Abstract

Purpose

In the USA, several studies have been conducted to analyze the energy consumption and atmospheric emissions of Warm-mix Asphalt (WMA) pavements. However, the direct and indirect environmental, economic, and social impacts, termed as Triple-Bottom-Line (TBL), were not addressed sufficiently. Hence, the aim of this study is to develop TBL-oriented sustainability assessment model to evaluate the environmental and socio-economic impacts of pavements constructed with different types of WMA mixtures and compare them to a conventional Hot-mix Asphalt (HMA). The types of WMA technologies investigated in this research include Asphamin® WMA, Evotherm™ WMA, and Sasobit® WMA.

Methods

To achieve this goal, supply and use tables published by the U.S. Bureau of Economic Analysis were merged with 16 macro-level sustainability metrics. A hybrid TBL-LCA model was built to evaluate the life-cycle sustainability performance of using WMA technologies in construction of asphalt pavements. The impacts on the sustainability were calculated in terms of socio-economic (import, income, gross operating surplus, government tax, work-related injuries, and employment) and environmental (water withdrawal, energy use, carbon footprint, hazardous waste generation, toxic releases into air, and land use). A stochastic compromise programming model was then developed for finding the optimal allocation of different pavement types for the U.S. highways.

Results and discussion

WMAs did not perform better in terms of environmental impacts compared to HMA. Asphamin® WMA was found to have the highest environmental and socio-economic impacts compared to other pavement types. Material extractions and processing phase had the highest contribution to all environmental impact indicators that shows the importance of cleaner production strategies for pavement materials. Based on stochastic compromised programming results, in a balanced weighting situation, Sasobit® WMA had the highest percentage of allocation (61 %); while only socio-economic aspects matter, Asphamin® WMA had the largest share (57 %) among the asphalt pavements. The optimization results also supported the significance of an increased WMA use in the U.S. highways.

Conclusions

This research complemented previous LCA studies by evaluating pavements not only from environmental emissions and energy consumption standpoint, but also from socio-economic perspectives. Multi-objective optimization results also provided important insights for decision makers when finding the optimum allocation of pavement alternatives based on different environmental and socio-economic priorities. Consequently, this study aimed to increase awareness of the inherent benefits of economic input–output analysis and multi-criteria decision making through application to emerging sustainable pavement practices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

1.1 The U.S. highways and warm-mix asphalts

The U.S. road system has one of the greatest network sizes and usage densities in the world with its immense statistics such as four million miles of network size and three million vehicle miles travelled per year (Highway Statistics 2010). Due to having such a wide network and immense usage characteristics, U.S. roads require tremendous new pavement construction, which results in a considerable amount of expenditures. On the other hand, since there is a rapidly growing trend in total Vehicle Miles Travelled—VMT (i.e., VMT has been doubled in the last 30 years), highway system capacity extension also constitutes a significant expenditure that comes along with maintenance expenditures (Highway Statistics 2010). All in all, the growing pattern in travel trends put a vital burden on the U.S. economy that is about $146 billion annually as highway maintenance and safety expenditure (Spending and Funding for Highways 2011). On the other hand, paving such a huge road network and keeping it maintained results in severe environmental burdens. In this context, there are various environmental impact categories that are addressed in previous studies (Horvath and Hendrickson 1998; Santero et al. 2011).

The U.S. highways are responsible for high resource consumption and environmental emissions, which make the sustainable pavement systems necessary for building greener roads. In this regard, warm-mix asphalt (WMA) has gained a tremendous interest and considered one of the most environmental friendly technologies for producing asphalt pavements (Rubio et al. 2012). WMAs have been gained popularity in terms of its eligibility of being produced at a lower temperature thus cutting process energy by 30 % (Larsen et al. 2004). WMA technologies show benefits for the environment because it produces asphalt at temperatures 20–40° lower in comparison to conventional hot-mix asphalt (Rubio et al. 2013). Among WMAs, Aspha-min® is a manufactured synthetic zeolite that improves the mix workability and aggregate coating at lower temperatures is realized. Sasobit® is a wax-type additive of coal gasification that melts in the asphalt binder at high temperatures. As a result, a reduction in the viscosity during mixing is achieved. However, EvothermTM uses a high-residue emulsion, which results in the improvement of the adhesion of the asphalt to the aggregate and the enhancement in mixture workability (Chowdhury and Button 2008). A reduction in energy requirements associated with the production of EvothermTM mixture of up to 55 % has been reported (Kristjánsdóttir et al. 2007). Although these reports show the significance of using different WMA additives towards achieving reduced energy consumption, a life cycle-based assessment model, which expands the system boundary of process life cycle inventories, will be vital for understanding the real impacts of WMA in pavement construction.

1.2 Life cycle sustainability assessment

With the increasing concerns related to integration of social and economic dimensions of the sustainability into LCA, traditional LCA approach has been transformed into a new concept, which is also called as Life Cycle Sustainability Assessment (LCSA). This concept was suggested by Klöpffer (2008) and Life Cycle Cost (LCC) and Social Life Cycle Assessment (SLCA) methods were integrated into the LCA framework (Finkbeiner et al. 2010; Traverso et al. 2012; Zamagni et al. 2012). In parallel with the current trend in LCA, this study envisions a comprehensive LCSA framework which evaluates the social, economic, and environmental impacts from a broader perspective: direct (on-site) and indirect (supply chain) burdens. Economic input–output (EIO) analysis is utilized in order to provide a holistic framework to trace the impacts across the supply chains in addition to direct impacts related to asphalt production processes. Since recent trends also emphasize the inclusion of three pillars of sustainability as economy, society, and the environment, the proposed sustainability scope perfectly fits to the needs of such a comprehensive sustainability assessment understanding (Guinée et al. 2011).

EIO analysis is a well-known tool that is commonly used to expand the system boundary of process life cycle inventories and thus analyses the supply chain wide resource requirements and environmental impacts of products or systems (Hendrickson et al. 2006; Suh et al. 2004). EIO analysis was theorized and developed by Wassily Leontief in 1970s, based on his earlier works in the late 1930s, for which he received the Nobel Prize (Leontief 1970). In the literature, EIO methodology has been used to analyze a wide range of policy issues in environmental, economic, and social areas, and several researchers utilized the EIO model for analyzing the sustainability impacts of infrastructures, energy technologies, sectors, international trade, and household demand (Egilmez et al. 2013; Huang et al. 2009; Huppes et al. 2006; Lenzen et al. 2012; Kucukvar and Tatari 2011; Kucukvar and Tatari 2012; Weber and Matthews 2007; Wiedmann et al. 2011).

