Abstract

Purpose

To construct future visions of how innovative technologies should be used in the envisioned sustainable society while being aware of system-wide environmental impacts, consequential life cycle assessment (c-LCA) is useful. To systematically evaluate the technologies being aware of uncertainties in choice of technologies made in the future, in this article, we propose a novel graphical representation for theoretical range of impacts that contain results from c-LCA studies. This approach allows analyses of the consequences of the technology introduction without conducting detailed modeling of consequences.

Methods

We stand on an assumption that the future environmental impacts reduced by a new technology depends on (1) how much the efficiency of the technology is improved, (2) how much of less-efficient technology is directly and indirectly replaced by the new technology, and (3) how much product is needed in the envisioned future. The difficulty in c-LCA is that items 2 and 3 are uncertain from various socioeconomic reasons that are often difficult to predict. By organizing the results from product LCAs in a systematic way, the proposed methodology allows exhibiting the range of consequential changes in environmental impact associated with a technology innovation, taking into account of those uncertainties on a plain coordinated by the amount of product needed in the future and environmental impact on horizontal and vertical axes, respectively.

Results

Part 1 describes the methodological framework in detail, whereas part 2 elaborates on the applications of the methodology. By taking transportation technologies assuming various energy sources in Taiwan, choices of technologies and evaluation of technology improvements serve as the case studies to demonstrate the application of the methodological framework.

Conclusions

By using the proposed method to organize the assumptions in c-LCA, discussions on different choices of technologies are made more systematic. In this way, stakeholders can focus on visions of the future society, which lead to different choices of technologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There is a growing concern toward achieving sustainable development in modern society, leading to innovation of a myriad of technologies. For effective policy making on emerging technologies, expected reductions in induced environmental interventions should be assessed from system-wide perspectives. To assist sustainable technology implementation planning, comprehensive tools and approaches that play an essential role in strategic policy decision have been presented (Robèrt 2000; Robèrt et al. 2002; MacDonald 2005). By carrying out environmental assessment already at the research and development stages, higher degrees of freedom with regarding to changes in in design of technology can be achieved. This has been highlighted in a previous study, and also a stochastic methodology to deal with associated uncertainties has been provided (Hoffmann 2001). Moreover, the perception that engineers have a responsibility not just to their employers or clients but also to the whole society is gradually being accepted in recent years (Clift 2006), and the method of evaluating the effectiveness of different cleaner technologies and how engineers can contribute in the method is illustrated (Clift 2006). As seen above, planners and engineers are requested to design solutions with a wider scope in project and product life cycles. Nowadays, even the researchers in laboratories working on small parts of the process systems are asked to team up and acquire implications to technology development from the system-wide studies (Fukushima et al. 2011).

Commonly, life cycle assessment (LCA) is considered as a useful tool for studying the system-wide environmental impacts of respective technologies. Regarding to system boundary selection and inventory data compilation, two approaches, namely, attributional LCA (a-LCA) and consequential LCA (c-LCA), are used (Ekvall and Weidema 2004; Ekvall and Andrae 2006); a-LCA highlights the environmental impacts associated with a product, and as demonstrated in carbon and water footprint activities, it is convenient in communication and identification of improvement opportunities of existing products, whereas c-LCA aims to describe the indirectly induced consequences of decision making, in addition to the direct ones, that is, process affected and impact directly induced by an action made. Both a-LCA and c-LCA can be used to support decision making, whereas the latter aims to deliver the information of marginal environmental consequences associated with a new action by integrating economic models to incorporate market information. As shown in a review by Earles and Halog (2011), c-LCA has emerged as a tool commonly for capturing the possible effects by affected technologies under physical, technological, economical, or political constraints applied to policy making and strategic environmental planning. For the purpose of change-oriented assessment for new technologies implementation in the future, c-LCA is the appropriate approach to support strategic policy making that identifies the environmental consequence regarding technical changes.

