Abstract

Marketplace preference for lower pesticide residues in foods has led to research to reduce the residue of chlorpropham (isopropyl N-3-chlorophenyl carbamate; CIPC), a postharvest-applied sprout inhibitor which is widely used around the globe to prevent sprouting of stored potatoes (Solanum tuberosum L.). Ethylene gas, an effective, safe and non-toxic sprout inhibitor used in several countries, sometimes has negative effects on the colour of processed potato products when used alone. Trials were conducted over 3 years using cv. Shepody (French fry) and cv. NorValley (potato chips/crisps) to determine whether a combination of these two sprout inhibitors, at reduced dosages, could inhibit sprouting while maintaining good processing colour. CIPC applied at 0, 0.1, 0.25 and 1.0 times the recommended dosage was combined with 4 μll−1 of ethylene gas applied or no ethylene at all (0 ethylene), for 1 day in 4 days, for 1 day in 2 days or continuously, in a factorial design. Sprout inhibition in both cultivars was excellent at all levels of CIPC application except the 0 rate. In both cultivars, sprouting was inhibited by the continuous ethylene treatment. However, all levels of ethylene exposure except the 0 rate negatively affected processing colour in both cultivars. The darkening was dose dependent, whereby the colour was darkest in continuous ethylene and was less affected by the intermittent exposures. In continuous ethylene, the colour was progressively lighter during storage after initial darkening. Shepody tubers appeared to be more sensitive to ethylene than the NorValley tubers. In Shepody only, colour in the ethylene of 1 day in 4 days treatments was progressively darker with increasing time in storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During long-term storage, potato (Solanum tuberosum L.) tubers age physiologically, progressing through dormancy, dormancy break and sprouting. Sprout management is an important aspect of successful long-term storage, to maintain good quality of the tubers for their intended purpose. Several methods are available to industry to control or prevent sprouting, including use of long-dormancy cultivars, low-temperature storage and application of sprout-inhibiting agro-chemicals.

By far, the most-used chemical sprout inhibitor worldwide is chlorpropham (isopropyl-(N-3-chlorophenyl) carbamate (CIPC), CAS # 101-221-3), which has been available for about half a century. It is effective, reliable and has relatively low toxicity in comparison with many pesticides (e.g. CIPC oral LD50 (rat) >2,000-4,200 mg/kg body mass; FAO 2005). However, there is decreasing market tolerance for all types of agrochemical residues in food products.

Since CIPC is applied postharvest directly to the marketed product (i.e. the potato tuber), CIPC residues are a possibility. Corsini et al. (1979) showed that a concentration of approximately 20 ppm (w/w) CIPC in the outer peel layer of tubers is necessary to effectively control sprouting during long-term storage. Whole-diet studies carried out in the 1980s and 1990s by the US Food and Drug Administration (FDA) indicate that CIPC is consistently among the three most abundant pesticides in the diet of adults in the USA, and furthermore, it comprises 90% of the pesticide residues found in potatoes (Gartrell et al. 1986; Gunderson 1988, 1995a, b). Although the FDA no longer routinely conducts whole-diet studies, it is likely that today's results would be similar because diet and sprout inhibitor use patterns from that period persist today in the USA and in many other developed countries.

Several alternative methods to inhibit potato sprouting have been identified in recent years (Buitelaar 1987; Prange et al. 1998; Kleinkopf et al. 2003), including low concentrations of ethylene gas (4 μll−1; Prange et al. 1998; Daniels-Lake et al. 2005). The toxicity of ethylene to humans and other animals is very low, e.g. the LC50 for mice in air is 950,000 μll−1 (O'Neil 2001), i.e. almost pure ethylene gas. The mode of action is a simple asphyxiant which displaces oxygen (O'Neil 2001). Ethylene is produced by all living organisms, and is a well-characterised plant growth regulator. It has been registered for use as a potato sprout suppressant in Canada since 2002, and is also approved for use in the UK and several other nations. However, ethylene sprout inhibitor can have negative effects on the final colour of processed potato products (Prange et al. 1998; Daniels-Lake et al. 2005, 2006). The response to ethylene is somewhat variable among cultivars, both in terms of the concentration necessary for adequate sprout inhibition and the effect on sugar metabolism and processed colour (Haard 1971; Jeong et al. 2002; Daniels-Lake et al. 2005, 2006).

