Abstract

Advanced oxidation processes (AOPs) and advanced reduction processes (ARPs) are a set of chemical treatment procedures designed to eliminate organic (sometimes inorganic) contamination in water and wastewater by producing free reactive radicals (FRR). UV irradiation is one of the factors that are effectively used in oxidation-reduction processes. Not only does the UV beam cause the photolysis of contamination, but it also leads to the product of FRR by affecting oxidants—reductant, and the pollutant decomposition occurs by FRR. UV rays produce active radical species indirectly in an advanced redox process by affecting an oxidant (O3, H2O2), persulfate (PS), or reducer (dithionite, sulfite, sulfide, iodide, ferrous). Produced FRR with high redox potential (including oxidized or reduced radicals) causes detoxification and degradation of target contaminants by attacking them. In this review, it was found that ultraviolet radiation is one of the important and practical parameters in redox processes, which can be used to control a wide range of impurities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As it has become an important issue for human health, the management and treatment of wastewater have significantly increased in the modern era by inventing and using conventional wastewater treatment (CWWT). CWWTs are classified as physical, chemical, and biological processes. The sequential or simultaneous use of these processes in combination may be an efficient way to degrade a resistant pollutant to CWWT that can be referred to as xenobiotics (anthropogenic chemicals that are toxic and dangerous). Therefore, tertiary or polishing methods are used to remove such pollutants, but limitations related to implementation in full scale and cost-benefit are still the notable factors limiting their practical use (Hossein Panahi et al. 2020).

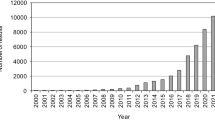

Among the tertiary methods, AOPs and ARPs are technologies that have received much attention during the last several decades. AOPs are a set of chemical purification procedures designed to degrade organic (sometimes inorganic) materials in water and wastewater by producing free reactive radicals (FRR) and pollutants oxidizing through them. Therefore, AOPs are based on the in situ generations of strong oxidants, i.e., hydroxyl radicals (OH•), sulfate (SO4•−), and superoxide (O2•−) radicals for the oxidation of organic pollutants (Khodadadi et al. 2020; Pandis et al. 2022; Saravanan et al. 2022). The simplest advanced oxidation process is the Fenton reaction, which is carried out by hydrogen peroxide along with an iron catalyst to produce OH• (Al-Musawi et al. 2019). Some of the AOPs use UV irradiation and ozone (O3) for improving process efficiency (Deng and Zhao 2015; Norabadi et al. 2020; Panahi et al. 2020). These AOP technologies have already been founded and began at full scale for water and wastewater treatment and water reuse facilities. UV irradiation is one of the factors that is effectively used in oxidation-reduction processes. Not only does UV light lead to the photolysis of pollutants, but it also causes the production of FRR by affecting oxidants—reductants, and the result is pollutant decomposition by FRR. On the other hand, the use of UV irradiation in advanced reduction processes is very effective and efficient in producing reductive radicals. One of the divisions made on the AOPs is based on light (UV or other sources), which is divided into two photochemical and non-photochemical processes (Fig. 1). Therefore, due to the prominent role of UV in AOPs and ARPs, the current study was aimed at a review of producing the possible FRR in AOPs and ARPs based on the use of UV irradiation (Hossein Panahi et al. 2023; Masoomeh Rahimi et al. 2022; Nasseh et al. 2022).

UV irradiation an overview

UV is photons in the range of electromagnetic waves with a wavelength in the range of 100 to 400 nm. Its production source includes natural (sunlight) and artificial (mercury vapor lamps, black lamps, incandescent lamps, etc.) sources. There are three types of UV radiation, which are classified according to the wavelength of their main emission band. They differ in their wavelength and application. The division of the ultraviolet region based on wavelength is as follows: (1) UVA (315–400 nm); (2) UVB (280–315 nm); and (3) UVC (100–280 nm).

Type A ultraviolet light is characterized by a maximum emission band, which is the closest to visible light; ultraviolet light of type B or medium-wavelength is biologically active, and it has an emission band of 312 nm. Short wavelengths or UVC can destroy bacteria and other small organisms. For this reason, they are used to disinfect surfaces such as hospital rooms. Studies have shown that short-wavelength ranges (UVC and UVB) are more widely used in chemical processes (Cortés et al. 2011). V irradiation is directly and indirectly involved in the AOPs and ARPs. In the direct route, UV photons can decompose organic matter through the mechanism of photolysis. Photolysis is defined as a chemical process in which chemical compounds or molecules are split into small units by the action of photons or absorbing light. The UV spectral range of interest for the UV photolysis applications in water is the UVC, where both the contaminants and the water constituents (dissolved organic and inorganic compounds) absorb the photons, but water molecules can produce hydroxyl radicals by absorbing photons (Eq. 1).

However, in the indirect route, UV radiation impacts a photocatalyst or oxidant, and during a series of chain reactions, various types of oxidizing species are produced by a high redox potential decompose organic materials.

Advanced oxidation processes based on UV

UV-based oxidant

H2O2 activation based on UV

Many AOPs use free radicals called highly reactive hydroxyl radicals (OH•) to reduce a wide range of organic pollutants in aqueous solutions. According to the literature, one of the most widespread UV/AOP processes is UV/H2O2, which is extensively studied due to its efficiency in producing FRR such as OH• (He et al. 2012). The UV/H2O2 process is an attractive option for generating non-selective and highly reactive radicals. In the UV/H2O2 process, H2O2 is made photolysis by UV irradiation to produce OH• whose redox potential is 2.7 V and 1.8 V in acidic and neutral solutions. Since OH• is short-lived, it is produced in situ during ozone- and UV-based processes by activating stable precursors such as H2O2 (Lee et al. 2020). The results of studies show that during the UV/H2O2 process, photolysis of these oxidants occurs at a wavelength of λ = 254 nm, which leads to the production of FRR such as OH• (Ike et al. 2018). Hydrogen peroxide (H2O2) is a beneficial oxidizer because it is an environmentally friendly oxidizer that only contains hydrogen and oxygen during decomposition (Zhao et al. 2021). The main disadvantage of hydrogen peroxide is its low oxidizing ability in environmental conditions, which must be activated to have proper performance. Moreover, to make photolysis, UV photons play a very important role in activating H2O2 and producing FRR. Also, the H2O2 dose directly affects the production of radicals, and thus the removal efficiency of pollutants will improve when the dose of hydrogen peroxide is optimal. The corresponding reactions in activating H2O2 and producing FRR are stated below (Eqs. 4–8).

According to Eq. 4, H2O2 changes into 2OH• by receiving UV photons (Eq. 4), and other H2O2 molecules that have not received UV photons convert into H+ and HO2− ionic forms (Eq. 5). Other related chain reactions are described in Eqs. 6–8.

Finally, OH• and \({\mathrm{HO}}_2^{\bullet }\) radicals are formed, which can play a role in the decomposition of organic substances. In addition to degrade organic pollutants, OH• can inactivate microorganisms, while \({\mathrm{HO}}_2^{\bullet }\) cannot have a noticeable effect on inactivating microorganisms (Zhao et al. 2018). The reaction of \({\mathrm{HO}}_2^{\bullet }\) with its reaction intermediates creates a scenario what H2O2 excessive concentration can lead to the consumption of OH• (scavenger phenomena), and OH• reacts with radical scavenger faster than the target pollutants. The graphical schematic of the UV/H2O2 process in producing FRR is shown in the second Fig. 2. UV/H2O2 processes are used to eliminate a lot of contamination including Pb–EDTA, Rhodamine B, melatonin, antipyrine, benzophenone-3, ofloxacin, and acetamiprid, and some of them along with possible radicals produced are presented in Table 1. UV/H2O2 is a fast process and has already been done on a large scale. Moreover, UV irradiation can serve as an effective disinfectant for a variety of microorganisms in addition to activate the H2O2. However, the residual hydrogen peroxide can be dangerous and can also have a negative impact on the process if not reduced. So, it may require removal downstream of the process (Chang et al. 2010; Hollman et al. 2020; Lee et al. 2020; Lee et al. 2021; Srithep and Phattarapattamawong 2017; Ye et al. 2022).

Persulfate activation based on UV

Persulfate-based advanced oxidation processes can be considered promisingly for the removal of stable micropollutants in water and wastewater treatment processes. The types of various persulfate (PS) species are peroxymonosulfate (PMS) and peroxy disulfate which can consider as stable oxidizers in solid state (compared to H2O2), cost-benefit (compared to ozone), high aqueous solubility (compared to permanganate), and high stability at the ambient environment (Wang et al. 2020).

