Abstract

Purpose

Heavy metal soil pollution in the coal chemical industrial area has attracted increasing attention with the rapid development of the coal chemical industry. The spatial distribution and the source of heavy metals in the soil in coal chemical industrial areas should be investigated to help prevent further heavy metal pollution in industrial areas, and reduce heavy metal exposure to factory workers.

Materials and methods

A coal chemical factory in northwest China was studied. A chessboard sampling method was used to collect 153 soil samples. An inductively coupled plasma mass spectrometer (ICP-MS) and a mercury vapor analyzer were used to quantify five heavy metals (Pb, Hg, Cd, Cr, and As). The spatial distributions of these five heavy metals were simulated using several statistical methods and the spatial maps of the five heavy metal concentrations were obtained.

Results and discussion

The mean concentrations of the heavy metals excluding Pb were higher than their respective soil background values in Ningxia Hui Autonomous Region (Ningxia). The concentrations of Hg, Cd, Cr, and As were 4.00, 4.00, 1.50, and 1.08 times of their background concentrations, respectively. In contrast to the production flow chart, the soil on both sides of the trunk road and the coal transport corridor at the factory had relatively high Pb and Cd concentrations. The slag dump of the gasification residues had the highest Cr concentration because of the local prevailing winds. Concentrations of Hg, Cd, and As in the downwind direction of the prevailing winds from the coal combustion unit chimney were significantly high.

Conclusions

In this study, the spatial distributions of five heavy metals (Pb, Hg, Cd, Cr, and As) in the soil at a coal chemical factory were obtained. The respective sources of heavy metals in the soil were determined. The present study provides a theoretical basis for the prevention and treatment of heavy metal pollution in coal chemical factories.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, the modern coal chemical industry, which utilizes coal gasification technology, has rapidly developed (Huang et al. 2015; Zhao 2011). During the production process, heavy metals in raw coal undergo physical and chemical changes and enter the environmental media including water, air, and soil (Zhao et al. 2014). Heavy metals accumulation in the soil results in exceeding the environmental standards in China and poses great risks to human health due to the exposure to the soil environment (Wang 2012; Wang et al. 2012). Heavy metals may cause carcinogenic and mutagenic effects. Heavy metals and other chemical carcinogens (Andersen 1990; Fan 1983; An et al. 2016) cause about 90% of human cancers. The “12th Five-Year Plan on Comprehensive Prevention and Control of Heavy Metal Pollution” of China clearly listed lead (Pb), mercury (Hg), cadmium (Cd), chromium (Cr), and arsenic (As) as prevention and control targets. Therefore, knowledge of the heavy metal pollution characteristics in the soil and their spatial distributions in the coal chemical industrial areas can help to decrease the occupational risk of coal chemical factory workers.

Kriging interpolation is a geostatistical spatial interpolation method, which is mainly used to study spatially distributed natural phenomena with certain structure and randomness (Hou 1998). Compared to the conventional analysis methods, which combine heavy metal migration models with classical probability statistics, geostatistical methods are less dependent on pollutant migration and diffusion mechanisms. In addition, the relative position between sampling points is taken into consideration in geostatistical methods, which is a unique advantage in determining the uncertainty in the pollutant spatial distribution (Wang and Qin 2006; Wang et al. 2008; Yang et al. 2009). The geostatistical analysis software has been widely used to simulate and predict heavy metal distribution in the soil. A previous study used the geostatistical software GS+ and geographic information systems (GIS) to calculate the spatial variation in the concentration of seven heavy metals in a 1019-km2 site (Zhang 2007). An indicator kriging method was used to analyze the heavy metals in the soil and their sources in a mining area in northeast India (Reza et al. 2015). Up to date, many researchers used kriging to calculate the spatial distribution of heavy metals in the soil of general urban or agricultural areas. Only a few studies focused on the industry, particularly, on the spatial variation of heavy metals in coal chemical industrial areas. Few studies combined the spatial distribution with the production units to determine the sources of heavy metals.

In this study, concentrations of five heavy metals (Pb, Hg, Cr, Cd, and As) were studied in 153 surface soil samples collected in a coal chemical factory in northwest China. The geostatistical analysis tool in ArcGIS 10.0 was used to simulate the spatial distribution of heavy metals in the soil and analyze the concentration variation of the heavy metals in the entire factory.

