Abstract

Purpose

Life cycle assessment (LCA) is a tool that can be utilized to holistically evaluate novel trends in the construction industry and the associated environmental impacts. Green labels are awarded by several organizations based on single or multiple attributes. The use of multi-criteria labels is a good start to the labeling process as opposed to single criteria labels that ignore a majority of impacts from products. Life cycle thinking, in theory, has the potential to improve the environmental impacts of labeling systems. However, LCA databases currently are lacking in detailed information about products or sometimes provide conflicting information.

Method

This study compares generic and green-labeled carpets, paints, and linoleum flooring using the Building for Environmental and Economic Sustainability (BEES) LCA database. The results from these comparisons are not intuitive and are contradictory in several impact categories with respect to the greenness of the product. Other data sources such as environmental product declarations and ecoinvent are also compared with the BEES data to compare the results and display the disparity in the databases.

Results

This study shows that partial LCAs focused on the production and transportation phase help in identifying improvements in the product itself and improving the manufacturing process but the results are uncertain and dependent upon the source or database. Inconsistencies in the data and missing categories add to the ambiguity in LCA results.

Conclusions

While life cycle thinking in concept can improve the green labeling systems available, LCA data is lacking. Therefore, LCA data and tools need to improve to support and enable market trends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Homeowners are key players in the residential building sector as they engage in a greater role in the decision making process regarding the location of project, type of construction, selection of building products, and in the ultimate use of their homes (Martin et al. 2007). Adoption of emerging and novel products is higher among single family custom home builders, multifamily builders, and national and regional builders when compared with other industries such as commercial builders (Koebel et al. 2004). A number of consumers care about the environmental and social impacts of the products they purchase and would prefer to buy green (McGraw-Hill 2010). But when it comes to actually selecting green products, consumers are uninformed about the products available and often question the reliability and quality over their traditional counterparts. Additionally, consumers are increasingly suspicious about the environmental claims of the manufacturer (Bonini and Oppenheim 2008).

While the green building materials industry has flourished, the labeling of green materials is disparate, confusing, and complex. Many certification programs are available for various products used in buildings such as Green Seal, Energy Star, the Carpet, and Rug Institute green label, Blue Angel, and many others (CRI 2010; EPA and DOE 2009; GreenSeal 2008; RAL gGmbH 2010). Many labels, such as flammable and toxic, are often based on single criteria and may be required by law for a product (James 1997). Marketing schemes often involve product information with generic claims of environmentally safe, recyclable, and biodegradable (Howett 1991).

Green labels are available for a variety of products used in buildings. The products evaluated for this research were carpets, paints, and linoleum flooring. Homeowners are most concerned with the indoor environmental quality of their residences; carpets, paints, and linoleum flooring are target products for improving air quality in homes. The three different products listed have varied labeling systems, though the emissions testing method for some labels might be the same with separate requirements for achieving the respective label.

Most labels are voluntary, third-party certifications, which mean they require an impartial organization to review the products that willingly choose their label. Some labels establish minimum content or emissions requirement for certain compounds like VOCs, formaldehyde, and other harmful items used either in manufacturing of the product or in some cases emitted when the product is in use. Some green labeling organizations like the National Sanitation Foundation (NSF) have various levels of labeling such as platinum, gold, and silver with platinum being the highest level a building product manufacturer can obtain and provide labels based on several criteria (NSF 2010). Table 1 provides a summary of the various labels available for carpets, paints, and linoleum flooring.

Given the confusing labeling systems, we investigated the potential use of life cycle assessment (LCA) to guide the development of green building product labels. A major criterion of this analysis is using current, off-the-shelf LCA data tools. We believe using current data and tools is important as we are at a critical point in the relationship between green building products (and labeling) and LCA. Basically, the green building market is growing (Construction 2010), and it is important to understand if LCA is leading or following the market.

LCA is a tool used to assess the environmental impacts of any product, process, or service. It is a cradle to grave tool that is can be used to evaluate complex systems such as buildings. Based on the International Organization for Standardization (ISO) 14040 series, LCA has four steps: (1) goal and scope identification, (2) life cycle inventory (LCI), (3) life cycle impact assessment (LCIA), and (4) interpretation (ISO 2006). Inventory data are collected from various databases and sources reflecting inputs to the system and outputs such as emissions. These inventory items are expressed as environmental impacts during the LCIA phase. The final step is to analyze the results and select the preferred product or process based on the generated results.