Assessing pavement designs from a life cycle perspective is crucial and necessary to have a holistic understanding about the complete picture so as to make long term successful policies (Santero et al. 2011). Several applications of LCA are available in the literature to analyze WMAs (Jamshidi et al. 2013; Jullien et al. 2011; Hassan 2010). In general, the results of those studies indicated that the emissions and energy consumption of the mixing process were reduced during the production and placement of WMA mixtures when compared to hot-mix asphalt (HMA). In addition to that, WMA pavement sections showed similar performance to those constructed with HMA mixtures. Although previously mentioned LCA studies have quantified some of the potential environmental impacts of WMAs, the role of the entire upstream supply chain during the production of asphalt additives, binders, metallic and nonmetallic minerals, and fuels used in different HMA and WMA mixtures, and related socio-economic impacts associated with utilization of these resources were generally excluded due to selection of smaller system boundaries.

A first detailed ecologically-based LCA (Eco-LCA) study was conducted by Tatari et al. (2012) where natural resource consumption and atmospheric emissions of various WMAs were analyzed and compared with HMA using the Eco-LCA software, which was developed by the Center for Resilience at Ohio State University (OSU—The Ohio State University 2009). The results of this study revealed that WMAs do not always have a better environmental performance than HMA, and there is significant variability among WMA technologies. In addition, material extraction and production phase was responsible for the highest amounts of ecological resource consumption. However, due to the large impacts on economy and the society, it is still necessary to account for the direct and indirect socio-economic implications of pavement construction. While environmentally extended EIO models can quantify environmental burdens, the Triple Bottom Line (TBL) EIO model is capable to quantify not only environmental pressures, but also social and economic impacts. This can be achieved by using an integrated approach, which integrates economic and social indicators of the sustainability into EIO framework as an addition to environment. TBL concept focuses on the three main pillars of sustainability: environment, economy, and society (Elkington 1998). In the literature, Foran et al. (2005a) developed a first comprehensive EIO-based TBL model of the industrial sectors of an entire economy for the Australia. This model integrated the EIO tables with environmental, economic, and social metrics for sectors in which all up-stream impacts are included. Although they are not for pavement construction and other heavy civil infrastructures, several studies were conducted using the EIO analysis by presenting first examples of TBL accounting in the EIO context (Foran et al. 2005b; Wiedmann and Lenzen 2009).

In addition, the World Input Output Database (WIOD) established a strong foundation for a multi-regional input–output (MRIO) framework by presenting supply and use tables for 40 countries, covering around 85 % of the world economy. This project was supported by the EU’s 7th Framework Program that presents the derivation of international trade and transport margins together with detailed supply and use tables at the world level. Together with extensive satellite accounts including environmental and socio-economic indicators, these databases can provide the necessary input to several types of EIO models that can be used to evaluate trade-offs between socio-economic and environmental objectives (Streicher and Stehrer 2012). Furthermore, the Global Trade Analysis Project (GTAP) also produces an extensive database of trade-linked input–output tables for the world economy, which involves about 57 sectors and 87 regions in the world (Hertwich and Peters 2009). Although GTAP is an extremely important tool for the modeling of the role of international trade in goods and services, environmental extensions are still limited to some energy and carbon indicators (Tukker et al. 2009).

In the literature, several studies have used EIO modeling to quantify the environmental implications of pavements from cradle to grave (Cas and Mukherjee 2011; Park et al. 2003; Treloar et al. 2004). In addition, the Pavement Life-Cycle Assessment Tool for Environmental and Economic Effects (PaLATE) was built to estimate the environmental burdens and life cycle costs associated with the pavement construction. This excel-based tool combined the EIO-LCA data with additional process-specific inventory to create a hybrid LCA framework (Santero et al. 2010). On the other hand, the scopes of current pavement LCA models are bounded by the most commonly used environmental impact categories such as water and energy use, atmospheric emissions, and waste; however, little attention paid to large scale economic and social implications of pavements. Hence, there is still a strong need to evaluate macro-level direct and indirect socio-economic implications of new WMA technologies for more comprehensive sustainability assessment. As classified in previous input–output databases and studies, import, income, gross operating surplus, government tax, injuries, and employment are considered as key socio-economic indicators (Foran et al. 2005a; Foran et al. 2005b; Hendrickson et al. 2006; GTAP 2008; Wiedmann et al. 2009; WIOD 2012). Using these indicators, this study aims to build a hybrid LCA model for evaluating not only environmental burdens but also socio-economic impacts of pavements constructed with different types of WMA mixtures and compare them to a conventional HMA design. To realize this goal, an industry-by-industry input–output model is utilized for assessing pavement sustainability. This model has been created by Kucukvar and Tatari (2013), which was initially used to quantify the sustainability implications of seven different U.S. construction sectors including buildings and heavy civil infrastructures. The types of WMA technologies analyzed in this research involve: Asphamin® WMA, EvothermTM WMA, and Sasobit® WMA.

1.3 Multi-criteria decision making

Multi-criteria Decision Making (MCDM) is a branch of a general class of operations research models which are used to solve decision making problems where multiple criteria and alternatives exist. Since, the optimal solution can be different based on each criteria, considering all criteria and providing an overall decision support to decision makers have been a critical topic of interest for researchers and practitioners. There are typically two types of MCDM categories, namely: Multi-attribute Decision Making (MADM) and Multi-objective Decision Making (MODM). The objectives can be used to select the best alternative or grouping alternatives into predefined preference sets based on the performance over multiple-criteria (Figueira et al. 2005). In general, MADM is an approach employed to solve problems including selection from among a finite number of alternatives (Rao 2007). On the other hand, in MODM problems, the goal is design rather than select by considering the tradeoffs within design constraints (Chang 2011). There are several types of MCDM models including weighted sum method (WSM), weighted product method (WPM), analytical hierarchy process (AHP), preference ranking organization method for enrichment evaluation (PROMETHEE), elimination and choice translating reality (ELECTRE), the technique for order preference by similarity to ideal solutions (TOPSIS), multi-attribute utility theory (MAUT), and compromise programming (Wang et al. 2009). Application of MCDM approaches has been extended to various areas including finance (Zopounidis and Doumpos 2002), environmental policy making (Greening and Bernow 2004), sustainable energy planning (Pohekar and Ramachandran 2004), and supplier selection (Ho et al. 2010).

Normalization and weighting are widely used methods in combined applications of LCA and MCDM. Normalization is a life cycle impact assessment tool (LCIA) that is used to express impact indicator data in a way that can be compared among impact categories. This procedure simply normalizes the impact results dividing by a selected reference value (ISO 14042). In addition, weighting, which is also referred to as valuation, is a step of LCIA in order to assign weights to the different environmental impact categories based on their importance. In general, weighting includes several activities such as identifying the priorities of decision makers, determining weights to assign on each impact category, and applying weights to impact categories (ISO 14042). Although, subjectivity makes weighting a challenge, weighting techniques are utilized for decision-making such as the Analytical Hierarchy Process (AHP) and Delphi method. For a discussion of weighting methods for LCA, please see Finnveden (1997) and Bengtsson (2001).

