Abstract

The atmosphere security and regulation of climate change are being continuously highlighted as a pressing issue. The crisis of climate change owing to the anthropogenic carbon dioxide emission has led many governments at federal and provincial levels to promulgate policies to address this concern. Among them is regulating the carbon dioxide emission from major industrial sources such as power plants, petrochemical industries, cement plants, and other industries that depend on the combustion of fossil fuels for energy to operate. In view of this, various CO2 capture and sequestration technologies have been investigated and presented. From this review, adsorption of CO2 on porous solid materials has been gaining increasing attention due to its cost-effectiveness, ease of application, and comparably low energy demand. Despite the myriad of advanced materials such as zeolites, carbons-based, metal-organic frameworks, mesoporous silicas, and polymers being researched, research on activated carbons (ACs) continue to be in the mainstream. Therefore, this review is endeavored to elucidate the adsorption properties of CO2 on activated carbons derived from different sources. Selective adsorption based on pore size/shape and surface chemistry is investigated. Accordingly, the effect of surface modifications of the ACs with NH3, amines, and metal oxides on adsorption performance toward CO2 is evaluated. The adsorption performance of the activated carbons under humid conditions is also reviewed. Finally, activated carbon-based composite has been surveyed and recommended as a feasible strategy to improve AC adsorption properties toward CO2.

Graphical abstract

The activated carbon surface in the graphical abstract is nitrogen rich modified using ammonia through thermal treatment. The values of CO2 emissions by sources are taken from (Yoro and Daramola 2020).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

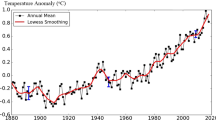

Globally, about 85% of the world energy need is supplied by fossil fuels combustion which is known to contribute to the increasing greenhouse gases concentration in the atmosphere (Nanda et al. 2015) (Rackley 2009). Although carbon dioxide (CO2) has the least global warming potential (GWP) of 1, when compared with the other greenhouse gases such as methane (21GWP) and nitrous oxide (310GWP), CO2 is considered the major culprit in the recent climate change, since the CO2 content has been elevated dramatically from 340 ppm in 1980 to 415 ppm in 2020 and expected to reach 570 ppm by 2100 (Yang et al. 2008) (Oh 2010) (ESRL 2019) (Yaumi et al. 2017a) (Leung et al. 2014). High greenhouse gases emissions (particularly CO2) allegedly contribute to ocean acidification and the earth temperature increase. At the current rate of the emission without abatement, it is anticipated that the temperature will increase by 1.9 °C in 2100 (Yang et al. 2008) (Saxena et al. 2014) which portends a spectre of adverse global implication such as climate change, intense rainfall, frequent heat waves and rising sea level. Consequently, Carbon Capture and Storage (CCS) technologies are reportedly in a dire need in order to reverse the effect of CO2 emission and conserve the environment (Ghiat and Al-Ansari 2021) (Nocito and Dibenedetto 2020). With CCS, the captured CO2 can be potentially employed in various applications such as enhanced oil recovery, production of chemicals, polymers, and cosmetics (Shi et al. 2015) (Zhang et al. 2020) (De Falco et al. 2016) (Von Der Assen and Bardow 2014). Continuous efforts to capture CO2 using established technologies have been deployed in laboratories and commercial sites. These technologies are absorption (physical and chemical separation) (Salvinder et al. 2019), adsorption (Abd et al. 2020b), cryogenic (Song et al. 2019), and membrane (Ma et al. 2020a) separations. Extensive experimental and computational investigations have been exhibited to evaluate the advantages/disadvantages of each technique. Out of the mentioned techniques, the chemical absorption using amines has been found to be industrially attractive in power and sweetening plants (Rochelle 2009) (Abd and Naji 2019) due to its high level of purity and recovery. Despite the application of the amine absorption method can attain CO2 removal up to 98% (Yeh et al. 2005), the drawbacks of this technology are high energy penalty (Abd et al. 2020a), corrosion issues (Abd et al. 2019), and a large quantity of absorber requirements (Yeh et al. 2005). Therefore, to alleviate the mentioned inherent issues related to amines chemical absorption, adsorption using solid materials has been recommended and investigated.

Many categories of porous solid materials were developed as CO2 adsorbents, among which include zeolites (Kumar et al. 2020), activated alumina (Mohammad et al. 2019), silica gel (Shen et al. 2018), pillared clays (Vilarrasa-García et al. 2017), carbon nanotubes (Lourenço et al. 2021), inorganic and polymeric resins (Meng et al. 2019), porous metal-organic frameworks (Younas et al. 2020), as well as activated carbons (Ho et al. 2021). Out of these porous materials, activated carbons, zeolites, metal organic frameworks have been reported to be efficient adsorbents for CO2 removal (Khan et al. 2021) (Peredo-Mancilla et al. 2019) (Bacsik et al. 2016). Zeolites and metal-organic frameworks adsorbents, however, suffer from some shortcomings like low thermal stability and low performance in presence of moisture. It is well-known that the activated carbons adsorbents possess a higher adsorption capacity in comparison to zeolite-based adsorbents (Pellerano et al. 2009). The interaction between the entrapped CO2 molecules and the adsorbent surface is weak, making the regeneration process easier (Hauchhum and Mahanta 2014). Although the weak interaction over the activated carbons makes them very sensitive to the temperature range, appropriate surface modification can alleviate this issue. Therefore, activated carbons are considered as potential porous materials for CO2 capture with high adsorption capacity and selectivity. Furthermore, activated carbons have other applications in different areas like supercapacitors, catalysis, and wastewater treatment (Stenny Winata et al. 2020) (Zhang et al. 2021) (Sadeek et al. 2020). Heretofore, there are review papers on activated carbons for adsorption of dyes and other hazardous materials that have been published previously, a review on the application of activated carbon, especially for carbon dioxide capture has not been made before. In this work, the contemporary ACs which have been deployed for CO2 adsorption, their preparation techniques, CO2 adsorption capacity, selectivity, strategies to enhance CO2 adsorption, and the impact of water presence on the ACs stability and performance are elucidated.

Activated carbon as CO2 adsorbent

Activated carbons (ACs) are broadly applied as adsorbents in CO2 capture owing to their high surface area and adsorption capacity. The large diversity of sources such as coal, char, peat, petroleum coke, lignite, wood, and other biomass sources can be employed to synthesize activated carbon materials. ACs precursors should possess high carbon and low ash contents, low volatiles matters, and low degradation tendency to keep the physiochemical characteristics (Manocha 2003)(Moreno-Castilla and Rivera-Utrilla 2001) (McDougall 1991) (Herawan et al. 2013). Thus, the selection of appropriate feedstock materials for ACs production considerably influences the properties of the activated carbon (Olivares-Marín et al. 2011). The main features that grabbed the attention to the ACs as CO2 adsorbents are their well thermal and chemical stability, their exceptional thermal conductivity, and low precursors cost. Besides, ACs have meso/micro-porous structure with fast adsorption and low energy demand for the regeneration process. The salient characteristic of the ACs over other adsorbents is the readily availability of raw materials with low cost in which helps in the production of a wide range of ACs adsorbents.

These auspicious features introduce ACs as attractive porous adsorbents for CO2 capture with high adsorption capacity (Zhao et al. 2018). This review examines the application of ACs for CO2 adsorption and removal from gas mixtures. Furthermore, the authors elaborate the adsorption and preparation mechanisms along with the limitation of applying this class of adsorbent for CO2 separation.

CO2 adsorption via the ACs

Selectivity of CO2 in gases mixture

Selectivity is a key parameter of assessment the adsorption performance of an adsorbent in a gas mixture. Specifically, selectivity is the mole ratio between the entrapped CO2 on the AC surface to that in the feed stream, unadsorbed at the breakthrough time (Kim and Suh 2011). CO2 removal process from other gases such as CO2/N2 in post-combustion, CO2/H2 in pre-combustion, CO2/O2 in air purification, and CO2/CH4 in natural gas sweetening and biogas upgrading are of significant importance in the industry. Some features of gases mixtures constituents considerably aid in achieving the separation such as kinetics diameter of gas molecule, and their electric properties. With respect to Table 1, adsorbent preparation for high-performance CO2 adsorption should have a compatible pore structure for CO2 molecules over other gases molecules. The CO2 capture from a gas mixture is governed by the ideal gas law that is strongly related to both temperature and pressure. Thus, the kinetic diameter and critical properties are major factors in the capture of CO2 from a mixture of gases. Adelodun and Jo (2013) reported that the diameters of CO2 and N2 molecules are smaller than most of the pores of AC surfaces (Adelodun and Jo 2013) which allows CO2 molecules to penetrate freely and attach to the wall of pores (Adelodun et al. 2014a). To elucidate selectivity further, it is important to primarily enlighten the principles, methods, and mechanisms entailed in adsorptive gas separation.

