Abstract

Five phenylethanoid glycosides (acteoside, isoacteoside, β-oxoacteoside, β-hydroxyacteoside, and salidroside) were isolated from a cell suspension culture of Olea europaea. We examined the biosynthesis of acteoside in olive cell cultures by using feeding experiments with stable isotope labeled precursors. The hydroxytyrosol moiety of acteoside is biosynthesized from tyrosine through dopamine, whereas the caffeoyl moiety of acteoside is biosynthesized from phenylalanine via a cinnamate pathway. Dopamine is incorporated into acteoside through oxidation to the corresponding aldehyde, reduction to the alcohol, and then β-glycosylation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Olea europaea L. (olive) is an evergreen tree native to the Mediterranean coast whose fruit and oil have been used for food and cooking. There are reports about the olive’s effectiveness in the prevention of heart aliments and hypertension [1]. The olive tree contains oleanane-type triterpenes, e.g., oleanolic acid, as a secondary metabolite; the triterpenes are accumulated in the fruit [2]. We induced olive cell cultures and investigated their components, expecting to obtain a large amount of the oleanane-type triterpenes and triterpene glycosides; however, no triterpene glycosides were isolated, and more ursane-type triterpenes than oleanane-type triterpenes were isolated from the cell suspension cultures [3]. We also determined that the main secondary metabolites in olive cell cultures were phenylethanoid glycosides.

Acteoside (verbascoside) is a typical phenylethanoid glycoside, which has antioxidant [4], anti-inflammatory [5], antihypertensive [6], and various other biological and pharmaceutical uses. Acteoside has a 3,4-dihydroxyphenylethanol (hydroxytyrosol) moiety as a partial structure, which is comparatively rare in secondary metabolites [7–9]; however, the biosynthesis of acteoside and other phenylethanoid glycosides has not been thoroughly investigated [10, 11]. In this paper, we report biosynthetic studies of phenylethanoid glycosides by using experiments feeding stable isotope labeled compounds into olive cell cultures.

Materials and methods

General procedures

l-[1-13C]Phenylalanine (99% isotopic abundance), l-[3-13C]phenylalanine (99%), and l-[1-13C]tyrosine (99%) were purchased from Sigma-Aldrich Chemical Co. l-[3-13C]Tyrosine (99%) and [1-13C]phenethylamine (99%) were purchased from ISOTEC Inc. [2,2-D2]Dopamine (97–98%), [1,1,2,2,-D4]dopamine (97–98%), l-[2,3-13C2-4-hydroxy-18O]DOPA (97% [13C], 95% [18O]), and [1-13C]2-phenylethanol (99%) were purchased from Cambridge Isotope Laboratories Inc. Diaion HP20 was purchased from Mitsubishi Chemical Co. Millex-GP 0.22 μm was purchased from Millipore Co. Other general materials were purchased from Sigma-Aldrich Co., Merck Co., or Wako Pure Chemical Industries, Ltd. NMR spectra were recorded on a JEOL JNM-LA500 spectrometer in CD3OD at 30°C. 1H NMR spectra were recorded at 500 MHz and the chemical shifts were referenced to 3.30 ppm for the central peak of CHD2OD in CD3OD. 13C NMR spectra were recorded at 125 MHz and the chemical shifts were referenced to 49.8 ppm for the central peak of CD3OD. The relative 13C abundance of individual carbon atoms (% 13C) was calculated by comparing the 13C signal integral between the 13C-labeled product and non-labeled samples. The values were referenced to 1.1% for the carbon signal of glucose-1 observed at 104.2 ppm (see Table 1) for labeled and non-labeled samples. HPLC was performed on a Shimadzu model LC-10 system with a SPD-10Avp photodiode array detector and an RID-10A refractive index detector. LC–electron spray ionization (ESI)–MS was performed on a Thermoquest model LCQ system in negative mode, equipped with a Hewlett-Packard HP1100 system. LC was performed using a Shim-pack CLC-ODS(M) column (4.6 × 250 mm) with 33% MeOH (flow rate 1.0 ml/min) at 40°C. Relative MS peak intensity of each sample was referenced to 100 for the peak of m/z 623 [M − H]−, the base peak observed with the natural acteoside.

