Abstract

Environmental problems caused by the food processing industry have always been one of the concerns for the public. Herein, for the first time, a gate-to-gate life cycle assessment (LCA) was employed to evaluate the environmental impact of rice bran oil production. Four subsystems, namely, transportation of the raw rice bran to oil factory, crude oil extraction, oil refining, and oil storage, were established. The product sustainability software GaBi and the method CML 2001-Jan. 2016 were used to calculate and analyze the environmental burdens at each stage of the rice bran oil production chain. The results show the oil refining stage had the greatest environmental impact, followed by the oil extraction stage. High demands for coal and electricity make a critical difference in generating vast majority of environmental impacts. Modifying the electricity source and replacing traditional fuels with cleaner ones will do bring benefits to the sustainable development of the industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The agri-food industry occupies an important position in the economy and society. Along with agricultural production, massive amounts of agricultural by-products are produced each year, some of which are used as animal feed or rejected as waste, leading to a great loss of natural nutrients as well as environmental pollution (Ben-Othman et al. 2020; Kalhor and Ghandi 2019; Lai et al. 2017; Zhang et al. 2019). High value-added utilization of these by-products has always been a public concern which deserves great attention (Lai et al. 2017; Rico et al. 2020). Global growing population calls for more agricultural products while combating the increasing burden on resources and environment, which indicates the need for more products rich in nutrition to be produced in ways that cause minimal impacts on the environment (Bommarco et al. 2013; Notarnicola et al. 2017; Soussana 2014). Low-carbon development concerns the future of humanity and has become a global consensus. Identifying and quantifying the environmental performance of agricultural and sideline products production process is of great significance for promoting the full utilization of industrial and agricultural wastes and increasing agricultural productivity (Ma et al. 2017; Wang et al. 2018; Wimbadi and Djalante 2020).

Edible oil is among products that make the largest environmental impacts in processes of production and consumption (Tukker and Jansen 2006). Rice bran oil, extracted from rice bran, is unique among edible oils as a rich source of nutritionally phytoceuticals such as γ-oryzanol, lecithin, squalene, phytosterols, polyphenols, tocopherols, tocotrienols, and trace minerals (Lai et al. 2019; Park et al. 2017). Rice bran is the most valuable byproduct of the rice milling with large and stable yield every year, which constitutes about 10% of the total weight of rough rice (Ghasemzadeh et al. 2018; Gul et al. 2015). According to statistics by the Food and Agriculture Organization, the global rice production is 782 million tons which resulted in more than 70 million tons of rice bran in 2018. Research studies on phytochemistry of rice bran have demonstrated that phytonutrients found in rice bran have potential applications in preventive and clinical medicine, particularly γ-oryzanol (Gallyas et al. 2019; Perez-Ternero et al. 2017; Samad 2015). In this context, rice bran oil is of steadily growing popularity, especially in Japan, Korea, India, China, and Indonesia (Friedman 2013; Lai et al. 2019).

Life cycle assessment (LCA) is a useful tool in identifying and quantifying the potential environmental impacts throughout a product’s life cycle, from the raw material acquisition through production, use, end-of-life treatment, recycling, and up to the final disposal (from cradle to grave). (ISO 14040: 2006 and ISO 14044: 2006). System boundaries can vary according to the specific research purpose. For the current study, a “from gate to gate” approach was applied.

Many research studies have been published on LCA of some major cooking oils. For example, Tsarouhas et al. (2015) assessed the environmental performance of olive oil production by investigated fourteen sub-systems of olive oil production in Greece, aiming to identify key areas for environmental impact improvement. Khatri et al. (2017) adopt a “from cradle to gate” approach in evaluating the environmental impacts of mustard oil production in India. Meanwhile, the effects of system variables such as oilseed processing scales, extraction method, and allocation choice on the LCA results were also studied. Khanali et al. (2018) quantified the environmental performance of packaged canola edible oil production in Isfahan province of Iran, and comparisons of environmental burdens at each stage were made to provide targeted suggestions to achieve efficient management as well as reduce environmental footprints. And Khatri and Jain (2017) in a review analyzed and discussed the application of life cycle analysis in edible oil systems to make predictions about the challenges that future research in this area might encounter, aiming to provide reference for the transition to sustainable agri-food system. However, none research on LCA of rice bran oil production can be found.

