Abstract

Purpose

Waste management for end-of-life (EoL) smartphones is a growing problem due to their high turnover rate and concentration of toxic chemicals. The versatility of modern smartphones presents an interesting alternative waste management strategy: repurposing. This paper investigates the environmental impact of smartphone repurposing as compared to traditional refurbishing using Life Cycle Assessment (LCA).

Methods

A case study of repurposing was conducted by creating a smartphone “app” that replicates the functionality of an in-car parking meter. The environmental impacts of this prototype were quantified using waste management LCA methodology. Studied systems included three waste management options: traditional refurbishment, repurposing using battery power, and repurposing using a portable solar charger. The functional unit was defined as the EoL management of a used smartphone. Consequential system expansion was employed to account for secondary functions provided; avoided impacts from displaced primary products were included. Impacts were calculated in five impact categories. Break-even displacement rates were calculated and sensitivity to standby power consumption were assessed.

Results and discussion

LCA results showed that refurbishing creates the highest environmental impacts of the three reuse routes in every impact category except ODP. High break-even displacement rates suggest that this finding is robust within a reasonable range of primary cell phone displacement. The repurposed smartphone in-car parking meter had lower impacts than the primary production parking meter. Impacts for battery-powered devices were dominated by use-phase charging electricity, whereas solar-power impacts were concentrated in manufacturing. Repurposed phones using battery power had lower impacts than those using solar power, however, standby power sensitivity analysis revealed that solar power is preferred if the battery charger is left plugged-in more than 20 % of the use period.

Conclusions

Our analysis concludes that repurposing represents an environmentally preferable EoL option to refurbishing for used smartphones. The results suggest two generalizable findings. First, primary product displacement is a major factor affecting whether any EoL strategy is environmentally beneficial. The benefit depends not only on what is displaced, but also on how much displacement occurs; in general, repurposing allows freedom to target reuse opportunities with high “displacement potential.” Second, the notion that solar power is preferable to batteries is not always correct; here, the rank-order is sensitive to assumptions about user behavior.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Millions of smartphones reach the end of their lives each year, making their responsible management an urgent environmental goal. Cell phone e-waste will continue to be a growing problem as more devices are produced—roughly 1.5 billion cell phones were sold worldwide in 2011 alone. The fastest growing segment of this market is smartphones, which grew 62.7 % from 2010 to 2011 and now account for nearly a third (32 %) of all handsets (IDC 2012; Canalys 2012). These devices are a tremendous e-waste challenge because smartphone users replace handsets after an average of only 2 years (Entner 2011; Singhal 2005; Google 2012) and they contain toxic materials such as copper, chromium, and flame retardants (Oiva et al. 2000; Lindholm 2003; Huisman 2004). In 2012, only 15 % of handsets were projected to be responsibly disposed; the vast majority of phones either remained in storage or were improperly disposed (ABI Research 2009). However, the versatility of smartphones opens up a variety of creative end-of-life (EoL) strategies that have not been previously exploited.

Currently, the only widespread EoL options for smartphones, like conventional cell phones, are recycling or refurbishment. In this paper, we examine another waste management option which leverages the power and flexibility of smartphones: repurposing them for a different task. Repurposing is a promising EoL option for three reasons: Firstly, it provides consumers with additional utility from a product that they might otherwise discard. Secondly, it reduces environmental impact if it avoids the production of purpose-built products with the same functionality, such as cameras, music players, video recorders, or other electronics. Thirdly, in contrast to refurbishment, which always regenerates the original functionality, repurposing allows freedom to choose functionality that maximizes the potential to avoid primary products.

To test the environmental impact of smartphone repurposing, we created a smartphone app, “ePark,” to repurpose two smartphones into personal in-car parking meters. We assessed the environmental impact of different used smartphone management decisions using established waste management Life Cycle Assessment (LCA) methodology. Three EoL options for smartphones were compared: repurposing into a parking meter using battery power, repurposing into a parking meter using portable solar power, and traditional refurbishment. To account for the secondary functions (other than waste management) provided by each option, we used system expansion with avoided burden and modeled displacement of two primary production devices: a purpose-built personal parking meter (displaced by the ePark) and a primary production smartphone (displaced by the refurbished smartphone).

This paper is organized as follows: Section 2 describes the goal and scope and inventory models for the LCA. Section 3 presents LCA impact results, contribution analysis, and sensitivity analysis. In Section 4 we draw conclusions from the results and discuss general findings and limitations of the study. Additional supporting information is occasionally referenced, which can be found in the accompanying Electronic Supplementary Material (ESM).

