Abstract

Purpose

The goal of this study was to use life cycle assessment (LCA) methodology to assess the environmental impacts of industrial and institutional cleaning products that are compliant with the Green Seal Standard for Cleaning Products for Industrial and Institutional Use, GS-37, and conventional products (non-GS-37-compliant) products.

Methods

The scope of the study was “cradle-to-grave,” to encompass the energy and material resources required for the production of raw material and packaging components to use and final disposal of the cleaning product. The generic functional unit for this study was annual cleaning of 100,000 ft2 of office space. The ReCiPe 2008 Midpoint (hierarchist perspective) impact assessment methodology was used including the following impact categories: climate change, ozone depletion, photochemical oxidant formation, particulate matter formation, human toxicity, terrestrial acidification, freshwater eutrophication, freshwater ecotoxicity, agricultural land occupation, natural land transformation, water depletion, and fossil depletion. General-purpose, glass, and restroom cleaning products were included in the study. Model products of GS-37-compliant, conventional concentrate, and conventional ready-to-use versions of each cleaning product were evaluated in the study.

Results and discussion

The conventional ready-to-use industrial and institutional cleaning product had the highest environmental impact in all product types and for the most impact categories analyzed. The GS-37-compliant products were lower than the conventional products in most impact categories studied. Furthermore, normalization of the results showed that the impact categories of marine ecotoxicity, human toxicity, and freshwater ecotoxicity were dominant, and the conventional products led these impact categories. The packaging and distribution stages were dominant for the conventional products, whereas the product formula (i.e., chemicals used in the product) contributed significantly to overall impacts for GS-37-compliant products. This is because the GS-37 standard addresses packaging and distribution, but could potentially further address the formula considerations.

Conclusions

The comparative life cycle assessment performed in this study showed that the Green Seal Standard for Cleaning Products for Industrial and Institutional Use, GS-37, identifies products with notably lower environmental impact compared to typical alternatives in the market. This reduced impact was a result of the requirements in the Green Seal standard that addressed the leading sources of the impacts (namely packaging, transportation) and is not included in any other standard or recognition program in North America.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Green Seal is a non-profit organization in North America that has over 30 leadership standards available to guide development of more sustainable products and services and to use in certification to help consumers and purchasers identify more sustainable products and services. The Green Seal Standard for Cleaning Products for Industrial and Institutional (I&I) Use, GS-37 (Green Seal 2009), is the most recognized in government green cleaning programs (ISSA 2009). This standard covers routine cleaning products such as hard surface (floor, glass, and restroom), toilet and urinal, and carpet cleaning products. The market for I&I cleaning products is about $8.8 billion in size (The Freedonia Group 2010). I&I green cleaning products are cost-competitive to conventional options so their use is growing in this market (Espinoza et al. 2010).

There have been only a few studies, such as USEPA (2002) and Koehler and Wildboz (2009), to evaluate life cycle environmental impacts associated with cleaning products. The USEPA (2002) study focused on I&I general purpose cleaning products and identified key considerations of these products that could reduce the life cycle impact of these products. The GS-37 standard aligns with the findings from the USEPA with restrictions on solvent-based ingredients and requiring responsible end-of-life recovery of packaging (e.g., recyclable packaging) and encouragement of the inclusion of post-consumer material in packaging. Koehler and Wildboz (2009) analyzed household cleaning products and concluded that the chemicals used in the products, product packaging, consumer use (amount of water and heating of water), and consumer transport of the products from the store were major drivers of environmental impacts of these ready-to-use products. This study builds off of these existing studies by evaluating the environmental profiles of conventional I&I cleaning products and those that meet the Green Seal GS-37 standard, since the GS-37 standard is widely used in the I&I market to identify preferable products.

2 Goal and scope definition

2.1 Goal

The goal of this study was to assess the environmental impacts of GS-37-compliant and conventional products (non GS-37-compliant) products through life cycle assessment methodology. It was also anticipated that results of the study would be able to provide guidance on environmental hot spots for these products and inform future development of the GS-37 standard.

