Abstract

Purpose

The article presents the method and results of the life cycle assessments (LCAs) of the Vestas' 2-MW GridStreamer TM wind turbines and outlines the state-of-the-art approach adopted. For more than 10 years, Vestas has prepared LCAs of wind power. However, since 2010, a step change in comprehensiveness has been employed, for example, conducting the LCA to individually assess all components within a wind turbine (being composed of around 25,000 parts).

Methods

Three LCAs have been conducted with the 2-MW GridStreamerTM turbines in accordance with ISO 14040/44 and critically reviewed by an expert. The goal was to evaluate potential environmental impacts and other non-impact indicators per kilowatt hour of electricity generated for a ‘typical’ 50-MW onshore wind plant.

The LCAs assessed all life cycle stages and were built using GaBi DfX software. A significant quantity of primary data were gathered, for example, covering over 100 Vestas' sites for manufacturing, sales and servicing, as well as establishing turbine use-phase performance (i.e. electricity generation, servicing, etc.) based on over 20,000 monitored wind turbines around the world, covering around 20 % of the current worldwide installed capacity.

Results and discussion

The baseline results show that per kilowatt hour of electricity generated by the 2-MW GridStreamer™ turbines have the following baseline performance: ADP elements 0.44 to 0.58 mg Sb-e, ADP fossil 0.10 to 0.13 MJ; acidification potential 37 to 45 mg SO2-e, eutrophication potential 3.7 to 4.5 mg PO4-e, freshwater aquatic ecotoxicity 100 to 130 mg DCB-e, global warming potential 7 to 10 g CO2-e, human toxicity potential 1,150 to 1,400 mg DCB-e, marine aquatic ecotoxicity potential 1,100 to 1,300 g DCB-e, photochemical oxidant creation 4 to 5 mg ethene, terrestrial ecotoxicity potential 19 to 24 mg DCB-e, return-on energy 8 to 11 months and recyclability 81 to 85 % of turbine mass.

Being equipped with extensive facts and comprehensive LCA models provides Vestas the basis to further integrate environmental considerations into product marketing, design and research, procurement and to deliver transparent information to stakeholders.

Conclusions

Overall, the article presents a case study of the LCA approach used to assess the potential impacts of 2-MW GridStreamer™ turbines based upon comprehensive product knowledge and represents a state-of-the-art approach to LCA modelling of wind power. The article discusses further applications of LCA internally to direct product improvement and for external communications and also highlights the LCAs' aim to improve transparency and robustness of previous LCAs of wind power.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Public awareness and concern for the effects of climate change and other environmental impacts has dramatically increased in recent years. Due to wind energy's significantly lower environmental burdens, compared with fossil fuel-based electricity generation, wind is well placed to contribute towards the global drive to help mitigate the effects of climate change and other potential environmental impacts.

This article presents the life cycle assessment results for the 2-MW GridStreamer TM turbines and underscores the approach adopted by Vestas Wind Systems A/S to help fulfil their on-going sustainability agenda and to provide publicly available and transparent assessments of wind power. Vestas is the world's largest wind turbine manufacturer selling both onshore and offshore turbines for electricity generation, having installed more than 46,000 wind turbines in 66 countries on six continents with a total installed capacity of about 50 GW, representing around 25 % of total worldwide installed wind capacity (WWEA 2011). Vestas operates over 100 sites around the world for manufacturing and sales and offers installation, repair and maintenance services to its customers.

For more than 10 years, Vestas has prepared life cycle assessments of various wind power plants (Elsam 2001, 2004; PE 2011a; Vestas 2006a, b, 2011a, b, c). The life cycle assessments (LCAs) are conducted in accordance with ISO standards (ISO 2006a, b) and assess all main parts of the different wind power plants over the entire life cycle.

In the recent article by Davidsson et al. (2012), which reviewed 12 available life cycle studies of wind energy systems with the aim to provide a comparative analysis of current LCA practice, one of the key recommendations is to mitigate the lack of transparency regarding LCAs of wind power, relating to underlying assumptions, calculations and conversions, as well as purporting to international collaboration to agree on LCA approaches and methods. The LCAs presented in this article were not included in that review, although one previous LCA conducted by PE International of the V112 3-MW turbine was assessed (PE 2011a). This article helps to address some of these issues, both by outlining the LCA methodology undertaken in the present LCAs, showing the on-going improvement of LCAs of wind power, and by providing a high degree of transparency of externally reviewed studies that are available publicly (Vestas 2011a, b, c). Further consideration is given throughout the article to some of the outcomes of Davidsson et al. (2012) in relation to the present LCAs.

Since 2010, Vestas has adopted a step change in comprehensiveness for conducting LCAs whereby the wind turbine's entire bill of materials is assessed, accounting individually for around 25,000 parts that make up the wind turbine and, in total, around 99.95 % of the total mass of the entire power plant. Also, in the manufacturing stage, the LCA considers information from all Vestas' global sites, and the use phase relies on Vestas' real-time performance data of over 20,000 monitored wind turbines around the world, covering around 20 % of the current worldwide installed wind capacity (Vestas 2011a). This level of detail and reliability in data represents a state-of-the-art approach to LCA modelling of wind power.