To the best of our knowledge, this is the first study to assess the environmental impact of rice bran oil production using LCA methodology. The objective was to identify and evaluate the environmental impact potential of rice bran oil production in the selected enterprise, and further comparative analysis of subsystems was conducted to identify the environmental hotspot and key factors that resulted in the majority of impact categories. As to the uncertainty of the research, effect of uncertainty in normalization step on the results was considered using a Monte Carlo simulation. Additionally, some practical and feasible proposals were put forward to promote the transformation and upgrading of edible oil production to cleaner production by improving the environmental performance of production activities.

Methodology

System description

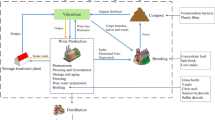

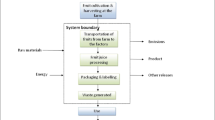

Panjin Best Oil Factory, a rice bran deep processing enterprise, was selected as the research object with annual processing 60,000 tons of rice bran and annual production of refined rice bran oil 30,000 tons. The production process route is the overall optimal for current optimization recommended by the engineer. Specific process and data on various stages and processes of rice bran oil production were mainly collected by interviewing with engineers and technical staff of the plant. The required background data for material and energy production were extracted from GaBi database. The process flowsheet diagram of rice bran oil production is depicted in Fig. 1.

The general stages of rice bran oil production include (1) transportation of the raw rice bran to the factory, (2) crude oil extraction, (3) oil refining, and (4) oil storage. Furthermore, to determine the key factors leading to prominent environmental burdens, the oil extraction stage is divided into pretreatment and oil leaching, and the oil refining stage includes degumming, decoloring, dewaxing, deacidification, alkali refining, secondary decoloring, deodorization, and defatting processes. The system flows and boundary of rice bran oil production investigated are shown in Fig. 2.

Transportation

The raw material, rice bran, is transported from rice plants in nearby and surrounding provinces to oil plant by 30-ton diesel trucks. Considering the locations of rice plants and oil plant comprehensively, the transportation distance was set as 510 km.

Oil extraction

Two sections, pretreatment of raw materials and oil leaching, are involved in this stage. Firstly, the raw rice bran enters the pretreatment workshop after separation by chaff rotary sifter. Impurities are removed with a vibrating screen and a magnetic separator. Subsequently, the rice bran enters the dryer for drying before being delivered to the bulking machine. Due to high moisture content, the puffed rice bran is air-dried and transported to the extraction workshop.

Once entering the extractor, the puffed rice bran is placed in different material compartments and leached in a countercurrent leaching way. After multiple cycles of leaching, the concentration of the mixed oil gradually decreased, and finally extracted with pure hexane solvent. At this time, the rice bran becomes bran meal, and is dripped and dried before transported to the desolventizer. The bran meal is heated, and the hexane steam is sent to condense for recovery. The mixed oil is treated by a three-stage evaporator to separate hexane solvent. The solvent removal process is performed under negative pressure, to ensure a low temperature environment so that the target product is light in color, which facilitates the later oil refining.

Oil refining

This stage consists of eight steps.

Degumming

The extracted oil from the leaching workshop is pumped into the filter to remove residual impurities. After being heated, it is sent to the acid refining mixer and fully contacted and mixed with the phosphoric acid and water input by the acid metering pump, so that the colloidal impurities of the oil mainly phospholipids can be hydrolyzed. Then the mixture is pumped into the centrifuge to separate the oil feet. The obtained oil is fully washed with water, which is separated by the centrifuge next. The residual water is removed under negative pressure to make the water content ≤ 0.5%. The chemical reaction equation involved in the degumming stage is shown in Eq. (1).

Decolorization

After degumming, the phospholipid remained in oil is removed with active clay to make preparations for dewaxing in the later. The oil is quantitatively mixed with activated clay in a negative pressure decolorization tower, and filtered after removing water at 105 °C. Usually, a closed leaf filter is adopted, and the filtered oil enters the dewaxing crystal growth tank.

Dewaxing

The phosphorus content in oil after decolorizing is ≤ 20 ppm, and now, it is time for dewaxing. After the decolorized oil enters the dewaxing crystal tank, it is cooled according to the scheduled cooling procedure. When it drops to 20 °C, the oil is fed into the filter machine by means of differential pressure or screw pump for filtration. Employing the box type filter press or the membrane filter press, of which the price of the latter is higher, but the filter cake can be compacted further after filtering to enhance the oil yield. During the filtration process, the ambient temperature should be controlled to be consistent with that of the oil.

