Abstract

Background, aim, and scope

North American pulp and paper mills are facing tremendous challenges, which may necessitate major mill modernizations. An example is process modification to reduce dependency on purchased power, which is an expensive resource. Such modifications may have environmental implications at the mills’ sites, on their product life cycle, and on other interconnected systems, and therefore, systematic tools such as life cycle assessment (LCA) need to be applied. Different LCA system boundary approaches can be used for such process design applications, and these approaches need to be compared to determine their respective benefits and limitations in this context. This study compares setting the system boundary according to a cradle-to-gate approach [attributional LCA (ALCA)] and a system expansion [consequential LCA (CLCA)] approach using a case study, which deals with implementing cogeneration and increased de-inked pulp production at an integrated newsprint mill.

Methodology

A case study considering various process options to reduce purchased electricity at an integrated newsprint mill is defined. These options include implementing cogeneration and increasing de-inked pulp production. The environmental impacts related to these process options are analyzed using two LCA methodologies. The first one consists in setting the system boundary according to a cradle-to-gate ALCA approach, while the second one uses a differential CLCA approach (system expansion). Comparisons of the two methods are based on different parameters: inclusion/exclusion of the indirect environmental consequences, selected allocation procedures, and effect of using the average versus the marginal technology for power production.

Results

Both the ALCA approach and the CLCA approach indicate that the process options are beneficial. However, the results show that indirect environmental consequences, which are assessed only with the CLCA approach, can be opposite to direct effects (e.g., the results can indicate an improvement of the direct impacts and a deterioration of the indirect ones). In addition, environmental impacts obtained by modeling the average or the marginal technology may be very different. Using an ALCA approach often necessitates the use of an arbitrary allocation procedure, which can greatly affect the results. On the other hand, ALCA can be used to perform “hot spots” identification, which, at this time, is not possible with CLCA.

Discussion

The cradle-to-gate boundary approach, which is usually used in the literature for pulp and paper process design applications, may not always be the most appropriate to determine the environmental consequences of implementing different process options. However, at this time, there is no method based on CLCA allowing for “hot spots” identification, and thus, a combined approach may be required for process design.

Conclusions

It is shown that the choice of the system boundary can significantly affect the results. More specifically, the usage of different allocation procedures in ALCA leads to different interpretation of the results, which does not occur when using the CLCA approach. CLCA provides more complete information for decision making for the cases where most of the consequences occur outside the life cycle of the product investigated.

Recommendations and perspectives

Research opportunities include developing methodologies to integrate ALCA and CLCA for improved process design applications and mechanisms for reducing uncertainty in CLCA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

North American pulp and paper mills are currently facing tremendous challenges from which energy prices is an important one. In order to remain competitive, they may be forced to consider major mill modifications to reduce their energy costs. This kind of modification may have environmental implications at the mill site, in its product life cycle, as well as on other interconnected systems. Life cycle assessment (LCA) has been used more abundantly to assess the environmental impacts of process modifications. Most applications have involved the selection of cradle-to-gate system boundary definition (i.e. from resource extraction to the manufacturing of the product). However, it has become increasingly apparent that limiting the system boundary to the investigated product system when assessing the environmental impact of a change to this product may lead to serious underestimation of the environmental consequences of such a change. This paper deals with this issue of system boundary selection.

1.1 System boundary selection for pulp and paper process design applications

A survey of the use of LCA in the pulp and paper industry (Gaudreault et al. 2007a, b) showed that the main applications can be classified in five categories: (1) comparison of products with the same function, (2) comparison of process options, (3) comparison of waste management options, (4) evaluation of new products, and (5) strategic planning. This paper focuses on the process options comparison application. Examples of applications for process selection include the comparison of alternatives concerning pulping processes (Vizcarra et al. 1999; Das and Houtman 2004; Salazar Zarate 2004), bleaching processes (Scheringer et al. 2000; Dias et al. 2002; Fu et al. 2005), energy strategies (Lopes et al. 2003; Salazar Zarate 2004; Cornejo et al. 2005), effluent treatment (Salazar Zarate 2004; Munoz et al. 2006), and chemical recovery (Rehnstrom 2003). The system boundaries that were defined in these studies are presented in Table 1. All previous LCA studies used a system boundary approach, which attempts to allocate the environmental impact due to one product and/or process. In order to do this, allocation procedures are used when multifunctional processes are necessary to achieve the main function of the system. For instance, chip usage for pulp production is often a by-product of sawmill operations for which the main product is lumber. Lumber production is not of interest when investigating the environmental impacts of pulping. Therefore, an allocation procedure should be selected to determine which proportion of the sawmill operations environmental impacts are imputable to chips versus lumber.