This article presents the LCA results for the 2-MW GridStreamerTM turbines (Vestas 2011a, b, c) and discusses how LCA considerations are being integrated into Vestas' business systems. The 2-MW GridStreamerTM turbines represent a modern technology, geared-drive turbine which, in the Mk 8 version, integrates the GridStreamerTM technology. The GridStreamerTM technology allows higher grid stability by synchronising power production with grid requirements. The 2-MW platform of turbines is installed globally, consisting of over 9,300 turbines (or 18.6 GW), which represents around 9 % of the current worldwide-installed wind capacity (WWEA 2011). As such, the 2-MW platform represents a substantial proportion of modern-installed wind capacity. The LCAs presented in this article build upon the entire bill of materials for the turbine, as well as including all main components of the complete power plant (up to existing grid connection), representing current technology for wind plant site connection and electricity transformation.

2 Methods

2.1 Aim and scope

Three LCAs of the 2-MW GridStreamerTM turbines (Vestas 2011a, b, c) have been conducted in accordance with ISO 14040/44 standards (ISO 2006a, b) and have been critically reviewed by an external expert. This indicates the objectivity of the studies and compliance with LCA standards. The reviewer additionally indicated the high level of maturity of the studies performed and the use of state-of-the-art methods (Vestas 2011a, b, c).

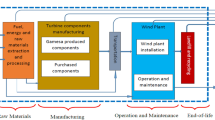

The goal of the LCAs was to evaluate the potential environmental impacts associated with the production of electricity from a 50-MW onshore wind plant comprised of 2-MW GridStreamer™ turbines. The studies assess a ‘typical’ wind plant layout based on Vestas' global supply chain. The system boundary of the wind plant assessed is shown in Fig. 1.

The LCAs assess all stages in the life cycle from cradle to grave, including raw materials; production of all parts of the wind plant; Vestas' manufacturing (including over 100 global production factories for casting, machining, tower production, generator production, nacelle assembly and blades production, as well as sales and servicing activities); all transport stages; wind plant installation and erection; servicing, replacement parts and operations; use-phase electricity generation; and end-of-life treatment. Figure 2 shows a diagram of the basic wind plant components.

2.2 Product description

The 2-MW GridStreamer™ range of turbines is Vestas' most proven turbine platform with over 9,300 turbines installed globally (Vestas 2012a, b). The platform provides new benchmarks of reliability, efficiency and competitive cost of energy for 2-MW turbines. The 2-MW GridStreamer™ range includes the onshore V80 2.0 MW, V90 1.8/2.0 MW and V100 1.8/2.0 MW, known collectively as the ‘2-MW platform’. The turbines share a significant number of common components (around 90 % of total weight), for example the nacelle, tower and all site parts (cabling, transformer, etc). The primary difference between the turbines relates to the blade size (80, 90 or 100 m in diameter), the generator output and the ‘hub and nose cone’ module which has some differences in construction. Figure 3 shows an open view of the nacelle of a 2-MW GridStreamer™ turbine.

The Mk 8 series of turbines are assessed in the LCAs. Also, a new upgrade to the 2-MW platform (Mk 9) will allow the V90 and V100 turbines to operate in stronger winds therefore generating more energy for the same megawatt rating of turbine. From a LCA perspective, the physical change to the upgraded turbine is minimal, relating to an upgraded gearbox of similar size and weight. The Mk 9 turbine was assessed in sensitivity analysis in the LCA.

2.3 Functional unit

The functional unit used for the LCA study is 1 kWh of electricity delivered to the grid by a wind power plant, which includes all losses up to the existing grid point. This is based on the turbine design lifetime of 20 years and total electricity generation based on average wind speeds in the respective International Electrotechnical Commission (IEC) wind class (refer to Table 1).

2.4 Electricity generation and plant lifetime

Electricity production of the wind turbine is substantially affected by the wind plant siting and site-specific wind conditions that the turbine operates under, so it is not always the size of the rotor or the generator rating (in megawatt) that determines the electricity production of the turbine. But wind class is a dominant factor. Nonetheless, electricity production is very accurately measured for Vestas' turbines when the wind speed and conditions are known.

Vestas' turbines are designed to meet different functional requirements both in terms of onshore and offshore locations, as well as the wind classes for which they are designed to operate. The wind classes range from low wind (IEC III), medium wind (IEC II) and high wind (IEC I), as defined by the International Electrotechnical Commission (IEC 2005). Table 1 shows the electricity generation of the turbines assessed for the wind classes they operate within.

The power plant lifetime is also a dominant factor when determining the impacts of the electricity production per kilowatt hour from the wind plant. The LCAs use a lifetime of 20 years which matches the standard design life; however, the wind turbine industry is still young (starting for Vestas in 1979), and few turbines have ever been disposed, reaching operational lives of 30 years and over, for other Vestas' turbine models. It is often wear or fatigue of the load-bearing components (such as tower fatigue) which limits the overall turbine lifetime. Many components can be routinely replaced as part of maintenance, except for the fixed parts (such as the tower, foundation and site cables, etc.) which are generally not replaced.