Deacidification

The phosphorus content in dewaxed oil is no more than 5 ppm. After passing through the heat exchanger and the heater, the temperature rises to 230–240 ℃ and the oil enters the physical deacidification tower. Under the condition that the vacuum residual pressure at the top of the tower is ≤ 300 Pa, the free fatty acids in oil are removed by the direct steam at the bottom of the tower, and the acid value of the oil output from the tower is between 2 and 3 mgKOH/g. After the oil passes through the heat exchange system, the temperature is further reduced to 50 ℃ via a cooler.

Alkali refining: The oil is proportionally mixed with sodium hydroxide (12% concentration) at 50 ℃, and then, they are delivered into a centrifugal to separate the soap feet. The clean oil needs to be tested for acid value and grain content. Normally, the acid value is between 0.3 and 0.4 mgKOH/g (phenolphthalein indicator); otherwise, the amount of liquid caustic soda should be adjusted. Peculiarly, the acid value should be maintained at 1.5 mgKOH/g if producing edible oil with high oryzanol content. The alkali refined oil needs to be washed with water, which is separated by a centrifuge afterwards. After being heated, it enters the dryer for negative pressure dehydration to bring the moisture content ≤ 0.5%. The chemical reaction equations involved in the alkali refining stage are shown in formulas (2) and (3).

Secondary decolorization

The soap and pigment remained in the alkali refined oil need to be removed. For this decolorization, the color of the oil is required to directly reach the target value, usually requiring the 5-inch groove of the Lovibond colorimeter R/Y/B = 5/35/0, and then, the heat-sensitive decolorization effect of the deodorization can make it reach R/Y/B = 4/35/0, reaching the national standard for first grade oil. The oil is quantitatively mixed with activated clay in the negative pressure decolorization tower, filtered after removing water at 105 ℃, and the decolorized oil enters the temporary storage tank before deodorization.

Deodorization

At this time, the phosphorus content in oil is close to zero. After passing through the heat exchanger and the heater, the temperature rises to 240–250 ℃ and the oil enters the deodorization tower. When the tower top vacuum residual pressure is ≤ 300 Pa, the low-boiling point substances in oil will be removed by the direct steam. Grease retention time in deodorant tower needs to be controlled. Excessive residence time will result in generation of toxic substances and the loss of oryzanol. After leaving the tower, the oil is cooled down and enters the degreasing crystal cultivation tank.

Defatting

The deodorized oil shall be cooled automatically according to the predetermined procedure. When it drops to minus 3 ℃, the oil is fed into the filter by differential pressure or screw pump for filtration. Then, the clean oil is filtered out and stored in a temporary tank. After passing the test, it is poured into the product oil tank through a safety filter with a pump.

Oil storage

The refined rice bran oil is temporarily stored in storage tanks for further packaging and sale.

Life cycle assessment

The study was performed following the methodological framework of LCA based on ISO (International Standardization Organization) 14,040 and ISO 14044 standards, which describes the principles and framework coupled with requirements and guidelines for life cycle assessment. There are four phases in an LCA study: (1) the goal and scope definition, (2) the inventory analysis, (3) the impact assessment, and (4) the interpretation.

Goal and scope definition

The goals of the LCA in this study are (i) to determine the material and energy flows and emissions throughout the rice bran oil production chain, (ii) to quantify the potential environmental impacts of the rice bran oil production processes in each stage (transportation, oil extraction, oil refining, and storage) and phases of different stages (pretreatment and oil leaching in the oil extraction stage, and degumming, decolorizing, dewaxing, deacidification, alkali refining, secondary decoloring, deodorization, and defatting in the oil refining stage), and (iii) to analyze and compare the environmental impacts at each stage and phase of production chain to identify environmental hotspots as well as factors that are critical to the outcome for further improvement.

The functional unit (FU) was determined to be one ton of refined rice bran oil. The system boundary was from gate to gate, including transportation of raw materials from rice factories, auxiliary materials and energy inputs, rice bran oil production, and emissions associated with these processes. The transport and disposal of by-products are not considered within the system boundaries since we pay close attention to the rice bran oil production process. In addition, no consideration is given to the environmental impact of worker activities.

