Abstract

Purpose

With the tremendous growth in the worldwide electronic information and telecommunication industries, there continues to be an increasing awareness of the environmental impacts related to the accelerating mass production, electricity use, and waste management of electrical and electronic products (e-products). Although Macau is a small region with a total land area of about 29.5 km2 and a population of 557,000 in 2011, there are two personal computers (PCs) for every household in Macau.

Methods

This paper aims to describe the application of life cycle assessment (LCA) to investigate the environmental performance of PCs in Macau. An assessment of the PC (focusing on the desktop PC) was carried out using a detailed modular LCA based on the international standards of the ISO 14040 series. The LCA was constructed using SimaPro software version 7.2 and expressed with both the Eco-indicator'99 method and the Centrum voor Milieuwetenschappen method. Life cycle inventory information was compiled by Ecoinvent 2.2 databases, combined with literature and field investigations of the actual situations.

Results and discussion

The established LCA study showed that the manufacturing and the use of such devices are of the highest environmental importance. In the manufacturing stage, the desktop contributes the most to the total environmental impacts (44.89 Pt), followed by the LCD screens (about 27.53 Pt), while the CRT screen, keyboard, and mouse are of minor importance. During the use phase, the environmental impact is due entirely to the consumption of electricity generated by coal, oil, natural gas, and hydropower. The electricity generated by coal is by far the most important, accounting for about 66 % of the total environmental impact, followed by oil and gas. Within the EoL treatment phase, using incineration, there will be little environmental impact. When adopting recycling technology in the EoL phase, apparent environmental benefits will be generated due mainly to avoiding emissions to water (arsenic ions and cadmium ions) and to air (SO2) in the primary production phase. For the competing technologies of CRT and LCD screens, the environmental impacts are different in different phases, but the total impacts over their entire life cycle are similar.

Conclusions

Results from a life cycle assessment can be used to compare the relative environmental impacts of competing technologies; it can also help designers and managers to focus efforts toward making environmental improvements to a particular technology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The demand for personal computers (PCs) is growing fast, driven by increasing prosperity and rapid technological change, and Macau is no exception. Macau society has experienced significant changes in the past decade. Rapid economic development has fostered the increased consumption of electronic products, especially PCs. The use of electrical and electronic products has become commonplace in households, as well as in government, institutions, organizations, and the business sector. In 2010, the total net import of PCs was about 94,447 units (in an area of only 29.5 km2 with a population of about 557,000). As shown in Table 1, the number of the desktop PCs and laptops was 154 units and 56 units per 100 households in Macau, respectively (Song et al. 2012b). This high usage of e-products, combined with the products’ decreasing lifetimes, has resulted in the generation of a large amount of e-waste in Macau. This generation was estimated at about 16 kg per capita in 2010, which is close to the average generation amount (16–18 kg per capita) in EU countries (UNU 2008), and it is estimated to continue to increase by 3 % a year (Song et al. 2012b).

While this increasing production and use has produced significant economic benefits and convenience at both the national and community levels, it has also placed increasing pressure on the local and global environments (Puckett et al. 2002; Widmer et al. 2005; Wong et al. 2007).

Throughout its life cycle, the PC generates many environmental impacts. The production of PCs is complex, utilizing many different substances, including both hazardous materials and precious metals. The use phase of a PC consumes considerable amounts of electricity. And, finally, the disposal of electronics [i.e., End-of-Life (EoL) treatment] can produce severe impacts on human health and on the ecosystem when they are not well managed. The more complex components of a PC—printed wiring boards (PWBs), for example—contain a large variety of substances, including precious metals such as gold, as well as hazardous materials such as lead (Morf et al. 2007; Robinson 2009). Other PC ingredients include brominated flame retardants, tin–lead soldering on the PCB, polychlorinated biphenyl in the transformer, and mercury in the switch (Qu et al. 2007; Deng et al. 2007; Liu et al. 2008). Human exposure to such chemical substances may increase the risk of developing cancer and can even be a direct cause of death (Tekwawa et al. 1997). Lead, and very high levels of PBDEs, PCDDs, PCDFs, PBDDs, and PBDFs, have been found in air, bottom ash, dust, soil, water, and sediments in the e-waste recycling areas of developing countries such as China and India (Sepúlveda et al. 2010; Fang et al. 2005; Li et al. 2007; Leung et al. 2008).