Principles and techniques of gas adsorption

Separation is a technology to detach the constituents of a mixture, this process often needs high energy for splitting the compositions of a mixture (Ducroux and Jean-Baptiste 2005). Likewise, separation can be achieved for a specific component in the mixture, and this attains when the components possess different affinities to the used adsorbent. Gases separation technologies include membrane technology, absorption processes, adsorption processes, and cryogenic technology (Abd et al. 2020b) (Eimer 2005). Among mentioned technologies, the adsorption method is an attractive choice by virtue of the high removal capacity, low energy demand, safe and easy maintenance, design flexibility, and environment friendly (Satyapal et al. 2001) (Liu et al. 2020a) (Abd et al. 2020b) (Keshavarz et al. 2021).

Adsorption technology comprises two main processes namely adsorption and regeneration or desorption. Through the adsorption step, a mixture of gases is passed over the adsorbent bed at specific operation conditions to adsorb the target component, then this step ensued by the regeneration step in which the entrapped gas is separated from the adsorbent and recycled the adsorbent for another cycle (Shah et al. 2020) (Ünveren et al. 2017). The adsorption process is therefore highly related to the desorption technology to regenerate the adsorbent. Various cyclic adsorption techniques are employed in gases adsorption such as inert purge cycles, the displacement cycles, pressure swing adsorption (PSA) (Abd et al. 2021), temperature swing adsorption (TSA) (Verougstraete et al. 2020), vacuum swing adsorption (VSA), and electric swing adsorption (ESA) (Grande and Rodrigues 2008). Although all the mentioned technologies are expedient for CO2 capture, PSA and TSA are more widely applied in CO2 removal. PSA employs high pressure to enforce CO2 molecules attach to the adsorbent surface then reducing pressure will free the CO2 molecules again at the desorption step. VSA is a recent technology adsorb CO2 at a pressure close to the ambient pressure. By contrast, TSA is applied hot steam to heat the adsorbent for CO2 capture and diminish the heat for the desorption process. PSA and VSA have some advantages over TSA like very fast adsorption (can happen in seconds up to a minute), low energy requirements, PSA can be used for bulk adsorption, and low operation cost.

It is important to notice that gas adsorption can achieve when different constituents of the adsorbent possess diverse abilities to capture. Furthermore, auspicious adsorbent should display appropriate features like high selectivity towards CO2, high loading capacity, and regenerability together with promising capture kinetics.

Mechanism of selective adsorption

Gas adsorption separation occurs over porous solid adsorbents into four different mechanisms such as molecular sieve impact, dynamic impact, kinetic impact, and quantum sieve impact. Intrinsically, it is authenticated that gas adsorption can happen through one or more mechanisms based on the surface nature of the used adsorbent (Keller and Staudt 2005) (Yang 2003).

Molecular sieve impact

The adsorption occurs according to the shape and size (kinetic diameter and collision distance) of the CO2 molecules. The kinetic diameter or collision distance is the closest distance or diameter between two molecules with zero kinetic energy that can approach each other, and collision happens. According to previous studies, this impact commonly occurs with both zeolite and carbon molecular sieve adsorbents (Davarpanah et al. 2020) (Morali et al. 2020). It is worth mentioning that operating conditions like temperature considerably influences the surface morphology of the adsorbent, this mechanism is therefore strongly related to the process temperature (Li et al. 2009).

Dynamic impact

It is applicable when the pores over the adsorbent surface are large; accordingly, all the gas mixture constituents can be through the inner wall of the adsorbent. Afterwards, the interaction between the target molecules and the adsorbent surface has a vital role to play in selective adsorption. That is strongly dependent on the adsorbate molecule and adsorbent surface nature such as polarizability, magnetic susceptibility, the permanent dipole moment, and the quadrupole moment (Mallesh et al. 2020) (Guo et al. 2020a).

Kinetic impact

This mechanism introduces when the dynamic mechanism is not applicable. The important issue in the kinetic separation is that the pore size of adsorbent should be controlled accurately between the kinetic diameters of the two molecules that require to be separated. The application of this mechanism is commonly employed in the capture of CO2 and CH4 gases via applying molecular sieve adsorbent as well as the separation of air using zeolite (Rocha et al. 2017) (Yang et al. 2019).

Quantum sieve impact

The adsorption with this mechanism is perfumed given the differences in diffusion speeds of the guest molecules and compatibility of the pore diameter with the de Broglie wavelength of these molecules. This impact can be specifically effective for isotopic separation such as H2/D2 separation (Garberoglio 2009) (Li et al. 2009).

Adsorbent selection benchmarks

Adsorbent selection significantly controls the adsorption performance and selectivity. Typically, the superior adsorbent is the one that possesses high adsorption capacity and selectivity towards the target constituent. For proper selection, the followings are to be considered: adsorbent nature and properties, and the adsorption technique. For bulk separation, the adsorbent should be selected on the basis of ease of regeneration. If the adsorption technique is not considered, the adsorption nature is the main benchmark for the selection of the proper adsorbent comprising the size and shape of the target molecule, the dipole moment, the quadrupole moment, and the polarizability. For instance, when the target molecule has a high dipole moment, the ideal adsorbent should possess a high polarized surface. Whereas, if the molecule has a high quadrupole moment, the surface of adsorbent should possess a high electric field gradient. By contrast, an adsorbent with a high surface area is compatible with the molecule with high polarizability (Yang 2003). Generally, the adsorption can occur physically via Van der Waals forces and/or chemically through the formation of a chemical bond between the target molecule and the adsorbent surface (Abd et al. 2020b).

As things stand now, the material of adsorbent should present some important characteristics to trade off the economic and the operational of adsorption separation which can be illustrated as i) high uptake capacity, ii) high selectivity, iii) fast adsorption/regeneration kinetics, iv) adequate mechanical strength, v) low material cost, vi) high surface area, vii) compatible pore size and relevant distribution, and viii) low heat of adsorption (Samanta et al. 2012). These features are desirable for ideal adsorbent material, however, scarcely can be presented in a single adsorbent.

The effect of AC on selective capture of CO2

Heretofore, various studies about the application of porous materials as adsorbents in gas separation processes have been presented and used (Férey 2008) (Chuah et al. 2020) (Kamran and Park 2021) (Modak and Jana 2019) (Hedin et al. 2013). Many studies have been exhibited and reported that ACs adsorbents are one of the best class of porous materials for adsorption of CO2 owing to the abundant raw materials with low cost, high specific surface area, and high adsorption features (Pardakhti et al. 2019) (Zhou et al. 2017) (Serafin et al. 2021). Besides, unlike zeolites and metal-organic frameworks adsorbents, ACs are hydrophobic and offer high stability in presence of water (González et al. 2013) (Majchrzak-Kucȩba and Nowak 2005) (Díaz et al. 2008). The main criterion of selecting an appropriate ACs adsorbent for CO2 capture is that the ACs pore diameter should match the kinetic diameter of the CO2 molecule. From this perspective, design the ACs structure based on this criterion can significantly enhance the CO2 uptake capacity and the selectivity. In a general sense, ACs adsorbents can be categorized based on their activation method into two types of physically activated carbons (pACs) and chemically activated carbons (cACs). The pACs adsorbents generally maintain the shape and texture of the raw material with a surface area up to 2000 m2/g (Kwiatkowski and Broniek 2017). Whereas cACs adsorbents possess high pore capacity and large surface area with controllable porosity (Fierro et al. 2007) (Sreńscek-Nazzal et al. 2013). Majority of ACs adsorbents are chemically activated that can reduce the losses in the raw materials and minimize tar production. In the subsequent section, the categories of ACs for CO2 capture are investigated.

Selective capture of CO2 using physically and chemically ACs

Various physically and chemically activated carbons adsorbents as depicted in Tables 2 and 3 have been employed in the CO2 capture to date. The selective capture can be attained on the basis of i) molecular sieve impact, ii) the interaction between CO2 molecules and adsorbent surface, and iii) the combination of both impacts.

Nowicki et al. (2015) compared the texture properties of physically and chemically activated carbons from the same precursor of cherry stones (Nowicki et al. 2015). They reported that the chemically activation produced porous carbon surface with high surface area of 1173 m2/g compared with physically activated carbon of 361 m2/g. Besides, it was noticed that the micropores volume on the chemically activated carbon to the total pores volume was in-between 0.95 and 0.96. Comparatively, the mesopores were the highest contributor on the surface of the physically activated carbon. Furthermore, the results revealed that the surface of the physically activated carbon was basic with pH range of 9.1 to 9.9, while the chemically activated carbon surface was acidic with pH up to 5.6. The same findings shared by (Yacob et al. 2014), proved that chemical activation is a promising technology for design high surface area porous materials compared to physically activation. Based on Tables 2 and 3, the chemically activated carbons possess higher CO2 uptake in comparison to the physically activated carbons; these high uptakes of chemical activated carbons can be assigned to the high surface area and the O functionalities groups on the adsorbent surface.