2 Methods

2.1 Goal, scope, and system boundary

The goal of the study was to compare three reuse options for EoL smartphones: traditional refurbishment, repurposing using battery power, and repurposing using portable solar power. To evaluate these options, we conducted a case study in which we wrote software for the HTC Magic and Nokia N80 smartphones to function as a purpose-built personal in-car parking meter, with functionality identical to the “Comet,” in regular use at the University of California, Davis (Fig. 1a) (we focus here on the HTC Magic, but in the ESM we briefly compare the results using the Nokia N80). For simplicity, we named the repurposed smartphone “ePark.” Technical details on programming effort and economic feasibility of creating the ePark are provided in a separate forthcoming article.

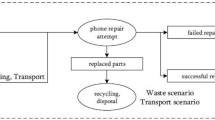

The scope of the study is defined by the system boundary depicted in Fig. 2. System boundaries were drawn to facilitate consistent and functionally equivalent comparisons between the three reuse options, not to capture every detail of each system. Where modeling simplifications were made, they were applied in a consistent manner across all product systems. Where real differences between the product systems exist, they were modeled as accurately as possible. Some processes that are identical across all three alternatives (most notably initial phone production and use) were excluded, in accordance with standard waste management LCA methodology (Finnveden 1999).

2.2 Functional unit and system expansion

The methodology for using LCA to measure the impacts of waste management strategies is well established (Clift et al. 2000; Finnveden 1999) and numerous examples exist for a variety of products (c.f., Cherubini et al. 2009; Fisher et al. 2006; Schmidt et al. 2007). The functional unit used in waste management LCAs is typically the management of a specified type and quantity of waste (Clift et al. 2000).

In our study, the functional unit is defined as the end-of-life management of a used smartphone. We study three types of reuse that provide this function: Refurbishment, repurposing with battery power, and repurposing with solar power. The secondary products of each reuse option are accounted for using consequential system expansion (Guinée et al. 2002), which includes the production and product use processes that are avoided by these secondary products. The system boundary thus contains EoL product reprocessing, use of secondary products generated by each reuse option, displaced production of primary products, and displaced use of these products (see Table 1).

A common simplification in comparative LCAs is to omit processes that are identical across alternatives; thus, in waste management LCAs the upstream processes that create the waste to be managed are typically excluded from the analysis (Clift et al. 2000; Finnveden 1999). In the current study, the primary production and use of the smartphone in its first life cycle is identical across all compared reuse options and is thus omitted. Waste management LCAs also frequently assume that the use phases of secondary and displaced products are identical and therefore exclude them. In the presented study, however, the use phases of secondary and displaced products are not identical and therefore have to be modeled explicitly. For example, the use phase of the repurposed smartphone involves power from a rechargeable battery or solar panel, whereas the use phase of the displaced primary parking meter is powered with disposable batteries.

A use time of 2 years was assumed for refurbished smartphones and displaced primary cell phones based on previous mobile phone LCAs and the fact that 2 years is the average replacement period for smartphones in developing countries (Entner 2011; Singhal 2005; Google 2012). A use time of 5 years was assumed for repurposed smartphones and the displaced primary parking meter based on the estimated technical lifetimes of smartphones and personal marking meters (Singhal 2005).

2.3 Displacement rate

Each waste management route produces secondary functions that need to be accounted for in the study. In accordance with consequential system expansion (Guinée et al. 2002), the system boundaries are expanded to include impacts from the secondary functions, as well as avoided impacts from displaced processes. Net life cycle impacts of each waste management option are equal to the incurred impacts minus any avoided impacts from displaced processes. It has been suggested in the literature that displacement of primary processes by secondary processes does not necessarily occur on a one-to-one basis (Ekvall 2000; Weidema 2000). We account for imperfect displacement through the concept of displacement rate, D, which is the amount of primary production and use prevented by the production and use of a unit of secondary product:

where ΔQ i is the change in quantity produced and used of product i. Therefore, net impacts for EoL product reprocessing, E netsec , can be expressed as the incurred impacts of reprocessing and secondary output use, E sec, minus the avoided impacts of primary production and output use, D ⋅ E prim:

where E prim and E sec are the impacts from producing and using a unit of primary and secondary product, respectively. E netsec is negative if avoided impacts are greater than incurred impacts, i.e., D ⋅ E prim > E secnet . The concept of displacement rate is particularly important in the case of refurbished smartphones displacing primary smartphones because there is considerable evidence in the literature that this displacement rate might be quite low. Geyer and Doctori Blass state, “Most US experts we interviewed believe that cannibalization rates [of primary cell phones by refurbished cell phones] are very low or even negligible. Combined with the assumption that first-time buyers of reused cell phones are likely to upgrade to new handsets when the reused ones are retired, reuse could even be regarded as stimulating future sales of new products” (Geyer and Doctori Blass 2009, p. 523). Skerlos et al. argue that “the majority of remanufactured handset users are first-time customers, originally not attracted to mobile telephony due to high costs of new handsets, but tending to change to new handsets later on,” and goes on to assert that it is “certain” that remanufacturing will not replace new phone manufacturing (Skerlos et al. 2003, p. 102). This view is supported by interviews with industry experts from handset manufacturers and refurbishers, who all estimate displacement of primary cell phones by refurbished phones between 0–5 %. Furthermore, it has been shown in the general case that if a new product model provides substantially greater service than an older model, demand for the older model has little effect on the demand for the new model (Thomas 2003).

