Abstract

Granular filters in hydraulically loaded earth structures constitute the ultimate barrier for the blockage of small particles moving through the structure regularly or along concentrated leaks. If filters are inefficient to block small particles several types of internal erosion may be initiated. A corresponding phenomenon appears during suffusion in a wide graded hydraulically loaded fill, when fine particles, embedded in the pore structure of a soil skeleton, are washed out. The cumulative constriction size distribution (CSD) is physically the key property that qualifies the soils retention capability as like a spatial acting sieve. Constrictions are defined as the narrowest sections of channels between larger volumes (pores) within the pore network of granular material, and they are the main obstacles for a small particle to overcome when flowing along pathways. At least three different approaches are available to determine and compute the CSD, i.e., experimental, numerical and analytical methods. The purpose of this review is to present and discuss these methods pointing out their limits, advantages and significance related to internal erosion phenomena.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

All types of internal erosion phenomena, filtration, suffusion, internal instability and even the initiation of piping are affected by the structure of the pore space and therefore by the soil’s structure. The condition for particles to pass through the pore space of a hydraulically loaded soil depends on their kinematics. Therefore, any estimation of particle movement needs to balance the size of potentially transported particles and the distribution of the size of the pores and their constrictions which are also called throats.

Porosity as well as pore space is clearly defined in geotechnical engineering quantitatively as the relative or absolute amount of space between the solid particles through which a fluid can flow. Nevertheless, in detail, pore space is a complex three-dimensional system of connected amorphous and tortuous channels with a scattering cross section and width along the length. In contrast to a soil’s particle, an individual pore has no discrete boundaries, and therefore, the definition of a pore requires certain distinctions.

The best assumption might be to define a single pore as the three-dimensional body of the relatively wide part of a channel that is constricted by two or more throats, which are the narrowest cross sections along any possible pathway. In case of a package of smooth spherical particles, this definition of a constriction as a local minimum of the width delivers a clear distinction of the interface of single pores. However, in case of a packing of amorphous-shaped particles or particles with a rough surface, this is not sufficient. A relative minimum in the cross section can also be generated by teeth on the grains surface as well as by flat- or needle-shaped grains which are projected into a pore body.

This effect might be explained by drawing an analogy between the pore space and a large conference room that could be divided into single rooms by sliding doors. In dependence of the opening of the doors, we perceive the space as a single room or as a set of separate rooms subjectively. Clear conditions are only given if the sliding doors are either totally open or nearly closed. To transfer this metaphor back to a 3-D pore space, we can state that the doors respectively the constrictions along the possible pathways define both, the boundary of a single pore and the size of a particle that might be washed through. To divide the space into single pores, we need a criterion to define a constriction, so-called merge criteria. One option that eliminates roughness effects is the definition that constrictions have to be formed as the area formed between different grains, touching each other.

At this stage, one needs to quantify the properties of the pore bodies and constrictions. We will not detail the definition generally taken by hydrologists for pore sizes and derived from mercury intrusion tests. In this approach, the pore is modeled by cylinder and the pore size distribution is rather related to the volume of pores accessible through throats of a given size. Then, it does not make distinction between pores and throats. Here, a pore is a finite volume entirely comprised between the planes restricting the pore body and associated to the throats. A pore size is supposed to be independent of the throat size say constriction size. To better compare different morphologies, the diameter of the equivalent sphere with a same volume can be built [8, 15, 18] (among others). The information is not lost since in the filtration context, the pore volume is associated with the amount of fine particles that can locally fill the void space. But one must keep in mind that a pore is not necessarily isotropic. Another way to define a pore volume is to compute the largest empty inscribed sphere inside the pore body and then strictly included in the void space [2, 18, 23, 25]. This definition though convenient to handle neglects part of the pore volume and even more if the pore shape is far from a sphere. A constriction size can be defined as the cross area within the plane corresponding to the identified throat. To handle this characteristic more easily, the diameter of the equivalent disk having the same area can be introduced [5, 27] (among others). For filtration processes where a fine particle approximated to a sphere (conservative statement) flows through a porous material, the success for crossing a constriction seems better related to the diameter of the inscribed disk belonging to the plane-throat and included in the void space. Then, this definition for the constriction size is widely considered [11, 12, 14, 16, 20, 22, 24, 26]. In passing, for hydraulic applications, Bryant et al. [5] have shown that averaging these two parameters provides a good estimate for the constriction size required in some methods to compute the hydraulic conductivity.

Anyway, a description of transport in porous media needs an adequate model of its pore space. Transport of fluids as well as movement of solid in soils is strongly influenced by the shape, width and roughness of the pore channels and by the size of the constrictions. All kind of internal erosion phenomena like cake filtration (retention at a soil layer interface), deep bed filtration (retention along a finite penetration) or suffusion (infinite transport of fines within a soil’s coarse structure) are governed by the constrictions along the flow paths. The statistical distribution of the size of the pore constrictions, the cumulative constriction size distribution (CSD), therefore is the most evident factor of influence.