Because PDS has a higher quantum efficiency (i.e., 0.7 mole/E for PDS and 0.5 mole/E for H2O2) and molar absorption coefficient than hydrogen peroxide (i.e., 21.1 M−1 cm−1 for PDS and 18.6 M−1 cm−1 for H2O2), so it has a higher photolysis rate (Ike et al. 2018). All the features of this material facilitate its transportation, storage, and use (Ding et al. 2020). Various persulfate species can be activated to produce FRR (SO4•−) by several agents such as UV irradiation, heat, ultrasound radiation, and transition metal oxides (Eqs. 1–4) (Bu et al. 2017; Gao et al. 2022; Varank et al. 2020; Waldemer et al. 2007).

Many activators have been evaluated for persulfate activating and considering the effective factors in choosing an activator such as economic, energy consumption, and potential pollution of heavy metals. UV irradiation is the most suitable agent for environmental applications (Cui et al. 2022; Wang et al. 2020). It is considered an environmentally friendly and efficient agent to activate an oxidant including PS and PMS which can generate SO4•−. Na2S2O8 and K2S2O8 (UV/PS) are the most common persulfate compounds that are used to supply sulfate ions in the advanced oxidation process. The graphical schematic of the UV/PS process is shown in the second Fig. 3. SO4•− by a high oxidation potential (E = 2.5–3.1 V) is the strongest oxidant after OH• that can decompose organic substances, and it is more stable than OH• and acts selectively in a wide range of pH. Contrary to OH•, SO4•− has a long half-life such it makes more efficient than OH•. SO4•− and OH• are produced according to the following equations (Eqs. 13–15) (Cui et al. 2022; Fu et al. 2019; Wang et al. 2020):

Moreover, SO4•− radicals have a longer lifespan (30–40 μs) compared to OH• (100 ns), which makes it more reactive to organic matter through the electron transfer mechanism (Hoang et al. 2022). They react with electron-donating groups such as hydroxyl (OH), alkoxy (-RO), and amino (-NH2) groups (Ou et al. 2017; Yu et al. 2021). SO4•− tends to react with organic matter through an electron transfer mechanism rather than H+ abstraction and is less affected by water matrix components such as natural organic matter (NOM) and alkalinity, indicating that SO4•− oxidation may complete OH-based AOPs with diverse combinatorial reactivates, product patterns, and energy yields (Qin et al. 2020a). SO4•− radicals prefer to attack nucleophile structures via electron transfer, which can degrade rapidly a wide range of organic contaminants (Liu et al. 2020) and is used to destroy various pollutants such as saccharin (Ye et al. 2022), ofloxacine (Liu et al. 2020), imidacloprid (Wang et al. 2020), and benzophenone-3 (Lee et al. 2021).

In a study conducted by Wang et al., the degradation pathway of imidacloprid is evaluated by SO4•−, and degradation pathways were proposed based on the produced intermediates (Wang et al. 2020). They report that the UV/PS process under similar conditions results in better degradation than the UV/PMS process. To explain this phenomenon, by activating PS or PMS under UV radiation, the rate of radical production can be calculated. A parameter called extinction coefficient (ε) of PS or PMS in Eq. 18 can greatly affect the radical rate in similar conditions. According to the relevant calculations, the extinction coefficient calculated in the same conditions for PS was higher than PMS, so it can be said that the radical production rate in the UV/PS system (radicals PS) was higher than in the UV/PMS system ( rradicals PMS). The rate of radical production is calculated as follows:

Some previous studies on the removal of many pollutants including antipyrine, sulfadimethoxine, benzophenone-3, ofloxacin, halostonitrile, chloramphenicol, acetamiprid, and Cu (II)-EDTA by the method of UV/persulfate and some of them with possible radicals produced are presented in Table 2. UV/persulfate does not produce sludge similar to the catalyst/persulfate. It is faster and more efficient than the hate/persulfate process and has been used on a large scale. However, the disadvantage of UV/persulfate is its inappropriate efficiency in the presence of turbidity, and the sulfate radical is quickly destroyed in alkaline environments. So UV/persulfate process is used in the tertiary stages of water purification.

Ozone activation based on UV

Previous reports show that the addition of UV radiation to ozonation (O3) improves the pollutant degradation process, which is attributed to the synergistic effect between O3 and UV. Ozonation is one of the powerful treatment methods used to remove some pollutants from aqueous solutions. However, O3 alone cannot achieve complete mineralization of these pollutants (Chai et al. 2018). O3 is an oxidant that can play a role in the decomposition of pollutants both directly and indirectly. In direct mode, O3 with a relatively high redox potential affects various bands of organic compounds and detoxifies them. But in the indirect mode, O3 turns into an active radical species in the UV/O3 system and produces different types of reactive oxygen species such as superoxide radical (O2•−), OH•, and singlet oxygen (1O2), and subsequently fast decomposition is its result (Wang et al. 2021a). The graphic representation of FRR in the UV/O3 process is shown in Fig. 4. In particular, the UV lamp provides the energy necessary to break the O3 chemical bonds within to produce reactive oxygen species with high reactivity (Eqs. 19–29) (Liu et al. 2021; Yang et al. 2020). In the synergistic reaction between O3 and UV beam, ozone is produced directly by Eqs. 19–21 and indirectly by Eqs. 22–29 (Emam 2012; Norabadi et al. 2020).

As we can find from the equations, the radicals including O•, OH•, HO2•, O2•, and HO2•− product play a role in the decomposition of organic matter. The degradation pathway of ciprofloxacin (CIP) by possible radicals under the UV/O3 process has been investigated in a study conducted by Liu et al. (see Fig 5. supplementary). The two main active sites of ciprofloxacin were in the aromatic tertiary amine group and the secondary aliphatic amine group in the piperazine ring. The primary attack site of 1O2 was the piperasing ring, and with the attack of 1O2, the hydroxyl present in the piperazine ring is removed, leading to the formation of CIPeI-3, CIPeI-5, CIP VI-1, and CIP-II-1. Cleavage of the aromatic ring of CIP-II-4 and CIP-II-5 led to the formation of CIP-1, which is attributed to electron transfer. In general, due to the attacking piperazine ring, 1O2and O2•− are processed to produce a keto derivative of the piperazine ring, pathway I, pathway II, pathway VI, and pathway VIII. Then, OH• attacks the C-C bonds, and CIP-III-1 is obtained. The anthranilic acid analog intermediate, CIP-III-2, is formed in the decarbonylation of CIP-III-1. Then, the quinolone group was cleaved by OH to produce CIP-III-3. In route IV, 1O2 attacks the cyclopropyl group (-C3H5) and oxidizes to the carboxylic acid product (CIP-IV-1) (Liu et al. 2021). Table 3 shows a list of pollutants decomposed in the UV/O3 method including ciprofloxacin, organophosphorus pesticides, carbamate pesticides, carbamate pesticides, N-Nitrosopyrrolidine, 17-estradiol, bisphenol A, benzalkonium sulfuronoside, and possible radicals produced in this process. O3/UV is more stoichiometrically efficient in generating OH• than H2O2/UV or H2O2/O3; however, it is less energetically efficient than H2O2/UV or H2O2/O3 for generating large quantities of OH• due to the low solubility of O3 in water compared to H2O2.

UV-based combination

Combined processes based on UV can be very diverse, and the reason for that is the key role of UV in AOPs, so that it cannot only be used alone but also play a multiple role in other complex combined AOPs. Below is an overview of the most likely AOPs UV-based.