On the other hand, an in-car parking meter provides a simple function, is not subject to fashion trends or consumer preferences, and is a purely utilitarian device. Therefore, if a consumer has a smartphone repurposed as a parking meter, there is no reason to purchase a newly manufactured parking meter. Using a repurposed phone as a parking meter is also not likely to spur future demand for in-car parking meters. Thus, it is reasonable to believe that each repurposed smartphone displaces a primary parking meter.

Partial displacement reduces the benefits of recycling or reuse; 100 % displacement means that each refurbished cell phone displaces the production of a new one, and the total market size is unchanged. However, if refurbished phones displace primary handsets at a rate of, say, 5 %, then only 1 out of 20 customers bought a refurbished handset instead of a new one; the other 19 increased the size of the cell phone market. We will return to this concept when discussing results in Section 3.

2.4 Inventory modeling

2.4.1 Refurbishing

Refurbishing is one of the three reuse routes for smartphones investigated in this manuscript. In this route, smartphones are collected and refurbished before being sold primarily in developing markets in Latin America, Africa, Asia, and Eastern Europe (Geyer and Doctori Blass 2009). Reverse logistics from first user to refurbisher are detailed in several sources (Geyer and Doctori Blass 2009; MPPI 2006; Silveira and Chang 2010). The ESM contains further detail on the reverse logistics and distribution model used in this study. In a typical refurbishing process, all collected handsets are sorted and tested and reconditioned as necessary, consuming on average 0.12 MJ of electricity per refurbished handset (Skerlos et al. 2003). All original batteries are recycled and replaced with new batteries shipped from China to the USA (see ESM for details). Aside from batteries, no data on average material requirements for refurbished phones (replacement parts, etc.) were available. A process inventory for lithium ion battery recycling, including avoided burden from metal and plastics recovery, was derived by customizing the inventory model of Fisher et al. (2006) (see ESM for details). This process inventory is used for all battery recycling processes in the study. A life cycle inventory for handset battery production was obtained by adding the inventory model of Notter et al. (2010) for lithium manganese oxide (LiMn2O4) rechargeable single cells with our own inventory model for the battery management system (see ESM for details). Distribution of refurbished smartphones from the refurbishing facility to the second user is discussed in the ESM.

Use-phase impacts of refurbished smartphones arise from battery charging during the 2-year use period. A recent study on users of Android HTC smartphones reported an average battery drain of 54 mA (Falaki et al. 2010). While Falaki et al. (2010) likely surveyed users in high-income countries and most refurbished smartphones are currently used in middle income countries, consumer surveys demonstrate similar smartphone usage patterns in both areas despite economic disparities (Google 2012; Ericsson 2011). At 54 mA, the 1,340 mAh HTC Magic battery will last 24.81 h. In order to achieve 2 years, i.e. 17,520 h, of use, the battery requires 706 full charge cycles. It is assumed that the replacement battery lasts through the entire 2 years (Choi and Lim 2002). The total energy required to charge the battery was calculated as:

where 3,600 is the number of seconds in an hour (to convert power to energy), 3.7 is the voltage of the HTC charger, and 1.1 accounts for a 10 % charging loss (Rydh and Sandén 2005). The Ecoinvent 2.2 Chinese low-voltage grid mix was used to model use-phase electricity consumption, since China is a major destination for refurbished handsets.

At the end of its life, the refurbished phone (handset and battery) is assumed to be landfilled in the country it was used in. Due to lack of more suitable process inventories, PE International processes for landfill of plastic and aluminum in Europe are used throughout the study as conservative proxies for e-waste in landfill (PE International 2012). While sending e-waste to landfill is a concern and banned in many places, studies suggest limited leaching of hazardous substances from cell phones (HML 2004; Lincoln et al. 2007). However, in the case of refurbished phone disposal, EoL impacts are significantly underestimated, since we use inventory data for modern sanitized landfills whereas most landfills in developing countries are simple unlined open pits (Osibanjo and Nnorom 2008).

