Abstract

Background, aim, and scope

The main primary energy for electricity in Thailand is natural gas, accounting for 73% of the grid mix. Electricity generation from natural gas combustion is associated with substantial air emissions. The two technologies currently used in Thailand, thermal and combined cycle power plant, have been evaluated for the potential environmental impacts in a “cradle-to-grid” study according to the life cycle assessment (LCA) method. This study evaluates the environmental impacts of each process of the natural gas power production over the entire life cycle and compares two different power plant technologies currently used in Thailand, namely, combined cycle and thermal.

Materials and methods

LCA is used as a tool for the assessment of resource consumption and associated impacts generated from utilization of natural gas in power production. The details follow the methodology outlined in ISO 14040. The scope of this research includes natural gas extraction, natural gas separation, natural gas transmission, and natural gas power production. Most of the inventory data have been collected from Thailand, except for the upstream of fuel oil and fuel transmission, which have been computed from Greenhouse gases, Regulated Emissions, and Energy use in Transportation version 1.7 and Global Emission Model for Integrated Systems version 4.3. The impact categories considered are global warming, acidification, photochemical ozone formation, and nutrient enrichment potential (NEP).

Results

The comparison reveals that the combined cycle power plant, which has a higher efficiency, performs better than the thermal power plant for global warming potential (GWP), acidification potential (ACP), and photochemical ozone formation potential (POCP), but not for NEP where the thermal power plant is preferable.

Discussion

For the thermal power plant, the most significant environmental impacts are from power production followed by upstream of fuel oil, natural gas extraction, separation, and transportation. For the combined cycle power plant, the most significant environmental impacts are from power production followed by natural gas extraction, separation, and transportation. The significant difference between the two types of power production is mainly from the combustion process and feedstock in power plant.

Conclusions

The thermal power plant uses a mix of natural gas (56% by energy content) and fuel oil (44% by energy content); whereas, the combined cycle power plant operates primarily on natural gas. The largest contribution to GWP, ACP, and NEP is from power production for both thermal as well as combined cycle power plants. The POCP for the thermal power plant is also from power production; whereas, for combined cycle power plant, it is mainly from transmission of natural gas.

Recommendations and perspectives

In this research, we have examined the environmental impact of electricity generation technology between thermal and combined cycle natural gas power plants. This is the overview of the whole life cycle of natural gas power plant, which will help in decision making. The results of this study will be useful for future power plants as natural gas is the major feedstock being promoted in Thailand for power production. Also, these results will be used in further research for comparison with other feedstocks and power production technologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background, aim, and scope

Electricity generation in Thailand predominantly relies on thermal and combined cycle generation technologies. Natural gas is the dominant fuel for electricity generation, accounting for about 73% of the total electricity generation. The remaining is made up of lignite/coal-fired power plants (16%), large-scale hydropower (6%), fuel oil (3%), and about 3% from renewables (IEA 2003). Natural gas is now regarded as a key energy source because of its stability of supply and cleanness. Furthermore, there is a tendency worldwide to promote fuel conversion from natural gas.

The electricity demand of Thailand has increased along with population growth since electricity is an essential factor in daily human activities, especially in the industrial and urban areas. The impacts of utilizing natural gas as the main feedstock must be realized and thoroughly assessed to avoid adverse effects to human health and the environment. Electricity production is still based on conventional combustion technologies of open-cycle and combined cycle thermal plants which are known to contribute air and other pollutants. Though natural gas is the cleanest burning conventional fossil fuel, the whole life cycle of natural gas power generation has many upstream processes before electricity generation. The upstream processes, such as natural gas exploration, and distribution, natural gas transmission also contribute to environmental impacts in addition to providing an efficient, competitively priced fuel for the generation of electricity. The reliability of natural gas in the power generation sector will continue to grow, and significant amounts will be utilized for power production. It is therefore necessary to assess thoroughly the environmental impacts from natural gas power production in order to quantify the emissions profile, as well as identify the environmental hotspots. The findings of this study are expected to provide an evidential support in strategic decision making and planning.

The ISO 14000 series demands continuous improvement in environment management systems of the product. Life cycle assessment (LCA), in ISO 14040 series, is a “cradle-to-grave” approach for assessing products and services (UNEP 1999). The approach is followed by evaluating all stages of a product’s life from the perspective that they are interdependent, meaning that one operation leads to the next. LCA enables the estimation of the cumulative environmental impacts resulting from all stages in the product life cycle, often including impacts not considered in more traditional analyses.