Increased awareness of the importance of environmental protection and the possible impacts associated with products manufactured, distributed, consumed, and EoL-managed has increased interest in the development of methods to better understand and address these impacts. One of the techniques being developed for this purpose is life cycle assessment (LCA) (ISO 2000; Rivela et al. 2006; Asari et al. 2008; Bakri et al. 2010; Prasara and Grant 2011; ETSI TS 103 199 2011). An LCA study can be used to evaluate environmental burdens associated with a product, process, or service by identifying energy and materials used and emissions released into the environment; moreover, it can identify opportunities for improvement (Consoli et al. 1993; LG 1997; Andrae et al. 2008). LCA methodology is the internationally standardized method for identifying and assessing the environmental impacts related to electronic products, and is considered one of the most effective management tools (Hischier and Baudin 2010; Socolof et al. 2005; Wäger et al. 2011; Wittmaier et al. 2009; Saner et al. 2012). At present, many studies have applied the LCA methodology to the impacts of PC products (Duan et al. 2009; Socolof et al. 2005; Choi et al. 2006) or to other information and communication technologies (Scharnhorst et al. 2005, 2006; Hertwich and Roux 2011). In addition, some studies have done some comparison of different research results, focusing on the consistency of environmental impacts (Anders and Andersen 2010; Andrae 2011; Teehan and Kandlikar 2012). In contrast to studies that encompass the entire life cycle of e-products, some studies focus on the end-of-life phase of e-products only (Wäger et al. 2011; Huisman 2003). The broad perspective of LCA, however, makes it possible to study all types of electrical and electronic equipment, throughout their life cycles, and also to take into account the significant environmental benefits of the electronic products.

For this study, a desktop PC system was chosen, as it is a very complex electronic device; and its results will allow general conclusions, applicable to the entire e-product industry, thereby providing some valuable information for the management of e-products and e-waste in Macau.

2 Materials and methods

2.1 Goals and scope

2.1.1 Objectives of the study

The environmental performance of the desktop PCs used in Macau was calculated by conducting an LCA study based on the international standards of the ISO 14040 series (ISO 2000; Rebitzer et al. 2004; Pennington et al. 2004). The product system analyzed in this study was a standard desktop PC that included a processing unit and a graphical user interface device (CRT or LCD monitor). The objective of this case study was to establish a scientific baseline that evaluates the key environmental impacts related to desktop PCs. Besides this detailed view on the environmental impacts of a desktop PC device, a second goal of the study was to do an initial comparison of the two competing graphical interface technologies on the market (i.e., CRT and LCD). The desktop PC was chosen because it is one of the most prevalent electronic devices in Macau, as mentioned above, and because the results of this study can lead to general observations that can be valuable for the entire e-product industry.

2.1.2 System boundaries

The scope of the present study was thus a traditional LCA from cradle to grave, i.e., from the extraction of the various resources used in the production of such a desktop PC device to the final dismantling and recycling or disposal activities at the end of the life of such a device. This scope is shown graphically in Fig. 1. Here, the production phase was completed in other regions and countries (primarily mainland China, Hong Kong, and the USA). For the distribution phase, ground and air transportation through other regions and countries were excluded from this study, and only ocean freight was considered (due to lack of the miles distances for ocean transportation, the linear distances between Macau and import regions were used in this study). In addition, the use phase was limited to Macau. When the desktop PCs reach their end-of-life phase, there are generally two treatment locations. The units from government agencies and private business enterprises end up mainly in municipal incineration in Macau, while other discarded PCs, especially those from household sources, are usually transported into mainland China (usually Guangdong Province) and end up in informal treatment facilities. For the informal recycling sectors, however, reliable quantitative data on e-waste flows treated under informal sectors in mainland China were not available; therefore, the environmental impacts were not considered in this study.