There are different models to simulate and understand fluid and particle transport in soils. A simple model considers continuous unconnected tubes with a fluctuating width. Laminar fluid flow can be described with the Hagen–Poiseuille equation, considering a tube with an equivalent cross section. Related to particle transport and internal erosion, this model corresponds to a sieve whose openings vary greatly in size, each opening representing the smallest constriction of such a virtual tube. Related to filtration or suffusion, this model shows that transport will be stopped if all the openings are clogged by the various sized particles of the transported soil. Theoretically, a boundary for particle transport exists, if there are particles in motion, larger than the major sieve opening size.

A more complex model of the pore space considers connected tubes, a three-dimensional random sequence of pores with a certain number of constrictions which control the transport. In contrast to the unconnected tube model, this spatial network has a dynamic character with a rather infinite number of pathways within this labyrinth and therefore a theoretically higher degree of passage through the system. If a certain pore path is blocked as the opening is too small for a particle to pass through, the flow as well as particle transport might be continued along a diversion until all the possible pathways in the overall direction of flow are blocked by rested particles. But there is always a principle that every pore path shows his ultimate width that controls the size of particles that are able to pass through. And again, transport of particles will be terminated after a certain dynamic process of diversion, if there are no more pathways through the entire soil body for a given size of mobile particle.

No matter which kind of model we use to assess the ability of internal particle transport in a soil; a simple model with unconnected tubes working as a spatial sieve or a complex three-dimensional network with an interaction between retained particles and pore paths, and we need to know at least two fundamental things, (i) the overall distribution of pore constriction sizes within the soil structure and (ii) the distribution of the smallest constriction size of a certain set of properly sequenced constrictions along a pore path, which corresponds to the effective performance of the pore space related to retention of particles. Therefore, the CSD of a soil’s structure is the most evident parameter to assess the ability of filtration, particle discharge and internal stability. Recently, proposals for a filter criterion were designed on the basis of the filter CSD [12, 20]. In the same way, a method to test the internal stability of granular soils was also based upon the CSD of the material [16]. This review presents, classifies, and compares methods that address constriction size measurements and the determination of the CSD. For this purpose, the non-experimental approaches were applied to a sphere packing in order to assess the different resulting CSDs for the same data set.

2 Experimental approaches

2.1 Replica technique to identify pore characteristics

An imprint of a soil’s original pore space gives a very good impression of the complex shape, network and tortuosity of pore paths. In order to fabricate a replica of a coarse soil’s pore system, high elastic liquid rubber can be pressed into the voids until the soil is saturated. After hardening, the grains can be removed gradually from the elastic matrix, cutting the network down into individual pores at apparent constrictions in accordance with the definition mentioned above. This method, first applied to analyze a pore space of natural gravel by Witt [33, 34], allows the extraction and statistical description of pore geometry and important indices such as number of pores per volume, distribution of pore size or number of the constrictions per pore, the so-called pore connectivity. Figure 1 shows such pore imprints of an uniformly graded gravel. This more or less dated method is limited to coarse soils. Nevertheless, due to the similarity of structure and shape of grains, the results are transferable to finer soils.

Separated individual pores of a gravel skeleton [33]

This replica technique might be improved by the sophisticated processing routes for the preparation of macroscopic ceramics [30]. Synthetic grains out of wax or polymeric material, mainly hollow polymeric beads, can be used as a natural template for the fabrication of a pore structure out of resin or ceramic. The grains structure can be saturated with either resin, ceramic powder or slurry, sedimented into the fluid or pressed into a paste. After drying of the pore matrix, polymeric grains can be removed at slow heating rates. Using ceramic powder or slurry as a pore fluid, the polymeric structure will be decomposed and diffused through the ceramic coating before sintering. This technique, established in the ceramic industry as a sacrificial template method, delivers a very precise pore network as a negative replica of the soil’s structure that can be analyzed by different kinds of measurements. In particular, the distribution of the sizes of pore connections, the CSD, can be determined by quantitative laser scanning methods. Figure 2 shows such an imprint of the pore space of a heterodisperse open-celled foam (Fraunhofer IKTS, Dresden, Germany).

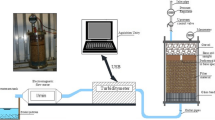

2.2 Base suspension method

Another experimental technique is derived from a former proposal by Soria et al. [29] and involves filtration tests performed on samples of a same granular material (same grading and porosity) but different thicknesses S (Fig. 3). A base material (fine particles) suspended in water is poured on the sample submitted to a constant hydraulic head. The fine particles that have successfully passed through the filter of thickness S are collected and a particle size distribution for this passing material is derived. Actually, the possible sizes of fine particles in the collected material are directly related to the ability for a particle of diameter d to cover a given distance within the void space of the granular filter (here filter thickness). Stating individual unidirectional pathways for particles [27], the probable path length covered by a particle of diameter d is related to the occurrence of the different constriction sizes within the filter. These occurrences are directly related to the CSD of the filter if we deal with homo-disperse filter material. In case of a heterodisperse packing, we obtain the distribution of the effective opening size of the filter, in particular the distribution of the smallest openings along a pathway, whose length depends on the thickness of the filter.