Most studies mentioned previously used a cradle-to-gate approach to establish the boundary, and two of them used a cradle-to-grave approach (i.e., use and final disposal of paper were also included in the assessment). Using these approaches does not allow investigating the potential indirect effects of selecting one process option versus another one because these occur outside the defined boundary. The potential indirect effects related to the studies are also presented in Table 1. An example of this can be demonstrated by the case of replacing a portion of the thermo-mechanical pulp (TMP) by de-inked pulp (DIP) and implementing cogeneration at a newsprint mill in order to reduce purchased electricity (Salazar Zarate 2004). In this case study, the cradle-to-gate boundary (from resource extraction to paper distribution) was used. The main effects on the process of implementing DIP pulp production and cogeneration were an increase of recycled fiber consumption, a reduction of chip (virgin fiber) consumption, an increased amount of steam to be generated from natural gas and/or wood waste (to compensate for the reduction of steam production due to the complete or partial shutdown of the TMP plant), and a decreased usage of purchased power. As a result of the system boundary selection, several underestimations of the environmental consequences related to process modification may have been made. For instance, the increased consumption of recovered fiber was dealt with using a landfill credit. However, the waste paper market may be competitive, and it is possible that the increased consumption of recycled fiber in the system results in the deviation of waste paper from other usages rather than from landfill. In order for these consequences to be revealed, it would have been necessary to expand the system boundary to the recycled paper market and alternative usage of waste paper. Another example is the decrease in chip consumption due to the reduction of TMP pulp production. Using the cradle-to-grave boundary and the selected allocation procedures, this reduction led to a proportional reduction of forest operations. Chips are a by-product of lumber production and will be produced, although the investigated system does not consume them anymore. Thus, in order to investigate the environmental consequences of this reduction, it is necessary to expand the system boundary to the chip market and to alternative usages. An equivalent reasoning can be applied to wood waste consumption. Finally, the process options significantly reduced purchased electricity consumption. Using classical ALCA, it would be assumed that the average technology is reduced, which may not be the case in reality.

The previous example as well as those presented in Table 1 show that indirect environmental consequences of a process design decision can occur outside the fixed cradle-to-gate or cradle-to-grave system boundary. There is no application of LCA for pulp and paper process design that systematically assesses the importance and relevance of setting the system boundary in a way that includes the indirect consequences of the process alternatives for design decision making. In addition, it was recognized that the influence of different allocation procedures on the results of LCA of wood-based products, and more specifically recycling, can be significant (Ekvall and Tillman 1997; Ekvall 1999a, b; Vogtlander et al. 2001; Guinee et al. 2004; Yamada et al. 2006). Usage of allocation procedures is a consequence of attempting to assign the environmental impacts to one specific product or process. This indicates the need to investigate alternative approaches for setting the system boundary that include the indirect environmental consequences and that avoid allocation procedures.

1.2 Methodological developments in LCA system boundary selection

The ISO 14040 standard (ISO 2006a) defines LCA as a tool that “addresses the environmental aspects and potential environmental impacts [...] of products throughout a product’s life cycle from raw material acquisition through production, use, end-of-life treatment, recycling and final disposal (i.e. cradle-to-grave)”. According to this standard, LCA has multiple applications, such as the identification of environmental improvement opportunities, market claims, and decision support. According to ISO, the choice of the processes to include in the system boundary depends on the goal and scope definition of the study. In this regard, there is a growing consensus in the LCA community that LCA applications can be classified in two main fields: LCA aimed at describing the life cycle environmental impact of a product, process, or service [accounting LCA or attributional LCA (ALCA)] and LCA aimed at describing the consequences of a specific decision [change-oriented LCA or consequential LCA (CLCA)] (Ekvall 1999b; Tillman 2000; Ekvall and Weidema 2004; Ekvall and Andrae 2006; Lesage et al. 2007a, b). The methodologies used for these two approaches are different, more specifically regarding system boundary selection and inventory compilation.

ALCA is more closely related to the classical ISO 14040 definition and proposed methodology although the standard now recognizes the differences in the two types of applications. The purpose of ALCA is to provide information concerning the environmental properties of a product’s life cycle. Therefore, effects on other life cycles are outside the ALCA system’s scope. Allocation procedures are used when multifunctional processes are necessary to deliver the main function of the investigated product, process, or service. Because the goal is to determine the environmental impacts imputable to one specific product, process or service, average technologies are modeled (e.g. for electricity production). Characteristics of CLCA when compared to ALCA are as follows:

-

No attempt is made to allocate environmental impacts to one specific product, process, or service, and thus, allocation is not required.

