanced batteries. Plenum, New York, p 154

Ogumi Z, Inaba M (1998) Bull Chem Soc Jpn 71:521

Dahn JR, Sleigh AK, Shi H, Reimers JN, Zhong Q, Way BM (1993) Electrochim Acta 38:1179

Dahn JR, Zheng T, Liu Y, Xue JS (1995) Science 270:590

Ohzuku T, Iwakoshi Y, Sawai K (1993) J Electrochem Soc 140:2490

Inaba M, Yoshida H, Ogumi Z, Abe T, Mizutani Y, Asano M (1995) J Electrochem Soc 142:20

Yamamoto O, Imanishi N, Takeda Y, Kashiwagi H (1995) J Power Sources 54:72

Xue J-S, Dahn J (1995) J Electrochem Soc 142:3668

Mansor MS (2005) Paper presented at Carbon 2005, 3–5 July, Cheju Island, South Korea

Fey GT-K, Chen C-L (2001) J Power Sources 97–98:47–51

Chang Y-C, Sohn H-J (2000) J Electrochem Soc 147:50–58

Funabiki A, Inaba M, Ogumi Z, Yuasa S-I, Otsuji J, Tasaka A (1998) J Electrochem Soc 145:172–178

Levi MD, Aurbach D (1997) J Phys Chem B 101:4641

Gnanaraj JS, Levi MD, Levi E, Salitra G, Aurbach D, Fischer JE, Claye A (2001) J Electrochem Soc 148:A525–A536

Takami N, Satoh A, Hara M, Ohsaki T (1995) J Electrochem Soc 142:371–379

Acknowledgment

The authors gratefully acknowledge the financial support of this work by MOSTI of Malaysia through the IRPA Programme (project no. 01-01-0057 EA 001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamisah, M.M., Siti Munirah, H. & Mansor, M.S. Electrochemical impedance study of lithium-ion insertion into rice husk carbon. Ionics 13, 223–225 (2007). https://doi.org/10.1007/s11581-007-0095-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-007-0095-x