Abstract

Background, aim, and scope

Life cycle assessment (LCA) was initially developed to answer questions about the environmental impact of available products and services, implying that the product system under study was possible to investigate in detail; however, if new products or processes are to be evaluated, several complications occur. So, this paper aims to review the methodological issues that need careful attention when LCA is used for evaluating novel products, processes, or production from an environmental standpoint, as well as to draw some recommendations related to the best approach when dealing with them.

Materials and methods

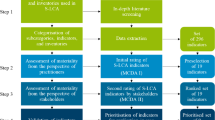

An initial brainstorming on the identification of methodological issues when applying the standard LCA methodology for the evaluation of novel products allowed the identification of the relevant aspects, on which a literature review was then performed. Periodical meetings took place for discussion of the significant references and an agreed approach validated through three case studies on the food sector was defined as result of the procedure.

Results

Five elements were identified as relevant for the specific application of LCA to novel products: type of LCA, functional unit, system boundaries, data gathering, and scenarios development. An analysis of the state of the art of the LCA methodology concerning each of them led to the definition of the recommended approach:

-

Type of LCA: prospective attributional LCA.

-

Functional unit (FU): physical FU or the inclusion of the economic dimension in the FU.

-

Scenarios development: future perspective of scenarios is required, although the particular method for scenarios development will depend on the aim of the study.

-

System boundaries: system expansion when possible and exclusion of those steps that are not affected.

-

Data gathering: specific data for the foreground system, while average data—but checking the suitability of using actual data—for the background system.

Discussion

The recommended approach was described through three case studies related to food products and processing. All were comparative studies, with the common element of including novel products (such as the production of new products from by-products) or novel processes (such as membrane technology or high pressure processing).

Conclusions

This paper has, in our opinion, helped in cleaning the area of the application of LCA to novel systems in particular related to food products and food processing which is an area of great development in the last years. The working procedure defined and applied here has worked fluently allowing the identification of the key methodological elements of an LCA and the associated state of the art, together with the validation through different case studies. The general application of our approach is difficult to assess; however, we feel confident regarding the recommendations proposed here and we hope they can be of use for other LCA users.

Recommendations and perspectives

We recommend using the approach defined here in order to check its applicability to other industrial sectors. By doing so, both us and other LCA users will benefit from the methodological improvements of this environmental management tool.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

Life cycle assessment (LCA) is one of the most widespread methods for assessing the environmental impact of products and services and has been applied in many sectors (Azapagic 1999; Baumann and Tillman 2004; Curran 2004). It was initially developed to answer questions about the environmental impact of available products. However, if novel or still underdevelopment products or processes are to be evaluated, difficulties are likely to occur. First, the inventory stage is more complex since there is no real production system to investigate; at best, there would be pilot experiments to rely on, but often, the assessment needs to be done based on lab scale information or theoretical data. Second, for comparative studies, the definition of functional unit gets complicated since the new product or process might have unique properties that make the comparison with present products difficult and less straightforward. Third, manufacture of products or the processes themselves can, in some cases, be expected to start several years ahead, and assumptions on surrounding systems (e.g., energy supply; marginal or average, as well as what production system to assume) will be required.

Food has been, and still is, well-investigated using LCA (i.e., Andersson 2000; Berlin 2005; Hospido 2005; Hospido et al. 2009; Jungbluth et al. 2000; Mattsson and Sonesson 2003; SIK 2007). Food products differ largely between sub-groups, e.g., the environmental impact from animal and vegetable products often differs by a factor of 10. Moreover, many food products have a short economic lifetime where old products are rapidly substituted by new. This replacement is driven by the strong competition between producers, and new products are an important part of business strategies as consumers favour new products, which are often perceived as superior to the present ones. On the other hand, the environmental assessment of novel products and processes is important for food producers since, lately, many of them have introduced sustainability as a core company goal. Hence, the need for a structured methodology is urgent. All this together makes food products and production very suitable, as cases when developing a methodology for LCA-based assessments of novel products and processes. In this paper, 'novel' refers to new or of a new kind. In terms of products, this means either entirely new products introduced to the market (e.g., products developed from food industry by-products) or products which have been altered somehow and, therefore, might replace similar products already on the market. Similarly, 'novel' processes imply new or improved techniques used in food production systems.