Callus induction of O. europaea and subcultures

The callus induction of O. europaea into CM-NH4 medium has already been reported [3]. The CM-NH4 agar medium was a modified Murashige and Skoog’s [12] agar medium with 30 g/l sucrose, 1 mg/l 2,4-dichlorophenoxyacetic acid, 0.1 mg/l kinetin, 7% coconut milk, and 9 g/l agar, supplemented with K+ instead of NH4 +. The calli cultured on the CM-NH4 agar medium were transferred to a DK-NH4 agar medium, which was CM-NH4 agar medium without coconut milk, and subcultured every 4 weeks at 25°C in the dark.

Extraction and isolation of phenylethanoid glycosides from the cultured cells of O. europaea

The olive cells (about 9 g, fresh weight (f.w.)) cultured for 4 weeks on a DK-NH4 agar medium were inoculated into 200-ml conical flasks containing 80 ml of DK-NH4 liquid medium and cultured on a rotary shaker (60 rpm) at 25°C in the dark. After four additional weeks of culturing, the cells were harvested and fresh cells from 6 flasks (190 g, f.w.) were homogenized and extracted twice with MeOH at room temperature. The MeOH extract solution was concentrated. The extract was partitioned between hexane and H2O. The H2O layer was passed through a Diaion HP20 column. The column was washed with H2O and then eluted with MeOH. The MeOH eluate was evaporated and then partitioned between n-BuOH and H2O. The n-BuOH extract (151 mg) was subjected to HPLC repeatedly using Millipore Prep Nova-Pak HR columns (6 μm, C18, 60 Å, 7.8 × 300 mm), 32% MeOH, 2.0 ml/min to yield compounds 1 (104 mg), 2 (5 mg), 3 (3 mg), and 4 (12 mg). The eluate before compound 1 was concentrated and subjected to HPLC using the same column (20% MeOH, 2.0 ml/min) to yield compound 5 (2 mg).

Acteoside (1)

Amorphous; negative ESI MS m/z: 623 [M − H]−; 1H NMR δ: 1.05 (3H, d, J = 6.5 Hz, rhamnose-6), 2.78 (2H, dd, J = 8.0, 7.0 Hz, H-7), 3.28 (1H, dd, J = 9.5, 9.5 Hz, rhamnose-4), 3.38 (1H, dd, J = 9.5, 8.5 Hz, glucose-2), 3.50–3.64 (5H, m, glucose-5, 6a, 6b, rhamnose-3, 5), 3.72 (1H, ddd, J = 9.0, 8.0, 7.0 Hz, H-8a), 3.81 (1H, dd, J = 9.5, 9.5 Hz, glucose-3), 3.91 (1H, dd, J = 3.5, 1.5 Hz, rhamnose-2), 4.04 (1H, ddd, J = 9.0, 8.0, 7.0 Hz, H-8b), 4.37 (1H, d, J = 8.5 Hz, glucose-1), 4.91 (1H, dd, J = 9.5, 9.5 Hz, glucose-4), 5.18 (1H, d, J = 1.5 Hz, rhamnose-1), 6.27 (1H, d, J = 16.0 Hz, H-8′), 6.56 (1H, dd, J = 8.5, 2.0 Hz, H-6), 6.67 (1H, d, J = 8.5 Hz, H-5), 6.69 (1H, d, J = 2.0 Hz, H-2), 6.77 (1H, d, J = 8.5 Hz, H-5′), 6.95 (1H, dd, J = 8.5, 2.0 Hz, H-6′), 7.05 (1H, d, J = 2.0 Hz, H-2′), 7.59 (1H, d, J = 16.0 Hz, H-7′); 13C NMR (see Table 1).

Isoacteoside (2)

Amorphous; negative ESI MS m/z: 623 [M − H]−; 1H NMR δ: 1.24 (3H, d, J = 6.0 Hz, rhamnose-6), 2.78 (2H, ddd, J = 7.0, 7.0, 2.0 Hz, H-7), 3.28–3.34 (1H, m, glucose-2), 3.40 (1H, dd, J = 9.0, 9.0 Hz, glucose-4), 3.50–3.56 (2H, m, H-8a, glucose-5), 3.52 (1H, dd, J = 9.0, 9.0 Hz, glucose-3), 3.68–3.78 (1H, m, rhamnose-3), 3.82–4.00 (3H, m, H-8b, rhamnose-2, 4), 4.32 (1H, d, J = 8.0 Hz, glucose-1), 4.34 (1H, dd, J = 12.0, 5.5 Hz, glucose-6b), 4.49 (1H, dd, J = 12.0, 2.0 Hz, glucose-6a), 5.16 (1H, d, J = 1.5 Hz, rhamnose-1), 6.28 (1H, d, J = 16.0 Hz, H-8′), 6.52 (1H, dd, J = 8.0, 2.0 Hz, H-6), 6.63 (1H, d, J = 8.0 Hz, H-5), 6.66 (1H, d, J = 2.0 Hz, H-2), 6.76 (1H, d, J = 7.5 Hz, H-5′), 6.88 (1H, dd, J = 7.5, 2.0 Hz, H-6′), 7.03 (1H, d, J = 2.0 Hz, H-2′), 7.55 (1H, d, J = 16.0 Hz, H-7′); 13C NMR (see Table 1).

