Abstract

Background and theory

Life cycle assessment (LCA) and life cycle inventory (LCI) practice needs to engage with the debate on water use in agriculture and industry. In the case of the red meat sector, some of the methodologies proposed or in use cannot easily inform the debate because either the results are not denominated in units that are meaningful to the public or the results do not reflect environmental outcomes. This study aims to solve these problems by classifying water use LCI data in the Australian red meat sector in a manner consistent with contemporary definitions of sustainability. We intend to quantify water that is removed from the course it would take in the absence of production or degraded in quality by the production system.

Materials and methods

The water used by three red meat supply systems in southern Australia was estimated using hybrid LCA. Detailed process data incorporating actual growth rates and productivity achieved in two calendar years were complemented by an input–output analysis of goods and services purchased by the properties. Detailed hydrological modelling using a standard agricultural software package was carried out using actual weather data.

Results

The model results demonstrated that the major hydrological flows in the system are rainfall and evapotranspiration. Transferred water flows and funds represent small components of the total water inputs to the agricultural enterprise, and the proportion of water degraded is also small relative to the water returned pure to the atmosphere. The results of this study indicate that water used to produce red meat in southern Australia is 18–540 L/kg HSCW, depending on the system, reference year and whether we focus on source or discharge characteristics.

Interpretation

Two key factors cause the considerable differences between the water use data presented by different authors: the treatment of rain and the feed production process. Including rain and evapotranspiration in LCI data used in simple environmental discussions is the main cause of disagreement between authors and is questionable from an environmental impact perspective because in the case of some native pastoral systems, these flows may not have changed substantially since the arrival of Europeans. Regarding the second factor, most of the grain and fodder crops used in the three red meat supply chains we studied in Australia are produced by dryland cropping. In other locations where surface water supplies are more readily available, such as the USA, irrigation of cattle fodder is more common. So whereas the treatment of rain is a methodological issue relevant to all studies relating water use to the production of red meat, the availability of irrigation water can be characterised as a fundamental difference between the infrastructure of red meat production systems in different locations.

Conclusions

Our results are consistent with other published work when the methodological diversity of their work and the approaches we have used are taken into account. We show that for media claims that tens or hundreds of thousands of litres of water are used in the production of red meat to be true, analysts have to ignore the environmental consequences of water use. Such results may nevertheless be interesting if the purpose of their calculations is to focus on calorific or financial gain rather than environmental optimisation.

Recommendations and perspectives

Our approach can be applied to other agricultural systems. We would not suggest that our results can be used as industry averages. In particular, we have not examined primary data for northern Australian beef production systems, where the majority of Australia’s export beef is produced.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background

The amount of water that is used in red meat production influences society’s view of its environmental sustainability compared to other protein sources. Life cycle impact assessment schemes for water use are currently under development, but until they have been adequately validated in multicountry, multiproduct trials and an international consensus on them is created, life cycle inventory data will be used in public debates. ‘Water use’ estimates determined using ‘virtual water’ and other water estimation methodologies vary widely; some values supported by original published work are shown in Table 1. The differences between such figures, and their absolute size, have caused considerable controversy in the media where they are often reported without any discussion of how they were calculated. We wished to inform the current debate by providing a more detailed inventory analysis built on primary process data from actual agricultural properties.

Reported water use estimates are often based on simple desktop calculations that consider all water inputs to production as water use. This may be appropriate for estimates intended to inform economic policy. For example, if the analyst wishes to identify ‘virtual water flows’ or ‘embedded water’ (Allan 1998; Zygmunt 2007) to determine whether a country is obtaining the most financial or calorific gain it can, all water that is an input to red meat production is relevant whether its ‘use’ causes environmental damage or not. Local primary data for such virtual water calculations is hard to obtain. Most authors taking this approach use literature data on plant requirements (‘evaporative water demand’; see Hoekstra and Chapagain 2007) and multiply this by the amount of plant products the livestock typically consume.

However, if the intention is to assess potential environmental damage, the virtual water approach is inappropriate. Instead, the analyst ought to consider whether environmental consequences result from water being an input to the system. In constructing the life cycle inventory, characteristics of the water source, such as whether (1) it is renewable, (2) extraction exceeds the renewal rate and (3) whether the extracted water is returned to the original watercourse in full, are understood to characterise whether water use is sustainable (Owens 2002). In practice, this means identifying water that is extracted from artesian sources or subjected to inter-basin transfer as inputs to a production processFootnote 1. Using these three criteria, in situ use of rain for pasture or dryland cropping is generally excluded because (1) it is renewable, (2) it cannot be used faster than it falls, and (3) it is not extracted from its original watercourse.