However, a general framework for modeling the interrelations among technologies is yet to be established. For primary indirect effects, market mechanisms and cost projections can help simulate some of the technology interactions by assuming that market penetration occurs according to the cost minimization principle. Power generation technologies such as solar cells (Fukushima and Kuo 2008), wind turbines (Kuo and Fukushima 2009), and fuel cells (Fukushima et al. 2004) are evaluated by this approach. In these studies, technology innovations are interpreted into cost reduction, which then drive the market penetration under constrained resource, social/political setting, and projections of various key factors. The studies also assessed which of the existing technologies are being replaced by the new technology and showing competition relationship among technologies in economic perspective. As to the secondary indirect effects, Hertwich (2005) has pointed out that a change in behavior driven by the technology introduction can induce nonlinear changes in the achieved environmental impact reduction and that accompanying benefits and negative side effects of technical change should not be neglected. Several quantitative models are also proposed, but none of them are comprehensive enough to cover all the secondary indirect effects. c-LCA aims at describing that both primary and secondary indirect effects thus have been attracting wide attentions recently; however, the standardized c-LCA procedure is still under development, which is strongly needed (Earles and Halog 2011).

Rather than trying to establish models to simulate detailed and specific interrelations among technologies implemented in the society, in this study, we propose a graphical representation for c-LCA that visualizes the theoretical range of environmental consequences assuming a set of technologies that are in the same domain. This visualization enables to identify the range of potential environmental consequence of a technology replacement within the defined technology domain. It effectively displays marginal changes in environmental impacts induced by the domain technologies. This method streamlines the c-LCA, avoiding detailed modeling of consequences while delivering useful information on how effectively technology implementation can reduce environmental impacts by indicating the changes in theoretical maximum and minimum environmental impacts obtained by exhaustive combination of technologies that satisfy a certain demand, rather than making a precise prediction of consequences. The article has been divided into two parts. Part 1 describes the methodological framework in detail, whereas part 2 focuses more on the applications of the methodology.

2 Methodology

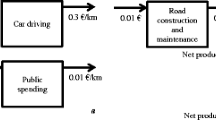

LCA is used to analyze the environmental impacts associated with a product. To complete the analysis, the product and every stage of its life cycle are explicitly described. When more than one (a) product that could deliver the same function or (b) life cycle pathways are in the scope of the study, the results from combinations of choices (often defined as scenarios) are presented. Figure 1 depicts a situation where N production scenarios and M use and disposal scenarios exist for a single product. That is, there are N routes of processes to produce a product and M ways to utilize it.

Uncertainty is always inherent to c-LCA because it relies on models to predict the consequences, which have varied types and levels of uncertainty. As c-LCA method is helping to form strategic decision, the uncertainty should be communicated to the decision makers. The novel graphical representation for c-LCA proposed in this study visualizes the theoretical range of environmental consequences without modeling the detailed consequences in the technology introduction into society. A detailed procedure of the methodology developed is described in this section.

2.1 Method of developing graphical c-LCA

This graphical c-LCA method designed for assessing technology is summarized in Fig. 2. It presents the major building blocks of the methodology, which are in accordance with the LCA framework. Four steps are included: (1) define a technology domain, (2) calculate associated impacts of selected domain technology, (3) generate a graphical representation, and (4) interpret the results and provide feedback information.

2.1.1 Step 1: define a technology domain

First, the evaluated technology domain should be defined. A process of production or utilization associated with the evaluated product is defined as a technology. Each technology is classified into either production or utilization technology. An initial collection of production and utilization technologies is set based on specific criteria and constraints. For example, “renewable hydrogen technologies” is assumed as the technology domain that produces and utilizes hydrogen via renewable energy sources. When a technology conforms to criteria and constraints set, that is, produce hydrogen using renewables, it can be chosen in the domain. This corresponds with the stage of “goal and scope definition” in the LCA framework.

2.1.2 Step 2: calculate associated impact of selected domain technology

Then, the environmental impacts of selected domain technologies are calculated. Cradle-to-gate and gate-to-grave LCAs are conducted for technologies in production and utilization stages, respectively. In this step, LCA of each of technologies is calculated separately. The interrelation among technologies is not considered at this step.

