Abstract

Benzene is one of the most common occupational hazards in the working environment which was in the list of group 1 carcinogens. This study applied four occupational health risk assessment models: EPA model; MOM model of Singapore; the International Council on Mining and Metals (ICMM) model, and the Technical guide WS/T 777–2021 of China. The models assessed both non-carcinogenic and carcinogenic effects of benzene for 1629 employees in 50 factories in Jiangsu Province (China) who were exposed to benzene in the working environment and analysis the risk between industries by principal component analysis (PCA) method. The highest occupational health hazard of benzene among the five industries is petroleum processing industry, then followed by chemical products manufacturing industry, special equipment manufacturing industry, wood processing and products industry, and at last the pharmaceutical manufacturing industry. The population of abnormal routine blood parameters in the subjects was mostly in the “wood products industry” group, and the concentration of benzene in “wood products industry” group is the lowest in 5 groups. The industries with low exposure concentration have higher blood abnormality rates; this may be caused by the fact that blood damage is more secretive under low occupational health risk.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Benzene is an aromatic hydrocarbon with the simplest structure. As a common organic solvent, benzene is widely used in industry. In the working environment, workers could be exposed to benzene in industries involving paint or petrochemicals (Burns et al. 2017). Due to the volatility of benzene, workers exposed to benzene mainly absorb benzene through the respiratory system. In addition, percutaneous absorption is also an important way for the body to absorb benzene when the worker expose to benzene vapor (Hostynek et al., 2012).The toxic mechanism of benzene is not fully understood. But it is generally believed that the toxicity of benzene is caused by its metabolites in vivo (Smith et al. 2011). According to the classification of the International Agency for Research on Cancer (IARC), benzene has been identified as a human carcinogen (Baan et al. 2009). There is already solid evidence suggest that even low-level occupational benzene exposure has hematotoxicity for employees (Ward et al. 1996). A study of 25,000 oil industry workers have suggested that low levels of long-term benzene exposure are associated with lymphohematopoietic cancers, including myeloid leukemia (AML), multiple myeloma (MM), and chronic lymphocytic leukemia (CLL) (Stenehjem et al., 2015). Although studies have shown that benzene is not associated with childhood acute lymphoblastic leukemia (ALL), exposure to benzene is associated with a higher risk of childhood AML when compared with child without benzene exposure (Janitz et al. 2017; Raaschou-Nielsen et al. 2018). But it is worth mentioning that if mothers exposed to benzene during pregnancy, this could increases the risk of childhood ALL (Zhou et al. 2014). Moreover, there are also reports that other cancers besides leukemia such as colorectal cancer, breast cancer, and skin cancer are associated with occupational benzene exposure of workers (Costantini et al. 2009; Stenehjem et al. 2017; Talibov et al. 2018). In addition to various researches reported the carcinogenicity of benzene, benzene has also been found to be related to other human diseases. It is reported that occupational benzene exposure could contribute to increased incidence of chromosome-defective sperm in male worker which indicated that benzene may have reproductive toxicity (Marchetti et al. 2012). Moreover, the most recent animal studies have found that exposure to benzene can cause insulin resistance in mice, which suggested that benzene may be one of the predisposing factors for diabetes and cardiovascular disease (Abplanalp et al. 2019).

Occupational exposure limits (OELs) play an important role in the risk assessment process (Maier et al. 2015). The OELs in China stipulates that the 8-h time-weighted average allowable concentration of benzene is 6 mg/m3. The OELs in the USA was 8-h time-weighted average (TWA) allowable concentration of benzene is 3.25 mg/m3.Although many organizations or institutions have defined OEL for benzene, there are still reports that workers in some countries and regions have exposed benzene more than the corresponding OEL (Akerstrom et al. 2016; Chung et al. 2010). However, research has suggested that even low levels of benzene exposure can have an impact on workers’ health (Stenehjem et al., 2015). Therefore, it is necessary to conduct health risk assessment on workers exposed to benzene. Health risk assessment is a qualitative or quantitative assessment of occupational harmful factors in the workplace, estimating the health damage that these occupational harmful factors may cause to workers, and assessing the possibility of health damage (Cai et al. 2018). The implementation of health risk assessment can provide a scientific basis for predicting the long-term effects of occupational harmful factors and formulating prevention and control strategies.

In this study, health risk assessment for workers was conducted by using the US National Environmental Protection Agency (EPA) inhalation risk assessment model, Singapore Ministry of Manpower (MOM) model, the International Council on Mining and Metals (ICMM) model, and the Technical guide for environmental health risk assessment of chemical exposure (WS/T 777–2021). The US National EPA inhalation risk assessment model and the Technical guide for environmental health risk assessment of chemical exposure (WS/T 777–2021) are quantitative risk assessment method that can be applied to assess the health risks of various industries with chemical poisons. The main process of EPA inhalation risk assessment model is the estimation of exposure concentration, carcinogenic and non-carcinogenic risk assessment (USEPA 2009). The ICMM and The Singapore semi-quantitative risk assessment model (MOM) is based on the hazard grade data, dose–response relationship and exposure grade. After comprehensive analysis, it conducts a semi-quantitative risk assessment grade of occupational exposure to the workers according to the risk matrix assessment formula (risk assessment = HR × ER).