Inventory analysis

In this section, an inventory of raw and auxiliary materials and energy consumed together with pollutant emissions to air, water, and soil throughout the life cycle of rice bran oil production per FU was established.

All data in this study are based on the production capacity and current situation of the enterprise studied. The daily processing capacity of crude oil extraction system is 150 tons, and that of oil refining system is 200 tons for the purpose of balancing production and sales,

Transport data on diesel fuel consumption came from truck drivers, and the relevant emissions were quantified referring to factors for diesel combustion based on the Eco-invent database. And the transport distance was determined comprehensively considering the locations of rice plants and the oil plant.

As for systems of the oil extraction, oil refining, and oil storage, data of each process, including input of raw and auxiliary materials, energy consumption, intermediate products, and process emissions output, were provided by the technical engineer according to the statistical yearbook and EIA reports of the enterprise. The data regarding the electricity generation, hard coal mining, and acquisition, as well as the production of other auxiliary materials, were primarily extracted from the GaBi database.

In addition, it is necessary to note that bleaching earth, mainly composed of bentonite, silicon dioxide, ferrous oxide, and alumina, was neglected in view of its small dosage and insignificant environmental impact. The waste water produced in the production process is disposed by the sewage treatment system before being discharged. The relevant discharge data in this article refers to that after sewage treatment. Finally, the life cycle inventory data to produce one ton of rice bran oil is shown in Table 1.

Impact assessment

The life cycle impact assessment is the core step of LCA, aiming to identify and evaluate the magnitude and significance of the potential environmental impacts. For this purpose, GaBi ts version 9.2.1.68 software was employed and the analysis herein is based on the CML2001-Jan. 2016 methodology. Mandatory elements: the selection of relevant impact categories, classification, and characterization were performed using a midpoint approach, and the World 2000 was adopted for the normalization step. The environmental impact categories investigated are presented in Table 2.

Allocation

Multi-output systems require allocation, to quantitatively associate inputs and outputs with the relevant products. For the present study, co-products were observed in both oil extraction and oil refining stages. Referring to study by Khanali et al. (2018), mass allocation is adopted for all subsystems. The inventory of each process is assigned to all of its products proportionally to their mass. The product systems are shown in Table S1, and the end-of-life scenarios of various byproducts are listed in Table S2.

Monte Carlo simulation

The Monte Carlo simulation captures the uncertainty of parameter estimation based on the probabilistic statistical theory by performing random experiments using the computer software to generate numbers randomly within the given range of variable parameters (Liu et al. 2017; Yuan et al. 2017). In this paper, the Monte Carlo simulation was employed to analyze the uncertainty of the LCA results with the software Oracle Crystal Ball 11.1.2.4. Random trials repeated 10,000 times each time. The general steps are as follows: (1) determine the parameter variables and their distribution functions involved in the model, (2) construct the model, (3) perform multiple random sampling based on the given parameter ranges, and (4) obtain the distribution of the output variables (Zhao et al. 2017).

Results

Table 3 shows the characterization results of rice bran oil production at subsystem level, from transportation of the raw material to the refined oil storage.

Besides, to consider the uncertainty in the normalization step, 10,000 iterations of Monte Carlo simulations were performed and the 95% confidence interval was calculated. The combined results are shown in Fig. 3. According to the results, the trends of the uncertainty ranges did not change the overall ranking of the stages.

As presented in Fig. 3, the normalization results for the transportation, oil extraction, oil refining, and oil storage stages were 6.31E − 11 years, 1.70E − 10 years, 1.81E − 10 years, and 1.11E − 11 years, respectively. The oil refining stage had the largest environmental impact, slightly higher than the oil extraction, followed by the transportation and oil storage stages.

As can be seen from the inventory, electricity demand for the refining stage was 37.2% higher than the oil extraction, whereas 21.55% higher coal consumption was observed in the extraction stage than that of the oil refining. Besides, the applications of chemicals such as hexane, sodium hydroxide, and phosphoric acid also generate significant impacts on the environment. More details are described below.

According to the characterization results, oil refining stage accounts for the largest share in most impact categories, contributing 35.85–80.51% to all impacts except ADPf, GWP, POCP, and FAETP, for which it contributes 35.95%, 38.9%, 21.67%, and 9.8%, respectively. The oil extraction stage contributes most to ADPf (41.09%), GWP (44.03%), and POCP (68.72%), and transportation contributes 80.15% to FAETP. No significant environmental impact was observed in the temporary storage stage.