Device for the base suspension method from Soria et al. [29]

The fine particles sequentially flow from a pore to another one passing through constrictions. Following Schuler [24], we suppose that the pore network is distributed according to a regular cubic network forming unit layers and that the path of a fine particle is mainly unidirectional. Consequently, the probability P u of passing one unit layer for a particle of diameter d is equal to the probability of passing one constriction, say P. Therefore, the probability of passing n layers is equal to P un . The probability \(P^{\prime}\) to be captured after a path corresponding to n layers is finally equal to \(P^{\prime} = 1 - P_{un}\) and the total distance S covered by the particle is equal to:

where s is the average thickness of a unit layer, say the mean pore diameter [26]. The inverse method (IM) by Soria et al. [29] leads to the CSD following three steps (Fig. 4):

-

Draw the particle size distributions (PSDs) of fine particles passed through the filter for different filter thicknesses S.

-

Consider a confidence level P′ of 95 %, the value for d c can be determined by drawing a horizontal line intercepting the grading curves. d c is the largest representative diameter of particles which can cover the filter thickness and thus associated with the largest representative constriction sizes for the considered filter thickness.

-

Assume a value for s, P u is calculated from Eq. 1, and the CSD point associated to a filter thickness S is determined.

Experiments IM to derive the CSD according to Soria et al. [29]

The result provided by this technique is very sensitive to the choice of the base material (grading) as to the number and frequency of fine particles that are poured. Indeed the range of the size of fine particles must be in the range of the constriction sizes to hold a physical meaning for the pore space. For example, too large particles will never enter the filter and too small particles being smaller than the percolation diameter will systematically cross the filter whatever its thickness. Moreover, bridging between the fine particles may occur in the pore space (group effect), which may artificially block pathways. All the details for the choice of the base material (grading, number of fine particles) were provided by simulations of these filtration tests by a discrete element method (DEM) and can be found in [28]. Other experimental details can be found in Wu et al. [35]. This technique generally gives only access to the sizes smaller than 50 % of the total constriction number, sizes that are in the range of the mode of the underlying probability density, say the most numerous constriction sizes within the filter. This limitation is due to the minimum filter thickness considered in the experiments which must provide a representative elementary volume, generally on the order of the size of the largest filter particle.

To illustrate this method, a PSD for a studied material (glass beads) is given in Fig. 5 and for this material in its loosest state (void ratio equal to 0.72), the CSD found using this technique is given in Fig. 6 [35]. It involves four different filter thicknesses ranging from D 100 to 10*D 100, D 100 being the diameter of the 100 % passing for the filter material. In this figure, the minimum constriction diameter d cmin is also given since it can be analytically approximated to D 0/6.5, D 0 being the diameter of the 0 % passing for the filter material. This smallest constriction is built with the three smallest filter particles approximated to spheres and in mutual contact.

Particle size distribution of the considered filter composed of glass beads [35]

In mechanical engineering, this experimental or even numerical approach is well known as the measurement of filter performance, which shows how effectively a filter is able to capture particles from a fluid. The result, the cumulative distribution of the governing constrictions along a certain pathway, is called filter retention efficiency or separation curve. As captured particles cause changes of the pore system, the result depends on the kind of dynamic of the hydraulic load that should be also able to remove previously captured particles during the test. According to our experience, the load of the particles in the suspension is another factor of influence, since too many particles cause bridging within the pore space. Finally, the best accuracy and a sharp retention characteristic are obtained by multi-pass tests, applying upstream and downstream flow using particle counters.

3 Numerical approaches

3.1 (Re)creation of a sample

At this step, different methods can be used. The DEM can be helpful to recreate a sample of grains with given geometrical properties to derive general features related to the influence of the grading, density, shape of particles. This method allows controlling the properties that are studied more carefully than in a sample with actual particles. We define three possible levels (level 0 to 2) for this technique. If very refined details are required for the grains or the actual sample, another technique is required (level 3).

-

Level 0 approximates the grains to spheres given by the sieving of the actual material.

-

Level 1 consists in the creation of a library of typical polyhedral particles which shape is derived from 3D images of the actual particles [3]. The polyhedral shape allows the possibility for plane contacts between grains.

-

Level 2 consists in creating an external mesh of the grains by 3D images of actual particles. This external fine mesh is then filled by overlapping spherical particles in order to totally fill the inner volume limited by the mesh [9]. Then, numerical samples composed of these particles can be recreated by different methods: one by deposit under gravity within a box at a given density state. The dynamic equations are solved so that a compatible mechanical equilibrium is obtained [21]. Different density states can be achieved by modifying the friction coefficient at contacts (decreasing the friction coefficient allows obtaining denser states in a quick way). This technique is supposed to be close to the method used to create samples in laboratories with actual soils. Nevertheless, it is known to be time consuming. The other technique consists in filling a given space by a certain predefined mass of particles associated to a targeted porosity. This geometrical filling is accompanied by a minimum mechanical compatibility: a particle that is introduced within the system must have three contact points with existing particles [19]. A final equilibrium [31] under gravity can be imposed to the system. This technique that does not precisely reflect actual conditions of “sample preparation” where both gravity forces and particle interactions are involved to create a mechanically stable solid structure is nevertheless very efficient since far less time consuming than the previous exposed technique.