A cradle-to-gate LCA is conducted for products produced by the technology to derive the environmental impact associated with the production of a unit amount of product. At the same time, resources (i.e., raw materials, land, factories for production, etc.) available for production are evaluated. To obtain the information described above, life cycle inventory analysis (LCI) and life cycle impact assessment (LCIA) are performed.

A gate-to-grave LCA is conducted for utilization of various technologies. Such analyses derive environmental impact reduction induced by the utilization of a unit amount in the respective technologies. Here, emissions that occur in the production pathways of displaced products are accounted for. At the same time, demands for functions delivered via respective utilization technologies are evaluated. Similarly, LCI and LCIA are required.

2.1.3 Step 3: generate a graphical representation

Next, a graphical representation can be generated using the results obtained from Section 2.1.2. Fig. 3 illustrates how an individual LCA result of a technology is assembled.

For the technologies classified in the production category, the production curve (P curve) is developed as shown in Fig. 3a, b. Each segment (P 1… P 4) represents different production technologies. A segment can be drawn in a coordinate with production and environmental impact of primary interest in horizontal and vertical axes, respectively. The segments are linked to form a curve that starts from the origin of the coordinate.

For the technologies classified in the utilization category, the utilization curve (U curve) is developed. Each segment (U 1… U 4) represents different utilization pathways. A U segment can be drawn in a coordinate with production and reduction in an environmental impact of primary interest in the horizontal and vertical axes, respectively. The segments are linked to form a curve that starts from the origin of the coordinate. For example, U in Fig. 3 depicts how a U curve would appear.

In Fig. 3a, if the segments are put in order according to their gradients (P 4→1, U 4→1), the constructed curves are convex upward, which are P max and U min curves, respectively. Such P and U curves show the maximum environmental impact and minimum environmental impact reduction over production, respectively. Conversely, Fig. 3b shows that if the segments were put in the reverse order (P 1→4, U 1→4), the P and U curves will be convex downward and show the minimum environmental impact (P min curve) and maximum environmental impact reduction (U max curve) over production using the same collection of production and utilization technologies. The P and U curves theoretically would lie somewhere between those two extremes, which intersect at the origin and at another end of the curves.

By combining the P and U curves, the impact curve (I curve) can be synthesized to show the net changes in environmental impact over the extent of a collection of technologies. Note that only the impacts that are directly associated with the individual technologies in the evaluated domain are evaluated here. For example, the I max and I min curves show the maximum and minimum environmental impacts induced by introducing those set of technologies. That is, for a certain amount (x h ) of feedstock utilized, the environmental impact induced from society is within the vertical range between the I max and I min curves at x h on the horizontal axis. How much the x h would depend on various socioeconomic factors of market penetration, such as cost, incentives introduced by the government, and oil price. Marginal additional impact (and impact reduction) varies over the demand of production and utilization. In this graphical representation, this is considered and expressed as the shape of the range in between the I max and I min curve.

2.1.4 Step 4: interpret the results and provide feedback information

The environmental effects among corresponding technologies are visualized and can provide information for strategic decision making. For example, different scenarios of technology introduction under various economical and social circumstances can be accessed via the graphical representation. Feedback such as technology reconsideration is obtained when the results need to be reexamined.

2.2 Indicators

To characterize the results from this methodology, the indicators are proposed, as shown in Fig. 4. The feedstock point A (x A , y A) indicates the maximum environmental impact (i.e., y A) induced by those chosen technologies among all possible technology implementations. As a convex upward curve, point A on the I max curve indicates the highest point and implies the possible maximum environmental impact value.

Then point B (x B, 0) can give an index of emission neutralization. As shown in Fig. 4, the y value (i.e., environmental impact) of the I max curve will be maintained as negative when the hydrogen amount is over point B (i.e., x B). In other words, when the feedstock amount exceeds x B, the environmental impact reduction can always be achieved.