2.1.3 Functional unit

The functional unit for the study was one unit desktop PC system (Dell), mainly produced in the mainland China, Japan, and USA, used during 8 years, 6.8 h/day in Macau; and end in the Macau Incineration Plant. The desktop PC considered in this study consists of four different subunits: the desktop computer itself, the screen (CRT 17-inch or LCD-17 inch), the standard keyboard, and the mouse. In addition, according to a field survey in 2010, the number of LCD and CRT monitors was 119 units and 35 units per 100 households in the usage stage, respectively. Therefore, the examined PC system was assumed to comprise 23 % CRTs and 77 % LCD screens.

2.2 Life cycle inventory

As in many other cases, the achievement of adequate LCI data in our study turned out to be virtually impossible because of a complete lack of willingness on the part of the companies producing this type of desktop PC device to divulge information on their product components and processes. Therefore, an “inverse approach” was used, utilizing a desktop PC device at the end of its life to identify these components and processes by dismantling the device. Where necessary, more detailed identification can be obtained by chemical analysis. In this way, a detailed composition of the desktop PC device was established, and its composition is summarized in Table 2.

In addition to determining the composition of the desktop PC, a complete environmental assessment of the manufacturing phase still required collecting data on the extraction and processing of materials (i.e., upstream processes), the production of the electronic components, and final assembly processes. For this purpose, the database Ecoinvent data v2.2 was used. This database contains international industrial life cycle inventory data on energy supply, resource extraction, materials supply, chemicals, metals, agriculture, waste management services, and transportation services, which can provide the most relevant, reliable, transparent, and accessible LCI data for users all over the world.

For the use pattern, it was assumed that a typical unit would be active 4.2 h per day and in either standby or sleep mode for 2.6 h per day, over a period of 4 years, before the complete system was handed over for EoL treatment. In addition, based on the field survey in 2010, the number of PCs in use at homes and offices were about 379.1 and 138.2 thousand units (including the laptop PCs), respectively. It was assumed that about 73 % of these were in home use and 27 % in office use, in Macau. For the use phase, the major environmental impact came from electricity consumption. According to the Statistics and Census Service Macao SAR Government (DSEC), the electricity in Macau comes from two sources—imported from mainland China (primary) and the power plant in Macau (Table 3). The primary resource for electricity generation in both Macau and China is coal, accounting for about 53 % of the electricity consumption in Macau.

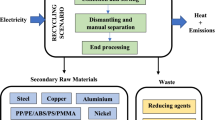

The total lifespan assumed in this study was 4 years, including the EoL treatment phase. In Macau, there are no specific e-waste recycling facilities (Song et al. 2012b). Because of Macau’s small geographic area and consequent high cost of land, solid waste incineration has been given a top priority over other waste disposal methods in Macau. According to the survey, some e-waste is mixed with household waste and, along with e-waste from the government sectors, is treated in the Macau Incineration Plant (MIP), which is equipped with pollution control systems, electricity generation, and scrap metal recovery facilities. The data on MIP was collected by a field survey. At present, the Macau government is carrying out a trial project on e-waste treatment, based primarily on Chinese manual dismantling technology (Song et al. 2012a). Therefore, we compared, by life cycle assessment, incineration and the trial project whose data was obtained from the field survey. The recycling technology used in the trial project is shown in Fig. 2, although because there were some restrictions in the trial project, some flow directions in Fig. 2 refer to the treatment method in mainland China.

Table 4 summarizes the key characteristics and assumptions used in this LCA study for the various components, materials, and processing steps of the examined desktop PC device.

2.3 Life cycle impact assessment (LCIA)

For the impact assessment, the two well-known Dutch LCIA methods were used: the Eco-indicator'99 and the so-called Centrum voor Milieuwetenschappen (CML) methodology (Guinee et al. 2001). The Eco-indicator'99 (end-point) and CML (mid-point) methods are complementary. The results of one method can be tested and verified by the other method, and at the same time, the sensitivity analysis of life cycle assessment can be completed through the two methods.