1.1 Life cycle inventory

Explaining the frequent absence of water use inventories in many agricultural life cycle assessments (LCAs), Mila i Canals et al. (2008) point out that LCA developed as a tool for industrial analysis in wet countries. Consistent with this, and presumably for practical reasons of data quality, LCA and allied studies of agriculture that do include water use generally exclude rain (Beckett and Oltjen 1993; Johnson 1994; Brent and Hietkamp 2003; Hospido et al. 2003; Brent 2004; Foran et al. 2005; Narayanaswamy et al. 2005; Coltro et al. 2006; Mila i Canals et al. 2006; Wood et al. 2006) and focus on water provided by large engineered systems from surface and groundwater storages. Even estimates of water use in agriculture by the Australian Bureau of Statistics (ABS) have excluded rain (ABS 2005).

Consistent with principles listed by Owens (2002), natural resource inventory theory distinguishes between the use of ‘deposits’ (which would include groundwater unlikely to replenish on human timescales), ‘funds’ (including rapidly replenished groundwaters) and ‘flows’ (Udo de Haes et al. 1999). The concept of flows is described as including ‘surface water’, which defines this water at a point after runoff has occurred. Reflecting this, some inventories differentiate between ‘blue’ and ‘green’ water, which relate to conventional fluvial and groundwater resources, and water vapour and groundwater present in the vadose zone, respectively (Falkenmark and Rockström 2006).

Another key aspect of interest in water use LCA is water quality. While LCA practitioners use midpoint indicators like eutrophication potential and aquatic ecotoxicity potential to characterise the impact of returning ‘wastewater’ to the environment, this degree of contamination also suggests the degree of use to the broader public and (ignoring hydrological parameters) if water is returned to the environment at or close to the quality at which it was extracted that use is considered sustainable (Owens 2002). This is a current problem for LCA; if we want to report meaningful inventory data, it must be informed by water quality issues in parallel with source sustainability issues.

A distinction is made in life cycle inventory (LCI) between ‘attributional’ and ‘consequential’ approaches to systems (Ekvall et al. 2005; Russell et al. 2005). If a pastoralist decides to let a property lie fallow and produce no beef, various systems will not operate. The consequence would be that water trough pumps would be switched off, fodder purchases would not occur, and other actions motivating a water flow would cease. However, the main water cycle processes of rainfall, evapotranspiration, runoff and infiltration will continue to occur; their relative scale will be determined by passive landscape features, vegetation and soil characteristics. The situation would be different for production of a flood- irrigated crop such as cotton. If a typical Australian cotton farmer chose not to produce cotton or other products in a particular year and let the property rest, the water budget of the property would be very different to a normal production year. Water control infrastructure (e.g. weirs and pumps) would not be actuated to cause the farm’s fields to flood. Overland flows would take their natural course. Therefore, such changes to fluvial and overland water flows would have to be considered in a consequential LCA of cotton production.

Depending on the purpose of the LCA, different temporal frames of reference may be appropriate. If one chose a frame of reference on the scale of centuries, the main changes in the water cycle would be due to landscape changes like deforestation and wetland destruction, which may have occurred shortly after the arrival of Europeans in Australia. If the frame of reference is a particular year (as in our study), then changes to foreground production systems that occur from year to year are more relevant. Construction of the tiny agricultural dams commonly used in Australia will not occur annually—such dams operate passively for much longer lifespans. There are large areas of northern Australia where agricultural interventions in the landscape are minor, where native pasture grows and cattle graze on that native pasture. Rainfall and evapotranspiration flows, which dominate farm hydrology, may not have changed significantly for a millennium. Can we say such flows are ‘used’ in meat production when they are practically unchanged? Our LCI approaches need to recognise this issue and report these flows separately.