UV/H2O2/O3 process

During previous reports, AOPs, especially O3 and their combination with H2O2 to increase the formation of OH•, have been shown as a sustainable and efficient approach (Boczkaj and Fernandes 2017). The graphical abstract of this system is depicted in Fig. 6. O3 can provide efficient degradation, but it is not affordable and cost-effective as well, and cost can be a limitation in these methods (Tollefsen et al. 2014). Also, hydrogen peroxide is a very popular oxidizing agent because it is a green and environmentally friendly chemical, such that water and oxygen are the only end products. In the UV/O3/H2O2 system, the amount of ozone consumption is reduced by adding UV; as a result, the degradation cost is reduced, and the oxidation capacity of the system is improved for decomposition of organic compounds. In other words, the simultaneous presence of both O3 and H2O2 oxidants during UV irradiation has a synergistic effect (Arslan et al. 2017). Due to the coexistence of several oxidizing species with different reactivity and selectivity (H2O2, O3, OH•, HO2•), a rapid removal of a pollutant can occur (Bavasso et al. 2020). In the presence of UV rays, H2O2 and O3 decompose to O2 and HO2• radicals (Eq. 27). OH•, which reacts quickly with organic substances, also is produced from the reaction between O3 and HO2• (Eq. 29) (Oturan and Aaron 2014). The chain reactions that explain the breakdown of O3 and H2O2 are summarized below (Eqs. 27–34):

As can be seen from the reactions (Eqs. 27–34), OH• and HO2• radicals are formed, and they play a role in the decomposition of pollutants depending on their redox potentials. A list of pollutants degraded in the UV/H2O2/O3 process including ortho-toluidine, furfural, azo dye AR88, winery wastewater, and possible radicals produced in Table 4 is stated. UV/H2O2/O3 process is more effective than UV/H2O2 and UV/O3 processes in eliminating organic substances due to the production of more free radicals. However, more materials and energy are consumed in the UV/H2O2/O3 process. In addition, the variety of free radicals is greater in the UV/H2O2/O3 process, which is considered one of its capabilities (Arslan et al. 2017; Boczkaj and Fernandes 2017).

UV/O3/persulfate system

In recent years, the structural diversity of micro-pollutants in different water matrices makes measuring their reduction efficiency has led to challenges for the general design of AOPs. In the UV/O3/PS process, UV activates the molecule O3 to OH• and PMS to SO4•−, which can be said that the produced radicals (OH• and SO4•−) are relatively stronger than the original molecules (O3 and PMS) (Yu et al. 2021). The various complex reactions in which FRR is produced are mentioned below (Eqs. 35–46):

As can be seen in chain reactions, the possible free radicals produced in the UV/O3/PS process include OH•, SO5•−, SO4•−, and O3•−. The FRR will play a role in the decomposition of organic pollutants due to their redox potential. Figure 7 shows the general schematic of free radical production in the UV/O3/PS system. UV/O3/persulfate process to remove various pollutants such as atrazine, Reactive Red 120 dye, clofibric acid, atenolol, diclofenac, and possible radicals produced in these processes is presented in Table 5. The most important feature of UV/O3/persulfate is the simultaneous production of two valuable radicals, SO4• and OH•, which cause the process to be highly efficient in eliminating pollutants in both acidic and alkaline environments. Moreover, considering the presence of ozone and persulfate oxidants, it can be noted that the most diverse free radicals are in the UV/O3/persulfate process and UV/H2O2/persulfate (Yu et al. 2021). But UV/O3/persulfate and UV/H2O2/persulfate processes, like most advanced oxidation processes, are used for the tertiary stages of water and wastewater treatment because they are not affordable for the primary and secondary stages of purification.

UV/oxidizing/photocatalyst system

Oxidation processes are based on the production of FRR, destroying a wide range of resistant and toxic organic pollutant (aromatic and aliphatic) compounds quickly and without selectivity and the production of free radicals in the processes that are auxiliary oxidizers. Like UV, it depends on ozone or special catalysts like titanium or zinc oxide (Wang and Wang 2018). The use of ultraviolet rays with a suitable oxidizing agent such as hydrogen peroxide or ozone is very effective for removing all types of resistant organic pollutants to biological decomposition. One of the most important combined processes based on ultraviolet rays is the UV/oxidizing/photo catalyst system. The basis of the UV/oxidizing/photocatalyst process is the production of FRR, which enables it to react quickly with organic compounds in aqueous solution. In this process, ultraviolet rays have multiple roles, and they can decompose the pollutant through three mechanisms. The first mechanism is the direct decomposition of the pollutant by ultraviolet rays, but this mechanism is not very likely due to the limitation in matching the wavelength of the pollutant with different bands in the pollutant, and it can be said that about 5% of the pollutant is decomposed by this mechanism. However, the highest percentage of pollutant removal in UV/H2O2/photocatalyst or UV/O3/photocatalyst systems is related to the next two mechanisms. In the second mechanism, UV affects the oxidizing substance (O3, H2O2, PS) and produces various radical species, causing the degradation of organic substances. In addition, the third mechanism is the effect of ultraviolet rays on the semiconductor material in the reactor, which is known as the photocatalytic process. The simultaneous presence of oxidizing and activating agents together in the UV/oxidizing/photocatalyst process leads to abundant and diverse production of free radicals with high redox potential, and their synergistic effect leads to the removal of organic substances with high efficiency (Aboudalle et al. 2018; Vo et al. 2019; Wang and Wang 2018). During these processes, the pollutants in water are completely decomposed into carbon dioxide and water molecules or other harmless substances under the influence of the synergistic effect in the reactor (Jahantigh et al. 2019; Malakootian et al. 2019; Mashayekh-Salehi and Moussavi 2016; Mehrjouei et al. 2015). The responsible chain reactions in the system are mentioned below (Eqs. 47–56):

In addition to ultraviolet rays, oxidizing agents (O3, H2O2, PS) can also decompose pollutants through different routes. There are two effective ways in the degradation of contaminants by oxidizing agents. First, a pollutant is directly oxidized to less toxic molecules by electrophilic attacks of the oxidizing agent; in this route, ozone has only a relative efficiency (Eqs. 47–56). Another way is the decomposition of the oxidizing agent to FRR and its attacks on the pollutant during a series of indirect oxidation reactions (Eqs. 57–65) (Dong et al. 2022; Mehrjouei et al. 2015).

In the process of photocatalytic ozonation, the synergistic effects of absorption, photolysis, photo-catalysis ozone, and the production of hydroxyl radicals occur mostly in a short reaction time. The effectiveness of ozone is increased when combined with processes such as UV light, catalysts, and hydrogen peroxide. Plus, a catalyst like UV plays the role of activation for the oxidant if the catalyst used in this system is not a semiconductor material, and the general corresponding reaction is stated below:

According to Eq. 66, FRR (such as SO4•−) forms during chain reactions. The general schematic of FRR production for the UV/O3/PS system is shown in Fig. 8. In the process of UV/oxidizing/photocatalyst system, various pollutants including amoxicillin, ampicillin, and cloxacillin antibiotics, real textile effluents, textile dyestuff, polyvinylpyrrolidone have been removed, which these compounds and also the radicals formed during these processes are shown in Table 6. The important point in the UV/oxidizing /photocatalyst process is that in addition to do photocatalytic reactions, the catalyst and UV simultaneously play a role in activating the oxidant, and it is considered one of the prominent features of the process. Here, there is a high diversity of active and radical species as well (Kurniawan et al. 2006; Zhang and Chu 2022).

UV-based photocatalyst

The photocatalytic process is one of the AOPs that has been widely investigated to remove various compounds resistant to biological degradation on a laboratory and pilot scale in the last decade. It is known as environmentally friendly, sustainable, and economical technology. In this process, a semiconductor material (ZnO; TiO2; WO3; SnO2; etc.) under UV radiation is used in both homogeneous and heterogeneous forms. In the UV/photocatalyst process, UV is not considered an activating agent, but its interaction with the catalyst leads to the production of free radicals. A graphical schematic of FRR production in a photocatalytic process is depicted in Fig. 9 (Guo et al. 2017; Khalid et al. 2017; Koe et al. 2020). The main characteristic of a semiconductor is the bandwidth of conductivity. The area between these two bands is known as the band gap. By irradiating UV to the catalyst, the absorption of photons having higher energies than that of the band gap leads to the transfer of an electron from the valence band to the conduction band, with the simultaneous production of gaps in the valence band (reaction 67). These gaps have a very high oxidation potential which is sufficient to produce hydroxyl radicals from water molecules and hydroxide ions adsorbed onto the semiconducting surface (reactions 68 and 69). The formed electrons can react with the adsorbed oxygen molecule and turn it into a superoxide radical (O2) which in turn reacts with proton to form peroxide radicals (reactions 70–72). Further, hydrogen peroxide acts as an electron receiver and, according to reaction 73, produces additional hydroxyl radicals. The adsorbed substrate (RXads) may be directly oxidized by electron transfer (reaction 74) (Arghavan et al. 2021, Kamani et al. 2023, Khodadadi et al. 2020, Khodadadia et al., Nasseh et al. 2020a, Nasseh et al. 2020b).