Other than to perform a thorough revision on the principal problems associated to the application of LCA in general (as deeply presented by Reap et al. (2008a, b)), the present paper aims to review the methodological issues that needs careful attention when LCA is used for evaluating novel products, processes, or production from an environmental standpoint. Besides, our objective also includes drawing suggestions related to the best approach when dealing with them. By means of the food processing sector as an example of application, case studies will be used to illustrate the methodological choices proposed. The general application of our approach is difficult to assess, and, as mentioned, our objective was not to carry out an in-depth review of the main problems associated to the LCA methodology. Nevertheless, we feel confident regarding the recommendations proposed here and we hope they can be of use for other LCA users.

2 Materials and methods

Standard LCA methodology (ISO14040 2006; ISO14044 2006) was used as the starting point for the brainstorming on the identification of methodological issues when applying this environmental tool for the evaluation of novel products. The working procedure advanced into the selection of the relevant aspects, on which a literature review was then performed. Periodical meetings took place for discussion of the significant references, and an agreed approach was defined as result of the procedure. Finally, the established recommendations were discussed by their application through case studies. The relevant aspect came out to be type of LCA, functional unit, scenario development, system boundaries, and data gathering which is further explained below.

2.1 Type of LCA

LCA studies are typically classified as accounting (also called descriptive, retrospective, or attributional) or change-oriented (also called prospective or consequential; Baumann and Tillman 2004). These two groups of terms have traditionally been considered contradictory between them but equivalent within them. However, Sandén et al. (2005) proposed another LCA typology that distinguishes three important dimensions and clarifies, from our point of view, the classification better:

-

Responsibility: attributional (state-oriented) versus consequential (effect-orientated). In the former, the object of study is assumed to be responsible for a share of the total environmental impact in a steady state, while in the latter, it is responsible for how the environmental impact is affected when the state is changed.

-

Time: retrospective (looking back) versus prospective (looking forward). The former looks back at historic environmental impact and the latter looks forward at future environmental impact.

-

Technical generality: product LCA versus technology LCA. The former seeks to investigate the impact of a specific product, plant, or production process, while the latter is an assessment of a more general technology.

In this line, Sandén and Karlström (2007) states that the traditional accounting type of LCA can be used to investigate how a technology or product would perform in a different steady state, regardless where, in time, this new steady state is located. So, prospective attributional LCA is assumed to be the most suitable approach to evaluate novel systems.

Regarding the third dimension, references representing technology are for example Jonasson and Sandén (2004) and PehntFootnote 1 (2006). Kilgus (2005) is an example of a reference considering product prospective attributional LCAs. In all of them, the key methodological challenges (the selection of a relevant state, and functional unit and set of alternatives) depend on the specific case under study. Therefore, the selection between product and technology is associated with the specific case study, and no general recommendation can be made.

2.2 Functional unit

Novel systems can represent new products that answer to new needs and need to be evaluated per se (stand-alone studies). They are also likely to describe situations where novel products will compete against similar products, if any, already in the market or situations where novel processing techniques are expected to replace already established ones in order to produce different (or similar) products. Comparison is, therefore, expected to occur, and the definition of the FU is then vital to ensure that the same function is fulfilled and that the comparison is meaningful (Baumann and Tillman 2004).

The classification of properties (obligatory, positioning, and market-irrelevant) defined by Weidema (2003) is recommended to be used as starting point for the correct definition of products under comparison. Obligatory and, whenever possible, positioning properties need to be covered by the functional unit defined. If positioning properties entail specific extra functions, these need to be considered as co-products, and system expansion is one of the recommended methods to do so (ISO14044 2006).