Tools such as LCA may help in overcoming some of the problems that might be created due to the increased construction activities of buildings. Buildings provide an opportunity for reducing greenhouse gases. Of the total building stock of 300 billion ft2, annually, 1.75 billion ft2 is demolished and 5 billion ft2 is renovated, and another 5 billion is newly constructed (Architecture 2030 2009). Previous LCA studies on buildings have focused on data available from existing projects (Guggemos and Horvath 2003; Junnila et al. 2006; Keoleian et al. 2000). Though these studies have shown which phases of the life cycle are energy intensive, they sometimes neglect the importance of other phases such as construction that are equally important (Bilec et al. 2006; Sharrard et al. 2008). The results from the aforementioned studies cannot be replicated in residences in a diverse geographic location with varied square footage and construction methods and using different materials. The studies are too case specific or focus on just one phase of the life cycle, leading to different results every time a study is conducted because each LCA uses a different method for assessing the environmental impacts of the structure. There is some consensus among reported building LCAs: the use phase is consistently the most energy intensive phase. As energy performance of buildings continues to improve, especially in the context of net-zero energy buildings, the energy, and environmental impact other building phases (e.g., materials) will have increasing importance.

One LCA means for selecting and evaluating products is the Building for Environmental and Economic Sustainability (BEES) tool created by National Institute of Standards and Technology (Lippiatt and Boyles 2001). BEES has a database of 280 building products to assist in selecting cost-effective and potentially green products. The tool is primarily useful for evaluating products during the manufacturing phase and has limited information in other phases such as installation, use, and maintenance.

Adopting an LCA-based approach for labeling of green products has the potential to boost the confidence of consumers, ultimately leading to increased use of green products in residential buildings. In general, LCA is often accepted as a method, but data availability is lacking. The presence of a variety of databases with different assumptions, boundaries, and location specific data leads to confusion about selection of appropriate data. The results of different LCA studies with diverse boundaries and assumptions lead to inconsistent results, causing doubts in the minds of the consumer about the authenticity of the products' green claims. We examined: labels, LCA method, and current databases. Further, we investigated if by using LCA we could elucidate whether a product labeled “green” exhibited improved life cycle environmental performance when compared with its traditional counterpart.

For this research, we used a previously developed life cycle template for residential structures (Rajagopalan et al. 2010) and analyzed life cycle results for generic and green-labeled building products of carpets, paint, and linoleum flooring to determine how effective LCA is in evaluating the products. Further, LCIs for the products were developed from different databases in order to evaluate the effect of different data sources on the resulting greenness of the products (e.g., ecoinvent (Frischknecht 2005) and environmental product declarations).

2 Method

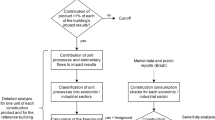

This study used publicly available databases to analyze various products and compare their LCA results. Products were compared gate to gate on 1-ft2 bases and also as integrated into a building assessment. “Publicly available” is defined herein as tools that can be easily downloaded or installed without a fee. Generic and green-labeled products were selected from BEES and comparative LCAs were performed to analyze if the products were deemed green or not. The method used by the authors is given below with a detailed description.

We used the green product-labeling grid developed by the Green Building Alliance (GBA) as a key to identify labels and corresponding products (GBA 2011). The green product-labeling grid lists many labels and certifications available for building products. Selection of products under consideration were based on several factors: (1) robustness of labeling system (e.g., multi- or single attribute, number of registered products), (2) current LCA data for a given green and traditional product, and (3) relevance to residential market place. For example, carpets have two or more labels available: Green Label/Green Label Plus and NSF-140 for carpets. Green Label/Green Label Plus focuses only on a single attribute (indoor environmental quality) for awarding labels to the products while NSF-140 is a multi-attribute standard. The main focus of single-attribute labels for carpets is indoor environmental quality while the multi-attribute standard follows LCA principles in its labeling process. The LCA data availability for carpets lead to the selection of BEES database. Based on these factors, the products were selected for analysis and shown in Table 2, column 1.