-

Indirect consequences of a specific decision regarding the investigated product, process, or service are systematically addressed, and consequently, the marginally affected technology is identified.

-

Parts of the system not affected by the decision are usually not considered, and only changes are calculated.

To the knowledge of the authors, only two case studies compared the results obtained with both ALCA and CLCA approaches (Ekvall and Andrae 2006; Lesage et al. 2007a, b). The first one (Ekvall and Andrae 2006) assessed the effects of replacing lead-containing by lead-free solder pastes, while the second one (Lesage et al. 2007a, b) focused on the environmental consequences of brownfield rehabilitation alternatives. The two studies illustrated the importance of modeling indirect environmental consequences. They also discussed the complementary knowledge resulting from the two approaches and the limited relevance of CLCA when direct environmental consequences are much more significant than indirect consequences. None of these case studies systematically demonstrated the advantages of CLCA due to avoiding subjective selection of allocation procedures. There is clearly a need for more case studies comparing the two approaches.

2 Objective

The objective of this paper is to compare the information provided by ALCA and CLCA approaches for decision making regarding the selection of process options aiming at reducing the dependency of an integrated newsprint mill to purchased electrical power. More specifically, the potential importance of indirect environmental consequences of the process options (addressed by CLCA but not by ALCA), the effects of the allocation procedure (in ALCA), and the implications of the two approaches for decision making are discussed.

3 Methodology

3.1 Case study presentation

The system under investigation consists of an integrated newsprint mill located in Ontario (Canada). Newsprint is produced using a mix of TMP and DIP. The TMP process, a significant electricity consumer, uses wood chips supplied by sawmills (by-product of lumber production) in the vicinity. Recycled paper is transported from urban locations as well as from smaller communities near the mill location. Four process alternatives are investigated in order to reduce mill dependency on external power sources. The four options consider an increase in cogeneration capacity from 2.5% up to 95% and of the DIP content of the paper from 20% up to 100% (shutting down the TMP process). The process options are presented in Table 2, and their main process implications were discussed previously (see section 1.1). All DIP options require new installations, except for one (D50C59), which requires retrofitting the existing system (combination of old process line with new equipment). These new installations have a slightly better yield (increase of 7.6%—less recycled paper is required to achieve the same quantity of newsprint) and generate less sludge compared to the base case (the current mill case). The cogeneration options comprise: (a) converting one natural gas boiler to burn wood waste and keeping existing turbo-generators in service (D50C60, D100C78, and D50C59) and (b) installing a new wood waste boiler, upgrading half of the boilers to higher pressure operation (900 psig), and adding a new turbo-generator (D100C95). The scenario combinations considered for this study are all economically viable (Janssen et al. 2006).

3.2 Summary of the LCA approaches used

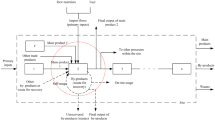

To achieve the proposed objectives, the four options are analyzed using the two LCA approaches. For both approaches, the four steps recommended by the ISO 14044 (goal and scope definition, inventory, impact assessment, and interpretation) were carried out (ISO 2006b). Details are given in Sections 3.3 and 3.4. To simplify the interpretation, the system boundary is divided into three subsystems: the foreground system, the background system, and the extended background system. The foreground system consists of the processes on which action can be taken by the newsprint manufacturer (i.e., the process located on the pulp and paper mill sites). The background system consists of other processes in the newsprint life cycle. The extended background system is set in order to account for potential indirect effects due to the implementation of the process options in the foreground system.

3.3 Attributional LCA

3.3.1 Goal and scope definition

Functional unit

A previous LCA aiming at comparing process options to reduce purchased power was carried out for this same case study using a cradle-to-gate boundary (Salazar Zarate 2004; Cornejo et al. 2005). Here, the functional unit is kept as originally defined for all options investigated: the production of one air-dried metric ton (1 admt) of newsprint.