Figure 4 shows the percentage contribution of each input consumed in oil refining stage in developing environmental impacts. It can be observed that emissions of background systems in generation of electricity and coal coupled with those pollutant emissions arising from fossil fuel combustion during oil refining constitute the most significant factors in computing impact categories, such as AP, HTP, MAETP, ODP, and TETP. Besides, the applications of auxiliary chemicals like sodium hydroxide and phosphoric acid contribute most to ADPe (55%) and EP (83%) impact categories, respectively.

According to in-depth analysis of normalization results, degumming, deacidification, and deodorization processes made outstanding contributions to the environmental impacts compared with the others.

As shown in Fig. 4, phosphoric acid consumed for the enzymatic hydrolysis of phospholipids in degumming process, is responsible for the vast majority of eutrophication impact (83%) in refining stage, but also generates remarkable effect on acidification potential with a contribution of 26%. Furthermore, according to the inventory, high amount of coal is required in both deacidification and deodorization steps to maintain the deacidification tower at 230–240 ℃ and the deodorization tower at 240–250 ℃ so that the steam inside the tower can keep carrying away the specific components smoothly. Consequently, the releases of sulfur dioxide, and nitrogen oxides from coal combustion in these processes, resulted in a share of 71% of acidification impact. Additionally, the discharge of wastewater containing phosphorus, COD, and ammonia in these three processes plays a secondary role in the formation of EP and AP impact categories. With regard to MAETP and HTP impact categories, discharges resulted from electrical power generating system and coal mining are two major contributors. As depicted in Fig. 4, the contributions to MAETP and HTP impact categories are 76% and 59% for the electricity generation, and 18% and 19% for the latter contributor, respectively.

Environmental impacts of crude rice bran oil production in the oil extraction stage are exhibited in Fig. 5. Compared with the refining stage, oil extraction stage ranked the first in fossil fuel consumption, greenhouse gas emissions, and photochemical ozone creation aspects. High volumes of raw material need to be processed in this stage, which resulted in 21.55% higher coal was consumed than the oil refining. As a result, fossil fuel production and emissions made considerable contributions in creations of ADPf and GWP impact categories both at rate of 93%. Meanwhile, the application of hexane solvent for higher oil extraction rate in oil leaching process plays a dominant role in aggravating POCP impact category.

Figure 6 demonstrates the normalized contribution of each stage in producing one ton of rice bran oil. It is evident that the oil refining stage has the highest contribution to the majority of the environmental impacts per one ton of rice bran oil production, due to high demands for electricity and fossil fuel which provides power for physical and chemical refining processes. The oil extraction stage follows next. From the total environmental impact, it is easy to find that the MAETP impact category occupies the most environmental burden in producing one ton of rice bran oil, wherein the major contribution arises from the background processes in production of energy mix. As graphically represented in Figs. 4 and 5, electricity at grid (background processes) serves as the most important contributors in creation of MAETP impact category; meanwhile, fossil fuel extraction and processing also play a significant role. Apart from this, the values for AP, ADPf, GWP, POCP, EP, and HTP impact categories are also prominent. It can be ascribable to the emissions of carbon dioxide, sulfur dioxide and nitrogen oxides from energy utilization and those pollutant discharges during the production of auxiliary chemicals such as phosphoric acid and hexane.

Sensitivity analyses of key parameters are shown in Fig. 7. It indicated that the LCA results were most sensitive to coal consumption and electricity use. Specifically, most of the life cycle impact categories in producing 1 ton of rice bran oil were most sensitive to coal consumption, such as abiotic fossil depletion, acidification, eutrophication, global warming, and photochemical ozone creation potential (Fig. 7a, b, c, e, and i). When the coal consumption changed by ± 20%, the life cycle global warming impact changed to 2445.89 and 1785.97 kg CO2-eq, respectively, corresponding to 115.9% and 84.63% of the baseline life cycle global warming impact, respectively. Besides, similar rates of change are observed in ADPf and AP impact categories. A 20% change in coal consumption results in 14.82% and 15.64% changes happening to abiotic fossil depletion and acidification impacts, respectively. In the same case, POCP changes by 9.34%, while EP is little fluctuation with a variation of 2.57%. Meanwhile, electricity usage is the second most important factor for life cycle environmental impact of rice bran oil production. Varying demand for electricity by ± 20% led to changes of life cycle marine aquatic ecotoxicity, ozone layer depletion, and human toxicity impacts by ± 11.56%, ± 12.93%, and ± 7.39%, respectively. In addition, freshwater aquatic ecotoxicity potential displays the greatest sensitivity to transport distance, generating a variation of ± 15.89% in respect to ± 20% change in transport distance. Other factors, such as wastewater volume and n-hexane discharge, caused 1.65% and 8.9% changes in EP and POCP, respectively, when changed by 20%.

