Abstract

Background, aim, and scope

Regional variations in the environmental impacts of plant biomass production are significant, and the environmental impacts associated with feedstock supply also contribute substantially to the environmental performance of biobased products. Thus, the regional variations in the environmental performance of biobased products are also significant. This study scrutinizes greenhouse gas (GHG) emissions associated with two biobased products (i.e., ethanol and soybean oil) whose feedstocks (i.e., corn and soybean) are produced in different farming locations.

Methods

We chose 40 counties in Corn Belt States in the United States as biorefinery locations (i.e., corn dry milling, soybean crushing) and farming sites, and estimated cradle-to-gate GHG emissions of ethanol and of soybean oil, respectively. The estimates are based on 1 kg of each biobased product (i.e., ethanol or soybean oil). The system boundary includes biomass production, the biorefinery, and upstream processes. Effects of direct land use change are included in the greenhouse gas analysis and measured as changes in soil organic carbon level, while the effects of indirect land use change are not considered in the baseline calculations. Those indirect effects however are scrutinized in a sensitivity analysis.

Results

GHG emissions of corn-based ethanol range from 1.1 to 2.0 kg of CO2 equivalent per kilogram of ethanol, while GHG emissions of soybean oil are 0.4–2.5 kg of CO2 equivalent per kilogram of soybean oil. Thus, the regional variations due to farming locations are significant (by factors of 2–7). The largest GHG emission sources in ethanol production are N2O emissions from soil during corn cultivation and carbon dioxide from burning the natural gas used in corn dry milling. The second largest GHG emission source groups in the ethanol production system are nitrogen fertilizer (8–12%), carbon sequestration by soil (−15–2%), and electricity used in corn dry milling (7–16%). The largest GHG emission sources in soybean oil production are N2O emissions from soil during soybean cultivation (13–57%) and carbon dioxide from burning the natural gas used in soybean crushing (21–47%). The second largest GHG emission source groups in soybean oil production are carbon sequestration by soil (−29–24%), diesel used in soybean cultivation (4–24%), and electricity used in the soybean crushing process (10–21%). The indirect land use changes increase GHG emissions of ethanol by 7–38%, depending on the fraction of forest converted when newly converted croplands maintain crop cultivation for 100 years.

Conclusions, recommendations, and perspectives

Farming sites with higher biomass yields, lower nitrogen fertilizer application rates, and less tillage are favorable to future biorefinery locations in terms of global warming. For existing biorefineries, farmers are encouraged to apply a site-specific optimal nitrogen fertilizer application rate, to convert to no-tillage practices and also to adopt winter cover practices whenever possible to reduce the GHG emissions of their biobased products. Current practices for estimating the effects of indirect land use changes suffer from large uncertainties. More research and consensus about system boundaries and allocation issues are needed to reduce uncertainties related to the effects of indirect land use changes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

Ethanol is a liquid fuel that is a renewable alternative for gasoline. The annual ethanol production capacity in the Unites States is around 35 billion liters per year in 2008 (Renewable Fuels 2008). Ethanol consumes about 27% of total corn production in the United States. Corn starch-based ethanol is expected to increase to 57 billion liters by 2015 (United States 2007).

Soybean oil is used in a wide variety of applications: food, fuel, lubricants, inks, polymers, and so on (United Soybean 2008). The United States produced 9.6 million metric tons of soybean oil in 2007, thus about 69% of total soybean production is processed in soybean crushing plants (American Soybean 2008). High petroleum prices and limited supplies will likely push more soybean oil toward industrial applications.

Several studies have examined the environmental performance of these two biobased products (Kim and Dale 2005, 2008a; Argonne National 2008; Li et al. 2006). Most studies on ethanol fuel compared its environmental impacts to those of gasoline, including vehicle operations in the analysis. A few studies have investigated regional variations in biobased products (Kim and Dale 2008a). The environmental impacts of corn and soybean production vary with farming locations and farming practices (Kim et al. 2008; Kim and Dale 2008b). Regional variations of greenhouse gas (GHG) emissions of corn and of soybean production differ by a factor of 3 and 4, respectively (Kim and Dale 2008b). The regional variations in biomass production are due to cropping management practices (e.g., tillage practices, application rate of nitrogen fertilization, irrigation, etc.), climate conditions (e.g., rainfall, temperature, etc.), soil textures, and so on. The environmental impacts associated with feedstock production contribute greatly to the environmental performance of biobased products (Kim and Dale 2005, 2008a); therefore, the regional variations in the environmental performance of biobased products are also significant. This study examines GHG emissions associated with two biobased products (i.e., ethanol and soybean oil) whose feedstocks (corn and soybean) are produced in different farming locations.