To evaluate the greenness of the product with LCA, data for 1 ft2 of the building product was obtained from the LCA database, BEES, a collection of product data obtained directly from manufacturers. Some manufacturers obtain green labels for their products and share their green-labeled product data. Such green-labeled products were compared with generic products available in BEES. When green-labeled products manufactured by renowned manufacturers was not available, green products were selected on the basis of recycled content in the product based on the assumption that products with recycled content utilize less virgin materials and are generally considered green. This method for analysis for products without associated green labels has certain drawbacks. The products have not gone through a rigorous labeling process and their comparison with other products is on the basis of a single attribute that an associated green label might consider. Due to lack of availability of appropriate data, the products without any green labels associated with them were used as a proxy.

Building products were also evaluated in a home and to compare them on a whole home level in addition to the product level to determine the relative LCA impacts. A previous study by the authors had compared homes made of different building products and materials. Rajagopalan et al. (2010) conducted an LCA case study comparing wall sections made of different materials. A comparative LCA was performed on a 2,450-ft2 home constructed from a building product called insulating concrete forms and a traditional wood home. The residential life cycle study was divided into five phases: raw materials extraction and manufacturing, transportation, construction, use, and end of life of home. Gate to gate LCAs on 1 ft2 of carpets, paints, and linoleum flooring was converted to 2,450-ft2 home LCAs by calculating the product impacts on a 2,450 two-storey home and adding the whole home impacts calculated by Rajagopalan et al. (2010) to the product impacts.

Finally, results were compared with other data sources of Interface Environmental Product Declarations (EPD) (TheGreenStandard.com 2010) and ecoinvent (Frischknecht 2005) to evaluate how the green-labeled products weighed against products from other data sources. The products selected for comparison are discussed below in detail, and Table 1 shows the products and databases utilized to construct LCIs.

2.1 Building product description

2.1.1 Carpets

BEES data was utilized to develop the LCA for generic and green carpet tiles. The carpet tile products selected were an anonymous carpet tile (environmental code C3020S), Bentley Prince Street's BPS UPC carpet tile (environmental code C3020VV), C&A ER3 modular tile (environmental code C3020X), and C&A Ethos modular tile (environmental code C3020Z). These aforementioned products referred to as “generic” for anonymous carpet tile and “green” carpet tile respectively for the other three carpet products were compared for their environmental performance based on 1 ft2 of material. The boundary for the “green” BPS UPC carpet tile inventory included the manufacturing phase, transportation of materials from manufacturing plant to construction site, use of carpet tile with a lifetime of 15 years and replaced three times over a 50-year use period of a home, and the end of life with almost 12.5 % of old carpet tiles reclaimed. BEES did not provide information for the anonymous “generic” carpet tile with respect to system boundary, data, and the life cycle phases included. All the products manufactured by BPS are certified to meet the Carpet and Rug Institute's Green Label Plus and all products also achieve the NSF-140 Sustainable Carpet Assessment Standard at the Platinum level according to the BPS website (BPS 2012).

The boundary for the “green” C&A ER3 and Ethos modular tiles inventory included the manufacturing, transportation of materials from manufacturing plant, use of carpet with a lifetime of 15 years and end of life with 100 % recyclable in the company's in-house recycling process. The products manufactured by the manufacturer are certified with Green Label Plus and the products also achieve the NSF-140 Sustainable Carpet Standard (Tandus 2011).

For comparing BEES data with other sources, EPD for Interface carpets was used (TheGreenStandard.com 2010). All products manufactured by the company obtain the Green Label/Green Label Plus and NSF-140 labels (Interface 2012). The Interface EPD uses a life cycle approach to analyze 1 m2 of carpet. The EPD LCIA results were analyzed using TRACI (Bare et al. 2003) and CML 2002 environmental impact methods (CML 2012).