2.2 Scope

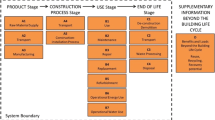

The scope of the study was “cradle-to-grave” which encompassed the energy and material resources required for the production of raw material and packaging ingredients and through to consumer use and final disposal of the cleaning product. The boundaries of this study, the life cycle phases and elements of the cleaning product included and excluded, are summarized in Table 1. The rationale for inclusion or exclusion in the system boundary is elaborated further in the life cycle inventory section of this paper.

General-purpose cleaning products were the focus of this study since they represent a significant proportion of the cleaning product market and Green Seal-certified (to GS-37) products. Two different general purpose formula bases were used for the GS-37-compliant products including a glucoside-based formula and a hydrogen peroxide-based formula to represent the two primary formula chemistries in the market. Both of these formula types were included in the study for compliant general purpose cleaning products. Glass and restroom cleaning products were also studied to note any differences across product categories and product chemistries. The results of these products will be discussed, but not detailed.

The GS-37 standard and its criteria were used to develop the model products for these categories. The criteria that were modeled in this study included: concentration, packaging, and some of the human health and environmental fate requirements. The GS-37 standard requires cleaning products to be sold at minimum concentration levels aimed to reduce packaging, manufacturing, and transportation of the product, whereas conventional products are available in concentrated and ready-to-use (RTU) forms. Therefore, for conventional products, both types of formulas were included in this study. GS-37 has a number of requirements that limit the use of materials that are hazardous to human health and the environment that end up excluding commonly used chemicals in conventional products. Therefore, the formulas of the products in the study differ due to this. There are other requirements in GS-37 that differentiate compliant products from conventional products that were not included in this study. For example, GS-37 requires the use of cold/unheated water for product performance/use, whereas conventional concentrated products often require heated water. The heating of water can be a significant source of impacts (Koehler and Wildboz 2009), but this was not included in this study due to the range of water use and temperatures of heated water. GS-37 does not allow for the use of ingredients that are asthmagens, a growing concern for cleaning products, but there is not a means to model this kind of end point in life cycle assessment. There are additional considerations included in GS-37 that were not included. This study was limited to the requirements in GS-37 that has available data and could be modeled using the life cycle assessment methodology. The result is a conservative estimate of the differences between compliant and conventional products.

2.2.1 Function and functional unit

The primary function of the cleaning products included in this study is to clean soil and dirt in an institutional/office space environment. The plausible secondary functions of these products such as to disinfect or polish were excluded from this study.

The generic functional unit for this study was annual cleaning of 100,000 ft2 of office space (50% hard floor area and 50% carpeted area). The amount of cleaning product needed to clean the office space is represented by the reference flow for each product type, summarized in Table 2 and is from the Green Cleaning Pollution Prevention Calculator (USEPA 2011). The Green Cleaning Pollution Prevention Calculator for the default functional unit stated above provides annual consumption of various types of I&I cleaning products such as floor, carpet, glass, restroom, general purpose, etc.

2.2.2 Temporal coverage

The composition profiles of conventional and GS-37-compliant products represent contemporary products available in the North American market. The LCI data on product ingredients, packaging materials, electricity grid, fuels, and end-of-life management of packaging materials represent the time period from 2003 to present.

2.2.3 Geographical and technological coverage

The composition of the I&I cleaning products, their manufacturing, and the environmental impacts were representative of the current technological mix of the products sold in the North American market.

2.2.4 Life cycle impact assessment methodology

For the purposes of this study, ReCiPe 2008 Midpoint (hierarchist perspective) impact assessment methodology was used (Goedkoop et al. 2009). The following impact categories were studied: climate change, ozone depletion, human toxicity, photochemical oxidant formation, particulate matter formation, ionizing radiation, terrestrial acidification, freshwater eutrophication, marine eutrophication, terrestrial ecotoxicity, freshwater ecotoxicity, marine ecotoxicity, agricultural land occupation, natural land transformation, urban land occupation, water depletion, metal depletion, and fossil depletion.