2 Methods

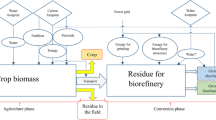

We chose 40 counties in Corn Belt States in the United States as biorefinery locations (i.e., corn dry milling, soybean crushing). Either a corn dry mill or a soybean crushing plant is located in most of the selected counties in this study (Renewable Fuels 2008; United Soybean 2008). Thus, we have 40 dry mills and 40 soybean crushing plants in the analysis. Each biorefinery utilizes biomass produced in its own county. We assume that corn and soybean produced in a selected county are enough to supply feedstock to its biorefinery even though the capacities of some biorefineries exceed county-level biomass production.

We estimate cradle-to-gate GHG emissions of ethanol and of soybean oil. The estimates are based on 1 kg of each biobased product (ethanol or soybean oil). The system boundary includes biomass production, the biorefinery, and upstream processes, which are energy, chemicals, enzymes, and yeast used in biorefineries. County-level GHG emissions of biomass are obtained from an LCI database for biomass productions that was created as a part of this project (Kim and Dale 2008b). County-level GHG emissions of biomass are differentiated with respect to biomass yield, crop management practices, changes in soil organic carbon levels, and nitrous oxide emissions from soil. County-level soil organic carbon and nitrogen dynamics are simulated by the DAYCENT model (Del Grosso et al. 2000, 2001; Natural Resource Ecology 2005), which can estimate carbon sequestration by soil and N2O emissions from soil. Current tillage practices (Conservation Technology Information 2007) are applied in the analysis. The detailed methodologies are available in the literature (Kim et al. 2008; Kim and Dale 2008b). Effects of direct land use change (dLUC) are included in the greenhouse gas analysis and measured as changes in soil organic carbon level, while effects of indirect land use change (iLUC) are not considered in the reference calculations. The effects of iLUC in the ethanol production system (but not soybean crushing) are scrutinized in a sensitivity analysis.

The soybean crushing process produces soybean oil and soybean meal. The processes in soybean crushing include soybean preparation, oil extraction, meal processing, solvent recovery, oil recovery, and oil degumming processes (Liu 1997; Erickson 1995; Sheehan et al. 1998). Dry milling produces ethanol and dried distillers grains with solubles (DDGS). The dry mill includes grinder, cooker, fermentation, distillation, and DDGS recovery processes (Renewable Fuels 2008). Site-specific process information on biorefineries is not available at this time. Industrial average information on soybean crushing and corn dry milling (Argonne National 2008; Sheehan et al. 1998; Wu 2008; McAloon et al. 2000) is used in the analysis. A small amount of hexane is consumed as make up in the soybean crushing process in which it is used as a solvent to extract soybean oil. Chemicals in corn dry milling include caustic soda, lime, sulfuric acid, and urea (McAloon et al. 2000).

The system expansion approach is adopted in allocating the environmental burdens to a biobased product. The alternative product for soybean meal is soybean, and the alternative products for DDGS are corn grain, soybean meal, and nitrogen in urea (Argonne National 2008; Arora et al. 2008). The GREET model (Argonne National 2008) assumes that 1 kg of soybean meal would displace about 1.2 kg of soybean, and that 1 kg of DDGS would displace 0.95 kg of dry corn, 0.30 kg of dry soybean meal, and 0.03 kg of nitrogen in urea. In this study, the GREET model’s assumptions for the displacements of co-products are used in the system expansion approach. The effects of a different allocation method (i.e., output mass allocation) are scrutinized in a sensitivity analysis. Most upstream processes are obtained from LCA databases and literature (Ecobilan 2008; Swiss Centre for Life Cycle Inventories 2008; Office of Industrial Technologies 2000; Atkinson and Mavituna 1991; Jiménez-González et al. 2000; Kim et al. 2009a). The effects of tillage practices are also investigated in a scenario analysis.

