Abstract

The main objective of this paper is to examine how different engineering soils react to environmental variations and to provide correlations to characterize their behaviour under null external mechanical stress. Two French and two Algerian soils with liquid limits ranging from 36 to 112 were prepared under both slurry and Proctor compaction conditions, and then subjected to drying–wetting paths with suction controlled from several kPa to several hundreds of MPa. Experimental results are presented in five diagrams to show globally and simultaneously the shrinkage–swelling, saturation–desaturation and water retention characteristics. A reasonable consistency was observed between the oedometric and drying curves of slurry, confirming the equivalence between hydraulic loading (suction) and mechanical loading (consolidation stress) on the volume change behaviour of different soils. As an intrinsic parameter of soil nature, liquid limit was found to have a significant influence on the shrinkage limit, air-entry suction and compressibility of both slurry and compacted samples. For that reason, correlations between these characteristics and liquid limit were set up, providing a good basis for a first estimation of the drying–wetting curves. At the micro-scale, new experimental results were obtained: either on drying or wetting path, the micro-pores were almost unaffected, whereas, when matrix suction increased from 0.1 to 8 MPa, the volume of macro-pores decreased to quasi-closure. At last, the analogy between the compaction and drying–wetting curves, and the comparison of different methods to determine the water retention curve were addressed. Such analogies and comparisons contribute to a better understanding of the mechanisms of mechanical stress and suction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Engineering soils refer to the soils used in various engineering constructions. Compared to the soils usually used in research works (e.g. pure kaolinite, illite and montmorillonite), they contain several minerals and thus have relatively complex hydraulic and mechanical behaviours. Under natural conditions, engineering soils are inevitably subjected to drying–wetting paths due to the fluctuations of relative humidity caused by, for example, moisture changes under rainy and drought conditions. This phenomenon plays a major part in many problems affecting geotechnical structures, for instance, settlement or crack of foundations during drying, swelling or collapse of embankments during wetting, etc. In France, the damage caused by soil shrinkage was estimated to be more than 3.3 billion euro in 2002 [87] and this amount has been increasing as a result of frequently extreme climate. For safety and economic reasons, it is useful, necessary and urgent to investigate the mechanisms involved in drying–wetting paths and to put the knowledge into engineering practice.

In the absence of external mechanical stress, free drying or wetting leads to changes in soil volume, water content as well as degree of saturation, and the key driving parameter associated with these changes is suction. Starting from the water-saturated condition, as suction increases, soil gets desaturated as a result of water transfer from the porous medium to the environment, which, at the same time, results in volume change (shrinkage). On the contrary, in the case of an air-saturated sample, with the decrease in suction, water enters the soil, leading to an increase in degree of saturation and volume (swelling). The cyclic variations of volume, water content and degree of saturation on drying–wetting paths are of considerable importance in soil mechanics applied to shallow foundations and were investigated both experimentally and numerically over the last decades.

In the context of landslides prevention, earthwork construction and, more recently, radioactive waste disposal, drying–wetting tests were performed in order to relate the shrinkage–swelling or water retention behaviour to suction (e.g. [7, 29, 33, 35, 58, 72, 80, 82, 86]). The fruitful experimental data permitted the determination of compressibility (e.g. [84, 85]), permeability (e.g. [37, 81]) as well as shear strength (e.g. [15, 38]) of different engineering soils, in particular expansive clay and collapsible loess. Several parameters affecting drying–wetting curves such as temperature (e.g. [41, 51, 74]), stress history (e.g. [56, 59, 64]) and mineralogy (e.g. [40, 88]) were highlighted and well-illustrated thanks to recently developed techniques such as mercury intrusion porosimetry (MIP), scanning electron microscopy (SEM) and micro-computed tomography (μ-CT) (e.g. [24, 71, 73]). In this domain, another interesting aspect is the analogy between the effect of mechanical stress and that of suction in terms of volume change. By comparing the results of mechanical consolidation and drying tests, some authors [14, 18, 46, 53, 57, 86] found that the drying curve of saturated slurry was equivalent to an isotropic or oedometric consolidation curve, provided that suction was smaller than the air-entry value, i.e. the soil remained quasi-saturated. As explained by Taibi [76], at the micro-scale, the increase in suction on drying path induces the formation of water menisci between soil particles. When the sample is in quasi-saturated state, water fills all the voids, and the stress field applied to soil particles by surrounding water (equal to the value of suction) can be considered to be identical to that of isotropic or oedometric consolidation stress.

The above experimental results promoted the development of several models. At first, correlations between the soil intrinsic parameters (such as liquid limit, plasticity index and pore size distribution) and the soil volume change, as well as water retention behaviour, were established [11, 16, 33, 35, 42, 59, 60]. Then, several elasto-plastic constitutive models were developed to predict with reasonable accuracy the volumetric deformations of unsaturated soils subjected to changes in stress and suction [6, 8, 48, 49, 61, 89]. However, most of these models are unable, in their present state, to calculate directly the corresponding changes in degree of saturation. In these models, the key parameters of the drying–wetting curves (e.g. air-entry suction, shrinkage limit) must be introduced. The knowledge of the drying–wetting curves is also required in semi-empirical models such as those proposed by [44, 55, 63].

The determination of drying–wetting curves is time-consuming and effort-requiring, so that it was, in most of the previous works, limited to the measurement of water content. The change in saturation with suction, however, was often not taken into account as it requires the determination of both water content and void ratio of soil specimens under each applied suction, which is usually cumbersome. Besides, as drying–wetting curves are highly stress dependent, the large quantity of experimental results in the literature for different stress histories (e.g. slurry, statically or dynamically compacted, normally or over-consolidated samples) is virtually difficult to use directly for modelling.

For the above reasons, based on experimental works conducted at Ecole Centrale Paris in the past decades [14, 33, 35, 88], a comprehensive experimental plan was set up to investigate the drying–wetting curves of four engineering soils prepared under both slurry and Proctor compacted conditions. The experimental results together with those reported in the literature for the same stress history conditions contribute: (1) to globally understand the drying–wetting curves and the effect of influencing factors (e.g. soil nature, initial water content, stress history); (2) to make a comprehensive analogy between hydraulic and mechanical loadings, for example, through the comparison between compaction and drying–wetting curves, the analogy between the effect of mechanical stress and suction on soil volume change behaviour, etc.; and (3) to correlate the main parameters of drying–wetting curves with liquid limit. In addition to bring out relatively comprehensive and systematic experimental data to the researchers for further numerical modelling and to the practicing engineers for a first estimation of the soil behaviour, the novelties of the paper are:

-

To show the drying–wetting paths in a global way and present compaction curves with matrix suction as well as iso-suction lines;

-

To provide new experimental proof about the suction effect on the micro-structure change of compacted clay;

-

To confirm with new experimental results the validity of the Terzaghi effective stress approach in quasi-saturated domain (i.e. when the applied suction is smaller than the air-entry suction).