Many studies have conducted risk assessments on the benzene exposure of the general population in the living environment in different country or regions (De Donno et al. 2018; Hu et al. 2018; Masih et al. 2018). However, the health risk assessment of benzene exposure for the occupational population is mainly concentrated in petroleum-related workplaces such as gas stations (Chaiklieng et al. 2019; Edokpolo et al. 2014). There are not many studies on occupational populations in other industries. This study intended to collect the benzene concentration monitoring data of benzene sentinel monitoring enterprises in Jiangsu Province and the occupational health examination data of benzene workers, evaluate the exposure level and health condition of benzene exposed occupational populations of different industries in Jiangsu Province. By using the 4 models above to conduct carcinogenic and non-carcinogenic risk assessments on benzene workers, the effects of occupational hazards are predicted, thereby protecting the health of workers exposed to benzene.

Materials and methods

Subjects and material

The subjects of this study were the sentinel monitoring of benzene-related enterprises in Jiangsu Province China, and all the employees who are exposed to benzene in these enterprises. Finally, this study included 50 factories that used benzene in the production process. There were 1629 workers included in this article exposed to the benzene working environment in these factories.

The monitoring data of benzene concentration in the working environment of these enterprises, the benzene exposure history of workers, and occupational health examination data were collected from the database of Jiangsu Provincial Center for Disease Control and Prevention.

All the subjects participated in the occupational health examination conducted by the Jiangsu Provincial Center for Disease Control and Prevention. The examination results including white blood cells (WBC), neutrophils (Neut), and platelets (PLT). According to China Diagnostic Standards for Occupational Benzene Poisoning (GBZ68-2013), if one of the conditions of WBC < 4 × 109/L or WBC > 10 × 109/L, NEUT < 2 × 109/L or NEUT > 7 × 109/L, PLT < 100 × 109/L or PLT > 300 × 109/L, Hb < 120 × 109/L or Hb > 160 × 109/L for men and Hb < 110 g/L or Hb > 150 g/L for women, RBC < 4.0 × 1012/L or Hb > 5.0 × 1012/L for men and Hb < 3.5 × 1012/L or Hb > 5.0 × 1012/L for women is met, it is regarded as routine blood parameters is abnormal.

Methods

Occupational health investigation and detection

The concentration of benzene in the working environment was measured according to the Chinese standard (GBZ/T 160. 42—2007 Determination of aromatic hydrocarbons in the air of Workplaces Aromatic Hydrocarbons) by solvent analysis-gas chromatography, and the results are converted into eight-hour time weighting average allowable concentration. The OELs in China stipulates that the eight-hour time-weighted average allowable concentration of benzene is 6 mg/m3. According to the OELs, determine whether the concentration of benzene in the workplace exceeds the standard.

Occupational health risk assessment

Four health risk assessment for workers was conducted by using the US National EPA inhalation risk assessment model, Singapore MOM model, the ICMM, and the Technical guide for environmental health risk assessment of chemical exposure (WS/T 777–2021). They were used to evaluate carcinogenic and non-carcinogenic risks of benzene workers. Four methods and processes were described in this paper.

-

1.

EPA

In this study, the US National EPA inhalation risk assessment model was used to perform carcinogenic and non-carcinogenic risk assessments for benzene workers. The model can be used as a risk assessment for occupational diseases such as tumors, acute and chronic chemical poisoning (USEPA 2009). The main process was estimating the benzene exposure concentration and assessing the carcinogenic and non-carcinogenic risks.

The exposure concentration is calculated based on the time-weighted average concentration (CTWA) measured in the air and the time characteristics of the exposure. The estimated formula is EC = (CA × ET × EF × ED)/AT, where EC is the exposure concentration, and the unit is μg/m3; CA is the concentration of harmful substances in the air, and the unit is μg/m3; ET is the duration of daily exposure, and the unit is h/day; EF is the frequency of exposure, and the unit is days/year; ED is the exposure experience, and the unit is year; AT is the average time of the contact cycle, and the unit is h. The average contact cycle time between carcinogenic risk assessment and non-carcinogenic risk assessment is different. In the carcinogenic risk assessment model, AT = life expectancy (years) × 365 days/year × 24 h/day, and in the non-carcinogenic risk assessment model, AT = exposed service life (ED) × 365 days/year × 24 h/day. According to the Jiangsu Statistical Yearbook 2018, the average life expectancy of the population in Jiangsu Province is 77.5 years.