3 Results and discussion

GHG emissions of corn-based ethanol range from 1.1 to 2.0 kg of CO2 equivalent per kilogram of ethanol, while GHG emissions of soybean oil are 0.4–2.5 kg of CO2 equivalent per kilogram of soybean oil. Our previous study shows that cradle-to-gate GHG emissions of ethanol range from 1.3 to 2.1 kg of CO2 equivalent per kilogram of ethanol (Kim and Dale 2008a), and the GREET model (Argonne National 2008) estimates that 1 kg of ethanol releases about 1.7 kg of CO2 equivalent when the displacement method is used in allocating GHG to ethanol. Mean GHG emissions of ethanol in this study are 1.5 ± 0.3 kg of CO2 equivalent per kilogram of ethanol. The GREET model also predicts that the cradle-to-gate GHG of soybean oil is about 1.2 kg of CO2 equivalent per kilogram of soybean oil. Mean GHG in this study is 1.2 ± 0.5 kg of CO2 equivalent per kilogram of soybean oil.

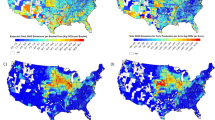

The regional variations due to farming locations are significant (by factors of 2–7). Ethanol produced in Johnson County, Iowa releases the least GHG emissions among the counties considered in this study, while ethanol produced in Montgomery County, Ohio produces the largest GHG emissions. Corn produced in Johnson County, Iowa also has the smallest GHG emissions (0.21 kg of CO2 equivalent per kilogram of corn) because of higher corn yield, higher carbon sequestration by soil, and lower N2O emissions from soil. Note that mean GHG emissions of corn over 40 counties are 0.36 ± 0.10 kg of CO2 equivalent per kilogram of corn. The largest GHG emissions associated with corn production occur in Montgomery County, Ohio (0.54 kg of CO2 equivalent per kilogram of corn). The fraction of conservation tillage for current corn culture in Johnson County, Iowa is about 0.76, while the fraction of conservation tillage in Montgomery County, Ohio is 0.2 (Conservation Technology Information 2007). Generally, ethanol produced in counties with higher fractions of conservation tillage provides lower GHG emissions if corn is produced at a similar yield. Carbon would be sequestered into soil as soil organic carbon under conservation tillage practices because soil is less disturbed under conservation tillage than under conventional tillage. Corn cultivation in Montgomery County, Ohio requires a high rate of nitrogen fertilizer, and its corn yield is below the average yield over 40 counties. The results show that areas with a higher fraction of conservation tillage, higher corn yield, and appropriate nitrogen inputs are more favorable to ethanol production from a climate change perspective. Conservation tillage can reduce fuel used in tillage operations and can increase soil organic carbon levels. Nitrogen inputs affect corn yield, GHG emissions associated with nitrogen fertilizer, and N2O emissions from soil.

Soybean oil produced in Tazewell County, Illinois releases the least GHG emissions among all counties considered because of (1) higher soybean yield, (2) higher fraction of conservation tillage practices (0.73), and (3) lower N2O emissions during soybean culture. Even though the largest GHG emissions associated with changes in soil organic carbon and N2O emissions from soil in the soybean oil production system occur in Becker County, Minnesota, the largest GHG emissions of soybean oil occurs in Saline County, Nebraska, which consumes more fuel due to irrigation. The properties of farming locations favorable to soybean oil production from a climate change perspective are similar to those indentified in the ethanol production system except for nitrogen fertilizer. In fact, soybean cultivation consumes very little nitrogen fertilizer.