The characterization factors and normalization/weighting values for the world for ReCiPe Midpoint methodology available in SimaPro 7 LCA software (PRé Consultants) were used. In addition, the results for the cumulative energy demand are also presented. The methodology for estimation of cumulative energy demand (CED) was based on Frischknecht et al. (2007).

2.2.5 Cutoff criteria

In this study, if the flow was less than 1% of the cumulative mass of all inputs and outputs of the LCI model, it may have been excluded, provided its environmental relevance was not of concern. The sum of neglected flows shall not exceed 5% of cumulative mass.

2.2.6 Allocation

The allocation procedures for recycling of packaging materials, as per the ISO 14044 (ISO 2006), were applied in this study. An open-loop approach with no changes in inherent properties of the recycled material was considered for recycling of packaging materials. As a consequence, system expansion and substitution methods were applicable, as per ISO 14044 (ISO 2006). The product system boundary was expanded to include end-of-life recycling, whereby use of primary or virgin materials was substituted by use of secondary or recycled materials. In addition, the environmental burdens associated with recycling were also included.

2.2.7 LCA software and database

The LCA model for each product was created using the SimaPro 7 software (current version 7.2.4) developed by PRé Consultants (PRé Consultants). The databases contained in the SimaPro software provided the LCI data for product ingredients, process and packaging materials, electricity grid, and fuels.

2.2.8 Critical review

The results of the study were provided to an independent expert panel for critical review. The panel consisted of the following members: Jim Darr (USEPA), Justine Weinberg (California Department of Public Health), and Weslynne Ashton (Illinois Institute of Technology).

2.3 Life cycle inventory

2.3.1 Product formula

The product formula stage refers to the chemicals used in the cleaning product. In this study, no primary data on the formulas of the cleaning products was collected from product manufacturers or suppliers. The formulas were based on Green Seal’s extensive research on the market sector. The formulas were not based on any particular product, but were designed to be an aggregate of products. For the GS-37-compliant general purpose cleaning products, two different formula chemistries were studied since the market research suggested these two main paths, glucoside-based and hydrogen peroxide-based. For conventional concentrate products, the representative formula was estimated based upon publicly available data and reference literature (Ahmed 2009; Flick 2006). The formulas for the conventional RTU products were estimated by diluting the conventional concentrate product with the appropriate dilution factor. In the baseline scenario, it was assumed the water content in the product formula was tap water. The formula data for GS-37-compliantFootnote 1 and conventional products are provided in Tables 3, 4, 5, and 6, respectively. The average of the lower and upper bound values of a chemical ingredient were used in the LCA model. The formulas were designed to be model formulas, examples, and any resemblance to a specific product is a coincidence. The LCI data for formula ingredients was selected from the Ecoinvent v 2.2 databaseFootnote 2 available in the SimaPro software. In a case when the Ecoinvent LCI data was a unit process data, the dataset was modified for North American energy boundary conditions. This was achieved by replacing the European electricity and fuels inputs with North American electricity and fuels datasets. It was assumed that technological coverage of European data can be considered representative for North America as well. The transportation distances were not modified in Ecoinvent datasets on account of lack information on distribution supply chain in North America. The 1% cutoff criterion was applied while customizing the Ecoinvent datasets. The cumulative sum of inputs from technosphere which were not customized did not exceed the 5%. If there was no LCI data available for a particular ingredient, proxy datasets were used. In some cases, the proxy dataset of an ingredient was created based upon the stoichiometry of the chemical synthesis to produce the ingredient, provided the LCI datasets for the reactants were available. The selection of the proxy LCI dataset was also done on the basis of similar functional performance, to use an alternate ingredient. The LCI datasets for each cleaning ingredient are provided in Online Resource 1. The transportation of chemical ingredients to the production facility was excluded since there was no data was available on a representative distribution supply chain for cleaning products. The ingredients used as fragrances and dyes in cleaning products were excluded as they are usually less than 1% by mass and also no suitable proxy LCI data was available for these ingredients.