Even though electricity generation from natural gas accounts for more than three quarters of the total natural gas utilization in Thailand, at the moment, there is little information about the environmental burdens over the whole life cycle of natural gas power production, thus, an LCA needs to be conducted. Also, electricity is a fundamental input to most products; hence, an LCA of electricity is essential information for conducting LCAs of any product or process.

The main objective of this study is to employ a life cycle approach in assessing and comparing the environmental impact from pollutants released during electricity generation as well as upstream processes. LCA is applied in order to evaluate, quantitatively analyze, and compare the environmental aspects of the full life cycle of natural gas combined cycle and thermal power plants. The result of this study can be used to compare other LCAs with various electricity generation systems in Thailand. This will give a picture of the environmental benefits and drawbacks of these various power generation technologies.

2 Materials and methods

2.1 Goal and scope of this study

The goal of this LCA research is to identify the environmental emissions from each process of natural gas power production since the cradle-to-gate of electricity production and to compare the environmental impacts from the emissions released during the generation processes of two different power plant technologies, namely, combined cycle and thermal. The main scope of this study is to provide the material balance and environmental information on existing from all the life cycle phases—natural gas extraction, crude oil extraction, gas separation plant, power plant, and transportation. All process of natural gas power plant is normalized to 1 MWh of electricity delivered from a power plant.

The data obtained for the LCA are mainly from primary sources such as plant information; secondary data such as existing literature data, calculations, and measurements are used in the absence of primary data.

2.1.1 Description of the study site

Bang Pakong power plant is presently Thailand’s biggest and most modern thermal power plant. With a capacity of 3,680 MW, it contributes 25% of all of Electricity Generating Authority of Thailand’s (EGAT) power generation. Its utilization of both thermal and combined cycle generating systems offers an efficient and reliable power service to drive the nation’s continuous economic and social development. Fuel feedstock for the Bang Pakong power plant mainly consists of natural gas, though Bang Pakong is designed to be capable of firing both natural gas and oil. The reserve oil is heavy oil and diesel fuel. Therefore, its burning of indigenous natural gas as a major fuel has significantly reduced the country’s dependence on imported oil, thus saving substantial money each year (EGAT 2005).

The electricity generation technologies for the Bang Pakong power plant are two technologies, namely, thermal and combined cycle. The thermal power plant consists of two 550 MW and two 600 MW units, making up the total electricity generation capacity of the thermal power plant of about 2,300 MW, with a net efficiency of about 39%. There are four combined cycle blocks in the power plant—two of 370 MW and two of 320 MW—giving a total electricity generation capacity of the combined cycle power plant of 1,380 MW, with a net efficiency of the generator of about 44% (EGAT 2005).

2.1.2 System boundaries

The research was designed to assess and analyze the following aspects:

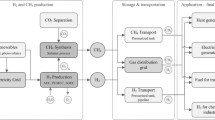

System boundary includes the entire life cycle of electricity production from Bang Pakong power plant, including natural gas production (case: Bongkot project), natural gas transmission (onshore–offshore only transmission section that concerns the Bang Pakong power plant), Rayong gas separation plant unit 1 and, finally, power generation at the Bang Pakong combined cycle power plant units 1–4 and thermal power units 1–4 (Fig. 1).

2.1.3 Functional unit

The functional unit for this research is 1 MWh net electricity generation from the natural gas power production.

2.1.4 Allocation procedure

Allocation is required for multi-input and multi-output processes (Baumann and Tillman 2004). In this research, the life cycle stages of a natural gas power plant are as follows:

First, natural gas production is the process for extracting the natural gas from a well. The main products of the process are natural gas, condensate, and crude oil. The environmental burdens from this stage are allocated based on mass.

Second, gas separation plant is the process for separating natural gas from the other products from the extraction stage. The final product of natural gas separation is methane (sale gas), ethane, propane, LPG, NGL, and CO2. Mass allocation is used for estimating the environmental burdens for the sale gas which is used for power production.

Finally, electricity generation at Bang Pakong has two technologies, namely, thermal and combined power plants. Mixed fuel feeds, natural gas, and bunker oil are used for the thermal power plant.

This study is concerned only with the portion of the environmental flows that focus on the main product of each process. The allocation ratios and results of allocation calculation are presented in Tables 1 and 2.