3 Results and discussion

3.1 Environmental impacts of the complete life cycle of a PC

The results of the impact assessment of the complete life cycle of a desktop PC device, as shown in Fig. 3, were that manufacturing (including raw material extraction and processing, components production, and PC assembly) and use generate significantly more impacts than the two other life stages. Despite the fact that desktop PCs are imported from mainland China, the USA, and other Asian countries and regions—which means long transportation distances in the distribution step—the impact due to distribution remains very low compared to all other phases, accounting for less than 0.1 %. Also, in Macau, the e-waste was treated in incineration plants with pollution control equipment; therefore, the environmental impact is very low, accounting for less than 0.5 %. At the same time, because some of the iron is recycled and the heat produced in the incineration process is used to generate electricity, there are some environmental benefits in this phase (see also Table 5). Another conclusion from Fig. 3 is that the environmental impacts on resources and human health are more significant in the life cycle assessment of desktop PCs than are the impacts on ecosystem quality.

These results are shown in more detail in Table 5, which lists the main contributors to the environmental impact, for the four relevant life stages. Here, the highest impacts were from As and Cd emissions to water, accounting for about 60 % of the environmental impact, from the first step—manufacturing, due to the extraction and processing of these metals. For the distribution step, the highest environmental impacts were from emission into the air. Due to the high electricity consumption of the desktop PC during its use phase, the most important impacts in this step were from emissions to the air, generated during the 4-year average effective lifespan for a desktop PC. Since, in Macau, electricity is produced mainly by coal, the high electricity use also causes high consumption of fossil resources, resulting in high SO2 and PM2.5 emissions. Because the electricity (produced by coal) is imported from mainland China, the main environmental impacts take place there. The EoL step shows small negative values for its part of the environmental impacts, especially for emissions to the air. This shows that there is an environmental benefit since recycling iron and thermal energy can be expressed as “avoided primary production.” However, the incineration process produces emissions to water, causing this impact to be large relative to other EoL impacts. Overall, though, the EoL phase has low environmental impact.

As can be seen from Table 6, all CML factors show a picture similar to the Eco-indicator'99 method—i.e., the distribution step was of no importance, and the EoL phase led to a more or less environmental benefit, while the remaining two phases (manufacturing and use) showed higher environmental impacts. In the details, however, there were rather large differences among the various impact factors. For environmental impacts (ADP, AP, GWP, and TETP), the use phase was the most important. For other impact categories, the manufacturing phase was of more importance. And the environmental impacts of HTP and FAETP in the EoL phase were relatively larger than those of other categories.

3.2 Details of the various life cycle phases

3.2.1 Manufacturing phase

As shown in Fig. 3, the manufacturing phase had the highest impact. Hence, a more detailed view into this first life stage was established, distinguishing first between the various parts that belong to such a PC system—i.e., the desktop PC itself, the screen (CRT, LCD), the keyboard, and the mouse. In Fig. 4, the resulting environmental impacts of these various parts are shown. The results show that the desktop PC had the greatest contribution to environmental impacts (44.89 Pt), followed by the LCD screens (about 27.53 Pt), while the CRT screen, keyboard, and mouse were of minor importance.

A more detailed view on the first three devices—the desktop PC and the two screen types—is shown in Figs. 5, 6, and 7 (expressed by CML method). Here, it can be seen that the environmental impacts of a desktop PC were clearly dominated by the PWB, which had an impact ranging from 43.47 % (PCOP) up to 76.99 % (MAETP) of the entire desktop PC. The actual weight of a motherboard accounts only for 6.3 %, as shown in Table 2. Another important component was the power supply (PS) with an impact between 6.27 % (MAETP) and 32.38 % (PCOP). Other components of the desktop PC were of much smaller importance.