β-Oxoacteoside (3)

Amorphous; negative ESI MS m/z: 637 [M − H]−; 1H NMR δ: 1.09 (3H, s, J = 6.5 Hz, rhamnose-6), 3.27–3.34 (1H, m, rhamnose-4), 3.50–3.65 (6H, m, glucose-2, 5, 6a, 6b, rhamnose-3, 5), 3.86(1H, dd, J = 9.5, 9.5 Hz, glucose-3), 3.93 (1H, dd, J = 3.0, 1.5 Hz, rhamnose-2), 4.47 (1H, d, J = 8.0 Hz, glucose-1), 4.92 (1H, d, J = 17.0 Hz, H-8a), 4.93 (1H, dd, J = 9.5, 9.5 Hz, glucose-4), 5.22 (1H, d, J = 1.5 Hz, rhamnose-1), 5.26 (1H, d, J = 17.0 Hz, H-8b), 6.27 (1H, d, J = 16.0 Hz, H-8′), 6.77 (1H, d, J = 8.5 Hz, H-5), 6.82 (1H, d, J = 8.0 Hz, H-5′), 6.95 (1H, dd, J = 8.0, 2.0 Hz, H-6′), 7.05 (1H, d, J = 2.0 Hz, H-2′), 7.42 (1H, d, J = 1.5 Hz, H-2), 7.43 (1H, dd, J = 8.5, 1.5 Hz, H-6), 7.59 (1H, d, J = 16.0 Hz, H-7′); 13C NMR (see Table 1).

β-Hydroxyacteoside (4)

Amorphous; negative ESI MS m/z: 639 [M − H]−; 1H NMR δ: 1.09 (3H, d, J = 6.5 Hz, rhamnose-6), 3.31 (1H, m, rhamnose-4), 3.45 (1H, dd, J = 9.0, 8.5 Hz, H-8a), 3.51–3.62 (6H, m, glucose-2, 5, 6a, 6b, rhamnose-2, 5), 3.84 (1H, dd, J = 9.5, 9.5 Hz, glucose-3), 3.92 (1H, dd, J = 3.5, 2.5 Hz, rhamnose-3), 3.97 (1H, dd, J = 9.0, 3.0 Hz, H-8b), 4.41 (1H, d, J = 8.0 Hz, glucose-1), 4.74 (1H, dd, J = 8.5, 3.0 Hz, H-7), 4.93 (1H, dd, J = 9.5, 9.5 Hz, glucose-4), 5.21 (1H, d, J = 1.0 Hz, rhamnose-1), 6.26 (1H, d, J = 15.5 Hz, H-8′), 6.70 (1H, d, J = 8.5, 2.0 Hz, H-6), 6.73 (1H, d, J = 8.0 Hz, H-5′), 6.77 (1H, dd, J = 8.5 Hz, H-5), 6.83 (1H, d, J = 2.0 Hz, H-2), 6.95 (1H, dd, J = 8.0, 2.5 Hz, H-6′), 7.04 (1H, d, J = 2.5 Hz, H-2′), 7.58 (1H, d, J = 15.5 Hz, H-7′); 13C NMR (see Table 1).