-

Level 3 involves a direct microtomography of the sample. It allows the 3D image processing of the soil’s structure and therefore visualization and description of both soil skeleton and pore space. A review of the use of tomography devices in geosciences to characterize the microstructure of the pore space can be found in [6, 32]. Considering the relation between sample size and resolution well-graded fine soils might be tested in small undisturbed samples, while non-cohesive coarser soils need a special preparation.

As a part of a research project dealing with suffusion in a gap-graded sandy gravel, Binner et al. [4] developed a technique of specimen preparation that guarantees that the structure of this particular grading maintains its integrity. In this preparation, the specimen was compacted and homogenized to preserve the natural bedding. Then, the sample was slowly saturated in epoxy resin. In order to avoid air blisters within the specimen, the vacuum technique can be applied during intrusion. As the hardened resin shows a very low attenuation coefficient, pores and grains could be distinguished easily in the images. Problems in defining the boundaries of natural grains arise from their surface roughness. To detect the entire structure of a representative sample, double-staged CT scans were produced: A specimen of 110 mm in diameter was scanned (209 μm), then cut into segments of 55 mm in length and scanned with a higher resolution (39 μm) (Fig. 7). The resulting data sets have to be computationally assembled and registered at the different resolution levels. This sample preparation and the resulting CT scans provide a data basis for a further analysis step that detects the pore network including the constrictions [10]. This part of the method is reviewed as the image-based Voronoi approach in Sect. 3.

The sphere packing involving the PSD shown in Fig. 5 and previously created by a DEM is shown in Fig. 8. This sample that is studied herein with different techniques was created with periodic lateral boundaries at the same void ratio as in the experiments.

3.2 Analysis of the sample

3.2.1 Delaunay approach

On the basis of the solid skeleton of the sample (DEM) which particles have to be approximated to spheres, a Delaunay radical tessellation of the space is built. It consists in partitioning the whole sample into tetrahedra whose vertices correspond to the centers of spheres (Fig. 9). The most important void volumes are found mainly in the center of the tetrahedra and can be associated to local pores. The narrowest constrictions are found on the faces of the tetrahedra. Herein, the constriction size is defined as the diameter of the largest empty disk on a tetrahedron face and included in the void space. A recursive algorithm is used to provide the correct value for the constriction size (Powell algorithm). One problem here arises when the candidate for the constriction overlaps a solid sphere belonging to another tetrahedron, which is contrary to its definition. The final constriction must consequently be built considering this solid particle in the process of optimization [21, 31]. A statistics can be obtained from all the constrictions coming from each face of all tetrahedra within the sample. According to Al-Raoush et al. [2], the tessellation of Delaunay tends to artificially subdivide the void space into too many void volumes, and more realistic statistics can be provided by merging certain Delaunay cells using a merging criterion. The problem arises from the definition of a pore that might not be restricted to a Delaunay cell. The merging criterion was not used in this study to derive the CSD but the estimate of the CSD is thus in the conservative side with respect to filtration property. All the details of this method as to possible merging criteria for Delaunay cells can be found in [21].

3.2.2 Voronoi-based approaches

Two approaches can be used to evaluate the distances within the pore space. Each point of the pore space is assigned a property, which is the distance to the nearest of the surrounding solid particles. Within a given region of the pore space, the point of maximal distance defines a pore center (large spheres at the crossings of the graph in Fig. 10). The loci of maximal distance between two adjacent pore centers draw the path for a particle flowing between the two pores (branches of the graph in Fig. 10). Then, the smallest distance along the path defines the constriction between the two pores (medium-sized sphere on a branch of the graph in Fig. 10).

One of the methods is an image-based processing pipeline [10] that can be applied irrespective of the particle shape and surface grain to voxel-based representations like the CT scans, resulting from the method of level 3 in Sect. 3.1. This pipeline implies to define the boundary between the solid space and the pore space to compute the distances within the pore space. It then computes a Voronoi-based decomposition of the image to find the pore centers and paths. The second method directly processes the geometry of a set of spheres having different radii and analytically computes the Voronoi diagram [13]. To detect the constrictions, the analytical descriptions of the Voronoi edges need to be sampled. As mentioned earlier, a merging criterion between two adjacent pores may be required when the smallest distance (constriction size) is very close to the maximum distance (characteristic attached to the pore center) since it tends to reveal that these two pores have a too high degree of interaction to be considered as distinct entities [10].

Figure 11 shows CSD computed by the Delaunay and the analytical Voronoi for the packing of glass beads given in Sect. 2.2. Here, the analytical Voronoi graph is denoted as “Direct Voronoi”. The CSD-labeled “002 Voxelization” was obtained by the Voronoi-based approach. To process the Voronoi-based approach, the sphere sample had to be scan-converted into a voxel representation of the spheres. The voxel size is 0.02 mm × 0.02 mm × 0.02 mm. The CSDs from Delaunay and “Direct Voronoi” approaches are almost confounded, but it was expected since they represent dual techniques for the tessellation of the space. One can note that the resolution associated with a voxel size equal to 0.02 mm was necessary to allow retrieving the CSD with an excellent quality. Different sizes for the voxels were studied (0.08, 0.04, 0.02 mm) and the sensitiveness of the result to the resolution is shown in Fig. 12.