2.4.2 Repurposing

The other two reuse options investigated in this study use the EoL handset to run the parking meter app, ePark. It is assumed that the cell phone owner downloads and installs the app, which means that no reverse logistics and distribution steps are involved. The owner also recycles the original battery, which is modeled identically as in refurbishing. During the use phase of ePark, power is delivered either by a new replacement battery or a new solar charger. The new battery and solar charger are both shipped from China to the USA (see ESM). The Battery ePark option uses the same battery production inventory model as the refurbishing option. Production of the solar charger for the Solar ePark option was custom-modeled by disassembling a PowerMonkey Explorer (see Fig. 1b) to compile a list of components and using the PE electronics database (PE International 2010). Because information on the exact manufacturing process was not available, industry-average data for small volume printed circuit board (PCB) fabrication were used. The solar charger contains a small battery, which is modeled using the inventory data of a lithium ion single cell without a battery management system.

The use phase for either ePark option assumes 11,000 use-hours. This is based on 5 years of use with 275 use-days per year (average working days +10 %) and 8 use-hours per day (see Table 1). For the Battery ePark, power consumption was measured to determine total energy required during the use period. While running the parking meter app, the Android HTC Magic consumed 160 mW of power. Therefore, the total energy consumed to charge the battery over the 5-year use period was calculated as:

accounting for unit conversions and charging loss as above.

The Ecoinvent 2.2 US average low-voltage grid mix was used to model use-phase electricity consumption (Ecoinvent Centre 2012). The Solar ePark has no use-phase impacts. Once the Battery ePark reaches the end of its life, the handset is landfilled and the replacement battery is recycled. In the case of the Solar ePark, the handset and the solar charger are landfilled, while the battery in the solar charger is recycled. Recycling and landfill processes are modeled identically as in the case of refurbishing.

2.4.3 Displaced cell phone production and use

An LCA of primary cell phone production was beyond the scope of this study. However, in 2005 Nokia commissioned an LCA of a typical cell phone and published environmental impact results in five categories (acidification, global warming, human toxicity, ozone depletion, and photochemical ozone creation) across three life cycle stages (manufacturing, transportation, and use) (Singhal 2005). The current study uses the manufacturing and transportation impacts from Singhal (2005) as proxy for cell phone production and distribution. It should be noted that Singhal (2005) studied a third-generation phone similar to a Nokia 3310, which is not a smartphone. Environmental impacts for smartphones are typically higher than those of traditional cell phones and arise from different materials and processes (Santavaara and Paronen 2013). Nokia has conducted subsequent studies on smartphones, but has only published greenhouse gas emission data, which prohibits their use in the present study. We can, however, compare greenhouse gas emissions from the traditional cell phone to those of current Nokia model smartphones as a first-order approximation of how impacts in other categories may differ and how those differences impact the results of this study. We will discuss the implications of this difference further in Section 3.1.

The inventory models for displaced primary phone use and landfill are identical with those used for refurbished phones since the displaced new phone would be used in the same way and the same geographic location. Displaced production and use impacts of the primary phone are subtracted from incurred impacts of EoL phone collection, refurbishing, and distribution, and refurbished handset use and disposal.

2.4.4 Displaced parking meter production and use

The primary production parking meter used for the study was the Comet, developed by Ganis Systems, Ltd. A process flow for Comet manufacturing is included in the ESM. A list of specific components in the Comet was obtained by disassembly. As with the solar charger, this list was used to create a specific process-based cradle-to-gate manufacturing model. According to the product specifications, the Comet will operate for 280 h on one non-rechargeable lithium ion button battery. Therefore, for 11,000 h (same use phase as ePark) 40 single-use 4.6 g lithium ion button batteries are required. The inventory model for the button batteries is the same as the one for the battery in the solar charger. Use-phase impacts from the Comet are different than those of the ePark due to the different power delivery systems (rechargeable battery/solar vs. disposable batteries). Displaced production and use impacts of the Comet are subtracted from incurred impacts of EoL phone repurposing, and ePark use and disposal.

2.5 Impact indicators

Environmental impacts were assessed in five categories: Acidification potential (AP), global warming potential (GWP), human toxicity potential (HTP), atmospheric ozone depletion potential (ODP), and photochemical ozone (smog) creation potential (POCP). All impacts were calculated using mid-point indicators from the November 2010 version of the CML 2001 characterization model (Guinée et al. 2002). While these five categories and the CML 2001 characterization model are used frequently in LCA literature, it would have been useful to look at a broader range of impact categories and indicator suites. However, this study is limited to these five indicators because they are the only ones reported in Nokia’s primary cell phone LCA (Singhal 2005).