Vestas operates sophisticated real-time diagnostic tools and sensors which measure individual turbine performance and fatigue, and it is possible to predict the lifetime of specific components for specific site conditions. Also, these systems monitor the current ‘health’ status of the turbine and record its power production. These systems operate on over 20,000 wind turbines around the world (of over 46,000 in total), which covers 20 % of the current worldwide installed wind capacity, providing very detailed and reliable data of turbine performance.

If comparisons of wind turbine performance from one turbine to another will be made, then it is important that this is made on an equivalent functional basis and should be compared within the same IEC wind class at equal average wind speeds. This will help to standardise comparisons of wind turbine performance.

Some LCAs of other wind plants, for example, as discussed by Davidsson et al. (2012), use a theoretical capacity factor of the wind turbine to estimate the energy produced from the particular wind power plant. The capacity factor is the ratio of the actual energy produced (in a given time period) divided by the hypothetical maximum possible, for example, if the wind plant is running continuously at full rated power, etc. It should be noted that the capacity factor is a derived figure and one which is location specific based on many wind plant characteristics, such as site wind conditions, plant layout, availability, wake losses, electrical losses, maintenance schedules, etc. The present LCAs do not use an assumed capacity factor (i.e. to estimate energy output), but specific data of turbine performance and wind plant losses are used to very accurately assess the electricity production from the wind plant. If other studies use an estimated capacity factor (i.e. one that is not derived from power plant performance, but estimated), then the authors recommend that extra sensitivity analysis in the LCA is required to show appropriate consideration of this uncertainty.

2.5 Data collection and product modelling

The LCAs adopt an attributional modelling approach to accurately portray the product life cycle of the wind plant. Other approaches may also potentially be relevant but have not been applied, such as input–output-based LCA, hybrid LCA or a consequential approach (Finnveden et al. 2009; Guinée et al. 2011), or these may be useful to fulfil missing inventory data. Future developments may also see the inclusion of wider sustainability considerations, pertaining to environmental, social and economic aspects, such as the LCSA framework discussed by Guinée et al. (2011), based on a multidisciplinary approach and collection of analysis methods.

Previous LCAs of Vestas' turbines (Elsam 2001, 2004; Vestas 2006a; PE 2011a) show that manufacturing and end-of-life are the most significant stages in the turbine life cycle. Conversely, turbine operation is not significant for total environmental impacts, except that electricity generation and turbine lifetime are critical factors when assessing potential impacts per kilowatt hour of electricity generated. Data collection focused on procuring precise data for the production, use and disposal stages.

Raw materials and production

Modelling of the life cycle begins with a bill of materials, which contains a part tree of all parts in the wind turbine. This is extremely extensive for a 2-MW GridStreamer™ turbine, consisting of around 25,000 parts for a standard turbine model. In the LCA model, a material dataset, manufacturing process and country of origin are assigned to each part. This builds a comprehensive product model of the entire turbine. The component and material data are extracted from Vestas' internal master-data systems, 3D-CAD system used for component design, and from supplier declarations and technical specifications. For the turbine itself, over 99.5 % of the total mass was mapped (gaps related to missing material data). All other parts in the entire power plant are included, such as foundations, cabling and transformer station, which covers over 99.95 % of the total plant mass. Consequently, the LCA model for one power plant consists of over 500,000 components, as well as additional production and end-of-life processes. This allows results to be analysed to a very high degree of detail for individual components, materials and manufacturing processes.

Modelling this many components “conventionally” in LCA is not practicable. However, using GaBi DfX software (PE 2011b) allows the complete bill of materials to be imported into the LCA model, and materials and manufacturing processes are mapped to individual components to create a complete ‘product-model’. Secondary datasets for production and processing are taken from recognised sources, such as Worldsteel (2010), Eurofer (2009), Plastics Europe (2010) and European Aluminium Association (2008), covering over 90 % of the turbine mass. Figure 4 shows a material breakdown of the V80 2.0-MW GridStreamer™ turbine.

Amongst other materials, the turbine also contains quantities of rare earth elements (i.e. neodymium and dysprosium) used in the permanent magnets of the turbine generator, as well as in magnets within the turbine tower for attaching internal fixtures. The production of these materials is based on production datasets for their sourcing from Europe and Asia (PE 2010).

Vestas' production

Over 100 Vestas' global factories and non-production sites are included in the LCA models. On a quarterly basis, Vestas' business units report all usage of materials, fuel and energy, as well as wastes and emissions (public data available at Vestas 2012a). Parameterised models were built in the GaBi software for each facility type, covering all inputs and outputs, production losses and internal recycling loops. This standardised modelling and reporting procedure allows easy inclusion of a large number of sites and update on an annual basis.

Transport

Transport includes all stages for raw materials, turbine components, wind plant components, maintenance and end-of-life disposal. The LCA uses primary fuel consumption data collected by Vestas for truck and sea vessel transport of turbine components (i.e. tower, blades and nacelle). Specific transport distances reflect the actual Vestas' supply chain, for example, tower manufacture reflects both Vestas' own production sites and supplier locations.