The paper follows the following structure: Sect. 1 introduces the background and main contributions of the present work, and paves the way for Sect. 2 that describes in details the global representation of drying–wetting curves; as routine parts, Sects. 3 and 4 introduce the experimental materials and methods, respectively. In Sect. 5, the experimental results on drying–wetting curves of four soils under slurry and Proctor compacted conditions are presented; by taking advantage of the data in this study and others available in the literature, Sect. 6 tries to correlate some important parameters of drying–wetting curves with liquid limit, and Sect. 7 is dedicated to illustrating and comparing the mechanisms of hydraulic and mechanical loadings; at last, Sect. 8 lists the main conclusions.

2 Global representation of drying–wetting curves under nil external mechanical stress

The first half of the twentieth century witnessed the expansion of interest in research about the relationship between water content and suction. Impressive studies, carried out by soil scientists (e.g. [20, 39, 66–68]), set up a fundamental basis for the subsequent investigation of drying–wetting curves in geotechnical engineering (e.g. [16, 26, 27]). In the late 1980s, the representation of drying–wetting curves was extended and developed into five diagrams that describe globally and simultaneously the shrinkage–swelling, variation of saturation and water retention behaviour of soils (e.g. [14, 45]). As shown in Fig. 1, the global presentation of drying–wetting curves consists of:

Global representation of drying–wetting curves for the saturated slurry of Jossigny silt (after Fleureau et al. [33])

-

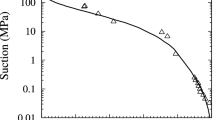

the shrinkage–swelling curves (Fig. 1a, b): in the upper left [w, e] diagram, as a measure of volume change, void ratio is plotted against water content. On the drying curve, the soil first follows the saturation line with the equation e = γ s/γ w × w. Then, as water content continues to decrease, void ratio tends towards a constant value. The shrinkage limit w SL is defined as the intersection between the saturation line and the horizontal asymptote of the dying or wetting curve when w tends to zero. In the upper right [s, e] diagram, void ratio is plotted against suction, showing the compressibility under hydraulic loading. The drying curve shows two distinct phases: a first phase which is similar to the compression of a saturated soil, as evidenced by the parallelism between the drying curve and the oedometric or isotropic compression curves; a second phase where the soil becomes quasi-rigid and behaves elastically. The transition suction between the two domains, s SL, is termed “shrinkage limit suction” and plays an important role in modelling [50, 61].

-

the saturation–desaturation curves (Fig. 1c, d): the middle left [w, S r ] diagram presents the change in degree of saturation with water content. At the beginning of the drying path, the degree of saturation changes insignificantly up to a point beyond which it decreases almost linearly with water content. This point, termed “air-entry point”, is defined as the intersection of the two asymptotic lines. The middle right [s, S r ] diagram shows the change in degree of saturation with suction. Corresponding to the air-entry value, the air-entry suction, s AE, is defined as the intersection of the asymptotic lines.

-

the water retention curve (WRC) (Fig. 1e): the last [s, w] diagram shows the capacity of gravity water to be absorbed by soil at different suctions and the water retention characteristics of the soil subjected to drying and wetting.

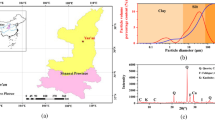

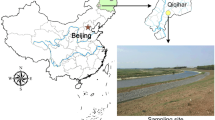

3 Materials

Two engineering soils from France (Camargue silt, Châtaignier clay) and two others from Algeria (Sikkak and Maghnia clays) were investigated in this research. Camargue silt is a core material currently used in the Rhône dikes of Camargue area in the south of France. It is very heterogeneous, consisting of both clay and silt particles. Châtaignier clay is a subgrade material extracted from a site (Châtaignier village) near the Tours–Bordeaux high-speed railway line in the south-west of France. It contains mainly clayey particles with large specific surface area, but also some sharp gravel with diameters of several centimetres, which were eliminated manually before the laboratory tests. Sikkak and Maghnia clays are local materials from the areas of Sikkak and Maghnia, 20 km north and 60 km north-west of the Tlemcen city, respectively, in the west of Algeria. Sikkak material was used in the core of an earth dam, and Maghnia clay is a bentonite deposit.

The grain size distribution and the main geotechnical properties of the four materials are shown in Fig. 2 and Table 1, respectively.

4 Methods

The materials taken from the different sites were first dried under laboratory conditions (20 ± 1 °C) for more than 3 weeks, then crushed with a rubber mallet and finally sieved at 2 mm. The passing particles were dried in an oven at 105 °C for about 2 days and mixed afterwards with the required quantity of distilled water to prepare the saturated slurry or compacted samples.

To prepare the saturated slurry, a quantity of distilled water corresponding to 1.5 times the liquid limit was mixed with 2 kg dried soil particles. In order to get rid of the air bubbles, the mixed slurry was stirred carefully by a mechanical agitator for more than 2 days. Oedometric and isotropic compression tests were performed on the prepared slurry.

Concerning the preparation of compacted samples, the moist Camargue, Sikkak and Maghnia soils were compacted under Proctor conditions in a mould, 11.6 cm high and 10.1 cm in diameter, in three layers, each layer receiving 25 blows from a 2.490 kg rammer dropping from a height of 30.5 cm. For comparison purposes, the Châtaignier clay was compacted with 15, 25 and 35 blows per layer, called reduced Proctor (RP), standard Proctor (SP) and enhanced Proctor (EP), corresponding to specific energies of 0.36, 0.60 and 0.84 MJ/m3, respectively.

During the Proctor test, suction was measured by means of filter-paper and thermocouple psychrometers. For the filter-paper method, the Whatman 42 filter-paper was cut into small pieces of 6 cm in diameter and then sandwiched into two ordinary filter-papers of 8 cm in diameter. The sandwiched filter-paper was carefully laid on each compacted layer, covered with the same soil and compacted again. The whole compacted sample was thereafter put in a plastic bag and sealed with a rubber ring. After 2 weeks, the filter-paper was taken out and its water content was measured quickly (within 5 s) by an analytical balance, with a precision of 0.001 g. The corresponding suctions in the first and second layers were back-calculated using the calibration curves of Chandler et al. [23]. For the thermocouple psychrometer method, the Wescor Dew Point Microvoltmeter (model HR-33T) was used to determine soil suction in the compacted Châtaignier clay. A calibrated ceramic transducer (model PCT-55) was buried into the compacted sample. After 2 days, equilibrium was reached and soil suction was calculated by comparing the measured relative humidity with that of calibration by NaCl solution. It must be noted that filter-paper measures the matrix suction while psychrometer measures total suction. More details about the filter-paper and thermocouple psychrometer methods can be found in the works of Bulut et al. [21] and Verbrugge [84, 85], respectively.