Discussion

The environmental performances show that the oil refining stage generates the largest environmental impact, slightly higher than the oil extraction stage on the whole. The results can be attributed to high level of coal and electricity consumption in these stages, which resulted in massive emissions released in both production and use phases. Energy-intensive characteristics of production lines and a high proportion of coal-based power generation make their dominant roles in developing environmental impacts. It can be observed that the enterprise relies mainly on electricity and fossil fuel for power providing, which exerts destructive effects on the environment. In many food processing industries, electricity and fuel consumption continues to dominate the generation of environmental impacts, especially MAETP and GWP impact category, for example, in production of processed tomato product De Marco et al. (2018) and sea cucumber Hou et al. (2019). To reduce emissions from electricity and fuel oil utilization, modifying the electricity source with substitution of portion of the electricity grid with electricity produced by the installed photovoltaic panels, and replacing the fuel used in the heat exchangers with biogas or liquefied petroleum gas, to some extent, can prevent the negative effects of fossil fuel-derived energy consumption. Wang et al. (2020) revealed that compared with the traditional coal-fired electricity generation, the solar photovoltaics electricity generation could reduce carbon emissions by 87.35–94.9%, which turned out to be a good alternative in reducing greenhouse gas emissions.

Reducing reliance on fossil fuels will significantly improve the environmental sustainability of production, which highlights the need for sustainable energy generation and renewable biofuel development (Bórawski et al. 2019). The utilization of crop residues for energy generation can not only reduce their environmental burden on society by refraining from faulty disposal of these leftover materials, but also alleviates energy shortages and fossil reserves depletion (Prasad et al. 2020). Quispe et al. (2019) investigated rice husk as an alternative energy source to coal for energy production. And it indicated that the environmental impacts of generating 1 MJ energy from rice husks were less than that from coal in global warming, acidification, and eutrophication categories, decreased by 97%, 88%, and 80%, respectively. It can be attractive that substituting fossil fuel partly with rice husk will not only improve the environmental performance of the systems studied but also solve the agricultural by-product rice husk disposal problem. Based on the fact that biomass, as a good resource with characteristics of renewability and low pollution, however discourages most enterprises due to its low energy density and high transportation costs, numerous researches have been performed to improve its practicality. For example, Thengane et al. (2020) assessed the life cycle emissions of processing rice husk into torrefied pellets for energy generation in different reaction conditions, and highlighted the techno-economic prospects for decentralized torrefaction facilities at rice mills. Moreover, Unrean et al. (2018) compared three different rice husk-to-fuel biorefinery technology-hydrothermal carbonization with pelletization, pyrolysis, and anaerobic co-digestion process in aspects of techno-economic performance and environmental impacts and drew the conclusion that compared with direct combustion for combined heat and power, these conversion technologies had lower impacts on global warming, photochemical oxidation, and acidification based on the LCA results. It suggests that co-product utilization combined with biorefinery technologies will bring it more competitive than fossil-based and direct combustion-based processes.

In this paper, the environmental performance of rice bran oil production was evaluated to provide reference for cleaner production of related edible oil industry. It can be concluded that the production, mining, and use of electricity and coal are the major reasons for most of the environmental burden, which enlightens us to improve the overall eco-friendliness by improving or upgrading related production technology, and using clean alternative energy. The transformation of the new energy structure based on clean energy and renewable energy power generation methods will bring unprecedented challenges.