Figures 1 and 2 show GHG emissions of individual sub-processes in ethanol and soybean oil, respectively. Other chemicals in Figs. 1 and 2 include agrochemicals, lime, and fertilizers (P and K). Other fuels include fuels used in biomass production except for diesel. Chemicals in Fig. 1 represent chemicals, enzymes, and yeast used in corn dry milling, while chemicals in Fig. 2 are hexane and water used in soybean crushing process. The largest GHG emission sources in ethanol production are N2O emissions from soil during corn cultivation and carbon dioxide from burning the natural gas used in corn dry milling. GHG emissions from N2O emissions from soil during corn cultivation are 0.2–0.8 kg of CO2 equivalent per kilogram of ethanol, accounting for 11–37% of the overall GHG emissions. Note that percentages here are ratios of the unallocated overall GHG emissions. GHG emissions associated with natural gas used in corn dry milling are 0.57 kg of CO2 equivalent per kilogram of ethanol, accounting for 24–37% of total GHG emissions. There are no significant regional variations in GHG emissions associated with corn dry milling. We assume that there are no technological variations between different locations due to lack of data. Only small regional variations in GHG emissions associated with corn dry milling are due to differences in the electricity grid. The second largest GHG emission source groups in the ethanol production system are nitrogen fertilizer (8–12%), carbon sequestration by soil (−15–2%), and electricity used in corn dry milling (7–16%). According to Wu’s report (Wu 2008), coal is still used as an energy source (13% of the total energy consumption) in some corn dry milling plants. GHG associated with coal consumption in dry milling accounts for 6–10% of total emissions. GHG emissions of enzymes, yeast, and other chemicals used in corn dry milling contribute less than 5% of total emissions. It is of interest that nitrogen fertilizer greatly affects N2O emissions from soil. Therefore, nitrogen fertilizer is one of the largest GHG emission sources in the ethanol production system. GHG emissions associated with carbon sequestration by soil, which reflects direct land use change, range from −0.26 to 0.06 kg of CO2 equivalent per kilogram of ethanol. Negative values are carbon sequestration by soil. As mentioned previously, carbon sequestration by soil depends greatly on tillage practice. GHG credits associated with DDGS displacement are 0.43 kg of CO2 equivalent per kilogram of ethanol and have no regional variations because DDGS likely displaces non-site-specific animal feeds. GHG credits from corn grain account for 59% of the overall credits from DDGS displacement, while the credits from soybean meal and from nitrogen in urea account for 25% and 16%, respectively.

GHG emissions of ethanol [N fertilizer_C nitrogen fertilizer; Other chemicals_C other fertilizers (P and K), herbicides, pesticides, and lime; N 2 O_C N2O emissions from soil during corn cultivation; SOC_C changes in soil organic carbon levels; Diesel_C diesel consumption in corn production; Other fuels_C electricity, natural gas, gasoline, liquefied petroleum gas used in corn production; Chemicals_D enzymes, yeast, water, and other chemicals used in dry milling; Avoided corn corn displaced by DDGS; Avoided SBM soybean meal displaced by DDGS; Avoided N-urea nitrogen in urea displaced by DDGS; suffix ‘C’—corn; suffix ‘D’—corn dry milling]

GHG emissions of soybean oil [N fertilizer_S nitrogen fertilizer; Other chemicals_S other fertilizers (P and K), herbicides, pesticides, and lime; N 2 O_S N2O emissions from soil during soybean cultivation; SOC_S changes in soil organic carbon levels; Diesel_S diesel consumption in soybean production; Other fuels_S electricity, natural gas, gasoline, liquefied petroleum gas used in soybean production; Chemicals_SC hexane and water used in soybean crushing; Avoided soybean soybean displaced by soybean meal; suffix ‘S’—soybean; suffix ‘SC’—soybean crushing]

Results show that the largest GHG emission sources in soybean oil production are N2O emissions from soil during soybean cultivation (13–57%) and carbon dioxide from burning the natural gas used in soybean crushing (21–47%). Even though a very small quantity of nitrogen fertilizer is applied during soybean cultivation, N2O emissions from soil are one of the largest GHG sources because of nitrogen fixation during soybean cultivation. GHG emissions associated with N2O emissions from soil in soybean oil production are 0.4–1.6 kg of CO2 equivalent per kilogram of soybean oil. The second largest GHG emission source groups in soybean oil production are carbon sequestration by soil (−29–24%), diesel used in soybean cultivation (4–24%), and electricity used in the soybean crushing process (10–21%). As was observed for ethanol production, carbon sequestration by soil varies with tillage practices and provides GHG credits where conservation tillage practices are dominant. GHG credits associated with soybean meal displacement are 1.4 kg of CO2 equivalent per kilogram of soybean oil.