Salidroside (5)

Amorphous; negative ESI MS m/z: 299 [M − H]−; 1H NMR δ:2.82 (2H, dd, J = 8.0, 6.5 Hz, H-7), 3.17 (1H, dd, J = 9.5, 7.5 Hz, glucose-2), 3.25 (1H, ddd, J = 9.5, 5.5, 2.5 Hz, glucose-5), 3.26 (1H, dd, J = 9.5, 9.0 Hz, glucose-4), 3.34 (1H, dd, J = 9.5, 9.0 Hz, glucose-3), 3.65 (1H, dd, J = 11.5, 5.5 Hz, glucose-6b), 3.69 (1H, ddd, J = 9.5, 8.0, 6.5 Hz, H-8a), 3.85 (1H, dd, J = 11.5, 2.5 Hz, glucose-6a), 4.02 (1H, ddd, J = 9.5, 8.0, 6.5 Hz, H-8b), 4.28 (1H, d, J = 7.5 Hz, glucose-1), 6.68 (2H, d, J = 9.0 Hz, H-3,5), 7.05 (2H, d, J = 9.0 Hz, H-2,6); 13C NMR (see Table 1).

Preparation of [2-13C]tyramine

[2-13C]Tyramine was prepared according to Sugimoto and Yamada [13]. A mixture of 100 mg l-[3-13C]tyrosine, 23 mg l-tyrosine decarboxylase (10 U), 25 ml 0.2 M acetate buffer (pH 5.5), and 50 ml H2O was incubated for 8 h at 37°C. The incubation mixture was made alkaline (pH 10) with ammonia water and extracted with EtOAc. The EtOAc layer was evaporated and 42 mg [2-13C]tyramine was obtained.

Feeding experiments using stable isotope labeled compounds

The olive cells (about 9 g, f.w.) cultured for 4 weeks on a DK-NH4 agar medium were inoculated into 200-ml conical flasks containing 80 ml of DK-NH4 liquid medium and cultured on a rotary shaker (60 rpm) at 25°C in the dark. After an additional 3 weeks of culture, 10 mg l-phenylalanine ([1-13C]:[3-13C] = 1:1), 10 mg l-tyrosine ([1-13C]:[3-13C] = 1:1), 5 mg l-[2,3-13C2-4-hydroxy-18O]DOPA, 10 mg [2,2-D2]dopamine, 10 mg [1,1,2,2-D4]dopamine, 10 mg [1-13C]2-phenylethanol, 10 mg [1-13C]phenethylamine, or 10 mg [2-13C]tyramine was administered to a cell suspension culture. The deuterium- or 13C-labeled compounds were dissolved in 3–4 ml water and sterilized by filtration (Millex-GP 0.22 μm). After administration, each culture was incubated for an additional week. Acteoside (1) was partially isolated (about 5 mg from each culture) as described above. In the [2-13C]tyramine feeding experiment, about 4 mg salidroside (5) was also isolated. In the feeding experiments using [1-13C]phenethylamine, [1-13C]2-phenylethanol, and phenethylamine, a new compound 6 was isolated with HPLC using the same conditions as for the isolation of salidroside. The relative abundance of each 13C-labeled compound was determined by 13C NMR, and the relative incorporation ratio of each deuterium-labeled acteoside was determined by ESI–LC–MS.

2-Phenethyl β-primeveroside (6)

Amorphous; negative ESI MS m/z: 415 [M− H]−; 1H NMR δ: 2.92 (2H, dd, J = 7.5, 7.5 Hz, H-7), 3.14–3.22 (3H, m, xylose-2, 4, 5a), 3.28-3.36 (3H, m, glucose-2, 3, 4), 3.42 (1H, m, glucose-5), 3.48 (1H, ddd, J = 10.5, 9.0, 5.5 Hz, xylose-4), 3.73 (1H, dd, J = 11.5, 5.5 Hz, glucose-6a), 3.76 (1H, ddd, J = 10.0, 7.5, 7.5 Hz, H-8a), 3.85 (1H, dd, J = 11.5, 5.5 Hz, xylose-5b), 4.05 (1H, ddd, J = 10.0, 7.5, 7.5 Hz, H-8b), 4.08 (1H, dd, J = 11.5, 2.0 Hz, glucose-6b), 4.29 (1H, d, J = 8.0 Hz, glucose-1), 4.31 (1H, d, J = 8.0 Hz, xylose-1), 7.15 (1H, m, H-4), 7.21–7.28 (4H, m, H-2, 3, 5, 6); 13C NMR δ: 37.2 (t), 66.8 (t), 69.8 (t), 71.1 (d), 71.4 (d), 71.8 (t), 74.8 (d), 75.0 (d), 76.9 (d), 77.6 (d), 77.9 (d), 104.4 (d), 105.4 (d), 127.2 (d), 129.3 (d × 2), 130.0 (d × 2), 140.0 (s).