The carcinogenic risk was determined by calculating the carcinogenic risk interval. The formula is Risk = IUR × EC, where Risk is the carcinogenic risk value, IUR is the inhalation risk unit, and EC is the exposure concentration. The IUR of benzene can be found in EPA’s Integrate Risk Information System (IRIS) database, which is (2.2–7.8) × 10−6 (µg/m3)−1 (Lamplugh et al. 2019). The carcinogenic risk interval is compared with the lifetime carcinogenic risk value of individuals. If the upper limit of the carcinogenic risk interval of benzene-exposed workers is less than 1 × 10−6, the subject is considered to have no cancer risk; if the lower limit of the interval is greater than 1 × 10−4, the subject is considered to be at high risk; and if the upper and lower limits of the interval are between 1 × (10−6–10−4), it is considered that the subject was at low risk (Lamplugh et al. 2019).

The non-carcinogenic risk is determined by calculating the value of the hazard quotient. The calculation formula is HQ = EC/Rfc, where HQ is the hazard quotient, EC is the exposure concentration, and Rfc is the reference value for inhalation toxicity. It is also queried from the US IRIS database. The Rfc of benzene is 3 × 102 mg/m3. The non-carcinogenic risk of benzene is mainly represented by a decrease in the WBC count. The hazard quotient is limited to 1. If the value of the hazard quotient is greater than or equal to 1, it is considered to be a high risk, and if the value is less than 1, it is considered to be in a safe range and consider as low risk.

-

2.

MOM

The Singapore Ministry of Manpower (MOM) semi-quantitative risk assessment model is based on the hazard grade data, dose–response relationship, and exposure grade. After comprehensive analysis, it conducts a semi-quantitative risk assessment grade of occupational exposure to the workers according to the risk matrix assessment formula (risk assessment = HR × ER), where HR represents hazard level and ER represents exposure level.

Calculation of weekly exposure levels (E)

where E is the weekly exposure mass concentration (mg/m3); F is the exposure frequency (times/week); D is the average duration of each exposure (h); M is the exposure mass concentration (mg/m3); W is the average working hours per week (40 h).

Determination of hazard level (HR)

The hazard classification of chemicals can be divided by toxicity of the chemicals. The hazard classification is usually divided into 5 levels: no risk (grade 1); low risk (grade 2); moderate risk (grade 3); high risk (grade 4); extreme risk (grade 5).

Determining of exposure level (ER)

The determination of exposure level should be first evaluated according to the formula E = F × D × M/W. E is the weekly TWA exposure level (PPM or mg/m3); F is the weekly exposure frequency; D is the average exposure time (h); M is the air detecting concentration (PPM or mg/m3); W is the average working time per week (40 h). The exposure level was determined by comparing the weekly time-weighted average exposure level (E) with the long-term occupational exposure limit (PEL).

Grading and evaluation

After obtaining the HR and ER of benzene, grade evaluation was carried out according to the formula. If the air monitoring concentration is lower than 1.2 mg /m3, it shall be calculated as 1.2 mg/m3, and the working time of 5–6 h per day shall be calculated as 6 h. The 6-person rotating position will be calculated by 1.5 h.

-

3.

ICMM

ICMM model was used to calculate the risk level of benzene; the formula was RR = C × PrE × PeE × U. C is the occupational health consequences, according to the degree of harm: unlikely to cause health effects assignment 1; reversible health effects that are not life-threatening assignment 15; permanent adverse health effects that do not significantly affect quality of life and longevity assignment 50, such as mild functional limitation or disability; permanent adverse health effects that may lead to a significant decrease in quality of life and/or life span assignment 100. PrE is exposure probability, which is assigned according to the possibility of exceeding the occupational exposure limit (OEL) as a result of testing: < 50% OEL is assignment 3; 50 ~ 100% OEL is assignment 6; ≥ 100% OEL is assignment 10. PeE is exposure time, and the value of exposure once a year is assignment 0.5; the number of exposures per year is assignment 1; exposure times per month is assignment 2; continuous exposure for 2 to 4 h per shift is assignment 6; continuous exposure for 8 h per shift is assignment 10. U is the uncertainty parameter: certainty is assignment 1; uncertain is assignment 2; very uncertain is assignment 3. Risk grades are divided according to RR: RR < 20 is tolerable risk; 20 ~ 70 is potential risk; 70 ~ 200 is high risk; 200 ~ 400 is very high risk; ≥ 400 is unacceptable risk (Mining and Metals, 2017).

-

4.