2.1.2 Paints

The LCI for the paint products were obtained from BEES and evaluated on a functional unit of 1 ft2 of paint used for interior walls. The paint products compared were generic virgin latex paint (environmental code C3012A), generic consolidated latex paint (C3012B), and generic reprocessed latex paint (C3012C). The first product, generic virgin latex paint, is made with virgin materials while the rest have recycled and post-consumer inputs in their manufacturing processes. The products are referred to as generic, green reprocessed (76 % post-consumer (PC)) and green consolidated (99 % PC) latex paint. The LCI phases included were raw materials extraction, manufacturing, transportation, and use phase. For the end of life, the paint was disposed in a landfill along with the surface it was painted on. During the use phase, the assumption of repainting every 4 years was made thus leading to 12 additional coats for a lifetime of 50 years of a home.

The generic virgin latex paint was compared with paint product from ecoinvent (Frischknecht 2005). The paint product selected for comparison was alkyl paint with 60 % water. Due to unavailability of data for a direct water-based paint comparison, the available data from ecoinvent was used. The LCIA results using TRACI for alkyl paint was compared with the generic virgin latex paint.

2.1.3 Linoleum flooring

Product level assessments of linoleum flooring were conducted using the linoleum flooring options available in BEES. The products compared were generic linoleum flooring (environmental code C3020B) and Forbo linoleum flooring (environmental code C3020R). Forbo linoleum flooring has the SMART certification (MTS 2010). The phases included in the LCA of 1 ft2 of flooring were raw materials extraction, manufacturing, and transportation, and use phase of 30 years. For the end of life, it was assumed that linoleum was transferred to a landfill.

Three products with a variety of labels and data sources are discussed in the Section 2. Table 2 provides a list of all the products, green labels, and data sources discussed in the paper.

3 Results

For all products evaluated, the LCA results are normalized to the maximum contributor in each impact category (Figs. 1, 2 and 3). The comparative results of generic and green carpet tiles show that the green carpet tile is environmentally preferable than the generic carpet tile in all impact categories except eutrophication, fossil fuel depletion, water intake, and human health (see Fig. 1). All carpet tiles have similar impact in the indoor air quality category; this is surprising given that indoor air quality, here measured as VOC emissions, is a significant attribute of a green carpet. The BEES database does not provide information on the generic carpet tile but the Bentley Prince Street carpet manufacturers and the C&A carpet manufacturers supplied data for the green carpet tile.

We analyzed the fossil fuel depletion and global warming profiles of the carpets in detail. Generally, the fossil fuel depletion profiles of products are expected to parallel global warming. But these results are contradictory to this premise. The inventory obtained shows that the BPS UPC green carpet tile has higher total fossil fuel depletion (11.2 MJ) when compared with the generic carpet tile (7.01 MJ). But the carbon dioxide (CO2) emissions from fossil fuel depletion do not follow this trend. The BPS UPC green carpet tile has slightly lower fossil CO2 emissions (4.3 kg) as opposed to the generic carpet tile (5.3 kg). The C&A green carpet tiles have lower fossil fuel depletion and low global warming potential as expected. According to the BEES manual, fuel extraction process is not included in the fossil fuel depletion category but it is captured in the global warming category and the fossil fuel depletion category only represents the quantity of fuel extracted while the characterization factors remain constant for the fuel. Based on this information, the fossil fuel depletion for the generic carpet tiles is lower because it uses larger quantities of coal whose characterization factors is lower (0.25 MJ/kg) and the BPS UPC green carpet tile uses higher quantities of natural gas and oil whose characterization factors are higher (7.8 and 6.12 MJ/kg).

Other inconsistencies in results occur in the water intake category where green carpet tiles have higher impacts than the generic carpet tiles. This impact category is not characterized through the TRACI impact assessment method but represents direct inventory water use. The inventory shows that the BPS UPC green carpet tile uses approximately 40 times more water and the C&A green carpet tiles use five times more water than the generic carpet tile. No justification is provided in the BEES LCI about the data presented.

The BEES weighting system did not have a significant impact on the results. To understand the effects of weighting on results was conducted by changing the BEES weighting system to an equal weighting system (with all categories equal to one), EPA scientific advisory board weighting, and a user defined weighting to analyze the difference in results. The results changed less than one percent in each category when the weighting system was changed from BEES stakeholder panel to EPA scientific advisory board weighting and no change was observed when the user defined weighting system was used.

