Abstract

Metal-capped microdisk cavity supporting surface plasmon polaritons (SPP)-guided whispering gallery mode (WGM) can achieve higher cavity factor Q than traditional microdisk cavity in sub-wavelength dimensions. We have numerically analyzed the limiting factors on Q using finite difference time domain method. The Q of SPP-guided WGM is primarily limited by the loss of metal. A thin metal-sandwiched microdisk cavity supporting long-range surface plasmon polariton mode was proposed to reduce the metal loss. The proposed cavities have been shown to increase cavity Q by more than 15-fold and reduce threshold gain by more than threefold as opposed to traditional microdisk cavities.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sub-wavelength optical cavities are potentially useful as building blocks for integrated photonic circuits. For this purpose, it is highly desirable to scale the optical cavities to sub-wavelength in all three dimensions. Microdisk cavities have been proposed and investigated as sub-wavelength semiconductor lasers [1]. However, the lateral dimension of the traditional microdisk cavities is still limited to the scale of free-space wavelength (λ) because large radiation loss in whispering gallery mode (WGM) limits the attainable Q when the disk diameter (D) is smaller than λ [2, 3]. Because metal can provide strong confinement of light which reduce radiation loss, studies of metallic cavities have been rapidly growing in recent years in order to design deep sub-wavelength optical cavities. However, the loss introduced by metal limits the Q below 300 for sub-wavelength metallic cavities [4–6]. The limit on cavity Q factor prevents such cavities to lase at room temperature. Efforts have been put to increase Q by incorporating low index materials [7, 8]. High Q semiconductor based sub-wavelength cavities are important for building electrically pumped lasers. In this letter, we show that the Q of metal-capped semiconductor microdisk is primarily limited by metal loss; and introducing a novel structure of thin metal sandwiched between semiconductor disks would drastically reduce the metal loss and increase Q.

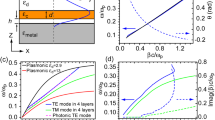

In traditional microdisk cavities the transverse confinement of the resonance modes is provided by the typical dielectric confinement of the air-cladded waveguide. To ensure that only the lowest order mode of the waveguide exists, the waveguide thickness need to be smaller than λ 0/2 n s where n s is the refractive index of semiconductor disk [9]. The effective refractive index (n eff) of the lowest order waveguide mode is usually more than 1.5 times smaller than n s. The reduction in n eff introduces large radiation loss in WGM and cavity Q is reduced drastically especially for sub-wavelength diameter, D [10]. The metal-capped microdisk structure has been proposed to increase n eff and therefore Q [11]. For the surface plasmon polaritons (SPP)-guided WGM supported in the metal-capped microdisk cavity, waves are confined in the transverse dimension by the SPP mode at the metal-dielectric interface. The n eff of the SPP mode is always larger than n s and is thus much larger than the n eff of air-cladded waveguide in traditional microdisks [12]. Therefore, the Q of WGM can be increased for sub-wavelength size cavities due to the improved optical confinement which minimizes the radiation loss. However, the additional metal loss experienced by SPP mode also puts a limit on the overall Q of SPP-guided WGM. In the newly proposed structure illustrated in Fig. 1b, the transverse confinement is provided by long-range surface plasmon polariton (LRSPP) confined in a thin metal film sandwiched between two layers of dielectrics with the same index. This LRSPP mode experiences a much lower metal loss and can elevate the limit on the Q of metallic microdisk cavity. To study the behaviors of the SPP as well as LRSPP-guided WGM, we used finite difference time domain (FDTD) method to simulate the resonance behaviors and specifically the Q of proposed metallic microdisk structures.

a Metal-capped microdisk cavity supporting SPP-guided WGM and b metal-sandwiched microdisk cavity supporting LRSPP-guided WGM. Tmetal and Tgain denotes the thickness of Ag and Gain region. D disk diameter. Ttop and Tbottom in (b) denotes the thickness of GaAs disk above and beneath Ag layer, respectively