As shown in the reactions, positive holes h+ are formed on the surface of the catalyst. They are very reactive, and when they come in contact with the pollutant, they decompose them. But the formed electron enters a chain of reactions, and O2•−, HO2•, OH•, and \(\bullet {\mathrm{RX}}_{\mathrm{ads}}^{+}\) radicals are formed. The most obvious difference between UV/photocatalyst process and other AOPs is producing h+, which can convert non-biodegradable organic substances into low-risk or safe substances. However, its main failure is the reusability of a photocatalyst and its application in homogeneous aqueous beds (Guo et al. 2017, Khalid et al. 2017, Koe et al. 2020).

The photocatalytic process can be combined with other methods and factors such as ultrasound and heat. Ultrasound waves (US) in the water media during the cavitation phenomenon and the creation of cavities with high temperature and pressure can directly contribute to the production of OH• (Saalbach et al. 2018). However, the use of this type of radiation alone requires a lot of time and energy to destroy resistant organic compounds. Therefore, the US is used in combination with other methods, which can be referred to as UV/hate, US/photocatalytic, UV/catalyst processes, etc. In the sonophotocatalytic process (US/photocatalytic), the following reactions may occur: (1) oncolysis of water, (2) reaction of H2O2 with hydrogen atoms consisting, (3) photodecomposition of hydrogen peroxide, (4) reaction of hydrogen peroxide with the superoxide radical anion formed during photocatalysis, and (5) the reaction of H2O2 with the conductive layer electrons (Eqs. 75–79). Several OH radicals usually recombine into H2O and H2O2 which are known as the scavenger phenomenon (Eqs. 80–83) (Norabadi et al. 2022; Saalbach et al. 2018).

H•, HO2•, and OH• radicals are the most common radicals produced during the sonochemical process, which can also interact with other oxidants to produce OH• (see Eqs. 75–77). The UV-based photocatalyst process has been used to remove pollutants such as phenol, amoxicillin, ampicillin, cloxacillin, reactive brilliant blue KN-R, and organic pollutants, a list of which as well as the radicals produced in the removal process are shown in Table 7.

UV/other activation agent

UV can also be used along with other activators (US, hate, catalyst) related to oxidizing compounds (O3, H2O2, PS). US waves are one of the most important activators that are used together with UV. The US plays a role in the production of free radicals based on the cavitation phenomenon. Cavitation events are classified into two groups: stable and transient. However, in both production groups, a very local temperature of about 4000 K and a pressure of more than 1000 atmospheres are observed. The energy of the event depends on the cavitation intensity, which in turn can depend on many factors, including the amplitude and frequency of the sound wave (Saalbach et al. 2018). During the formation and collapse of bubbles, critical temperature and pressure conditions (about 5000 K and 500 atmospheres) are created, following this water sonolysis process, and then the formation of H• and OH• free radicals can happen as fast as oxidation. In contrast to other combined methods, the integration of UV with other activators aims to improve the process efficiency with the help of synergistic effects so that maximum efficiency can be achieved in the shortest time. A graphical schematic of FRR production in UV/other activation agents is observed in Fig. 10. In this route, UV only plays the role of direct pollutant decomposition, and the photolysis process occurs, which was mentioned earlier. The removal of pollutants including melatonin, sulfosalicylic acid, real textile effluents, and organic pollutants by methods including UV/Fe(II)/H2O2, UV/O3/TiO2, UV/Fe(II)/H2O2, and UV/TiO2/H2O2/Fe(III) as well as radicals produced in these processes is shown in Table 8. These processes have been investigated more on a laboratory scale, and examining the efficiency of two electromagnetic activating agents (UV/US) is not very common due to high energy consumption. On the other hand, the use of UV and metal catalysts pointed out problems such as producing sludge and reducing the efficiency of ultraviolet rays in activating the oxidant by absorbing the metal catalyst.

Advanced reduction processes (ARPs)

Recently, a new group of water and wastewater treatment methods called advanced reduction processes (ARPs) has been proposed and is being developed on a laboratory scale. AOPs, ARPs, and combined advanced oxidation/reduction processes (AO/RP) are highly efficient technologies in the elimination of emerging micro-pollutants from water and wastewater. Almost all types of aqueous solution pollutants, including pesticides, PPCPs (pharmaceuticals and personal care products), dyes, plasticizers, and toxic metals are successfully removed from aqueous solution systems using various AO/RPs. All the AO/RPs rely on the generation of free radicals/species (i.e., •OH, SO4•−, eaq−, SO3•−, H•), which react with the target contaminants, resulting in their decomposition. A redox reaction includes AOP and ARP. Therefore, there is an ARP along with the AOP, and it is used to remove reduced contamination. An ARP decomposes oxidized pollutants by generating highly reactive reducing radicals (RRR) through a combination of reagents and activation agents (see general reactions in Fig. 11). Important activators that have been mentioned in various studies are UV beams and US waves. In this paper, an overview of UV processes has been studied; therefore, ARPs are classified into several categories below.

UV/dithionite

Dithionite ions (S2O42−), a powerful reducing agent, are encouraging reductants for application in ARPs, as they have a weak S-S bond which is readily cleaved into sulfur dioxide radical anions (SO2●−) by activation methods. The dithionite absorbs UV radiation at a wavelength of 315 nm when UV collides with dithionite ions, and the result is the production of reduced SO2●− radicals (see Eqs. 84, 85). In fact, ultraviolet rays by affecting the S-S bond and breaking it into two parts produce radicals including sulfur dioxide ion, dithionite ion, and hydrate electron.

Both dithionite and sulfur dioxide radicals are strong reductants. The literature has reported that the standard reduction potential of sulfur dioxide radical and dithionite is −0.66 V and −1.12 V (at pH 7 and 25 °C) respectively. UV/dithionite system can be utilized for the elimination of dyes, refractory organic compounds in the petrochemical industry, antibiotics, and nitrates. The graphical schematic of RRR production in the UV/dithionite process is displayed in Fig. 12.

Some of it convert to other products (bisulfite, metabisulfite, thiosulfate, and trithionate) when dithionite enters an aqueous solution, and they are responsible for pollutant decomposition. The next factor in the decomposing of organic pollutants is reduced radicals caused by the impact of UV on dithionite. However, pollutant decomposition in the UV/dithionite process will occur in an acidic aqueous bed (Jung et al. 2018a; Jung et al. 2018b).

It has been reported in several studies that the UV/dithionite process has been used to eliminate organic contaminants such as arsenite, acid yellow 17, and selenite, and the summary of possible radicals produced is reported in Table 9. In these studies, the photolysis of dithionite and the efficiency of the produced radicals in pollutant removal have been evaluated.

UV/sulfite

Both UV and sulfite (SO2−) are commonly used in wastewater treatment disinfection; UV is a standalone process, and sulfite is a dechlorination chemical. Nevertheless, when these two factors are used together, an advanced reduction process takes place. Sulfite can strongly absorb UV beams at 254 nm and pH 10 with a molar absorption coefficient of 18.2 M−1 cm−1. Initially, the result of the interaction between UV and sulfite is the production of e−aq and SO3•− which is presented in Eq. 86. In UV/sulfite, ultraviolet rays excite the electron located in the S-O bond to create the sulfide radical, and other radicals are created in a chain of reactions.

Other chain reactions that lead to radical production are described below:

It can be seen that the strong radicals including H• (−2.9 V), SO3•−, and e−aq (−2.3 V) are formed in this process. From Fig. 13, the graphical schematic of RRR production in the UV/sulfite process can be seen. It is also pointed out that compared with common reluctance (i.e., ferrous iron, sulfide, dithionite), the interaction between UV beam and sulfite reluctant is demonstrated to be the highest effective ARP, which corresponds to the massive yield of eaq− therein (Milh et al. 2021). In Table 10, the possible radicals produced and pollutants removed by the UV/sulfite process are explained in detail. One of the most obvious features of the process is that the UV/sulfite process can reduce pollutants in anaerobic conditions when most processes cannot be used in anaerobic conditions. Also, in cases where the use of H2O2 is not preferred, the UV/SO32− process may be an interesting alternative. However, it should be noted that the reaction rate constants of the UV/SO32− process in general are lower than those of a UV/H2O2 process (Liu et al. 2014; Xiao et al. 2017; Xie et al. 2017).