3 Results

Impact assessment results for each reuse option in each impact category are presented in Table 2. As discussed, each reuse option has the potential to displace a primary product. Refurbishing displaces a certain amount of primary cell phone production; ePark displaces primary parking meter production. The incurred impacts for each reuse option are shown in Table 2 as positive numbers, whereas the avoided impacts of the corresponding displaced primary production and use are shown below as negative numbers. The net impacts of each reuse option are calculated by subtracting the avoided impacts from the incurred impacts, as shown in Eq. 2. The displacement rate used for each displaced product is shown in the second column of the table and total primary phone impacts are included for reference in the penultimate row. Primary parking meter production is modeled with full displacement by ePark; based on the discussion in Section 2.3, primary phone displacement of 5 % was used to calculate net impacts.Footnote 1

Examining the gross and net impacts in Table 2, the model produces a clear preference order between the three reuse options. Refurbishing has higher impacts in all categories except ozone depletion. The ODP impact of primary phone production reported in the Nokia study is an order of magnitude higher than the ODP impacts of any other production process in our study. This suggests that the ODP results should be interpreted with great caution. In all other categories, refurbishing has net impacts greater than zero, indicating that it creates additional environmental impacts due to substantially increasing the total size of the cell phone market.

According to the model, the environmentally preferred option would be to repurpose a used smartphone. Given the use-phase parameters in the baseline model, the battery ePark has lower potential impacts than the solar ePark across all five categories despite requiring new battery production. The Battery ePark is the only reuse option with net environmental benefits across all five impact categories. It is important to remember that these findings are subject to uncertainty introduced by the various model assumptions, the most important of which are the displacement rates.

3.1 Displacement break-even analysis

While it seems quite plausible that repurposing a smartphone as a parking meter would simply be a substitute for a primary parking meter and thus avoid its production, the question of primary phone displacement is much more complex, since it involves market segmentation and growth. This creates large uncertainty in assessing the net environmental benefits of cell phone refurbishing. In fact, different levels of displacement can reverse the preference ordering of the reuse options. For instance, if 100 % primary cell phone displacement is assumed, refurbishing results in the lowest AP, GWP, ODP and POCP impacts. However, with 5 % displacement, refurbishing has the highest impacts in all categories except ODP.

The estimation of actual displacement rates is very difficult and outside the scope of this study. However, it is useful to calculate the “break-even” displacement rate for comparison. The break-even displacement rate (D B. E.) is defined as the percentage of primary phone production and use displaced at which refurbishing results in impacts equal to the Battery ePark (the reuse option with the highest net benefits). The break-even displacement rate for each category can be calculated by dividing the difference between the refurbished phone impacts and the Battery ePark net impacts by primary phone impacts:

The last row of Table 2 displays the break-even displacement for each impact category. This number represents the minimum primary cell phone displacement rate needed for refurbishing to have equal benefits as repurposing. For instance, if primary cell phone displacement was 59.47 %, GWP benefits from refurbishing and Battery ePark would be equal. A break-even displacement rate greater than 100 % indicates that refurbishment is never preferred in that category even with one-to-one primary phone displacement. Low break-even displacement rates, such as in the ODP category, indicate that very little displacement is needed in order for refurbishing to be preferred. This analysis allows for a clearer understanding of the role of primary phone displacement without knowing the true displacement rate.

As mentioned, the primary phone impacts presented here are drawn from a previous LCA of an older Nokia phone (Singhal 2005), and likely underestimate the impacts of newer smartphones. One way to see how this difference may affect the results is to substitute the global warming manufacturing phase impacts of the newer Nokia Lumia 820 (Nokia 2012) and recalculate the break-even displacement rate in the global warming category. Using 10.4 kg CO2-eq. in place of the older model’s 7.8 kg CO2-eq., the break-even displacement rate becomes 50.96 %, as compared to 59.47 %. Even using an upper-end global warming figure from an Apple iPhone 4s of 36 kg CO2-eq. (Apple 2013), the break-even displacement rate is 21 %—still four times higher than industry experts estimate.

3.2 Impact contribution analysis

Figure 3 displays the contribution analysis results, where the impacts of each product and impact category are broken into life cycle stages. The contribution analysis reveals several interesting results. Both refurbished phone and Battery ePark impacts are dominated by use-phase electricity. Comparison of refurbished phone GWP impacts to Battery ePark GWP impacts shows the difference between Chinese and US electricity: after adjusting for the difference in use period, the Chinese energy mix emits over two times more CO2-eq emissions per MJ than the US energy mix.