The Technical guide for environmental health risk assessment of chemical exposure (WS/T 777–2021)

The exposure of inhalation of benzene

The exposure of inhalation of benzene of general adults is calculated by the following formula:

where ADD is the daily exposure (mg/m3); C is the concentration of benzene in the air (mg/m3); EF is the exposure frequency (day/a); ED is the exposure period (a); ET is the exposure time (h/day); AT is the mean time (h), the number of hours corresponding to ED for non-carcinogenic effects; 613,200 (hours of 70 years) for carcinogenic effects.

Quantitative of risk

Non-carcinogenic risk:

Non-carcinogenic risk by inhalation was calculated by the following formula:

where HQ is the non-carcinogenic risk; ADD is the daily exposure (mg/m3); Rfc is the reference concentration (mg/m3).

Carcinogenic risk:

Carcinogenic risk by inhalation (CR) was calculated by the following formula:

where CR is the carcinogenic risk; ADD is the daily exposure (mg/m3); IUR is the unit of inhalation risk (m3/μg); CF is the conversion factor, 1000 μg/mg.

Risk level

Non-carcinogenic risk:

-

HQ ≤ 1: indicates that exposure does not exceed the adverse reaction threshold and the non-carcinogenic risk is low.

-

HQ > 1: indicates that the exposure exceeds the threshold and the non-carcinogenic risk is high, which should be concerned.

Carcinogenic risk:

-

CR = 1.0 × 10−6 means that 1 in 1 million people is likely to develop cancer.

-

CR < 1.0 × 10−6 indicates a lower risk of cancer. CR is 1.0 × 10−6 ~ 1.0 × 10−4, which has a certain risk of cancer and should be paid attention. CR > 1.0 × 10−4 is associated with high risk of cancer and should be paid close attention (National Health Commission 2021).

Statistical analysis

All statistical analyses were performed using SPSS software (SPSS23.0, IBM, Chicago, USA). The categorical variables were expressed as percentages and analyzed by the bilateral chi-square test or Fisher’s exact probability method. Continuous variables were expressed as mean ± standard deviation and analyzed by rank-sum test, t-test, or one-way ANOVA.

Then mark the original data standardization (Z-score method) by SPSS, getting new data, and then we did the principal component analysis by KMO test and Bartlett sphere test method to test the applicability of PCA analysis.

Results

General information

The basic information of the subjects is shown in Table 1. There are statistical differences in the age, gender, benzene exposure years, and benzene exposure concentration of the five groups we divided. The group “Pharmaceutical” had the largest average age, and the benzene exposure age in “Special equipment” group is the biggest. “Chemical” group has the highest benzene exposure concentration (Table 1). Then, we analyzed the routine blood parameters of benzene-exposed workers in the five groups, and listed the abnormal routine blood parameters with abnormal low value and high value respectively, the difference of the abnormal PLT counts and abnormal RBC counts in five industries was not statistically significant (Table 2).

WBC counts: the proportion of the workers with abnormal white blood cell count among the study objects was significantly higher in the wood products industry and chemical products manufacturing industry than the other three groups (p < 0.05). Neut counts: the proportion of the workers with abnormal neutrophilic granulocyte count among the study objects was significantly higher in the wood products industry and special equipment industry groups than that of the other three groups (p < 0.05). Hb counts: the proportion of the workers with abnormal Hemoglobin count among the study objects was significantly higher in the Wood products industry than that of the other four groups (p < 0.05, Table 3).

Results of occupational health risk assessment for benzene workers

EPA model

The results of EPA risk assessment showed that 53 (3.25%) of the 1629 subjects enrolled in this study were at high carcinogenic risk, and the average carcinogenic risk range is 1.087–3.856 × 10−6, subjects with high carcinogenic risk are mainly in pharmaceutical manufacturing, followed by chemical products manufacturing and special equipment manufacturing industry. The remaining 1576 (96.75%) subjects were assessed as no carcinogenic risk, and the average cancer risk range is 0.029–0.102 × 10−6.

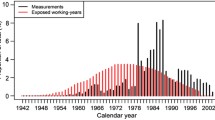

The non-carcinogenic risk of benzene can be assessed by calculating the HQ value. HQ ≥ 1 is considered as high risk, HQ < 1 is considered as low risk (Fig. 1). The result shows that 87.54% of the subjects had low risk of non-carcinogenic, and the average non-carcinogenic risk is 0.435, and 12.46% of the subjects had HQ > 1and the average non-carcinogenic risk is 5.746, more than 1. subjects with high non-carcinogenic risk are mainly in pharmaceutical manufacturing, followed by chemical products manufacturing and special equipment manufacturing industry, then wood processing industry and petroleum, coal and other fuel processing industries (Fig. 2). It can be seen that the distribution of carcinogenic and non-carcinogenic risk levels in the industry can remain consistent.

Then the results of health risk assessment by five industry groups were pairwise compared: the carcinogenic risk of chemical manufacturing and special equipment manufacturing groups in EPA model was significantly higher than that of the other three groups (p < 0.05). Non-carcinogenic health risks were significantly higher in the special equipment manufacturing group than in the other four groups (p < 0.05, Supplementary Table 2).