MCDM models have been extensively applied to LCA. To give a few examples, Kohn (2010) applied an integration of MCDA and LCA to a case study of switchgrass production as a biofuel in the state of California. In other research, MCDM is coupled with LCA to solve decision conflicts in composite material selection (Milani et al. 2011). Boufateh et al. (2011) used MCDM to analyze the results of LCA for different textile products. Linkov and Seager (2011) presented an approach for using MCDM to integrate uncertain information collected from risk analysis and LCA in the context of nanomanufacturing and management of contaminated sediments. In addition, Liu et al. (2012) combined risk assessment and LCA with MCDM. The researchers applied this methodology to a case study in waste recycling facility to assess its environmental aspects. Kiran and Rao (2013) also proposed an integration of LCA with MCDM for planning, designing, and commissioning of green buildings. Related to construction of pavements, literature includes only a handful of works related to highway management and pavement treatment or restoration. For instance, Filippo et al. (2007) proposed a Fuzzy MCDM for ranking environmentally valid highway restoration by priority. The proposed approach supports decisions on which road segments require the restoration related works and services. In another work, an AHP-based MCDM approach was utilized for the Highway Development and Management Tools (Casifo et al. 2002). Several attributes including social benefits, environmental effects, safety impacts, and strategic importance of roads are incorporated into a unified decision-making framework. Additionally, evaluation of sustainable drainage systems within the context of an overall decision-support framework is studied. Several technical, ecological, social, and economic factors are integrated into a MCDM framework (Ellis et al. 2004). However, there is only one found in the literature that considers LCA and MCDM as an integrated decision making framework for road construction. In this work, Giustozzi et al. (2012) studied the evaluation of the environmental impact of road maintenance activities using MCDM. Life cycle cost of maintenance activities are coupled with environmental impacts and incorporated into the MCDM framework.

Such integration of decision analysis techniques with LCA in fact can provide a very critical guidance to decision makers, which can contribute to the development of sustainable pavement strategies significantly. Although the LCA methods have recently gained interest in pavement research, such integration of LCA of pavement alternatives with MCDM can play a vital role for the evaluation of life cycle performance-based sustainable pavement systems. Therefore, this study proposes an integration of TBL-LCA with MCDM in order to assess the socio-economic and environmental implications of pavement alternatives and optimize the allocation of pavement mixtures considering a set of conflicting objectives.

2 Methods

In this research, the life cycle phases of materials extraction and processing, transportation of pavement materials, asphalt mixing process, and construction of pavements have been included within the scope. The use phase is not included because pavement sections were constructed with equivalent performances. First, the TBL-LCA model is built by using numerous environmental and socio-economic sustainability indicators. Second, the life cycle inventory of pavement designs are presented with corresponding data sources. Third, sustainability impacts of the HMA and WMAs have been calculated. Fourth, MODM model, namely compromise programming, is developed to solve the multi-objective optimization problem which has the tradeoffs between environmental and socio-economic indicators. This optimization model is built upon obtained LCA results to determine the optimal asphalt pavement allocation strategy for a functional unit of one-km pavement using sustainability weights ranging between 0 and 1. Finally, the findings are summarized, and the limitations are pointed out.

2.1 TBL-LCA model

This research analyses the life cycle sustainability implications of different pavement systems using EIO-based sustainability accounting framework. The holistic sustainability assessment framework is developed by combining the supply and use tables published by the U.S. Bureau of Economic Analysis (BEA—Bureau of Economic Analysis 2002) with the selected environmental and socio-economic sustainability metrics. In this research, the supply and use tables are converted into a symmetric industry-by-industry input–output table. This conversion is applied since Leontief’s basic input–output methodology presents the financial flows between industrial sectors without distinguishing between primary and secondary products produced by sectors. However, using this method, it is possible to account for the fact that some industries can produce more than one commodity, such as secondary products and by-products (Wachsmann et al. 2009). For example, hydrogen can be produced as a by-product in petroleum refineries, which can also be produced separately by chemical manufacturing industry as a primary product (UN 1999). In this context, the Eurostat manual presents several methods used to convert supply and use tables into symmetric tables (Eurostat manual of supply and use and input–output tables 2008).

In this article, we present an input–output based approach for calculating the sustainability performance of pavements. To realize this goal, industry-by-industry input–output methodology has been utilized. This format was also used in previous TBL-EIO models developed for the US, UK, and Australian economies (Foran et al. 2005a; Kucukvar and Tatari 2013; Wiedmann et al. 2009). In these models, the input–output multipliers represented the total impacts, which are direct plus indirect (supply chain) embodiments per unit of final demand of commodities produced by industrial sectors. An industry-by-industry TBL-LCA model has been used for pavement analysis. Then, a vector of total sustainability impacts is formulated as follows:

In Eq. 1, r is the total impacts vector that represents total sustainability impacts per unit of final demand, and E dir represents a diagonal matrix, which accounts for the direct sustainability impact per dollar of output, I refers to the identity matrix, and f is the total final demand vector for commodities produced by industries. In addition, B is the input requirements for products per unit of output of an industry matrix, and D is the market-share matrix. Also, the term [(I-DB)−1] represents the total requirement matrix, which is also known as the Leontief inverse and DB is the direct requirement matrix, which is denoted as A matrix in the Leontief’s model (Miller and Blair 2009). For more explanation about the integration of the supply and use tables into industry-by-industry input–output model and calculation of the net sustainability impacts, please see the reference paper published by Kucukvar and Tatari (2013).

2.2 Sustainability indicators

In this paper, the purpose is to develop a comprehensive EIO based sustainability accounting framework. Therefore, several indicators are intended to be used. The summary of the selected sustainability indicators are provided in Table 1 with details. These sustainability indicators are used as multipliers in the EIO framework to quantify each of the 426 sectors’ sustainability impacts. To obtain the aforementioned multipliers, several publicly available data sources including Bureau of Economic Analysis (BEA—Bureau of Economic Analysis 2002), Energy Information Administration (EIA 2011), Bureau of Labor Statistics (BLS—Bureau of Labor Statistics 2002), Global Footprint Network (GFN 2010), and Carnegie Mellon’s EIO-LCA software (CMU 2002) are utilized (For a more detailed explanation of the indicator selection, see Kucukvar and Tatari (2013).

2.3 Pavement design and life cycle inventory

In this paper, four pavement sections were designed considering intermediate traffic volume and a generic design structure, which consisted of an asphalt surface layer and a base course layer. In terms of the thickness of the base course layer, 25 cm was taken as reference value for all four sections. In the surface layer of the first three sections, Aspha-Min®, Sasobit®, and EvothermTM WMA mixtures were used. On the other hand, a conventional HMA mixture was used in the fourth section (see Tatari et al. (2012) for more information about the properties of HMA and WMA mixtures). The Mechanistic Empirical Pavement Design Guide (MEPDG) software was used to conduct the pavement analyses. During the pavement analyses, the thickness of the asphalt layer that is required for each section to have an international roughness index (IRI) value of 433 cm/km at the end of the design period was determined. In this context, the IRI is the terminal value recommended by the Federal Highway Administration (FHWA) and used in the MEPDG (FHWA 1998).