Other novel potato sprout inhibiting compounds have also been identified and developed as commercial products over the past several years. Some are effective in combination with CIPC, which can reduce the potential for CIPC residues (e.g. CIPC can be used with dimethylnaphthalene; Beaver et al. 2003). Therefore, it was hypothesised that ethylene gas could be applied in combination with a low rate of CIPC, to reduce the potential for CIPC residues in the treated tubers while maintaining both adequate sprout inhibition and good processed colour.

Materials and Methods

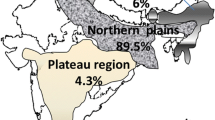

A 3-year study was undertaken at the Agriculture and Agri-Food Canada potato postharvest research facilities at the Atlantic Food and Horticulture Research Centre (AFHRC) in Kentville, Nova Scotia, Canada, to test the hypothesis. Potato storage trials were conducted during the fall to spring storage seasons, i.e. November to April in 2005–2006, 2006–2007 and 2007–2008. Each year, tubers of a French fry cultivar, cv. Shepody, were obtained from two commercial growers in New Brunswick, Canada; the two lots of Shepody tubers constituted the two replicates used in the trials. Tubers of a chipping (i.e. crisping) cultivar, cv. NorValley, were obtained from one commercial grower in Nova Scotia, Canada; replication of NorValley was from within the single lot of tubers each year. Tubers of each cultivar were shipped to AFHRC shortly after harvest.

Soon after arrival at AFHRC, samples of healthy, reasonably uniform tubers (9 to 11 tubers, 150 to 300 g each, total sample mass ca. 2 kg) were selected from within each lot of potatoes and placed in small onion mesh bags. The samples were labelled, weighed and stored in sealed 0.34-m3 stainless steel storage chambers (constructed locally). Each chamber contained four PVC baskets (NPL-655; Norseman Plastics, Rexdale, ON, Canada) into which the samples were distributed according to the experimental design. All chambers were stored in darkness inside a refrigerated cold room. The storage temperature was maintained at 13 °C for 3–4 weeks to encourage suberization of any harvest or transport injuries, then reduced 1 °C per week to 9 °C and held at 9 °C until the trials were completed.

Humidified ventilation air was supplied to each chamber, via 3-mm I.D. nylon tubing (Bowman Products, Moncton, NB, Canada), which entered through one end of each chamber and was exhausted at the opposite end via 12-mm I.D. pvc tubing (Canron coldwater pipe, IPEX Inc., Toronto, ON, Canada) to the outdoor atmosphere. Exhaust from the chambers was assisted by a fan in the building ductwork. Ventilation air was supplied to each chamber at ca. 2 l min−1 for two 6-h ventilation periods, alternated with 6-h static periods, each day. Although these ventilation rates were lower than the rates used in commercial potato storage facilities, previous testing confirmed it to be adequate to deliver the ethylene treatments and maintain O2 and CO2 at near-ambient concentrations (Daniels-Lake, unpublished). In commercial potato storage facilities, ventilation is used to manage pile temperature in addition to managing CO2 and O2 concentrations, but in the reported research, the temperature control function was achieved by room refrigeration. Therefore the ventilation rates used in here should not be compared directly with rates used in commercial settings.

The storage treatments consisted of ethylene gas, combined with chlorpropham CIPC treatment. In addition to the ethylene and CIPC treatments, untreated control samples which were not treated with either sprout inhibitor were stored and ventilated as described above. An outline of the treatment combinations and a key to the abbreviated names for the treatments can be found in Table 1. Each treatment combination was applied to a single storage chamber which held tubers from both replicates of each cultivar.