Methods of Technical guide for environmental health risk assessment of chemical exposure (WS/T 777–2021)

The results of risk assessment by method of WS/T 777–2021 showed that 71 (4.36%) of the 1629 subjects enrolled in this study were at high carcinogenic risk, and the average carcinogenic risk range is 76.84–272.43 × 10−6, subjects with high carcinogenic risk are mainly in chemical products manufacturing, followed by special equipment manufacturing industry;1558(95.64%) subjects were assessed as “existing carcinogenic risk,” and the average cancer risk range is 6.273–22.240 × 10−6 (Fig. 3).

The non-carcinogenic risk of benzene can be assessed by calculating the HQ value. HQ ≥ 1 is considered as high risk, HQ < 1 is considered as low risk.

The result shows that 1621 (99.51%) workers had low risk of non-carcinogenic, and the average non-carcinogenic risk (HQ) is 0.116, and 8 (0.49%) workers had HQ > 1, the average non-carcinogenic risk is 4.046, more than 1. Subjects with high non-carcinogenic risk are mainly in chemical manufacturing industries (Fig. 4).

Then, the results of health risk assessment (WS/T 777–2021) by five industry groups were pairwise compared: The carcinogenic risk of Chemical manufacturing was significantly higher than that of the other four groups (p < 0.05), followed by Special equipment manufacturing which was significantly higher than that of the other three groups (p < 0.05); non-carcinogenic health risks were significantly higher in the chemical manufacturing group than in the wood products industry and petroleum processing industry groups (p < 0.05), and the difference was not statistically significant compared with the other two groups (Supplementary Table 4).

MOM model

As the result of MOM health risk assessment, 1206 (74.03%) of the 1629 subjects enrolled in this study were at high risk (grade 4), and the average range of carcinogenic risk R is 1.374; and 423 (25.97%) were at extreme risk (grade 5) and the average range of carcinogenic risk R is 3.524. Subjects with extreme risk (grade 5) are mainly in pharmaceutical manufacturing, followed by wood processing industry, chemical products manufacturing, and special equipment manufacturing industry (Fig. 5).

Then the results of health risk assessment (MOM) by five industry groups were pairwise compared: the carcinogenic risk of petroleum, pharmaceutical, and special equipment industries was significantly higher than that of the other two groups (p < 0.05, Supplementary Table 6).

ICMM model

The results of ICMM showed that there were significant differences in occupational health risk levels among the five groups (p < 0.05, Table 4).

Results of PCA of the four occupational health risk assessment models

Process of PCA

As the result of principal component analysis, the first 2 principal components explained the 94.569% of the total variance, which means that these 2 principal components extracted can represent 94.569% of the information of the original 8 risk indicators, and it is certainty to evaluate the occupational health risks of benzene by the extracted principal components. Therefore, two principal components are extracted, namely y1 and y2.

The KMO value is 0.845, indicating that there is a certain correlation between the indicators. The result of Bartlett sphere test is 82,882.156, and the Sig value is 0.00 (Supplementary Table 7), indicating that the rejection of correlation coefficient is a unit matrix, that is, each index is correlated. Both test results indicate that the data is applicable to the factors (Xiaojun 2016).

Calculation of the principal component coefficient

According to the two principal component coefficients (Table 5), the linear combination of y1 and y2 is obtained:

According to the comprehensive score, the highest occupational health hazard of benzene among the five industries is Petroleum, coal and other fuel processing industries, then followed by chemical products manufacturing industry, special equipment manufacturing industry, wood processing and wood products industry, and at last the pharmaceutical manufacturing industry (Fig. 6).

Discussion

The EPA model and the GB777 assessment method both involve carcinogenic and non-carcinogenic risk assessment, so the consistency of the results of these two models was compared. According to the analysis of EPA model and WS/T 777–2021 assessment method, it can be seen that the distribution of carcinogenic and non-carcinogenic risk grades obtained by the two models can be basically consistent within the industries. The risk assessment result R of ICMM model is divided into four levels, and the risk of Singapore MOM model is divided into five levels, which cannot be directly compared. In order to make the risk levels by different models comparable, risk ratio (RR) is introduced, which is the ratio of the risk level assessed by a model and the highest risk level of the model. RR refers to the relative risk level, and RR > 0.5 determines that the risk level is above medium risk. However, all RR values calculated by the ICMM model were considered as intolerable risk (grade 4) in the subjects we studied. The risk assessment level of MOM and ICMM is not completely consistent. MOM can more objectively and accurately assess the occupational health risk level of benzene exposure in benzene-related industries. In addition, among the occupational health risk assessment results of benzene related enterprises obtained by the four models, all reflect that pharmaceutical manufacturing has the highest level of occupational health risk, followed by chemical raw materials and chemical products manufacturing and special equipment manufacturing industry, wood processing industry, and petroleum industry. The reliability of the model was verified by evaluating the consistency between the RR obtained by each model and the IR of the industry. The chemical products manufacturing, petroleum processing industries, wood processing, and products industry, special equipment manufacturing industry, and pharmaceutical manufacturing industry were selected as the typical industries for this study based on their inherent risks (IRs). The IRs of industries were directly obtained from a normative document formulated by a government department in China (namely, the “Management catalogue of occupational hazard risk classification for construction projects” issued by the State Administration of Work Safety of China). According to the document, the five industries were classified as “severe “which is consistent with the findings of the health risk assessment models in this paper.