Our approach is then to include system expansion when feasible and use a mass-based functional unit, which is normally the option used (Schau and Fet 2008). When the properties of the new products cannot be completely described by a mass-based functional unit, the combination of physical and economic parameter units is recommended as the inclusion of the economic dimension is likely to be the better way to complete the accurate description of the product.

2.3 Scenarios development

At the time an LCA study is performed, novel products are likely to still be under development (laboratory or pilot scale), so the analysis would take place in a supposed future scenario where the product or process is available on a hypothetical industrial scale. A key methodological issue is the definition of the relevant future state (Jonasson and Sandén 2004). This relevant state may be performed by scenario development. There are several methods for scenario development with a future perspective, but three main categories were distinguished by Börjesson et al. (2005): predictive scenarios, explorative scenarios, and normative scenarios. According to Weidema et al. (2004) the two basic approaches of scenarios in the context of LCA are what-if scenarios which can be considered as a predictive scenario and cornerstone scenarios which fall into the category of explorative scenarios. What-if scenario is used when a quantitative comparison of selected options is requested. Cornerstone scenario is used when a guidance of a potential direction of future development is desired.

There are significant differences in which parts within the system boundaries will be affected in a scenario, and that depends on the time perspective. If the process or the production system associated to a product are already available but have not yet been used in the particular area of investigation, the time perspective can be much shorter (some months or 1 year). This short-time perspective is used by Berlin and Sonesson (2008) in their development of what-if scenarios of industrial production scheduling. Comparing this with a novel process that just have been tested in a lab scale, the time perspective in the latter case will then be further on in the future (several years). If changes in society will take place depending on the novel product or process, the foreground system boundary need to be expanded to include all changes. An example of cornerstone scenarios 20 years ahead with societal changes is Sonesson and Berlin (2003). To conclude, the time perspective decides how thoroughly the analysis of the future will be. For a short time-perspective, only activities within the foreground system are likely to change, but for a longer time, perspective activities within the background system must be changed as well.

2.4 System boundaries

Among the several dimensions stated by Tillman et al. (1994), the definition of the system boundaries within the technical systems seems to be the most specific for the type of studies considered in this paper. It includes both the boundaries relative to production capital or personnel, as well as the borders in relation to other products' life cycles.

Regarding the former, the general recommendation is to disregard capital and personnel when evaluating novel food products. However, and taking into account the review by Frischknecht et al. (2007) as well as the paper by Muñoz et al. (2006), where infrastructure was found to be a relevant parameter when comparing processes on lab scale and on industrial scale, a sensitivity analysis is suggested in order to evaluate the possible implications of infrastructure exclusion.

When the same process(es) is shared by several products or functions, boundaries in relation to other products' life cycles need to be defined. Subdivision, system expansion, and allocation are the hierarchical recommendation by the ISO standards (ISO14044 2006). The classification of what is included in the system under study and what is excluded from the system is tightly dependent on the functional unit defined, and system expansion was already chosen as the preferable option.

Finally, conventional and novel products are likely to share some parts of the production chain and, therefore, to include the whole life cycle in the analysis is not required. So for comparative studies, we suggest to only include the parts of the chain that are affected by the change in production technique (Fig. 1). For example, if a process change affects the raw material efficiency, i.e., if the amount of raw material needed to produce the functional unit is changed, then all upstream stages will be included in the analysis. Similarly, if the novel processing affects the product quality in a way that will result in a different downstream handling of the product, those stages are included in the system boundary.

2.5 Data gathering

Within an LCA, processes are generally divided into a foreground and a background system (Tillman 2000; Clift 2005).

Data describing the foreground system should be collected from the specific case study, trying to get representative and updated data of the steady state performance of the system. When dealing with novel products, this can be particularly difficult as such a steady state is probably lacking, and data will then be derived from experiments in the laboratory (Muñoz et al. 2006; Norgate et al. 2007; von Gleich et al. 2008) or from computer modelling (Krewer 2008). However, these lab-related data can change significantly during the scaling to industrial applications (i.e., Muñoz et al. (2006) studied the implications of different scales in the performance of an LCA and found that the results and conclusions obtained through the streamlined laboratory-derived LCA and the detailed full-scale LCA did not match, to the extent that the evaluated technologies were ranked in a different order) and, therefore, sensitivity analysis based on learning curves or experts estimations can be suitable.