Comparing the two ePark options, Solar ePark has no use-phase impacts, but incurs transportation AP and GWP impacts and has much larger manufacturing impacts across all categories. A contribution analysis of manufacturing process impacts is discussed in the ESM. Battery ePark benefits from requiring very little long-distance shipping and charging energy. Since battery production creates lower impacts than solar charger production, the Battery ePark outperforms its solar counterpart in all five categories.

The majority of impacts of both primary products (primary cell phone and primary parking meter) occur during manufacturing, attributable to raw material extraction. Note, however, the primary parking meter’s 40 lithium button batteries are grouped in the manufacturing phase, not in the use phase. Primary parking meter manufacturing impacts are broken down further in the ESM.

Landfill impacts are very small across all products and impact categories; in no instance did they contribute more than 1 % of total lifecycle impacts. However, as stated in Section 2.4.1, the end-of-life model was necessarily simplified, and actual impacts are likely to be higher.

3.3 Standby power consumption

The Battery ePark and refurbished smartphone require battery charging, but additional power is also consumed by the plugged-in battery charger itself—with or without the phone connected—called “standby power.” An estimated 5–13 % of all power worldwide is consumed solely by standby power (Lebot et al. 2000). Consequently, the USA and European Union have both passed regulations to limit the permitted standby power consumption for consumer electronics to 0.5 W (U.S. Congress 2007; European Union 2008). Due to regulations, charger standby power has decreased over time (Singhal 2005), but still remains significant.

Our initial results showed that standby power was a critical driver of overall environmental impacts. The amount of standby power consumed depends on user charging behavior. If the user conscientiously unplugs the charger when not charging the battery, or if the user has too few plugs to allow leaving the charger plugged-in (as may be the case for refurbished phone users), standby power will be near zero. If the user leaves the charger plugged-in at all times, the standby power will be significant. To better understand variations in the consumption between chargers we conducted measurements of nine different chargers manufactured from 2006 to 2011 (available in the ESM). The HTC Magic charger recorded a standby consumption of 0.34 W. Therefore, the total energy consumed by the charger alone over the 2-year use period (in the case of the refurbished phone) can be calculated by multiplying its power consumption by the number of seconds in the use period:

From this calculation, the importance of standby power becomes clear: In the case of refurbishing, over 1.5 times as much energy is used by the idle charger than is used to actually charge the battery. In the case of the ePark Battery, the figure is 53.61 MJ (over the 5-year use period), representing over 7.5 times more energy compared to charging energy alone.

Rather than complicate the presentation of impact results with this uncertain variable, we conducted sensitivity analysis to determine the impacts of different charging scenarios. The additional global warming impacts from standby power are shown in Table 3 for 0, 50, and 100 % charger plug-in scenarios. The results show that standby power is a significant factor, and assumptions made about user behavior can reverse the overall impact results. For instance, if the Battery ePark charger is left plugged-in more than 20 % of the 5-year use period, Solar ePark has lower GWP impacts.

4 Conclusions

In summary, our LCA model suggests that repurposing represents a preferable EoL management option to refurbishing for used smartphones. While modeling simplifications were necessary, the results are very robust to assumptions about primary phone displacement, as evidenced by break-even displacement rates in four of the five impact categories well above what is expected to actually occur. Battery power was found to be preferable to solar power for the repurposed phone, but this finding is sensitive to assumptions about charger standby power consumption.

Two areas require more attention to improve future assessments of electronics reuse. The first is the environmental impacts of e-waste in the developing world and in landfills. Data limitations necessitated EoL modeling that does not reflect actual conditions in the developing world. However, these limitations do not affect the general direction of the results: Better EoL inventory models would increase the net impacts of refurbishing. The second area is inventory data for handheld electronics battery production. Due to lack of data, we were forced to use production data for a different lithium battery chemistry. Given the environmental importance of handheld electronics, further work is needed to develop detailed inventory data for LiCoO2 battery production. Nonetheless, we believe the presented results are robust.

The results of the study point to two generalizable findings:

First, that displacement of primary products is a key factor affecting whether any EoL management strategy is environmentally beneficial. The potential for benefit depends not only on what is displaced but, more importantly, how much displacement occurs. This concept is illustrated by handset refurbishing: even though a refurbished phone potentially displaces a complex and environmentally harmful device, the fact that the displacement rate is likely to be low leads refurbishing to create additional environmental impacts rather than net benefits. By contrast, the ePark displaces a relatively simple device, but is likely to create full displacement which would ensure net environmental improvement.