In the case of the two types of screens shown in Figs. 6 and 7, the respective screen material and PWB contributed the most to the environmental impacts of these components. In case of the CRT screen, the cathode ray tube itself and the PWB were together responsible for more than 80 % of the environmental impact of this device. Here, the glass in the CRT was responsible for the main part, mainly due to its high weight. In case of the competing LCD technology, the PWB had by far the greatest contribution to the environmental impact, with an impact between 27.36 % (GWP) and 56.24 % (MAETP), followed by the LCD panel and the assembly process. Within the LCD panel, glass and various coatings were responsible for the highest impact.

3.2.2 Use phase

The environmental impact of the use phase was due only to the use of electricity (here the electricity was generated by coal, oil, natural gas, and hydropower)—i.e., the use-phase contributions to the impact were equal to those of the respective electricity mix. For the desktop and the two screens, their environmental impacts were mainly based on their power and their respective proportions (two screens). Therefore, the desktop had more environmental impact than the two screens in the use phase, with the LCD screen contributing more than the CRT screen.

From Fig. 8, it can be seen that in the use phase, the electricity generated by coal was of much more importance, accounting for about 66 % of the total environmental impact, followed by oil and gas. The electricity generated by hydropower consumed fewer fossil and metal resources, and released almost no any gas emissions to the air, and hence was cleaner than the other three electricity sources. Hydropower contributed about 10.88 % of the electricity used, but only 0.10 % of the environmental impact in the use phase.

From the above analysis, we can know that the electricity generated by different fuels have a high sensitivity on the environmental impacts. In addition, the life time of desktop PCs directly related to the electricity consumption of the use phase, therefore the life time will have a large influence on the environment impact of use phase.

3.2.3 EoL phase

For the last life stage—the EoL treatment—the actual impact in Macau came mainly from the incineration process of desktop PCs, as shown in Fig. 9. Here, it is shown that the desktop owned the largest environmental impacts in the EoL phase, followed by the LCD screen.

The impacts of incineration are relatively small, and some steel and electricity are recovered, but a large amount of resources—e.g., steel, plastic, copper, aluminum, and some others—are wasted in the incineration process. End-use product recycling is one approach to waste management that can reduce the burden to the environment, such as reducing the landfill space. Recycling also reduces the consumption of refined materials and energy used (saving resource usage) for new material extraction (Witoon et al. 2008). It thus helps to improve environmental performance over the life cycle of products and also generates market values for selling recovered materials.

Using the recycling technology of the trial project on e-waste treatment in Macau, the environmental impacts are shown in Fig. 9. In contrast to the incineration process (with its negative environmental impacts), the results show that the recycling treatment will bring a great environmental benefits, about −14.12 Pt. Similar to the incineration treatment, the recycling of the desktop would also be of the most importance, accounting for about 71 % of the environmental impact, followed by the LCD screen.

For the desktop, more detailed environmental impact results for the various components are shown in Fig. 10, expressed by the CML 2001 method. It can be seen that only four processes contributed to the benefits—the recycling of metal parts (including the plastic and chipboard), the reuse of the HDD, the reuse of the memory bank, and the recycling of the PS. The others were of minor importance, as their value never contributed more than 10 % to the overall benefits. In the case of the two screens, shown in Figs. 11 and 12, the respective metal recycling (including metal, plastic, and chipboard) contributed the most to the environmental benefit for the CRT and LCD screens. For the CRT screen, the other environmental benefits came from the treatment of the PWB and the CRT itself, and the environmental impacts were caused by the manual dismantling and treatment of cables and the PWB. In case of the LCD screen, except for the metal recycling, the benefits were generated by the PWB treatment, while the dismantling process contributed the most to the environmental impact.

A more detailed view of the three devices—the desktop PC and the two screen types—is shown in Table 7. It can be seen that avoiding emissions to water, especially for arsenic and cadmium, were the most important environmental benefits for the desktop, accounting for about 44.7 %, followed by avoided emissions to the air. For the two screen types, the most environmental benefits were obtained through avoiding emissions to the air.

3.3 Comparison between competing technologies (LCD, CRT)

Due to the different sizes of the devices examined, reflecting the limits and market conditions of the various technologies, a comparison based on the numbers of these devices in use for the above study would not really be accurate. Therefore, a relative comparison was established instead. For the EoL phase, the recycling technology was considered. Hence, a comparison between one 17-inch CRT screen and one 17-inch LCD screen could be established, and is shown in Fig. 13.