On the other hand, studies showed that the UV/sulfite process produced more diverse free radicals in aerobic conditions than in anaerobic conditions. Therefore, the presence of oxygen improves the ability of the process to eliminate reducible pollutants (Cao et al. 2021). UV/sulfite has been used to eliminate various contaminations, some of which are mentioned in Table 10, and the possible radicals produced during each process are as well mentioned.

UV/sulfide

Another sulfur-containing compound used in reduction processes to produce reduced radicals is sulfide (S2−). Sulfide can absorb UV beam at 190–250 nm, and hydrogen sulfide (H2S) compounds are used to supply sulfide ions. In Eq. 94, producing HS•− radical in the UV/sulfide process is mentioned, but the study regarding the use of the UV/sulfide process is limited.

UV/iodide

Another mineral compound that can be used as a reducer agent to produce reduced radicals in ARP is iodide (I2). Iodide can be excited by UV beams because iodide can absorb UV beams at 248 to 254 nm. Therefore, this property leads to the occurrence of an ARP between UV and iodide, and a large number of eaq– reducer radicals in the aqueous solutions can be created. In other words, the Van der Waals bond between two atoms of the iodine element is broken by the absorption of ultraviolet rays at 254 nm, and the result is creating iodine radicals. The graphic schematic of the UV/iodide process to produce free reducer radicals is depicted in Fig. 14. Studies have shown that the UV/iodide system produces fewer free radicals than the UV/sulfite system, and its possible cause is attributed to the presence of scavengers. In the UV/iodide system, the reducing agent is iodine ions, and in order to prepare them, potassium iodide is used. The simultaneous presence of UV beam and iodide ions in an aqueous solution leads to the production of reducing radicals during a chain of reactions, which is mentioned below (Eq. 95):

UV/iodide process has been used both alone and in combination with the AOP process to remove various pollutants, including N-nitrosodimethylamine, perfluorooctane sulfonate, Ocuflox, and codeine phosphate, which is mentioned in Table 11, and the corresponding radical for each process is indicated as well. Iodide has a higher molar absorption coefficient at 254 nm than sulfite; this means that the ability to produce hydrated electrons by the process of UV/iodide is greater than that of the UV/sulfite system. However, some studies have indicated that target contaminant transformation rates are faster in the UV/sulfite system compared to the UV/iodide system. On the other hand, iodine ion has high electronegativity properties, and depending on the conditions of the aqueous solution, it can have a negative or positive effect on the UV/iodide system.

UV/ferrous

Ferrous iron (Fe2+) is one of the parameters that can be used in both oxidation and reduction. The Fenton process, the simplest AOP, will occur when ferrous iron is simultaneously homogenized in an aqueous media with hydrogen peroxide (H2O2), where ferrous iron plays the role of catalyst, and by activating H2O2, hydroxyl radical (OH•) is produced. Moreover, when ultraviolet rays are irradiated to an aqueous bed containing ferrous iron in the presence of oxygen, the result is an AOP and the production of OH•. However, an ARP occurs and a reducing radical (eaq–) is created when UV beams are irradiated to Fe2+ ions in the absence of oxygen in a water media. The solution of Fe2+ absorbs the UV beam with a maximum of 220 nm, and UV irradiation promotes the formation of hydrogen and aqueous electrons. The overall reaction of the UV/Fe2+ process is given in Eq. 103.

Hydrogen and aqueous electrons are the most likely reductant agents that are formed in the UV/Fe2+ process. The graphical schematic of RRR production in the UV/ Fe2+ system is seen in Fig. 15. UV/Fe2+ process has rarely been utilized until now as an independent process for free reducer radical generation and removal of a pollutant. For example, in a study, the UV/Fe2+ process was utilized to eliminate vinyl chloride, and the only active species produced was eaq– (Liu et al. 2013). In other words, the UV/Fe2+ process has been anaerobically utilized to improve other basic oxidation processes. Of these, UV/US/Fe2+ (bisphenol degradation) (Torres et al. 2007), UV/Fe2+/H2O2 (dye degradation) (Kang et al. 1999), UV/S2O82−/Fe2+ (diclofenac sodium removal) (Rehman et al. 2021) processes, etc. can be mentioned. The most important unfavorable feature of the UV/Fe2+ process is the reduction of ferrous iron to ferric iron, which can lead to the formation of sediments and clogging. But in order to prevent the problem, it combines with other processes.

Conclusion

In this study, the application of ultraviolet rays in redox reactions was reviewed. The results indicated that ultraviolet irradiation is an important parameter in oxidation and reduction reactions so its combination with any oxidizing or reducing agent leads to the production of free radicals. In other words, ultraviolet rays activate oxidizing and reducing substances and improve pollutant detoxification by producing free radicals. The most possible and the strongest radical species in the redox process based on UV irradiation were included reducer (I●, H●, OH●, SO3●−, eaq−, SO2●−, HS●, S2O4●−, S2O3●−, and S●−) and oxidizer (OH•, O2•−, O3•−, HO2•, HO3•, HO4•, SO5•−, SO4•−, O•, and S2O8•−) agents. Therefore, it can be concluded that the UV ray is an inseparable factor in redox processes and improves the processes directly and indirectly.

Change history

16 January 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11356-024-31991-1

References

Aboudalle A, Djelal H, Fourcade F, Domergue L, Assadi AA, Lendormi T, Taha S, Amrane A (2018) Metronidazole removal by means of a combined system coupling an electro-Fenton process and a conventional biological treatment: by-products monitoring and performance enhancement. J Hazard Mater 359:85–95

Alhamedi FH, Rauf MA, Ashraf SS (2009) Degradation studies of Rhodamine B in the presence of UV/H2O2. Desalination 239:159–166

Al-Musawi TJ, Kamani H, Bazrafshan E, Panahi AH, Silva MF, Abi G (2019) Optimization the effects of physicochemical parameters on the degradation of cephalexin in sono-Fenton reactor by using Box-Behnken response surface methodology. Catal Lett 149:1186–1196

Arghavan FS, Hossein Panahi A, Nasseh N, Ghadirian M (2021) Adsorption-photocatalytic processes for removal of pentachlorophenol contaminant using FeNi3/SiO2/ZnO magnetic nanocomposite under simulated solar light irradiation. Environ Sci Pollut Res 28:7462–7475

Arslan A, Topkaya E, Özbay B, Özbay I, Veli S (2017) Application of O3/UV/H2O2 oxidation and process optimization for treatment of potato chips manufacturing wastewater. Water Environ J 31:64–71

Azizi S, Sarkhosh M, Najafpoor AA, Mohseni SM, Maaza M, Sadani M (2021) Degradation of codeine phosphate by simultaneous usage of eaq− and •OH radicals in photo-redox processes: influencing factors, energy consumption, kinetics, intermediate products and degradation pathways. Optik 243:167415

Bao Y, Deng S, Jiang X, Qu Y, He Y, Liu L, Chai Q, Mumtaz M, Huang J, Cagnetta G, Yu G (2018) Degradation of PFOA substitute: GenX (HFPO–DA ammonium salt): oxidation with UV/persulfate or reduction with UV/sulfite? Environ Sci Technol 52:11728–11734

Bavasso I, Poggi C, Petrucci E (2020) Enhanced degradation of paracetamol by combining UV with electrogenerated hydrogen peroxide and ozone. J Water Process Eng 34:101102

Boczkaj G, Fernandes A (2017) Wastewater treatment by means of advanced oxidation processes at basic pH conditions: a review. Chem Eng J 320:608–633

Bu L, Zhou S, Shi Z, Bi C, Zhu S, Gao N (2017) Iron electrode as efficient persulfate activator for oxcarbazepine degradation: performance, mechanism, and kinetic modeling. Sep Purif Technol 178:66–74

Cao Y, Qiu W, Li J, Jiang J, Pang S (2021) Review on UV/sulfite process for water and wastewater treatments in the presence or absence of O2. Sci Total Environ 765:142762

Chai S, Wang Y, Zhang Y-N, Zhao H, Liu M, Zhao G (2018) Construction of a bifunctional electrode interface for efficient electrochemical mineralization of recalcitrant pollutants. Appl Catal B Environ 237:473–481

Chang M-W, Chung C-C, Chern J-M, Chen T-S (2010) Dye decomposition kinetics by UV/H2O2: initial rate analysis by effective kinetic modelling methodology. Chem Eng Sci 65:135–140