When the above steps were performed, the compacted sample was carefully cut into small bricks of 2–3 cm3, with smooth surfaces. Then, the small specimens, slurry or compacted, were put into different devices for drying–wetting tests.

Four methods, namely tensiometric plate, osmotic, desiccator and dynamic vapour sorption (DVS) methods, were used to control soil suction. Tensiometric plate controls suction between a few kPa and 20 kPa. It consists of a sintered glass with low porosity that serves as a semi-permeable filter, set in a glass funnel. Soil sample is placed on the sintered glass in contact with a reservoir filled with de-aired water and connected to a horizontal measurement tube. When the measurement tube is placed lower than the reservoir, it imposes a negative pressure (i.e. a pressure lower than the atmospheric) to the water in the reservoir. To produce suctions in the range from 100 to 8000 kPa, the osmotic method was used. The sample is placed on a dialysis membrane, which is tightly sealed by two clamps, and then put into the polyethylene glycol (PEG) 20,000 solution until equilibrium (2 weeks). The value of suction depends on the concentration of PEG. For higher values of suction, the method consists in putting the sample in an atmosphere with a given relative humidity. This is achieved either with saturated salt solutions or a dynamic vapour sorption (DVS) device. When a saturated salt is in thermodynamic equilibrium with its vapour, the relative humidity of the surrounding atmosphere remains constant at a given temperature. The relative humidity depends on the nature of the chemical salt. The DVS device is a vapour generator with precise control of relative humidity and temperature that allows measuring the resulting weight of the sample. It must be noted that, for the methods described above, both tensiometric plate and osmotic technique control matrix suction, whereas the desiccator and DVS techniques control the total suction in soil samples. Details of the tensiometric plate method are given by ASTM D 6836-02 [10] and Vanapalli et al. [83]; the osmotic method is described by Blatz et al. [17], and Fleureau and Kheirbek-Saoud [34]; the desiccator and DVS technique are referred to the work of Coronado et al. [25] and Li [53].

In addition to the above methods, the suction effect on compacted clay was studied at the micro-scale by performing mercury intrusion porosimetry (MIP) tests on compacted Châtaignier clay samples that had been subjected to different suctions. The method, which consists mainly of freeze-drying and mercury intrusion steps, is described and analysed in Delage et al. [31].

5 Experimental results

This section includes four subsections, which introduce successively the results of: (1) Proctor compaction test on Châtaignier clay; (2) drying–wetting tests on Camargue silt as well as Châtaignier, Sikkak and Maghnia clays prepared under saturated slurry condition; (3) drying–wetting tests for the above four materials compacted with standard Proctor compaction energy; (4) drying–wetting tests on Châtaignier clay compacted under different conditions. In addition, results of suction effect on the macro- and micro-pores of Châtaignier clay are also presented.

5.1 Compaction curves

Figure 3 presents the compaction curves and the contours of equal suction for the Châtaignier clay. As compaction energy increases from 0.36 (RP) to 0.84 MJ/m3 (EP), the optimum water content decreases from 40 to 33.5%, while the corresponding dry density increases from 1.26 to 1.37 g/cm3. As already observed by several authors, higher compaction energy is accompanied by higher maximum dry density and lower optimum water content. On the dry side of the optimum (e.g. w < 30%), the contours of equal suction are almost vertical, showing that suction is independent of dry density whereas, on the wet side, the contours of matrix suction become progressively parallel to the saturation line. Similar results were reported for different soils such as Chinese loess [52], Boom clay [70] and Speswhite kaolin [78]. These results illustrate that, for clayey soils, matrix suction is mainly determined by the absorbed water in the intra-aggregate voids: on the dry side, compaction stress compresses inter-aggregate voids that do not contain (or contain very little) free water, and intra-aggregate voids are almost not compressed, so that suction is not influenced; by contrast, on the wet side, as the degree of saturation increases, loading mechanism begins to affect the intra-aggregate voids, resulting in lower measured matrix suctions.

Figure 3 also presents the relationship between suction and water content. In a semi-logarithmic coordinate system, matrix suction is observed to be a linear function of water content on both sides of the optimum. The absolute value of the slope on the wet side of the optimum appears to be larger than that on the dry side, resulting from the different fabrics of compacted soils on the dry and wet sides. Similar results were reported by Marinho and Stuermer [58], Fleureau et al. [35] and Taibi et al. [77] for several soils in a relatively large range of liquid limits.

5.2 Drying–wetting curves of saturated slurries

Figures 4 and 5 present the drying–wetting curves of the four soils prepared as slurries. The global representation highlights the difference in soil volumetric and saturation behaviours with respect to water content and suction: in the (w, e) and (w, S r ) planes, the drying and wetting curves approximately coincide with each other; however, in the (s, e), (s, S r ) and (s, w) planes, an apparent hysteresis is observed. Such observations illustrate that hysteresis is apparent in the plane of void ratio or saturation versus suction, and it almost disappears when plotting the parameters against water content. Besides, the experimental results show the significant influence of liquid limit on the characteristics of drying–wetting curves: when liquid limit increases from 36 to 112, shrinkage limit increases from 19 to 24%, and the air-entry suction goes up, from 600 to 3000 kPa.

In order to show the analogy between the effect of suction and that of mechanical stress, the oedometric curve was compared with the drying curve in the same diagram (Fig. 6). The results show that: for Camargue, Sikkak and Maghnia materials, the drying curve is very close to the oedometric curve; however, for Châtaignier clay, the slope of the drying curve was found to be a bit smaller than that of the oedometric curve—such difference may come from the effect of the semi-permeable membranes in both tensiometric plate and osmotic techniques.

Comparison of drying curves with oedometric or isotropic compression curves, and with the empirical correlation proposed by Biarez and Favre [13]

In the work of Biarez and Favre [13], the authors found that isotropic consolidation curve can be characterized by the following reference lines:

For comparison purpose, the above reference lines were plotted and show satisfactory ability to predict both oedometric and drying curves for Camargue, Sikkak and Maghnia materials.