Changes in background systems could be divided into those related to time, not affected by the foreground system, and those related to the scale of penetration of the studied product, indirectly affected by the foreground system (Jonasson and Sandén 2004). The former is related to how far in the future the relevant state is defined (see Section 2.3), while the latter is mainly important for technology LCAs where the behaviour of the foreground system can affect the background systems, such as the changes in the electricity mix due to the large scale of penetration of solar cells (Sandén et al. 2005; Pehnt 2006). Average data, representing the future time when the analysis is located and not current data, are assumed to be suitable for the former type of changes. The existence of the second type of changes will depend on the particular sector assessed and, in this sense, references concerning energy and transport systems can be found in (Pehnt 2006; Jonasson and Sandén 2004, respectively), where technological changes, more than products, that are likely to affect background systems such as the electricity production mix, were the focus of the study. In many other situations, the background system will not be affected by the system under study, and therefore those changes will not take place.

Conclusively, our recommended approach would join the use of on-site specific data combined with sensitivity analysis to evaluate the possible scale-up effects for the foreground system and average data at the relevant stage in the future when the study is placed for the background data. Regarding the latter, each case study will define the requirements of forecasting in order to properly define the background system at the relevant state; and for short-time case studies, actual average data are suitable as the background changes are likely to be slower than those affecting the foreground system.

3 Results

The previous section has described the key methodological issues and the associated review carried out regarding the state of the art of the LCA methodology. As a summary, Table 1 recapitulates the above-described suggested choices for dealing with each issue.

Then, and following the working procedure defined above, Table 2 summarises the application of our approach in three different case studies, which are shortly described below.

3.1 Membrane filtration (CS1)

The first case study deals with the implementation of membrane filtration technology (ultrafiltration, UF, and nanofiltration, NF) in two different food processing industries in Sweden: a dairy and an abattoir by-product treatment industry. The aim was to increase process efficiency and to compare the environmental impact of today's process combination with the new scenarios that include membrane technology (Davis et al. 2007). Each industry and the studied process combinations are described below.

3.1.1 Dairy (CS1A)

Rinse milk is a mixture of water and milk that is created when water is flushed through the processing units in order to clean the equipment. At the dairy plant in this study, about 12,000 L of rinse milk is generated each day. Presently it is used as animal feed, but its value can be increased if it is used in fermented milk products. By applying NF, the rinse milk could be concentrated from 3% dry matter content to about 11%, which is required to be used in the production of fermented milk. Here, the aim was to compare the environmental impact of current fermented milk production using condensed milk, with the impact of producing fermented milk with nanofiltered rinse milk. The FU of the study is 10,000 L of fermented milk, plus a certain amount of feed (feed from today's system: 4,693 L of rinse milk; feed from NF system: 158 kg soy meal). The soy meal is included in the NF system so that both systems deliver the same function (i.e., fermented milk plus feed). In the comparison of the two process combinations, only the difference in raw milk requirement was taken into account in the analysis. Moreover, the environmental impact of the actual milk treatment step, which is identical in both process combinations, was also excluded.