For paints, the normalized environmental impacts (see Fig. 2) of generic latex paint are higher than the other two products when 1 ft2 of wall paint is the functional unit in all impact categories except global warming where green latex paint with 76 % PC materials has the highest impact. The green latex paint might be perceived to have lower impacts especially in global warming but the results show otherwise. This disparity is caused by the manufacturing process for the green paint with PC products which is different from the paint made with virgin materials. The perception that paint with 99 % PC materials will have lower impacts than paint with lower percent of PC materials is inconsistent with respect to global warming. The counterintuitive results for paints in the fossil fuel depletion and global warming categories are consistent with the carpet tiles results. Here again, changing the weighting does not change the results significantly.

In the case of linoleum flooring, green linoleum flooring performs better in all categories except human health cancer (see Fig. 3). Notably, there is an insignificant difference between green and generic linoleum flooring in smog and water intake categories. The counterintuitive trends seen for carpets and paints in the fossil fuel depletion and global warming categories are not observed in linoleum flooring.

Next, we examined the relative importance of green products in the overall life cycle of a residential home. For carpets, the 1-ft2 results were scaled up to the total carpet area required for a 2,450-ft2home and the LCA results of carpet tiles were added to the LCA results of a whole home using the aforementioned residential life cycle study (Rajagopalan et al. 2010). Similarly, for paint and linoleum flooring, the functional units were scaled up to a whole home and added to the residential life cycle model. The comparisons of the carpet tiles assessed from the perspective of a whole house shows that the impacts of carpets are overshadowed by the use phase of the entire house; as shown in Table 3, the GWP of carpets contributes less than one percent to the total GWP of the house. Similar impacts are noticed in the smog impacts (see Table 3) where the impact of all building products is less than 1 % to the total home smog impacts. Only two categories (global warming and smog) are illustrated as representative of the entire home impacts. The impacts of flooring are also insignificant when compared to the impacts of the entire home. The use phase of an entire home dominates over the life cycle of specific products such as carpet tiles, paints, and linoleum flooring.

When the products are compared on an individual basis, for example, when generic carpet tile is compared with a green carpet tile, the impacts of generic carpet tile are higher. But when the impacts are scaled up to the whole home, the home impacts are two to five orders of magnitude higher than the building product impacts. The results are shown in Table 3 where the impacts of the building products have negligible impacts in comparison to the impacts of the home.

The BEES database provides only one data point for comparing green and non-green products. A comparison of results was performed to illustrate the differences in the LCA data from other databases. Since a variety of databases are used in this study, only acidification, eutrophication, global warming, and smog categories could be compared across the products as these are the only common categories. The results in Fig. 4 are normalized to the highest value from a database in the impact category for a product. For comparing carpet results, Environmental Product Declarations (EPD) by carpet manufacturing companies such as Interface was used (TheGreenStandard.com 2010). For paint, the comparison was performed using data from other databases such as ecoinvent (Frischknecht 2005). The BEES data for carpet tiles is provided by Bentley Prince, a sister company of Interface Carpets. The data may not be comparable for both products as they are not exactly the same, but other data was not available.

The BEES database and Interface EPD have similar results for acidification, eutrophication, and global warming categories. But the smog result from Interface is insignificant when compared with the BEES data for carpet tiles. Differences in manufacturing process may lead to higher or lower impacts in the categories but both the data points have dissimilar results in smog whereas other impact categories correlate.

For paints, the only data available yielded unequal comparison. As the analysis shows, the ecoinvent data has insignificant impacts in all categories compared. Insufficient data prohibits the authors from including additional data points for comparisons for both paints and carpets. Rajagopalan et al. (2010) have shown how unrelated and isolated processes contribute the maximum to a unit process and cause ambiguity in the LCA results. An approach where every process can be modeled and the whole process diagram of a product can be controlled needs to be built-in to every database.

4 Discussion

Life cycle thinking, in theory, has the potential to guide the development of green product labeling systems, but current state of LCA leads to results that are uncertain and strongly dependent upon the source or database. Inconsistencies in the data and missing categories add to the ambiguity in LCA results. While life cycle thinking in concept can improve green labeling systems, LCA data is lacking. For example, the products pertaining to this research were selected on the basis of labeling systems (e.g., Green Label Plus for carpets, a single attribute label) their relevance to the residential building sector, and availability of data in the current LCA databases. The LCA results had inconsistencies in several impact categories such as fossil fuel depletion, global warming, indoor air quality, and water intake. The green products, even though labeled green by single and multi-attribute labels and standards, did not always have lower impacts than its non-green counterparts. As already shown in Table 1, several standards use a life cycle approach but the fact remains that the current databases available for LCA do not provide a consistent labeling platform. LCA and green building design has been successful, especially in Europe, where data is collected through EPDs and then made available to the general public.