5.3 Drying–wetting curves of standard Proctor compacted samples

Figures 7 and 8 present the drying–wetting curves under standard Proctor compaction conditions. For comparison purpose, the corresponding drying–wetting curves of saturated slurry were plotted using dashed lines.

Concerning the volume change behaviour, starting from the optimum point, the samples subjected to suctions larger than the initial one experience shrinkage, those subjected to suctions lower than the initial one experience swelling. In the (s, e) plane, the wetting curve is approximately linear, similar to those reported in the literature [35, 41, 77, 82]. For the two French soils, the slope of the wetting curve is smaller than that of the drying curve, showing that compressibility under suction loading (drying) is larger than that under suction unloading (wetting). Such results are similar to those of oedometric tests, where compressibility under mechanical loading is generally larger than that during unloading. However, for the two Algerian soils, the results are opposite, probably due to the presence of montmorillonite in the two clays, which generally exhibits a large expansibility during wetting. In the study, the wetting curve of the compacted sample is superposed to that of the oven-dried slurry. Even so, one should be careful about this similarity as the micro-structures of the Proctor compacted soil and oven-dried slurry are quite different: compacted samples generally show a bimodal pore structure while oven-dried slurry samples usually feature unimodal pore structure.

In addition to the above shrinkage–swelling curves, the MIP tests provide a micro-approach to investigate the variation of the pore size distribution during drying and wetting. As shown in Fig. 9, on the wetting path, water moves into the compacted sample and creates more inter-aggregate pores, so that the volume of major inter-aggregate pores increases; on the other hand, on the drying path, as suction increases, water flows out of compacted samples and the major inter-aggregate pore volume decreases. Besides, it is interesting to note that the major inter-aggregate pores become closed at suctions as high as 8 MPa, which is consistent with the macroscopic behaviour in which the shrinkage limit suction is also about 8 MPa. For the studied material and the applied suction, the major intra-aggregate pores with a diameter of about 20 nm were almost unchanged. The above results confirm the observation of Alonso et al. [9] that, for non-active clay, suction and stress applied to compacted specimens modify mainly the macro-porosity.

As regards the water retention behaviour, in the (s, w) plane, again, the wetting curve of compacted samples is very close to that of dried slurry. Similar to the suction change with respect to water content of the compacted path (Fig. 3), the drying and wetting curves can be represented by two linear lines in a semi-logarithmic plane. The absolute value of the slope, termed water capacity, reflecting the ability of the soil to absorb water, was used in various numerical correlations [35, 59, 60] to predict the water retention curve.

5.4 Drying–wetting curves of samples compacted at different energies and water contents

Figure 10 compares the drying–wetting curves of the Châtaignier clay compacted at three different water contents: w SPO − 5, w SPO and w SPO + 5. In general, the drying–wetting curves of the optimum condition lie between those prepared on the dry and wet sides of the optimum, as shown in the (s, e), (s, S r ) and (s, w) planes. For the sample compacted at w SPO − 5, the air-entry suction is smaller than those at w SPO + 5 and w SPO. This can be inferred from the different micro-structures of the compacted samples: compared to the samples compacted at w SPO + 5 and w SPO. Samples at w SPO − 5 usually exhibit larger major inter-aggregate pores, which is consistent with the lower air-entry suction. However, as regards the volume change and water retention behaviours, the results of this study, together with those presented by Fleureau et al. [35], Marinho [57] and Marinho and Stuermer [58], show that the effect of the initial water content is negligible for compacted clays.

Figure 11 shows the drying–wetting curves of the samples prepared at different compaction energies. Many experiments (e.g. [35, 58]) showed the influence of compaction energy on drying–wetting curves and in particular the air-entry suction. This is not obvious in this study for the reasons that: (1) the applied energies (0.36, 0.6 and 0.84 MJ/m3) are not distinct enough to observe a clear difference; (2) dispersion of experimental results comes from the difficulty of the volume measurement. However, from the results, one can at least conclude that the compaction energy (in the tested range) has a limited influence on drying–wetting curves for the tested clayey soils.

6 Correlation

Historically, liquid limit (w L) was deemed to be a suitable intrinsic parameter to represent the nature of soil (e.g. [22, 33, 35, 79]). From an engineering point of view, such representation provides an effective way to correlate the main geotechnical properties with soil nature. In this regard, liquid limit was chosen, in this study, as the basic parameter to characterize the main properties of the drying–wetting curves.

6.1 Correlations of air-entry suction and variation of water content with liquid limit for saturated slurries

In order to highlight the effect of soil nature on drying–wetting curves, the four soils described in this study, together with 17 other soils from the literature (Table 2), were considered and their characteristics were analysed. Correlations have been established between the air-entry suction (s AE) and variation of the water content (Δw L-SL) with liquid limit (Fig. 12):

with Δw L-SL, the change in water content from liquid limit (w L) to shrinkage limit (w SL): Δw L-SL = w L − w SL; R, the regression coefficient.

6.2 Correlation of the wetting path for the standard Proctor compacted soils

As shown in Table 3, a total of 50 soils were analysed for the modelling of the wetting path. Figure 13 provides the correlations between the swelling index and liquid limit:

with C ms, swelling index with respect to void ratio; D ms swelling index with respect to water content.

In addition, with this relatively large quantity of experimental data, it is also possible to correlate the properties of soils at standard Proctor optimum (SPO) with liquid limit:

where w SPO, s SPO and ρ d-SPO represent the water content, suction and dry density at standard Proctor optimum, respectively.

7 Discussion

In this section, the effects of mechanical stress and suction are compared in terms of volume change for saturated slurry; hence, analogy between compaction curve and drying–wetting curves will be examined, and at last, the results of different ways of measuring and controlling suction will be synthesized and evaluated.

7.1 Comparison of the mechanical stress and suction for the saturated slurry

As previously observed by several researchers (e.g. 14, 18, 46, 52, 56), when the applied suction was smaller than the air-entry suction, drying curve presented in the [log(s), e] coordinate system was in fact very close to the oedometric or isotropic curve in the [log(p), e] coordinate system. Such observation is important as it reflects that suction and mechanical stress may have the same effect on the volume change behaviour if the soil is quasi-saturated. Further inspection of these previous results shows that the Terzaghi effective stress initially proposed for saturated soil (s = 0) is still valid for unsaturated soil (0 < s < s air). From a theoretical point of view, these observations and inferences are reasonable as the water menisci formed in the sample can result in a real attractive force between particles, which should have the same effect as that induced by external mechanical loading.