Samples treated with CIPC were dipped in 1.0%, 0.25% or 0.1% a.i. (w/v) water emulsion of CIPC (Sprout-Nip EC, 350 g/l a.i., Stanchem Inc., Etobicoke, ON, Canada), in late November or early December after suberization and cooling were finished. The full label rate for this product is 1.0% a.i. After dipping, the bags of tubers were allowed to air dry for 3–4 h before being replaced in the storage chambers.

For the ethylene treatments, sufficient ethylene (Canadian Liquid Air, Kentville, NS, Canada) from compressed gas cylinders was added to the ventilation air through a gas distribution board (constructed on-site) to provide the sprout-inhibiting concentration of 4 μll−1 in the chamber atmospheres, as described in Daniels-Lake et al. (2005). Ethylene concentrations in the chambers were quantified by gas chromatography, using the method described in Daniels-Lake et al. (2005). A multi-channel timer (ChronTrol, San Diego, CA, USA) was used to deliver the ethylene either daily, or for only 1 day in 2 days, or 1 day in 4 days, throughout the duration of the trials. The ethylene treatments commenced at the full rate, within 2 days of the tubers being loaded into the storage chambers. This was during the suberization period, i.e. before the CIPC application. Although an abrupt start of ethylene treatment can increase tuber sugar concentrations and darken colour, this impact was reduced by commencing the treatment during the warm suberization period (Daniels-Lake et al. 2006). The abrupt start was necessary to achieve the intermittent treatment method, which also reduces the impact on colour while providing good sprout inhibition (Daniels-Lake et al. 2006).

Evaluations were conducted at the start of the trials (initial fry/chip colour only), after the suberization/cooling phase (i.e. ca. 2 weeks after CIPC application and ca. 4 weeks after the ethylene treatments had commenced), and at 4-week intervals thereafter to early April. The tuber responses evaluated were sprouting, fry/chip colour, weight loss and disease/disorder incidence. Sprouting data collected included mass of sprouts 2–5 and >5 mm in length, and the length of the longest sprout in a sample of ten tubers.

French fry colour of the tubers was assessed using discs 2.5 cm in diameter cut from a central longitudinal slice 8 mm thick, which were deep fried at 190 °C in 100% canola oil (Sun Wah Trading, Etobicoke, ON, Canada). One disc was evaluated from each of the tubers in a sample. The colour of each cooled disc was measured with an Agtron reflectance colourimeter (M-35-D, Agtron Inc., Sparks, NV, USA), calibrated at 0% and 100% reflectance with Agtron colour standards (#00 and #56, respectively; Agtron Inc.) The reflectance scores were expressed as Agtron percent reflectance units (ARu), whereby a light-coloured fried disc received a high numerical score and a dark disc received a low score. Scores greater than 100 ARu were possible, if the colour of a fried disc was lighter than the #56 standard (very pale grey colour) used for calibration of the instrument.

Potato chip colour was assessed by frying ten median slices (each 1.3 mm thick) from each tuber in a sample in canola oil at 185 °C until bubbling almost stopped. Slices were rinsed briefly in distilled water and patted dry before frying. The colour of a sub-sample of cooled, crushed chips was assessed with a Hunter Lab colourimeter (LabScan model WE, Lyssack Associates, Toronto, Canada). Only the *L (luminosity) and *a (red to green) values are reported.

Weight loss was calculated as a percentage of initial tuber mass. The affected portion of any diseased tubers was visually estimated as a fraction of the total surface area of the tuber. The occurrence of tuber disorders such as brown centre-hollow heart, tuber greening, vascular discolouration or any other disorders, was recorded when observed. In the 2007–2008 trial only, samples from the control, CIPC, low-rate CIPC and very-low-rate CIPC treatments stored until January and until April were shipped to a private lab (Research and Productivity Council, Fredericton, NB, Canada) for measurement of their CIPC residue. The method used was solvent wash with analysis by gas chromatography/mass selective detection.