Allocation procedures and displacement scenarios are very important life cycle factors in both ethanol and soybean oil. Adopting output mass allocation assigns about 58% and 18% of the overall GHG emissions to ethanol and to soybean oil, respectively. The system expansion approach allocates 72–82% (21–65%) of the overall GHG emissions to ethanol (soybean oil). The system expansion is the more relevant allocation approach because output mass is not a primary driving force for the process. However, a weak point of the system expansion approach is uncertainties in the alternative product systems, for example, uncertainties in the displacement scenarios. A report from the US EPA (United States Environmental Protection 2007) suggests that 1 kg of DDGS would displace 0.5 kg of corn grain and 0.5 kg of soybean meal. The US EPA’s displacement scenario increases GHG emissions of ethanol by 6–10% because of lower GHG credits for DDGS displacement. There are few soybean meal displacement scenarios available at this time; this is a prime area for research. We arbitrarily decrease the quantity of soybean displaced by soybean meal by 17%, which increases GHG emissions of soybean oil by 9–61%.

N2O emissions from soil during biomass production and carbon dioxide emissions from energy consumption in biorefinery are the most environmentally sensitive aspects in both ethanol and soybean oil production systems in terms of climate change potential. The ethanol production system is selected to evaluate feasible improvement options. Winter cover crop practice is one such option to reduce N2O emissions from soil during corn cultivation (Snapp et al. 2005). Winter cover crops can enhance soil organic carbon sequestration and also serve as a nitrogen scavenger (Snapp et al. 2005). Winter cover crop practice combined with no-tillage reduces N2O emissions from soil by 25–64%, resulting in GHG emissions of ethanol between 0.6 and 1.2 kg of CO2 equivalent per kilogram of ethanol. Thus, winter cover crop practice combined with no-tillage lowers GHG emissions of ethanol by 23–60%. Another benefit from winter cover crop practice is more carbon sequestration by soil and less leaching of soluble nitrogen species to ground and surface waters. Biomass, particularly crop residues, can be a good energy source for biorefineries and displace fossil energy use such as natural gas and coal. Corn stover is a good candidate for an energy source only if soil erosion is maintained at a tolerable level. Utilization of corn stover as an energy source in corn dry milling plants reduces GHG emissions of ethanol by 20–58% when 50% of corn stover produced in cornfield is collected from a no-tilled cornfield. Combining winter cover crop practice and corn stover utilization further reduces GHG emissions of ethanol by 47–105%, resulting in −0.06–0.7 kg of CO2 equivalent per kilogram of ethanol. Ethanol produced in Sauk County, Wisconsin under the combined improvement options offers GHG benefits (net carbon sequestration) because of more carbon sequestration by soil as soil organic carbon due to winter cover crop practice and no-tillage practice.

Indirect land use change (iLUC) in the ethanol production system is based on the scenario that when existing cornfields are diverted to ethanol production, undisturbed ecosystems (grassland or forest, etc.) elsewhere might be converted to croplands to produce feed (food) in consequence of ethanol production. We have serious intellectual and pragmatic concerns with the current iLUC approach. iLUC makes domestic industries responsible for the environmental impacts of their competitors worldwide, and for supply chains over which domestic industries have no influence. iLUC also does not take into account unused arable land (at least a billion acres worldwide) that is not currently part of the market. Another troubling fact is that iLUC is entirely driven by price signals. Therefore, anything that drives up agricultural prices will “cause” iLUC, including the Conservation Reserve Program which removes environmentally sensitive croplands from production—thereby driving up crop prices. An unintended but unavoidable consequence of iLUC logic is that agricultural communities must stay forever poor. Any increase in their wealth must “cause” iLUC,

As life cycle practitioners, we are also concerned about attempts to link iLUC and life cycle analysis (LCA). The current iLUC approach violates at least two fundamental principles of LCA: (1) equivalent system boundaries and (2) allocation of environmental burdens among the various products of the system—world cropland in this case. As of this date, only biofuel must submit to the greatly enlarged system boundaries required by iLUC. Biofuel competitors do not have to shoulder this burden. Also, land gives us multiple products including food, animal feed, fiber, and biofuel. iLUC currently assigns the entire incremental burden of hypothetical land use change to the biofuel and none to any of the other products from land. This does not seem to be intellectually defensible.