Even though with some deviations for Châtaignier clay, the experimental results in Fig. 6 provide rigorous proof to confirm the above observation from the literature and the theoretical explanation about the equivalent effect of suction and mechanical stress on volume change behaviour. In the figure, both suction and consolidation stress lead to the volumetric change of samples, and if the difference resulting from the effect of semi-permeable membrane is neglected, the drying curve (caused by suction increase) can be considered to be equal to the oedometric or isotropic curve, which is in fact as a result of mechanical stress.

In addition, the empirical correlation line of Biarez and Favre [13], which was initially developed to predict the isotropic curve, is able to characterize, in a concise way, the drying curve in the [log(s), e] plane. In order to further examine the possibility of directly using this empirical method to predict drying curve, the experimental data of the four soils used this study and other 7 soils from the work of Fleureau et al. [33] were collected and then conjunctively presented in Fig. 14. From the figure, the isotropic correlation lines (dashed line) determined according to Eqs. (1) and (2) are reasonably consistent with experimental drying curves of various soils with liquid limit ranges from 27 to 160. Such observation confirmed that, for a first estimation, the drying curve can be reasonably represented by the correlations line of Biarez and Favre [13].

Representation of experimental drying curves for the soils of this study and several others from Fleureau et al. [33] in the void ratio versus suction diagram

Based on Figs. 6 and 14, one can conclude that, for the saturated or quasi-saturated soil, the mechanical stress has an equivalent effect as suction in terms of volume change and Terzaghi effective stress is still valid; for a first estimation of the drying curve, the correlation line of Biarez and Favre [13] can be used.

7.2 Analogy between compaction curve and drying–wetting curves

In the literature, the comparison between compaction and drying–wetting curves has not been much addressed. In the work of Fleureau et al. [35], however, the authors observed the possibility to derive the wetting curves of four soils from compaction tests in which suction was measured. Even though starting from different initial point and following very different processes (either hydraulic or mechanical), it is interesting to note, in the (w, s) plane, the similarity between compaction curve and wetting curve for Proctor compacted samples. In this study, the interest of further comparing the drying–wetting curves with compaction curve lies in examining whether the above correspondence exists or not in other planes [e.g. (w, S r ), (s, S r )], for different soils and under different compaction conditions.

With the compaction curve in Fig. 3, it is possible to present the compaction curve in a more comprehensive way with the following calculations:

Figure 15 presents the global representation of compaction curves at standard Proctor compaction energy and of the drying–wetting curves. Even though with different results on a different soil, our observation is similar to that of Fleureau et al. [35]. In the air-occlusion zone that corresponds to the wet side of the optimum (w > w opt), the compaction curve is very close to the wetting curve. In this regard, it is possible to derive the wetting curve of the compacted soil from the measurements of suction after compaction at different water contents larger than the optimum. Below the air-occlusion zone (w < w opt), the compaction path is located below the drying curve as a result of the presence of a large quantity of air bubbles. To highlight such difference, it is necessary to understand the nature of compaction and drying–wetting curves:

-

the compaction curve describes the final state of soil samples after a mechanical process during which the air phase is compressed or driven out at different initial water contents. Generally, the line representing this mechanical process is vertical in the (S r , w) diagram as water content can be considered as constant.

-

the drying–wetting curves describe the final state of samples compacted at a selected water content after a hydraulic process in which water is transferred from samples to the environment or inversely. The hydraulic process can be represented by the inclined dotted lines in Fig. 15.

More specifically, in the (w, s) plane, the compaction curve is consistent with the drying–wetting curves, especially on the wet side of the optimum.

7.3 Comparison of the water retention curves obtained by different methods

In this study, water retention curves were determined using three approaches: direct measurement of suction and water content in compaction test; measurement of water content under controlled suction conditions during drying–wetting tests; and calculation of the equivalent suction and water content from MIP test.

As shown in Fig. 16, for the direct measurement of suction, the two methods, filter-paper and psychrometer, show an excellent consistency in spite of the relatively limited number of experimental data; as regards suction control, the experimental results of DVS are in very good agreement with those of the desiccator; comparing the WRC from suction measurement and suction control, the results are satisfactory, even though there are some differences for suctions smaller than 1000 kPa, probably due to (1) the metamorphism of the filter-paper (presence of mould) under high water content conditions; (2) the fact that the tensiometric plate and osmotic methods measure matrix suction, whereas the psychrometer measures total suction.

Determination of the water retention curve (WRC) from suction control, suction measurement and mercury intrusion porosimetry (MIP) tests (“Traditional” means the tensiometric plate, osmotic and desiccator methods; DVS represents the dynamic vapour sorption method; to transfer the original data to the modification, a quantity of 10% of the residual water content was added to the original data of the MIP test)

Previous works (e.g. [28, 54, 62, 65, 69]) suggested the possibility to derive the water retention curve from MIP test. Assuming that the mercury intrusion process, in which the non-wetting liquid (mercury) penetrating the porous medium full of a wetting fluid (mercury vapour under vacuum) is equivalent to the drying path in which the wetting liquid (water) moves out of soil. The equivalent suction and water content can be calculated as follows:

in which s is the suction corresponding to the mercury intrusion pressure (p Hg); T w, T Hg represent the surface tensions of water and mercury, respectively (at 20 °C, T w = 72.75 × 10−3 N/m for air–water interface and T Hg = 485 × 10−3 N/m for liquid mercury–mercury vapour interface); θ w and θ Hg are the contact angles of water–solid and mercury–solid phases (θ w = 0° and θ Hg = 140°); w, V mercury and m s represent the equivalent water content, intruded mercury volume and solid mass, respectively.

Figure 16 shows the comparison between the water retention curve (WRC) derived from the MIP test and that derived from drying–wetting tests. In general, there is a similar shape for the two WRC curves, but that determined by MIP test (empty circle line) is located on the left side of that of the drying–wetting experiments.

However, according to some authors (Cui [28], Romero [69]), if a residual water content (e.g. 10% for the very plastic Châtaignier clay) is taken into account, the modified results (solid circle line) are reasonably close to the experimental data, especially for suctions larger than 3 MPa. Considering the high plasticity of the Châtaignier clay and the high percentage of non-accessible pores by mercury, such results are reasonable and acceptable.

8 Conclusion

The tests that were presented in this paper were initially intended to show the interest of the global representation of the drying–wetting curves of different engineering soils. Such representation allows particularly monitoring the saturation of the soil, linking swelling–shrinkage characteristics with suction, etc. Several interesting and useful features have been emphasized.