The basic assumptions made are as follows. A 30-year design period was used during the pavement analysis. The initial two-way average annual daily truck traffic (AADTT) was assumed to be 2,000 vehicles/day considering 50 % trucks in the design direction and 95 % trucks in the design lane. For the vehicle class distribution, number of axles per truck of each class, and axle configuration categories, the default values given by the MEPDG software were used. The traffic growth rate was assumed 5 % per year. Level I input was used for the asphalt concrete mixtures layers, while Level II inputs were used for the base and subgrade layers. The input parameters such as base material, and subgrade soil for the HMA and WMA mixtures were obtained from Hurley et al. (2009).

Based on the conducted MEPDG, the required asphalt layer thickness values were calculated as 12 cm for Aspha-Min®, 11.4 cm for Sasobit®, EvothermTM, and HMA sections. The corresponding volumes of HMA and WMA pavements were quantified by multiplying the width, the depth and the length of the pavement, which was selected to be a two-lane highway with a total width of 7.2 m and a length of 1 km. Later, the total weight of each of the HMA and WMA mixtures was calculated by multiplying the calculated volumes with corresponding densities. The calculated weights were allocated for each component, such as limestone, natural sand, asphalt binder, RAP, and WMA additives, based on the percent values of mixture composition provided in Tatari et al. (2012), thus the inventory required for HMA and WMA pavements were determined (see Table 2).

Limestone, natural sand, and asphalt binder were the main industrial inputs for the all pavements, which were provided by the following sectors, respectively: Lime and Gypsum Product Manufacturing (NAICS 327410), Sand, Gravel, Clay, and Refractory Mining (NAICS 212320), and Petroleum Refineries (NAICS 324110). Aspha-min® and EvothermTM were used as chemical additives in the WMA pavements, which were manufactured by the Other Basic Inorganic Chemical Manufacturing sector (NAICS 325180) and Sasobit® was produced by the Petrochemical Manufacturing (NAICS 325110) sector. As the main resource used in the transportation of pavement materials to construction site, the Truck Transportation sector (NAICS 484000) is used for calculating sustainability impacts of pavement material transport while impacts of construction activities including pavement laying and compaction are quantified by using the sector of the Highway Construction (NAICS 237310) from the EIO table. As the main resource used during the asphalt production in the mixing plant, natural gas was provided by the Natural Gas Distribution sector (NAICS 221200).

Direct and indirect impacts related to consumption of resources during materials production, transportation, mixing, and construction are calculated through the TBL-LCA model. Firstly, the monetary values of each material input are calculated using the producer prices. These monetary values represent the economic input of each related sectors, which are also the calculated demand as a result of a certain activity such as natural gas required for the mixing process. After calculating the monetary values, each of them are multiplied by environmental and socio-economic impact multipliers obtained from the TBL-LCA model. The environmental and socio-economic input–output multipliers of these sectors are presented in Tables 3 and 4.

In terms of the mixing energy consumption (MJ per ton WMA and HMA processing), National Center for Asphalt Technology (NCAT)’s field study, which includes the natural gas consumption data, is utilized to calculate the total energy consumed during HMA and WMA mixing phase (Hurley et al. 2009). The total energy consumption per ton asphalt mixing was multiplied with the total weight of the mixtures to obtain the total energy consumption of 1-km pavement sections. The GHG emission factors associated with HMA and WMA mixing operations were obtained from the asphalt plant stack emissions report, which was published by the NCAT (Hurley et al. 2009). The onsite life cycle inventory data including toxic releases into air, hazardous waste, and water consumption for manufacturing of asphalt mixture was determined by utilizing the TBL-LCA tool for North American Industry Classification System (NAICS) sector 324121, Asphalt Paving Mixture and Block Manufacturing sector. The amount of diesel consumption during the construction of asphalt pavements were obtained from the previous pavement energy studies (Ang et al. 1993; Zapata and Gambatese 2005). Other environmental loads including on-site and indirect emissions, hazardous waste, water use, and land footprint are calculated by using the multipliers of the Highway Construction sector.

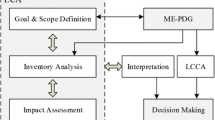

Finally, transportation-related tail-pipe GHG emission data were determined using the emission factors provided by the National Renewable Energy Laboratory (NREL)’s life cycle inventory database for a single-unit truck (NREL—National Renewable Energy 2010). The unit was the per ton-km transportation of the pavement materials to the project field. The distance between pavement materials and construction site is assumed to be 50 km for each pavement system. The emission data consists of GHGs including nitrous oxide (N2O), carbon dioxide (CO2), and methane (CH4). Also, all other direct and indirect environmental impacts are calculated using the Truck Transportation sector. First, the total ton-km transportation requirement of each pavement is calculated by multiplying total weight of materials with total transportation distance. Later on, the obtained value is multiplied with the unit cost related to per ton-km transportation with trucking in the U.S. (Raballand and Macchi 2008). This economic output is then linked to the Truck Transportation sector of the EIO model. Fig. 1 presents the system boundary of a hybrid LCA model.

2.4 A compromise programming approach

MODM is critical for finding a feasible alternative that yields the most preferred set of values for the objective, which aims to maximize the sustainability impacts toward identifying optimal pavement design strategy. In order to realize this goal, a compromise programming model, which is widely used for solving multi-objective linear, nonlinear or integer programming problems, is developed to optimize multiple sustainability objectives. The main idea in compromise programming model, which was first developed by Zeleny (1973), is to seek a solution closest to the ideal point. It uses a distance-based function in order to minimize the distance between ideal and compromise solutions. Eq.2 defines the La metric used to find the distance between two points of Z *k and Zk(x) and indicates the degree of closeness to the ideal point (Chang 2011).

In this equation, Z *k is the ideal value for the objective k and Zk(x) is the achievement level of the objective k. Each objective function can have different unit, and therefore normalization is needed before the optimization model is constructed. The values after normalization will be confined to a given range such as 0 to 1. The normalization function Z can be expressed as (Chang 2011):

After completing the normalization procedure, the distance-based compromise programming formulation can be written as:

Subject to:

In this formulation, Z * k represents the ideal solution for objective k. Each objective function should be optimized individually in order to find the amount of Z *k . Also, the parameter p represents the total number of objectives and πk is a weight that can be arbitrarily assigned by the decision makers to account for the relative importance of each objective. Environmental and socio-economic weights are represented by πk , which ranges from 0 to 1 for each of the objective function. After developing the mathematical structure of the compromise programming, this optimization model is coupled with uniformly distributed input variables to account for the uncertainty. The optimization model is presented as follows:

-

Index

-

i: Sustainability indicator

-

m: Pavement type indicator

-

p: Number of pavement types

-

r: Number of environmental indicator

-

s: Number of socio − economic indicator

-

-

Parameters

-

A im : The impact of pavement m for environmental indicator i

-

B im: The impact of pavement m for socio − economic indicator i

-

W im : The weight of environmental indicator i for pavement m

-

-

Decision variable

-

Xim: The percentage use of pavement type m for sustainability indicator i

-

Objective functions

Subject to

Z1(x) denotes the environmental objective function and Z2(x) represents the socio-economic objective function. A im is denoted as the environmental impact of pavement type m for the indicator i whereas B im is denoted as the socio-economic impact (Eq. 7). The total of X im is 1 (Eq. 8). W im represents the weight of each environmental impact indicator: energy consumption, GHG emissions, hazardous waste generation, toxic releases into air, and ecological land use. The total of W im is 1. These weights are obtained from Version 4.0 of the BEES (Building for Economic and Environmental Sustainability) software which was introduced by the National Institute of Standards and Technology (NIST; Lippiatt 2007). Since there is no separate weighting category for our five land footprint indicators, their weights are assumed to be identical. In order to develop this set of weights, NIST solicited input from a volunteer stakeholder panel. The weights of environmental impacts and their calculation method can be found in Gloria et al. (2007).