Additionally, in systems where they have changed, associating the changed flow with a functional unit (production of 1 kg of red meat) seems difficult when any relevant landscape change (e.g. deforestation) occurred some decades ago and the land may have been used for a large number of different cropping and grazing activities since then. This change may or may not have been originally made for the purposes of livestock grazing. Moreover, in mixed farming regions, the maintenance of land in a cleared state may be driven more by other operations that use the land in rotation (e.g. cropping) rather than for livestock production per se. Notwithstanding this, livestock production does contribute to maintaining land in a cleared state in some instances, and in some cases, this may actually increase the amount of runoff from the system, effectively increasing the flow of blue water and adding complexity to the discussion (Scanlon et al. 2007). In this case, maintaining a hectare of land for red meat production may be a more appropriate functional unit than the provision of a kilogram of red meat. But the dominant cultural dialogue regarding water use in food products is always denominated in terms of the ultimate product units. Therefore this approach is unhelpful for analysts wishing to engage in that dialogue.

1.2 Life cycle impact assessment

Recent life cycle impact assessment (LCIA) proposals on water use suggest assessing consideration of the lifetime of available reserves (Heuvelmans et al. 2005) or the energy required to return water inputs to their original functionality (Stewart and Weidema 2005). The latter approach appeals for its consistency with assessment methods for other resources. Both methods consider the removal of water from its original location as part of the definition of use, while the latter also incorporates water quality issues. Leaving aside the practical difficulties that may arise in dealing with a distributed inland resource like rain, a key communication problem here is that, whether it is the most theoretically elegant denominator or not, volumetric units are the currency of the public water use debate, so LCI or LCIA intended to inform the debate needs to report their results in litres rather than energy demand (or ‘kilograms of antimony equivalent’ included among suggestions by Mila i Canals et al. 2008).

Recently, the ratio of water use to renewable water resource was proposed as a characterisation factor for scaling water obtained from different sources over a product life cycle and reporting a screening-level water use midpoint indicator in litres (Mila i Canals et al. 2008; Pfister et al. 2009). This would avoid this communication problem but, as recognised by its proponents, is dependent on the scale of the normalising renewable water resource datum, which may not be known for background system products and might be unclear even for the foreground system depending on the extent of centralised infrastructure available to supply the water to it. Additionally, many Australian river systems exhibit extremely variable flow rate distributions, and this variability rather than the average flow may be critical for endemic species, so basing sustainability assessment on such averages could overlook the key aspects of water use which threaten biodiversity. Nevertheless, the use of such an approach promises to provide a bridge to eventual use of midpoint indicators for the protection of human health, the biotic environment and resources (Bayart et al. 2010; Pfister et al. 2009).

2 Materials and methods

2.1 Scope of the LCA

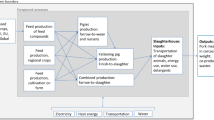

The functional unit of this LCA is defined as ‘the delivery of 1 kg of HSCW meat to the meat processing works product gate for wholesale distribution’. Three supply systems were considered:

-

An organic beef supplier in Victoria. This is a relatively small operation (500 ha) on gently undulating coastal land with a long-term average annual rainfall of 940 mm. The property does not require irrigation supplies so the main use of potable water is at the meat processing works.

-

An export beef supplier in New South Wales (NSW). This is a large property (2,800 ha) of mostly hilly land running both sheep and cattle, with some cropping on alluvial soils to provide fodder. The long-term average rainfall is 590 mm but supplies are bolstered by the availability of groundwater, a potable water network and an irrigation canal.

-

A sheep-meat supplier in Western Australia (WA). This is a sheep grazing property (1,100 ha) on gentle hills, which supplements its income by producing barley and wheat for sale. It receives a long-term average of 460 mm of rain supplemented by a potable water network and groundwater supplies.

The production of red meat during the years 2002 and 2004 was estimated based on farm-specific production data. A portion of the NSW product was grown in a feedlot. Detailed growth estimates for the farms and feedlot were based on process data from site visits, dialogue with property managers and interrogation of farm and feedlot management information systems. In the case of the meat processing works, local published data were used (MLA 2002). For the NSW supply system, the data were aggregated by considering the proportion of the product made at the farm and the feedlot, and the product flow directly from the farm to the meat processing works relative to the product flow via the feedlot. In that case, as in the other two states, the kilogram HSCW denominator refers to the meat leaving the meat processing works gate, rather than the amount leaving the farm. The water inputs and outputs were allocated to red meat production in accordance with the relative mass of the red meat and its by-products.