Concerning the drying–wetting curves of the saturated slurries:

-

hysteresis is apparent in the plane of void ratio or saturation versus suction, and it almost disappears when plotting the parameters against water content;

-

as the representative parameter of soil nature, liquid limit has an essential influence on the characteristics of the drying–wetting curves of slurries or samples compacted under standardized conditions, in particular the air-entry suction and shrinkage limit water content;

-

the mechanical stress (oedometric or isotropic loading) and suction have an equivalent effect in terms of volume change in the quasi-saturated domain, showing the validity of the Terzaghi effective stress for saturated soils under suction; the empirical correlations of Biarez and Favre [13] were shown to provide a fairly good first estimation of drying curve.

As regards the drying–wetting curves of the compacted samples:

-

from a microscopic point of view, suction has a significant influence on the inter-aggregate pores and a suction large enough may lead to the closing of the inter-aggregate pores, whereas the intra-aggregate pores are not influenced in the case of the studied soil and applied suctions;

-

the initial compaction water content influences the air-entry suction and the soil sample prepared on the dry side of the optimum has a smaller air-entry suction, whereas, for the studied soil (Châtaignier clay) and the applied energies (0.36, 0.60 and 0.84 MJ/m3), the influence of energy on the drying–wetting curves is negligible.

In addition, the comparison between the different curves highlighted several interesting observations:

-

even though very different mechanisms are involved, the compaction curve is close to the wetting curve in the air-occlusion zone corresponding to the wet side of the Proctor optimum; therefore, it is possible to determine the wetting curve from the suctions measured after Proctor compaction tests;

-

the different methods of controlling and measuring suction showed a reasonable agreement in the determination of the water retention curve; the water retention curve determined from the pore size distribution curve proved consistent with the drying curve for suctions higher than 3 MPa.

Finally, correlations between different characteristic parameters of drying–wetting curves were established. Satisfactory results were obtained using the liquid limit to model the drying–wetting curves, without excluding other intrinsic parameters for further comprehensive modelling.

Abbreviations

- C ms :

-

Swelling index with respect to void ratio

- D ms :

-

Swelling index with respect to water content

- e :

-

Void ratio

- e SPO :

-

Void ratio at standard Proctor optimum

- G s :

-

Solid density

- I P :

-

Plasticity index

- m s :

-

Mass of solid

- s :

-

Suction

- s AE :

-

Air-entry suction

- s SL :

-

Shrinkage limit suction

- s SPO :

-

Suction at standard Proctor optimum

- S r :

-

Degree of saturation

- T Hg :

-

Surface tension of mercury

- T w :

-

Surface tension of water

- w :

-

Water content

- w L :

-

Liquid limit

- w P :

-

Plastic limit

- w SPO :

-

Water content at standard Proctor optimum

- w SL :

-

Water content at shrinkage limit

- w AE :

-

Water content at air-entry

- θ w :

-

Contact angle of water–solid phases

- θ Hg :

-

Contact angle of mercury–solid phases

- ρ d :

-

Dry density

- ρ d-SPO :

-

Dry density at standard Proctor optimum

- Δw L-SL :

-

Water content change from liquid limit to shrinkage limit

- γ s :

-

Specific weight of grains

- γ w :

-

Specific weight of water

References

AFNOR (1991) Sols: reconnaissance et essais - Détermination de la masse volumique des particules solides des sols - Méthode du pycnomètre à eau, AFNOR NF P94-054. AFNOR Group, France

AFNOR (1992) Sols: reconnaissance et essais - Analyse granulometrique des sols - Méthode par sédimentation, AFNOR NF P94-057. AFNOR Group, France

AFNOR (1996) Sols: reconnaissance et essais - Analyse granulométrique - Méthode par tamisage à sec après lavage. AFNOR NF P94-056. AFNOR Group, France

AFNOR (1993) Sols: reconnaissance et essais - Détermination des limites d’Atterberg - Limite de liquidité à la coupelle - Limite de plasticité au rouleau, AFNOR NF P94-051. AFNOR Group, France

AFNOR (2014) Sols: reconnaissance et essais - Détermination des références de compactage d’un matériau - Essai Proctor normal - Essai Proctor Modifié. AFNOR NF P94-093. AFNOR Group, France

Alonso EE, Gens A, Josa A (1990) A constitutive model for partially saturated soils. Géotechnique 40(3):405–430

Alonso EE, Romero E, Hoffmann C, García-Escudero E (2005) Expansive bentonite-sand mixtures in cyclic controlled-suction drying and wetting. Eng Geol 81(3):213–226

Alonso EE, Pereira JM, Vaunat J, Olivella S (2010) A microstructurally based effective stress for unsaturated soils. Géotechnique 60(12):913–925

Alonso EE, Pinyol NM, Gens A (2013) Compacted soil behaviour: initial state, structure and constitutive modelling. Géotechnique 63(6):463–478

ASTMD 6836-02 (2003) Standard test method for determination of the soil water characteristic curve for desorption using a hanging column, pressure extractor, chilled mirror hygrometer, and/or centrifuge. Annual book of ASTM standards. Section 4: soil and rock, vol 04.08. American Society for Testing Materials, West Conshohocken

Benchouk A, Derfouf M, Abou-Bekr N, Taibi S (2012) Behaviour of some clays on drying and wetting paths. Arab J Geosci 6(12):4565–4573

Benchouk A (2014) Comportement hydromécanique des sols fins compactés au voisinage de la saturation. Doctoral dissertation, Université Abou-Bekr Belkaid de Tlemcen, Algeria

Biarez J, Favre JL (1975) Parameters filling and statistical analysis of data in soil mechanics. In: Proceedings of 2nd international conference on applications of statistics and probability in soil mechanics, Aachen 2, pp 249–264

Biarez J, Fleureau JM, Zerhouni MI, Soepandji BS (1987) Variations de volume des sols argileux lors de cycles de drainage-humidification. Rev Fr Géotech 41:63–71

Biarez J, Fleureau JM, Taibi S (1994) Critère de résistance maximale des sols non saturés: Approche expérimentale et modélisation. In: Proceedings of the 13th International Conference on Soil Mechanics and Foundation Engineering, New-Delhi, January, Oxford & I.B.H. Pub. co., pp 385–388

Black WPM (1962) A method of estimating the California bearing ratio of cohesive soils from plasticity data. Géotechnique 12(4):271–282

Blatz JA, Cui YJ, Oldecop L (2008) Vapour equilibrium and osmotic technique for suction control. Geotech Geol Eng 26(6):661–673

Blight GE (1966) Strength characteristics of desiccated clays. J Soil Mech Found Div 92(6):18–38

Bourokba MS, Hachichi A, Fleureau JM (2007) Comportement de l’argile de Mers El Kebir sur chemin d’humidification drainage. Colloque sols et matériaux à problèmes.9-11 Février, Tunis