Capture of CO2 over activated carbon on the basis of size/shape

Many ACs adsorbents are feasible for the adsorption of different gases based on size and shape (Foley 1995) (Burchell et al. 1997) (Silvestre-Albero et al. 2011) (Demiral and Demiral 2018). This means that the molecule can pass via the pores only if the kinetic diameters of both the adsorbate molecule and the pore are tunable as shown in Fig. 1 (Casco et al. 2014). Wilcox et al. (2014) reported that whenever the diameters of the adsorbent pore and CO2 molecule are matchable, the CO2 molecules will never evade the adsorbent surface (Wilcox et al. 2014). In CO2 adsorption at atmospheric pressure and temperature, the narrower micropore with a size less than 1 nm is suitable, since it helps in keeping the CO2 molecule into the pore wall (Chen et al. 2013) (Plaza et al. 2012) (Sevilla et al. 2012) (Sevilla and Fuertes 2011b). Besides, the pore size less than 1 nm can possess high selectivity towards CO2 molecules in a mixture of N2/CO2, since it will prevent the passage of the N2 molecules through the pore wall (Liang et al. 2019). By contrast, small pore size has low adsorption performance because it is closer to the kinetic diameter of the CO2 molecule (around 0.33 nm) (Deng et al. 2015). Whereas, the pore size of more than 1 nm is not desirable for CO2 capture at low pressures, because dense pack of the CO2 molecules may not be achieved (Wei et al. 2012). With this in mind, structural analyses are essential to describe the concept of adsorption based on pore size and shape. For example, Ello et al. (2013) elucidated the application of synthesis high ultra-micropores volume in the removal of CO2 at low pressures (Ello et al. 2013). Although C600K5 sample had the largest surface area of 1890 m2/g compared with C600K3 sample of 1250 m2/g, its CO2 loading was 4.2 mmol/g lower than the adsorption capacity of C600K3 sample of 4.4 mmol/g. This can be attributed to the impact of pore volume and structure in which C600K5 was 0.28 cm3/g and 0.29 cm3/g for C600K3. Likewise, Zhu et al. (2014) introduced similar results whereby AC from sawdust that possessed the highest surface area of 2435 m2/g was ineligible for capture a large amount of CO2, because of the low micropore volume that comprises only 29 % from the total pores volumes (Zhu et al. 2014). By contrast, another AC prepared from sawdust with surface area up to 1643 m2/g had CO2 uptake of 8 mmol/g owing to the high micropores volumes of 78%. Hence, it can be concluded that the rate of micropores volume on the surface of the AC is a major contributor to the adsorption performance of CO2.

Morali et al. (2019) modified a commercial AC surface by decomposition of methane to form narrow micropores that are compatible to capture CO2 with high adsorption capacity up to 1.7275 mmol/g at 273 K and 1 bar (Morali et al. 2019). Hence, the modified surface structure improved the selectivity of CO2 over N2 up to 22.84 with 40.37 kJ/mol heat of adsorption. It is confirmed that the uptake rate of the excluded gases like CH4 was almost zero. Herein the selective capture of CO2 was attained due to the existence of narrow-micropores (Morali et al. 2019). Other examples are CMS-1 and CMS-A that are employed for selective capture of CO2 over CH4 on the basis of size and shape exclusion (Song et al. 2017) (Song et al. 2018). These adsorbents can be convenient for the selective adsorption of CO2 over CH4 particularly in biogas upgrading and natural gas sweetening. In this sense, Canevesi et al. (2018) studied the upgrading of biogas mixture using the concept of molecular sieve impact for enhancing the selection of CO2 over CH4 (Canevesi et al. 2018). The results revealed that this type of adsorbent possessed an excellent selectivity and high CO2 adsorption capacity with biomethane purity up to 97.5% and recovery of 90% at 5 bar and 298 K. Furthermore, Zhang et al. (2013) studied the relation between the pore size and the CO2 uptake at different temperatures over AC prepared from polyaniline and KOH as activation agent (Zhang et al. 2013). They concluded that the CO2 uptake capacity of the prepared AC considerably relied on the fine pore size more than the surface area and/or pore volume. Also, they reported that the pore size less than 0.54 nm exhibited high CO2 adsorption at high temperature like 75 °C which can be compatible to adsorb CO2 from a hot stream. Moreover, Sethia and Sayari (2015) prepared a strict micropores AC surface for CO2 adsorption with rich nitrogen surface content up to 22 wt.% (Sethia and Sayari 2015). The modified adsorbent had a great adsorption performance with a capacity of 5.39 mmol/g at 298 K and 1 bar. They assigned this performance to the tunable pore size with CO2 molecule kinetic diameter and high nitrogen content on the adsorbent surface. Likewise, Alabadi et al. (2015) developed a high surface area with a suitable pore size for CO2 capture using direct carbonization under N2 in a tubular reactor (Alabadi et al. 2015). The adsorbent had a significant CO2 loading of 7.49 mmol/g at 273 K due to the exceptional micropore structure.

Capture of CO2 over activated carbon on the basis of interaction between CO2 and adsorbent

The second essential parameter for the selective capture of CO2 is the interaction forces between the adsorbate molecule and the surface of the porous material. Accordingly, in some ACs adsorbents, the adsorption can be attained on the basis of the kinetic or thermodynamic equilibrium impact. Thus, the selective adsorption is following the adsorbate features like H-bonding, polarity, quadruple moment, and the surface properties of the adsorbent. For CO2/CH4 mixture, the adsorption happens on the basis of the large quadrupole moment of CO2 whereas the CH4 molecule is nonpolar. Singh et al. (2019b) prepared PAN-AC via carbonization and chemical activation using four activation agents (Singh et al. 2019c). They conducted that the selectivity for CO2 is high due to the kinetic impact and the quadruple moment of CO2. Also, Sugiyama and Hattori (2020) fluorinated pitch-based activated carbon in a temperature range from 25 to 200 °C to modify the microporosity and improve the interactions between the weakened C-F bonds and CO2 molecules (Sugiyama and Hattori 2020). They found that the modified adsorbent presented an excellent selectivity and high CO2 adsorption capacity. Wang et al. (2016) exhibited a comprehensive study to elucidate the importance of surface chemistry properties on the CO2 loading and the selectivity in the CO2/CH4 mixture (Wang et al. 2016). They functionalized AC surface with different functional groups like −OH groups, −CO groups, and −COOH groups and compared the selectivity towards CO2 with and without these groups to evaluate the impact of the electrostatic interaction under different pressures. Their results revealed the presence of electrostatic interaction improves the CO2/CH4 selectivity and enhance the adsorption rate. Besides, Sánchez-Sánchez et al. (2014) stated that the presence of electrostatic interaction can play a vital role in supporting the adsorption at high adsorption temperature (Sánchez-Sánchez et al. 2014).

Guo et al. (2021) developed a porous activated carbon from poplar sawdust through two activation steps namely high sulfur content-waste liquid ensued by second activation using K2C2O4 (Guo et al. 2021). They successfully modified rich S, N, O porous AC with high CO2 loading performance and selectivity. They measured the CO2 adsorption capacity before (1.99 mmol/g) and after (2.56 mmol/g) doping the surface of the activated carbon with sulfur waste liquid. This increase in adsorption capacity can be ascribed to the heteroatoms impact that resulted from the introduction of surface functionalities such as -OH, S, N. The presence of -OH groups manipulates the electron distribution on the carbon surface and generates H2-bonds with the CO2 molecules (Hong et al. 2019). Besides, the introduction of oxidation state S and N can improve the CO2 capture through the interaction of these groups and the CO2 molecules (Seema et al. 2014) (Wu et al. 2020). Therefore, the interaction between CO2 molecule and the surface of the AC can play a vital role in the enhancement of the selectivity towards CO2.

Capture of CO2 over activated carbon on the basis of size/shape exclusion and interaction between CO2 and adsorbent

Besides the impact of pore size/shape and the interaction between adsorbate and adsorbent, some ACs can selectively capture the target molecule based on both impacts. In order to describe the adsorption of CO2 via this impact, Wang et al. (2016) introduced a good example to evaluate the combination of both pore size and adsorbent/adsorbate interaction impacts for CO2 adsorption by preparing AC with various pore sizes and different surface chemistry features (Wang et al. 2016). The selectivity for capture CO2 over CH4 was much higher owing to two mechanisms: i) tunable pore size with the kinetic diameter of the CO2 molecule, ii) presence of electrostatic interaction, since quadrupole moment of CO2 molecule enhanced the interaction and improved the adsorption energy. PSS550 and PS550 (Igalavithana et al. 2020) are the other worthy illustrations of ACs adsorbents that can selectively entrap CO2 on the basis of both impacts. They reported that both ACs possessed a high affinity to capture CO2 in comparison to N2 which can be assigned to the effects of pore size and the considerable interaction of CO2 molecule and adsorbent that arose from the high N containing functional groups. Dilokekunakul et al. (2020) synthesized an AC from bamboo waste via heat treatment and modified to enrich the surface with O2/N2 groups by integration using urea, air, and KOH activation (Dilokekunakul et al. 2020). They stated that the prepared ACs showed high CO2 adsorption capacity and selectivity due to the interaction between CO2 molecule and N-functional group, along with the compatible pore size.