A customised partial factorial design was used to assess four levels of CIPC (0, 0.1, 0.25 and 1.0 times the standard rate) in combination with four levels of exposure to 4 μl l−1 ethylene (none, 1 day in 4 days, 1 day in 2 days and continuous). Replication was within years (two replicates per cultivar) and across years (3 years), and the data from all years were combined for statistical analysis. Data were evaluated by analysis of variance (ANOVA) and further analysed by orthogonal contrasts, using GenStat statistical software (GenStat Committee 2008). Unless otherwise noted, only results significant at P ≤ 0.05 are discussed.

Results and Discussion

Weight Loss, Diseases and Disorders

In Shepody tubers, there were no significant differences in weight loss or diseases and disorders attributable to treatment. Although there were differences in accumulated weight loss associated with storage time, i.e. weight loss increased as storage duration increased, these differences are usual during long-term storage. There were no statistical interactions between treatment and storage time in either weight loss or diseases and disorders in Shepody tubers (data not shown).

In NorValley tubers, there were no differences in diseases and disorders attributable to treatment or time or the interaction of these two factors. In regard to weight loss, there were differences attributable to storage treatments, time in storage and the interaction of treatment × time (P = 0.041, P < 0.001 and P = 0.001, respectively). The check (untreated) tubers lost less weight than tubers in the other treatments, and this difference increased with increasing duration of storage (Table 2). The reason for this is not entirely clear, but two factors are likely important, i.e. relatively little sprouting was observed in the check treatment, and stress caused by the other treatments may have increased tuber respiration rates and therefore weight loss.

Sprout Inhibition

Rylski et al. (1974) recognised that ethylene has multiple effects on potato tubers. When a sufficient concentration is applied for a brief duration, e.g. 2 μll−1 for 3 days, the gas breaks dormancy and encourages the tubers to sprout. However, if the exposure is prolonged for several weeks or months, the ethylene inhibits the elongation of those sprouts (Rylski et al. 1974). Low doses of ethylene and short or interrupted exposures can favour either effect, or each in turn (Haard 1971; Timm et al. 1986; Daniels-Lake et al. 2005, 2006). This apparently depends on cultivar and the physiological age of the tubers, but much additional research would be needed to delineate all of the details of these responses and is beyond the scope of the trials reported here.

The ethylene concentration used in these trials, i.e. 4 μll−1, has been used successfully to inhibit sprouting in research and commercial-scale trials over many years (Prange et al. 1998; Jeong et al. 2002; Daniels-Lake et al. 2005, 2006), and furthermore, it is the named concentration in the Canadian registration for ethylene potato sprout inhibitor. However, the majority of this work used cv. Russet Burbank and Shepody potatoes; for some cultivars a higher concentration is needed to adequately control sprouting (Daniels-Lake and Prange, unpublished data). Indeed, the commercial ethylene providers in the UK routinely apply 10 μll−1 for potato sprout control, and the UK regulations allow up to 50 μll−1 (J. Barnes, BIOFRESH UK, personal communication). The intent of the trials reported here was to determine if low doses of CIPC and ethylene could be used together to manage sprouting in storage.

Interestingly, there was very little sprouting in either cultivar in these trials, even in the untreated tubers. Each year the trials ended in early April, at which time Shepody can be expected to be sprouting vigorously, and NorValley less so (Daniels-Lake and Prange, unpublished data). There was concern that the tubers might have been treated with maleic hydrazide sprout inhibitor in the field before harvest, but further investigation did not confirm this. The observations were similar in all 3 years, and are therefore presented here.

Due to the biassing effect of the large number of zero values in the dataset of the sprouting characteristics, the data were restricted before statistical analysis to include only the last three evaluation dates (when sprouts were observed) and only treatments in which sprouting was observed. The data were also transformed to log10 values for analysis, and the results backtransformed for presentation.