3.1.2 Abattoir (CS1B)

The plant processes bones and fat from Swedish abattoirs and turns them into several products: meat and bone meal, fat, protein powder, bone chips, and calcium powder. An economic analysis performed by the industry showed that the membrane technology was best utilised for upgrading the process water from by-products originating from pigs (steaming of the bones to remove the fat results in a solid fraction, fat, and a liquid fraction called process water) and ultimately improving the quality and value of the protein powder. Here, an environmental assessment has been conducted for today's process combination compared to three different combinations using UF and NF for producing different quantities and qualities of the protein powder. The FU of the systems is the amount of raw material (bones) processed in 1 year at the plant (the reason, partly, for this choice was that a very important function of the plant is to process the residual flows from Swedish slaughterhouses). The proportions of final products vary, partly in volume but also in quality. This is something that is not reflected in the FU. Therefore, to give a fair comparison, the results from the study are presented in two ways: (1) related to the FU, and (2) related to both the FU and the total economic profit of the products, i.e., the environmental impact per year divided by the yearly profit of the products generated by each combination. The differences between the four process combinations lie in how the process water originating from pig by-products is utilised. The amount of input to all combinations is the same, but the quantity of each generated product differs; and, in the case of protein powder, the quality is also enhanced by incorporating membrane filtration-processed water into the protein powder, which gives it a better flavour and thereby a higher economic value.

Data on the background system were taken from databases. The process data at the dairy and the abattoir were obtained from personal communication with personnel at the plants. The calculation of the profits for the products in the abattoir case study were based on running costs such as labour, energy, water, etc., and investment costs.

3.2 High pressure (CS2)

The second case study describes the use of high pressure (HP) processing, a novel technology that inactivates microorganisms by subjecting the food to elevated pressures, with or without the addition of heat. In this way, the amount of time the food is heated is significantly reduced compared to conventional heating or heating is avoided completely, and the food retains its fresh-like character better.

The aim of the study was to compare the environmental impact of fresh tomato salsa (untreated) and HP-treated salsa with conventional heat treated tomato salsa (Davis et al. 2009). The resulting products are slightly different in terms of freshness, storage requirement, and shelf life. The composition of the untreated and HP-treated salsa is slightly different to the conventionally heat-treated salsa which contains tomato purée. Since the products being compared have slightly different composition and will be stored differently after production, the system includes all the steps from agriculture up to consumption at the household. The FU of the study was 1 kg of salsa at the consumer. It was not feasible to include the economic value of the products in the FU, since no data on price for HP-treated salsa were available.

The data for industrial processing of conventional tomato salsa were gathered from a producer in Sweden. Regarding the energy use for the high pressure processing, data from models and experts were used. Data for cultivation of tomatoes and onions were taken from published reports (Cederberg et al. 2003; Högberg 2009), and data on energy production, transport, and glass were taken from the Ecoinvent database (Hedemann and König 2007).

3.3 Liquefaction of red cabbage trimmings (CS3)

Finally, a novel treatment of a food processing waste is presented. Traditionally, the disposal of vegetable by-products from cutters and other vegetable processors was cattle feed. However, changes in legislation into a more restricted control of the use of these residues are likely to press and reduce this way of disposal and, consequently, new routes need to be evaluated.

The Brassica vegetables are converted to sliced fresh and frozen products for the consumer and retail markets, but about 15% (weight) ends up as by-products. This study aims to answer the question "Among the different options to deal with red cabbage trimmings (RCT), which is the alternative with less environmental impact associated?". The function of the system is then to process the RCT. The FU defined was 1,000 kg of RCT leaving the red cabbage slicing process. Based on expert judgments on profitability, several scenarios [(a) present disposal, (b) the novel processing where a maximum benefit is expected from the production of different value-added products (dietary fibre, phytochemical-rich juice, pectin, and modified hairy regionsFootnote 2), and (c) the default option for an organic waste: composting)] were defined for comparison. The three systems were expanded so as to include the alternative means of production for all the products obtained.

Data gathering for the foreground system combined computer modelling for the novel process (Krewer 2008) and real data for already existing production processes (of each particular product or the most similar available ones). Regarding the background system, the time horizon (5–10 years) was considered short enough to use present data from databases (Hedemann and König 2007).

4 Discussion

All the case studies presented here (Table 2) are comparative studies within the food sector, with the common element of including novel products or processes. The case studies regard the production of new products from by-products (CS1A and CS2) and the treatment of by-products from the food industry by membrane technology or high pressure processing (CS1B and CS3). For all of them, the prospective attributional LCA is, from our point of view, the proper type of LCA as it gives a description of a hypothetical future situation where those products and/or processes are available and can be effectively compared.