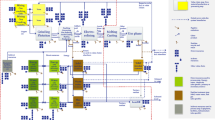

System boundary and allocation procedures

For the case of the ALCA, the foreground and background systems (paper production and its upstream processes) are included in the boundary (see Figs. 1 and 2). This system boundary allows the description of environmental impacts attributable to newsprint production before and after implementing each of the proposed process modifications. Using this approach, a decision must be made regarding multifunctional processes present within the boundary: sawmill operations and open-loop recycling of waste paper. The sawmill produces three main products: lumber, chips, and wood waste; only chips are of interest. In this study, the allocation of the burden of these three products is performed based on mass. This choice has been shown to have little effect on the results in a previous study (Salazar Zarate 2004). On the other hand, it was recognized that the influence of different allocation procedures on the results of LCA of wood-based products, and more specifically open-loop recycling, can be significant. The allocation procedure selected for open-loop recycling should ensure that the inputs and outputs associated with the unit processes for extraction and processing of raw materials and final disposal of products are shared by more than one product system (Ekvall and Tillman 1997; ISO 2006b). Several approaches that recognize this feature and which reflect different perspectives regarding how the environmental impacts are shared in the fiber life cycle are available. The systematic comparison of all these allocation procedures is outside the scope of this paper, but in order to assess the potential effects of the allocation procedures on the results, two pertinent and feasible methods are selected: the cut-off method and the extraction-load method. The cut-off method takes a perspective according to which each product in the fiber life cycle is only responsible for the environmental impacts that it directly causes. Using this approach, the recycled material used in the investigated system does not carry any burden from virgin material production. This method is selected for several reasons. Firstly, from the available methods, it is the only one directly applicable to the cradle-to-gate boundary where the actual end-of-life (disposal and/or recycling) of the product investigated is not assessed. Secondly, this method has the advantage of eliminating uncertainty regarding: (a) the number of times that a material is recycled, (b) where the investigated product is located in the fiber life cycle, (c) how original virgin fiber was processed, etc. Finally, it is the method that best reflects the ability of the paper manufacturer to control the amount of recycled fiber it uses and his lack of control over whether the final product is going to be recycled or not. Using this approach, the environmental impacts of the recycling process, considered here to be collection, sorting, and reprocessing (repulping and de-inking) of the material, are all allocated to the product using the recycled fiber. The system boundary for this first allocation procedure is shown in Fig. 1. The second allocation approach (extraction load) builds on a perspective according to which all material will end up as waste and that final disposal is an inevitable consequence of raw material extraction. The cradle-to-gate boundary presented for the cut-off method is not suitable to apply this allocation method. However, like illustrated at Fig. 2, it can be slightly modified to include any final disposal due to material extraction. This method is pertinent for this case study because the alternatives consume different amounts of waste paper and thus different quantities of virgin fiber, which results in more or less material to be disposed of. Using this approach, all impacts of the recycling process itself are assigned to the investigated product.

Main assumptions

The main assumptions for the cradle-to-gate system are available elsewhere (Salazar Zarate 2004). Additional assumptions are required for the second allocation procedure tested. The final disposal is considered to be landfill of waste paper with incineration of the biogas but without energy recovery. This assumption is based on data availability.

3.3.2 LCI, LCIA, and interpretation

Primary data is used to model the foreground system and, generic data from the ecoinvent database, to model the background system. The American LCIA method (TRACI) is used to characterize the environmental impacts (Bare et al. 2003). This method includes nine environmental indicators: global warming (GW), ozone depletion (OD), acidification (AC), eutrophication (EU), photochemical smog formation (PS), ecotoxicity (ECO), human health cancer (HHC), human health non-cancer (HHNC), and human health particulates (HHP). LCIA indicators assess the potential environmental impacts due to emissions and not the actual impacts. For instance, a higher score for the HHC indicator indicates that the system emits more emissions, which potentially cause cancer. Normalization is the calculation of the magnitude of an impact category result relative to some reference information. The main objective of normalization is to better understand the relative significance of each indicator. The reference system must be meaningful for the decision makers. In this study, the reference system is the newsprint production system before any modifications (Eq. 1, N i,j , normalized LCA result for the option i and impact category j; C i,j characterization result for the option i and impact category j; and BC, base case). The choice of the normalization reference can change the conclusions drawn from LCIA. This is not investigated in this paper. Weighting is the process of converting indicator results of different impact categories using numerical factors based on value choices. No weighting is performed in this study. Interpretation is performed through contribution and sensitivity analyses. This paper does not include any uncertainty analysis.

3.4 Consequential LCA

3.4.1 Goal and scope definition

Functional unit

The functional unit plays a more important role in CLCA than in ALCA. It should be set to reflect the effects of product substitution (Weidema 2003). The objective of this study is to assess the “system boundary” aspect of CLCA and not the selection of the functional unit (recognizing it may be as important). For this reason, it is assumed that the product from the modified system directly substitutes the product from the original, causing only a change of the environmental impacts per functional unit. No rebound effect is assumed, and the functional unit is defined similarly to the ALCA case (1 admt of newsprint).

System boundary

The system boundary for the CLCA approach is shown in Fig. 3. Only the processes affected by the alternatives are included. These processes are in the foreground, background, or extended background system. The main extended background processes included in the system are other chipping operations, the waste paper market, other waste paper users, waste paper landfill, and electricity marginal technology.