2.3.2 Manufacturing

The GS-37-compliant products were concentrated (see Section 2.3.5) according to the minimum product concentration criterion in GS-37. This was a higher level of concentration than the conventional product since the GS-37 concentration requirement represents the leadership in the market, not the average. There are also many ready-to-use products available as conventional products. As a result, it is anticipated that the manufacturing inputs would be greater for the amount of conventional products used for cleaning the same functional unit. However, no data was collected from compliant and conventional product manufacturers on manufacturing, so production of cleaning product was not included in this study. This ends up being a conservative assumption which would favor the conventional products since it is anticipated that there are more processing inputs (e.g., energy, water) and outputs (e.g., waste) to make the more dilute products.

2.3.3 Packaging

The packaging containers considered for the compliant and conventional products were a 1-gal containerFootnote 3 and a 32-oz spray bottle,Footnote 4 respectively. The primary packaging material for each cleaning product was virgin high-density polyethylene (HDPE)—the same for both the compliant and conventional products. The packaging information was based on Green Seal’s extensive research on the market sector. The HDPE LCI data was Plastics Europe inventory data available through the Ecoinvent database. The packaging LCI data was available as a system process data; therefore, it could not be customized for North American energy boundary conditions. There was no data available on the secondary and tertiary packaging for each product; therefore, they were excluded from the study. Similar to manufacturing, this exclusion would tend to offset higher environmental burdens (more packaging requirement for conventional products for same the functional unit) for conventional products.

2.3.4 Distribution

In the baseline scenario, it was assumed that the finished product gets transported a total distance of 1,600 km. This was roughly estimated to represent the distance from a cleaning product manufacturing facility in the Midwest region of the USA to a final point of use on the East Coast of the USA. A diesel-powered combination truck LCI dataset from USLCI database available in SimaPro was used for modeling the distribution stage.

2.3.5 Use

In the baseline scenario, the compliant products were diluted using tap water. The tap water LCI data from Ecoinvent was modified for North American energy boundary conditions. The dilution factors for each compliant product type were as follows:

-

General purpose—1:32

-

Glass and Restroom—1:16

In the baseline scenario, it was assumed that the dilution ratio of a conventional product was less than the GS-37 requirement (based on market surveys conducting during the development of the concentration criterion included in GS-37). While many conventional products are available in RTU format (Espinoza et al. 2010), the following dilution factors for each conventional product type were used to provide a more conservative evaluation (it is worth noting that at the time of this study, the GS-37 standard was the only standard in the USA that required minimum concentration levels):

-

General purpose—1:16

-

Glass and Restroom—1:8

The use of wipes for glass cleaning products and use of cleaning mops and dilution equipment were excluded from this study as they are considered equivalent for compliant and conventional products. GS-37 has additional requirements that affect the use phase of the life cycle, but were not included in the study. For example, GS-37 requires that the product perform with unheated tap water, whereas conventional concentrated products typically use heated tap water. This was not included in the study due to data and modeling limitations. User health considerations such as exposure to asthmagens, sensitizers, and other hazards were also not included in the study. This is due to LCA methodology limitations since LCA is not set up to represent a risk or hazard assessment that can quantify specific risks or hazards to a specific target population (USEPA 2006). A different method of study would be needed to understand these issues.

2.3.6 End-of-life

The end-of-life LCI data for HDPE recycling was based upon work conducted by Franklin Associates (2010). The recycling rate of 17% for HDPE was based upon Franklin Associates (2010) and USEPA (2010). The amount of packaging material not recycled was assumed to be disposed in a landfill. The Ecoinvent LCI data on disposal of polyethylene in sanitary landfill was considered in the LCA model. The environmental impacts associated with discharge and treatment of wastewater were done under the assumption that wastewater generated as a result of cleaning (except for glass cleaning products) undergoes significant dilution after it is discharged into a combined sewer. As a result, the quality of wastewater to be treated from cleaning product use can be considered to be of similar quality as the urban wastewater. The Ecoinvent LCI data on moderately large wastewater treatment for capacity class 2 (representative of 71,100 per capita equivalents) was used to model the environmental impacts associated with wastewater treatment.