2.2 Life cycle inventory

The life cycle stages for natural gas power production from the cradle-to-grid are as follows:

-

(a)

Natural gas extraction: The natural gas used as feedstock for the Bang Pakong power plant is mainly extracted from the Gulf of Thailand at the Bongkot site under the control of PTT Exploration and Production Co. Ltd (PTT Plc.). The focus of this study was on the main production of natural gas at the Bongkot site (Anon 2006a).

-

(b)

Natural gas separation: The raw natural gas from the Gulf of Thailand, which is composed of various kinds of very useful hydrocarbons, is transmitted to a gas separation plant at Rayong province for separation and processed for further utilization rather than for using only as fuel. This plant is also controlled by PTT Plc. The Rayong gas separation plant has many units for gas separation, but this research focused on only unit 1. In the Rayong gas separation plant, the concentration of air pollutants is measured via stack emissions through the continuous emission monitoring (CEM) data (Anon, PTT’s Quality Occupational Health, Safety, and Environmental Division, PTT Public Company Ltd., 2006, personal communication).

-

(c)

Transportation: For this phase, LCI data were required for natural gas and fuel oil transportation via pipeline and ship. Fuel oil transmission to the Bang Pakong power plant is controlled by PTT Plc. A significant source for crude oil is imported from the Middle East and is controlled by PTT Plc. and is stored at its Sriracha oil terminal before being transported to Bang Pakong power plant via ship and pipeline (Sriracha Oil Terminal, 2007, personal communication). As primary data were not available for natural gas transmission, secondary data following the Global Emission Model for Intergraded Systems (GEMIS) version 4.3 method (GEMIS 2007) was used to estimate fugitive methane emissions from transmission processes—including natural gas and fuel oil.

-

(d)

The upstream of fuel oil: Inventory data for the processes of crude oil extraction and fuel oil refining, only for thermal power plant, were retrieved and estimated from the Greenhouse gases, Regulated Emissions, and Energy use in Transportation (GREET) model 1.7 (Wang 2006). This model evaluates energy and emission impacts of fuel oil from well to tank (upstream of fuel oil).

-

(e)

Natural gas power plant: In the Bang Pakong power plant, focus was on the raw material and environmental releases from the thermal plant units 1, 2, 3, and 4 and combined cycle plant units 1, 2, 3, and 4. The concentration of air pollutants are measured via stack emissions through the CEM data, which is a method widely implemented by EGAT in all its power plants (Electricity Generating Authority of Thailand, 2006, secondary data and CEMs report).

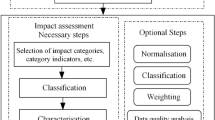

2.3 Life cycle impact assessment

The air emissions released from the natural gas power plant and upstream process of natural gas can be classified into respective impact categories following the results of the inventory data by stressors and area impact. The air emission substances considered in this research are CO2, CH4, CO, N2O, SO2, NOx, and total suspended particulates (TSP). This study employed the environmental design of industrial products methodology (Wenzel et al. 1997). The impact categories considered are global warming potential (GWP), acidification potential (ACP), nutrient enrichment potential (NEP), and photochemical ozone formation potential (POCP).

2.4 Life cycle interpretation

The data collected from inventory analysis that is analyzed and classified into impacts of relevant categories can be interpreted into measurable impacts. The interpretation of results can provide an explanation of the relationship between resource usage and impacts generated from different processes of power production at a natural gas power plant.

3 Results and discussion

According to the goal and methodology of this research, the results of this study describe steps of the LCI, impact assessment, and interpretation. The results for each life cycle stage are presented separately.

3.1 Life cycle inventory

For this study, the input and output information was collected directly from the study site. Some data such as volume of wastewater in the Bang Pakong power plant was acquired from the environmental impact assessment report since this data was not available from plant report at the study site.

-

(a)

Natural gas extraction: The raw material and environmental data requirement was based on the goal and scope collected from January 2005 to December 2006. The Bongkot natural gas field does not produce wastewater; however, about 99% of the sea water obtained from drilling is discharged back to the sea. The solid waste from Bongkot can be separated into hazardous waste and non-hazardous waste (PTT Exploration and Production Public Company Limited (PTTEP), 2006, personal communication). The final inventory results before allocation are shown in Table 1.