Input–output analysis was subsequently used to complement the system modelling, taking into account purchased inputs to the farming enterprises for which primary LCI data were unavailable. This applied a recently developed Australian hybrid LCA model (Rowley et al. 2009). Further detail on the overall model is provided in Peters et al. (2010).

The flows into agricultural operations were classified according to a scheme based on matters raised in previous work (Udo de Haes et al. 1999; Owens 2002; Stewart and Weidema 2005; Bayart et al. 2010). We identify in situ rainfall as the most sustainable water source for agricultural use and list it as a unique local ‘flow resource’. Non-passive surface water transfers (or ‘diversions’) of ‘flow’ resources (Udo de Haes et al. 1999), which reduce natural water flows in their original watercourses, are grouped by a separate set of shaded cells. These include agricultural irrigation supplies, water which had been transferred from another source by importation of animals or feed and reticulated town water supplies. We also separately inventoried bore water use as a ‘fund’ in Udo de Haes’ sense of the term. Whether the aquifers are deep or shallow was not identified in this study, so this is an environmentally conservative use estimate for this type of source. We subsequently group transferred flows and funds as ‘transferred water’—a collective LCI category for reporting water use where the water of source is not as sustainable as local precipitation. This definition is similar in effect to that of the ABS. Reflecting Owens (2002) concern that output quality also defines the degree of environmental impact, we non-quantitatively classified output flows as ‘high quality’ (evaporated water from fields and animals), ‘moderate quality’ (deep drainage and runoff, which would be less pure than the original rain), ‘low quality’ (excreted water and discharges to sewer) and ‘alienated’ water (water removed from the environment in the product). We subsequently group moderate quality, low quality and alienated flows as ‘net use’—a collective LCI category for reporting water use where the discharge quality is not as high as water vapour.

2.2 Hydrological modelling

To obtain more accurate estimates of water use in beef production than is typically available to LCA practitioners, we used a hydrological model based on MEDLI, a model for analysing effluent reuse systems. A 51-year (1957–2007) climate file for each site was obtained from the Australian Bureau of Meteorology. This includes daily meteorological data for rainfall, evaporation, solar radiation, minimum and maximum temperatures. Soil parameters were based on broadscale soil and landscape information contained in the Digital Atlas of Australian Soils and from information supplied by each property manager. The modelling used USDA runoff curves based on the dominant soil type for each property and the topography, with curve numbers ranging from 74 for pastures on sandy soils to 83 for cereal crops on duplex soils.

Modelling was undertaken for native pastures, improved pastures, wheat, barley and oats. Grazing was simulated in the model by harvesting when pasture yield reached 1,000–1,500 kg DM/ha and by reducing nutrient removal to simulate the low net export of nutrients from a grazing system. In the irrigated hay runs, the pastures are periodically cut, harvested and removed from the site. For the cereal crops, the grain and straw are harvested and removed at the end of the cropping cycle. The irrigation model inputs include irrigator type, irrigation area size and irrigation scheduling rules. We modelled a low-pressure travelling irrigator with scheduling based on a soil water deficit. The volume of irrigation water available was limited to the amounts used by each property manager. The effluent inflow to the holding pond for the feedlot model was estimated to be 50 ML in 2002 and 48 ML in 2004. The model was calibrated for nitrogen, phosphorus and salinity concentrations typical for a feedlot of similar size and configuration, for which primary data were available. Due to the below average rainfall for the 2 years of interest, the volume of effluent irrigated was also low (∼0.75 ML/ha). Each model run was performed for the entire 51-year period. The rainfall, evapotranspiration, runoff, deep drainage and plant yield were then extracted for the years 2002 and 2004. The rainfall measured on each property for the study years was sometimes different from the rainfall data used in the modelling but in most cases, this was not significant.

3 Inventory results

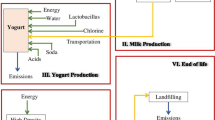

The inventory of inflows and outflows from the systems under study are shown in Table 2 and, of these data, Fig. 1 shows the water flows for the Victorian farm in 2004 (excluding flows at the meat processing works) as a Sankey diagram. It is striking how the water exchanges between the atmosphere and the farm (rain and evapotranspiration) dominate the overall water budget. The dominance of these two flows is even more extreme for the other five cases, where deep drainage is less important.