Buckingham E (1907) Studies on the movement of soil moisture. U. S. Department of Agriculture Bureau of Soils-Bulletin No. 38, p 64

Bulut R, Lytton RL, Wray WK (2001) Soil suction measurements by filter paper. In: Vipulanandan C, Addison MB, Hasen M (eds) Expansive clay soils and vegetative influence on shallow foundations. ASCE geotechnical special publication no. 115, Houston, Texas, pp 243–261

Casagrande A (1948) Classification and identification of soils. Trans Am Soc Civil Eng 113(1):901–930

Chandler RJ, Crilly MS, Smith MG (1992) A low-cost method of assessing clay desiccation for low-rise buildings. Proc Inst Civil Eng Civil Eng 92(2):82–89

Cnudde V, Boone MN (2013) High-resolution X-ray computed tomography in geosciences: a review of the current technology and applications. Earth Sci Rev 123:1–17

Coronado O, Caicedo B, Taibi S, Correia AG, Fleureau JM (2011) A macro geomechanical approach to rank non-standard unbound granular materials for pavements. Eng Geol 119(1):64–73

Croney D (1952) The movement and distribution of water in soils. Géotechnique 3(1):1–16

Croney D, Coleman JD (1954) Soil structure in relation to soil suction. J Soil Sci 5:75–84

Cui YJ (1993) Etude du comportement d’un limon compacté non saturé, et de sa modélisation dans un cadre élasto-plastique. Doctoral dissertation, Ecole Nationale des Ponts et Chaussées, France

Derfouf FEM, Allal MA, Abou-Bekr N, Taibi S (2013) Mesure et prédiction des chemins de drainage humidification. Application à l’argile d’un noyau de barrage. Rev Fr Géotech 142:49–60

Derfouf FEM (2014) Contribution à l’étude des sols fins non saturés: Aspects du comportement volumique. Doctoral dissertation, Université Abou-Bekr Belkaid de Tlemcen, Algeria

Delage P, Marcial D, Cui YJ, Ruiz X (2006) Ageing effects in a compacted bentonite: a microstructure approach. Géotechnique 56(5):291–304

Fleureau JM, Soemitro R, Taibi S (1992) Behaviour of an expansive clay related to suction. In: Proceedings 7th international conference on expansive soils, Dallas, vol 1, pp 173–178

Fleureau JM, Kheirbek-Saoud S, Soemitro R, Taibi S (1993) Behaviour of clayey soils on drying–wetting paths. Can Geotech J 30(2):287–296

Fleureau JM, Kheirbek-Saoud S (2001) Retrait et Gonflement des sols soumis à un cycle de drainage humidification. Colloque international «Génie Civil et Constructions», Université de Damas, Syrie, 1–3 Octobre

Fleureau JM, Verbrugge JC, Huergo PJ, Correia AG, Kheirbek-Saoud S (2002) Aspects of the behaviour of compacted clayey soils on drying and wetting paths. Can Geotech J 39(6):1341–1357

Fredlund DG (1967) Comparison of soil suction and one-dimensional consolidation characteristics of a highly plastic clay. National Research Council of Canada, Division of Building Research, Technical Paper 245

Fredlund DG, Xing A, Huang S (1994) Predicting the permeability function for unsaturated soils using the soil-water characteristic. Can Geotech J 31(4):533–546

Fredlund DG, Xing A, Fredlund MD, Barbour SL (1996) The relationship of the unsaturated shear strength function to the soil-water characteristic. Can Geotech J 33(3):440–448

Gardner W, Israelsen O, Edlefsen N, Clyde D (1922) The capillary potential function and its relation to irrigation practice. Phys Rev 20(2):196–205

Geremew Z, Audiguier M, Cojean R (2009) Analyse du comportement d’un sol argileux sous sollicitations hydriques cycliques. Bull Eng Geol Environ 68(3):421–436

Ghembaza MS, Taibi S, Fleureau JM (2007) Effet de la température sur le comportement des sols non saturés sur les chemins de drainage et d’humidification. Can Geotech J 44(9):1064–1081

Gupta S, Larson WE (1979) Estimating soil water retention characteristics from particle size distribution, organic matter percent and bulk density. Water Resour Res 15(6):1633–1635

Hagiwara M, Takenaka H (1985) Shrinkage and structure of allophane soil. Soils Found 25(2):77–85

Ho DYF, Fredlund DG, Rahardjo H (1992) Volume change indices during loading and unloading of an unsaturated soil. Can Geotech J 29(2):195–207

Indarto (1991) Comportement des sols soumis à une pression interstitielle négative: application aux silos. Doctoral dissertation, École Centrale Paris, France

Jennings JE (1961) A revised effective stress law for use in the prediction of the behaviour of unsaturated soils. In: Conference on pore pressure and suction in soils (British National Society of Soil Mechanics). Butterworth, London, pp 26–30

Kheirbek Saoud S (1994) Comportement mécanique de le couche de foundation d’une voie ferrée. Doctoral dissertation, École Centrale Paris, France

Kohgo Y, Nakano M, Miyazaki T (1993) Theoretical aspects of constitutive modelling for unsaturated soils. Soils Found 33(4):49–63

Kohgo Y, Nakano M, Miyazaki T (1993) Verification of the generalized elastoplastic model for unsaturated soils. Soils Found 33(4):64–73

Kohgo Y (2002) Elastoplastic models for unsaturated soils with two suction effects and unsaturated soil behaviour. In: Proceedings of the 3rd international conference on unsaturated soils. Swets & Zeitlinger, Lisse, pp 905–915

Laloui L, Salager S, Rizzi M (2013) Retention behaviour of natural clayey materials at different temperatures. Acta Geotech 8(5):537–546

Li ZM (1995) Compressibility and collapsibility of compacted unsaturated loessial soils. In: Proceeding of the 1st international conference on unsaturated soils, Paris, vol 1, pp 139–144

Li ZS (2015) Etudes des propriétés hydromécaniques des sols argileux non saturés proches de la saturation. Doctoral dissertation, Ecole Centrale Paris, France

Liu XF, Buzzi O, Yuan S, Mendes J, Fityus S (2016) Multi-scale characterization of the retention and shrinkage behaviour of four Australian clayey soils. Can Geotech J 53(5):854–870

Lloret A, Alonso EE (1985) State surfaces for partially saturated soils. In: Proceedings of the 11th international conference on soil mechanics and foundation engineering, San Francisco, vol 2, pp 557–562

Lu N, Likos WJ (2006) Suction stress characteristic curve for unsaturated soil. J Geotech Geoenviron Eng 132(2):131–142