Finally, at point C, the maximum emission reduction can be expressed. On account of point C (x C, y C) being on I min curve and showing the lowest point, point C can indicate the maximum emission reduction amount (y C) and the most appropriate amount (x C) for society attributable to the highest reduction potential. Even if the feedstock utilization exceeds x C, the environmental impact remains negative compared with the benchmark situation at the origin of the figure.

2.3 Contribution of technology innovation/breakthrough

This proposed methodology can also be used to evaluate a technology breakthrough/improvement. The composite of technologies including the evaluated innovation can be constructed by changing or adding the segments in the P and U curves. Examples of modification of P min and U max curves owing to various types of innovation are shown in Fig. 5, that is, the extension in capacity of P 1 (dotted line in P′), improvement in efficiency of P 3 (P 3′ of P′) and technical innovation (U N of U′). The innovation will change the curves and thus change the I min curve. In the same manner, the I max curve is modified, and the new indicators are obtained.

By presuming the availability of resources in the future, demands of services, and a technology domain that consists of multiple related technologies and their future performances, the three indicators are obtained using the method described in Section 2.2. To evaluate the changes in environmental impacts for a given innovation, we compare the three indicators before and after the innovation. The system-wide environmental impact reduction by technology innovation is explored, making it possible to provide feedback to the early stage of technology design or develop a more strategic policy.

Furthermore, this methodology can be used to assess different impact categories together with a main impact category, according to the focused interest, as demonstrated in the following case study.

3 Results

The graphical representation for c-LCA is used to assess the environmental impacts in the future society by utilizing a set of technologies under different criteria. The achievements are summarized as two points listed below: (1) it allows the understanding of technologies and their environmental aspects in relation to other required or coexisting technologies in the defined domain and (2) it visualizes the theoretical range of environmental consequences assuming technologies that are in the same domain, which are furthermore conducts the maximum reduction that could be achieved, the maximum environmental impact caused by technology implementation, and the absolute reduction amount.

This achievement can be applied in a strategic way when designing the future possible society. The maximum environmental impact potential can be evaluated before the introduction of those set of technologies. The appropriate feedstock utilization can also be assessed to ensure the positive effect on society. Those achievements play a role in providing the possibility of feedback on target efficiencies and consequential environmental benefits to the stakeholders such as technology developers or researchers and policy makers. For technology developers, they can know how sustainably they can contribute to the whole society or which part they can make more efficient. For governmental policy makers, they can realize the future consequences when several energy policies are to be implemented. Because the different economic and social constraints would make the assessment complicated, this method can allow stakeholders to focus on the discussion of visions of the future society using the graph.

4 Discussion

A graphical representation for c-LCA is developed to allow decision makers to strategically analyze the choices of technologies to be used in the future, being aware of uncertainties induced by various factors that require use of more detailed models to simulate consequences. It can also be used to evaluate technology improvements/breakthroughs under a specific vision, in which the technology improvements are broken down into “per-product emission reduction” and “yield enhancement.” This methodology shows the possibility of feedback on target efficiencies and consequential environmental benefits to the researchers developing the technologies being assessed. Three indicators are defined in the use of this proposed methodology: maximum environmental impact, emission neutralization, and maximum emission reduction. These provide information on the relationship between feedstock utilization and the associated environmental impact.

However, the methodology suffers from a number of limitations at present. This methodology might have a limitation on when to consider several environmental, economic, and social indexes at the same time for the visual aspect. For example, it can be extended into three dimensions to compare two different indexes, yet it is not easy to understand if it is extended into more than three dimensions. In this case, the aggregation method might be applied, although some information on the characteristics of the index may be lost by the aggregation. That is, if the selected impact categories are integrated into a single index, the differences of impacts among various processes cannot be identified. For instance, a process that emits lower greenhouse gas emission may have a higher acidification potential. If several indexes are integrated, the information on the trade-off between them might be lost. In this study, we showed that this methodology is useful when the net utilization impacts are negative, whereas the production impacts are positive. In other cases, it seems that the usefulness of this methodology is limited.