Suppression of acteoside production in olive cells using putative inhibitors

Olive cells were cultured as in the previous experiment. After 2 weeks of additional culturing, 16 mg α-methyltyrosine in 2 ml water (final concentration 1 mM), 24 mg benserazide hydrochloride in 2 ml water (final concentration 1 mM), or 2 ml water was administered into a cell suspension culture. Each compound was sterilized by filtration (Millex-GP 0.22 μm). After administration, each culture was incubated for an additional 2 weeks, after which the cells were harvested and freeze-dried. The dried cells were extracted twice with MeOH at room temperature. The MeOH extracts were concentrated and partitioned between n-BuOH and H2O twice. The n-BuOH extracts were concentrated and dissolved up to 10 ml with MeOH. Ten microliters of the solution was injected into the HPLC system fitted with a Shim-pack CLC-ODS(M) (5 μm, C18, 100 Å, 4.6 × 250 mm) column and the elution was monitored at 330 nm. The eluate was MeOH/H2O/AcOH (50:100:1, v/v/v), the column temperature was 40°C, and the flow rate was 0.5 ml/min. The content of acteoside was calculated by identifying peak areas. The analysis of each sample was performed in triplicate.

Results and discussion

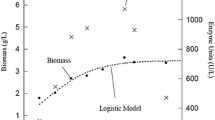

The induction of olive callus was performed in several modified Murashige and Skoog’s agar media. In these media, the callus was induced in CM-NH4 agar medium supplemented with K+ instead of NH4 + and containing 2,4-dichlorophenoxyacetic acid, kinetin, and coconut milk [3]. The cell growth was better in CM-NH4 medium than in DK-NH4 medium, which was CM-NH4 medium without coconut milk. However, the production of acteoside quantified by HPLC analysis was better in a DK-NH4 liquid medium than in a CM-NH4 liquid medium (data not shown). Therefore, the induced olive callus was subcultured into the DK-NH4 agar medium every 4 weeks.

Compounds 1–5 were isolated using HPLC, and identified as acteoside [14], isoacteoside [15], β-oxoacteoside [16], β-hydroxyacteoside [16], and salidroside [7], respectively, using spectra data (Fig. 1). In the olive callus, acteoside was a main secondary metabolite whose content was over 1.7% dry weight (d.w.). This olive cell line will be useful for the provision of acteoside to study biosynthesis or for pharmaceutical activities. The production of phenylethanoid glycosides in olive cell suspension cultures is reported here for the first time, although small amounts of acteoside were isolated from olive fruit [17].

We performed labeled precursor feeding experiments to clarify the biosynthetic route to acteoside in olive cells. The 13C-labeled phenylalanine was incorporated into the caffeoyl moiety of acteoside with a 6–7% enrichment at C-7′ and C-9′ carbons, but not incorporated into the hydroxytyrosol moiety (Table 2). The 13C-labeled tyrosine was incorporated into the hydroxytyrosol moiety with over 25% enrichment at C-7 carbon (Table 2). Therefore, the biosynthetic pathway to the hydroxytyrosol moiety starts from tyrosine, i.e., different from that of the caffeoyl moiety. The labeled tyrosine was also slightly incorporated into the caffeoyl moiety at C-7′ and C-9′ carbons (Table 2). Phenylalanine ammonia lyase does not generally catalyze tyrosine turnover; however, from our results, phenylalanine ammonia lyase partially catalyzes tyrosine turnover in the olive cells. The 2,3-13C2-labeled DOPA was incorporated at C-7 and C-8 carbons at about 12% but not into the caffeoyl moiety (Table 2). DOPA would be biosynthesized from tyrosine using tyrosine hydroxylase, as reported in the callus of Portulaca grandiflora [18].