Chen L, Cai T, Cheng C, Xiong Z, Ding D (2018) Degradation of acetamiprid in UV/H2O2 and UV/persulfate systems: a comparative study. Chem Eng J 351:1137–1146

Chen Z, Fang J, Fan C, Shang C (2016) Oxidative degradation of N-Nitrosopyrrolidine by the ozone/UV process: kinetics and pathways. Chemosphere 150:731–739

Chiou C-H, Wu C-Y, Juang R-S (2008) Influence of operating parameters on photocatalytic degradation of phenol in UV/TiO2 process. Chem Eng J 139:322–329

Cortés J, Alarcón-Herrera M, Villicaña-Méndez M, González-Hernández J, Pérez-Robles J (2011) Impact of the kind of ultraviolet light on the photocatalytic degradation kinetics of the TiO2/UV process. Environ Prog Sustain Energy 30:318–325

Cui J, Cai S, Zhang S, Wang G, Gao C (2022) Degradation of a non-oxidizing biocide in circulating cooling water using UV/persulfate: kinetics, pathways, and cytotoxicity. Chemosphere 289:133064

Deng Y, Zhao R (2015) Advanced oxidation processes (AOPs) in wastewater treatment. Curr Pollut Rep 1:167–176

Ding X, Gutierrez L, Croue J-P, Li M, Wang L, Wang Y (2020) Hydroxyl and sulfate radical-based oxidation of RhB dye in UV/H2O2 and UV/persulfate systems: kinetics, mechanisms, and comparison. Chemosphere 253:126655

Dong G, Chen B, Liu B, Cao Y, De Jourdan B, Stoyanov SR, Ling J, Ye X, Lee K, Zhang B (2022) Comparison of O3, UV/O3, and UV/O3/PS processes for marine oily wastewater treatment: degradation performance, toxicity evaluation, and flocs analysis. Water Res 226:119234

Elmolla ES, Chaudhuri M (2010) Photocatalytic degradation of amoxicillin, ampicillin and cloxacillin antibiotics in aqueous solution using UV/TiO2 and UV/H2O2/TiO2 photocatalysis. Desalination 252:46–52

Emam EA (2012) Effect of ozonation combined with heterogeneous catalysts and ultraviolet radiation on recycling of gas-station wastewater. Egypt J Pet 21:55–60

Fu Y, Wu G, Geng J, Li J, Li S, Ren H (2019) Kinetics and modeling of artificial sweeteners degradation in wastewater by the UV/persulfate process. Water Res 150:12–20

Gao Y, Wang Q, Ji G, Li A (2022) Degradation of antibiotic pollutants by persulfate activated with various carbon materials. Chem Eng J 429:132387

Garcia JC, Oliveira JL, Silva AEC, Oliveira CC, Nozaki J, De Souza NE (2007) Comparative study of the degradation of real textile effluents by photocatalytic reactions involving UV/TiO2/H2O2 and UV/Fe2+/H2O2 systems. J Hazard Mater 147:105–110

Guo Y, Qi P, Liu Y (2017) A review on advanced treatment of pharmaceutical wastewater. In: IOP Conference Series: Earth and Environmental Science. IOP Publishing, p 012025

He X, Pelaez M, Westrick JA, O’shea KE, Hiskia A, Triantis T, Kaloudis T, Stefan MI, Armah A, Dionysiou DD (2012) Efficient removal of microcystin-LR by UV-C/H2O2 in synthetic and natural water samples. Water Res 46:1501–1510

Hoang NT, Nguyen VT, Tuan NDM, Manh TD, Le P-C, Van Tac D, Mwazighe FM (2022) Degradation of dyes by UV/persulfate and comparison with other UV-based advanced oxidation processes: kinetics and role of radicals. Chemosphere 298:134197

Hollman J, Dominic JA, Achari G (2020) Degradation of pharmaceutical mixtures in aqueous solutions using UV/peracetic acid process: kinetics, degradation pathways and comparison with UV/H2O2. Chemosphere 248:125911

Hossein Panahi A, Al-Musawi TJ, Masihpour M, Fard SFT, Nasseh N (2023) Photocatalytic degradation of humic acid using bentonite@Fe3O4@ZnO magnetic nanocomposite: an investigation of the characterization of the photocatalyst, degradation pathway, and modeling by solver plugin. Water 15:2931

Hossein Panahi A, Meshkinian A, Ashrafi SD, Khan M, Naghizadeh A, Abi G, Kamani H (2020) Survey of sono-activated persulfate process for treatment of real dairy wastewater. Int J Environ Sci Technol 17:93–98

Hou S, Ling L, Shang C, Guan Y, Fang J (2017) Degradation kinetics and pathways of haloacetonitriles by the UV/persulfate process. Chem Eng J 320:478–484

Ike IA, Linden KG, Orbell JD, Duke M (2018) Critical review of the science and sustainability of persulphate advanced oxidation processes. Chem Eng J 338:651–669

Irmak S, Erbatur O, Akgerman A (2005) Degradation of 17β-estradiol and bisphenol A in aqueous medium by using ozone and ozone/UV techniques. J Hazard Mater 126:54–62

Jabbari F, Eslami A, Mahmoudian J (2020) Degradation of diclofenac in water using the O3/UV/S2O8 advanced oxidation process. Health Scope 9(2)

Jahantigh A, Kamani H, Norabadi E, Bazrafshan E, Sancholi F, Meshkinian A (2019) Efficiency evaluation of photocatalytic process using ZnO nano catalyst for removal of 2, 4, 6-trichlorophenol by response surface methodology. J Res Environ Health 5:205–216

Jiraroj D, Unob F, Hagege A (2006) Degradation of Pb–EDTA complex by a H2O2/UV process. Water Res 40:107–112

Jung B, Farzaneh H, Khodary A, Abdel-Wahab A (2015) Photochemical degradation of trichloroethylene by sulfite-mediated UV irradiation. J Environ Chem Eng 3:2194–2202

Jung B, Safan A, Duan Y, Kaushik V, Batchelor B, Abdel-Wahab A (2018a) Removal of arsenite by reductive precipitation in dithionite solution activated by UV light. J Environ Sci 74:168–176

Jung B, Safan A, Duan Y, Kaushik V, Batchelor B, Abdel-Wahab A (2018b) Removal of Se(IV) by the dithionite/ultraviolet advanced reduction process: effects of process variables. Environ Eng Sci 35:927–936

Kamani H, Ashrafi SD, Lima EC, Panahi AH, Nezhad MG, Abdipour H (2023) Synthesis of N-doped TiO2 nanoparticle and its application for disinfection of a treatment plant effluent from hospital wastewater. Desalin Water Treat 289:155–162

Kang S-F, Liao C-H, Hung H-P (1999) Peroxidation treatment of dye manufacturing wastewater in the presence of ultraviolet light and ferrous ions. J Hazard Mater 65:317–333

Khalid N, Majid A, Tahir MB, Niaz N, Khalid S (2017) Carbonaceous-TiO2 nanomaterials for photocatalytic degradation of pollutants: a review. Ceram Int 43:14552–14571

Khodadadi M, Al-Musawi TJ, Kamani H, Silva MF, Panahi AH (2020) The practical utility of the synthesis FeNi3@SiO2@TiO2 magnetic nanoparticles as an efficient photocatalyst for the humic acid degradation. Chemosphere 239:124723

Khodadadi M, Rodriguez-Couto S, Arghavan FS, Panahi H (2020) Synthesis and characterization of feni3@ sio2@ tio2 nano-composite and its application as a catalyst in a photochemical oxidation process to decompose tetracycline. Desalination and Water Treatment 195

Koe WS, Lee JW, Chong WC, Pang YL, Sim LC (2020) An overview of photocatalytic degradation: photocatalysts, mechanisms, and development of photocatalytic membrane. Environ Sci Pollut Res 27:2522–2565

Kurniawan TA, Lo W-H, Chan G (2006) Radicals-catalyzed oxidation reactions for degradation of recalcitrant compounds from landfill leachate. Chem Eng J 125:35–57

Lee J, Von Gunten U, Kim J-H (2020) Persulfate-based advanced oxidation: critical assessment of opportunities and roadblocks. Environ Sci Technol 54:3064–3081

Lee Y-M, Lee G, Zoh K-D (2021) Benzophenone-3 degradation via UV/H2O2 and UV/persulfate reactions. J Hazard Mater 403:123591