2 Materials and methods

2.1 Overview of study site

The study site is located in the eastern part of the Ningxia Hui Autonomous Region (Ningxia) (Fig. 1a). The coal chemical factory was tested at the end of 2010 and became fully operational by the end of 2011. The surrounding terrain of the factory is relatively flat, with a gentle slope in the southeast-northwest direction and a gradient lower than 10°. The location is in a continental hinterland and has a typical continental monsoon climate, with low precipitation, high evaporation, abundant sunshine, and large day and night temperature difference. The prevailing winds are from the northwest direction with a strong transportation capacity. The secondary prevailing winds are from the south-southwest direction.

An aerial view of the study site was obtained via remote sensing technology (Fig. 1b). The aerial map was divided into ten units compared with the factory layout (Fig. 1c). When the factory is in operation, coal firstly enters the power unit and then the gasification unit via the coal transport corridor in the southeast corner. Temporary individual slag dumps were set up to the north of the gasification and power units. Three chimneys were built in the southeast corner of the power unit.

2.2 Sample collection

A 50 × 50 m systematic sampling design method was used to sample the soil due to the flat and complete terrain and the variation in pollutant concentrations at different production units (Liu 1987) (Fig. 2). The sampling point, which fell in the reservoirs, the factory plant, slag, or other inaccessible areas, was shifted or skipped. A global positioning system (GPS) was used to obtain the geographical coordinates of the sampling points (Fig. 2).

The surface (0–20 cm) soil samples were air-dried at 25 °C. Big particles like stones and animal residues were manually removed from the samples. The soil samples were then ground and sieved with a nylon sieve (2 mm in diameter). Subsequently, an agate mortar and a pestle were used to grind the samples and the ground samples were sieved again to the size less than 100 mesh. The screened samples were stored in bottles for analysis.

2.3 Sample testing

The United States Environmental Protection Agency (USEPA) standard method was used to quantify Pb, Cd, Cr, and As in the soil samples (Chen 2011). Samples were digested with a microwave digestion system (Milestone, Milano, Italy). An inductively coupled plasma mass spectrometer (X series II ICP-MS, Thermo Scientific Xseries 2, Thermo Fisher Scientific, Waltham, MA, USA) was then used to quantify the samples. Mercury quantification was carried out using a DMA-80 mercury analyzer (Milestone Srl, Italy). Each sample was measured in triplicate and the mean value was calculated.

2.4 Kriging interpolation method

Kriging interpolation is also known as local spatial interpolation. Based on spatial autocorrelation, kriging interpolation uses the structure of the raw data and the semivariance function of the regionalized variables to interpolate unknown sampling points of regional variables using linear, unbiased, and optimal estimation (Tang and Yang 2006). The equation of kriging interpolation used in this study is the following:

where Z(x0) is the concentration of the heavy metal to be tested, n is the number of sampling points, Z(x i )is the heavy metal concentration at the ith sampling point, and λ i is the set of weight coefficients. The selection of Σλ i = 1; λ i ensures that the estimation of Z(x0) is unbiased and the estimated variance is the minimum.

Several types of kriging interpolation methods can be used on different conditions or for different purposes. For example, ordinary kriging is used when the data are normally distributed and spatially auto-correlated with unknown expected value (Tang and Yang 2006).

2.5 Software platform

SPSS Statistics 19.0 was used to calculate descriptive statistics and perform multiple stepwise regression analysis. ArcGIS 10.0 was used for semivariance analysis, interactive semivariance analysis, kriging, spatial autocorrelation analysis, map digitalization, mapping and cropping of interpolation results, and cross-validation.

3 Results and discussion

3.1 Heavy metals in the soil of the coal chemical factory

The measured heavy metal concentrations (Pb, Hg, Cd, Cr, and As) at the study site are shown in Table 1.

Except for Pb, which had a lower concentration than the background value, the concentrations of other four heavy metals in the soil were higher than their background values in Ningxia (Table 1). In addition, the concentrations of Hg and Cd were three times higher than their background values, the Cr concentration was 1.5 times of its background value, and the As concentration was 1.08 times of its background value. Therefore, heavy metal accumulation in the soil was caused by coal chemical production.

The variations in Pb, Cr, and As concentrations were weak (coefficient of variation < 0.1) and the data were less disperse, indicating that there were no significant differences in the concentrations of the three heavy metals in the soil from various parts of the factory. Hg and Cd showed moderate variation (0.1 < coefficient of variation < 1) indicating significant enrichment of the two heavy metals and the enrichment was concentrated.