Results and Discussion

Simulation Conditions

The FDTD simulation presented here is performed by using a commercial FULLWAVE package from the RSoft Design Group. The metal is chosen to be Ag for minimizing the metal loss. The refractive index of metal n metal is assigned as 0.13 + 10.1i for silver at λ = 1,400 nm [13]. The refractive of semiconductor n semi is assigned as 3.4 for GaAs. In FDTD simulation, in order to resolve the smallest fields and structures the grid size needs to be 10 times smaller than both the effective wavelength (λ 0/n eff) and the size of the smallest structures. In the lateral dimension, using a grid size of 30 nm fulfills the above two requirements for wavelength assumed as 1,400 nm and D larger than 300 nm. In the transverse dimension, the grid size is chosen to be 2 nm in metal and 18 nm in semiconductor considering that the penetration depth of SPP mode is 21 nm into Ag and 184 nm into GaAs at λ = 1,400 nm. The source for exciting SPP mode is in TM polarization which has the transverse magnetic field component perpendicular to the metal–semiconductor interface.

Metal-Capped Microdisk Cavity

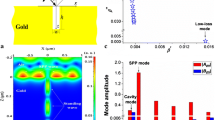

Waves propagating in the metal-capped microdisk cavity depicted in Fig. 1a are simulated by FDTD. The thickness of metal layer T metal is assumed as 200 nm which is thick enough to prevent SPP mode at metal–semiconductor interface from being coupled to the metal-air interface. We first consider a passive cavity by assuming the thickness of gain region T gain as 0. We also ignore the radiation into substrate by assuming T Bottom as infinite. Cavities with nonzero T gain and finite T bottom will be studied in later sections. The mode profile in Fig. 2a reveals that the lateral confinement in x–y plane is provided by WGM just like in traditional microdisk cavities. On the other hand, the transverse mode profile in Fig. 2b reveals that the transverse confinement in the z dimension is provided by SPP mode with amplitude that peaks at metal–semiconductor interface and decays exponentially into both metal and semiconductor layers. In Fig. 3a, the simulated Q at λ 0 = 1,400 nm corresponding to the metal-capped microdisk cavity in Fig. 1a is compared with traditional microdisk cavity with air cladding. The thickness of traditional microdisk is assumed to be 200 nm which is just below λ 0/2 n s for ensuring single waveguide mode. The Q of SPP-guided WGM, Q SPP+WGM, is limited by two factors expressed in Eq. 1. One is SPP limited Q, Q SPP, which accounts for the metal loss experienced by the propagating SPP mode due to penetration into the metal layer. The other is WGM limited Q, Q WGM, which accounts for the radiation loss experienced by WGM in the lateral direction.

a Lateral (Z = 0) and b transverse (X = 0) mode patterns of SPP-guided WGM for the metal-capped structure depicted in Fig. 1a with infinite Tbottom. c Transverse (X = 0) mode pattern of LRSPP-guided WGM for the metal-sandwiched structure depicted in Fig. 1b with Tmetal = 100 nm and d with Tmetal = 20 nm. Ttop and Tbottom are assumed as infinite. The coupling between modes at two metal-semconductor intergfaces is stronger in (d) with a smaller Tmetal than in (c) with a larger Tmetal

a Q of air-cladded waveguide-, SPP-, and LRSPP-guided WGM with various Tmetal versus disk diameter. Ttop and Tbottom are assumed as infinite. The mode with smallest D/λ on each curve has a mode number m = 3. Mode difference between adjacent modes on each curve is 1. For Tmetal = 200 nm, the Q of LRSPP-guided is identical to SPP-guided WGM because there is no coupling between modes at two Ag-GaAs interfaces. b Q LRSPP versus Tmetal