Park et al. (2021) designed highly porous carbon adsorbent for CO2 adsorption from three different gases mixtures namely CO2/CH4, CO2/H2, and CO2/N2 under both pre-/post-combustion conditions (Park et al. 2021). The developed adsorbent afforded a conspicuous adsorption performance with CO2 uptake up to 22.1 mmol/g at 25 bar and excellent selectivity over other gases. The significant CO2 uptake and the excellent selectivity can be ascribed to the very high surface area (3010 m2/g), total pore volume (1.053 cm3/g), and the considerable O content on the surface of the carbon adsorbent which provides a catchy functional surface functional groups to the CO2 molecules. Likewise, the ACs possess high potential for CO2 adsorption owing to the stability of their pores features like shapes, sizes, and surface characteristics. These outstanding characteristics are attained through various modifications technologies which are discussed in Section 6.

CO2 adsorption capacity

Adsorption capacity is considered as the most imperative characteristic in rating the adsorption performance that is highly related to the surface area and pore size/shape of the adsorbent. Because of their high surface area, activated carbons possess high CO2 loading in comparison to other adsorbents like zeolites. Along with surface area, CO2/adsorbent surface interactions, and temperature and pressure exert an effect on the CO2 loading rate (Rehman et al. 2021) (Melouki et al. 2020). Extensive research has been carried out about this area, and the majority are based on the gravimetric capacity which is estimated as the weight percent of CO2 gas to the total weight of the system. Zhou et al. (2018) exhibited a study to investigate the relationship between the feedstock and surface area/CO2 uptake on five ACs with different properties and features including BAC-650, RHC-650, PSC-600, CSC-650, and ANC-700 (Zhou et al. 2018). All the CO2 adsorption capacities were measured at the same temperature and pressure of 273 K and 1 bar. The findings established that out of the mentioned ACs, RHC-650 possessed the highest CO2 loading with 7.55 mmol/g. One of the best-recorded amounts of CO2 loading belongs to activated mesopores biocarbon (30.2 mmol/g) at 30 bars. This remarkable CO2 loading is associated with an ultra-high surface area of 3298 m2/g that presented by (Singh et al. 2017). Singh et al. (2019a, 2019b) presented the MPCs with the highest CO2 loading value of 39.1 mmol/g at 30 bars and 273 K (Singh et al. 2019a). The BET surface area of the proposed adsorbent was 3617 m2/g, and the pore volume was 2.16 m3/g.

It can be concluded that the CO2 loading rate considerably depends on the surface morphology of the AC adsorbents at high pressure. Thus, one of the efficacious strategies for enhancing the rate of CO2 loading is to improve the surface area and pore volume of the ACs. Number of new ACs adsorbents that are expedient for CO2 removal at high pressure regimes are summarized in Table 4. Also, the evaluation of CO2 loading capacity at low pressure is highly important, since the CO2 partial pressure produced by the power plant flue gas is lower than atmosphere pressure. Therefore, ACs with high adsorption ability at low pressures can be employed for capture and sequestration of CO2 from power plant (Jiang et al. 2019) (Majchrzak-Kucȩba et al. 2019). Number of ACs adsorbents that are suitable for CO2 adsorption at low pressures systems are tabulated in Table 5. Besides the uptake rate and selectivity that are the most paramount factors in rating the ACs for CO2 removal, the heat of adsorption is another important parameter that will be described in the next section.

Heat of adsorption

The heat of adsorption or isosteric heat is a crucial parameter in appraising the adsorption mechanism over the ACs adsorbents and other types. Isosteric heat elucidates the ACs’ affinity to capture CO2 in which presents the strength of the interaction between the entrapped molecule and adsorbent surface. According to Zhou et al. (2018), isosteric heat is a function of the binding strength which can roughly indicate the required energy for the desorption step (Zhou et al. 2018). Zhou et al. (2018) synthesized five types of ACs using five different feedstocks to assess the impact of raw material on the CO2 adsorption performance (Zhou et al. 2018). Part of their study was the evaluation of isosteric heat of the five prepared adsorbents. The heat of adsorption was estimated using the Clausius−Clapeyron equation to adsorb CO2 isothermally at 273, 298, and 303 K as shown in Fig. 2. Three highlights can be emerged from the isosteric heat behaviors are that the heats of adsorption of the five ACs are ranging from 22 to 37 kJ/mol which were half that of chemosorption of 60 to 90 kJ/mol. It can be concluded that the adsorption of CO2 on the mentioned adsorbents was physisorption. Second, the heats of adsorption declined as the CO2 uptake increase which indicated that adsorption sites of the five ACs were heterogeneous. Third, it is observed that the heats of adsorption of the five adsorbents were different at the same CO2 loading which can be attributed to the impact of the feedstock type and properties. These findings are understood because of the ACs synthesized from different feedstocks which possessed different surface morphology.

Isosteric heats of different adsorbents (using Clausius-Clapeyron model) namely i) five ACs to capture CO2. Reprinted from (Zhou et al. 2018), ii) four ACs modified with chitosan as source of N2 to capture CO2. Reprint from (He et al. 2021), iii) four ACs modified with chitosan and TEA as source of N2 to capture CO2. Reprint from (Keramati and Ghoreyshi 2014), iv) Poly(vinylidene chloride)- AC to capture CO2. Reprinted from (Cai et al. 2014), v) metal oxide modified-AC to capture CO2. Reprinted from (Schott et al. 2017). All the figures reproduced with permissions

Also, Sreńscek-Nazzal and Kiełbasa (2019) modified three commercial chemically activated carbons using KOH and K2CO3 agents for enhancing their reactivity to adsorb CO2 (Sreńscek-Nazzal and Kiełbasa 2019). Their results shared a number of similarities with (Zhou et al. 2018) findings, they deployed the Clausius−Clapeyron equation to evaluate the isosteric heat. The heats of adsorption of the modified ACs adsorbents were ranging between 28 to 37 kJ/mol indicates the adsorption of CO2 over these adsorbents was physisorption which is related to the presence of weak Van der Waals bonds according to (Silva et al. 2016). Besides, they found that a slight decrease in heat of adsorption when the degree of surface coverage increases, which can be assigned to the strong connections between the CO2 molecules and the surface of the ACs. Furthermore, Guo et al. (2020a, 2020b) synthesized four ACs adsorbents derived from waste sugarcane bagasse for CO2 adsorption (Guo et al. 2020b). Interestingly, two ACs (AC-A and CAC-P) adsorbents showed that the heats of adsorbent increased at the point of CO2 uptake increased, and this can be attributed to the reinforced intermolecular interaction between CO2 molecules and adsorbent surface (Zhou et al. 2011). Nevertheless, the other two ACs (PAC-C and CAC-S) decreases as the CO2 uptake increases due to the inhomogeneous features of the surfaces of both adsorbents (Zhou et al. 2011). Moreover, He et al. (2021) prepared ACs adsorbents from rice husk to capture CO2 by carbonization and chemical activation using KOH (He et al. 2021). Afterwards, the synthesized adsorbents are modified using chitosan as a source for nitrogen. The heats of adsorption of the ACs before and after modification were 14.48 kJ/mol and 30.21 kJ/mol respectively. The relationship between the heat of adsorption for both ACs and the CO2 uptake are shown in Fig. 2. It is noted that the heat of adsorbents for both samples decrease as the CO2 uptake increases. The possible explanation is that at the beginning of the adsorption, active pores bind with the CO2 molecules and the heat of adsorption will be high, then the CO2 molecules will consume most of the active sites on the surface of the adsorbents and the heat of adsorption will decrease. Figure 2 summarized some other examples of the isosteric heats for various ACs with different surface modifications such as the behavior of the isosteric heats with metal oxides modification, and amines treatment. Table 6 summarizes some other studies about the heat of adsorption of various types of ACs adsorbents.

To the end, if the isosteric heat is high, it indicates that the adsorbent surface possesses a high affinity to capture CO2, as well as it delineates that the required energy for desorbing the CO2 molecules is high. Therefore, optimum ACs isosteric heat for CO2 adsorption should offer an ideal heat of adsorption to trade off the adsorption affinity and energy penalty.