As can be seen in Table 2 from the relative errors in the data, the level of agreement between the estimates of total inputs and outputs is quite good with a maximum relative total error of 6.3%. The most significant flows in the table are the rainfall, evapotranspiration, deep drainage and runoff. These are all supplied by the MEDLI model, and the mass balance on the output of this modelling tool does not always close completely. This is primarily in response to the relationship between plant water usage and soil moisture. The primary water input to the properties is rainfall during the calendar year. In some cases, the sum of evapotranspiration, drainage and runoff is greater than total rainfall because the program also estimates stored soil moisture from the previous year. In years where a surplus is observed in the water balance, this was usually in the order of 10–20 mm of stored soil moisture across the property, which is considered a relatively minor error. It was difficult to accurately assess soil moisture retrospectively for the supply chain properties, and considering that the error was relatively small, no further adjustment was made.

Readers will recognise variation between properties and years in the figures. The NSW figures show a system that relies on less rainfall than the WA property, but more than the Victorian property. On the other hand, the NSW system relies more on reticulated water because of the feedlot and its use of cotton products for cattle feed.

Inter-annual variation is particularly apparent in the rows that relate to rainfall, evapotranspiration, deep drainage and runoff. The main factor is the changes between the type of agricultural business being run at the properties between years, resulting in different intensities of productive activity on the farms. Particular attention is drawn to the Victorian property which in 2002 operated as a finishing enterprise for traded cattle purchased as weaners. Since this type of system excludes breeding stock, which require more water per unit of liveweight gain than non-breeding stock, water usage was expected to be 30–50% lower than a system including these cattle. In fact, the per kilogram HSCW figures are even lower than that, reflecting this and other sources of inter-annual variation including climate (14% less rain fell in 2002). As a proportion of total red meat exports, sheep purchases by the WA property varied significantly between years (zero in 2002 and 80% of exports in 2004). In this case, the climate was relatively consistent between years, and the variation in the per HSCW figures has mostly to do with the variation in agricultural business practice between years. These two cases illustrate the responsiveness of the model to such changes in the primary data of the underlying systems.

On the other hand, inter-annual variation is less apparent for the engineered water input categories and the lower quality water output categories. This is to be expected because the agricultural system managers are able to control these flows relative to the needs of the production system, compared with the variability of rainfall in Australia.

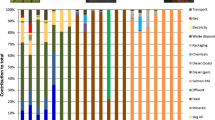

The results are summarised in Table 3. This aggregates the water flows in the previous table that are considered less sustainable by virtue of the supply characteristics (transferred flows and funds) or by virtue of the discharge quality (output quality moderate, low or alienated). This reflects the general concerns of LCA theorists and our contention that rain that is an input to pasture whether or not cattle graze on it, and is returned to its source at a high quality, should be addressed separately in LCA studies from other water flows. The table shows that the water flows exist in a relatively small range for both years in the systems without a feedlot: Water use is 18–52 L/kg HSCW under the ‘net water use’ definition and 27–214 L/kg HSCW for the transferred water definition. The NSW system, with its feedlot and irrigated agriculture at the farm, is estimated to have used around 34 and 540 L/kg HSCW depending on which definition is selected. Most of the difference is due to the purchase of irrigated feeds by the feedlot.

Our results indicate that water used to produce red meat in southern Australia is 18–540 L/kg HSCW, depending on the supply system, reference year and whether we focus on source or discharge characteristics.

4 Comparison with previous studies

Foran et al. (2005), who used a system analysis methodology very different to ours, generated a result within the range of results shown in Table 3. Those authors used an economics-based input–output analysis and the ABS definition of water use (ABS 2005), which excludes rain. By this definition, dryland cropping does not require added water, which is consistent with the published LCA of Australian wheat (Narayanaswamy et al. 2005). Comparison with our work relies on industry-level wholesale pricing: $3.5/kg beef and $4.2/kg (beef/sheep/pork/chicken products) calculated from their data. On this basis, they suggest that 209 L/kg is used in the beef industry and 79 L/kg for the other meat products. The masses refer to industry output of all ‘meat products after slaughtering’.

Calculating ‘water footprints’ for various countries, Hoekstra and Chapagain (2007) multiplied the water demand of crops by the amount of crops produced in different countries. No quantitative distinction was made between irrigation supply and rain. For example, an amount of 1,334 kL water per tonne of wheat is cited (compare this with 0.6 kL/t for Australian dryland wheat products; Narayanaswamy et al. 2005). Allocation to multiple products was based on the economic value of the products. Those authors estimated 17,112 L/kg for the production of Australian beef. This is not broken down into its constituents, but the global data are, indicating that roughly 1% of the total is due to ‘direct consumption’ and the remainder for feed production.