There were no differences in either cultivar in sprout mass in either of the two size categories, but there were differences in the maximum sprout length. In both cultivars, no sprouts were observed in any treatments which included CIPC, with or without ethylene (Figs. 1 and 2). Corsini et al. (1979) found that a concentration of 2 ppm (w/w) in whole tubers is needed to prevent sprouting for 8–12 months in cv. Russet Burbank. In the trials reported here even the low rates of CIPC controlled sprouting in both cultivars, with or without ethylene. CIPC residue in whole tubers was 0, 4.8, 2.2 and 1.7 μgg−1 in Shepody and 0, 4.3, 3.0 and 2.8 μgg−1 in NorValley in tubers from the control, CIPC, low-rate CIPC and very low-rate CIPC treatments, respectively, at the April evaluation. Although these concentrations were lower than the concentrations observed in January (data not presented), they were clearly sufficient to inhibit sprouting in both cultivars (Figs. 1 and 2).

Only tubers in the check, ethylene and Eth1in4 treatments produced sprouts of a measurable length (Figs. 1 and 2). In Shepody, there was a significant treatment × time interaction (P = 0.011), with longer sprouts at the later evaluation dates and shorter sprouts on tubers in the ethylene treatment compared with the check and Eth1in4 treatments (e.g. 2.2, 4.7 and 4.6 mm, respectively, in April). In NorValley tubers, only the main effect of treatment was significant (P = 0.008). However, the trend was similar, with shorter sprouts in tubers from the ethylene treatment than in the Check and Eth1in4 treatments (i.e. mean maximum length was 1.2, 4.2 and 4.3 mm, respectively).

The ethylene did not inhibit sprouting as strongly as CIPC in these cultivars, although continuous exposure to the gas in the ethylene treatment did result in shorter sprouts than in the check and Eth1in4 treatments. However, no apparent advantages to combinations of CIPC and ethylene sprout inhibitors were observed in these trials.

Processing Colour

Fry colour in Shepody covered a wide span during these trials (Table 3). The chip colour of NorValley tubers had a smaller span, but the trends were the same in both cultivars. Although fry colour and chip colour are measured in different units using different instruments, both the Agtron reflectance (fry colour) and Hunter *L (chip colour) measurements address the light-to-dark colour of the tested product using a 1 to 100 scale where a higher number indicates a lighter colour. The range of colour scores observed was much larger in Shepody fry colour than in NorValley chip colour (e.g. mean colour scores were 18% and 7% darker than the initial colour, respectively). This suggests that the Shepody tubers were more sensitive to the storage treatments than were the NorValley tubers. Indeed, fry colour of Shepody tubers has been found to be more sensitive than fry colour of cv. Russet Burbank tubers to both ethylene (Jeong et al. 2002) and low temperature (Gichohi and Pritchard 1995).

In both cultivars, the colour of processed samples was negatively affected by some treatments (Table 3), and the treatment × time interactions were significant (P < 0.05). However, there were no differences in colour among the CIPC application rates. For example, fry colour in Shepody was 89, 91 and 89 ARu in the CIPC, low-rate CIPC (LCIPC) and very low-rate CIPC (VLCIPC) treatments, respectively, at the April evaluation (Table 3). This was also observed when CIPC and ethylene were applied together, e.g. fry colour of Shepody tubers exposed to ethylene 1 day in four was 55, 55 and 53 ARu with no CIPC, low-rate CIPC and very-low-rate CIPC, respectively, at the April evaluation. Similarly, in NorValley in both the Hunter *L and *a chip colours, the scores were not significantly different among the CIPC treatments (Table 3). The more notable point is that in both cultivars the treatments which included ethylene had darker colour than the non-ethylene treatments (Table 3). Furthermore, the data also suggested a dose response among the ethylene treatments. Therefore the CIPC treatments were combined and the colour data were re-analysed to further investigate the effects of the ethylene treatments. The 12 treatments were divided into four groups, i.e. no ethylene applied, ethylene applied 1 day in four, ethylene applied one day in two, and continuous ethylene (NoEth, 1:4Eth, 1:2Eth, DailyEth, respectively). The treatments included in each of these groups are listed in Table 4.