Main assumptions

When extending the boundary to the indirect effects (extended background), it is necessary to identify what are the actual consequences of the process modifications. This task is complicated and uncertain. Assumptions regarding the consequences are summarized in Table 3. Assumptions are made regarding how landfill activity is reduced or how less recycled paper is available for other systems as a consequence of increased consumption of recycled fiber. A methodology based on price elasticity in order to do so was proposed (Ekvall and Weidema 2004). Based on this approach, it is possible to calculate how the supply will be affected due to a change in the demand or vice versa. In this study, default price elasticity (Palmer et al. 1997) is assumed. This leads to the case where the increase of recycled fiber in the investigated system is fulfilled by the deviation of 62% from landfill and 38% from other usages. Furthermore, it is considered that the reduction of recycled pulp production in other systems due to an increase use of recycled paper in the investigated system is compensated by an increase in a mixture of virgin kraft and TMP pulp. This new consumption of virgin fiber results in increased forest operations and in an additional extracted material, which will have to be disposed of ultimately. The final disposal is assumed to be landfill of waste paper with incineration of the biogas but without energy recovery. Implementing the four process options also results in a decreased usage of wood chips. Wood chips used in the system are a by-product of sawmill operations and thus will still be produced if the demand decreases. In many cases, pulp and paper mills are purchasing wood logs to transform them into chips themselves. It is assumed that the decreased use of chips in the studied system will lead to a decreased production of chips from logs in other systems and ultimately a reduction in forest operations. Therefore, less virgin material will be extracted, and this material will not have to be disposed of at its end of life. Another consequence of implementing the process options is the reduction in electricity consumption. Using the procedure proposed by Weidema et al. (1999), coal is identified as the marginal technology for electricity production. The alternatives also consume more wood waste than the base case. Wood waste is a by-product of other operations and is a constrained product. However, it is assumed that large volumes of wood biomass are potentially available in the form of forest residues, which are usually not recovered and can be used within the system. Finally, the reduction in natural gas consumption and the increased or decreased consumption of chemicals is set to produce a proportional change in the production of those materials. It is important to mention that the changes in the paper process will potentially affect other activities than the ones mentioned here. However, it is assumed that further system expansion would bring too much uncertainty and thus would not provide information useful for decision making.

3.4.2 LCI, LCIA, and interpretation

Primary data is used to model the foreground system, and generic data from the ecoinvent database are used to model the background and extended background systems. Only differences in the processes included are calculated (Eq. 2; N i,j , normalized LCA result for the option i and impact category j; ΔC i,j , change in characterization result due to option i and impact category j; and BC, base case). The LCIA and interpretation are performed as for the ALCA approach.

3.5 Comparing the two approaches

A systematic comparison of the two approaches is done in order to determine their benefits and limitations in the process design context. For this, it is necessary to express the results of the two approaches in a comparable way. For this reason, the results from ALCA are also calculated in a differential manner (Eq. 3; N i,j , normalized LCA result for the option i and impact category j; C i,j , characterization result for the option i and impact category j; and BC, base case).

Equations 2 and 3 express the changes caused by the alternatives: Eq. 2 is limited to the changes in the cradle-to-gate system boundary, whereas Eq. 3 expresses the change in the whole technological system (in the limits of uncertainty). Since both equations express the change compared to the base case, the differential from the base case to itself has a zero value. The two approaches are compared under three different points of view: effects of including indirect effects into the analysis, effects of the marginal technology, and effects of the allocation procedure. Finally, implications for process design of the two approaches are investigated.

4 Results

To better interpret the results, it is necessary to understand their uncertainty. No systematic uncertainty analysis is performed for this case study. However, using an estimate of uncertainty on the mass balances as well as uncertainty ranges available from the database used, the options can be considered as different if they differ from more than 0.1 in the case of ALCA and 0.5 in the case of CLCA (normalized values), keeping in mind that some impact categories may be more uncertain than others. Options are considered the same for smaller deviations.

4.1 Attributional LCA: cut-off allocation procedure

Using this approach to compare the environmental impacts of different process options, the following question is answered: “Given that it has been considered that newsprint production was responsible only for direct environmental impacts, what is its environmental footprint before and after the process modifications?” The results are presented in Fig. 4. To interpret the results, it is important to understand that the significance of the results is considered to be a function of the difference with the original environmental impact affected to the newsprint production (normalization by the base case). The results shown in Fig. 4 indicate that the four options have a beneficial effect on the newsprint production environmental profile for all impact categories. For some impact categories (OD, AC, EU, ECO, HHC, HHNC, and HHP), it is difficult to differentiate between the alternatives. Either data should be improved to reduce this uncertainty, or these impact categories should not be used for decision making regarding the selection of the best alternative because it is considered that all alternatives perform the same. For other impact categories (GW and PS), options involving complete substitution of TMP pulp by DIP pulp (options 2 and 3) are clearly superior to options involving only a partial substitution (options 1 and 4). The main reason for this is the greater reduction of electricity consumption.