The labeled acteosides obtained from feeding experiments using two kinds of deuterium-labeled dopamine were analyzed by LC–ESI–MS. The relative peak intensity and incorporation ratio of each compound are shown in Table 3. [2,2-D2]Dopamine was incorporated into 20% acteoside with two deuteriums (Table 3). [1,1,2,2-D4]Dopamine was incorporated into 10% acteoside with three deuteriums or 4% with two deuteriums (Table 3). The results show that the hydroxytyrosol moiety of acteoside is biosynthesized from dopamine. Dopamine was biosynthesized by the decarboxylation of DOPA. [1,1,2,2-D4]Dopamine was oxidized to 2-(3,4-dihydroxyphenyl)-[1,2,2-D3]acetoaldeyde, reduced to 2-(3,4-dihydroxyphenyl)-[1,2,2-D3]ethanol, and incorporated into acteoside with three deuteriums. The 2-(3,4-dihydroxyphenyl)-[1,2,2-D3]ethanol was partially oxidized to 2-(3,4-dihydroxyphenyl)-[2,2-D2]acetoaldehyde and reduced to 2-(3,4-dihydroxyphenyl)-[2,2-D2]ethanol. This is why the acteoside with three or two deuteriums was observed in the feeding experiment of [1,1,2,2-D4]dopamine.

[2-13C]Tyramine was enzymatically synthesized from [3-13C]tyrosine by tyrosine decarboxylase [13]. [2-13C]Tyramine was incorporated into 50% acteoside at C-7 carbon (Table 2). [2-13C]Tyramine was also incorporated into salidroside (5), which is a minor phenylethanoid in olive cells (Fig. 2). The production of salidroside was increased 12-fold and labeled almost totally at C-7 carbon when [2-13C]tyramine was fed to the culture. Therefore, salidroside was biosynthesized from tyramine via p-hydroxyphenylacetoaldehyde and tyrosol (p-hydroxyphenylethanol). It has been reported that, in cell suspension cultures of Rhodiola sachalinensis, external tyrosol improved salidroside production [19]. In cultured olive cells, the 13C-labeled tyramine incorporation into acteoside was also observed, but the incorporation ratio for acteoside was less than that for salidroside. In cell suspension cultures of Syringa vulgaris, the incorporation of salidroside to acteoside has been observed [11]. However, based on our results from the tyramine feeding experiment, the incorporation of salidroside into acteoside would be rare in olive cell cultures. The labeled tyramine would be incorporated into acteoside via dopamine or hydroxytyrosol.

In the feeding experiment of benserazide, a DOPA decarboxylase inhibitor, the production of acteoside was reduced to 66%. This result shows that DOPA decarboxylase exists in olives and has an important role in the biosynthesis of acteoside. On the other hand, α-methyltyrosine, an inhibitor of tyrosine hydroxylase, did not reduce acteoside production.

The proposed biosynthetic pathway to acteoside in olive cells is shown in Fig. 3. The hydroxytyrosol moiety of acteoside was biosynthesized from tyrosine through DOPA and dopamine. The amine moiety of dopamine was oxidized to aldehyde, reduced to alcohol, and then β-glycosylated. The olive has alternative biosynthetic pathways available, e.g., from tyramine to acteoside via dopamine or from tyrosol to acteoside via hydroxytyrosol; however, the pathway from tyrosine to acteoside via DOPA and dopamine is the main biosynthetic pathway to acteoside.

[1-13C]2-Phenylethanol and [1-13C]phenethylamine were not incorporated into acteoside but incorporated into a new compound 6 which was not detected in the control cell culture. We isolated 6 using HPLC and identified it as 2-phenethyl β-primeveroside (Fig. 1), which is widely detected in various plants [20–22]. The relative isotopic abundance of 6 from [1-13C]2-phenylethanol and [1-13C]phenethylamine was over 99%, making 6 the biotransformation product of phenethylamine via phenylethanol in olive cell suspension cultures, not biosynthesized de novo (Fig. 2). From the results of our feeding experiments, the hydroxyl group at C-4 in the benzene ring is important for the biosynthesis of acteoside. Phenylethanoid glycosides are contained in various plant species [23], and the mechanism of glycosylation via the oxidation of amine would be a relatively common reaction in plant secondary metabolism. Further molecular biological research into the glycosylation and total biosynthetic mechanisms of phenylethanoid glycosides is in progress.