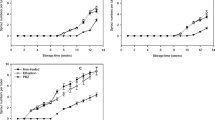

The fry colour of Shepody potatoes in the NoEth group was lighter than the fry colour of tubers in the other three groups at all evaluation dates (P < 0.001; Fig. 3). At the early evaluations, the darkest fry colour was in the DailyEth group, with the colour of the 1:2Eth and 1:4Eth groups intermediate between the NoEth and DailyEth groups. This is in agreement with previous work which found a dose response to the frequency of exposure (Daniels-Lake et al. 2005, 2006), i.e. the negative effect of ethylene on fry colour is progressively reduced when ethylene exposure is interrupted by more days without ethylene. The fry colour of tubers in the 1:4Eth and 1:2Eth treatments were not significantly different at the December evaluation.

With increasing time in storage, fry colour in the NoEth and DailyEth groups was slightly lighter. However, the fry colour in the 1:4Eth group darkened sharply as storage time increased, and was darker than all other groups at the final evaluation in April (Fig. 3). The colour of tubers in the 1:2Eth tubers also darkened slightly with time, but not as much as tubers in the 1:4Eth group. The greater darkening of fry colour in tubers in the 1:4Eth group may be associated with the greater sprout growth observed in the Eth1in4 treatment which is one member of this group (Table 4). However, since the other two treatments included in this group did not produce appreciable sprouting, it is more likely that the darker fry colour is a direct effect of the intermittent exposure to ethylene gas on the cellular metabolism of the no-longer-dormant tubers. Shepody is known to be relatively sensitive to ethylene gas (Daniels-Lake et al. 2006), and the darker colour of all ethylene groups compared with the NoEth group supports this contention. However, this is the first reported test of interrupted ethylene exposure on Shepody tubers. In Russet Burbank tubers, long interruptions in ethylene exposure (4 or 7 days) darkened fry colour in comparison with untreated tubers, but these treatments had little or no effect on sprout growth (Daniels-Lake et al. 2006). The high sensitivity of Shepody tubers to ethylene may have contributed to the strong darkening in the 1:4Eth group observed here, in contrast to the results reported for Russet Burbank.

The observations in NorValley tubers (Fig. 4) are similar to the findings for Shepody. NorValley potato chips from tubers in the NoEth group were lighter in colour than the other groups and the DailyEth group had the darkest colour (Hunter *L luminosity; P < 0.001; Fig. 4a). The Hunter *L scores of the 1:2Eth and 1:4Eth groups were essentially identical throughout the storage period, and were intermediate between the DailyEth and NoEth groups (e.g. Hunter*L scores were 60, 61, 56 and 67, respectively, at the December evaluation). These relationships persisted throughout the storage period. However, the chip colour of tubers from the DailyEth group was progressively lighter with increasing time in storage (Fig. 4a). This recovery with time was similar to the response in Russet Burbank fry colour (Prange et al. 1998; Jeong et al. 2002; Daniels-Lake et al. 2005, 2006). In a similar manner, chips from NorValley tubers in the DailyEth group had higher redness scores than chips from tubers in the NoEth group, but the difference diminished with increasing time in storage (Fig. 4b). Note that for the redness characteristic (Hunter *a), a lower score is preferred. At the final evaluation in April, both luminosity and redness of chips from NorValley tubers in all ethylene groups was similar. Also, the *L and *a scores in the ethylene groups were more similar to the NoEth group in April than in December (Fig. 4). This suggests that NorValley is relatively tolerant of ethylene treatment with regard to effects on sugar metabolism and processing colour, and that the effect of continuous exposure to ethylene diminishes over time in NorValley tubers.

In summary, the data suggest that more study is needed to determine whether ethylene can be combined with reduced-rate CIPC application to control sprouting in these, or other, cultivars during long-term storage. However, the findings regarding the sensitivity of NorValley and Shepody potatoes to continuous and intermittent ethylene exposure may be valuable to the industry as the use of ethylene sprout inhibitor continues to expand in response to consumer demand for reduced pesticide residues in foods.