Our previous study (Kim et al. 2009b) estimates GHG emissions associated with iLUC in two different types of undisturbed ecosystems (i.e., grassland or forest) occurring in the same 40 counties in the United States. The primary GHG emission sources associated with iLUC are carbon releases during land clearing at the land conversion event and carbon changes in soil organic carbon levels in newly converted croplands. The results from the previous study (Kim et al. 2009b) are used here to determine the effects of indirect land use changes on the ethanol production system. Average GHG emissions due to iLUC over cropping years instead of time series GHG emissions are used here to determine the effects of cropping year in newly converted cropland. Results are shown in Fig. 3, where ‘Ref’ represents mean GHG emissions of ethanol over the 40 counties without the effects of iLUC. The current tillage practices are applied to newly converted croplands. As seen in Fig. 3, the effects of iLUC vary with cropping year and fraction of forest converted. For example, when newly converted croplands maintain crop cultivation for 100 years, the indirect land use changes increase mean GHG emissions of ethanol by 7–38%, depending on the fraction of forest converted. If newly converted ecosystems are used as croplands for only 20 years, the indirect land use changes increase mean GHG emissions of ethanol by 48–170%. The fraction of forest converted also greatly affects greenhouse gas emissions associated with iLUC.

4 Conclusions, recommendations, and perspectives

Regional variations in GHG emissions of biobased chemicals are significant. Farming sites with higher biomass yield, lower nitrogen fertilizer rate, and less tillage are favorable to future biorefinery locations in terms of global warming. For existing biorefineries, farmers are encouraged to apply a site-specific optimal nitrogen fertilizer rate, to convert to no-tillage and to adopt winter cover practices to reduce GHG emissions of their biobased products when possible. An appropriate nitrogen rate could increase corn yield and minimize GHG emissions of corn (Kim and Dale 2008c). This, of course, is one of the key objectives of precision agriculture. Energy consumption in the biorefinery is also an important GHG emission source. Utilization of crop residues as an energy source in the biorefinery is a feasible improvement practice only if soil erosion is maintained at a tolerable level.

References

American Soybean Association (2008) Soy Stats 2008. http://www.soystats.com/2008/non-frames.htm, accessed December, 2008

Argonne National Laboratory (2008) Greenhouse gases, regulated emissions, and energy use in transportation (GREET) computer model 1.8b. http://www.transportation.anl.gov/modeling_simulation/GREET/index.html, accessed December, 2008

Arora S, Wu M, Wang M (2008) Update of distillers grains displacement ratios for corn ethanol life-cycle analysis. Argonne National Laboratory. http://www.transportation.anl.gov/pdfs/AF/527.pdf, accessed December, 2008

Atkinson B, Mavituna F (1991) Biochemical engineering and biotechnology handbook. Stockton, New York

Conservation Technology Information Center (2007) National Crop Residue Management Survey. http://www.conservationinformation.org/?action=members_crm, accessed December, 2008

Del Grosso SJ, Parton WJ, Mosier AR, Ojima DS, Kulmala AE, Phongpan S (2000) General model for N2O and N2 gas emissions from soils due to denitrification. Global Biogeochem Cycle 14:1045–1060

Del Grosso SJ, Parton WJ, Mosier AR, Hartman MD, Brenner J, Ojima DS, Schimel DS (2001) Simulated interaction of carbon dynamics and nitrogen trace gas fluxes using the DAYCENT model. In: Shaffer MJ, Ma L, Hansen S (eds) Modeling carbon and nitrogen dynamics for soil management. Lewis, Boca Raton, pp 303–332

Ecobilan (2008) DEAMTM LCA database

Erickson DR (1995) Practical handbook of soybean processing and utilization. AOCS, St. Louis

Jiménez-González C, Kim S, Overcash M (2000) Methodology for developing gate-to-gate life cycle inventory information. Int J LCA 5:153–159

Kim S, Dale BE (2005) Life cycle assessment of various cropping systems utilized for producing biofuels: bioethanol and biodiesel. Biomass & Bioenergy 29:426–439

Kim S, Dale BE (2008a) Life cycle assessment of fuel ethanol derived from corn grain via dry milling. Bioresource Technol 99:5250–5260