When translating the properties classification presented above into food products, obligatory properties could be those associated to provide nutrition (energy, protein, carbohydrates, fat, vitamins, etc.), while positioning properties could be those related with improved taste, lower price, lower carbon footprint, or convenient packaging. Obligatory properties can be quite well-represented by a physical FU (mass- or nutrient-based one), but the inclusion of positioning properties is more difficult to carry out in this sense. Davis et al. (2007) suggested and successfully put into practise the combined utilisation of physical and economic parameters by presenting the results of the abattoir by-product treatment industry by mass and economic profit (CS1B), and showing the different classification of the options under study in terms of contribution to global warming potential and the other impact categories analysed. Profits or prices of novel products can however be unknown as they might not yet be in the market and, in those cases, expert estimations can be used to guess a range of possible values and a break-even value can be calculated. Just for clarification, Fig. 2 presents a hypothetical comparison where the conventional product has an environmental impact of 150 units/FU and a known price of 15 units/FU, while novel product has a higher environmental burden (i.e., 170 units/FU) and unknown price that estimation can be assumed to vary from 10-25 units.

Modifications of processes due to the implementation of novel technologies are likely to be well-described by the definition of what-if technological scenarios, whereas experts' opinions based on the likely achievable profitability from the waste were used for the definition of the by-product and waste management alternatives.

As recommended, system expansion was applied whenever possible (CS1A and CS3) in order to make the alternatives equivalent in terms of outputs from the system. On the other hand, all studies except for CS2 presented common steps that can be excluded without affecting the comparison carried out.

Regarding the data gathering, several types of data were collected from the description of the foreground system (from lab scale to real industrial facilities, as well as computer modelling results) depending on the case study. However, for the background data, actual LCA database were always used as all the case studies presented can be considered short-time.

5 Conclusions

This paper has described the process carried out in order to define a methodological approach for the application of LCA to novel products as well as the validation through case studies from a particular industrial sector. By doing so, this paper contribute with recommendations of the application of LCA to novel systems, in particular, related to food products and food processing that is an area of great development in the last years.

The working procedure defined and applied here has worked fluently allowing the identification of the key methodological elements of an LCA and the state of the art associated methodology, together with the demonstration through different case studies. The proposed suggestions are not as related to the food sector, although they were validated using studies from the food sector, we cannot foresee problems using the recommendations for other areas as well.

6 Recommendations and perspectives

We recommend using the approach defined here in order to check its applicability to other industrial sectors, as specific focus has been paid on the food processing one. By doing so, both us and other LCA users will benefit from the methodological improvements of this environmental management tool.

Notes

The author named his approach Dynamic LCA, considering that "dynamic does not necessarily mean that the development of the product and background system is modelled continuously, but rather it means that a future state of the system is modelled considering the future characteristics of the background and the model system" (Pehnt 2006).

Schols et al. (1990) described the isolation and characterization of a cell-wall polysaccharide from the liquefaction of apple juice, which are called modified hairy regions. Its beneficial uses are still under research and the possible replaced products are not yet identified. As a result, this product was disregarded and excluded in all the scenarios.

References

Andersson K (2000) LCA of food products and production systems. Int J Life Cycle Assess 5(4):239–248

Azapagic A (1999) Life cycle assessment and its application to process selection, design and optimisation. Chem Eng J 73:1–21

Baumann H, Tillman AM (2004) The hitchhiker's guide to LCA: an orientation in life cycle assessment methodology and application. Studentlitteratur, Lund, Sweden. ISBN: 91-44-02364-2

Berlin J (2005) Environmental improvements of the post-farm dairy chain production management by systems analysis methods. Thesis. Department of Energy and Environment, Chalmers University of Technology; Gothenburg, Sweden

Berlin J, Sonesson U (2008) Minimising environmental impact by sequencing cultured dairy products: two case studies. J Clean Prod 16:483–498