The five heavy metals excluding Pb exceeded the respective Ningxia background values by more than 80% in all the samples, indicating the accumulation of the four heavy metals throughout the site.

3.2 Normality testing and spatial autocorrelation analysis

SPSS 19.0 was used for Kolmogorov-Smirnov (K-S) normality testing. The spatial autocorrelation tool (Moran I) in the ArcGIS 10.0 spatial statistics toolbox was used for the autocorrelation analysis (Table 2).

The K-S test of the interpolated point series of five heavy metals showed that five data sets were all normally distributed (P > 0.05, confidence level 95%) (Table 2). According to the Z value and P value of the spatial autocorrelation, five data sets showed significant positive spatial autocorrelations (Cai et al. 2012; Fei et al. 2013). The results of the integrated analysis showed that ordinary kriging can be used for further data analysis.

3.3 Spatial variation structure analysis

Semivariance analysis is a key to the analysis of the spatial variation structure of variables and plays an important role in controlling the number of sampling points and increasing the accuracy of interpolated values. The accuracy of a semivariogram model depends on the standard error of the mean of the cross-validation (should approach zero as possible), and the root mean squared error (should approach 1 as possible) (Wang and Wu 2014). Table 3 shows the semivariogram fitting and analysis structure of five heavy metal concentrations at kriging interpolation points.

The ratio of nugget value C0 to the sill value (C0/Sill) of the interpolated values of five heavy metals was between 0 and 37.076%, which is far lower than 75% (Li and Ma 2008). Therefore, the variation of five heavy metal concentrations caused by regional factors was significantly higher than that caused by non-regional factors (i.e., random factors).

The R2 of the cross tests (Fig. 3) for all the five metals were all above 0.93 and there were no outliers in the data, suggesting the predicted results were reliable to be used to analyze the actual distribution of the heavy metals.

3.4 Spatial distribution of heavy metal concentrations

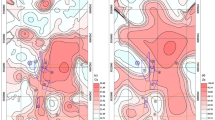

3.4.1 Spatial distribution of Pb and Cd in the soil

Figure 4 shows that the areas with high soil Pb and Cd concentrations were located on both sides of the coal transport corridor and the surrounding personnel entrance, with concentrations showing a stepwise decrease from the coal transport corridor and both sides of the road. A series of studies were carried out on the soil-wheat system and found that the wheat plants on both sides of the road were severely affected by Pb pollution (Li 2005). The heavy metals on both sides of the road were proposed to come from the combustion of leaded gasoline, lubricants, and wear and tear of vehicle tires and mechanical equipment (Zou 2008). A study found that the main pollutant in the soil near to the roads in Beijing was Cd, which was mainly from vehicle emissions, wear and tear of tires, and dust produced during braking (Wang 2014). Based on these previous results and the spatial distribution of Pb and Cd concentrating on both sides of the highway and the coal corridor in our study, we infer that traffic had the greatest effect on soil Pb and Cd concentrations and the source of Pb accumulation on both sides of the coal transport corridor was the wear and tear of mechanical equipment, the burning of lubricating oil, etc.

Figure 4a shows that high Pb concentration also occurred at the flue gas outlet and in the downwind direction besides the traffic and transportation corridors. Thus, flue gas emission had an effect on soil Pb accumulation, which was supported by the previous study that the Pb concentrations in raw coal and gasification residues were far lower than that in the flue gas emission (Zhang et al. 2017). In addition, the year-around prevailing wind in the area also played an important role, making the distribution of Pb on the right side of the road broader than the left side.

Figure 4b shows that the high Cd regions were along the transportation routes and near the flue gas outlet. A high concentration area formed in the downwind direction of the flue gas outlet. In addition, a study found that Cd was relatively easy to be volatilized during coal combustion (Xu et al. 2004). Moreover, the Cd content of the flue gas was higher than that of raw coal and gasification residues (Zhang et al. 2017). Therefore, flue gas emission was supposed to play a role in the Cd in the soil. However, the spatial distribution of Cd along the traffic and coal transport corridor was wider than that of Pb (Fig. 4a), indicating the traffic had a greater impact on the distribution of Cd than Pb. In addition, the northwest dominant wind followed by the southwest southerly wind shifted the spatial distribution of Cd to the northeast.

For the prevention and control of Pb and Cd in the plant area, we should strengthen the control of traffic sources and the management of flue gas emissions. Staff working in the dynamic unit, total variation unit, and production units on both sides of the traffic line should be protected particularly from Pb and Cd.