Synthesis of pristine AC

Pristine activated carbons are physical or/and chemical activation of carbonaceous material with high carbon content. Firstly, the raw material is cut into small pieces and washed repeatedly to remove the unwanted particles. Afterwards, the small pieces can be fed to the pyrolysis or carbonization reactor and then the activation can take place.

Physical activation

Through physical activation, the activation agent plays a vital role in the formation of the adsorbent structure at a temperature range of 1073 to 1273 K (Kopac and Toprak 2007) (González et al. 2009) (Sajjadi et al. 2019). CO2, steam, and O2 are common activating reagents usage in the production of the ACs adsorbents. The activation agents infiltrate into the internal structure of the carbon surface and gasify the carbon atoms causing change in the pores structures by opening and widening the inaccessible pores (Dalai and Azargohar 2007). The physical activation of carbon results in an enhancement of the internal surface area and promotes the presence of O2 functional groups such as phenolic, ketonic, and carboxylic groups. Along with agent type, activation duration and temperature are major parameters through the physical activation in the configuration of the carbon surface (Hagemann et al. 2018).

CO2 among other agents is preferably used owing to its ability to produce narrow micropores that are suitable for the kinetic diameter of the CO2 molecule (Kwiatkowski and Broniek 2012); whereas the activation via steam expands the existing pores (Sajjadi et al. 2019). The creation of micropores with sizes ≈ 0.55 nm affords ample space for the CO2 molecule to allocate in the pore wall (Xu et al. 2018b). Conversely, the application of O2 and steam as activation agents results in a very fast reaction with random porous structure and considerable losses in the raw materials. For the mentioned reasons, O2 and steam are not recommended in the majority of cases. The reaction nature of CO2 or steam with carbon is endothermic which needs reaction temperature in the range of 973 to 1173 K to separate carbon atoms. The reactions of activation applying CO2 includes Boudouard reaction as below (Sajjadi et al. 2019) (Hagemann et al. 2018):

The reaction pathway starts by dissociation of CO2 on the carbon surface and produces surface oxide along with CO. Afterwards, the surface oxide desorbs from the surface and the overall reaction is displayed below (Sajjadi et al. 2019):

Owing to the small size of the water molecule in comparison to the size of the CO2 molecule, this can facilitate the activation via steam. Steam commonly employs to form porosity and O2 functional groups on the carbon surface like carboxylic, carbonyl, ether and phenolic hydroxyl groups. The activation duration is up to 3 h deploying superheated steam with a temperature range of 1073 K and 1173 K (Ahmed et al. 2016) and flowrates between 2 ml/sec and 5 ml/sec (Budinova et al. 2006) (Mestre et al. 2007) (Maroto-Valer et al. 2005). The reaction pathway of the activation of carbon surface using steam are explained below (Lussier et al. 1998) (Sajjadi et al. 2019):

The activation process using steam starts from the transfer of O2 from water to the carbon surface to generate O2 oxide and may release CO. CO can elevate the gasification rate through scavenging the surface oxide to form O2. Afterwards, the water/gas shift reaction takes place which is broken the water into CO2 and H2 that may enhance the surface activation. The overall reaction of carbon surface activation using steam can be described as below (Aworn et al. 2008):

The carbon activation via steam modifies the surface porosity structure by eliminating trapped products that existed into the carbon material and enhances the meso/micropores distribution (Dalai and Azargohar 2007) (Feng et al. 2018) (Rodríguez-Reinoso et al. 1995).

These reactions are related to the activation temperature with different extents, however many authors deal that the reactivity in presence of steam is higher than that of CO2 (Román et al. 2008) (Rodríguez-Reinoso et al. 1995). The activation temperature is a decisive factor in determinant the reaction rate and the formation of the porous structure. Hong et al. (2016a, 2016b) executed a comprehensive study to evaluate the impact of activation temperature (range 700 to 950 °C) on the surface morphology of AC (Hong et al. 2016a). They revealed that an increase in the activation temperature caused an enlargement of surface area from 1023 to 2750 m2/g along with pore volume.

The mechanism of O2 activation of carbon-based materials can be illustrated by following reactions pathways (Tam and Antal 1999) (Plaza et al. 2014).

Employing oxygen as an activation reagent is an economically viable choice for the physical activation of the carbon surface. The activation pathway commences with the chemisorption of O2 on the carbon surface to generate surface oxides; this reaction is exothermic and can exist even at low temperatures (Sajjadi et al. 2019). The desorption of CO and CO2 is the final step through the activation.

The main shortcomings through the physical activation are the high energy requirements owing to dual thermal cooling routs, and high activation temperature causing a reduction in carbon yield in which don't meet the industrial scale of 20 to 40 wt.% (Loredo-Cancino et al. 2013).

Chemical activation

Chemical activation is an alternative method to produce activated carbon including the impregnation of high carbon material with a specific concentration of activation agent then carbonization. The parameters that influence the production of the porous structure via chemical activation involve raw material constituents, the temperature of activation, type of activating agent and impregnation ratio (Asadullah et al. 2014) (Sreńscek-Nazzal et al. 2013) (Soares Maia et al. 2018). Higher impregnation ratio (raw material/agent) can result in the formation of AC with large pore capacity and high surface area since the typical ratio has been nominated in the range of 1: 0.5 to 5: 1 (Fierro et al. 2007) (Kalderis et al. 2008) (Rashidi and Yusup 2016). The degree of activation is strongly related to the dosage used, besides the chemical type, mixing level, and both temperature and duration of activation (Caglayan and Aksoylu 2013). Alhamed et al. (2015) stated that high chemical content and surplus reaction time can result in a reduction of pore volume owing to the collapse of carbonaceous surface structure (Alhamed et al. 2015).

Various chemical activating agents are employed in the production of ACs adsorbents include three main classes namely alkaline, acidic, and neutral activating agents. The common alkaline activating agents used in the activation of carbon surface can be categorized into three types. First are the strong alkaline agents such as KOH and NaOH (Zhang et al. 2019) (Wu et al. 2017). Second are the middle alkaline agents such as K2CO3 and Na2CO3 (Sayğılı and Sayğılı 2019) (Mao et al. 2020). Third are the weak alkaline agents such as K2SiO3 (Mao et al. 2020), Na2SiO3 (Gao et al. 2015), K2B4O7 (Gao et al. 2015), Na2Al2O4 (Gao et al. 2015), CH3COOK (Li et al. 2018), and K3PO4 (Xi et al. 2018). The acidic activating agents such as H3PO4 (Brito et al. 2018), H2SO4 (Legrouri et al. 2005), HNO3 (Liu et al. 2011), and H2O2 (López de Letona Sánchez et al. 2006) are also used extensively in preparing of high surface area activated carbon. Besides, many neutral activating agents are applied in the formation of ACs materials such as ZnCl2 (Sayğili and Güzel 2016), FeCl3 (Bedia et al. 2018), K2SO4 (Park et al. 2015a), NaNH2 (Singh et al. 2019b), and NH4Cl (Moussavi et al. 2013). Further discussion about the impact of the most applied agents in the activation of the carbon surface is summarized and discussed in Table 7.

The activating agents are responsible for the determination of the activation temperature along with the carbon precursor, the heating source and style of heating, and the mixing technique. Generally speaking, the typical range of activation temperatures is between 400 and 500 °C with acidic agents, and 750 to 850 °C with alkaline agents (Ayinla et al. 2019) (Redondo et al. 2015). Many studies reported the effects of activation temperature on the surface morphology in presence of various chemical agents. For example, Brito et al. (2018) and (Li et al. 2017) stated that increase the activation temperature with KOH above 761.9 °C (potassium boiling point) transformed KOH into free metallic potassium in which can interpose into the carbon layers and enlarge the surface area of the AC (Brito et al. 2018) (Li et al. 2017). Besides, Mestre et al. (2014) revealed that there was no CO and CO2 release from the surface of the carbon with temperature lower than 750 °C that can serve as a physical activation agent for the creation of the porous surface (Mestre et al. 2014). With acidic agents, Jagtoyen and Derbyshire (1998) noticed that increase in the activation temperature above the 450 °C weakened the thermal stability of H3PO4 and secondary contractions of these structures took place, hence collapsing or shrinking pores happened (Jagtoyen and Derbyshire 1998).

In comparison to the physical activation, the chemical activation method possesses many advantages like the reduction of the tar production, low activation temperature, shorter activation time, more porous structure, and manageable porosity development. By contrast, the main drawbacks of the chemical activation are extra rinsing step for cleaning the excessive agent, and secondary pollution issues.