Background electricity

Choices of electricity mix selected for manufacturing steps can affect the LCA results. For the current LCAs, country-specific average electricity mixes have been used based on the country producing each component to reflect the actual supply-chain geographies.

Turbine installation/decommissioning

Specific data are used for usage of cranes, onsite vehicles, diggers and generators for laying the foundations, erecting the turbines, laying site cables, installing/erecting the transformer station and connecting to the existing grid. Provision of roads, working areas and turning areas is included.

Turbine operation

Use-phase electricity generation accounts for wind turbine availability (i.e. the capability of the turbine to operate when wind is blowing), wake losses (i.e. the decreased electricity generation capacity of the turbine that is downwind of another turbine) and transmission losses, described in Section 2.4.

Turbine servicing

Serviced parts, such as oil, filers and replaced components (due to wear and tear of moving parts within the lifetime of a wind turbine), are included.

End-of-life

The LCA model adopts an avoided impacts approach, as compared to a recycled-content approach, which is aligned with the approach supported by the metals industry (Atherton 2006). As stated by Ekvall and Weidema (2004), whichever recycling approach is adopted, the inflows and outflows of recycled materials should be consistent. For the wind power plant, environmental credits are assigned for recycling of metals only, for example, based on Worldsteel (2010) inventories for steel scrap value. Also, it has been assumed that all materials entering the production system are sourced from primary material; however, for iron, steel, aluminium and copper, the secondary (or scrap metal) inputs to primary production have been adjusted to assign a burden to all secondary metal inputs (using primary production or worldsteel ‘scrap value’ for these burdens). This provides a consistent approach to crediting for end-of-life recycling. The use of an avoided impacts approach also provides a very ‘usable’ business measure to drive up the total recyclability of the wind turbine, which can be accurately measured using the LCA models. This in turn drives business activities, for example by focusing on recycling/reuse of non-metallic parts, such as composite blade materials, controllers and polymers. It is also recognised that, from a scientific perspective, both recycling approaches may be applied to wind turbines, as adopted by Crawford (2009) where a recycled-content approach is used, for example. Additionally, guidance already exists for preparing an Environmental Product Declaration (EPD) based on ISO 14025 (2006c) for electricity generation and distribution via the Product Category Rules (Envirodec 2007, 2011). In general, the EPD guidance aligns with the current LCAs (which are in compliance with ISO 14040/44), relating to functional unit, system boundaries and general data quality requirements, etc. However, for the EPD approach, end-of-life and recycling credits are excluded from the boundary, meaning that a recycled-content approach is adopted in the EPD. Given that both approaches can be applied, it may be beneficial to show the consequences of both crediting approaches in future LCA results via sensitivity analysis.

Additionally, the end-of-life disposal of the wind plant has been modelled in a part-specific manner. The GaBi DfX software has the function to disassemble the entire turbine (or parts of it) into its source components and dispose of these parts through different routes and disposal efficiencies. This allows for an extremely detailed end-of-life model to be created that is part specific, for example, components that are easily dismantled and recycled (e.g. the steel tower) will receive higher efficiencies than other parts of the turbine. The entire power plant is broken down into all major components or assemblies, and each receives specific recycling and disposal rates based on industry data.

As is apparent, the LCA models provide a tremendous level of detail for examining the performance of the wind turbine and its individual components. Furthermore, the LCA models include various ‘product options’ for the turbines, such as differing tower heights or foundation types, which may vary depending on customer or site-specific requirements. These product options are not ‘used’ in the baseline LCA model of a typical wind plant; however, this flexible approach to LCA modelling allows Vestas to create tailored LCAs of a specific wind power plant, for example, giving Vestas' customers the opportunity to obtain a detailed (and externally reviewed) assessment of their own specific wind plant.

2.6 Impact assessment

The impact categories assessed in the LCA represent those likely to arise from a wind plant system, based on the CML (2009) baseline characterisation factors for mid-point potential impacts. A series of detailed sensitivity analyses were also conducted which explore the primary uncertainty in the LCA models.

The CML impact categories focus on the so-called ‘midpoints’ of the cause–effect chain. This means that the method aggregates data for the inventory flows and characterises their potential impacts in various categories (e.g. global warming, acidification, etc.) but do not go as far as to assess the endpoints, such as loss of biodiversity, damage to human health, etc. caused by these impacts, as developed in methods such as Eco-Indicator 99 (Goedkoop and Spriensma 1999) or ReCipe (Goedkoop et al. 2009). As such, the impact assessment results generated do not predict impacts on category end points, the exceeding of thresholds, safety margins or risks.

In general, a life cycle assessment cannot always address all environmental concerns, such as the potential impacts of land use, noise or potential local impacts on flora and fauna. As such, a LCA should not stand alone in the assessment of technologies; but other environmental management techniques, such as risk assessment and environmental impact assessment, for example, are valuable tools that address these environmental concerns. These types of assessments are usually conducted as part of the local permitting and planning process for installation of a wind plant.