For D/λ below 0.7, the radiation loss is larger than the metal loss. QSPP+WGM is primarily limited by QWGM. For D/λ above 0.7, the metal loss is larger than the radiation loss. The upper bound of Q SPP+WGM is Q SPP independent of disk size. Q SPP is 306 for Ag and GaAs system at λ = 1,400 nm. On the other hand, the Q of air-cladded waveguide-guided WGM is limited by radiation loss only. The effective index of air-cladded waveguide (n eff = 2.74) is smaller than that of SPP mode (n eff = 3.61) and introduces a large radiation loss of WGM. The metal-capped microdisk scales more favorably than the air-cladded microdisk for smaller size microcavities by providing higher Qs: as D/λ below 0.86, the overall Q of air-cladded waveguide-guided WGM drops below Q SPP of the metal-capped microdiskas shown in Fig. 3a. By using SPP transverse confinement, the radiation loss limited Q of traditional microdisk that exponentially depends on the diameter of microcavity is giving away to the metal-limited loss in SPP.

Metal-Sandwiched Microdisk Cavity

For metal-capped microdisk cavity, the Q is primarily limited by the metal loss which depends on the overlapping of electric field of the cavity modes with metal. The metal loss can be reduced by introducing LRSPP mode supported in a thin metal film sandwiched between identical semiconductor layers. The magnitude of metal loss is determined by the fraction of field inside the metal. LRSPP is the coupled mode of surface waves at two metal–semiconductor interfaces. When metal film is thick, surface waves propagating at two metal–semiconductor interfaces are not coupled and they propagate as two independent SPP modes. When metal film becomes thin, the two surface waves interact with each other and form a coupled surface plasmon mode. Such coupled surface plasmon mode has field penetrates more into bounding semiconductors. The penetration depth into GaAs is plotted against Ag thickness in Fig. 3b This results in the decrease of the fraction of field inside the metal and therefore the decrease of metal loss of such coupled mode [14], leading to longer propagation length and hence the name long-range SPP. The proposed metal-sandwiched microdisk structure depicted in Fig. 1b supports LRSPP in the transverse dimension by introducing a thin metal disk sandwiched between semiconductor disks. Again, we consider a passive cavity by assuming T gain as 0 and ignore the radiation into substrate at bottom and air on top by assuming both T top and T bottom as infinite. Cavities with nonzero T gain, finite T top, and finite T bottom will be studied in later sections. The lateral mode pattern of metal-capped microdisk cavity has a WGM profile as in Fig. 2a. The transverse mode profiles in Fig. 2c, d reveal that the LRSPP modes are coupled modes propagating at both metal–semiconductor interfaces. Thicker metal has weaker coupling of two modes and less field penetration into semiconductor as show in Fig. 2c. This leads to only a small amount of decrease of metal loss. Thinner metal has stronger coupling of two modes and more field penetration into semiconductor as show in Fig. 2d. This leads to a larger amount of decrease of metal loss. In Fig. 3a the simulated Q at λ = 1,400 nm corresponding to the metal-sandwiched microdisk cavity is shown for different T metal. The cavity Q of LRSPP-guided WGM for T metal = 200 nm coincides with SPP-guided WGM because the surface wave at each interface propagates as uncoupled SPP mode for thick metal. Similar to SPP-guided WGM, the Q of LRSPP-guided WGM, Q LRSPP+WGM, is limited by two factors expressed in Eq. 2.

For D/λ below 0.7, Q LRSPP+WGM is also primarily limited by Q WGM as in the case for Q SPP+WGM. Q LRSPP+WGM is slightly smaller than Q SPP+WGM because of the smaller n eff of LRSPP mode relative to SPP mode. For D/λ larger above 0.7, Q LRSPP+WGM is no longer capped by Q SPP at about 310 as in the case of Q SPP+WGM. Q LRSPP keeps increasing as D/λ increases. The upper limit of Q LRSPP+WGM is set by Q LRSPP which is larger with smaller T metal. Figure 3b shows the Q LRSPP with varying T metal. This put a upper limit for Q LRSPP+WGM with fixed T metal. For T metal = 20 nm, Q LRSPP+WGM can reach about 4800. The range where cavity Q of metallic microdisk cavity is larger than traditional microdisk is expended for any microdisks with D/λ below ∼1.15. The achievable Q LRSPP+WGM can be further increased by using smaller T metal. As a comparison, cavity Q is about 270, 310, and 4,400 for tradional microdisk, metal-capped microdisk, and metal-sandwiched microdisk with T metal = 20 nm when D/λ is about 0.85.