Surface chemistry of ACs

The main parameters that considerably influence or control the adsorption using ACs are chemical nature of CO2, AC surface morphology, method of activation, pressure and temperature of preparation, and CO2 surface binding energies of the functionalities on the ACs. Through the physical adsorption, the AC is generally governed by interparticle diffusion in the pores, since the size and distribution of pores on the AC surface are the key parameters in this regard. The chemical features of ACs adsorbents are strongly related to these properties, as the surface heterogeneity depends on the existence of heteroatoms like oxygen, nitrogen, hydrogen, sulfur, and phosphorus. The amount and kinds of these functionalities on the AC surface are assigned to the nature of the feedstock and/or presented through the activation step. During the formation of an AC, the materials are under the air, H and O elements will fix on the surface that can offer various oxygenated functionalities on the adsorbent surface with different level of affinity towards CO2 molecules (Lahaye 1998a). László and Szucs (2001) stated that the acidic properties of the ACs surfaces are strongly dependent on the oxygenated functionalities (László and Szucs 2001). These oxygen functionalities are categorized into acidic, basic, and neutral. It is noteworthy that the classification of these functionalities is based on the p-electrons and thermal refractivity, assigned to the bond energies they possess, alternative to traditional pH (Lahaye 1998a) (Shafeeyan et al. 2010). Figure 3 depicts common examples of oxygen functionalities on the AC surface like carboxylic, lactone, phenol, carbonyl, pyrone, and chromene. The availability of these groups considerably influences by detecting the affinity level of the AC surface towards CO2 molecules.

Also, it has been revealed that these groups can be decomposed at various range of temperatures, releasing CO2 and CO based on the thermal refractivity of each element as shown in Fig. 4. Mainly, groups with high acidity that possess low bond energy release CO2 at relatively low temperatures, whereas those with low acidity that have high bond energy evolve CO2 at high temperatures. All the basic functional groups expel CO chemical complexes since they offer highly enhanced thermal stability (László and Szucs 2001) (Shafeeyan et al. 2010) (Figueiredo et al. 1999) (Shen et al. 2008).

Extensive studies have been presented for tunable the amount and kinds of these chemical complexes on the ACs surfaces using different types of organic/inorganic media, based on the target gas, operation conditions, and energy demand (Polovina et al. 1997) (Moreno-Castilla et al. 1995) (Lozano-Castelló et al. 2002) (Lozano-Castelló et al. 2002) (Soto-Garrido et al. 2003) (Yang et al. 2008) (Pellerano et al. 2009) (Silvestre-Albero et al. 2009) (Somy et al. 2009) (Daud and Houshamnd 2010) (Muzic et al. 2010). For improving the uptake efficacy of ACs adsorbents towards CO2, the basic characteristics should be considerably enhanced employing different modification methods and agent like NH3 modification and introduction of metal oxides.

Methods to improve CO2 adsorption capacity over ACs

The surface of the pristine AC is restructured to adjust the surface chemistry of the adsorbent to improve their basicity. The surface modifications improve the CO2 adsorption by enhancing the uptake rate and selectivity. In the literature, many studies investigated the application of metal doping method to modify the surface adsorbent involves different types of metals like alkaline earth metal (Mg or Ca) and transition metals like Cu, Cr, Ni, or Fe (Rashidi and Yusup 2016). Also, owing to the acidic nature of CO2, it is anticipated that introducing Lewis bases onto the ACs surfaces can improve both adsorption capacity and selectivity of CO2 (Shafeeyan et al. 2010).

Drage et al. (2007) reported that the surface chemistry of AC is ruled by the heteroatoms like O2 and N2, and managed by the nature of the raw materials and the activation conditions (Drage et al. 2007). However, the surface chemistry of the virgin ACs are not strong enough to improve the interactions between the CO2 molecules and the adsorbent surface at elevated temperatures and to enhance the selectivity towards CO2 over other pollutants. These functional groups can be changed via either thermal or chemical treatment by means of producing adsorbents that are capable of specific applications (Chingombe et al. 2005). Thus, surface modifications of virgin ACs should be thoroughly investigated to enhance their CO2 uptake and selectivity. Yin et al. (2007) categorized the modifications methods into three types namely physical (heat treatment), chemical (acidic, basic, impregnation), and biological (Yin et al. 2007). Because the CO2 molecules are classified as a Lewis acid, affinity of AC to CO2 can be conducted on the basis of chemical treatment through enhancing its basicity properties neutralization of acidic functional group or to replace the acidic group with basic functionalities (Rashidi and Yusup 2016).

Nitrogen-modified ACs

The adsorption capacity of pristine ACs towards CO2 is relatively low owing to the high stability of the graphene layers that generated through the activation step, making their uptake capacity comparatively underrate. Thus, it is essential to modify the surface area and pore size using proper basic functional groups. One of the best common technologies for improving the AC surface basicity is to eliminate or reutilize the surface oxygen functional groups (Lahaye 1998b). Alternatively, these groups can be replaced by appropriate nitrogen functional groups which possess a high affinity towards CO2 molecules (Plaza et al. 2009a) (Shafeeyan et al. 2010) (Shen et al. 2008) (Yang et al. 2008) (Abe et al. 2000) (Gray et al. 2004) (Arenillas et al. 2005) (Shafeeyan et al. 2012) (Chen et al. 2014). The N-doped AC can be synthesized through heat treatment using NH3 or impregnation via amine functional gropes (Pevida et al. 2008) (Houshmand et al. 2011). Besides, it can be modified from raw materials rich with nitrogen like animal wastes (Han et al. 2020) (Tsai et al. 2019).

Surface modification via ammonia

Thermal treatment using NH3 commonly called amination includes the heating of pristine ACs to a specific temperature (473 to 1073 K) under NH3 atmosphere for a specific time, then cooling the treated ACs to ambient temperature using nitrogen flow (Shafeeyan et al. 2012) (Pevida et al. 2008). Stöhr et al. (1991) stated that upon the treatment temperature, the NH3 treatment at high temperature (873 to 1173 K) considerably increased the AC activity (Stöhr et al. 1991).

The NH3 through the heating process disbands to various free radicals like NH2, NH, atomic H2, and N2 in which reacts with carbons to produce nitrogen functionalities like -CN, pyridinic, and pyrrolic as depicted by Fig. 5 (Shafeeyan et al. 2010) (Pevida et al. 2008). The reaction of NH3 with carboxylic acid sites onto the carbon can produce ammonium salts via dehydration reaction and result in amides and nitriles:

Besides, amines could be produced through the substitution of OH groups:

In the reaction with NH3 under high temperatures ether-like O2 surface groups are easily substituted by −NH− on the carbon surface to produce imine and pyridine functionalities as depicted in Fig. 6 (Pevida et al. 2008) (Jansen and van Bekkum 1994) (Vinke et al. 1994) (Mangun et al. 2001) (Jansen and van Bekkum 1995). The formation of nitrogen functionalities on the AC surface can be established by an increase in the N2 content according to the nitrogen-carbon analyzer. In this context, Plaza et al. (2010a, 2010b) stated that the N2 content on the modified AC will elevate from 0.7-1 wt.% up to 4.5 wt.% (Plaza et al. 2010a).

Imine and pyridine production pathway from conversion of chemisorbed O2 (ether-like). Reproduced from (Stöhr et al. 1991)

Aside from the aforementioned reactions, one more possible reaction has been reported by (Zhang et al. 2016) (Shafeeyan et al. 2010) (Laheäär et al. 2014). That is postulated the formed free radicals are responsible for the creation of narrow microporosity and improvement in the surface area because of the reaction of these radicals and carbon within the mesopores walls that turn in releasing gases products such as H2, CH4, HCN, and C2N2 (Heidari et al. 2014) (Plaza et al. 2010a) that can help in developing the surface porosity particularly the microporosity (Laheäär et al. 2014).

It has been reported that pristine AC surface is non-reactive towards ammonia gas, thus pre-oxidation before the NH3 treatment is proposed (Wang et al. 2021) (Adelodun et al. 2014b). With this technology, the AC will be heated with air up to a certain temperature, then ammonia is presented into the reactor (Shafeeyan et al. 2012) (Shafeeyan et al. 2011). Shafee0yan et al. (2011) reported that the introduction of O2 functional groups can help in the reaction of NH3 free radicals by acting as anchoring sites (Shafeeyan et al. 2011). Plaza et al. (2009a, 2009b, 2009c) studied the modification of virgin AC using NH3 for the production of high capacity adsorbents for CO2 capture (Plaza et al. 2009b) (Plaza et al. 2009c). Besides, they investigated the impact of treatment temperature and revealed that the best temperature to achieve high adsorption capacity was 800 °C. Their findings emphasized the merits of the NH3 treatment in modifying the AC for CO2 adsorption. Also, David and Kopac (2014) performed a comparison study to investigate the performance of NH3 treatment and amines modifications on the AC surface (David and Kopac 2014). They reported that the NH3 treatment was more effective in the modification of the AC surface in comparison to the MEA amine treatment concerning the CO2 adsorption capacity under identical conditions.