In this study, the minimum concentration of benzene in 50 factories is 0.2 mg/m3, and the maximum concentration is 32.3 mg/m3 which located in chemical industries. there were 35 monitoring sites where benzene concentration monitoring exceeds China’s OELs, and these 35 monitoring sites are all in “chemical raw materials and chemical products manufacturing” industry. The result suggested that the benzene concentration in the “chemical product manufacturing industry group was the highest, and the “wood products industry” group was the lowest in five industry groups, but the population of abnormal routine blood parameters of the 1629 subjects was mostly in the “wood products industry” group, the industry with low exposure concentration have higher blood abnormality rates. Some studies (Koh et al. 2015) suggested that if a worker showed an abnormal cell count, the worker may have been transferred to a less exposed or non-exposed department; we did not rule out that this is one of the cause of the high abnormal blood routine parameters in the low benzene exposure group. Study found that among the industrial sources of PAHs, the coking industries is the most serious PAH emission industry (Ravindra et al. 2008). So, the petroleum, coal, and other fuel processing industries is highly risky, which is known to state regulators; because of the highest benzene exposure, and prone to lead to acute blood damage, companies and countries pay more attention to the protection of workers in the petroleum, coal, and other fuel processing industries and can take more measures to reduce the exposure of benzene, such as more automation, more job rotations, and more daily monitoring. The R value of “wood products industry” group by the four assessment models showed that it is almost in “no risk,” “low risk,” and “medium risk” which may cause low attention of the risk of benzene exposure such as low frequency of job rotation. With the development of productivity and the increasing awareness of workers’ protection, the concentration of benzene in the workplace is generally lower than the detection limit, and high concentration of acute benzene poisoning with obvious symptoms have been relatively rare. This may cause chronic blood damage, and research found that effects of low doses cannot be predicted by the effects observed at high doses (Vandenberg et al. 2012). However, the monitoring data of benzene concentration in the production environment cannot accurately reflect the actual situation and physical changes of individual exposure, especially the accumulation of a certain amount in the body (Carrieri et al. 2019), and these data have no practical significance for workers continuously exposed to low doses. So, we suggested that blood damage under low concentration exposure of benzene is much less predictable and detectable than that under high concentration. After investigation of the subjects of the wood products industry group mostly from painting related job, it is considered that exposure to paint-related materials is equivalent to longer exposure to benzene, a risk factor for abnormal routine blood parameters. Therefore, for the low benzene exposure industries, companies, and the country need to pay more attention and give more policy improvements and strengthen the management of daily monitoring. The health hazards suffered by the occupational population due to exposure to low concentration benzene should not be ignored.

In our study, all the subjects considered to have different degrees of carcinogenic risk by four health risk assessment models. The reasons for this result may be various. First of all, the four models have different evaluation methods and calculation parameters respectively, we considered to group the individuals into five different industries and compare their risk level. Then, compared with previous studies, the exposure concentration of benzene in the working environment is higher than that in residential, offices, and outdoor (Hu et al. 2018; Huang et al. 2013). Our research selected the occupationally exposed population. The OELS of benzene concentration in China is higher than the OELS of other institutions or countries (Edokpolo et al. 2015). In Thailand, there is a risk assessment of benzene for gas station workers showed that 70.67% of gasoline workers have a lifetime risk of cancer and the result shows that 51.33% of workers with HQ > 1 (Chaiklieng et al. 2019). There is a study in Italy conducted the inhalation risk analysis of benzene of general populations in three towns and the HQ was < 1 in all monitoring sites (De Donno et al. 2018). Therefore, the concentration of benzene in the working environment of enterprises is relatively high. These results suggested that Chinese workers may suffer huge occupational health risks. The health hazards suffered by the occupational population due to exposure to benzene should not be ignored. The Chinese government should establish a lower OELS to protect the health of the occupational population.