Liu H, Gao Y, Wang J, Ma D, Wang Y, Gao B, Yue Q, Xu X (2021) The application of UV/O3 process on ciprofloxacin wastewater containing high salinity: performance and its degradation mechanism. Chemosphere 276:130220

Liu X, Liu Y, Lu S, Wang Z, Wang Y, Zhang G, Guo X, Guo W, Zhang T, Xi B (2020) Degradation difference of ofloxacin and levofloxacin by UV/H2O2 and UV/PS (persulfate): efficiency, factors and mechanism. Chem Eng J 385:123987

Liu X, Vellanki BP, Batchelor B, Abdel-Wahab A (2014) Degradation of 1,2-dichloroethane with advanced reduction processes (ARPs): effects of process variables and mechanisms. Chem Eng J 237:300–307

Liu X, Yoon S, Batchelor B, Abdel-Wahab A (2013) Photochemical degradation of vinyl chloride with an advanced reduction process (ARP) – effects of reagents and pH. Chem Eng J 215:868–875

Liu Y, Hua L, Li S (2010) Photocatalytic degradation of reactive brilliant blue KN-R by TiO2/UV process. Desalination 258:48–53

Lucas MS, Peres JA, Puma GL (2010) Treatment of winery wastewater by ozone-based advanced oxidation processes (O3, O3/UV and O3/UV/H2O2) in a pilot-scale bubble column reactor and process economics. Sep Purif Technol 72:235–241

Malakootian M, Mahdizadeh H, Dehdarirad A, Amiri Gharghani M (2019) Photocatalytic ozonation degradation of ciprofloxacin using ZnO nanoparticles immobilized on the surface of stones. J Dispers Sci Technol 40:846–854

Mashayekh-Salehi A, Moussavi G (2016) Removal of acetaminophen from the contaminated water using adsorption onto carbon activated with NH4Cl. Desalin Water Treat 57:12861–12873

Masoomeh Rahimi S, Hossein Panahi A, Sadat Mazari Moghaddam N, Allahyari E, Nasseh N (2022) Breaking down of low-biodegradation Acid Red 206 dye using bentonite/Fe3O4/ZnO magnetic nanocomposite as a novel photo-catalyst in presence of UV light. Chem Phys Lett 794:139480

Mehrjouei M, Müller S, Möller D (2015) A review on photocatalytic ozonation used for the treatment of water and wastewater. Chem Eng J 263:209–219

Milh H, Yu X, Cabooter D, Dewil R (2021) Degradation of ciprofloxacin using UV-based advanced removal processes: comparison of persulfate-based advanced oxidation and sulfite-based advanced reduction processes. Sci Total Environ 764:144510

Nasseh N, Al-Musawi TJ, Miri MR, Rodriguez-Couto S, Hossein Panahi A (2020a) A comprehensive study on the application of FeNi3@SiO2@ZnO magnetic nanocomposites as a novel photo-catalyst for degradation of tamoxifen in the presence of simulated sunlight. Environ Pollut 261:114127

Nasseh N, Hossein Panahi A, Esmati M, Daglioglu N, Asadi A, Rajati H, Khodadoost F (2020b) Enhanced photocatalytic degradation of tetracycline from aqueous solution by a novel magnetically separable FeNi3/SiO2/ZnO nano-composite under simulated sunlight: efficiency, stability, and kinetic studies. J Mol Liq 301:112434

Nasseh N, Samadi MT, Ghadirian M, Hossein Panahi A, Rezaie A (2022) Photo-catalytic degradation of tamoxifen by using a novel synthesized magnetic nanocomposite of FeCl2@ac@ZnO: a study on the pathway, modeling, and sensitivity analysis using artificial neural network (AAN). J Environ Chem Eng 10:107450

Norabadi E, Ashrafi SD, Kamani H, Jahantiq A (2022) Degradation of 2, 6-dichlorophenol by Fe-doped TiO2 sonophotocatalytic process: kinetic study, intermediate product, degradation pathway. Int J Environ Anal Chem 102:7720–7735

Norabadi E, Panahi AH, Ghanbari R, Meshkinian A, Kamani H, Ashrafi SD (2020) Optimizing the parameters of amoxicillin removal in a photocatalysis/ozonation process using Box-Behnken response surface methodology. Desalin Water Treat 192:234–240

Oturan MA, Aaron J-J (2014) Advanced oxidation processes in water/wastewater treatment: principles and applications. A review. Crit Rev Environ Sci Technol 44:2577–2641

Ou H-S, Liu J, Ye J-S, Wang L-L, Gao N-Y, Ke J (2017) Degradation of tris (2-chloroethyl) phosphate by ultraviolet-persulfate: kinetics, pathway and intermediate impact on proteome of Escherichia coli. Chem Eng J 308:386–395

Panahi AH, Kamranifar M, Moslehi MH, Rodriguez-Couto S, Nasseh N (2020) Synthesis and characterization of FeNi3 nanoparticles and their application as catalysts for penicillin G degradation in a Fenton-like reaction. Desalination and Water Treatment 181

Pandis PK, Kalogirou C, Kanellou E, Vaitsis C, Savvidou MG, Sourkouni G, Zorpas AA, Argirusis C (2022) Key points of advanced oxidation processes (AOPs) for wastewater, organic pollutants and pharmaceutical waste treatment: a mini review. ChemEng 6:8

Parilti NB, Akten D (2010) Application of Box–Wilson experimental design method for the solar photocatalytic degradation of textile dyestuff with Fe(III)/H2O2/solar UV process. Desalination 260:193–198

Poulopoulos SG, Yerkinova A, Ulykbanova G, Inglezakis VJ (2019) Photocatalytic treatment of organic pollutants in a synthetic wastewater using UV light and combinations of TiO2, H2O2 and Fe (III). PLoS One 14:e0216745

Qin W, Lin Z, Dong H, Yuan X, Qiang Z, Liu S, Xia D (2020a) Kinetic and mechanistic insights into the abatement of clofibric acid by integrated UV/ozone/peroxydisulfate process: a modeling and theoretical study. Water Res 186:116336

Qin W, Lin Z, Sun L, Yuan X, Xia D (2020b) A preliminary study on the integrated UV/ozone/persulfate process for efficient abatement of atrazine. Ozone Sci Eng 42:558–564

Rao YF, Chu W (2009) A new approach to quantify the degradation kinetics of linuron with UV, ozonation and UV/O3 processes. Chemosphere 74:1444–1449

Rasoulzadeh H, Azarpira H, Alinejad N, Sheikhmohammadi A (2022) Efficient degradation of Ocuflox in a neutral photo oxidation/reduction system based on the enhanced heterogeneous-homogeneous sulfite-iodide cycle. Optik 257:168878

Rehman F, Ahmad W, Sayed M (2021) Mechanistic investigations on the removal of diclofenac sodium by UV/S2O82−/Fe2+, UV/HSO5−/Fe2+ and UV/H2O2/Fe2+-based advanced oxidation processes. Environ Technol 42:3995–4005

Saalbach K-A, Ohrdes H, Twiefel J (2018) Closed loop cavitation control–a step towards sonomechatronics. Ultrason Sonochem 44:14–23

Samadi MT, Khodadadi M, Rahmani AR, Allahresani A, Saghi MH (2010) Comparison of the efficiency of simultaneous application of UV/O3 for the removal of organophosphorus and carbamat pesticides in aqueous solutions. Water Wastewater 73:69–75

Saravanan A, Deivayanai VC, Kumar PS, Rangasamy G, Hemavathy RV, Harshana T, Gayathri N, Alagumalai K (2022) A detailed review on advanced oxidation process in treatment of wastewater: mechanism, challenges and future outlook. Chemosphere 308:136524

Shad A, Chen J, Qu R, Dar AA, Bin-Jumah M, Allam AA, Wang Z (2020) Degradation of sulfadimethoxine in phosphate buffer solution by UV alone, UV/PMS and UV/H2O2: kinetics, degradation products, and reaction pathways. Chem Eng J 398:125357

Sharma S, Patel S, Ruparelia J (2015) Feasibility study on degradation of RR120 dye from water by O3, O3/UV and O3/UV/persulfate. In: Multi-Disciplinary Sustainable Engineering: Current and Future Trends, Proceedings of the 5th Nirma University International Conference on Engineering. Ahmedabad, India, pp 26–28

Sheikhmohammadi A, Yazdanbakhsh A, Moussavi G, Eslami A, Rafiee M, Sardar M, Almasian M (2019) Degradation and COD removal of trichlorophenol from wastewater using sulfite anion radicals in a photochemical process combined with a biological reactor: mechanisms, degradation pathway, optimization and energy consumption. Process Saf Environ Prot 123:263–271