-

(b)

Natural gas separation: The time of record of resource was from January 2005 to December 2005. The emissions coming from this process include the flue gas from separating non-hydrocarbon and hydrocarbon compounds. The air pollutants measured by the CEM are CO, NOx, and SO2 (Anon, PTT’s Quality Occupational Health, Safety, and Environmental Division, PTT Public Company Ltd., 2006, personal communication). CO2 is calculated via US.EPA AP-42 method (USEPA 1995). All the wastewater from the gas separation plant (units 1, 2, and 3) is treated in one unit of the wastewater treatment plant. Solid waste from the production process includes mercury removal sieve waste, benfield sludge produced from gas separation unit 1 only, gas filter, and used oil. The unit processes for gas separation for both thermal and combined cycle power plants are shown in Table 2.

-

(c)

Transportation: Natural gas is transported only via pipeline. The total distance from natural gas extraction to the natural gas power plant is 690 km. For offshore, the distance from extraction process was separated into two parts: about 171 km via a 0.81-m (32-in) diameter pipeline and about 415 km via a 0.86-m (34-in) diameter pipeline. For onshore transmission, this report focused on the main pipeline from the gas separation plant to the Bang Pakong power plant, which extended about 104 km via a 0.71-m (28-in) diameter pipeline (Anon 2006b). The total methane emission to the atmosphere from the thermal power plant is 166.78 g/MWh, but for the combined cycle power plant, about 281.15 g/MWh using GEMIS version 4.3. The higher value for the combined cycle arises due to higher amounts of natural gas being required; part of the energy requirement for the thermal power plant is from fuel oil; whereas, the combined cycle is totally fired by natural gas. For fuel oil transportation, the fuel consumption from ship transportation was calculated for round trip of all navigation—from the Middle East to Sriracha (16,000 km) and Sriracha to Bang Pakong upload station (100 km)—fuel oil used being 30 t per 8,000 km and 150 L/h, respectively. The diameter of the pipeline between Bang Pakong upload stations to Bang Pakong power plant is 0.45 m (Sriracha Oil Terminal, 2007, personal communication). The air emissions concerned with fuel oil transmission are CO2, CO, CH4, NOx, N2O, and SO2. The result of estimated air emission following GEMIS version 4.3 methods of fuel oil transportation are 25.08, 1.81, 0.33, 4.88, 0.13, and 0.06 g/MWh, respectively.

-

(d)

The upstream of fuel oil: The air emissions estimated from the GREET model 1.7 are CO2, CO, CH4, NOx, N2O, and SO2. The results of this estimate are 34,090.02, 41.29, 393.86, 142.33, 0.65, and 77.14 g/MWh, respectively.

-

(e)

Natural gas power plant: The raw material information was collected from January 2004 to December 2006. Emissions data for CO, NOx, SO2, and TSP were collected from the CEM database for the period January 2004 to December 2005. The CEM data were collected based on hourly average records (Electricity Generating Authority of Thailand, 2006, secondary data and CEMs report). CO2 was calculated via US.EPA AP-42 method (USEPA 1995). The wastewater from electricity generation is from hot water rejection and water loss and evaporation in the process. The cooling tower at the Bang Pakong power plant is operated in case the production process rejects the hot water at temperatures more than 35°C. The thermal power plant produces solid waste in the form of fly ash, bottom ash, and other waste, i.e., waste oil and damaged resin. Bottom ash includes slag and particles that are coarser and heavier than fly ash. The combined cycle power plant produces filter board and other waste, i.e., waste oil and damaged resin (Electricity Generating Authority of Thailand, 2006, secondary data and CEMs report).

The consolidated inventory data after allocation for the thermal and combined cycle power plants are presented in Tables 3, 4, 5, and 6.

3.2 Life cycle impact assessment

From the data of inventory analysis, the environmental impact potentials resulting from the air pollutant emissions for the production of 1 MWh of electricity from thermal power plant (feedstock: natural gas 150 m3 and diesel oil 108.65 L) and combined cycle power plant (natural gas feedstock 252 m3) can be assessed. The results of impact assessment for the whole life cycle of thermal and combined cycle power plants are presented in Tables 7 and 8, respectively.

3.3 Life cycle interpretation

The thermal power plant burns natural gas and fuel oil, and the combined cycle power plant burns only natural gas. The computation of potential environmental impacts is based on the air emissions released during the life cycle of power production. The higher global warming, acidification, and photochemical ozone depletion potential are from the thermal power plant. The higher potential of nutrient enrichment is from the combined cycle power plant. For both technologies of electricity generation, the highest impact for all categories considered (except photochemical formation) comes from power production. Details for each impact category are discussed in the sections below.