A detailed process analysis of US beef production (Beckett and Oltjen 1993) produced results between ours and those of Hoekstra and Chapagain (2007). Their estimate of 3,682 L/kg is dominated by irrigation of feed supplies. Water use for crops is based on irrigation use, and defined as ‘water which is diverted from possible use by humans’. So rain is excluded, but in the USA, 23% of the main feedstuff (alfalfa) is irrigated, and there is a large (two million hectares) area of irrigated pasture. If we substitute data for dryland wheat into this work, and remove the large irrigated pasture, their results are broadly consistent with ours.

Pimentel and Pimentel (2003) estimate that beef production requires 105,400 L/kg. Unfortunately they neither define water use nor describe their methodology in detail in this recent publication, referring instead to Pimentel (1980), who provides some data on fodder and grain consumption but does not divulge the volume of water required to grow fodder and grain. Judging by the data presented, the authors appear to adopt an approach broader than that taken by Hoekstra and Chapagain (2007), that is, one which counts all rain inputs to cropping and pasture as water used, rather than a retrospective estimate of evapotranspiration water used for pasture production. The calculations of Pimentel and Pimentel (2003) are similar to Hoekstra and Chapagain (2007) because they do not distinguish between in situ rain and engineered water supplies. This accounts for the differences between their work and ours.

5 Interpretation

We would like to emphasise that our results only represent three production systems and 2 years. It would be ambitious to take an average of these data or name a particular number as representative of water use by southern red meat producers in Australia—we are more comfortable talking about the range of results. They do nevertheless demonstrate that, from an environmental perspective, the use of water by red meat production in Australia is less than 1,000 L/kg HSCW, and several orders of magnitude lower than some authors have suggested.

Two key factors cause the considerable differences between the data presented by different authors: the treatment of rain and the feed production process. The first factor is often assumed to be a simple matter of exclusion or inclusion by many authors, but in fact deserves careful definition. While we argue that this flow may not be relevant to consequential environmental analysis, it should be noted that the hydrology-based approach we used to estimate rain inputs used here may provide a better estimate of the water use values used in ‘virtual water studies’ than the metabolic calculations typically in use because they include water needed for the maintenance of vegetation which maintains soil structure and prevents erosion, rather than just the metabolic needs of livestock. It could be argued that in studies which aim to optimise economic or calorific outcomes using attributive analysis, water needed for landscape maintenance is relevant to the ability to produce the functional unit. Regarding the second factor, most of the grain and fodder crops used in the three red meat supply chains we studied in Australia are produced by dryland cropping. In other locations where surface water supplies are more readily available, such as the USA, irrigation of cattle fodder is more common. So whereas the treatment of rain is a methodological issue relevant to all studies relating water use to the production of red meat, the availability of irrigation water can be characterised as a fundamental difference between the infrastructure of red meat production systems in different locations.

Grazing properties are open systems, so rain on a property is a special kind of dispersed renewable resource, which, like oxygen gas, is supplied by natural processes and is present no matter how the property is operated. When we consider this issue, and the differences between foreign farming systems and Australian ones, the differences between higher and lower water use calculations which have been published become clear. We have examined the literature with regard to normal LCA practice and aspects of the methodological basis for estimating water use in the production of red meat. This indicates that, for environmental assessment, rainfall is generally excluded from calculations on account of methodological and practical considerations. To allow us to nevertheless examine three southern red meat production systems from a variety of accounting perspectives, we have applied a standard agricultural hydrological modelling tool (MEDLI) to provide us with an assessment of the behaviour of rainfall at the properties participating in this study. This modelling has demonstrated that when rain is included in the accounts, the results of our assessments are similar to those of other authors reporting high water use in red meat production. However, when we consider the use of water in red meat production from a sustainability perspective, we should identify the kinds of processes used to intervene in the water cycle in obtaining water, and the quality of the water when it is returned from the production system under study. Taking either of these perspectives independently, the amount of water used in the production of red meat in the southern supply systems we studied is several orders of magnitude lower.