Shokri A, Mahanpoor K, Soodbar D (2016) Degradation of ortho-toluidine in petrochemical wastewater by ozonation, UV/O3, O3/H2O2 and UV/O3/H2O2 processes. Desalin Water Treat 57:16473–16482

Srithep S, Phattarapattamawong S (2017) Kinetic removal of haloacetonitrile precursors by photo-based advanced oxidation processes (UV/H2O2, UV/O3, and UV/H2O2/O3). Chemosphere 176:25–31

Suave J, José HJ, Moreira RDFPM (2018) Photocatalytic degradation of polyvinylpyrrolidone in aqueous solution using TiO2/H2O2/UV system. Environ Technol 39:1404–1412

Sun Z, Zhang C, Chen P, Zhou Q, Hoffmann MR (2017a) Impact of humic acid on the photoreductive degradation of perfluorooctane sulfonate (PFOS) by UV/iodide process. Water Res 127:50–58

Sun Z, Zhang C, Zhao X, Chen J, Zhou Q (2017b) Efficient photoreductive decomposition of N-nitrosodimethylamine by UV/iodide process. J Hazard Mater 329:185–192

Tan C, Gao N, Deng Y, Zhang Y, Sui M, Deng J, Zhou S (2013) Degradation of antipyrine by UV, UV/H2O2 and UV/PS. J Hazard Mater 260:1008–1016

Tang X, Guo Z, Xue H, Guo X, Kang C (2011) Notice of Retraction: Degradation of Furfural by UV/O3/H2O2 Technology. In: 2011 5th International Conference on Bioinformatics and Biomedical Engineering (pp. 1–4). IEEE

Tian Y, Shen W, Jia F, Ai Z, Zhang L (2017) Sulfite promoted photochemical cleavage of s-triazine ring: the case study of atrazine. Chem Eng J 330:1075–1081

Tollefsen KE, Scholz S, Cronin MT, Edwards SW, De Knecht J, Crofton K, Garcia-Reyero N, Hartung T, Worth A, Patlewicz G (2014) Applying adverse outcome pathways (AOPs) to support integrated approaches to testing and assessment (IATA). Regul Toxicol Pharmacol 70:629–640

Tong S-P, Xie D-M, Wei H, Liu W-P (2005) Degradation of sulfosalicylic acid by O3/UV O3/TiO2/UV, and O3/VO/TiO2: a comparative study. Ozone Sci Eng 27:233–238

Torres RA, Pétrier C, Combet E, Moulet F, Pulgarin C (2007) Bisphenol A mineralization by integrated ultrasound-UV-Iron (II) treatment. Environ Sci Technol 41:297–302

Varank G, Yazici Guvenc S, Dincer K, Demir A (2020) Concentrated leachate treatment by electro-fenton and electro-persulfate processes using central composite design. Int J Environ Res 14:439–461

Vo HN, Le GK, Nguyen TM, Bui XT, Nguyen KH, Rene ER, Vo TD, Cao ND, Mohan R (2019) Acetaminophen micropollutant: historical and current occurrences, toxicity, removal strategies and transformation pathways in different environments. Chemosphere 236:124391

Waldemer RH, Tratnyek PG, Johnson RL, Nurmi JT (2007) Oxidation of chlorinated ethenes by heat-activated persulfate: kinetics and products. Environ Sci Technol 41:1010–1015

Wang J, Liu H, Ma D, Wang Y, Yao G, Yue Q, Gao B, Wang S, Xu X (2021a) Degradation of organic pollutants by ultraviolet/ozone in high salinity condition: non-radical pathway dominated by singlet oxygen. Chemosphere 268:128796

Wang J, Wang S (2018) Activation of persulfate (PS) and peroxymonosulfate (PMS) and application for the degradation of emerging contaminants. Chem Eng J 334:1502–1517

Wang Q, Rao P, Li G, Dong L, Zhang X, Shao Y, Gao N, Chu W, Xu B, An N (2020) Degradation of imidacloprid by UV-activated persulfate and peroxymonosulfate processes: kinetics, impact of key factors and degradation pathway. Ecotoxicol Environ Saf 187:109779

Wang X, Huang X, Zuo C, Hu H (2004) Kinetics of quinoline degradation by O3/UV in aqueous phase. Chemosphere 55:733–741

Wang Z, Liu W, Chen H, Zhang Z, Yang Z, Yang Q (2021b) Photoreductive degradation of CCl4 by UV-Na2SO3: influence of various factors, mechanism and application. Environ Technol 42:217–226

Xiao Q, Ren Y, Yu S (2017) Pilot study on bromate reduction from drinking water by UV/sulfite systems: economic cost comparisons, effects of environmental parameters and mechanisms. Chem Eng J 330:1203–1210

Xie B, Li X, Huang X, Xu Z, Zhang W, Pan B (2017) Enhanced debromination of 4-bromophenol by the UV/sulfite process: efficiency and mechanism. J Environ Sci 54:231–238

Xu X-R, Li X-Y, Li X-Z, Li H-B (2009) Degradation of melatonin by UV, UV/H2O2, Fe2+/H2O2 and UV/Fe2+/H2O2 processes. Sep Purif Technol 68:261–266

Xu Z, Shan C, Xie B, Liu Y, Pan B (2017) Decomplexation of Cu (II)-EDTA by UV/persulfate and UV/H2O2: efficiency and mechanism. Appl Catal B Environ 200:439–447

Yang S, Song Y, Chang F, Wang K (2020) Evaluation of chemistry and key reactor parameters for industrial water treatment applications of the UV/O3 process. Environ Res 188:109660

Yang Z, Yi Z, Jiang X, Jiang W, Lim TM (2013) Comparison of the degradation of azo dye AR88 by several oxidation processes. Fresenius Environ Bull 22:236–241

Yazdanbakhsh A, Eslami A, Mahdipour F, Ghanbari F, Ghasemi SM, Atamaleki A, Maleksari HS, Lin K-YA (2021) Dye degradation in aqueous solution by dithionite/UV-C advanced reduction process (ARP): kinetic study, dechlorination, degradation pathway and mechanism. J Photochem Photobiol A Chem 407:112995

Ye C, Ma X, Deng J, Li X, Li Q, Dietrich AM (2022) Degradation of saccharin by UV/H2O2 and UV/PS processes: a comparative study. Chemosphere 288:132337

Yu X, Qin W, Yuan X, Sun L, Pan F, Xia D (2021) Synergistic mechanism and degradation kinetics for atenolol elimination via integrated UV/ozone/peroxymonosulfate process. J Hazard Mater 407:124393

Zhang Y, Chu W (2022) Bisphenol S degradation via persulfate activation under UV-LED using mixed catalysts: synergistic effect of Cu–TiO2 and Zn–TiO2 for catalysis. Chemosphere 286:131797

Zhao K, Su Y, Quan X, Liu Y, Chen S, Yu H (2018) Enhanced H2O2 production by selective electrochemical reduction of O2 on fluorine-doped hierarchically porous carbon. J Catal 357:118–126

Zhao Q, Li N, Liao C, Tian L, An J, Wang X (2021) The UV/H2O2 process based on H2O2 in-situ generation for water disinfection. J Hazard Mater Lett 2:100020

Author information

Authors and Affiliations

Contributions

All persons who meet authorship criteria are listed as authors along with related activities. Kindly, you can see the role of each author below:

MTS: presenting research ideas, conception and design of study, and acquisition of data.

AAE: revising the manuscript and improving English.

AHP: drafting the manuscript, revising the manuscript, and improving the English.

AR: analysis and/or interpretation of data, drafting the manuscript, and acquisition of data.

KK and HA: conception and design of study and acquisition of data.

Corresponding author

Ethics declarations

Ethics approval

This work received ethical approval from Hamadan University of Medical Sciences (IR.UMSHA.REC.1401.315).

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Guilherme Luiz Dotto

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The correct family name of the last Author is Abdipour.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Samadi, M.T., Rezaie, A., Ebrahimi, A.A. et al. The utility of ultraviolet beam in advanced oxidation-reduction processes: a review on the mechanism of processes and possible production free radicals. Environ Sci Pollut Res 31, 6628–6648 (2024). https://doi.org/10.1007/s11356-023-31572-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-31572-8