3.3.1 Global warming potential

GWP is contributed to mainly by CO2 emissions with a small contribution from CH4, N2O, and CO. There is a significant potential resulting from power plant and upstream processes. By considering the whole life cycle of the natural gas power plants, the thermal power plant has a higher GWP than the combined cycle power plant.

The most significant process contributing to GWP for both types of power plants is fuel combustion contributing about 89.1% for thermal technology and 90% for combined cycle power plants. The next significant contribution for the thermal power plants is from the upstream process of fuel oil (6.3%) followed by natural gas extraction (2.5%). Natural gas separation (1.9%) has a smaller contribution with the least contribution being from natural gas transmission (0.3%) due to fugitive methane emissions. For combined cycle power plant, the second contribution comes from natural gas extraction (5.3%) and natural gas separation (4.0%) followed by natural gas transmission (0.7%).

The most significant air pollutant emitted is CO2 from thermal and combined cycle plants contributing 98% and 99% of the total GWP, respectively. In the whole life cycle of thermal plant, CO2 emission contributed from power plants is 91% from the combustion process followed by the upstream of fuel oil process of 5%. Smaller emissions are from natural gas extraction and the separation process of 4%. For the combined cycle power plant, the CO2 released from the power plant is 91% followed by natural gas extraction (5%) and the natural gas separation process (4%).

A detailed look at the inventory results revealed that among the two types of plants (excluding upstream process), thermal power plants contributed more global warming due to the nature of the combustion process since the thermal power plant is less efficient than combined cycle and also because fuel oil is used along with natural gas.

A comparison of the results of this study was done with those by Kannan et al. (2005) who studied the combined cycle plant life cycle. The GWP for the literature study was about 473,000 g CO2-eq/MWh (excluding transmission and distribution losses), which is lower than that obtained in this study. This is mainly due to the higher efficiency of the power production (50% as compared to 44% in this study) as well as non-inclusion of transmission and distribution losses.

3.3.2 Acidification potential

The ACP is contributed by NOx and SO2 emissions. For the combined cycle power plant, SO2 emissions are not a significant pollutant as only natural gas is used as the fuel. For the thermal plant, SO2 is the bigger contributor at about 61% of the total ACP, the remaining 39% being from NOx. The greatest effect of this potential comes from power production. This is due to the production of SO2 from fuel oil combustion contributing to about 91% of the total impact, followed by the upstream process of fuel oil contributing 8% in this process at the thermal power plant. NOx emission contributed from natural gas combustion accounts about 83%, though natural gas contains a very low content of nitrogen (hence, low fuel NOx) but is combusted at high temperature which releases nitrogen oxides (thermal NOx), contributing to the ACP for both plants. NOx emission from the upstream of fuel oil is 17%. For the combined cycle power plant, the most significant contribution to this potential comes from NOx emission (99%). The ACP for the thermal plants is double than that of the combined cycle plants.

3.3.3 Photochemical ozone formation potential

For the POCP, the major contributing gases are CO and CH4 from power generation (50%), the upstream of fuel oil (33%), natural gas extraction (11%), and transmission (5.5%) for the thermal power plants. For power generation, the impact is entirely from CO emissions as the CH4 emissions were below detection limits. However, CH4 emissions from crude oil extraction are the predominant contributor to the upstream of fuel oil phase. For the combined cycle power plant, the main contribution is from the natural gas extraction (66%) followed by natural gas transmission (34%). For both cases, the contribution of POCP from natural gas transmission is due to the leakage of methane.

3.3.4 Nutrient enrichment potential

The NEP is higher in the combined cycle than the thermal power plants. The major gases contributing are NOx and N2O, but the most significant contribution comes from NOx (>99.5%). The most significant source related to nutrient enrichment is power production. For the thermal plant, 82% of NEP is from the power plant followed by the upstream of the fuel oil process which contributes about 17%. A minor contribution is from the natural gas separation process. For the combined cycle plant, more than 99% of NOx is released from the power plant and a very small contribution from the gas separation process. The feedstock consumption of natural gas used for the power plant is greater for the combined cycle on a per MWh basis. Therefore, The NOx emissions from the combined cycle plants are expected to be higher than thermal power plants despite higher efficiency because of higher temperature in the combined cycle plants causing higher NOx emissions. Secondary combustion with excess air also contributes to higher thermal NOx production. Hence, the NEP from the thermal power plants is about 21% lower than the combined cycle power plants.