What is more, the Voronoi graph allows extracting some basic but interesting information like the pore bodies, the constriction sizes and the pore paths [10]. As an example, Fig. 13 shows the result of diameter filtering of pore paths for the sphere packing shown in Fig. 8. Starting from the initial graph (a), successively paths which cannot be passed by a grain of certain diameter due to a geometric condition are eliminated. The diameter of the grain that might be able to pass corresponds to the smallest constriction along this path. The graph in (c) is filtered by the largest diameter that holds the top/bottom connection. In parallel experiments, a particle with 1.66 mm is identified as the largest mobile one. The figures illustrate the dramatic decline of possible pathways with increasing the size of a moving particle, and this demonstrates the steep distribution of the controlling constrictions that is significant for a sharp limit of the performance of the skeleton working as a spatial filter.

Diameter filtering of pore paths: The initial graph visualizing all paths is filtered by different diameter thresholds. All paths up to the threshold are removed [10]; a initial graph, b 1.52 mm, c 1.66 mm

4 Analytical approach

The analytical approach aims to compute the CSD from essential information about the granular material, say the PSD and sometimes the relative density. They consist in applying a probabilistic scheme to an assumed geometric packing structure within the filter [24, 26]. Here, the particles are approximated to spheres.

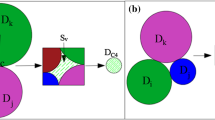

For the densest geometric configuration, Silveira [26] assumed that any constriction is made up of three mutually tangent spheres S i , S j and S k with respective diameters d i , d j and d k , and respective probabilities of occurrence p i , p j and p k (Fig. 14). Then, a constriction is characterized by d c3, the diameter of the disk which is externally tangent to the three disks, resulting from the intersection of spheres S i , S j and S k with the plane passing by their centers. d c3 is calculated from Descartes’ theorem. This constriction size is associated with a probability p c3 which is the probability of occurrence for the group (S i ; S j ; S k ) where r i , r j and r k denote the number of occurrences of d i , d j and d k , in the group of three particles (r i + r j + r k =3), respectively.

Geometrical configuration 3-P and constriction associated with the densest state [26]

Silveira et al. [27] assumed that, in a loose state, the constriction size d c4 is equal to the diameter of the disk whose area is equal to A v , the maximum enclosed area formed by four tangent particles S i , S j , S k and S l (Fig. 15a). Thus, d c4 overestimates the diameter of the sphere which could pass through the constriction since four coplanar particles are scarce in an actual sample. This size is then corrected by a coefficient equal to 0.82. The constriction size d c4 is associated with a probability p c4, which is the probability of occurrence for the group (S i ; S j ; S k ; S l ) where r i , r j , r k , r l denote the number of occurrences of d i , d j , d k , d l in the group of four particles (r i + r j + r k + r l = 4), respectively. Schuler [24] also considers four tangent particles, but two distinct constriction sizes d 1 and d 2 are derived (Fig. 15b).

At this point, one needs to determine the occurrence of a particle diameter which is given by a PSD of the assembly of spheres. Actually, the occurrence of a given constriction size is related to the possibility for contact between particles able to create such constriction. For example, a large constriction results from the contact between large particles if arch effects in the assembly of spheres are neglected. As the coefficient of uniformity of the assembly of spheres increases, one could expect that the occurrence of large constrictions decreases since there is a small probability that these particles will be in mutual contacts. This is not found here if the occurrence of a particle diameter is derived from the PSD by mass (usual PSD) [7]. It implies that this PSD gives too much importance to large particles. Regarding more carefully how contacts between given particle can occur, one can claim that the occurrence of a given constriction size is related to the number of particles able to create such constriction which implies that a PSD by number should rather be used [17]. Nevertheless, using a PSD by number, Musso and Federico [17] found that the fine range of particles is mainly responsible for the constriction sizes and consequently that a sand with few gravel will give a similar CSD than a gravel with few sand. This is not expected and may be due to an excessive importance given to the smaller particles when a PSD by number is used [11]. Then, Humes [11] proposed to use a PSD by lateral surface area pointing out that when a total lateral surface area of a class of particles increases, the probability that these particles belong to an arrangement that will create a constriction increases as well.

This general approach to computing the CSD is a purely geometrical one where mechanics that rules any solid equilibrium is disregarded. But the void space of an actual assembly of particles is structured by a mechanical compatible process and the loosest state cannot be reduced to four-particle configurations and constrictions in the densest state should not only be made up of three tangent filter particles. Taking into account the limits of the approaches by Silveira [26, 27] or Schuler [24], Locke et al. [14] proposed to use a weighted contribution of these two reference geometrical states giving more importance to the 4-P configuration for loose states and to the 3-P configuration for dense states.

Locke et al. [14] computed first the CSD for the “mechanically compatible” loosest state. The analytical CSD proposed by these latter authors allows obtaining for each value P c (% of constrictions smaller) the corresponding constriction diameter d cL . Reboul et al. [22] validated and modified by a multiplicative coefficient equal to 1.11 their analytical model (Eq. 4). This result was found closer to statistics obtained on numerical samples of spherical material (Delaunay approach).