References

Beaver RG, Devoy ML, Schafer R, Roggle BD (2003) CIPC and 2,6-DIPN sprout suppression of stored potatoes. Amer J Potato Res 80:311–316

Buitelaar N (1987) Sprout inhibition in ware potato storage. In: Rastovski A, van Es A (eds) Storage of potatoes: post-harvest behavior, store design, storage practice, handling. Pudoc, Wageningen

Corsini D, Stallknecht G, Sparks W (1979) Changes in chlorpropham residues in stored potatoes. Amer Potato J 56:43–50

Daniels-Lake BJ, Prange RK, Nowak J, Asiedu SK, Walsh JR (2005) Sprout development and processing quality changes in potato tubers stored under ethylene: 1. effects of ethylene concentration. Amer J Potato Res 82:389–397

Daniels-Lake BJ, Prange RK, Kalt W, Walsh JR (2006) Methods to minimize the effect of ethylene sprout inhibitor on potato fry colour. Potato Res 49:303–326

FAO (2005) Pesticide residues in food—2005. World Health Organization—Food and Agriculture Organization of the United Nations, FAO Corporate Document Repository online, www.fao.org/docrep/009/a0209e/a0209e0a.htm. Accessed 6 April 2010

Gartrell MJ, Craun JC, Podrebarac DS, Gunderson EL (1986) Pesticides, selected elements and other chemicals in adult total diet samples, October 1980–March 1982. J Assoc Offic Anal Chem 69:146–159

Genstat Committee (2008) Genstat, 11th edn. VSN International Ltd, Hemel Hempstead, UK

Gichohi EG, Pritchard MK (1995) Storage temperature and maleic hydrazide effects on sprouting, sugars, and fry colour of Shepody potatoes. Amer Potato J 72:737–747

Gunderson EL (1988) FDA total diet study, April 1982–April 1984, dietary intakes of pesticides, selected elements and other chemicals. J Assoc Offic Anal Chem 71:1200–1209

Gunderson EL (1995a) Dietary intakes of pesticides, selected elements and other chemicals: FDA total diet study, June 1984–April 1986. J Assoc Offic Anal Chem 78:910–921

Gunderson EL (1995b) FDA total diet study, July 1986–April 1991, dietary intakes of pesticides, selected elements and other chemicals. J Assoc Offic Anal Chem 78:1353–1363

Haard NF (1971) Differential response of cold-stored potato tubers to ethylene. Amer Potato J 48:183–186

Jeong J-C, Prange RK, Daniels-Lake BJ (2002) Long-term exposure to ethylene affects polyamine levels and sprout development in ‘Russet Burbank’ and ‘Shepody’ potatoes. J Amer Soc Hort Sci 127:122–126

Kleinkopf G, Oberg N, Olsen NL (2003) Sprout inhibition in storage: current status, new chemistries and natural compounds. Amer J Potato Res 80:317–328

O'Neil MJ (ed) (2001) The Merck Index. Merck Research Laboratories, Whitehouse Station, NJ, p 674

Prange RK, Kalt W, Daniels-Lake BJ, Liew CL, Page RT, Walsh JR, Dean P, Coffin R (1998) Using ethylene as a sprout control agent in stored ‘Russet Burbank’ potatoes. J Amer Soc Hort Sci 123(3):463–469

Rylski I, Rappaport L, Pratt HK (1974) Dual effects of ethylene on potato dormancy and sprout growth. Plant Physiol 53:658–662

Timm H, Hughes DL, Weaver ML (1986) Effect of exposure time of ethylene on potato sprout development. Amer Potato J 63:655–666

Acknowledgements

The authors gratefully acknowledge the financial assistance of the Nova Scotia Technology Development Program (Project DEV24-047) in this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contribution # 2379, Atlantic Food and Horticulture Research Centre, Agriculture and Agri-Food Canada, Kentville, Nova Scotia, Canada.

Rights and permissions

About this article

Cite this article

Daniels-Lake, B.J., Pruski, K. & Prange, R.K. Using Ethylene Gas and Chlorpropham Potato Sprout Inhibitors Together. Potato Res. 54, 223–236 (2011). https://doi.org/10.1007/s11540-011-9188-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11540-011-9188-z