5 Conclusions and recommendations

By collecting more data on a wider variety of corresponding technologies in the selected domains, a technology assessment platform can be constructed. It is recommended that such a platform be constructed to make the most of the technological assets generated as a result of research activities. As a result, the platform enables the optimization of the possible future society reflecting various criteria and constraints.

The proposed methodology distinguishes the uncertainty regarding the choice of technologies that arise as a consequence of various considerations from other types of uncertainties and visualize the prior. This approach is particularly useful for assessing different scenarios of the technology implementation. In this way, stakeholders (e.g., technology developers and policy makers) can focus on visions of the future society, which include different choices of set of technologies.

Both existing and new technologies can be assessed in the proposed framework. Varied levels of uncertainty in the existing and new technologies should be noted but currently not assessed in the proposed methodology.

Abbreviations

- c-LCA:

-

Consequential life cycle assessment

- P curve:

-

Production curve

- U curve:

-

Utilization curve

- I curve:

-

Impact curve

- GHG:

-

Greenhouse gas

- P min :

-

Minimum environmental impact induced from production process

- P max :

-

Maximum environmental impact induced from production process

- U min :

-

Minimum emission reduction from utilization process

- U max :

-

Maximum emission reduction from utilization process

- I min :

-

Minimum environmental impact of applying composite technology

- I max :

-

Maximum environmental impact of applying composite technology

References

Clift R (2006) Sustainable development and its implications for chemical engineering. Chem Eng Sci 61:4179–4187

Earles JM, Halog A (2011) Consequential life cycle assessment: a review. Int J Life Cycle Assess 16:445–453

Ekvall T, Andrae ASG (2006) Attributional and consequential environmental assessment of the shift to lead-free solders. Int J Life Cycle Assess 5(11):344–353

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J Life Cycle Assess 3(9):161–171

Fukushima Y, Kuo YM (2008) Evaluation of GHG emission reduction potentials of PV system considering power mix shifts. J Energ Eng-ASCE 134(2):58–62

Fukushima Y, Shimada M, Kraines SB, Hirao M, Koyama M (2004) Scenarios of solid oxide fuel cell introduction into Japanese society. J Power Sources 131:327–339

Fukushima Y, Huang YJ, Chen JW, Lin HC, Whang LM, Chu H, Lo YC, Chang JS (2011) Material and energy balances of an integrated biological hydrogen production and purification system and their implications for its potential to reduce greenhouse gas emissions. Bioresour Technol 102(8):8550–8556

Hertwich EG (2005) Consumption and the rebound effect. J Ind Ecol 9:85–98

Hoffmann VH (2001) Multi-objective decision making under uncertainty in chemical process design. Dissertation, Swiss Federal Institute of Technology Zürich

Kuo YM, Fukushima Y (2009) Greenhouse gasses and air pollutants emission reduction potentials of photovoltaic and wind power systems introduction scenarios using power mix optimization models. J A&WMA 59:360–372

MacDonald JP (2005) Strategic sustainable development using the ISO 14001 Standard. J Cleaner Prod 13:631–643

Robèrt KH (2000) Tools and concepts for sustainable development, how do they relate to a general framework for sustainable development, and to each other? J Cleaner Prod 8:243–254

Robèrt KH, Schmidt B, Larderel JA et al (2002) Strategic sustainable development—selection, design and synergies of applied tools. J Cleaner Prod 10:197–214

Acknowledgements

Parts of this study were supported financially by the National Science Council of Taiwan (97-2221-E-006-044-MY3) and NCKU Landmark Projects (C034, new researchers category).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Sangwon Suh

Rights and permissions

About this article

Cite this article

Chen, IC., Fukushima, Y., Kikuchi, Y. et al. A graphical representation for consequential life cycle assessment of future technologies. Part 1: methodological framework. Int J Life Cycle Assess 17, 119–125 (2012). https://doi.org/10.1007/s11367-011-0356-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-011-0356-9