Conclusion

This study evaluated environmental impact of rice bran oil production using life cycle thinking from the transportation of raw materials to the finished products before factory. The LCA results indicated that the oil refining stage had the largest environmental impact, followed by the oil extraction stage, slightly lower at the same order of magnitude. It can be ascribable to the high demands for coal and electricity, which turned out to be the dominant contributors to the most impact categories. To relieve these impacts, modifying the electricity source, for example, increasing proportion of electricity from hydro power and solar photovoltaic, rather than traditional coal-fired ones, and substituting the fuel used in the boiler and heat exchanger systems with biogas can be beneficial.

As a supplement to the research studies on cleaner production of edible oil industry, this research takes the unit operations that constitute the processes into account, rather than regarding the industrial process as a “black box,” enhancing the transparency and reproducibility. Based on the LCA results, it is expected to provide references for enterprises to make decisions on the transformation of energy structure to clean energy.

Data availability

Not applicable.

References

Ben-Othman S, Jõudu I, Bhat R (2020) Bioactives from agri-food wastes: present insights and future challenges. Molecules 25:510

Bommarco R, Kleijn D, Potts SG (2013) Ecological intensification: harnessing ecosystem services for food security. Trends Ecol Evol 28:230–238

Bórawski P, Bełdycka-Bórawska A, Szymańska EJ, Jankowski KJ, Dubis B, Dunn JW (2019) Development of renewable energy sources market and biofuels in The European Union. J Clean Prod 228:467–484

De Marco I, Riemma S, Iannone R (2018) Uncertainty of input parameters and sensitivity analysis in life cycle assessment: an Italian processed tomato product. J Clean Prod 177:315–325

Friedman M (2013) Rice brans, rice bran oils, and rice hulls: composition, food and industrial uses, and bioactivities in humans, animals, and cells. J Agric Food Chem 61:10626–10641

Gallyas F, Lee S, Yu S, Park HJ, Jung J, Go G-W, Kim W (2019) Rice bran oil ameliorates inflammatory responses by enhancing mitochondrial respiration in murine macrophages. PLoS ONE 14:10

Ghasemzadeh A, Baghdadi A, Z E Jaafar H, Swamy MK, Megat Wahab PE (2018) Optimization of flavonoid extraction from red and brown rice bran and evaluation of the antioxidant properties. Molecules 23, 1863.

Gul K, Yousuf B, Singh AK, Singh P, Wani AA (2015) Rice bran: nutritional values and its emerging potential for development of functional food—a review. Bioactive Carbohydrates and Dietary Fibre 6:24–30

Hou H, Shao S, Zhang Y, Kang H, Qin C, Sun X, Zhang S (2019) Life cycle assessment of sea cucumber production: a case study, China. J Clean Prod 213:158–164

Kalhor P, Ghandi K (2019) Deep eutectic solvents for pretreatment, extraction, and catalysis of biomass and food waste. Molecules 24:4012

Khanali M, Mousavi SA, Sharifi M, Keyhani Nasab F, Chau K-W (2018) Life cycle assessment of canola edible oil production in Iran: a case study in Isfahan province. J Clean Prod 196:714–725

Khatri P, Jain S (2017) Environmental life cycle assessment of edible oils: a review of current knowledge and future research challenges. J Clean Prod 152:63–76

Khatri P, Jain S, Pandey S (2017) A cradle-to-gate assessment of environmental impacts for production of mustard oil using life cycle assessment approach. J Clean Prod 166:988–997

Lai WT, Khong NMH, Lim SS, Hee YY, Sim BI, Lau KY, Lai OM (2017) A review: Modified agricultural by-products for the development and fortification of food products and nutraceuticals. Trends Food Sci Technol 59:148–160

Lai O-M, Jacoby JJ, Leong W-F, Lai W-T (2019) Chapter 2 - Nutritional studies of rice bran oil, in: Cheong, L.-Z., Xu, X. (Eds.), Rice bran and rice bran oil. AOCS Press, pp. 19–54.