Several additional, non-impact indicators were assessed, as follows:

-

Primary energy from renewable raw materials (megajoule net value)

-

Primary energy from resources (megajoule net value)

-

Water use (mass)

-

Turbine recyclability (percent turbine mass)

-

Return-on energy (months)

Specifically, for water use, the present LCAs only account for net freshwater use—meaning that only the total input of freshwater used for production and disposal processes is accounted for. Nonetheless, for this to be treated more thoroughly, further consideration should be made regarding types of water used, inclusion of local water scarcity as well as differentiation between watercourses and quality aspects (Berger and Finkbeiner 2010), which will aid more accurate decision making.

3 Results for 2-MW GridStreamer™ wind turbines

The LCA provides accurate and robust results by utilising the very detailed LCA models developed in the inventory stage, which cover 99.95 % of the wind plant, and include a detailed range of sensitivity analyses. For the V80 2.0-MW GridStreamer™ turbine, the whole-life results are shown in Table 2, which show that the manufacturing phase dominates the life cycle, followed by end-of-life management where environmental credits are received for recycling of metals. The plant setup and operation stages have much less significance.

Figure 5 presents the potential impacts for manufacture, plant setup and operation (i.e. all life cycle stages excluding end-of-life). The results show that the nacelle, tower and site parts (primarily site cables) contribute most significantly across all impact categories. The next most significant components relate to the turbine foundation and blades. Vestas' factories contribute between 1 and 8 % across all impact categories. Transport is included for each part and is not disaggregated. The following sections describe the potential impacts in more detail for the global warming potential, return-on energy and turbine recyclability.

3.1 Global warming potential

Table 3 shows the whole-life global warming potential per kilowatt hour of electricity produced by the various GridStreamerTM turbines. Overall, the manufacturing stage dominates the life cycle, with the production of the tower (25–30 %), site cables (20 %), nacelle (15 %), blades (10–15 %) and foundations (10 %) which are the primary components contributing to global warming. Vestas' production and operations contribute around 3 % and end-of-life contributes around −30 % for the environmental credit associated with metal recycling. Transport in total over the life cycle contributes around 8 % to global warming potential.

3.2 Return-on energy

Return-on energy provides an indication of the energy balance of the power plant, showing the relationship between the energy requirement over the whole life cycle of the wind plant (i.e. to manufacture, setup, operate, service and dispose) versus the electrical energy output of the wind plant. The payback period is measured in months where the energy requirement for the life cycle of the wind plant equals the energy it has produced, using the following equation:

The above measure may be calculated in two basic ways: (1) based on the net electrical energy output of the wind plant or (2) based on the equivalent primary energy output of the wind plant. In both cases, the primary energy requirement for the whole life cycle of the wind plant is divided by the electrical energy output (either net or primary) from the wind plant and then multiplied by the power plant lifetime in months.

Table 4 shows the results for the 2-MW GridStreamerTM turbines based on net energy which ranges from 8 to 11 months return-on energy. This may be interpreted that the wind plant will return between 22 and 30 times more energy back to society than it consumed over the wind plant life cycle. Accounting for the return-on energy based on the equivalent primary energy approach gives a significantly lower payback period of between 2 and 4 months for all turbines assessed. The latter (primary energy) measure gives a relative theoretical return-on energy because the electrical energy from the turbine is converted to the primary energy of a typical electrical grid mix for different world regions. This approach accounts for the efficiency of the electricity power stations when determining the primary energy. There is no distinction made here as to whether or not base-load energy mix or marginal-load energy mix should be assessed, but in this article, an average electricity mix for Europe, Australia and USA were analysed. The net return-on energy approach does not include these relative conversions and therefore provides an absolute indication of performance.

In real terms, whichever approach is used, the return-on energy provides a measure of the energy that is returned back to society from investing in the wind plant. This provides a robust measure when choosing between where to invest energy and the resulting payback to society as a whole. For example, fossil-based electricity sources, such as coal, oil or gas, will consume the intrinsic energy of the fuel in generating electricity during operation (with energy efficiency conversion of up to 45 % with latest technologies for coal power and a global average of 28 % IEA 2006) and will therefore always be net consumers of energy, returning less energy back to society than is consumed throughout the life cycle. Conversely, data shown in Höök et al. (2012) for energy-return-on-energy investment only appear to account for the capital energy investment of the power plants and exclude the inherent energy in the fuel to operate the plants, which is why return-on energy for these fossil fuels ranges from around 20 to 100 times. However, this appears nonsensical, as the dominant energy contributor (i.e. the fuel itself needed to generate the electricity) is missing from the equation; if included, the return-on energy would at best be below 0.5 times—or 50-fold to 60-fold lower than wind. This does not mean to suggest that wind power is entirely independent of fossil energy in its own life cycle, conversely, but it does show the clear relationship of energy investment versus return-on energy back to society.