References

Ferrara LA, Raimondi AS, d’Episcopo L, Guida L, Dello Russo A, Marotta T (2000) Olive oil and reduced need for antihypertensive medications. Arch Intern Med 160:837–842

Bianchi G, Murelli C, Vlahov G (1992) Surface waxes from olive fruits. Phytochemistry 31:3503–3506

Saimaru H, Orihara Y, Tansakul P, Kang YH, Shibuya M, Ebizuka Y (2007) Production of triterpene acids by cell suspension cultures of Olea europaea. Chem Pharm Bull 55:784–788

Xiong Q, Kadota S, Tani T, Namba T (1996) Antioxidative effects of phenylethanoids from Cistanche deserticola. Biol Pharm Bull 19:1580–1585

Murai M, Tamayama Y, Nishibe S (1995) Phenylethanoids in the herb of Plantago lanceolata and inhibitory effect on arachidonic acid-induced mouse ear edema. Planta Med 61:479–480

Ahmad M, Rizwani GH, Aftab K, Ahmad VU, Gilani AH, Ahmad SP (1995) Acteoside: a new antihypertensive drug. Phytother Res 9:525–527

Han X, Zhang T, Wei Y, Cao X, Ito Y (2002) Separation of salidroside from Rhodiola crenulata by high-speed counter-current chromatography. J Chromatogr A 971:237–241

Kim HJ, Yu YG, Park H, Lee YS (2002) HIV gp41 binding phenolic components from Fraxinus sieboldiana var. angustata. Planta Med 68:1034–1036

Tokar M, Klimek B (2004) Isolation and identification of biologically active compounds from Forsythia viridissima flowers. Acta Pol Pharm 61:191–197

Andary C, Ibrahim RK (1986) Biosynthetic capacity of stachys seedlings for verbascoside and related caffeoyl derivatives. Z Naturforsch C 41:18–21

Ellis BE (1983) Production of hydroxyphenylethanol glycosides in suspension cultures of Syringa vulgaris. Phytochemistry 22:1941–1943

Murashige T, Skoog F (1962) Revised medium for rapid growth and bioassays with tobacco tissue cultures. Physiol Plantarum 15:473–497

Sugimoto Y, Yamada Y (1993) Involvement of tyramine in bisbenzylisoquinoline biosynthesis in cultured roots of Stephania cepharantha. J Nat Prod 56:1229–1233

Nishibe S, Sardari S, Kodama A, Horita K, Kudo M, Koike K, Nikaido T (1997) Constituents of bark of Fraxinus americana. Nat Med 51:482–485

Owen RW, Haubner R, Mier W, Giacosa A, Hull WE, Spiegelhalder B, Bartsch H (2003) Isolation, structure elucidation and antioxidant potential of the major phenolic and flavonoid compounds in brined olive drupes. Food Chem Toxicol 41:703–717

Nishibe S, Sasahara M, Ying J, Lu YC, Tanaka T (1993) Phenylethanoid glycosides from Plantago depressa. Phytochemistry 32:975–977

Fleuriet A, Macheix JJ, Andary C, Villemur P (1984) Identification and determination of verbascoside by high-performance liquid chromatography in the fruit of six cultivars of Olea europaea l. C R Acad Sci III Vie 299:253–256

Yamamoto K, Kobayashi N, Yoshitama K, Teramoto S, Komamine A (2001) Isolation and purification of tyrosine hydroxylase from callus cultures of Portulaca grandiflora. Plant Cell Physiol 42:969–975

Xu JF, Liu CB, Han AM, Feng PS, Su ZG (1998) Strategies for the improvement of salidroside production in cell suspension cultures of Rhodiola sachalinensis. Plant Cell Rep 17:288–293

Inagaki J, Watanabe N, Moon JH, Yagi A, Sakata K, Ina K, Luo S (1995) Glycosidic aroma precursors of 2-phenylethyl and benzyl alcohols from Jasminum sambac flowers. Biosci Biotechnol Biochem 59:738–739

Otsuka H, Takeda Y, Yamasaki K (1990) Xyloglucosides of benzyl and phenethyl alcohols and Z-hex-3-en-1-ol from leaves of Alangium platanifolium var. trilobum. Phytochemistry 29:3681–3683

Watanabe S, Hashimoto I, Hayashi K, Yagi K, Asai T, Knapp H, Straubinger M, Winterhalter P, Watanabe N (2001) Isolation and identification of 2-phenylethyl disaccharide glycosides and mono glycosides from rose flowers, and their potential role in scent formation. Biosci Biotechnol Biochem 65:442–445

Jimenez C, Riguera R (1994) Phenylethanoid glycosides in plants: structure and biological activity. Nat Prod Rep 11:591–606

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saimaru, H., Orihara, Y. Biosynthesis of acteoside in cultured cells of Olea europaea . J Nat Med 64, 139–145 (2010). https://doi.org/10.1007/s11418-009-0383-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11418-009-0383-z