The CSD found by the analytical approach for the packing of spheres whose grading was done in Sect. 2.2 is shown in Fig. 16 together with the one obtained by the Delaunay approach and the one given by the experimental method [29].

For other densities, Locke et al. proposed another analytical formula for the computation of the CSD taking into account the relative density of the material. For this case, Reboul et al. [22] proposed another approach based on a key information for the CSD, say the value of the minimum constriction size d cmin, which is explicitly known for a granular spherical material. For a given void ratio e of the material, the model for the CSD is written:

and e max the maximum void ratio for the material. The derived CSD where found in a very good agreement with the CSD obtained for three materials having different PSD and for densities ranging between the mechanical loosest state to the mechanical densest state. This model was found more efficient than Locke’s formula to retrieve the results obtained by the Delaunay approach. Nevertheless, the analytical form proposed either by Locke et al. or Reboul et al. for the CSD is only valid for continuously graded material. For gap-graded material for which the contact between grains is grain size selective, a more sophisticated model was designed in order to keep the quality of the prediction:

with A and B two parameters depending on the PSD of the material. The identification procedure of these parameters is given in [22].

5 Discussion

The porosity-related characteristic of a soil skeleton, loaded by a fluid flow, is of fundamental evidence for the analysis and examination of flow and internal erosion associated with particle transport. Traditional methods to measure pore size distribution like mercury intrusion porosimetry or statistical analysis of 2D thin plane slices deliver some important parameters and geometrical considerations but not the size and spatial distribution of the pore constrictions along the possible pathways through the pore network of a granular soil, which governs mainly the transport and retention processes of solid in the pore space. Authentic pore space imprints of a soil skeleton got from the replica techniques give an excellent visual impression of the complexity of such a structure. Some effects like typology of grains, relative density of packing or tortuosity of the pore paths can be examined at least qualitatively. Important statistical date like connectivity of the pores or number of pores per length can be analyzed quantitatively. Therefore such imprints can help to understand the nature of pore space and to define an adequate lattice for numerical modeling.

In order to determine the absolute filtration performance characteristic of a soil skeleton, the capacity to retain moving particles, either internally in case of suffusion or at an interface in case of a protection filter, the base suspension method is the most appropriate measure to get reliable overall data. The separation capacity, defined as relation of retained to applied particle load, can be measured at different hydraulic condition including cyclic loading. Related to the model of pore network, the result corresponds to the cumulative distribution of the smallest constriction of the pore paths along the overall lengths of the pathway. There are two main restrictions in carrying out such tests with natural soils (i) the size of the test equipment and (ii) the general problem of preparing homogeneous specimen, both especially if we deal with wide graded soils. Therefore, the reproducibility is influenced by two main reasons, boundary effects in case of relatively thin or slim specimen, and preferred pathways or fingering resulting from unavoidable segregation. Nevertheless, there is another restriction of a different kind: the base suspension method implies the existence of a directional flow (with fine particles in suspension), which interacts with a given soil structure. We know that a certain anisotropy (texture) may exist inducing privileged directions for contacts between the filter particles. A collateral incidence of this may be the existence of a topology, revealing directional properties. Actually, the experimental device implies that the direction of the flow (either downward or upward) is parallel to the direction of the deposit. On site the direction of the flow is on the average perpendicular to the direction of the deposit, say gravity. So far, the impact of this issue on the final CSD is unclear and further research is required in this respect.

μCT scanning methodology allows extracting networks of a real soil’s pore space as well as the description and visualization of the pore space topology and the skeleton [1]. Once all data were available in the appropriate resolution the location and sizes of pores and their constrictions can be determined for statistical purposes or for creating quantitatively a 3D pore network. Coupled with the adequate constitutive law, this scientific tool can also be used to simulate fluid flow, particle movement, capillary effects under unsaturated conditions, load-deformation considerations or physico-chemical effects of sorption within the pore space. However, this approach is also limited by the specimen preparation and by the restrictions resulting from micron scale surface roughness and internal stratification of single grains as well as due to the trade-off between the specimen size and the resolution of the scans. The higher the resolution is, the smaller the specimens have to be in order to guarantee a good image quality for the image processing. Thus, the resolution and partial volume effects restrict the size of smallest detectable structures, because only structures larger than the voxel size of a scan can be resolved. Besides, with view to extract the constrictions and their distribution, the method needs a clear definition of both a single pore and its confining boundaries, the constrictions. As this is not available several routines of merge algorithms are in use leading to different results [10]. With view to describe internal erosion phenomena, pore-space network models from μCT scan are an emerging powerful tool to visualize pore space and pathways for particle movement. A quantitative analysis and prediction of different kind of erosion phenomena needs further research and development. The analytical approaches considering a virtual soil structure out of spheres as well the numerical simulation of such structures using DEM-method do not suffer in such a manner under a strong and accurate definition of a single pore and constriction, if all the particles are part of the structure. For relatively uniform soils, these approaches lead to an accurate prediction of the CSD, which is in good accordance with experimental measurements. According to the assumptions about grain contact conditions, there is a shift or different inclination of the cumulative CSD. Nevertheless, a simulation of a structure involving a wide range of particle sizes will also show problems in defining single pores at one hand and in handling the amount of data with standard computers at the other hand. Apart from these issues, one must remember that the computer time consumption dramatically increases with the extent of particles sizes range. Probably some hierarchical approaches, dividing the space into scaled subspaces or restrictions to the true minimum representative elementary volume will enable these approaches also for this kind of soils.