Liu J, Li YP, Huang GH, Zhuang XW, Fu HY (2017) Assessment of uncertainty effects on crop planning and irrigation water supply using a Monte Carlo simulation based dual-interval stochastic programming method. J Clean Prod 149:945–967

Ma X, Wang Y, Wang C (2017) Low-carbon development of China’s thermal power industry based on an international comparison: review, analysis and forecast. Renew Sustain Energy Rev 80:942–970

Notarnicola B, Sala S, Anton A, McLaren SJ, Saouter E, Sonesson U (2017) The role of life cycle assessment in supporting sustainable agri-food systems: a review of the challenges. J Clean Prod 140:399–409

Park H-Y, Lee K-W, Choi H-D (2017) Rice bran constituents: immunomodulatory and therapeutic activities. Food Funct 8:935–943

Perez-Ternero C, Alvarez de Sotomayor M, Herrera MD (2017) Contribution of ferulic acid, γ-oryzanol and tocotrienols to the cardiometabolic protective effects of rice bran. Journal of Functional Foods 32:58–71

Prasad S, Singh A, Korres NE, Rathore D, Sevda S, Pant D, (2020) Sustainable utilization of crop residues for energy generation: a life cycle assessment (LCA) perspective. Bioresource Technology 303, 122964.

Quispe I, Navia R, Kahhat R (2019) Life Cycle Assessment of rice husk as an energy source. A Peruvian case study. J Clean Prod 209:1235–1244

Rico X, Gullon B, Alonso JL, Yanez R (2020) Recovery of high value-added compounds from pineapple, melon, watermelon and pumpkin processing by-products: An overview. Food Research International 132, 109086.

Samad N (2015) Rice bran oil prevents neuroleptic-induced extrapyramidal symptoms in rats: possible antioxidant mechanisms. J Food Drug Anal 23:370–375

Soussana J-F (2014) Research priorities for sustainable agri-food systems and life cycle assessment. J Clean Prod 73:19–23

Thengane SK, Burek J, Kung KS, Ghoniem AF, Sanchez DL (2020) Life cycle assessment of rice husk torrefaction and prospects for decentralized facilities at rice mills. J Clean Prod 275:123177

Tsarouhas P, Achillas C, Aidonis D, Folinas D, Maslis V (2015) Life Cycle Assessment of olive oil production in Greece. J Clean Prod 93:75–83

Tukker A, Jansen B (2006) Environmental impacts of products: a detailed review of studies. J Ind Ecol 10:159–182

Unrean P, Lai Fui BC, Rianawati E, Acda M (2018) Comparative techno-economic assessment and environmental impacts of rice husk-to-fuel conversion technologies. Energy 151:581–593

Wang C, Engels A, Wang Z (2018) Overview of research on China’s transition to low-carbon development: the role of cities, technologies, industries and the energy system. Renew Sustain Energy Rev 81:1350–1364

Wang C, Cheng X, Shuai C, Huang F, Zhang P, Zhou M, Li R (2020) Evaluation of energy and environmental performances of solar photovoltaic-based targeted poverty alleviation plants in China. Energy Sustain Dev 56:73–87

Wimbadi RW, Djalante R (2020) From decarbonization to low carbon development and transition: a systematic literature review of the conceptualization of moving toward net-zero carbon dioxide emission (1995–2019). J Clean Prod 256:120307

Yuan Q, Song G, Fullana-i-Palmer P, Wang Y, Semakula HM, Mekonnen MM, Zhang S (2017) Water footprint of feed required by farmed fish in China based on a Monte Carlo-supported von Bertalanffy growth model: a policy implication. J Clean Prod 153:41–50

Zhang H, Sun H, Zhou S, Bai N, Zheng X, Li S, Zhang J, Lv W (2019) Effect of straw and straw biochar on the community structure and diversity of ammonia-oxidizing bacteria and archaea in rice-wheat rotation ecosystems. Sci Rep 9:9367

Zhao L, Ji Y, Yao J, Long S, Li D, Yang Y (2017) Quantifying the fate and risk assessment of different antibiotics during wastewater treatment using a Monte Carlo simulation. J Clean Prod 168:626–631

Acknowledgements

The authors warmly thank Dr. Haochen Hou for the technical support in Monte Carlo simulations.

Funding

This study was supported by the General Project of the Natural Science Foundation of Liaoning Province (2019-MS-044).

Author information

Authors and Affiliations

Contributions

Lihui Sun: Conceptualization; Project administration; Roles/Writing — original draft; Writing — review and editing;

Yuying Wang: Roles/Writing — original draft; Investigation; Data curation;

Yuqing Gong: Resources; Validation;

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Loubet

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sun, LH., Wang, YY. & Gong, YQ. Life cycle assessment of rice bran oil production: a case study in China. Environ Sci Pollut Res 29, 39847–39859 (2022). https://doi.org/10.1007/s11356-021-18172-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-18172-0