3.3 Turbine recyclability

Recyclability measures the proportion of the turbine (in percent mass) that can be usefully recycled at end-of-life, accounting for specific recycling rates of various components. The measure only relates to the turbine itself and excludes other wind plant components (i.e. foundation, site cabling, transformer station, etc.) using the following equation:\( \; {\text{Turbine}}\,{\text{recyclability \; }}\left( {{\text{in \; }}\:{\text{percent}}} \right) = {\text{sum}}\,{\text{of}}\,{\text{all}}\,{\text{turbine}}\,{\text{parts}}\left( {\frac{{{\text{metal}}\,{\text{recycling}}\,{\text{rate \; }}\left( {{\text{in}}\,{\text{percent}}} \right) \times {\text{metal \; }}\:{\text{part}}\,{\text{mass \; }}\left( {{\text{in}}\,{\text{kilogram}}} \right)}}{{{\text{total}}\,{\text{part}}\,{\text{mass}}\left( {{\text{in}}\,{\text{kilogram}}} \right)}}} \right) \) The metal components of iron, steel, aluminium and copper contribute to recyclability. Table 5 shows the results for the GridStreamer™ turbines. By analysing the wind turbine to cover 25,000 parts that make up the turbine provides very detailed and reliable results. The primary reason for variation in recyclability between the 2-MW GridStreamerTM turbines relates to the tower construction, where a turbine operating in a higher wind class requires a higher strength tower, using more steel for the same height.

4 Discussion

The article presents a case study for the application of LCA to a complex wind-turbine product and presents some of the results of these studies. This delivers value to Vestas and its various stakeholders, though being equipped with extensive facts and state-of-the-art LCA models, which is providing the basis to further integrate environmental considerations into product communications, design and research optimisation, procurement and to deliver transparent information to customers, consumers and governments.

The article aims to present a transparent and robust approach to the LCA modelling of wind power systems and to show improvement in the methods and comprehensiveness of LCA application from previous studies of wind energy. Some points highlighted in Davidsson et al. (2012), such as the need for greater transparency and standardisation of methods and calculations, are comparatively addressed in the article. Vestas aims to work with best available LCA approaches to assess the performance of its products, as well as to provide openly transparent and robust LCA studies.

Some further discussion about the characterisation of natural resource use is also worth noting. As with all material-based products or energy systems, there will be some kind of resource use (both energy and material resources) associated with the life cycle of that product or service. LCA methods to characterise resource depletion account for the geological reserves and the anticipated depletion rates (CML 2009), and they are usually presented in mass of antimony equivalents. The quantity of reserve may relate to, for example, the ultimate reserve (every element in the earth's crust), extractable reserve or the economic reserve. The current LCAs use the established CML3.6 (2009) method for resource depletion, although some evidence shows that the methods to measure resource use requires further consensus (Finnveden 2005). In the context of rare earth elements (REEs), there is often a discussion about the use of these metals for renewable energy systems, such as wind turbines. They are also commonly used in many different industries and a wide range of products, including a large number of common personal and household products such as hybrid car motors, MP3 players, computer hard drives, low-energy light bulbs, LCDs and mobile phones, as well other industrial sectors such as medical imaging, catalysts to process crude oil and military hardware such as radars and guidance systems (Delaney 2010). Also, it is a common misconception that REEs are actually scarce materials—in reality, they are not very scarce at all and there is an abundance in the earth's crust. Nonetheless, they may present more of a political scarcity issue in so far as the vast majority of the world's supply is from China (Chen 2011), which potentially presents an issue of security of supply and pricing. In relation to wind turbines, the use of REE actually provides environmental benefits for the product, allowing more compact and energy efficient turbines to be built, which reduces the reliance on resource use. These elements are used in the wind turbine generator, for permanent magnet generators, as well as in the tower magnets for fixing internal tower components (as briefly outlined in the example below for tower magnets).

Through identifying environmental ‘hotspots’, Vestas is able to direct potential product improvements, for example, the LCA of the V112 3.0-MW turbine has been used to set targets to reduce the turbine's global warming potential per kilowatt hour by 15 % and to increase the turbines recyclability to 85 % by 2015. Vestas has also set stringent targets for increased use of renewable energy and renewable electricity across all Vestas' business units and factories (e.g. use of 100 % renewable electricity by 2012). The impact of achieving these targets is included in the product LCA models, allowing traceability and management at both a business-unit and product level.

The LCA approach is also being used within other parts of the Vestas' business, such as the environmental assessment of alternative technologies or supply chain sourcing options which aim to simultaneously lower the cost of energy for wind and reduce environmental impacts. Two examples include

-

Magnets are used in a turbine tower for the fixation internal components (e.g. ladders, fixtures, etc.). On the V112 3.0-MW turbine with an 84-m tower, the use of magnets will result in a saving of around 10 tonnes of steel per turbine versus the traditional solution of welding because the thickness of the steel plate in the tower can be reduced. This equates to avoiding around 8.0 tonnes of CO2 equivalents per turbine over the life cycle (or about 0.3 % of total wind plant GWP), as well as significant cost savings and improved safety for manufacturing and assembly operations.