Consequently, a stochastic multi-objective optimization model is combined with the LCA results to optimize the multiple environmental and socio-economic objectives, simultaneously. MATLAB® programming software is then used for coding the compromise programming algorithm (MATLAB 2012). A uniform distribution was assumed for each selected input variable. Then, using the value of each indicator in a given range, a stochastic compromise programming model has been utilized for finding the optimal allocation of different pavement types.

2.5 Analysis results

The study results are based on sustainability impact analysis and stochastic compromise programming, which are presented in the following sub-sections.

2.6 Environmental impacts

The environmental impacts of each of the analyzed pavements are computed in terms of water and energy consumption, GHG emissions, hazardous waste generation, and toxic releases into air. As shown in Fig. 2, Asphamin® has the highest environmental impacts than other pavement types with an exception of GHG emissions. This pavement type is followed by EvothermTM and Sasobit®, respectively. In terms of LCA phases, materials extraction and processing and construction are found to have the largest contributions. On the contrary, for GHG emissions, mixing phase has the second largest impact after manufacturing of pavement materials. Especially, total GHG emissions are found to be the highest for EvothermTM, which also has the largest emissions during the mixing phase (see Fig. 2). NCAT’s field experiment results indicate that EvothermTM used 14.5 % more energy than HMA and emitted larger quantities of GHGs. On the contrary, the total natural gas consumption is reduced by 8.8 % for Asphamin® and 17.9 % for Sasobit® (Hurley et al. 2009). In terms of GHG emissions and energy consumption, Sasobit® shows the minimum values compared to other WMAs and HMA control mix.

Fig. 3 also presents the net land footprint of each pavement design in terms of global hectares (gha). Based on the total land use results, HMA has the lowest footprint with an exception of CO2 uptake land when compared to other pavements. When we looked more closely at life cycle phases, materials extraction and processing and construction phases represent two dominant phases for land footprint categories such as fishery, grazing, forestry, and cropland. For CO2 uptake land, after materials extraction and processing, the mixing phase has the second largest contribution. In addition, this land footprint category is responsible for the highest footprint compared to other land use types. Asphamin® and EvothermTM represent the pavement mixtures with maximum CO2 uptake land utilization due to high emissions in pavement material production and energy requirement during the mixing phase whereas Sasobit® has the lowest land footprint result, which is also parallel to total GHG emission findings.

2.7 Socio-economic impacts

As can be seen from Fig. 4, Asphamin® has the highest socio-economic impacts than other pavement types. The differences in thickness of the Asphamin® design played an important role in this finding because more materials extracted and processed for construction of this pavement structure, which in turn required more transport and construction fuel. This pavement technology is followed by EvothermTM. On the contrary, Sasobit® and HMA control-mix have shown similar performances in terms of analyzed socio-economic indicators. For import, gross operating surplus (GOS) and government tax indicators, materials extraction and processing phase has the dominant contribution. The use of bitumen, which is used as a binder in asphalt mixture, resulted in the highest import values compared to other materials. In addition, construction of pavements has the second largest impact on the overall employment, income, and work-related injuries after manufacturing phase. Conversely, socio-economic impacts are found to be minimal for transportation and mixing phases. When we looked more closely at injury results, pavement materials manufacturing and construction phases have the highest values, which indicate the importance of work safety in production and construction processes when paving the U.S. highways. It is also important note that to there is a positive correlation between total income and number of injuries. In general, sector with high income rate generated more employment, which resulted in higher amount of work-related injuries. This is because the number of full-time employees is multiplied with corresponding injury rates to obtain the total number of injuries. The overall socio-economic impact results are presented in Fig. 4.

2.8 Stochastic compromise programming results

In Sections 3.1 and 3.2, it was assumed that the input parameters were known with certainty. Therefore, the model outputs, including environmental and socio-economic results, did not address the variability that is inherent in the input variables. In order to account for the variability of critical input variables, a uniform distribution was assumed for each selected variable. The utilization of probabilistic values enabled us to estimate the impact of the variability in consumption of WMA additives (−30 % to +30 %), the transportation distance of the pavement materials to mixing sites (50–500 km) and the amount of mixing energy (−10 % to +10 %). Similar uncertainty ranges were also used in previously published LCA study for uncertainty analysis (Tatari et al. 2012).

In this analysis, a compromise programming model is utilized in order to find the most appropriate allocation of pavement alternatives based on different weights of environmental and socio-economic indicators. As shown in Fig. 5, the percentage rates of allocation of each pavement methods has been ranged between 0 and 1. As mentioned before, Asphamin® WMA has the highest socio-economic impacts among other alternatives, and therefore when the socio-economic weight (SEW) is critical, this method has the highest allocation rate with more than 50 %. The percentage of allocation of this method is very sensitive to the change of weights, as it drops dramatically by increasing environmental weight (EW). While EW is greater than 0.4, Asphamin® WMA is not a suitable option among other alternatives.

Moreover, in a balanced weighting situation in which environmental and socio-economic indicators have equal importance, Sasobit® has higher percentage with a share of 61 %. This is followed by HMA at 25 % and Evotherm at 9 %, respectively. Interestingly, the allocation percentage of HMA stays almost the same for the rest of EWs (greater than 0.5), with only 3 % changes in allocation results. In addition, when environmental indicators have more importance compared to socio-economic indicators, Sasobit® WMA is still the most preferred method. Specifically, while EW is greater than 0.5, the allocation of this pavement technology ranged between 66 % and 70 %. Also, when the weights vary between 0.5 and 1, the percentage of allocation of EvothermTM stays almost the same, with only 4 % variation.

It is also critical to note that in 2010, approximately 360 million tons of asphalt pavement materials produced in the USA in which 42 million tons (12 %) were produced using WMA technologies (U.S. Department of Transportation 2010). When looked more closely at the compromise programming results, it is found that U.S. pavements utilize approximately 3.52 times more HMA than the scenario where environmental and socio-economic indicators are equally important. Hence, the results clearly support the significance of an increase in WMA use for sustainable pavement construction. The optimal utilization of each pavement mixture is presented in Fig. 5 based on varied environmental and socio-economic weights.