Kim S, Dale BE (2008b) Annual report for Life cycle assessment to improve the sustainability and competitive position of biobased chemicals: a local approach, funded by the U. S. Department of Energy and the U. S. Department of Agriculture. Grant Agreement No.: 68-3A75-6-509. Michigan State University

Kim S, Dale BE (2008c) Effects of nitrogen fertilizer application on greenhouse gas emissions and economics of corn production. Environ Sci Technol 42:6028–6033

Kim S, Dale BE, Jenkins R (2008) Life cycle assessment of corn grain and corn stover in the United States. Int J LCA 14(2):160–174

Kim S, Jiménez-González C, Dale EB (2009a) Enzymes for pharmaceutical applications―a cradle-to-gate life cycle assessment. Int J LCA. http://www.springerlink.com/content/t1xg271325q223l0/fulltext.html

Kim H, Kim S, Dale BE (2009b) Biofuels, land use change and greenhouse gas emissions: some unexplored variables. Environ Sci Technol 43:961–967

Li Y, Griffing E, Higgins M, Overcash M (2006) Life cycle assessment of soybean oil production. J Food Process Eng 29:429–445

Liu K (1997) Soybeans: chemistry, technology, and utilization. Chapman & Hall, New York

McAloon A, Taylor F, Yee W, Ibsen K, Wooley R (2000) Determining the cost of producing ethanol from corn starch and lignocellulosic feedstocks. NREL/TP-580-28893. National Renewable Energy Laboratory, Colorado

Natural Resource Ecology Laboratory (2005) Century soil organic matter model: user's guide and reference, Colorado State University. http://www.nrel.colostate.edu/projects/century5/reference/index.htm, accessed December, 2008

Office of Industrial Technologies (2000) Chapter 5 Agricultural chemicals: fertilizers, energy and environmental profile of the U.S. chemical industry. In Energy and environmental profile of the U.S. chemical industry. US Department of Energy. http://www.eere.energy.gov/industry/chemicals/pdfs/profile_chap5.pdf, accessed December, 2008

Renewable Fuels Association (2008) Historic U.S. fuel ethanol production. http://www.ethanolrfa.org/industry/statistics/, accessed December, 2008

Sheehan J, Camobreco V, Duffield J, Graboski M, Shapouri H (1998) Life cycle inventory of biodiesel and petroleum diesel for use in an urban bus. NREL/SR-580-24089. National Renewable Energy Laboratory, Colorado

Snapp SS, Swinton SM, Labarta R, Mutch D, Black JR, Leep R, Nyiraneza J, O'Neil K (2005) Evaluating cover crops for benefits, costs and performance within cropping system niches. Agr J 97:322–332

Swiss Centre for Life Cycle Inventories (2008) The Ecoinvent Database

United States (2007) The Energy Independence and Security Act of 2007 (H.R. 6). http://frwebgate.access.gpo.gov/cgi-bin/getdoc.cgi?dbname=110_cong_bills&docid=f:h6enr.txt.pdf, accessed December, 2008

United Soybean Board (2008) Product information. http://www.soybiobased.org/productinfo/, accessed December, 2008

United States Environmental Protection Agency (2007) Regulatory impact analysis: renewable fuel standard program—Chapter 6 Life cycle impacts on fossil energy and greenhouse gases. EPA420-R-07-004. http://www.epa.gov/otaq/renewablefuels/420r07004cover-overview.pdf, accessed December, 2008

Wu M (2008) Analysis of the efficiency of the U.S. ethanol industry 2007. Argonne National Laboratory. http://www1.eere.energy.gov/biomass/pdfs/anl_ethanol_analysis_2007.pdf, accessed December, 2008

Acknowledgements

The authors gratefully acknowledge financial support provided by the U. S. Department of Energy and the U. S. Department of Agriculture (Grant Agreement No. 68-3A75-6-509) and by the DOE Great Lakes Bioenergy Research Center (Grant No. DE-FC02-07ER64494).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S., Dale, B.E. Regional variations in greenhouse gas emissions of biobased products in the United States—corn-based ethanol and soybean oil. Int J Life Cycle Assess 14, 540–546 (2009). https://doi.org/10.1007/s11367-009-0106-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0106-4