-

Sulphur hexafluoride (SF6) gas is a very potent greenhouse gas which may be used in the turbine switchgear. The switchgear protects and isolates the electrical components of the turbine and contains around 7 kg of SF6 gas per turbine. The gas acts as an electrical insulator and allows for compact design of switchgear units. But if improperly disposed at end-of-life whereby the gas is released to the atmosphere, then this will contribute very significantly to the total global warming burdens of about 160 tonnes of CO2 equivalents per turbine or about 10 % of total wind plant GWP (PE 2011a). Consequently, Vestas has established procedures and is working in partnership with customers and suppliers to assure the safe operation, disposal and selection of switchgears used by Vestas.

Vestas' newest and 100 % dedicated offshore turbine, the V164-7.0 MW, has undergone a screening LCA as an integral part of the product development process. The LCA was based on other more detailed LCA models and was prepared to enable managers and designers to include environmental considerations in decision making. The LCA has identified areas of the turbine performance where potential improvements can be made earlier in the design phase.

As mentioned, by creating such comprehensive LCA models described in this article, Vestas can now offer customers the option to acquire a detailed and tailored LCA of their own wind power plant. The LCA can be developed at an early stage in the wind project before the plant is operational, taking into account turbine type, local site conditions and production supply chain. This will provide customers with transparency and key facts for their business requirements and stakeholders.

5 Conclusions

Overall, the article presents a case study of the LCA approach used to assess the potential impacts of the 2-MW GridStreamer™ turbines, which represents a state-of-the-art approach to LCA modelling of wind power. The LCAs are based on highly detailed LCI component models (of around 25,000 parts per turbine and covering the entire wind power plant), allowing detailed and transparent product analysis, as well as using industry-published LCI datasets and current best practice for methodological choices for life cycle modelling, such as recycling approach, and the application of established mid-point impact characterisation (CML 2009) models. Alternative approaches to LCA modelling (for example, input–output LCA, hybrid LCA or future LCSA methods) may also be useful, as well as some additional areas where further sensitivity analysis could improve presentation of results, e.g. to show results for avoided-impact versus recycled-content crediting approaches at end-of-life and to include additional sensitivity analysis for other studies where only ‘estimated’ capacity factors have been used. Additionally, to improve standardisation of LCA studies, we recommend that wind turbines are only compared within equal (IEC) wind classes, as well as including appropriate sensitivity analysis in the LCAs in order to assess primary assumptions and uncertainties. In terms of non-traditional LCA impact results, the measure presented here of net-return-on energy provides a real-life indicator for the electrical energy performance of the wind turbine, which correlates to a contribution between 22 and 30 times more energy back to society as a whole, than is consumed by the wind plant over the life cycle. The current LCAs also demonstrate an improvement in LCA application over previous studies of wind power, from a perspective of both transparency, as well as comprehensiveness of LCA modelling. Lastly, the article discusses some further applications of using LCA as a tool for both internal and external business processes, for example, to direct product improvements and for external communications, as well as highlighting improved transparency and robustness.

References

Atherton J (2006) Declaration by the metals industry on recycling principles. Int J Life Cycle Assess 12(1):59–60

Berger M, Finkbeiner M (2010) Water footprinting: how to address water use in life cycle assessment? Sustainability 2(4):919–944

Chen Z (2011) Global rare earth resources and scenarios of future rare earth industry. J Rare Earth 29(1):1–6

CML (2009) CML 3.6 developed by the Centre for Environmental Studies (CML). November 2009. University of Leiden, The Netherlands. http://cml.leiden.edu/software/data-cmlia.html. Accessed October 2011

Crawford RH (2009) Life cycle energy and greenhouse emissions analysis of wind turbines and the effect of size on energy yield. Renew Sustain Energy Rev 13(9):2653–2660

Davidsson S, Höök M, Wall G (2012) A review of life cycle assessments on wind energy systems. Int J Life Cycle Assess. doi:10.1007/s11367-012-0397-8

Delaney K (2010) Rare earth supply and national security & clean energy, TREM 10. Understanding the fundamentals, Hilton Washington Embassy Row, March 17, 2010. Rare Earth Industry and Technology Association (REITA)

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J Life Cycle Assess 9(3):161–171

Elsam (2001) Life cycle assessment of turbines. Report 01-488 (no. 138094) from July 2001. Elsam Engineering A/S, Denmark

Elsam (2004) Life cycle assessment of offshore and onshore sited wind farms. Doc. no. 200128. Elsam Engineering A/S, Denmark. www.vestas.com/en/about-vestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

Envirodec (2007) Product Category Rules (PCR) for preparing an Environmental Product Declaration (EPD) for electricity, steam, and hot and cold water generation and distribution. PCR CPC 17. Version 1.1, 2007-10-31

Envirodec (2011) Product Category Rules (PCR) for preparing an Environmental Product Declaration (EPD) for electricity, steam, and hot and cold water generation and distribution. PCR CPC 17. Version 1.1, 2007-10-31

Eurofer (2009) Life cycle inventory study on stainless steel production in the EU, November 2009. European Confederation of Iron and Steel Industries, Eurofer: www.eurofer.org cited in PE International (2011) GaBi DfX software. PE International, Leinfelden-Echterdingen, Germany

Europe P (2010) PlasticsEurope's cycle inventory datasets cited in PE International (2011) GaBi DfX software. PE International, Leinfelden-Echterdingen, Germany