4 Conclusions and perspectives

The aim of this study was to assess and compare the potential environmental impacts of the whole life cycle of natural gas power plants with two technologies: thermal and combined cycle. The thermal power plants considered use of natural gas (56% by energy content) and fuel oil (44% by energy content); whereas, the combined cycle power plants operate primarily with natural gas. The potential environmental impacts were compared based on 1 MWh produced for both the electricity generation technologies. The global warming, acidification, and POCPs of the thermal power plant were higher than combined cycle power plants; whereas, the NEP was lower.

The higher GWP of the thermal gas power plants are due to the use of both fuel oil and natural gas feedstock as well as lower efficiency. The thermal power plants have more emissions of acidifying gases from fuel oil and power production processes. The POCP of the thermal power plants was higher because of CO emissions from power production and CH4 emissions from crude oil extraction. The NEP of the combined cycle power plant was higher because of greater thermal NOx production due to higher temperatures, as well as secondary combustion with excess air.

For the thermal power plants, the largest contribution to all the impact categories considered is from power production; whereas, the POCP is contributed mainly by natural gas extraction and transmission for the combined cycle power plants. The GWP contribution from other life cycle phases in decreasing order of magnitude are upstream of fuel oil, natural gas extraction, natural gas separation plant, and natural gas transmission, respectively, for the thermal power plants. For the combined cycle power plants, the sequence is the same as thermal power plants except that there is no contribution from the upstream of fuel oil. For the ACP, the second highest contribution for the thermal power plants is from the upstream processes of fuel oil, viz., crude oil extraction and oil refining. The upstream processes of fuel oil are also having significant contribution to POCP followed by natural gas extraction and transmission.

The results of this study help identify the major environmental aspects of power production from natural gas using the two technologies. It is clear that the performance of thermal power plants would improve if the amount of fuel oil used is reduced. Also, the efficiency of the combined cycle power plants is lower than that observed in literature; an effort should be made to identify the cause so that appropriate measures can be taken. Though based on the current situation, the results will be useful for future power plants as natural gas is the major feedstock being promoted in Thailand for power production. The results will also be useful for further research for comparison with other feedstocks and power production technologies.

References

Anon (2006a) Environmental division annual database. PTT Exploration and Production Public Company Limited

Anon (2006b) Natural gas transmission control center. PTT Public Company Limited

Baumann H, Tillman A-M (2004) The hitch hiker’s guide to LCA. Studentlitteratur AB, Lund, Sweden

EGAT (2005) Bang Pakong power plant. Electricity Generating Authority of Thailand, http://www.egat.co.th

GEMIS (2007) Global Emission Model for Integrated Systems (GEMIS) 4.3 database (2007). Öko-Institut Darmstadt, Germany, http://www.oeko.de/service/gemis/en/index.htm

IEA (2003) Fuels Share for Electricity Generation in Thailand. International Energy Agency, http://www.iea.org

Kannan R, Leong KC, Osman R, Ho HK, Tso CP (2005) Gas fired combined cycle plant in Singapore: energy use, GWP and cost—a life cycle approach. Energy Convers Manag 46:2145–2157

UNEP (1999) Framework of life cycle assessment. The United Nations Environment Programme, http://www.unep.or

USEPA (1995) Compilation of air pollutant emission factors AP-42. US Environmental Protection Agency, http://www.epa.gov/ttn/chief/ap42

Wang M (2006) Greet 1.7 Beta—transportation fuel cycle model. US Department of Energy, Argonne National Laboratory, Argonne, Illinois

Wenzel H, Hauschild M, Alting L (1997) Environmental assessment of products, vol 1. Kluwer Academic Publishers, US

Acknowledgements

The authors would like to acknowledge the Joint Graduate School of Energy and Environment (JGSEE) for providing financial support for this research. Our appreciations also go to the Electricity Generating Authority of Thailand (EGAT), PTT Exploration and Production Co. Ltd., PTT Public Company Ltd., and the Rayong gas separation plant for information.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Andreas Ciroth

Rights and permissions

About this article

Cite this article

Phumpradab, K., Gheewala, S.H. & Sagisaka, M. Life cycle assessment of natural gas power plants in Thailand. Int J Life Cycle Assess 14, 354–363 (2009). https://doi.org/10.1007/s11367-009-0082-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0082-8