Aside from modification using pure NH3, Jurewicz and co-workers proposed and investigated the surface modification using NH3-air mixture through a technology called ammoxidation (Jurewicz et al. 2003) (Jurewicz et al. 2003) (Jurewicz et al. 2004) (Jurewicz et al. 2006). They stated that ammoxidation technology improved the electrical capacitance of the ACs. Plaza et al. (2010a, 2010b) modified the ACs surface prepared from wood via chemical activation for CO2 adsorption using the ammoxidation technique (Plaza et al. 2010b). They reported that the CO2 uptake capacity was almost the same as the adsorption capacity of the modified AC using pure NH3 under the same operative conditions. Also, Jansen and van Bekkum (1994) evaluated the surface chemistry of AC under the animation and ammoxidation modification during temperature range of 873 and 1173 K (Jansen and van Bekkum 1994). They found that the nitrogen content and surface fractions under animation process were 4.4 wt.% and 0.14, whereas 3.2 wt.% and 0.11 under the ammoxidation process. Table 8 summarized some other studies of ACs modifications using NH3 gas.

Surface modification via amines

Besides the NH3 treatment, the N2 functionalities can be formed into the carbon surface using wet impregnation technology, where amine solvent can be employed as a source of N2 groups. The application of amines as a source for nitrogen in wet impregnation is expected to bring the same features as chemical absorbents plus the advantages of lower energy demand in the desorption step, ease handling, and avoid the corrosion issues (Plaza et al. 2007) (Chatti et al. 2009). Owing to these features, wet impregnation technology of the amine compounds on the AC is widely investigated. This technology includes mixing the amine solution and ACs at a specific temperature, time, and stirring conditions (Bezerra et al. 2011). Houshmand et al. (2011) reported that the N2 functionalities from the amine impregnation on the surface of ACs are well-distributed and physically adsorbed through dipole–dipole interaction, van der Waals forces, hydrogen bonding, acid-base interaction, or ion-exchange mechanism (Houshmand et al. 2011). Simultaneously, CO2 adsorption on the amine-modified ACs is via multiple pathways include pore diffusion, chemical bonding, simultaneous physisorption, and chemisorption process (Raja Shahrom et al. 2019). Nevertheless, the activity of the amine-modified ACs is remarkable at high temperatures, since the formed amine groups lean to block the pores on the ACs at ambient temperature and consequently minimize the surface area and micropore volume (Plaza et al. 2007). Khalil et al. (2012) revealed that the impregnation process using AMP and MEA blocked most of the pores on the ACs surface and forming enormous active sites that improved the CO2 adsorption uptake and selectivity (Khalil et al. 2012). Also, they reported that the adsorption here is mainly chemisorption and the high improvement in the breakthrough time can be attributed to the chemical bond between the CO2 and amines molecules. Plaza et al. (2007) mentioned that it is important to maintain the physisorption adsorption along with chemisorption, so that the modified AC can be deployed to capture CO2 at both high and ambient temperatures (Plaza et al. 2007). Additionally, Bezerra et al. (2011) claimed that wet impregnation technology should be carefully performed in a way that amino groups can uniformly distribute onto the AC surface without collapsing or clogging in pore structures in order to allow both diffusion and adsorption processes (Bezerra et al. 2011).

Arenillas et al. (2005) implied that mesoporous AC is a compatible baseline for the impregnation modification, as it manages good and uniform distribution of amine onto the surface of pristine AC and results in high CO2 uptake capacity at elevated temperatures, whereas the surface morphology controls the CO2 uptake at low temperatures (Arenillas et al. 2005). Table 8 tabulates the recent trends in the application of amine functionalized ACs for CO2 capture. Based on Table 9, it has been observed the efficacy of amine modified ACs adsorbents for CO2 at high temperatures which is indicator for the presence of chemisorption. Furthermore, Varghese and Karanikolos (2020) mentioned that the increase in CO2 adsorption capacity is attributable to the expansion of amine in the pores (Varghese and Karanikolos 2020). For example, PEI amine molecules reside inside the pores and only the external surface sites of PEI are accessible to the CO2 molecules at low temperature. However, these molecules will expand and fill in the mesostructured materials, and accordingly, becomes more accessible towards the CO2 molecules (Chen et al. 2020). Typically, the CO2 molecule reacts with the N2 groups from amine impregnation to produce carbamate as depicted in the below reactions (Azmi et al. 2020) (Molavi et al. 2018) (Nie et al. 2018) (Sarmah et al. 2013). There is a controversy about the specific reaction pathway however, the common belief is through the intermediate formation of a zwitterion (Zelenak et al. 2008) followed by deprotonation by a Brønsted base (Nakao et al. 2019) i.e. an amine.

Besides, several studies reported that the adsorption can be existed by the combination of mechanisms like adsorbents capture CO2 through the production of carbamic acid pairs (Milner et al. 2017) along with ammonium carbamates, this opinion however is predominantly outcast owing to the instability of carbamic acid. Also, Saha and Kienbaum (2019) supposed that H2 bonding presents to be the key factor in capture CO2 (Saha and Kienbaum 2019).

To the end, the modification via amine will enhance the adsorption capacity and promote the selectivity under humid conditions however, they are generally exhibited slow adsorption kinetics and needed comparatively high temperatures for the desorption process (Milner et al. 2017). Also, it is essential to mention that excessive amine loading cause block of the pores on the surface of the supporter which can reduce the accessibility of CO2 molecules and decrease micropores volume. This confirms the findings by (Plaza et al. 2007) and (Heidari et al. 2014). Studies that discussed the decrement in surface area and/or pore volume owing to the amine modifications can be explored throughout the previous studies (Khalil et al. 2012) (Wang et al. 2017a) (Kamarudin et al. 2018) (Boonpoke et al. 2012).

Kamarudin et al. (2018) is a good example of the implementation of amines modification on the AC surface (Kamarudin et al. 2018). They exhibited a comprehensive evaluation of modifying the activated carbon prepared from kenaf using twelve different types of amines (Kamarudin et al. 2018). The adsorption process carried out using a single bed column under 1.5 bar pressure. Figure 7 summarized the CO2 uptakes of pristine AC and the amines modified ACs with amine loading up to 50 wt.%; the combination of the primary and secondary recorded the highest CO2 adsorption capacity of 0.914 mmol/g as depicted with TEPA modification. Also, DIPA improved the AC surface basicity and the adsorption capacity owing to the four methyl groups (-CH3) in DIPA. Whereas primary amines like DGA introduced higher CO2 uptakes in comparison to AMP owing to the steric character of AMP that minimized the stability of carbamates and then adsorption capacity.

CO2 uptakes rates of pristine AC and amines functionalized AC. Reproduced with permission from (Kamarudin et al. 2018)

Metal oxides modified ACs

Along with the N-doping technology, metal impregnation is another feasible technology to improve the CO2 uptake capacity and selectivity. Metal impregnation technique can be described as impregnation of metals on the carbon structure which can be justified by a chemical reaction between the metal oxides and CO2 molecules. In this context, Hosseini et al. (2015) stated that the introduction of CuO on the carbon structure can improve the uptake capacity towards acid gases like CO2, because the metallic oxides are classified as electron donors (Hosseini et al. 2015). In contrary to N-doping technology, the metal impregnation technique for CO2 adsorption is scarce. Table 10 summarizes the recent trends in the metal impregnation for CO2 adsorption.

The importance of metal impregnation method involves the employment of alkaline earth metals like Mg, and Ca (Yong et al. 2001) (Son et al. 2005) and transition metals like Cu, Co, Ni, Fe, and Cr (Son et al. 2005) (Somy et al. 2009) (Li et al. 2010) which is clarified as possible improvement of CO2 capture owing to the strong affinity of metals and CO2 molecules particularly at a high temperatures. Yong et al. (2001) informed that the introduction of earth metals on the ACs surface can generate a basic surface that possesses high affinity regarding CO2 and thus enhances the CO2 uptake rate and selectivity (Yong et al. 2001). Also, Hosseini et al. (2015) who investigated the activity of CO2 capture on the copper/zinc modified AC proposed that the catalytic surfaces offer active sites to entrap a single CO2 (Hosseini et al. 2015). The O2 atoms in the CO2 molecules will approach and chemisorb onto the cationic Cu2+ and Zn2+ on the carbon surface, since shorten the distance between the cations and CO2 will favor the capture process owing to the lesser adsorption energy. Metal impregnation includes the mixing of ACs with inorganic salts that have certain metals, and then a calcination step at elevated temperatures. Because the presence of metal impregnation changes the surface chemistry, Alvim-Ferraz and co-authors studied the impact of metal impregnation on the char surface before and after activation (Alvim Ferraz et al. 1999) (Alvim-Ferraz and Gaspar 2003) (Alvim-Ferraz and Gaspar 2005). They reported that the introduction of transition metals oxides particularly CoO, Co3O4, and CrO3 before the activation step, the metals can work as catalysts to assist faster reaction and creation of large micro/meso-pores. The modification of large micropores offer free access to metals oxides and helps in advance the deposition onto the surface, whereas the large mesopores will improve the dispersion of the metallic species and improve their efficiency (Alvim-Ferraz and Gaspar 2003) (Alvim-Ferraz and Gaspar 2005). On the other hand, the metal impregnation of the same metal oxides on the carbon surface after activation will result in a reduction of the surface area and the pore volume (Alvim-Ferraz and Gaspar 2005). This reduction can be assigned to the deposition of the metal compounds into the pores onto the carbon surface. In agreement with this finding, Moradi (2014) revealed that the Fe-doping on the micropores AC reduced the surface area and the pore volume to 1511 m2/g and 0.81 cm3/g in comparison to the pristine carbon material that had surface area and pore volume of 1640 m2/g and 0.93 cm3/g (Moradi 2014).