4.2 Attributional LCA: extraction-load allocation procedure

This approach answers the same question as the cut-off allocation procedure. However, it considers newsprint production responsible for more impacts in the fiber life cycle. It builds on the fact that all virgin material extracted will end up as waste and that final disposal is an inevitable consequence of raw material extraction to allocate the final disposal of fiber to the system were the virgin fiber is consumed. Each option (including the base case) consumed a different amount of virgin fiber and thus is responsible for a different amount of final disposal. The results presented in Fig. 5 indicate that the implementation of all process options is beneficial for the environmental profile of newsprint production. Furthermore, more impact categories allow differentiating the options when compared to the cut-off allocation procedure.

4.3 Consequential LCA

This approach answers a very different question regarding the comparison of process options. It compares the overall change (including the indirect effects or effects on the extended background system) in environmental impacts due to the implementation of process options. The environmental profile of newsprint production (or environmental consequences directly imputable to newsprint production) is not calculated. In Fig. 6, a negative result means an improvement. This figure shows that, given that two options are considered different if they differ from more than 0.5, all impact categories (except OD) are improved by all options. The deterioration in OD is not significant compared to the improvement in the other indicators. The CLCA approach indicates a clear distinction for options involving a complete replacement of the TMP by the DIP pulp.

4.4 Effects of including indirect environmental consequences (extended background)

From this point on, all the results (including ALCA results) are expressed in their differential form (Eqs. 2 and 3). To demonstrate the potential effect of including the indirect environmental consequences of implementing the options, the impacts of the foreground and background systems are compared with those of the extended background systems for the GW and EU indicators (see Figs. 7 and 8). First, the GW indicator is an example where indirect effects can be significant compared to the direct effects. Second, the EU indicator is an example where indirect effects are in the opposite direction from other effects (i.e., an overall improvement in the life cycle but a deterioration in other systems). In this case, the increase of EU in the background system is due to mills that would have to use more virgin fiber pulp to compensate for the lose in recycled paper. These two observations illustrate the importance of including the indirect effects for decision accounting for all potential impacts. In this case, the inclusion of those effects would not have changed the decision. However, in some cases, a change in the decision would happen.

4.5 Effects of the marginal technology

Another distinction between ALCA and CLCA is the usage of the average and marginal technology. One example of this is the electricity production. In ALCA, the goal is to draw the environmental profile of the investigated system before and after implementing the process options. Since the electricity grid is only marginally affected by a change in electrical consumption by the mill, its fuel mix is about the same, and therefore, the average mix is used. However, in CLCA, the goal is to describe the environmental consequences of implementing those options. For this reason, the marginal technology that is actually affected by implementing the options has to be identified. In this case study, the marginal electricity production affected by a change in electricity consumption by the mill is assumed to be electricity from coal combustion (Weidema et al. 1999). The effect of this choice for the AC indicator is shown in Fig. 9. Benefits from a reduction in electricity consumption is much greater for CLCA than for ALCA because electricity from coal, rather than a mix of coal, hydroelectricity, and nuclear, is modeled.

4.6 Effects of allocation

The last significant difference between ALCA and CLCA is that ALCA needs the selection of allocation procedures. The effect of using an allocation procedure rather than another one is shown in Fig. 10. This figure compares the results of CLCA with those obtained using the two allocation procedures (cut-off and extraction load) for the HHC indicator. While CLCA describes the total environmental consequences caused by each option, ALCA tries to allocate a portion of these consequences to the investigated system. It can be seen that the choice of the allocation procedures can allocate a different amount of the total environmental consequences to the investigated system. In this case study, the selection of one procedure over another makes a difference regarding the potential to differentiate the options.

4.7 “Hot spots” identification

In the process design process, LCA can also be used to support alternative generation using contribution analyses for which, at this time, there is no method based on CLCA. Such analyses are presented in Table 4. When using a cut-off allocation procedure, it can be deduced that reducing electricity consumption will have a positive effect on the environmental profile of newsprint production. The same conclusions can be made using an extraction-load procedure. However, more improvement opportunities are identified. An example is waste paper landfill (result from virgin fiber extraction) that contributes significantly to several impact categories. The newsprint producers can have a direct effect on the material, which ends into the landfill by controlling the amount of virgin fiber they extract from the environment. In this case, the extraction-load allocation procedure better reflects the ability of the producers to improve. The main limitation of using ALCA to identify potential environmental improvement is that potential indirect effects are never considered in the assessment, and thus, real opportunities are possibly not identified.