Green products will be used in a building, and when compared to the whole life cycle building impacts, many of the product impacts are minimal, but are still a part of the entire life cycle and should not be discounted. Some of the most toxic or human health impacts can occur during the manufacturing phase, while the energy use and associated greenhouse gases occur during the use phase. Therefore, all categories and all phases need to be considered. Product level/cradle to gate LCAs are an important part in understanding the product as a whole but a move towards systems level LCAs for labeling will help in incorporating all aspects of the product such as the manufacturing of the product itself and its use in a building and its disposal or reuse along with other building products.

5 Conclusions

LCA data and tools need to improve to parallel or exceed market trends. Further, LCAs results vary depending on the boundary, database, and functional unit selected, and the filtering of the inventories and impact assessment methods takes a considerable amount of time, which the average homeowner (or designer) typically lacks. Statistical models that address the uncertainty associated with data should be incorporated into the labeling process. Decision makers are concerned with the possible ranges of outcomes for their actions (Sugiyama et al. 2005). Including uncertainty into the LCI process and into green labels may help in the understanding the green claims of a product. Developing manufacturer-based LCA tools and databases in parallel with green labels may help to improve the consistency of labels. The US market, which is primarily the focus of this study, can look toward the success of the European market.

To incorporate LCA-based labeling, more detailed information about the variety of building products and their manufacturing process needs to be documented. Improving the quality of data will help in reducing uncertainty in the labeling system. A move towards ISO 14001 standards for labeling was studied previously and it was found that having an ISO standard instead of an ecolabel does not oversimplify the product and provides room for changes and alterations in the future, thus using a holistic approach (Ball 2002).

Revamping the entire labeling process is an exercise which will lead to a lot of confusion owing to the use of labeled products in several buildings. But inclusion of LCA in the labeling process, as already discussed, is a good practice. The authors propose the following changes to improve the labeling systems for building products:

-

A label should at the least be a multi-attribute label with an LCA component in the labeling process. There are already some standards which are multi-attribute and the authors propose that all green labels adopt the standard for their labeling process.

-

The LCA results are an important part of the labeling process and they should be accessible to all consumers. The system boundaries, databases used, the assumptions made to conduct the LCA and an explanation of the results should be transparent and accessible according to ISO EPD reporting protocol.

-

LCA signage similar to the one proposed in Table 2, column 6 will provide information on the pros and cons of the product and the consumer can decide on the product of their choice based on their preferences.

-

A transparent labeling process will prevent doubts about green claims made by the manufacturer and help in providing more information to the consumer, the decision maker in the purchase of green products.

References

Architecture 2030 (2009) Climate change, global warming and the built environment- 2030. Architecture 2030, Inc. Santa Fe, NM. www.architecture2030.org

Ball J (2002) Can ISO 14000 and eco-labelling turn the construction industry green? Build Environ 37:421–428

Bare J, Norris G, Pennington D, McKone T (2003) The tool for the reduction and assessment of chemical and other environmental impacts. J Ind Ecol 6:49–78

Bilec M, Ries R, Matthews HS, Sharrard AL (2006) Example of a hybrid life-cycle assessment of construction processes. J Infrastruct Syst 12:207–215

Bonini S, Oppenheim J (2008) Helping “green” products grow. McKinsey Quarterly, October 2008

BPS (2012) Bentley Prince Street-Home. The Green Standard Environmental Product Declaration System. www.bentleyprincestreet.com

CML (2012) Heijungs R. CMLCA:scientific software for LCA. Leiden University. www.cmlca.eu

Construction MH (2010) Green source: the magazine of sustainable design. McGraw Hill Construction

CRI (2010) Green label/green label plus. Carpet and Rug Institute

DGS (2011) California gold sustainable carpet standard. California Department of General Services