One of the benefits of doing detailed hydrological modelling of a foreground agricultural system is the relative certainty with which it allows analysts to use LCIA processes such as that outlined recently by Pfister et al. (2009), which necessitates geographical identification of the production system. For the future application of this kind of method to multicomponent manufactured goods (e.g. pre-mixed foods with fibre-based packaging), more detailed LCI databases will be needed in order to allow LCA tools to identify the location of water uses in background systems on a watershed scale.

Another aspect of LCI methodology which we may increasingly need to consider if we wish to understand the environmental impacts of water use is the potential for environmental damages to non-freshwater systems. Hitherto, the focus of methodological developments has understandably been driven by agricultural use of freshwater, and it is difficult to imagine estuarine or ocean waters being depleted by human uses. However, as noted previously (Peters and Rowley 2009), there is potential for environmental damage associated with filtration processes and changes in temperature and salinity when these water sources are used. We therefore consider that in addition to the classifications used here, people engaged in LCI development should include estuarine and ocean water demands as separate flows in their inventories.

6 Recommendations and perspectives

Whether or not a litre of water is used is related in the public mind and in theory, not only just to the extent to which it is physically removed from natural systems but also to the quality of the water when it is returned to the environment from the production system. We argue that the approach to reporting life cycle inventory data in policy discussions must be mindful of the needs of the data user. Where the focus is on economics and the water transactions between nations, it may be appropriate to include rain in virtual water. Where the focus is on the reduction of environmental burdens, we believe that approach is inappropriate because it fails to consider the environmental significance of water use.

In order to develop estimates that reflect those characteristics, we determined that property-scale hydrological modelling would be a worthwhile approach, with the aim of producing a rich data set. In this study, we report and group our results on the basis of several definitions of water use, including one that is consistent with normal LCA practice and the work of the ABS. Given that both the source of the water used in agriculture and the quality at which it is discharged are relevant in discussions about environmental sustainability, we suggest that analysts who are asked to contribute to public discussions ought to calculate the amount of water used in production by aggregating transferred funds and flows, and aggregating flows of water discharged at reduced quality, and report either the higher of the two figures or preferably the range.

There are many points in the process of designing a method for assessing water use in agricultural production at which value judgements may arise. The more complex the systems and environmental issues we address in LCA, the more unavoidable this becomes. Some alternatives have been proposed for the purpose of environmental assessment, but are yet to be fully validated in case studies. The key, as always, is to ensure that the goal of the study, its informational context and the assumptions made are clear. One can only hope that if more emphasis is placed on this by analysts in discussion with the media, their work will be interpreted more appropriately.

Considering that the majority of Australian beef production comes from northern Australia, it would be worthwhile to extend this work to an assessment of the water used in red meat production in that region.

Notes

Owens refers to ‘watersheds’. This may not be as clear as possible in this context. For example, transfers from part of the 106 km2 Murray-Darling watershed to another part of it might not be considered using this terminology. We think ‘watercourses’ is clearer

References

ABS (2005) 4610.0 Water Account Australia 2004-05. www.abs.gov.au. 28 Nov 2006

Allan JA (1998) Virtual water: a strategic resource, global solutions to regional deficits. Ground Water 36:545–546

Bayart J, Bulle C, Deschenes L, Margni M, Pfister S, Vince F, Koehler A (2010) A framework for assessing off-stream freshwater use in LCA. International Journal of LCA (in press)

Beckett JL, Oltjen JW (1993) Estimation of the water requirement for beef production in the United States. J Anim Sci 71:818–826

Brent A (2004) A life cycle impact assessment procedure with resource groups as areas of protection. Int J Life Cycle Assess 9(3):172–179

Brent A, Hietkamp S (2003) Comparative evaluation of life cycle impact assessment methods with a South African case study. Int J Life Cycle Assess 8(1):27–38

Coltro L, Mourad AL, Oliveira PAPLV, Baddini JPOA, Kletecke RM (2006) Environmental profile of Brazilian Green Coffee. International Journal of LCA 11(1):16–21

Ekvall T, Tillman A-M, Molander S (2005) Normative ethics and methodology for life cycle assessment. J Clean Prod 13:1225–1234

Falkenmark M, Rockström J (2006) The new blue and green water paradigm: breaking new ground for water resources planning and management. J Water Resour Plan Manage 132(3):129–132

Foran B, Lenzen M, Dey C (2005) Balancing act—a triple bottom line analysis of the Australian economy. CSIRO, Canberra