Our research has the following advantages compared with previous research: our research used the first-hand data to conduct health risk assessment, and the results are more credible; we chose a new methodology introduced in 2021. We built a new evaluation index based on the four models to evaluate the size of the hazards between industries, instead of just analyzing the correlation of the four models. Our research includes occupational groups in different industries, and evaluates the health risks of employees in these industries, which is more socially meaningful than a study that only conducts risk assessment on employees of a certain company. Our research also has some drawbacks. We only focused on employees who were directly exposed to benzene, other people who are in office areas or nearby residential areas may also be exposed to a certain concentration of benzene. We will conduct research on these people in the future.

Conclusions

In summary, principal component analysis (PCA) adequately showed occupational health hazards of benzene exposure in the petroleum industries are higher than the other four industries we studied. According to the four health risk assessment models, the “chemical raw materials and chemical products manufacturing industry” is basically the most serious in “high risk” level, and the industry of “wood processing and products” is generally the most serious in “low risk” level or “medium risk” level, but the proportion of the workers with abnormal routine blood parameters among the study objects was significantly higher in the wood products industry than that of the other four groups (p < 0.05). increased attention should be focused on the occupational population exposed to low concentration benzene by daily monitoring of benzene concentration, strengthening the management and relevant policy designation.

Data availability

No data are available. Internal data used in this protocol are highly sensitive and confidential and only accessible to approved personnel. Linked data are kept securely by Jiangsu CDC. Researchers interested in collaborations or further information are invited to contact the corresponding author.

References

Abplanalp WT et al (2019) Benzene exposure induces insulin resistance in mice. Toxicol Sci 167:426–437. https://doi.org/10.1093/toxsci/kfy252

Akerstrom M et al (2016) Personal exposure to benzene and 1,3-butadiene during petroleum refinery turnarounds and work in the oil harbour. Int Arch Occup Environ Health 89:1289–1297. https://doi.org/10.1007/s00420-016-1163-1

Baan R et al (2009) A review of human carcinogens–Part F: chemical agents and related occupations. Lancet Oncol 10:1143–1144. https://doi.org/10.1016/s1470-2045(09)70358-4

Burns A et al (2017) Combined analysis of job and task benzene air exposures among workers at four US refinery operations. Toxicol Ind Health 33:193–210. https://doi.org/10.1177/0748233715619072

Cai Y et al (2018) Occupational health risk assessment in the electronics industry in China based on the occupational classification method and EPA model. Int J Environ Res Public Health 15. https://doi.org/10.3390/ijerph15102061

Carrieri M et al (2019) Effect of benzene exposure on the urinary biomarkers of nucleic acid oxidation in two cohorts of gasoline pump attendants. Int J Environ Res Public Health 16. https://doi.org/10.3390/ijerph16010129

Chaiklieng S et al (2019) Risk assessment on benzene exposure among gasoline station workers. Int J Environ Res Public Health 16. https://doi.org/10.3390/ijerph16142545

Chung E-K et al (2010) Characteristics of occupational exposure to benzene during turnaround in the petrochemical industries. Saf Health Work 1:51–60. https://doi.org/10.5491/shaw.2010.1.1.51

Costantini AS et al (2009) Exposure to benzene and risk of breast cancer among shoe factory workers in Italy. Tumori 95

De Donno A et al (2018) Health risk associated with exposure to PM and Benzene in Three Italian Towns. Int J Environ Res Public Health 15

Edokpolo B et al (2014) Health risk assessment of ambient air concentrations of benzene, toluene and xylene (BTX) in service station environments. Int J Environ Res Public Health 11:6354–6374. https://doi.org/10.3390/ijerph110606354

Edokpolo B et al (2015) Health risk assessment for exposure to benzene in petroleum refinery environments. Int J Environ Res Public Health 12:595–610. https://doi.org/10.3390/ijerph110606354

Hostynek JJ et al (2012) Benzene absorption in animals and man: an overview. Rev Environ Health 27. https://doi.org/10.1515/reveh-2012-0008

Hu R et al (2018) Levels, characteristics and health risk assessment of VOCs in different functional zones of Hefei. Ecotoxicol Environ Saf 160:301–307. https://doi.org/10.1016/j.ecoenv.2018.05.056

Huang L et al (2013) Health risk assessment of inhalation exposure to formaldehyde and benzene in newly remodeled buildings. Beijing Plos One 8:e79553. https://doi.org/10.1371/journal.pone.0079553

Janitz AE et al (2017) Benzene and childhood acute leukemia in Oklahoma. Environ Res 158:167–173. https://doi.org/10.1016/j.envres.2017.06.015

Koh D-H et al (2015) The relationship between low-level benzene exposure and blood cell counts in Korean workers. Occup Environ Med 72:421–427. https://doi.org/10.1136/oemed-2014-102227

Lamplugh A et al (2019) Occupational exposure to volatile organic compounds and health risks in Colorado nail salons. Environ Pollut (Barking, Essex : 1987) 249:518–526. https://doi.org/10.1016/j.envpol.2019.03.086