Also, Hosseini et al. (2015) mentioned that metal impregnation can be further improved through acidic pretreatment of the carbon surface before impregnation (Hosseini et al. 2015). They reported that the acids can work as oxidizers and thus, elevate the amount of O2 functional groups that are proton donors. The acid-treated carbon surface will possess a strong connection with metal ions to form a metal complex, owing to the production of high polarity on the treated carbons. Besides, because the CO2 molecule has a high quadrupole moment, the introduction of polar groups can considerably boost the CO2 uptake and selectivity (Álvarez-Gutiérrez et al. 2015). In order to investigate the desorption process, the temperature increased to 353 K at 1 bar for Cu/Zn modified adsorbent and unmodified adsorbent (Hosseini et al. 2015). They stated that the regeneration of the unmodified AC adsorbent required less regeneration time by 20% in comparison to the modified AC.

In addition to the wet-metal impregnation, solid/solid mixing carbon and metal precursors have been recently postulated (Przepiórski et al. 2013a). The reason behind the blending of both metal and carbon material is to produce a porous surface that includes active chemical for effective adsorption. Przepiórski and co-workers investigated the one stage pyrolysis technology of the mixture of PET waste with dolomite or limestone at temperatures range of 1123 K to 1273 K (Przepiórski et al. 2013b) (Przepiórski et al. 2013a) (Przepiórski et al. 2013c). Through the thermal treatment, dolomite or limestone decompose to produce CaO and MgO whereas emitting CO2 gas, and PET will transform into char. From an adsorption point of view, composite carbon-metal is a precious adsorbent for CO2 capture, because it blends physical interaction owing to the micropores features and the chemical interaction between the basic sites and CO2 molecules. Generally, a mixture of metal carbonates and carbonaceous precursors is favorable, since the metal carbonates will release CO2 gas that will serve as an activation agent for subsequently AC production, while the introduction of metal oxides can considerably fix the CO2 molecules onto the adsorbent surface and enhance the chemisorption process.

By contrast, Przepiórski et al. 2013c reported that the residual contents of CaO and MgO are high which illustrates the escalation of the process temperature was not enough to regenerate the CO2 completely. This is attributable to the strong interaction between the CO2 molecules and the involved oxides in the adsorbents. Also, owing to the carbon losing through the regeneration step, the metals oxides may gradually increase which can influence the adsorbent performance.

A new technique for boosting CO2 capture over AC

Alternative to the aforementioned modifications techniques, new methods have been proposed to enhance the AC surface for CO2 adsorption. One of the effective technologies for enhancing the CO2 uptake and selectivity that is excited the researchers recently is developing AC composites. The interesting criterion of employing AC composites is their synergistic impacts on their uptake behaviors. Several studies reported the usage of AC-based composites with reliable properties for CO2 adsorption such as graphene, zeolite, and metal-organic framework.

Graphene-AC composite is introduced as an effective adsorbent for CO2 with ultra-high surface area and compatible pore structure. For example, AC-PVA-GNP composite is synthesized from AC and graphene nanoplatelets with polyvinyl alcohol as a binder via hydrothermal route (Pal et al. 2019). This composite possessed an ultra-high surface area of 2730 m2/g with a higher CO2 adsorption capacity of 1.347 cm3/g in comparison to the pristine AC. This remarkable CO2 adsorption performance can be assigned to the high surface area and developing compatible pore size to the CO2 molecules. Also, adding the graphene nanoplatelets enhanced the thermal value and diffusivity that elevated as the GNP rate in the composite increased. The impact of reduced graphene oxide (rGrO) on the CO2 uptake capacity of novel activated carbon from glucose and dicyandiamide was prepared and investigated by (Xiao et al. 2020). They developed series of rGO/NPC as AC based composites through hydrothermal route. The findings revealed a significant improvement in CO2 adsorption capacity of 2.176 mmol/g at 1 bar and 5.77 mmol/g at 5 bars in comparison to the pristine carbon adsorbent. This adsorption enhancement can be ascribed to the significant increase of surface area owing to the addition of graphene oxide, since the highest surface area of the developed composite was 882.3 m2/g compared with virgin carbon with 2.88 m2/g. Also, the introduction of graphene oxide developed new micropores sites that were suitable to entrap CO2 molecules.

Aside from graphene, zeolite is an excellent nominee to develop AC based composite. Rostami et al. (2016) designed ACZC composite by employing zeolite 13x and commercial AC for CO2 capture from CO2/N2 mixture (Rostami et al. 2016). Their findings revealed significant improvement in CO2 uptake and selectivity, since the ACZC composite had a CO2 loading capacity of 6 mmol/g. Also, it is interesting to mention that the heat of adsorption for the developed composite was 27.29 kJ/mol which was higher in comparison to the pristine adsorbent of 25.27 kJ/mol. This indicated that the developed composite enhanced the chemisorption compared to the virgin surface, whereas the adsorption governed by the physisorption. Moreover, Table 11 summarizes some other examples of AC-based composites for CO2 adsorption. In order to attain a compatible AC-based composite to capture CO2, an optimum content of filler such as rGO, zeolite, or MOF should be specified and considered. Many publications have been introduced so far; however, for the purpose of CO2 capture over ACs-based composite, just a few papers are available. Concerning the importance of the fillers on the adsorption performance and selectivity of AC-based composite, more evaluation is required in this topic in future research.

The impact of moisture on CO2 capture over ACs

The water content in biogas mixture is up to 10% (Ryckebosch et al. 2011) and 9 to 12 vol.% in flue gas from coal plant (Wang et al. 2017b); hence, it is important to evaluate the impact of water content on the CO2 uptake capacity for AC based adsorbents. It has been reported that the presence of water has a negative impact on the adsorption of CO2 over both MOFs and zeolites adsorbent, whereas the water impact on the CO2 adsorption over ACs adsorbents remains controversial. For pristine AC, Xu et al. (2011) studied the effect of water content at different concentrations on the adsorption of CO2 from flue gas over AC (Xu et al. 2011). They reported that the presence of water may not considerably influence the CO2 adsorption performance over the used AC adsorbent. This can be attributed to that water adsorption produces peculiar three-dimensional water clusters and networks, that depends on a cooperative impact including both fluid-fluid interactions and fluid-solid ones with compatible active sites which bears a resemblance to (McCallum et al. 1999). Another explanation by (Paneth and O’Leary 1985) corroborates this finding that the separation mechanism of ACs is following the kinetic impact, since CO2 adsorbs faster than water.

For modified AC, some studies stated that the presence of water enhances CO2 adsorption. Wang et al. (2017a, 2017b) revealed that the presence of 10 wt.% water can promote the CO2 uptake over TEPA-modified AC owing to the formation of bicarbonate instead of carbamates under dry conditions (Wang et al. 2017b). In the same context, Irani et al. (2017) stated that the presence of 1 vol.% of water can increase the adsorption capacity of CO2 by 56%, however the CO2 uptake rate decreases as the water content increases more than 1 vol.% (Irani et al. 2017). The same findings reported by (Liu et al. 2017), however, provided no description. Correspondingly, Hahn et al. (2015) observed that the presence of moisture decreased the adsorption capacity but increased the breakthrough and saturated capacities (Hahn et al. 2015). This action can be assigned to the formation of water film over the adsorbent surface at water concentration higher than 5 vol.%, which minimizes the interaction between the CO2 molecules and the amine sites and results in lowering the uptake capacity. With these disparate findings, the impacts of moisture on the CO2 adsorption over ACs remains contentious. Also, most of the investigations analyzed the impacts of water on the adsorption capacity with presenting possible explanations; there is a lack of a comprehensive evaluation of the adsorption process in presence of water vapor.

Conclusion and future perspectives