The main criticism arises from the assumption of spherical particles, which is also inherent to the analytical approach of the filtration problem. Real soil grains have a shape far from a sphere and also from an ellipsoid. Depending on the chemical composition and the genesis of grains, soil particle shape can be rounded, sub-rounded, flat or angular, while the structure varies from loose to dense. Maybe the influence of the non-spherical particles is overestimated, as the error in assumption of the true contact radius has a random character and might be averaged out due to the large number of combinations. However, the comparison of imprints of the pore space of a real soil and such one of spherical particles having the same grading curve and density show that structures of non-spherical graded particles have a pore space with less regularity and a more fuzzy character (Fig. 1). Further research should be done to highlight these effects. Other obvious issue related to the assumption of spherical material is that the CSD at any density state is defined considering the CSD for the loosest state. From Eq. 2, the property of the loosest state (density) that is dependent on the angularity of particles in actual soils is not considered. Some illustration of the possible impact of this restriction can be seen in [35] and further research is required to more accurately adapt the analytical CSDs to actual soils. Independently of these sources of error, the procedures of simulation can be used to study effects like relative density, compaction, local segregation and in detail the change in pore space data due to retention. And once validated such computer simulations, these routines would allow to find the most important relation, the correlation of grain size distribution of a soil and its CSD and therefore would allow to predict the retention capacity of a grading curve.

6 Conclusion

Methods to visualize, analyze, simulate and describe the structure of the pore space of non-cohesive soils have been presented and discussed. The main purpose of these procedures is to predict the CSD in order to assess the capability of a soil skeleton to retain moving particles transported by an internal fluid flow. There is no doubt that the size of the constrictions between the single pores is the most evident parameter governing passage or retention along pore paths in a dynamic process of spatial filtering.

All the methods are based on specific requirements and show their particular limitation related to absolute size of gradation, type of grain size distribution, particle shape, accuracy, computer time consumption and handling of data obtained. For uniformly graded soils with mainly rounded particles, the analytical approaches seem to be a promising method to calculate the CSD and combine the result with a quantitative assessment of filter capability. If partly done by some researchers, a future aim should be to use these methods more extensively to evaluate the grain size criteria currently used in engineering practice. The more scientific approach starts with μCT scans of real soil structures that are the base for the description and visualization of the complex structure of a pore network. But especially for naturally shaped grains this technique needs some algorithm to extract the parameters of interest, the distribution of the constrictions as well as the quantitative description of the pore paths. The aim of the research in that field should be to find adequate criteria for merging pore throats at one hand and to compute absolute data for the numerical simulation of transport and retention related to internal erosion phenomena at the other. For naturally shaped grains, the analytical methods need to be qualified and further on adapted to consider the influence of angularity and elongation of grains.

At any moment, the studies involving the computation of the CSD have considered the possible influence of the texture of the solid fraction in the method. Future works need to clarify the possible directionality of the CSD. Finally, the challenging task may be to extend these procedures to substantially non-uniform soils to consider effects of heterogeneity in both grain skeleton and pore structure.

References

Al-Kharusi AS, Blunt MJ (2007) Network extraction from sandstone and carbonate pore space images. J Petrol Sci Eng 56(4):219–231

Al-Raoush R, Thompson K, Willson C (2003) Comparison of network generation techniques for unconsolidated porous media. Sci Soc Am J 67:1687–1700

Azma E, Radja F, Peyroux R, Richefeu V, Saussine G (2008) Short-time dynamics of a packing of polyhedral grains under horizontal vibrations. Eur Phys J E 26(3):327–335

Binner R, Homberg U, Prohaska S, Kalbe U, Witt KJ (2010) Identification of descriptive parameters of the soil pore structure using experiments and CT data. In: Proceedings of the 5th international conference on scour and erosion, pp 397–407

Bryant S, King P, Mellor D (1993) Network model evaluation of permeability and spatial correlation in a real random sphere packing. Transp Porous Media 11:53–70

Cnudde V, Boone M (2013) High-resolution X-ray computed tomography in geosciences: a review of the current technology and applications. Earth Sci Rev 123:1–17

De Mello VFB (1977) Reflections on design decisions of practical signifiance to embankment dams. Géotechnique 27(3):281–355

Delerue J, Perrier E, Zu Z, Velde B (1999) New algorithms in 3d image analysis and their application to the measurement of a spatialized pore size distribution. Phys Chem Earth 24:639–644

Garcia X, Akanji LT, Blunt M, Matthai S, Latham J (2009) Numerical study of the effects of particle shape and polydispersity on permeability. Phys Rev E (N021304):1–9

Homberg U, Baum D, Prohaska S, Kalbe U, Witt KJ (2012) Automatic extraction and analysis of realistic pore structures from ct data for pore space characterization of graded soil. In: Proceedings of 6th international conference on scour and erosion (ICSE-6); paper 181