For the entire life cycle of CRT and LCD screens, the environmental impacts were similar—44.32 Pt and 44.92 Pt, respectively. As can be seen from Fig. 13, the CRT technology showed the higher environmental impact is in the distribution and use phases due to its higher weight and power requirements. The LCD technology, on the other hand, showed more impact in the manufacturing phase. In the EoL phase, when the recycling technology was used, the two technologies could both create some environmental benefits, due to the recycling of valuable resources and reused components. However, because of the limitations of the recycling technology, the CRT screen can produce a larger benefit than the LCD screen. In addition, the largest environmental impacts appeared in the use phase for the CRT technology, while for the LCD technology, the manufacturing phase had the most impact. For the influence categories, the two technologies were similar; their impacts on human health were the largest, followed by the impacts on resources.

While the environmental impacts of the two screens were different in different phases, their overall impacts were similar, but because the LCD screen is lighter and more convenient, and uses less power, the LCD technology is gradually replacing the CRT technology.

4 Conclusions

The desktop PC contributes to a variety of environmental impacts throughout its entire life cycle. In the whole life time of desktop PCs, the manufacture and use phases generate more impacts than the two other life stages—distribution and EoL treatment. Within the manufacturing step of a desktop PC system, the desktop contributes the most to the total environmental impacts (44.89 Pt), followed by the LCD screen (about 27.53 Pt), while CRT screen, keyboard, and mouse are of minor importance. In Macau, the electricity generated by coal is by far the most important, accounting for about 66 % of the total environmental impact, followed by oil and gas. Within the EoL treatment phase, using incineration, there will be little environmental impact. When adopting the recycling technology in the EoL phase, an apparent environmental benefits will be generated due mainly to the avoidance of emissions to water (arsenic ions and cadmium ions) and emissions to the air (SO2) in the primary production.

For the competing technologies (CRT and LCD screens), the environmental impacts are different in different phases, although the total impacts over their entire life cycles are similar. Because the LCD screen is lighter and more convenient, and uses less power, however, this is gradually replacing the CRT technology.

Based on the results of this study, some recommendations are considered as priority areas for action for ensuring long-term sustainability, for policy makers. The most important environmental impacts arising from the desktop PC, outside the EoL phase, are directly related to their high levels of energy use (fossil energy and electricity) and their emissions to water, air, and soil. Thus, promoting the transition to environmentally friendly energy sources and increasing the energy efficiency within various life cycle stages will reduce the environmental impacts of the desktop PC. Second, a more directly applicable approach could be the promotion of more environmentally friendly products (eco-design). The best approach, however, would be to focus on reducing overall energy consumption and emissions. For future e-waste treatment in Macau, recycling technology is recommended to deal with the e-waste to recover and recycle more of the valuable materials.

References

Anders ASG, Andersen O (2010) Life cycle assessments of consumer electronics—are they consistent? Int J Life Cycle Assess 15:827–836

Andrae ASG (2011) European LCA standardization of ICT: equipment, networks, and services. In: Finkbeiner M (ed) Towards life cycle sustainability management, 1st edn. Springer, Berlin. Aug. 28–31, Berlin, Germany, pp 483–493

Andrae ASG, Norihiro I, Hiroshi Y, Atsushi I (2008) Life cycle assessment of Japanese high-temperature conductive adhesives. Environ Sci Technol 42:3084–3089

Asari M, Fukui K, Sakai S (2008) Life-cycle flow of mercury and recycling scenario of fluorescent lamps in Japan. Sci Total Environ 393(1):1–10

Bakri SNS, Ramasamy RK, Surif S (2010) Life cycle assessment of magnetic and electronic ballast for 36-W fluorescent lamp. Int J Life Cycle Assess 15:837–841

Choi B, Shin H, Lee S, Hur T (2006) Life cycle assessment of a personal computer and its effective recycling rate. Int J Life Cycle Assess 11(2):122–128