EPA, DOE (2009) Energy Star. EPA & DOE

Frischknecht R (2005) Ecoinvent data v1.1 (2004) from heterogenous databases to unified and transparent LCI data. Int J Life Cycle Assess 10:1–2

GBA (2011) Green buildings product initiative. Green Building Alliance. www.gbapgh.org

Greenguard (2012) GREENGUARD Environmental Institute- Certifying low-emitting Products, creating healthier indoor environments. www.greenguard.org

GreenSeal (2008) Green seal™ environmental standard for paints and coatings. Green Seal, Washington, DC

Guggemos AA, Horvath A (2003) Strategies of extended producer responsibility for buildings. J Infrastruct Syst 9:65–74

Howett C (1991) The green labeling phenomenon: problems and trends in the regulation of environmental product claims. Va Envtl LJ 11:401

Interface (2012) InterfaceFLOR. Interface Global. www.interfaceflor.com

ISO (1997) Environmental management-life cycle assessment- principles and framework. ISO 14040. In International Organization for Standardization. Switzerland

ISO (2006) ISO 14040- environmental management- life cycle assessment- principles and framework. In International Organization for Standardization. Switzerland

James S (1997) Informing the green consumer: the debate over the use and abuse of environmental labels. J Ind Ecol 1:11–21

Junnila S, Horvath A, Guggemos AA (2006) Life-cycle assessment of office buildings in Europe and the United States. J Infrastruct Syst 12:10–17

Keoleian GA, Blanchard S, Reppe P (2000) Life-cycle energy, costs, and strategies for improving a single-family house. J Ind Ecol 4:135–156

Koebel C, Papadakis M, Hudson E, Cavell M (2004) Diffusion of innovation in the residential building industry. HUD's Office of Policy Development and Research and Partnership for Advancing Technology in Housing (PATH)

Lippiatt B, Boyles A (2001) Using BEES to select cost-effective green products. Int J Life Cycle Assess 6:76–80

Martin J, Swett B, Wein D (2007) A market engagement framework for developers and builders. Erb Institute for Global Sustainable Enterprise, University of Michigan, Ann Arbor, MI

MBDC (2010) Cradle to cradle design. McDonough Braungart Design Chemistry. www.mbdc.com

McGraw-Hill (2010) Green source: the magazine of sustainable design. McGraw Hill Construction

MTS (2010) SMART consensus sustainable products standards market transformation to sustainability

NSF (2010) NSF-140 sustainable carpet assessment standard. NSF International/ANSI

Rajagopalan N, Bilec MM, Landis AE (2010) Residential life cycle assessment modeling: comparative case study of insulating concrete forms and traditional building materials. J Green Build 5:2–13

RAL gGmbH (2010) The Blue-Angel eco-label with brand character. Healthy living with the Blue Angel. www.blauer-engel.de

RFCI (2012) Resilient Floor Covering Institute. www.rfci.com

SCS (2010) Recycled Content Certification Scientific Certification Systems

SCS (2011a) SCS Sustainable choice. Scientific certification systems

SCS (2011b) Environmentally preferable products. Scientific certification systems

SCS (2012) Indoor Advantage™ Gold Scientific Certification Systems

Sharrard AL, Matthews S, Reis R (2008) Estimating construction project environmental effects using an input–output-based hybrid life-cycle assessment model. J Infrastruct Syst 14:327–336

Sugiyama H, Fukushima Y, Hirao M, Hellweg S, Hungerbühler K (2005) Using standard statistics to consider uncertainty in industry-based life cycle inventory databases. Int J Life Cycle Assess 10:399–405

Tandus (2011) Tandus flooring. Tandus flooring

The Home Depot (2010) Eco options. The Home Depot. www.homedepot.com

TheGreenStandard.com (2010) InterfaceFLOR environmental product declaration in accordance with ISO 14025. LaGrange, Georgia

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Martin Baitz

This research was conducted when the authors were at University of Pittsburgh.

Rights and permissions

About this article

Cite this article

Rajagopalan, N., Bilec, M.M. & Landis, A.E. Life cycle assessment evaluation of green product labeling systems for residential construction. Int J Life Cycle Assess 17, 753–763 (2012). https://doi.org/10.1007/s11367-012-0416-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-012-0416-9