This concept challenges standard notions about waste management. Typically, the best EoL option is seen as the one that maximizes the reuse potential of a product or material, or that competes with the primary product with the highest environmental impact. Under this philosophy, a piece of used electronic equipment should be refurbished to its highest technical functionality. With this new insight about displacement, however, the best management option would not maximize the used device’s technical potential, but maximize what we call “displacement potential”—referring to the product between the environmental profile of the competing primary product and the quantity displaced. Thus, the difference between refurbishing and repurposing in general is revealed: Refurbishing a device merely returns the functionality of the original device; by contrast, repurposing allows the possibility to change the functionality. This freedom allows one to seek out opportunities for high displacement potential—typically utilitarian devices that have little fashion or aesthetic value. While it may seem inefficient to use a high-powered smartphone as a simple camera, a music player, or a glorified stopwatch, if these reuses displace primary production more efficiently, they could be the preferred EoL management options.

The second general finding is that the common notion that solar power is preferable to rechargeable batteries is not always correct. In the case presented, solar power resulted in higher impacts than rechargeable battery power. The fact that battery power is preferred over solar power may at first seem counter-intuitive, but it makes sense considering the trade-off between a primary parking meter and a Solar ePark. On one hand, parking meter services could be delivered by a primary parking meter, a relatively simple electronic device. On the other, the Solar ePark requires a relatively complex solar charger. Using the Solar ePark essentially trades a simple device for a complex one.

However, this result is contingent on two assumptions: First, that the portable solar charger is only used to power the ePark and is landfilled after use, and second, that the battery charger is unplugged when not in use. Both assumptions are debatable. If the solar charger was used to charge two different devices, or if it was used for an additional 5 years with, say, another ePark, it would be allocated only half of the impacts presented here, which would make it more attractive than battery power. Alternatively, if the battery charger is assumed to be left plugged-in more than 20 % of the time, the standby power impacts outweigh the solar charger impacts. This finding arises from the fact that solar chargers and batteries have different impact profiles: Rechargeable batteries have lower production impacts but significant use-phase impacts, whereas solar chargers have higher production impacts but no use-phase impacts. The general lesson is that assessments of portable solar vs. rechargeable battery power hinge largely on assumptions about consumer use behavior—if long use-phase periods, multiple uses, or unconscientious charger usage are assumed, solar power is likely to have lower impacts than battery power. Reliable behavioral models are therefore needed to make accurate comparisons of the two systems.

One important outcome of this case study was an understanding of the obstacles to successful repurposing and how to incorporate repurposing into the design of electronics in order to overcome them. These considerations are the subject of another forthcoming manuscript that focuses on the technical aspects of the case study.

Notes

Because the relationship is linear, the interested reader can use the total primary phone impacts shown in the penultimate row of Table 2 with any displacement rate to calculate net impact.

References

ABI Research (2009) “Green Mobile Devices.” http://www.abiresearch.com/research/1004179

Apple (2013) “iPhone 4s Environmental Report.” http://images.apple.com/environment/reports/docs/iPhone4s_product_environmental_report_sept2013.pdf

Canalys (2012) “Smart Phones Overtake Client PCs in 2011.” Canalys.com. http://www.canalys.com/newsroom/smart-phones-overtake-client-pcs-2011

Cherubini F, Bargigli F, Ulgiati S (2009) Life cycle assessment (LCA) of waste management strategies: landfilling, sorting plant and incineration. Energy 34(12):2116–2123

Choi SS, Lim HS (2002) Factors that affect cycle-life and possible degradation mechanisms of a Li-ion cell based on LiCoO 2. J Power Sources 111:130–136

Clift R, Doig A, Finnveden G (2000) The application of life cycle assessment to integrated solid waste management: Part 1—Methodology. Process Saf Environ Prot 78(49):279–287

Ecoinvent Centre (2012) Ecoinvent Database V2.2”. Ecoinvent Centre, Dubendorf

Ekvall T (2000) A market-based approach to allocation at open-loop recycling. Resour Conserv Recycl 29(1–2):91–109

Entner R (2011) International comparisons: the handset replacement cycle

Ericsson (2011) Traffic and market data report: on the pulse of the networked society

European Union (2008) Directive 2005/32/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Standby and Off Mode Electric Power Consumption of Electrical and Electronic Household and Office Equipment

Falaki H, Mahajan R, Kandula S, Lymberopoulos D, Govindan R, Estrin D (2010) Diversity in smartphone usage. Proceedings of the 8th International Conference on Mobile Systems, Applications, and Services - MobiSys ’10: 179. doi:10.1145/1814433.1814453. http://portal.acm.org/citation.cfm?doid=1814433.1814453

Finnveden G (1999) Methodological aspects of life cycle assessment of integrated solid waste management systems. Resour Conserv Recycl 26:173–187

Fisher K, Wallen E, Paul Laenen P, Collins M (2006) Battery waste management life cycle assessment