5 Discussion

In the previous sections, it has been demonstrated that the usage of CLCA instead of ALCA for a pulp and paper process design application can lead to different results for several reasons: (1) It includes the indirect environmental consequences of implementing the options; (2) it attempts to model the technology that is actually affected instead of using an average; and (3) it avoids the selection of an arbitrary allocation procedure. This illustrates that the cradle-to-gate, which was generally used in the literature, may not always be the best approach for assessing the environmental impacts of process options. To decide which option should be implemented (from an environmental standpoint), it is necessary to weight the relative importance of the different impact categories. In this study, no weighting was necessary because, if we consider only the impact categories for which it is possible to differentiate between the options, these vary in the same direction for the three approaches. Although CLCA gave more information about the indirect effects, it would not have changed the conclusions of the study.

On the other hand, the ALCA approach used in the literature has the advantage of allowing for identifying opportunities for improvement, which is useful for defining process alternatives in process design applications. Like mentioned previously, the available methods do not allow for including potential indirect environmental consequences in the analysis. However, at this time, there is no methodology based on CLCA for hot-spot identification. A solution could be a combined usage of ALCA and CLCA.

6 Conclusions

In this paper, two LCA approaches (ALCA and CLCA) were compared for a process design application and more specifically for selecting the most environmentally preferable process option to reduce electricity consumption at a pulp and paper mill. While ALCA was used to assess the environmental profile of newsprint before and after implementing the process alternatives, CLCA aimed at comparing the environmental consequences of those alternatives. It was demonstrated that the indirect effects, which are assessed only when using CLCA, can be significant and in an opposite direction compared to the direct ones. Thus, their inclusion in the analysis can have an effect on the final decision. However, in this case study, it has been demonstrated that they will not change the decision. Furthermore, it has been demonstrated that taking two different and subjective perspectives to perform an allocation procedure in ALCA can affect the results. In this specific case, the extraction-load allocation procedure was a better approximation of the results obtained using CLCA. CLCA highlights the indirect consequences and does not depend on an allocation procedure, but care must be taken regarding the large uncertainties when modeling the indirect environmental consequences. On the other hand, ALCA is still required to identify environmental opportunities, but a methodology that combines efficiently ALCA and CLCA may result in the identification of more relevant improvement opportunities.

7 Recommendations and perspectives

The combined usage of CLCA with ALCA is probably the most optimal approach to process design applications. Indeed, in process design applications, alternatives can be numerous, and it may not be very practical to define a complete attributional LCA for each of those. A very interesting feature of CLCA is that only the affected processes are modeled. However, since a broader scope of activities is covered, it may be difficult to find the data. On the other hand, modeling the environmental impacts of a base case using ALCA is a good basis for identifying opportunities for improvement and defining process design, although the incorporation of some CLCA elements may be required to ensure that the best opportunities are identified. Another application for which CLCA cannot be used at this time is the benchmark of the environmental profile of a given system in time. Finally, an important issue in using LCA for process design decision making is uncertainty. In ALCA, uncertainty is limited compared to CLCA because there is no need to estimate potential indirect environmental consequences. Procedures based on market elasticity, such as the used for paper recycling, can help in this task, but they are still very uncertain. In addition, when assessing process design options, flows affected can be numerous, and it may be difficult to handle them. There is a need for procedures to identify which flows to focus on when performing a CLCA analysis.

References

Bare JC, Norris GA, Pennington DW, McKone T (2003) Traci: the tool for the reduction and assessment of chemical and other environmental impacts. J Ind Ecol 3–4(6):49–78

Cornejo F, Janssen M, Gaudreault C, Samson R, Stuart PR (2005) Using life cycle assessment (LCA) as a tool to enhance environmental impact assessment (Eia). Chem Engi Transact 7:521–528

Das TK, Houtman C (2004) Evaluating chemical-, mechanical-, and bio-pulping processes and their sustainability characterization using life-cycle assessment. Environ Prog 4(23):347–357

Dias A, Lopes E, Arroja L, Capela I, Pereria F (2002) Life cycle assessment of paper production from eucalyptus globulus. Case study of the Portuguese industry. Appita J 1(55):21–26

Ekvall T (1999a) Key methodological issues for life cycle inventory analysis of paper recycling. J Cleaner Prod 4(7):281–294