3 Conclusions and recommendations

A comprehensive hybrid TBL-LCA model is developed to evaluate macro-level environmental and socio-economic implications of using WMA technologies in construction of asphalt pavements in the United States. This holistic analysis complements previous LCA studies by evaluating pavements not only from emissions and energy consumption standpoint, but also from socio-economic perspectives. Furthermore, compromise programming results provide a vital guidance for policy makers when optimizing the use of pavement types based on different environmental and socio-economic priorities. As a result, this research aimed to increase awareness of the inherent benefits of TBL-oriented EIO analysis and constrained stochastic optimization through application to emerging sustainable infrastructure practices. Based on analysis results, the followings are highlighted:

-

Asphamin® WMA was found to have the highest environmental and socio-economic impacts in comparison with other pavement designs.

-

WMAs did not perform better in terms of environmental impacts compared to HMA. However, they appeared to perform better when socio-economic indicators of sustainability were considered.

-

Among the life cycle phases, material extraction and processing was found to have the highest contribution to all environmental impact indicators that showed the importance of cleaner production strategies for sustainable pavement construction.

-

The overall GHG emissions were to be highest for EvothermTM due to higher energy use and mixing emission factors. On the contrary, Sasobit® had the best performance in terms of minimum carbon footprint.

-

Although WMA generally performed better in terms of reduced mixing emissions, inclusion of direct and indirect manufacturing related impacts have changed the overall comparisons. Materials extraction and processing had the dominant impact on overall carbon and toxic emissions results.

-

In terms of socio-economic impact results, material extraction and processing and construction phases were found to have the largest contributions when compared to mixing and transportation of pavement materials.

-

Stochastic compromise programming results also indicate that when environmental indicators have more importance, Sasobit® is favored. On the other hand, if only socio-economic aspects were considered, Asphamin® WMA had the highest percentage of allocation compared to other WMA types.

-

In a balanced weighting scenario where environmental and socio-economic weights were equal (EW, 50 %; SEW, 50 %), Sasobit® was allocated at 61 %, HMA at 25 %, and EvothermTM at 9 %. In all the cases, HMA mixture was also allocated that is ranging from 13 % to 24 %.

-

When considering current HMA consumption amounts in the U.S. highways, it is likely to conclude that there is a strong need on increasing the percentage share of WMA mixtures in order to achieve more balanced sustainability performance goals for future. This policy recommendation is proven by the optimization model findings.

-

The main lesson learnt from this study is that even though mixing phase is important, it should not be the only criteria to evaluate the overall sustainability performance of WMA and HMA pavements. The supply chain, which includes the contribution of all indirect economic sectors for materials extraction and processing, is also critical for a more holistic analysis. In addition, extending the system boundary by considering the interactions between U.S. sectors helps us to capture all indirect impacts that might minimize errors related to using narrow system boundaries for impact analysis.

Although a hybrid TBL-LCA model is developed, uncertainty in the LCA results and limitations of the current EIO method should be taken into account by decision makers. The first is that, this paper used a single-nation input–output model rather than a global multi-regional input–output (MRIO) framework. Hence, current results have some important uncertainties related to using domestic technology assumption for imported materials. Current input–output model can be extended beyond the boundary of the U.S. economy to account for the global impacts of the pavement construction by considering the role of the imported products such as bitumen, fuels, and WMA additives. The importance of using MRIO models can be found in the literature (Hertwich and Peters 2009; Kanemoto et al. 2011; Tukker et al. 2009).

While the current work used a high-resolution U.S. supply and use tables (discerning 426 sectors), there is aggregation-related uncertainties in the final results since several subsectors are evaluated under the same main sector. These uncertainties can be minimized by using more specific process inventory data for products analyzed under highly aggregated sector like chemical product manufacturing. Another important limitation was also related to transportation because current paper used the truck transportation sector to calculate sustainability impacts of pavement material transport. Truck transportation is a very non-homogeneous service sector that comprises several establishments primarily engaged in providing general freight. The detailed LCA of freight transportation by modes is critical and can be found in the literature (Facanha and Horvath 2007).

Inevitably, variability ranges chosen for mixing energy, transportation distance, and WMA additive consumption are also subject to uncertainties. With changing variability ranges, MODM model might give different results for the allocation of WMAs. Furthermore, another greatest weakness of MODM model is the subjectivity of the weighting step that is needed to value the different environmental impact categories. Although weighting is widely used in LCA, the weighting stage is the least developed of the impact assessment steps which can be improved by using multi-criteria evaluation techniques such as panel methods or AHP (Hermann et al. 2007; Gloria et al. 2007). For future research, authors also suggest to evaluate other WMA technologies such as Synthetic Zeolite and WAM-Foam as more sustainability indicators become readily available using more process-specific life cycle inventory data.

References

Ang B, Fwa T, Ng T (1993) Analysis of process energy use of asphalt-mixing plants. Energ 18(7):769–777

BEA (Bureau of Economic Analysis) (2002) Benchmark input–output data. U.S. Bureau of Economic Analysis. Retrieved from <http://www.bea.gov/industry/io_benchmark.htm> Accessed 15 March 2013

BLS (Bureau of Labor Statistics) (2002) Industry injury and illness data. Retrieved from <http://www.bls.gov/iif/oshsum.htm>. Accessed 15 March 2013

Bengtsson M (2001) Weighting in practice. Implications for the use of life‐cycle assessment in decision‐making. J Ind Ecol 4:47–60

Boufateh I, Perwuelz A, Rabenasolo B, Jolly-Desodt AM (2011) Multiple criteria decision-making for environmental impacts optimization. Int J Bus Perf Supp Chain Model 3(1):28–42

Cas D, Mukherjee A (2011) Calculation of greenhouse gas emissions for highway construction operations by using a hybrid life-cycle assessment approach: case study for pavement operations. J Constr Eng Manage 137(11):1015–1025

Casifo S, Di Graziano A, Kerali HR, Odoki JB (2002) Multicriteria analysis method for pavement maintenance management. Transp Tes Rec J Transp Res Board 1816:73–84

Chang NB (2011) Systems analysis for sustainable engineering. McGraw-Hill Professional Publishing, New Jersey, p 655

Chowdhury A, Button JW (2008) A Review of Warm Mix Asphalt. College Station, Texas, p 75

CMU (2002) EIO-LCA (Economic Input-Output Life Cycle Assessment). http://www.eiolca.net/cgibin/dft/display.pl. Accessed 15 February 2013

Egilmez G, Kucukvar M, Tatari O (2013) Sustainability assessment of U.S. manufacturing sectors: an economic input output-based frontier approach. J Clean Prod 53:91–102

Elkington J (1998) Partnerships from cannibals with forks: the triple bottom line of 21st‐century business. J Environ Qual Manage 8(1):37–51