Heuvelmans G, Muys B, Feyen J (2005) Extending the life cycle methodology to cover impacts of land use systems on the water balance. Int J Life Cycle Assess 10(2):113–119

Hoekstra A, Chapagain A (2007) Water footprint of nations: water use by people as a function of their consumption pattern. Water Resour Manag 21:35–48

Hospido A, Moreira T, Feijoo G (2003) Simplified life cycle assessment of Galacian milk production. Int Dairy J 13:783–796

Johnson B (1994) Inventory of land management inputs for producing absorbent fiber for diapers: a comparison of cotton and softwood land management. For Prod J 44:39–45

Mila i Canals L, Burnip GM, Cowell SJ (2006) Evaluation of the environmental impacts of apple production using Life Cycle Assessment (LCA): case study in New Zealand. Agric Ecosyst Environ 114:226–238

Mila i Canals L, Chenowith J, Chapagain A, Orr S, Anton A, Clift R (2008) Assessing freshwater use impacts in LCA: part I—inventory modelling and characterisation factors for the main impact pathways. International Journal of LCA 14:28–42

MLA (2002) Eco-efficiency manual for meat processing. Meat and Livestock Australia, Sydney, p 138

Narayanaswamy V, Altham W, van Berkel R, McGregor M (2005) Application of life cycle assessment to enhance eco-efficiency of grains supply chains. 4th Australian Life Cycle Assessment Conference—Sustainability Measures for Decision Support, Sydney, 23–25 February, Australian Life Cycle Assessment Society, Melbourne

Owens JW (2002) Water resources in life-cycle impact assessment. J Ind Ecol 5(2):37–54

Peters G, Rowley HV (2009) Environmental comparison of biosolids management systems using life cycle assessment. Environ Sci Technol 43(8):2674–2679

Peters GM, Rowley HV, Wiedemann S, Tucker R, Short M, Schulz M (2010) Red meat production in Australia—a life cycle assessment and comparison with overseas studies. Environ Sci Technol. doi:10.1021/es901131e

Pfister S, Koehler A, Hellweg S (2009) Assessing the environmental impacts of freshwater consumption in LCA. Environ Sci Technol 43(11):4098–4104

Pimentel D (1980) Handbook of energy utilisation in agriculture. CRC, Baton Roca, 0-8493-2661-3

Pimentel D, Pimentel M (2003) Sustainability of meat-based and plant-based diets and the environment. Am J Clin Nutr 78:660S–663S

Pimentel D, Houser J, Preiss E, White O, Fang H, Mesnick L, Barsky T, Tariche S, Schreck J, Alpert S (1997) Water resources: agriculture, the environment, and society: an assessment of the status of water resources. Bioscience 47(2):97–108

Rowley HV, Lundie S, Peters GM (2009) A hybrid model for comparison with conventional methodologies in Australia. Int J Life Cycle Assess 14(6):508–516

Russell A, Ekvall T, Baumann H (2005) Life cycle assessment—introduction and overview. J Clean Prod 13(13–14):1207–1210

Scanlon BR, Jolly I, Sophocleous M, Zhang L (2007) Global impacts of conversions from natural to agricultural ecosystems on water resources: quantity versus quality. Water Resour Res 43(3):WO3437

Stewart M, Weidema B (2005) A consistent framework for assessing the impacts from resource use—a focus on resource functionality. Int J Life Cycle Assess 10(4):240–247

Udo de Haes H, Jolliet O, Finnveden G, Hauschild M, Krewitt W, Müller-Wenk R (1999) Best available practice regarding impact categories and category indicators in life cycle assessment. Int J Life Cycle Assess 4(3):167–174

Wood R, Lenzen M, Dey C, Lundie S (2006) A comparative study of some environmental impacts of conventional and organic farming in Australia. Agric Syst 89:324–348

Zygmunt J (2007) Hidden waters—a waterwise briefing. Waterwise, London

Acknowledgement

We wish to thank Meat and Livestock Australia for funding this research and the farm managers who supplied data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Annette Koehler

Rights and permissions

About this article

Cite this article

Peters, G.M., Wiedemann, S.G., Rowley, H.V. et al. Accounting for water use in Australian red meat production. Int J Life Cycle Assess 15, 311–320 (2010). https://doi.org/10.1007/s11367-010-0161-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-010-0161-x