3.4.2 Spatial distribution of Hg and As in the soil

Figure 5 shows that the highest Hg and As soil concentrations occurred in the area to the south of the power unit and showed a drop-shape with south-north distribution longer than the east-west distribution, and the southern coverage was greater than the northern coverage.

A study showed that under the high temperature in the coal combustion boilers, almost all Hg was converted to Hg0, more than 90% of which was emitted with the flue gas (Sun and Bai 2008). When the temperature reached 815 °C, almost all Hg in the coal was released (Zhang et al. 2003). In addition, As was mainly converted into fly ash and gaseous oxides during coal combustion (Lu et al. 2003). The distribution of Hg and As in this study mainly concentrated around the flue gas outlet and in the downwind direction of the power unit (Fig. 5). Therefore, flue gas discharge was the main source of soil Hg and As, which was also influenced by the dominant northwesterly wind followed by the southwest southerly wind.

To prevent and control the pollution of Hg and As, it is necessary to strengthen the control of flue gas emissions. It is suggested to strengthen protective measures for workers in the power unit, near the entrance of the logistics and in the south of the gasification unit.

3.4.3 Soil Cr simulation results and analysis

Figure 6 shows that sampling sites with high soil Cr concentrations were located to the northeast of the gasification unit and power unit. The soil Cr concentration in the entire factory showed a stepwise distribution with highest concentrations at the slag dump of the gasification and power units and a decrease towards the four corners of the site. The decrease was slower in the northwestern and southern directions. A previous study found that Cr concentrations at the gasification slag during coal chemical production were significantly higher than those of raw coal and flue gas (Zhang et al. 2017). Another study found that the volatilization temperature of Cr was greater than 1500 °C and the volatilized amount was low (Li 2011). Therefore, the slag dumps of the gasification and power units were the main sources of Cr, which was further spread by the prevailing wind (Fig. 6).

For the prevention and control of Cr, it is recommended to strengthen the management of heap dregs in the plant area and strengthen the protective measures in the gasification and power unit as well as in the southern area of methanol synthesis unit.

In summary, integrated prevention of these five heavy metal pollution can be achieved by the source control at the gasification and power units and by the control of the motor vehicle within the factory.

4 Conclusions

The major sources of the five heavy metals in the soil were determined. As and Hg mainly came from flue gas emissions, Cr from the slag dump, and Pb and Cd mainly from traffic emissions followed by the flue gas. The spatial distribution of the heavy metals in a coal chemical factory is mainly affected by the source and the prevailing wind. The key areas for the prevention and control of the five heavy metals are as follows: the gasification unit, the power unit, and the coal transport corridor. Compared to the conventional methods for source apportionment and characterization of heavy metals in the soil, the method used in the present study is more intuitive and accurate. Future research should focus on the factors that affect the distribution of heavy metals, the ability of heavy metals to diffuse in the soil, the location of emission sources, and the factors that affect flue gas deposition, all of which can provide more instructive guidance in the prevention and protection of metals.

References

An YQ, Zhang RQ, Yuan SH (2016) Health risk assessment of heavy metals in farmland soil in Hebei Province. Occup Health 09:1252–1255

Andersen O (1990) Biological effects of heavy metals. Volume II: metal carcinogenesis. By E. C. Foulkes. Q Rev Biol 68:134

Cai FF, Pu LJ, Zhang J, Zhao Y, Zhu M (2012) Identification and analysis of spatial economic structure in Jiangsu province by applying exploratory spatial data analysis (ESDA). Econ Geogr 32(3):24–30 (in Chinese)

Chen S (2011) Improvement on the pre-treatment methods of the determination of heavy metals in soil. Environ Dev 12:155–156 (in Chinese)

Fan BT (1983) Chemical carcinogens in the environment. Environment Pollution and Prevention 3:21–25 (in Chinese)

Fei F, Debin DU, Heng LI (2013) Spatial-temporal characteristics of scientific and technological resources allocation efficiency in prefecture-level cities of China. Acta Geograph Sin 68(10):1331–1343

Hou JR (1998) Practical Geostatistics. China Land Press, Beijing (in Chinese)

Huang GS, Li ZY, Wang JM (2015) Development status of coal chemical industry in China and its influence on the petrochemical industry. Chemical Industry and Engineering Progress 02:295–302 [in Chinese]

Li J (2005) Heavy metal pollution and migration on soil-wheat system on both sides of the Zheng-Bian road. Dissertation, Henan University (in Chinese)