Ellis JB, Deutsch JC, Mouchel JM, Scholes L, Revitt M (2004) Multicriteria decision approaches to support sustainable drainage options for the treatment of highway and urban runoff. Sci Total Env 334:251–260

Eurostat manual of supply, use and input–output tables (2008) Luxembourg

Facanha C, Horvath A (2007) Evaluation of life-cycle air emission factors of freight transportation. Environ Sci Technol 41(20):7138–7144

FHWA (1998) Life-cycle cost analysis in pavement design - Pavement Division Interim Technical Bulletin

Figueira J, Greco S, Ehrgott M (2005) Multiple criteria decision analysis: state of the art surveys, vol 78. Springer, New York

Filippo S, Martins Ribeiro PC, Kahn Ribeiro S (2007) A fuzzy multi-criteria model applied to the management of the environmental restoration of paved highways. Transp Res Part D Transp Env 12(6):423–436

Finkbeiner M, Schau EM, Lehmann A, Traverso M (2010) Towards life cycle sustainability assessment. Sustain 2(10):3309–3322

Finnveden G (1997) Valuation methods within LCA – where are the values? Int J Life Cycle Assess 2:163–169

Foran B, Lenzen M, Dey C (2005a) Balancing Act: a triple-bottom-line analysis of the Australian economy. CSIRO, Australia, p 75

Foran B, Lenzen M, Dey C, Bilek M (2005b) Integrating sustainable chain management with triple bottom line accounting. Ecol Econ 52(2):143–157

Giustozzi F, Crispino M, Flintsch G (2012) Multi-attribute life cycle assessment of preventive maintenance treatments on road pavements for achieving environmental sustainability. Int J Life Assess 17(4):409–419

Global Footprint Network (2010) National footprint accounts: ecological footprint and bio-capacity. Retrieved February 15, 2013, from http://www.footprintnetwork.org/en/index.php/GFN/page/footprint_for_nations

Gloria TP, Lippiatt BC, Cooper J (2007) Life cycle impact assessment weights to support environmentally preferable purchasing in the United States. Environ Sci Technol 41(21):7551–7557

Greening LA, Bernow S (2004) Design of coordinated energy and environmental policies: use of multi-criteria decision-making. Energ Policy 32(6):721–735

GTAP (2008) Global Trade Analysis Project. Version 7. Department of Agricultural Economics, Purdue University, US. Retrieved from https://www.gtap.agecon.purdue.edu/databases/default.asp

Guinée JB, Heijungs R, Huppes G, Zamagni A, Masoni P, Buonamici R, Ekvall T, Rydberg T (2011) Life cycle assessment: past, present, and future. Environ Sci Technol 45:90–96

Hassan M (2010) Evaluation of the environmental and economic impacts of warm-mix asphalt using life-cycle assessment. Int J Constr Edu Res 6(3):238–250

Hendrickson CT, Lave LB, Matthews S (2006) Environmental life cycle assessment of goods and services: an input–output approach, 1st edn. Resources for the Future, Washington DC

Hermann BG, Kroeze C, Jawjit W (2007) Assessing environmental performance by combining life cycle assessment, multi-criteria analysis and environmental performance indicators. J Clean Prod 15(18):1787–1796

Hertwich EG, Peters GP (2009) Carbon footprint of nations: a global, trade-linked analysis. Environ Sci Technol 43(16):6414–6420

Highway Statistics (2010) Retrieved from http://www.fhwa.dot.gov/policyinformation/statistics/2010/vmt422.cfm

Ho W, Xu X, Dey PK (2010) Multi-criteria decision making approaches for supplier evaluation and selection: a literature review. Euro J Oper Res 202(1):16–24

Horvath A, Hendrickson C (1998) Comparison of environmental implications of asphalt and steel-reinforced concrete pavements. Trans Res Record 1626:105–113

Huang YA, Lenzen M, Weber CL, Murray J, Matthews HS (2009) The role of input–output analysis for the screening of corporate carbon footprints. Econ Syst Res 21(3):217–242

Huppes G, Koning A, Suh S, Heijungs R, Oers L, Nielsen P, Guinée JB (2006) Environmental impacts of consumption in the European Union: high-resolution input–output tables with detailed environmental extensions. J Ind Ecol 10(3):129–146

Hurley GC, Prowell BD, Kvasnak AN (2009) Ohio field trial of warm mix asphalt technologies: construction summary. Auburn, AL

ISO (14042) Environmental management—life cycle assessment—life cycle impact assessment. Geneva: International Standard Organization

Jamshidi A, Hamzah MO, You Z (2013) Performance of warm-mix asphalt containing Sasobit®: state-of-the-art. Constr Buil Mater 38:530–553

Jullien A, Baudru Y, Tamagny P, Olard F, Zavan D (2011) A comparison of environmental impacts of hot and half-warm mix asphalt. Routes/Roads, Belgium, p 350

Kanemoto K, Lenzen M, Peters GP, Moran D, Geschke A (2011) Frameworks for comparing emissions associated with production, consumption, and international trade. Environ Sci Technol 46(1):172–179

Kiran BA, Rao PN (2013) Life cycle assessment (LCA) and multi-criteria decision making (MCDM) for planning, designing and commissioning of green buildings. Int J Adv Trends in Compute Sci Eng 2(1):476–479

Klöpffer W (2008) Life cycle sustainability assessment of products. Int J Life Cycle Assess 13:89–95

Kohn JL (2010) Multiple criteria decision analysis for the selection of a land use impact method for a life cycle assessment of switchgrass as a bioenergy feedstock in the Pee Dee region of South Carolina. Doctoral dissertation, Clemson University

Kristjánsdóttir Ó, Muench ST, Michael L, Burke G (2007) Assessing potential for warm-mix asphalt technology adoption. Trans Res Rec J Trans Res Board 2040:91–99

Kucukvar M, Tatari O (2013) Towards a triple bottom-line sustainability assessment of the U.S. construction industry. Int J Life Cycl Assess 18(5):958–972

Kucukvar M, Tatari O (2011) A comprehensive life cycle analysis of cofiring algae in a coal power plant as a solution for achieving sustainable energy. Energ 36(11):6352–6357

Kucukvar M, Tatari O (2012) Ecologically based hybrid life cycle analysis of continuously reinforced concrete and hot-mix asphalt pavements. Transp Res Part D Trans Environ 17(1):86–90

Larsen O, Moen O, Robertus C, Koenders B (2004) WAM Foam asphalt production at lower operating temperatures as an environmentally friendly alternative to HMA. Proceedings of the 3rd Eurasphalt and Eurobitume Congress (Vol. 1). Vienna

Lenzen M, Moran D, Kanemoto K, Foran B, Lobefaro L, Geschke A (2012) International trade drives biodiversity threats in developing nations. Nature 486(7401):109–112

Leontief W (1970) Environmental repercussions and the economic structure: an input–output approach. Rev Econ Stat 52:262–271