Börjesson L, Höjer M, Dreborg K-H, Ekvall T, Finnveden G (2005) Towards a user’s guide to scenarios—a report on scenario types and scenario techniques. Environmental strategies research—fms; Stockholm, Sweden

Cederberg C, Wivstad M, Bergqvist P, Mattsson B, Ivarsson K (2003), Analys av olika strategier för att minska risken med kemiska bekämpningsmedel (analysis of different strategies to reduce the risk of pesticides, in Swedish), Rapport MAT21 no 6/2005, SIK—The Swedish Institute for Food and Biotechnology, Gothenburg, Sweden

Clift R (2005). Integrating LCA and process flow sheeting to analyse industrial ecosystems. Presented at the Seminar on Energy and Industrial Ecology. Norwegian University of Science and Technology, 11 may, Trondheim (Norway). http://www.indecol.ntnu.no/indecolwebnew/events/guestlectures/documents/energyseminar110505/Roland%20Clift.pdf

Curran M (2004) The status of life cycle assessment as an environmental management tool. Environ Prog 23(4):277–283

Davis J, Sonesson U, Östergren K (2007) Development of an LCA methodology to assess the environmental impacts of process changes: two case studies in Sweden. Food Manuf Effic 1(2):1–10

Davis J, Moates G, Waldron K (2009) High-pressure processing: a step toward sustainability?, Food Safety Magazine, October/November 2009

Frischknecht R, Althaus HJ, Bauer C, Doka G, Heck T, Jungbluth N, Kellenberger D, Nemecek T (2007) The environmental relevance of capital goods in life cycle assessments of products and services. Int J Life Cycle Assess 12(1):7–17

Hedemann J, König U (2007) Technical Documentation of the ecoinvent Database. Final report ecoinvent v2.0 No. 4, Institut für Umweltinformatik, Hamburg, DE, Swiss Centre for Life Cycle Inventories, Duebendorf, CH, for ecoinvent members only

Högberg J (2009) European tomatoes—comparing global warming potential, energy use and water consumption form growing tomatoes in Sweden, the Netherlands and the Canary Islands using life cycle assessment, Master thesis from Department of Environmental Systems Analysis at Chalmers University of Technology. Gothenburg (Sweden)

Hospido A (2005) Life cycle assessment as a tool for analysing the environmental performance of key food sectors in Galicia (Spain): milk and canned tuna. Thesis. Department of Chemical Engineering, University of Santiago de Compostela, Santiago de Compostela, Spain

Hospido A, Milà i Canals L, McLaren S, Truninger M, Edwards-Jones G, Clift R (2009) The role of seasonality in lettuce consumption: a case study of environmental and social aspects. Int J Life Cycle Assess 14(5):381–391

ISO14040 (2006) Environmental management—life cycle assessment—principles and framework

ISO14044 (2006) Environmental management—life cycle assessment—requirements and guidelines

Jonasson K, Sandén BA (2004) Time and scale aspects in LCA of emerging technologies: case study on alternative transport fuels. CPM-report 2004:6. http://www.cpm.chalmers.se/document/reports/04/CPM_Report_2004_6_Time%20and%20Scale%20Aspects%20in%20LCA.pdf

Jungbluth N, Tietje O, Scholz RW (2000) Food purchases: impacts from the consumers’ point of view investigated with a modular LCA. Int J Life Cycle Assess 5(3):134–142

Kilgus D (2005) Life cycle assessment of a demonstration project—vehicle use of hydrogen-blended natural gas. ESA report 2005:16. http://www.esa.chalmers.se/Publications/PDF-files/Thesis/ESA200516.pdf

Krewer C (2008) Environmental LCA of utilizing red cabbage trimmings as novel products Simulation of environmental impact, costs and microbiological activity related to processing red cabbage trimmings Master thesis from Department of Environmental Systems Analysis at Chalmers University of Technology. Gothenburg, Sweden