Geyer R, Doctori Blass V (2009) The economics of cell phone reuse and recycling. Int J Adv Manuf Technol 47(5–8):515–525

Google (2012) Our Mobile Planet. August. http://www.thinkwithgoogle.com/mobileplanet/en/

Guinée JB, Gorree M, Heijungs R, Huppes G, Kleijn R, de Koning A, van Oers L et al (2002) Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. Kluwer, Dordrecht

HML (2004) E-waste Report: determination of regulated elements in seven types of discarded consumer electronic products. Hazardous Material Laboratory (HML), Cal EPA, Sacramento

Huisman J (2004) QWERTY AND Eco-efficiency analysis on cellular phone treatment in Sweden, TU Delft, The Netherlands, commissioned by El-Kretsen, Stockholm, Sweden

IDC (2012) IDC worldwide quarterly mobile phone tracker

Lebot B, Meier A, Anglade A (2000) Global implications of standby power use. In: The Proceedings of ACEEE Summer Study on Energy Efficiency in Buildings. Asilomar, CA

Lincoln JD, Ogunseitan OA, Shapiro AA, Saphores J-D M (2007) Leaching assessments of hazardous materials in cellular phones. Environ Sci Technol 41(7):2572–2578

Lindholm ME (2003) Toward Environmentally Conscious Product Design 1—a Comprehensive DfE Implementation in New Generation Cellular Phones, Proceeding of the ISEE 2003, 19-22 May 2003, Boston, MA

MPPI (2006) Guideline on material recovery and recycling of end-of-life mobile phones. Geneva, Switzerland

Nokia (2012) Nokia Lumia 820 Eco Profile.” http://nds1.nokia.com/eco_declaration/files/eco_declaration_phones/Lumia_820_Eco_profile.pdf

Notter DA, Gauch M, Widmer R, Wäger P, Stamp A, Zah R, Althaus H-J (2010) Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environ Sci Technol 44(17):6550–6556

Oiva L, Oppermann W, Middendorf A, Zuber K-H, Stobbe I (2000) Case study on the environmental impacts of a mobile phone, Proceedings of EGG 2000, 11-13 September 2000, Berlin, Germany

Osibanjo O, Nnorom IC (2008) Material flows of mobile phones and accessories in Nigeria: environmental implications and sound end-of-life management options. Environ Impact Assess 28(2–3):198–213

PE International (2010) GaBi Electronics Database. Leinfelden-Echterdingen, Germany

PE International (2012) GaBi Professional Database. Leinfelden-Echterdingen, Germany

Rydh CJ, Sandén BA (2005) Energy analysis of batteries in photovoltaic systems. Part I: performance and energy requirements. Energy Convers Manag 46(11–12):1957–1979

Santavaara I, Paronen N (2013) Nokia’s product life cycle assessment over the years, including challenges and key findings.” In The 6th International Conference on Life Cycle Management, 4–7. Gothenburg

Schmidt JH, Holm P, Merrild A, Christensen P (2007) Life cycle assessment of the waste hierarchy—a Danish case study on waste paper. Waste Manag 27(11):1519–1530

Silveira GTR, Chang SY (2010) Cell phone recycling experiences in the United States and potential recycling options in Brazil. Waste Manag 30(11):2278–2291

Singhal P (2005) Integrated product policy pilot project—stage I Final Report: Life Cycle Environmental Issues of Mobile Phones. Espoo, Finland

Skerlos SJ, Morrow WR, Chan KY, Zhao F, Hula A, Seliger G, Basdere B, Prasitnarit A (2003) Economic and Environmental Characteristics of Global Cellular Telephone Remanufacturing. In: IEEE International Symposium on Electronics and the Environment, 2003, 99–104. IEEE. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=1208055

Thomas VM (2003) Demand and dematerialization impacts of second-hand markets: reuse or more use? J Ind Ecol 7(2):65–78

U.S. Congress (2007) Energy Independence and Security Act of 2007

Weidema B (2000) Avoiding co-product allocation in life-cycle assessment. J Ind Ecol 4(3):11–33

Acknowledgments

We would like to thank Péter Boda from the Nokia Research Center in Palo Alto, CA for their support of this work. Additionally, we would like to thank Linda Gaines at Argonne National Laboratories for her insights on battery production, and Lee Hefernan at PowerTraveller for providing detailed logistics information.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Stig Irving Olsen

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 798 kb)

Rights and permissions

About this article

Cite this article

Zink, T., Maker, F., Geyer, R. et al. Comparative life cycle assessment of smartphone reuse: repurposing vs. refurbishment. Int J Life Cycle Assess 19, 1099–1109 (2014). https://doi.org/10.1007/s11367-014-0720-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-014-0720-7