Threshold Gain to Compensate Cavity Loss

When utilizing the cavity in laser, the threshold gain determines the lasing properties. The threshold gain required to compensate the cavity loss is not only related to the cavity Q but also the confinement factor of the mode in the gain region. For SPP and LRSPP modes, field peaks at metal–semiconductor interfaces. Placing the gain layer right next to the interface as shown in Fig. 1a and b can provide the largest confinement factor. For single mode waveguide, field peaks at the center of waveguide. Placing the gain layer at the center of air-cladded waveguide can provide the largest confinement factor. For LRSPP-guided WGM, while Q increases with smaller T Ag, the confinement factor decreases due to the larger penetration depth. The overall affect of varying T metal on threshold gain can be studied by simulation. Figure 4a shows the threshold gain for traditional microdisk with air cladding, metal capped microdisk, and metal-sandwiched microdisk of various T metal. The metal-capped microdisk has a lower threshold gain than traditional microdisk with air cladding for D/λ up to 0.85 because of the larger Q. However, for D/λ between about 1 and 1.15, although the metal-sandwiched microdisk with T metal of 20 nm has a higher Q, the weaker confinement of LRSPP mode makes the threshold gain of metal-sandwiched microdisk larger. The metal-sandwiched microdisk has a lower threshold gain than traditional microdisk with air cladding for D/λ up to 1 instead of 1.15.

a Threshold gain required for air cladding waveguide-, SPP-, and LRSPP-guided WGM with various Tmetal versus disk diameter. Ttop and Tbottom are assumed as infinite. The mode with smallest D/λ on each curve has an azimuthal mode number m = 3. Mode number difference between adjacent modes on each curve is 1. b Threshold gain required for lossless propagation of LRSPP versus Tmetal. Tgain is assumed as 100 nm

Figure 4b shows the required gain to compensate the propagation loss of LRSPP mode with varying T metal. This required gain represents the lowest threshold gain of metal-sandwiched microdisk with fixed T metal. For T metal larger than 50 nm, the lowest threshold gain is larger than that for metal-capped microdisk at about 670 cm−1. This is because the field existing in the top semiconductor layer reduces the confinement factor in the gain region. For T metal smaller than 50 nm, the lowest threshold for metal-sandwiched microdisk is smaller than metal-capped microdisk and can be reduced to about 170 cm−1 for T metal of 20 nm. To illustrate the effectiveness of this approach, the threshold gain can be further reduced to 60 and 25 cm−1 for T metal of 10 and 5 nm. As a comparison, threshold gain is about 730 and 670 cm−1 for traditional microdisk and metal-capped microdisk when D/λ is about 0.85. This reduction in threshold gain is crucial considering that the maximum modal gain achieved in QDs and QWs on GaAs substrate is about 50 cm−1 at wavelength above 1.3 μm [15, 16].

Size Limit in the Transverse Dimension

The above calculations are based on infinitely thick semiconductor disks. However, in order to achieve subwavength cavity in all three dimensions, we need to consider finite semiconductor layers T top and T bottom which can affect the transverse mode and the cavity Q factor. In Fig. 5a, cavity Q of LRSPP-guided WGM is plotted against finite T top while assuming infinite T bottom with different T metal for azimuthal mode number of eight which has D/λ just below 1. Since the reduction of metal relies on the symmetry of the refractive indices of semiconductors on two sides of the metal, T top need to be thick enough to provide the symmetry for LRSPP mode to exist. Threshold gain starts to approach the value for perfectly symmetric structure as shown in Fig. 4b when top semiconductor layer is thick enough for supporting LRSPP. Threshold gain approaches the value for SPP guide WGM when TTop approaches zero if metal is thick.