Consoli F, Allen D, Boustead I, Fava J, Franklin W, Jensen AA (1993) Guidelines for life-cycle assessment: a ‘code of practice’. Society of Environmental Toxicology and Chemistry (SETAC) (SETAC Workshop, Sesimbra, Portugal, 31 March–3 April 1993)

Deng W, Zheng J, Bi X, Fu J, Wong M (2007) Distribution of PBDEs in air particles from an electronic waste recycling site compared with Guangzhou and Hong Kong, South China. Environ Int 33(8):1063–1069

Duan H, Eugster M, Hischier R, Streicher-Porte M, Li J (2009) Life cycle assessment study of a Chinese desktop personal computer. Sci Total Environ 407:1755–1764

European Telecommunications Standards Institute (2011) ETSI TS 103 199 V1.1.1 (2011-11) Environmental Engineering (EE); Life Cycle Assessment (LCA) of ICT equipment, networks and services; General methodology and common requirements. http://www.etsi.org/deliver/etsi_ts/103100_103199/103199/01.01.01_60/ts_103199v010101p.pdf

Fang GC, Wu YS, Huang SH, Rau JY (2005) Review of atmospheric metallic elements in Asia during 2000–2004. Atmos Environ 39:3003–3013

Guinee J, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A et al (2001) Life cycle assessment—an operational guide to the ISO standards. Leiden University: Centre of Environmental Sciences (CML)

Hertwich EG, Roux C (2011) Greenhouse gas emissions from the consumption of electric and electronic equipment by Norwegian households. Environ Sci Technol 45:8190–8196

Hischier R, Baudin I (2010) LCA study of a plasma television device. Int J Life Cycle Assess 15:428–438

Huisman J (2003) Quantifying recyclability and eco-efficiency for end-of-life treatment of consumer electronic products. PhD thesis, Delft University of Technology

ISO (International Standard Organization) (2000) 14040 series: environmental management—life cycle assessment—principles and framework. ISO 14040 series. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htmc?csnumber-37456. (Accessed 29 Feb 2012)

Leung AOW, Duzgoren-Aydin NS, Cheung KC, Wong MH (2008) Heavy metals concentrations of surface dust from e-waste recycling and its human health implications in Southeast China. Environ Sci Technol 42(7):2674–2780

LG (LCA Guide) (1997) A guide to approaches, experiences and information source. Environmental Issue Series No. 6. European Environmental Agency

Li H, Yu L, Sheng G, Fu J, Peng P (2007) Severe PCDD/F and PBDD/F pollution in air around an electronic waste dismantling area in China. Environ Sci Technol 41(16):5641–5646

Liu H, Zhou Q, Wang Y, Zhang Q, Cai Z, Jiang G (2008) E-waste recycling induced polybrominated diphenyl ethers, polychlorinated biphenyls, polychlorinated dibenzo-p-dioxins and dibenzo-furans pollution in the ambient environment. Environ Int 34(1):67–72

Morf LS, Tremp J, Gloor R, Schuppisser F, Stengele M, Taverna R (2007) Metals, non-metals and PCB in electrical and electronic waste—actual levels in Switzerland. Waste Manag 27:1306–1316

Pennington DW, Potting J, Finnveden G, Lindeijer E, Jolliet O, Rydberg T et al (2004) Life cycle assessment Part 2: current impact assessment practice. Environ Int 30(5):721–739

Prasara J, Grant T (2011) Comparative life cycle assessment of uses of rice husk for energy purposes. Int J Life Cycle Assess 16:493–502

Puckett J, Byster L, Westervelt S, Gutierrez R, Davis S, Hussain A et al (2002) Toxics link India exporting harm, the high-tech trashing of Asia. The Basel Action Network (BAN) and Silicon Valley Toxics Coalition (SVTC); Seattle, WA, USA, February 25

Qu W, Bi X, Sheng G, Lu S, Fu J, Yuan J et al (2007) Exposure to polybrominated diphenyl ethers among workers at an electronic, waste dismantling region in Guangdong, China. Environ Int 33(8):1029–1034

Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, Rydberg T et al (2004) Life cycle assessment Part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30(5):701–720

Rivela B, Moreira MT, Muñoz I, Rieradevall J, Feijoo G (2006) Life cycle assessment of wood wastes: a case study of ephemeral architecture. Sci Total Environ 357(1–3):1–11

Robinson BH (2009) E-waste: an assessment of global production and environmental impacts. Sci Total Environ 408:183–191

Saner D, Walser T, Vadenbo CO (2012) End-of-life and waste management in life cycle assessment—Zurich, 6 December 2011. Int J Life Cycle Assess 17(4):504–510

Scharnhorst W, Althaus H-J, Classen M, Jolliet O, Hilty LM (2005) The end-of-life treatment of second generation mobile phone networks: strategies to reduce the environmental impact. Environ Impact Assess Rev 25(5):540–566

Scharnhorst W, Hilty LM, Jolliet O (2006) Life cycle assessment of second generation (2G) and third generation (3G) mobile phone networks. Environ Int 32(5):656–675

Sepúlveda A, Schluep M, Renaud FG, Streicher M, Streicher R, Hagelüken C, Gerecke AC (2010) A review of the environmental fate and effects of hazardous substances released from electrical and electronic equipments during recycling: examples from China and India. Environ Impact Assess Rev 30:28–41

Socolof ML, Overly JG, Geibig JR (2005) Environmental life-cycle impacts of CRT and LCD desktop computer displays. J Clean Prod 13:1281–1294

Song Q, Wang Z, Li J, Duan H (2012a) Sustainability evaluation of an e-waste treatment enterprise based on energy analysis in China. Ecol Eng 42:223–231

Song Q, Wang Z, Li J (2012b) Residents’ behaviors, attitudes, and willingness to pay for recycling e-waste in Macau. J Environ Manage 106:8–16

Teehan P, Kandlikar M (2012) Sources of variation in life cycle assessments of desktop computers. J Ind Ecol 16:S182–S194

Tekwawa M, Miyamoto S, Inaba A (1997) Life cycle assessment: an approach to environmentally friendly PCs. Electronics and the environment. Proceedings of the 1997 IEEE international symposium on 5–7 May 1997, San Francisco, CA, USA

UNU (United Nations University) (2008) Review of Directive 2002/96 on Waste Electrical and Electronic Equipment

Wäger PA, Hischier R, Eugster M (2011) Environmental impacts of the Swiss collection and recovery systems for Waste Electrical and Electronic Equipment (WEEE): a follow-up. Sci Total Environ 409:1746–1756

Widmer R, Oswald-Krapf H, Sinha-Khetriwal D, Schnellmann M, Böni H (2005) Global perspectives on e-waste. Environ Impact Assess Rev 25(5):436–458

Witoon A, Pornpote P, Daniel JW, Woranut K (2008) LCA of spent fluorescent lamps in Thailand at various rates of recycling. J Clean Prod 16:1046–1061

Wittmaier M, Langer S, Sawilla B (2009) Possibilities and limitations of life cycle assessment (LCA) in the development of waste utilization systems—applied examples for a region in Northern Germany. Waste Manag 29:1732–1738

Wong CSC, Duzgoren-Aydin NS, Aydin A, Wong MH (2007) Evidence of excessive releases of metals from primitive e-waste processing in Guiyu, China. Environ Pollut 148(1):62–72

Acknowledgments

The authors would like to thank Dr. Duan Huabo (Tsinghua University) for his constructive and detailed reviews of this manuscript. This study was funded by the National High Technology Research and Development Program of China (863 program, 2009AA06Z304), and the University of Macau.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Roland Hischier

Rights and permissions

About this article

Cite this article

Song, Q., Wang, Z., Li, J. et al. Life cycle assessment of desktop PCs in Macau. Int J Life Cycle Assess 18, 553–566 (2013). https://doi.org/10.1007/s11367-012-0515-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-012-0515-7