2.3.7 Data quality

The formula data for compliant products can be considered to be of very good to excellent quality, as it is based on actual product data. However, for conventional concentrate products, the data quality can be considered to be of good to very good quality since it was based on publicly available information. The Ecoinvent database can be considered to be the most current, comprehensive, accurate, and transparent source of LCI data which is publicly available and the data quality can be considered of excellent quality.

3 Results and discussion

3.1 Life cycle impact assessment

3.1.1 General purpose

The life cycle impact assessment (LCIA) of the general purpose cleaning products are shown in Table 7. The product with the highest environmental impact for most of the categories studied was the conventional RTU product. The hydrogen peroxide-based GS-37-compliant cleaning product did not have the highest impact for any of the categories studied and had the lowest environmental burden of all of the products studied in most impact categories except for climate change, ozone depletion, natural land transformation, and fossil depletion. For the glucoside-based GS-37compliant product, the ozone depletion, terrestrial ecotoxicity, agricultural land occupation, and natural land transformation impacts were higher than the other products. This is due to the use of fatty alcohol from coconut oil and palm kernel oil in the lauryl glucoside ingredient (Online Resource 2). The conventional concentrate was higher than all other products studied for fossil depletion. This is due to the use of petroleum-based ethoxylate and HDPE packaging. Both of the GS-37-compliant products (glucoside-based and hydrogen peroxide-based) were lower than the conventional products in most impact categories.

The LCIA results of the glass and restroom cleaning products indicated a similar trend as the general purpose cleaning products; the conventional RTU product had a higher environmental burden in most impact categories except for higher land use impacts for the compliant product (Online Resources 3 and 4). However, the compliant glass cleaning product had higher water depletion impacts, driven by water use during irrigation of palm fruits. The compliant restroom cleaning product did not indicate any appreciable difference in the trend.

The cumulative energy demand results for all cleaners are illustrated and discussed in the Online Resource 5. The CED for the conventional RTU product was an order of magnitude higher than compliant and conventional concentrated products. The ratio of renewable energy portion of CED to total CED was higher for compliant products on account of the higher use of bio-based ingredients in these products compared to the conventional products.

3.1.2 Contribution by life cycle stage

The breakdown of LCIA results by life cycle stage for the compliant and conventional RTU general purpose cleaning products are shown in Figs. 1 and 2, respectively. The contribution from the product formula for the compliant product dominated most of the impact categories except for water depletion where water used for dilution was significantly higher than water used in product formula. In the case of the conventional RTU product, the contribution from packaging and distribution was dominant in categories such as climate change, fossil depletion, and cumulative energy demand, whereas contribution from product formula was dominant in categories such as ozone depletion, land use, and water depletion. The breakdown of LCIA results by life cycle stage for glass and restroom cleaning products is shown in Online Resources 3 and 4, respectively. The results indicated a similar trend as the general purpose cleaning products—the product formula dominated the source of impacts for the compliant product whereas the end-of-life (EoL) packaging stage dominated for the RTU product.

3.1.3 Normalization

The breakdown of normalized LCIA results by life cycle stage for compliant and conventional RTU general purpose cleaning product are shown in Figs. 3 and 4, respectively. For each product, the impact categories of marine ecotoxicity, human toxicity, and freshwater ecotoxicity were dominant. These leading impact categories were highest in Table 3 for the conventional products.

3.2 Sensitivity analysis

The life cycle impact assessment results for compliant products were dominated by the product formula, whereas for conventional RTU products, the distribution of the finished product and primary packaging of the cleaning product contributed significantly to the overall impacts. The influence of variations of the product formula and distribution were illustrated through additional sensitivity analysis.