Ekvall T (1999b) System expansion and allocation in life cycle assessment—with implications for wastepaper management. Ph.D. thesis, Chalmers University of Technology, Sweden

Ekvall T, Andrae ASG (2006) Attributional and consequential environmental assessment of the shift to lead-free solders. Int J Life Cycle Assess 5(11):344–353

Ekvall T, Tillman A-M (1997) Open-loop recycling: criteria for allocation procedures. Int J Life Cycle Assess 3(2):155–162

Ekvall T, Weidema BP (2004) System boundaries and input data in consequential life cycle inventory Analysis. Int J Life Cycle Assess 3(9):161–171

Fu GZ, Chan AW, Minns DE (2005) Preliminary assessment of the environmental benefits of enzyme bleaching for pulp and paper making. Int J Life Cycle Assess 2(10):136–142

Gaudreault C, Samson R, Stuart PR (2007a) Life-cycle thinking in the pulp and paper Industry. Part I: current practices and most promising avenues. Tappi J 7(6):25–31

Gaudreault C, Samson R, Stuart PR (2007b) Life-cycle thinking in the pulp and paper industry. Part 2: LCA studies and opportunities for development. Tappi J 8(6):3–10

Guinee JB, Heijungs R, Huppes G (2004) Economic allocation: examples and derived decision tree. Int J Life Cycle Assess 1(9):23–33

ISO (2006a) Environmental management–life cycle assessment—principles and framework. ISO 14040. International Organization for Standardization, Geneva

ISO (2006b) environmental management–life cycle assessment—requirements and guidelines. ISO 14044. International Organization for Standardization, Geneva

Janssen M, Cornejo F, Stuart PR (2006) Techno-economic considerations for dip production increase and implementation of cogeneration at an integrated newsprint mill. Pulp Pap-Canada 9(107):33–37

Lesage P, Ekvall T, Deschênes L, Samson R (2007a) Environmental assessment of Brownfield rehabilitation using two different life cycle inventory models—Part 1: methodological approach. Int J Life Cycle Assess 6(12):391–398

Lesage P, Ekvall T, Deschênes L, Samson R (2007b) Environmental assessment of Brownfield rehabilitation using two different life cycle inventory models—Part 2: case study. Int J Life Cycle Assess 7(12):497–513

Lopes E, Dias A, Arroja L, Capela I, Pereira F (2003) Application of life cycle assessment to the Portuguese pulp and paper industry. J Cleaner Prod 1(11):51–59

Munoz I, Rieradevall J, Torrades F, Peral J, Domenech X (2006) Environmental assessment of different advanced oxidation processes applied to a bleaching kraft mill effluent. Chemosphere 1(62):9–16

Palmer K, Sigman H, Walls M (1997) The cost of reducing municipal solid waste. J Environ Econ Manag 2(33):128–150

Rehnstrom C (2003) LCA of two chemical recovery processes in the pulp industry—a case study. Nord Pulp Pap Res J 3(18):344–354

Salazar Zarate ES (2004) Life cycle assessment (LCA) of newsprint production at an integrated mill. Ecole Polytechnique, Montreal

Scheringer M, Halder D, Hungerbuhler K (2000) Comparing the environmental performance of fluorescent whitening agents with peroxide bleaching of mechanical pulp. J Indust Ecol 4(3):77–85

Tillman A-M (2000) Significance of decision-making for LCA methodology. Environ Impact Asses 1(20):113–123

Vizcarra A, Lo V, Bicho PA, Watson PA (1999) A cradle-to-gate life cycle assessment of straw pulp incorporation into telephone directory-grade paper. TAPPI J 2(82):115–122

Vogtlander JG, Brezet HC, Hendriks CF (2001) Allocation in recycling systems—an integrated model for the analyses of environmental impact and market value. Int J Life Cycle Assess 6(6):344–355

Weidema BP (2003) Market information in life cycle assessement. Danish Environmental Protection Agency, Copenhagen

Weidema BP, Frees N, Nielsen A-M (1999) Marginal production technologies for life cyle inventories. Int J Life Cycle Assess 1(4):48–56

Yamada H, Daigo I, Matsuno Y, Adachi Y, Kondo Y (2006) Application of Markov chain model to calculate the average number of times of use of a material in society—an allocation methodology for open-loop recycling. Int J Life Cycle Assess 5(11):354–360

Acknowledgements

This project was supported by Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Rita Schenk

Rights and permissions

About this article

Cite this article

Gaudreault, C., Samson, R. & Stuart, P.R. Energy decision making in a pulp and paper mill: selection of LCA system boundary. Int J Life Cycle Assess 15, 198–211 (2010). https://doi.org/10.1007/s11367-009-0125-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0125-1