Mattsson B, Sonesson U (2003) Environmentally friendly food processing. Woodhead Publishing Limited, Cambridge, UK. ISBN 85573 6772

Muñoz I, Domenech X, Malato S (2006) Life cycle assessment as a tool for green chemistry: application to different advanced oxidation processes for wastewater treatment. CIEMAT, Madrid, Spain. ISBN 84-7834-520-5

Norgate TE, Jahanshahi S, Rankin WJ (2007) Assessing the environmental impact of metal production processes. J Clean Prod 15:838–848

Pehnt M (2006) Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew Energy 31:55–71

Sandén BA, Karlström M (2007) Positive and negative feedback in consequential life-cycle assessment. J Clean Prod 15:1469–1481

Sandén BA, Jonasson KM, Karlström M, Tillman AM (2005) LCA of emerging technologies: a methodological framework. LCM 2005—innovation by life cycle management; Book of Proceedings. Barcelona, Spain, September 5–7, 2005, pp 37–41

Schau EM, Fet AM (2008) LCA studies of food products as background for environmental product declarations. Int J Life Cycle Assess 13(3):255–264

Schols HA, Posthumus MA, Voragen AJG (1990) Structural features of hairy regions of pectins isolated from apple juice produced by the liquefaction process. Carbohydr Res 206:117–129

SIK (2007) The Swedish Institute of Food and Biotechnology. 5th International Conference LCA in foods. Book of Proceedings. SIK, Gothenburg, Sweden, 25–26 April. http://www.sik.se/lcafoods2007

Sonesson U, Berlin J (2003) Environmental impact of future milk supply chains in Sweden: a scenario study. J Clean Prod 11:253–266

Reap J, Roman F, Duncan S, Bras B (2008a) A survey of unresolved problems in life cycle assessment. Part 1: goal and scope and inventory analysis. Int J Life Cycle Assess 13:290–300

Reap J, Roman F, Duncan S, Bras B (2008b) A survey of unresolved problems in life cycle assessment. Part 2: impact assessment and interpretation. Int J Life Cycle Assess 13:374–388

Tillman AM (2000) Significance of decision-making for LCA methodology. Environ Impact Assess Rev 20(1):113–123

Tillman AM, Ekvall T, Baumann H, Rydberg T (1994) Choice of system boundaries in life cycle assessment. J Clean Prod 2(1):21–29

von Gleich A, Steinfeldt M, Petschow U (2008) A suggested three-tiered approach to assessing the implications of nanotechnology and influencing its development. J Clean Prod 16:899–909

Weidema BP (2003) Market information in life cycle assessments. Technical report, Danish Environmental Protection Agency (Environmental Project no. 863). http://www2.mst.dk/udgiv/publications/2003/87-7972-991-6/pdf/87-7972-992-4.pdf

Weidema BP, Ekvall T, Pesonen HL, Rebitzer G, Sonnemann GW, Spielmann M (2004) Scenarios in life cycle assessment. SETAC, Pensacola FL, USA. ISBN 1-880611-57-0

Acknowledgements

This work has been carried within the framework of two EU-6FP-funded projects: Novel Processing Methods for the Production and Distribution of High-Quality and Safe Foods (NovelQ; ref: FOOD-CT-2005-015710) and Reducing food processing waste (REPRO; ref: FOOD-CT-2005-006922). Dr. Hospido acknowledges the Spanish Ministry of Education and Science for financial support during her postdoctoral stay at SIK (Jose Castillejo Programme) as well as the Xunta de Galicia for her postdoctoral fellow position (Isidro Parga Pondal Programme).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Niels Jungbluth

An erratum to this article can be found at http://dx.doi.org/10.1007/s11367-010-0168-3

Rights and permissions

About this article

Cite this article

Hospido, A., Davis, J., Berlin, J. et al. A review of methodological issues affecting LCA of novel food products. Int J Life Cycle Assess 15, 44–52 (2010). https://doi.org/10.1007/s11367-009-0130-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0130-4