3.2.1 Bio-based ingredients

The contribution to overall life cycle impacts from the product formula for compliant products was substantial. Some of the ingredients such as surfactants in cleaning products can be derived from both petrochemical and bio-based or renewable feedstocks. The objective of this sensitivity analysis was to compare the environmental profile of a general purpose compliant product formula with a greater amount of bio-based ingredients as compared to the baseline scenario formula. To do this, the ethoxylated alcohol (AE7) from petrochemical source was replaced with ethoxylated alcohol (AE7) from coconut oil. The results are shown in Table 8. The increase in land use impact was substantial (more than 100%), whereas the reduction in impacts for other categories was marginal. The renewable energy portion of cumulative energy demand increased by 10%, whereas the non-renewable portion declined by 14%. A similar analysis for the compliant glass and restroom cleaning product is shown in Online Resources 3 and 4, respectively. When the conventional formula contained bio-based ingredients (as compared to the based scenario of being made from petrochemical-based ingredients), the land use impacts also increased. This increase ended up resulting in the conventional product overtaking the compliant product in all impact categories except one, natural land transformation.

3.2.2 Distribution

The contribution to environmental impacts from transportation of the finished product was significant for the conventional RTU product. In the baseline scenario, it was assumed that finished product gets transported 1,600 km from the point of manufacturing to its point of use destination. So, the distance was reduced to 160 km in a sensitivity analysis (see the results in Table 9). The reduction in impacts was greater for the conventional RTU product than the compliant product. The reduction in impacts was most significant in categories such as climate change, photochemical oxidant formation, and particulate matter formation. This directly correlated to reduction in fuel use (i.e., diesel). The results for glass and restroom cleaning products are shown in Online Resources 3 and 4, respectively, and the results do not deviate from general purpose cleaning product results.

4 Conclusions

This comparative life cycle assessment study demonstrated that general purpose cleaning products and other types of cleaning products (i.e., glass and restroom) compliant to the Green Seal Standard for Cleaning Products for Industrial and Institutional Use, GS-37, had substantially lower environmental impacts than typical alternatives in the market, conventional cleaning products. This was driven by the criteria in the GS-37 standard that require products to be highly concentrated and to meet a comprehensive set of health and environmental criteria for the product formula (i.e., chemicals used in the product). The criteria are unique to Green Seal’s program, since no other standard or related programs in North America at the time of the study had such requirements (e.g., minimum product concentration). The compliant products had lower impacts across most of the impact categories studied, with the compliant, hydrogen peroxide-based product having the lowest impacts. The primary packaging and transportation of finished product were the major contributors to the impacts from conventional products, especially the ready-to-use product. Thus, efforts to reduce packaging and transportation are important considerations to reduce overall impacts. The GS-37 standard includes criteria to address these issues (e.g., minimum product concentration requirements). Once the impacts from packaging and transportation are reduced, it was found that the product formula becomes the major contributor to environmental impacts (as shown for compliant products), though with a lesser overall impact. Koehler and Wildboz (2009) found a similar result for household cleaning products, that as the final product’s water content decreases, the chemical formula rises in importance while packaging decreases in importance. The impacts from the product formula were higher with the use of bio-based ingredients. This, thus, represents a potential area for future study and development for the GS-37 standard.

The criteria from GS-37 that were included in this study represent a subset of the criteria included in the GS-37 standard (namely, since LCA methodology cannot model all of the criteria and secondarily due to data limitations). The additional requirements in GS-37 are expected to lead to further reductions in the environmental impact of compliant products. These include minimum product performance thresholds, use of unheated water, avoidance of health hazards, and through to environmental fate considerations. For example, overuse of products from being low performers and heating water for cleaning are expected to substantially contribute to the overall impact of conventional products. In addition, the GS-37 standard requires health-based criteria and environmental thresholds be met such as acute toxicity (high LD50), no carcinogens or reproductive toxins, no asthmagen ingredients, and limits for skin and eye irritation and skin sensitization, among others, that cannot be evaluated using LCA methodology.

The LCA study provided guidance on the effectiveness of some of the criteria in the GS-37 standard as well as additional areas to further optimize. However, LCA had limitations in assessing all of the criteria in the standard. Additional research would be required to provide that insight. However, this study confirmed that the Green Seal Standard for Cleaning Products for Industrial and Institutional Use, GS-37, is uniquely positioned to serve as an effective framework for the development and identification of more sustainable I&I cleaning products.