Li Y (2011) Experimental study on high temperature removal and migration and transformation of trace elements in coal gasification. Dissertation, Huazhong University of Science and Technology (in Chinese)

Li YZ, Ma JH (2008) Kriging interpolation and its application to environmental noise assessment in Kaifeng. Environ Sci Technol 31(3):103–105 (in Chinese)

Liu SY (1987) Layout of farmland soil monitoring spots and sample collection. Journal of Agro-environment Science 05:24–26 (in Chinese)

Lu J, Sun JM, Zhao CM (2003) Occurrence of As in coal and its behavior during coal combustion. Coal Geology Exploration 05:6–9 (in Chinese)

Reza SK, Baruah U, Singh SK, Das TH (2015) Geostatistical and multivariate analysis of soil heavy metal contamination near coal mining area, northeastern India. Environ Earth Sci 73(9):5425–5433

Sun LM, Bai YY (2008) Analysis of mass distribution and transformation of mercury in coal combustion on coal-fired power plant. Clean Coal Technol 14(5):93–95 (in Chinese)

Tang GA, Yang X (2006) Experimental tutorial on ArcGIS (Geographic Information System) spatial analysis. China Science Publishing and Media Ltd, Beijing (in Chinese)

Wang CL, Zheng WJ, Wang HJ, Zeng XD, Ji SL (2012) The relationship between heavy metals enrichment characteristics and soil acidification for environmental media in Yantai of Shandong Province. Rock Miner Anal 02:361–369

Wang HX (2012) Pollution ecology. Higher Education Press, Beijing (in Chinese)

Wang P (2014) Current status of soil heavy metal pollution on both sides of a road in Beijing and risk evaluation. Dissertation, Beijing University of Civil Engineering and Architecture (in Chinese)

Wang Q, Wu XH (2014) A study on parameters setting of ordinary kriging interpolation to total soil nitrogen concentration in Chaihe River Basin. J Yuxi Normal Univ 30(8):28–31 (in Chinese)

Wang XJ, Lai JQ, Lu YH, Li DS, Zhou JH, Wang JW (2008) Main source of soil heavy metal pollution based on factor analysis in Taiyuan. Ecol Environ Sci 17(2):671–676 (in Chinese)

Wang XS, Qin Y (2006) Environmental risk and sources of heavy metals in Xuzhou urban topsoil. Geochimica 35(1):88–94 (in Chinese)

Xu LS, Cheng JF, Zeng HC (2004) Experimental investigation of the release characteristics of trace elements As, Cd, and Cr during the combustion of coal. J Eng Thermal Energy Power 05:478–482+547–548 (in Chinese)

Yang ZP, Lu WX, Liu XR, Xin X (2009) Sources identification of heavy metals in urban soil of Changchun based on principal component analysis. Urban Environ Urban Ecol 5:29–33 (in Chinese)

Zhang CB (2007) Soil heavy metal identification and analysis in classical contamination zone. Dissertation, Nanjing Institute of Soil Science, Chinese Academy of Sciences (in Chinese)

Zhang JY, Zheng CG, Liu J, Liu HM (2003) Experimental study on volatility of trace metals in coal combustion. China National Symposium on Combustion 1043–1046 (in Chinese)

Zhang K, Yang JJ, Bai L, Qiang CD, Wang SD (2017) Soil heavy metal pollution and source analysis of a coal chemical factory in northwest China. J Mining Sci Technol 2(02):191–198 (in Chinese)

Zhao JF (2011) Analysis and policy recommendation on coal industry clean-using from the perspective of low-carbon economy. J China Coal Soc 03:514–518

Zhao SH, Chen ZL, Zhang TP, Pan WB, Peng XC, Che R, Ou YJ, Lei GJ, Zhou D (2014) Effects of stabilization treatment on migration and transformation of heavy metals in mineral waste residues. Environ Sci 04:1548–1554 (in Chinese)

Zou W (2008) Focus on vehicular heavy metal pollution. China Quality News (Beijing):06–10 (in Chinese)

Acknowledgements

The authors would like to thank the National Basic Research Program of China (973 Program, No. 2014CB238906) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Claudio Bini

Rights and permissions

About this article

Cite this article

Zhang, K., Qiang, C. & Liu, J. Spatial distribution characteristics of heavy metals in the soil of coal chemical industrial areas. J Soils Sediments 18, 2044–2052 (2018). https://doi.org/10.1007/s11368-018-1972-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11368-018-1972-9