Humes C (1996) Geofilters’96. In: A new approach to compute the void size distribution curves of protective filters. Bitech, Montreal, pp 57–66

Indraratna B, Raut A, Khabbaz H (2007) Constriction-based retention criterion for granular filter design. J Geotech Geoenviron Eng 133(3):266–276

Lindow N, Baum D, Hege HC (2011) Voronoi-based extraction and visualization of molecular paths. IEEE Trans Vis Comput Graph 17(12):2025–2034

Locke M, Indraratna B, Adikari G (2001) Time-dependent particle transport through granular filters. J Geotech Eng Div ASCE 127(6):521–528

Lucknikov V, Gavrilova M, Medvedev N, Voloshin V (2002) The voronoi-delaunay approach for the free volume analysis of a packing of balls in a cylindrical container. Future Gener Comput Syst 18:676–679

Moraci N, Mandaglio M, Ielo D (2012) A new theoretical method to evaluate the internal stability of granular soils. Can Geotech J 49:45–58

Musso A, Federico F (1983) Un metodo geometrico-probabilistico per la verifica dei filtri. Rivista Italiana di Geotecnica 4:173–193

Nolan G, Kavanagh P (1994) The size distribution of interstices in random packings of spheres. Powder Technol 78:231–238

Powell MJ (1980) Computer-simulated random packing of spheres. Powder Technol 25(1):45–52

Raut A, Indraratna B (2008) Further advancement in filtration criteria through constriction-based techniques. J Geotech Geoenviron Eng 134(6):883–887

Reboul N, Vincens E, Cambou B (2008) Statistical analysis of void size distribution in a simulated narrowly graded packing of spheres. Granul Matter 10(6):457–468

Reboul N, Vincens E, Cambou B (2010) A computational procedure to assess the distribution of constriction sizes for an assembly of spheres. Comput Geotech 37(1):195–206

Rémond S, Gallias J, Mizrahi A (2008) Characterization of voids in spherical particle systems by delaunay empty spheres. Granul Matter 10:329–334

Schuler U (1996) Geofilters’96. In: Scattering of the composition of soils—an aspect for the stability of granular filters. Bitech, Montreal, pp 21—34

Silin D, Patzek T (2006) Pore space morphology analysis using maximal inscribed spheres. Phys A 371:336–360

Silveira A (1965) An analysis of teh problem of washing through in protective filters. In: 6th international conference on soil mechanics and foundation engineering, Montreal, Canada, vol 2, pp 551–555

Silveira A, de Lorena Peixoto Jr J, Nogueira J (1975) On void size distribution of granular materials. In: 5th panamerican conference on soil mechanics and foundation engineering, Buenos Aires, Argentina, vol 3, pp 161–176

Sjah J, Vincens E (2013) Determination of the constriction size distribution of granular filters by filtration tests. Int J Numer Anal Methods Geomech 37(10):1231–1246

Soria M, Aramaki R, Viviani E (1993) Experimental determination of void size curves In: Filters in geotechnical and hydraulic engineering. Rotterdam: Balkema, pp 43–48

Studart AR, Gonzenbach UT, Tervoort E, Gauckler LJ (2006) Processing routes to macroporous ceramics: a review. J Am Ceram Soc 89(6):1771–1789

To H, Scheuermann A, Williams D (2012) A new simple model for the determination of the pore constriction size distribution. In: Proceedings of 6th international conference on scour and erosion (ICSE-6); paper 082

Wildenschild D, Hopmans J, Vaz C, Rivers M, Rikard D, Christensen B (2002) Using X-ray computed tomography in hydrology: systems, resolutions and limitations. J Hydrol 267:285–297

Witt K (1986) Filtrationsverhalten und bemessung von erdstoff-filtern. verffentl. Tech. Rep. 104, D. Inst. F. Bodenmechanik und Felsmechanik. Universitt Karlsruhe. Heft

Witt K (1993) Reliability study of granular filters. In: Brauns J, Heibaum M, Schuler U (eds) Filters in geotechnical and hydraulic engineering. Balkema, Rotterdam, pp 35–41

Wu L, Nzouapet BN, Vincens E, Bernat-Minana S (2012) Laboratory experiments and the determination of the constriction size distribution of granular filters. In: Proceedings of 6th international conference on scour and erosion (ICSE-6); paper 142

Acknowledgments

The first author wants to acknowledge the French Agency of Research (ANR) and the French Network for Civil Engineering and Urbanization (RGCU) for the financial support provided to the national research project ERINOH “internal erosion in hydraulic structures” from which many results presented herein were obtained. The second author wishes to acknowledge the German Research Foundation (DFG) for supporting the research project “Conditions of suffusive erosion phenomena in soils”. Special thanks to Mrs. D. Böttge, Fraunhofergesellschaft ITKS, Dresden, for the photographs of ceramic structures, Fig. 2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vincens, E., Witt, K.J. & Homberg, U. Approaches to determine the constriction size distribution for understanding filtration phenomena in granular materials. Acta Geotech. 10, 291–303 (2015). https://doi.org/10.1007/s11440-014-0308-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-014-0308-1