Notes

Also referred to as compliant product

http://www.ecoinvent.org/database/ (Accessed January 25, 2011)

Weight = 120 g

Weight = 65 g

References

Ahmed FU (2009) Industrial and institutional cleaners. In: Zoller U, Sosis P (eds) Handbook of detergents, part E: applications. CRC Press, Boca Raton, pp 201–253

Espinoza T, Geiger C, Everson I (2010) The real costs of institutional “Green” cleaning. http://www.sfenvironment.org/downloads/library/the_real_costs_of_green_cleaning_v6.pdf Accessed 1st March, 2011

Flick EW (2006) Advanced cleaning products formulations database. William Andrew Publishing. http://www.knovel.com/web/portal/browse/display?_EXT_KNOVEL_DISPLAY_bookid=1345&VerticalID=0 Accessed 4 January, 2012

The Freedonia Group (2010) Industrial and Institutional (I&I) Cleaning chemicals to 2014. Cleveland, OH

Frischknecht R, Jungbluth N, Althaus HJ, Bauer C, Doka G, Dones R, Hischier R, Hellweg S, Humbert S, Köllner T, Loerincik Y, Margn M and Nemecek T (2007) Implementation of life cycle assessment methods. Ecoinvent report no 3, Dübendorf, Accessed 25th January, 2011

Franklin Associates (2010) Life cycle inventory of 100% post consumer HDPE and PET recycled resin from postconsumer containers and packaging. Franklin Associates, Prairie Village

Goedkoop M Heijungs R, Huijbregts M, Schryver AD, Struijs J, Zelm RV (2009) Report: “ReCiPe 2008 A life cycle impact assessment method which comprises harmonized category indicators at the midpoint and the endpoint level. First edition, Report I: Characterisation, 6th January, 2009”. http://www.lcia-recipe.net Last accessed January 2011

Green Seal (2009) Green Seal Standard for Cleaning Products for Industrial and Institutional Use, Fifth Edition. Green Seal, Washington, D.C. http://www.greenseal.org/Portals/0/Documents/Standards/GS-37/GS-37_Cleaning_Products_for_Industrial_and_Institutional_Use_Standard.pdf Accessed 10th March, 2011

ISSA (2009) Green Cleaning Product Procurement Policies, Initiatives, and Requirements in the U.S. Lincolnwood, IL

Koehler A, Wildboz C (2009) Comparing the environmental footprints of home-care and personal-hygiene products: the relevance of different life-cycle phases. Environ Sci Tech 43:8643–8651

USEPA (2002) Life cycle review of products and services in support of the environmentally preferable purchasing program. United States Environmental Protection Agency (USEPA), Washington, DC

USEPA (2006) Report: “Life cycle assessment: Principles and Practice”. http://www.epa.gov/nrmrl/lcaccess/pdfs/600r06060.pdf Accessed on 10th October 2011

USEPA (2010) Report: “Municipal Solid Waste in the United States: 2009 Facts and Figures”. http://epa.gov/osw/nonhaz/municipal/pubs/msw2009rpt.pdf Accessed on 2nd February 2011

USEPA (2011) Green Cleaning Pollution Prevention Calculator, http://www.fedcenter.gov/janitor/index.asp

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Gerald Rebitzer

Electronic supplementary material

Below is the link to the electronic supplementary material.

Online Resource 1

LCI dataset for each chemical ingredient (DOC 39 kb)

Online Resource 2

Drivers for environmental impacts (DOC 173 kb)

Online Resource 3

Results for glass cleaners (DOC 166 kb)

Online Resource 4

Results for restroom cleaners (DOC 33.5 kb)

Online Resource 5

Cumulative energy demand results for all cleaners (DOC 14.9 kb)

Rights and permissions

About this article

Cite this article

Kapur, A., Baldwin, C., Swanson, M. et al. Comparative life cycle assessment of conventional and Green Seal-compliant industrial and institutional cleaning products. Int J Life Cycle Assess 17, 377–387 (2012). https://doi.org/10.1007/s11367-011-0373-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-011-0373-8