European aluminium association (2008) EAA environmental profile report for the EU aluminium industry, EAA, April 2008 cited in PE International (2011) GaBi DfX software. PE International, Leinfelden-Echterdingen, Germany

Finnveden G (2005) The resource debate needs to continue. Int J Life Cycle Assess 10(5):372

Finnveden G et al (2009) Recent developments in life cycle assessment. J Environ Manage 91(1):1–21

Goedkoop M, Spriensma R (1999) The eco-indicator 99—a damage oriented method for life cycle impact assessment. PRe´ Consultants, Amersfoort, The Netherlands

Goedkoop M, Heijungs R, Huijbregts MAJ, De Schryver AM, Struijs J, van Zelm JR (2009) ReCiPe 2008—a life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level, 1st ed.; Report I: Characterisation, 2009. Available at www.lcia-recipe.net/

Guinée JB, Heijungs R, Huppes G, Zaagmo A, Masoni P, Buonamici R, Ekvall T, Rydberg T (2011) Life cycle assessment: past, present, and future. Environ Sci Technol 45(1):90–96

Höök M, Li J, Johansson K, Snowden S (2012) Growth rates of global energy systems and future outlooks. Nat Resour 21(1):21–41

IEC (2005) INTERNATIONAL STANDARD, IEC 61400-1: wind turbines—part 1: design requirements. Third edition 2005-08. International Electrotechnical Commission, Geneva, Switzerland

International Energy Agency (2006). Focus on clean coal. International Energy Agency, Paris, France. www.iea.org/work/2006/gb/papers/focus_on_coal.pdf. Accessed March 2012

ISO (2006a) ISO 14040. Environmental management—life cycle assessment—principles and framework (second edition, 2006-07-01). Geneva, Switzerland

ISO (2006b) ISO 14044. Environmental management—life cycle assessment—requirements and guidelines (first edition, 2006-07-01). Geneva, Switzerland

ISO (2006c) ISO 14025:2006 environmental labels and declarations—type III environmental declarations—principles and procedures. Geneva, Switzerland

PE International (2010) Life cycle inventory datasets for neodymium and dysprosium metal production. PE International, Leinfelden-Echterdingen, Germany

PE International (2011a) Life cycle assessment of electricity production from a V112-3.0 MW wind plant—February 2011. PE International, Leinfelden-Echterdingen, Germany. www.vestas.com/en/aboutvestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

PE International (2011b) GaBi DfX software. PE International, Leinfelden-Echterdingen, Germany

Vestas (2006a) Life cycle assessment of electricity produced from onshore sited wind power plants based on Vestas V82-1.65 MW turbines. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. www.vestas.com/en/about-vestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

Vestas (2006b) Life cycle assessment of offshore and onshore sited wind power plants based on Vestas V90-3.0MW turbines. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. www.vestas.com/en/about-vestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

Vestas (2011a) Life cycle assessment of electricity production from a V80-2.0MW Gridstreamer wind plant—December 2011. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. www.vestas.com/en/about-vestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

Vestas (2011b) Life cycle assessment of electricity production from a V90-2.0MW GridStreamer wind plant—December 2011. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. www.vestas.com/en/about-vestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

Vestas (2011c) Life cycle assessment of electricity Production from a V100-1.8MW GridStreamer wind plant—December 2011. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. www.vestas.com/en/about-vestas/sustainability/wind-turbines-and-the-environment/life-cycle-assessment-(lca).aspx. Accessed October 2011

Vestas (2012a) Vestas signs 56MW order in Italy. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. www.vestas.com/Default.aspx?ID=10332&action=3&NewsID=3013. Accessed March 2012

Vestas (2012b) Vestas by numbers. Vestas Wind Systems A/S, Alsvej 21, 8900 Randers, Denmark. http://data.vestas.com. Accessed October 2011

Worldsteel (2010) Worldsteel life cycle inventory study for steel industry products. World Steel Association. www.worldsteel.org cited in PE International (2011) GaBi DfX software. PE International, Leinfelden-Echterdingen, Germany

WWEA (2011) World wind energy report 2010. World Wind Energy Association. April 2011. www.wwindea.org/home/images/stories/pdfs/worldwindenergyreport2010_s.pdf. Accessed October 2011

Acknowledgments

We thank Prof. Dr. Matthias Finkbeiner (chairman of Sustainable Engineering, Department of Environmental Technology, Technische Universität Berlin and chairman of ISO TC207 SC5 Life Cycle Assessment) for his expert review of the LCAs in accordance with paragraph 6.2 of ISO 14040/44. He acted as a consultant in this capacity and did not represent his employer. We also thank the reviewers during the submission of the manuscript to the International Journal for LCA for their valuable and constructive comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Matthias Finkbeiner

Rights and permissions

About this article

Cite this article

Garrett, P., Rønde, K. Life cycle assessment of wind power: comprehensive results from a state-of-the-art approach. Int J Life Cycle Assess 18, 37–48 (2013). https://doi.org/10.1007/s11367-012-0445-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-012-0445-4