Marinho FAM (1994) Shrinkage behaviour of some plastic soils. Doctoral dissertation, University of London, UK

Marinho FAM, Stuermer M (2000) The influence of the compaction energy on the SWCC of a residual soil. Advances in unsaturated geotechnics. ASCE geotechnical special publication, Colorado, Denver, USA, pp 125–141

Marinho FAM (2005) Nature of soil-water characteristic curve for plastic soils. J Geotech Geoenviron Eng 131(5):654–661

Marinho FAM (2006) A method of estimating the soil-water retention curve for plastic soils. In: Miller GA, Zapata CE, Houston SL, Fredlund DG (eds) Fourth international conference on unsaturated soils, Carefree (Arizona). ASCE, pp 1473–1481

Modaressi A, Abou-Bekr N, Fry JJ (1996) Unified approach to model partially saturated and saturated soils. In: Proceeding of the 1st international conference on unsaturated soils, Paris, vol 3, pp 111–116

Muñoz-Castelblanco JA, Pereira JM, Delage P, Cui YJ (2012) The water retention properties of a natural unsaturated loess from northern France. Géotechnique 62(2):95–106

Nanda A, Delage P, Nedjat N, Fry JJ, Gatmiri B (1993) Evaluation de la sécurité des remblais en cours de construction: le code UDAM. Rev Fr Géotech 62:23–34

Ng CWW, Pang YW (2000) Influence of stress state on soil-water characteristics and slope stability. J Geotech Geoenviron Eng 126(2):157–166

Prapaharan S, Altschaeffl AG, Dempsey BJ (1985) Moisture curve of compacted clay-mercury intrusion method. J Geotech Eng ASCE 111(9):1139–1146

Richards LA (1941) A pressure-membrane extraction apparatus for soil solution. Soil Sci 51(5):377–386

Richards LA (1942) Soil moisture tensiometer materials and construction. Soil Sci 53(4):241–248

Richards LA (1949) Methods of measuring soil moisture tension. Soil Sci 68(1):95–112

Romero E (1999) Characterization and thermo-hydro-mechanical behaviour of unsaturated Boom clay: an experimental study. Doctoral dissertation, Universitat Polytècnica de Catalunya, Spain

Romero E, Gens A, Lloret A (1999) Water permeability, water retention and microstructure of unsaturated compacted Boom clay. Eng Geol 54(1):117–127

Romero E, Simms PH (2008) Microstructure investigation in unsaturated soils: a review with special attention to contribution of mercury intrusion porosimetry and environmental scanning electron microscopy. Geotech Geol Eng 6(26):705–727

Romero E, Della Vecchia G, Jommi C (2011) An insight into the water retention properties of compacted clayey soils. Géotechnique 61(4):313–328

Romero E (2013) A microstructural insight into compacted clayey soils and their hydraulic properties. Eng Geol 165:3–19

Salager S, Rizzi M, Laloui L (2011) An innovative device for determining the soil water retention curve under high suction at different temperatures. Acta Geotech 6(3):135–142

Sayad-Gaidi S (2003) Ecoulements dans les milieux poreux peu perméables saturés et non saturés. Doctoral dissertation. Université du Havre, France

Taibi S (1994). Comportement mécanique et hydraulique des sols soumis à une pression interstitielle négative - etude expérimentale et modélisation. Doctoral dissertation. Ecole Centrale Paris, France

Taibi S, Fleureau JM, Abou-Bekr N, Zerhouni MI, Benchouk A, Lachgueur K, Souli H (2011) Some aspects of the behaviour of compacted soils along wetting paths. Géotechnique 61(5):431–437

Tarantino A, De Col E (2008) Compaction behaviour of clay. Géotechnique 58(3):199–213

Terzaghi K, Peck RB (1967) Soil mechanics in engineering practice, 2nd edn. Wiley, New York

Tripathy S, Tadza MYM, Thomas HR (2014) Soil-water characteristic curves of clays. Can Geotech J 51(8):869–883

Van Genuchten MT (1980) A closed form equation predicting the hydraulic conductivity of unsaturated soils. Soil Sci Soc Am J Impact 44:892–898

Vanapalli SK, Fredlund DG, Pufahl DE (1999) The influence of soil structure and stress history on the soil-water characteristics of a compacted till. Géotechnique 49(2):143–159

Vanapalli SK, Nicotera MV, Sharma RS (2008) Axis translation and negative water column techniques for suction control. Geotech Geol Eng 26(6):645–660

Verbrugge JC (1974) Contribution à la mesure de la succion et de la pression interstitielle dans les sols non saturés. Doctoral dissertation, Université Libre de Bruxelles, Belgium

Verbrugge JC (1978) Emploi d’une méthode psychrométrique dans des essais triaxiaux sur un limon remanié non saturé. Revue Canadienne de Géotechnique 15(5): 501–509, and 1979 Discussion 16(3): 615–616

Verbrugge JC, Fleureau JM (2002) Bases expérimentales du comportement des sols non saturés. Coussy O, Fleureau JM (eds) Mécanique des sols non saturés Coll. MIM. Hermès, Paris, pp 69–112

Vincent M (2003) Retrait-gonflement des sols argileux: méthode cartographique d’évaluation de l’aléa en vue de l’établissement de PPR. 3ème conférence SIRNAT-Forum des journées pour la Prévention des Risques Naturels, Orléans, janv. 2003

Wei X, Hattab M, Fleureau JM, Hu R (2013) Micro-macro-experimental study of two clayey materials on drying paths. Bull Eng Geol Environ 72(3–4):495–508

Wheeler SJ, Karube D (1996) Constitutive modelling. In: Proceeding of the 1st international conference on unsaturated soils, Paris, vol 3, pp 1323–1356

Yong RN, Warkentin BP (1975) Soi1 properties and behaviour, development in geotechnical engineering series, Chap. 4. Elsevier, Amsterdam, p 4

Zerhouni MI (1991) Rôle de la pression interstitielle negative dans le comportement des sols-Application au calcul des routes, Doctoral dissertation, Ecole Centrale Paris, France

Acknowledgements

The authors would like to gratefully acknowledge the scholarship from China Scholarship Council (File No. 2010691009) and the financial supports from the French National Project «TerreDurable» (ANR 2011 VILD 004 01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, ZS., Benchouk, A., Derfouf, FE.M. et al. Global representation of the drying–wetting curves of four engineering soils: experiments and correlations. Acta Geotech. 13, 51–71 (2018). https://doi.org/10.1007/s11440-017-0527-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-017-0527-3