Linkov I, Seager TP (2011) Coupling multi-criteria decision analysis, life-cycle assessment, and risk assessment for emerging threats. Environ Sci Technol 45(12):5068–5074

Lippiatt BC (2007) BEESRG 4.0: Building for Environmental and Economic Sustainability Technical Manual and User Guide

Liu KFR, Ko CY, Fan C, Chen CW (2012) Combining risk assessment, life cycle assessment, and multi-criteria decision analysis to estimate environmental aspects in environmental management system. Int J Life Cycle Assess 17(7):845–862

MATLAB (2012) Version 7.14.0. Natick. The MathWorks Inc, Massachusetts

Milani AS, Eskicioglu CK, Robles KB, Bujun K, Hosseini-Nasab H (2011) Multiple criteria decision making with life cycle assessment for material selection of composites. Express Polymer Lett 5(12):1062–1074

Miller RE, Blair PD (2009) Input–output analysis: foundations and extensions (2nd ed.). Cambridge, MA

NREL—National Renewable Energy Laboratory (2010) U.S. life-cycle inventory database. Retrieved March 5, 2013, from https://www.lcacommons.gov/nrel/search

OSU- The Ohio State University (2009) Eco-LCA software, ecologically based life cycle assessment, 1997 U.S. benchmark model. Columbus,OH

Park K, Hwang Y, Seo S, Seo H (2003) Quantitative assessment of environmental impacts on life cycle of highways. J Constr Eng Manage 129(1):25–31

Pohekar SD, Ramachandran M (2004) Application of multi-criteria decision making to sustainable energy planning—A review. Renew Sustain Energ Rev 8(4):365–381

Rao RV (2007) Introduction to Multiple Attribute Decision-making (MADM) Methods. Decision Making in the Manufacturing Environment: Using Graph Theory and Fuzzy Multiple Attribute Decision Making Methods, pp 27–41

Raballand G, Macchi P (2008) Transport prices and costs: the need to revisit donors’ policies in transport in Africa, Washington, D.C. from:ipl.econ.duke.edu/bread/papers/0809conf/Raballand.pdf

Rubio MC, Martínez G, Baena L, Moreno F (2012) Warm mix asphalt: an overview. J Clean Prod 24:76–84

Rubio MC, Moreno F, Martínez-Echevarría MJ, Martínez G, Vázquez JM (2013) Comparative analysis of emissions from the manufacture and use of hot and half-warm mix asphalt. J Clean Prod 41:1–6

Santero NJ, Masanet E, Horvath A (2010) Life-cycle assessment of pavements: a critical review of existing liteature and research. Portland Cement Association, Skokie, Illinois, USA

Santero NJ, Masanet E, Horvath A (2011) Life-cycle assessment of pavements. Part I Crit Rev Res Conser Recy 55(9–10):801–809

Spending and Funding for Highways. (2011) (p. 8). Retrieved from http://www.cbo.gov/sites/default/files/cbofiles/ftpdocs/120xx/doc12043/01-19-highwayspending_brief.pdf

Streicher G, Stehrer H (2012) Whither Panama? Constructing a consistent and balanced world SUT system including international trade and transport margins. 7th EU-framework project, World Input–output Database: construction and applications, Vienna, Austria

Suh S, Lenzen M, Treloar GJ, Hondo H, Horvath A, Huppes G, Jolliet O et al (2004) System boundary selection in life-cycle inventories using hybrid approaches. Environ Sci Technol 38(3):657–664

Tatari O, Nazzal M, Kucukvar M (2012) Comparative sustainability assessment of warm-mix asphalts: a thermodynamic based hybrid life cycle analysis. Res Conser Recy 58:18–24

Traverso M, Finkbeiner M, Jørgensen A, Schneider L (2012) Life cycle sustainability dashboard. J Ind Ecol 16(5):680–688

Treloar GJ, Love PE, Crawford RH (2004) Hybrid life-cycle inventory for road construction and use. J Constr Eng Manage 130(1):43–49

Tukker A, Poliakov E, Heijungs R, Hawkins T, Neuwahl F, Rueda-Cantuche JM, Bouwmeester M (2009) Towards a global multi-regional environmentally extended input–output database. Ecol Econ 68(7):1928–1937

UN (1999) Studies in methods: handbook of national accounting. United Nations Department for Economic and Social Affairs, Statistics Division, New York, USA

U.S. Department of Transportation (2010) Warm-mix asphalt technlogies and research. Retrieved March 30, 2013, from U.S. Bureau of Labor Statistics. (2002). Industry injury and illness data. Retrieved January 5, 2012, from http://www.bls.gov/iif/oshsum.htm. Accessed 30 March 2013

Wachsmann U, Wood R, Lenzen M, Schaeffer R (2009) Structural decomposition of energy use in Brazil from 1970 to 1996. App Energ 86(4):578–587

Wang JJ, Jing YY, Zhang CF, Zhao JH (2009) Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew Sustain Energ Rev 13(9):2263–2278

Weber CL, Matthews HS (2007) Embodied environmental emissions in U.S. international trade, 1997–2004. Environ Sci Technol 41(14):4875–4881

Wiedmann T, Lenzen M (2009) Environmental management accounting for cleaner production. Unravelling the impacts of supply chains: a new triple-bottom-line accounting approach and software tool (S. Schaltegger, M. Bennett, R. L. Burritt, & C. Jasch, Eds.) Eco-Eff Ind Sci 24:65–90

Wiedmann T, Lenzen M, Barrett JR (2009) Companies on the scale: comparing and benchmarking the sustainability performance of businesses. J Ind Ecol 13(3):361–383

Wiedmann T, Suh S, Feng K, Lenzen M, Acquaye A, Scott K, Barrett JR (2011) Application of hybrid life cycle approaches to emerging energy technologies–the case of wind power in the UK. Environ Sci Technol 45(13):5900–5907

WIOD (2012) World input–output database: construction and applications, FP7 Research Project, 2009–2012. Retrieved from www.wiod.org

Zamagni A, Guinée J, Heijungs R, Masoni P (2012) Life cycle sustainability analysis. Life cycle assessment handbook: a guide for environmentally sustainable production. pp 453–474

Zapata P, Gambatese JA (2005) Energy consumption of asphalt and reinforced concrete pavement materials and construction. J Infra Syst 11(1):9–20

Zeleny M (1973) In: Cochrane JL, Zeleny M (eds) Compromise programming in multiple criteria decision making. University of South Carolina Press, Columbia, SC, pp 262–301

Zopounidis C, Doumpos M (2002) Multi-criteria decision aid in financial decision making: methodologies and literature review. J Mult-Criteria Dec Analy 11(4–5):167–186

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Marzia Traverso

Rights and permissions

About this article

Cite this article

Kucukvar, M., Noori, M., Egilmez, G. et al. Stochastic decision modeling for sustainable pavement designs. Int J Life Cycle Assess 19, 1185–1199 (2014). https://doi.org/10.1007/s11367-014-0723-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-014-0723-4