Maier A et al (2015) State-of-the-Science: The Evolution of Occupational Exposure Limit Derivation and Application. J Occup Environ Hyg 12(Suppl 1):S4–S6. https://doi.org/10.1080/15459624.2015.1060329

Marchetti F et al (2012) Occupational exposure to benzene and chromosomal structural aberrations in the sperm of Chinese men. Environ Health Perspect 120:229–234. https://doi.org/10.1289/ehp.1103921

Masih A et al (2018) Exposure levels and health risk assessment of ambient BTX at urban and rural environments of a terai region of northern India. Environ Pollut (Barking, Essex : 1987) 242:1678–1683. https://doi.org/10.1016/j.envpol.2018.07.107

Mining ICo, Metals (2017) Good practice guidance on occupational health risk assessment. Int Counc Min Met

National Health Commission, P. (2021) The National Health Commission of the People’s Republic of China-Technical guide for environmental health risk assessment of chemical exposure. WST 777–2021, china

Raaschou-Nielsen O et al (2018) Ambient benzene at the residence and risk for subtypes of childhood leukemia, lymphoma and CNS tumor. Int J Cancer 143:1367–1373. https://doi.org/10.1002/ijc.31421

Ravindra K et al (2008) Atmospheric polycyclic aromatic hydrocarbons: source attribution, emission factors and regulation. Atmos Environ 42:2895–2921. https://doi.org/10.1016/j.atmosenv.2007.12.010

Smith MT et al (2011) Benzene, the exposome and future investigations of leukemia etiology. Chem Biol Interact 192:155–159. https://doi.org/10.1016/j.cbi.2011.02.010

Stenehjem JS et al (2015) Benzene exposure and risk of lymphohaematopoietic cancers in 25 000 offshore oil industry workers. Br J Cancer 112:1603–1612. https://doi.org/10.1038/bjc.2015.108

Stenehjem JS et al (2017) Aromatic hydrocarbons and risk of skin cancer by anatomical site in 25 000 male offshore petroleum workers. Am J Ind Med 60:679–688. https://doi.org/10.1002/ajim.22741

Talibov M et al (2018) Benzene exposure at workplace and risk of colorectal cancer in four Nordic countries. Cancer Epidemiol 55:156–161. https://doi.org/10.1016/j.canep.2018.06.011

USEPA, E. (2009) Risk assessment guidance for superfund volume I: human health evaluation manual (Part F, supplemental guidance for inhalation risk assessment). Office of Superfund Remediation and Technology Innovation Environmental Protection Agency. EPA-540-R-070–002

Vandenberg LN et al (2012) Hormones and endocrine-disrupting chemicals: low-dose effects and nonmonotonic dose responses. Endocr Rev 33:378–455. https://doi.org/10.1210/er.2011-1050

Ward E et al (1996) Risk of low red or white blood cell count related to estimated benzene exposure in a rubberworker cohort (1940–1975). Am J Ind Med 29:247–257. https://doi.org/10.1002/(sici)1097-0274(199603)29:3%3C247::aid-ajim4%3E3.0.co;2-n

Xiaojun C (2016) Analysis of the operating performance of listed banks in China-based on the methods of principal component analysis, factor analysis and cluster analysis. J Suzhou Univ 31(7). https://doi.org/10.3969/j.issn.1673-2006.2016.07.006

Zhou Y et al (2014) Maternal benzene exposure during pregnancy and risk of childhood acute lymphoblastic leukemia: a meta-analysis of epidemiologic studies. PLoS ONE 9:e110466. https://doi.org/10.1371/journal.pone.0110466

Acknowledgements

We thank the research subjects, the 1629 benzene exposed workers, for their active participation and the strong support of Jiangsu Center for disease prevention and control, as well as the teachers and students who provide help for the data processing of this paper. Finally, I would also like to thank Jiangsu Science and education strong health innovation team for its funding.

Funding

This study was mainly supported by Jiangsu Province’s Outstanding Medical Academic Leader program (CXTDA2017029).

Author information

Authors and Affiliations

Contributions

LZ: methodology, software, investigation, writing—review and editing. PS: methodology, software, formal analysis, investigation. HZ, LH, DS, YZ, BZ, BW: resources, writing—review and editing, supervision.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

In abiding with the ethical requirements, the study conformed to the Declaration of Helsinki and was nominated to be exempted from institutional ethical review by the Research Ethics Board of Jiangsu Provincial CDC. Official permission was taken from each respondent for this study, and informed consent was obtained from all participants.

Consent for publication

Consent given by all contributing authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Lotfi Aleya

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, L., Sun, P., Sun, D. et al. Occupational health risk assessment of the benzene exposure industries: a comprehensive scoring method through 4 health risk assessment models. Environ Sci Pollut Res 29, 84300–84311 (2022). https://doi.org/10.1007/s11356-022-21275-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-21275-x