In Fig. 5b, cavity Q of LRSPP-guided WGM is plotted against finite T bottom while assuming infinite T top with different T metal for mode number of 8. T bottom needed to achieve minimum threshold gain is related to the penetration depth since cavity with smaller T bottom causes larger radiation into GaAs substrate and increases the threshold gain. For T metal of 20 nm, threshold gain smaller than 200 cm−1 can still be achieved for diameter of 1,400 nm by choosing T top of 400 nm and T bottom of 900 nm for cavity size being sub-wavelength in all three dimensions.

Summary

We have analyzed the scaling property of novel metallic microdisk cavities. Simulation results tell us that metal-capped microdisk can provide larger cavity Q factor and lower threshold gain than the traditional microdisk cavity with air cladding when the disk diameter scales below wavelength. Metal-sandwiched microdisk provides even larger cavity Q and lower threshold gain by incorporating long-range surface plasmon mode. Cavity Q over 4,000 and threshold gain below 200 cm−1 can be achieved for cavity size being sub-wavelength in all three dimensions with this type of novel microcavities.

References

McCall SL et al (1992) Whispering-gallery mode micordisk lasers. Appl Phys Lett 60:289–291

Zhang Z et al (2007) Visible submicron microdisk lasers. Appl Phys Lett 90:111119

Song Q, Cao H, Ho ST, Solomon GS (2009) Near-IR subwavelength microdisk lasrs. Appl Phys Lett 94:061109

Hill MT et al (2007) Lasing in metallic-coated nanocavities. Nat Photonics 1:589–594

Feigenbaum E, Orenstein M (2007) Optical 3D cavity modes below the diffraciton-limit using slow-wave surface-plasmon-polaritons. Opt Express 15(5):2607–2612

Manolatou C, Rana F (2008) Subwavelength nanopatch cavities for semiconductor plasmon lasers. IEEE J Quantum Electron 44(5):435–447

Mizrahi A et al (2008) Low threshold gain metal coated laser nanoresonators. Opt Lett 33(11):1261–1263

Min B, Ostby E et al (2009) High-Q surface–plasmon-polariton whispering-gallery microcavity. Nature 457:455–458

Chin MK, Chu DY, Ho S-T (1994) Estimation of the spontaneous emission factor for microdisk lasers via the approximation of whisepring gallery modes. J Appl Phys 75(7):3302–3307

Heebner JE, Bond TC, Kallman JS (2007) Generalized formulation for performance degradations due to bending and edge scattering loss in microdisk resonators. Opt Express 15(8):4452–4473

Kim MW et al (2009) Sub-wavelength surface plasmon optical cavity—scaling, amplificaiton and coherence. Journal of Selected Topics in Quantum Electronics 15(5):1521–1528

Barnes WL, Dereux A, Ebbesen TW (2003) Surface plasmon subwavelength optics. Nature 424:824–830

Johnson PB, Christy RW (1972) Optical constants of the Noble metals. Phys Rev B 6(12):4370–4379

Sarid D (1981) Long-range surface-plasma waves on very thin metal films. Phys Rev Lett 47(26):1927–1930

Egorov AY, Zhukov AE, Ustinov VM (2001) 1.3 μm GaAs-based quantum well and quantum dot lasers: comparative analysis. J Electron Mater 30(5):477–481

Amano T et al (2007) Laser characteristics of 1.3-μm quantum dots laser with high-density quantum dots. Journal of Selected Topics in Quantum Electronics 13(5):1273–1278

Acknowledgments

We are grateful to Prof. P. C. Ku for discussions and to DARPA/MTO for financial support

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, YH., Guo, L.J. High Q Long-Range Surface Plasmon Polariton Modes in Sub-wavelength Metallic Microdisk Cavity. Plasmonics 6, 183–188 (2011). https://doi.org/10.1007/s11468-010-9185-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11468-010-9185-0