Abstract

Ecofriendly exploration of Arjun bark (Terminalia arjuna) is a herbal natural colorant for cotton dyeing. This is because the demand for natural dyes has been increased worldwide due to their therapeutic usage and other food, textiles, agriculture, engineering, and medical applications. Therefore, this study has been carried out due to the isolation of colorant from Arjun bark in an acidified methanolic medium after exposure to ultrasonic rays up to 60 min. Additionally, using bio-mordants, it has been found that the application of 10% of Zeera (Cuminum cyminum) extract as meta-bio-mordant, 3% of Ilaichi (Elettaria cardamomum) extract as meta-bio-mordant, and10 % of Harmal (Peganum harmala) and Neem (Azadirachta indica) extract as meta-bio-mordants has given excellent color strength. These bio-mordants have not only made the coloration process more eco-friendly, viable, and greener, but also improved color strength with various tonal effects from red to reddish brown shades. Thus, it has been found that ultrasonic treatment as an environment-friendly tool has not only enhanced the color strength of natural colorant isolated from Arjun bark onto the cotton fabric under mild conditions.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Effluent shed by industries have a big share in global warming (Rani and Shanker 2021; Mahdi et al. 2021). Even their wastes in form of toxic, non-desirable chemicals are destroying water bodies, agri-land, and atmosphere which in turn destroy the beauty of the globe (Bhatia et al. 2017; Reck et al. 2020). Their preserves in the water system are causing a low level of photosynthesis which in turn not only destroying aquaculture but also creating many lethal and carcinogenic diseases (Ahsan et al. 2020; Hynes et al. 2020). Many world-renowned associations such as the Environmental Protection Agency (EPA), Food and Agriculture Organization (FAO), Ecological and Toxicological Associations of Dyes and Pigments (ETAD), and World Health Organization (WHO) have now seriously taken this matter under observation and compelled the stakeholders, industrialists, and traders that such carcinogenic products should be replaced with green, sustainable, and eco-friendly products in all applied fields (Ahmed et al. 2019; Iyer 2018; Adeel et al. 2020a).

Plants, insects, fungi, algae, minerals, flora, and fauna are the biggest source of bio-colors. Due to having excellent biological characteristics and herbal nature natural colorants, these not only have bright shades but also pose no threat to global (Yılmaz and Bahtiyari 2020). Their waste can be recycled, and even the waste crude material can act as fertilizer for agri-land. Their handling does not need any care, and their utilization is much fruitful for heating a sustainable lifestyle (Silva et al. 2020). Due to such benefits, industrialists are using them in almost every field (Rashdi et al. 2020).

Arjun (Terminalia arjuna) being an evergreen plant with a supported trunk belongs to the Combretaceae family (Devi et al. 2020; Saivaraj and Chandramohan 2018). It is used widely in the field of Chinese, Greek, and Ayurvedic (Indian) schools of medicine due to its excellent anti-ischemic, anti-oxidant, anti-inflammatory, anti-bacterial, anti-mutagenic, anti-viral, anti-acne, and anti-cancer activities (Adeel et al. 2021a; Amalraj and Gopi 2017). Because of these properties, it is used to cure cardiac stress, dysentery, asthma, skin allergies, and oral cavity infection and is considered an excellent tonic for the heart and cancer (Khaliq and Fahim 2018). The phytochemical analysis of Arjun bark shows that it contains tannin, flavonoids, triterpenoids, saponins, sterol, arjunic acid, baicalein, gallic acid, ellagic acid, etc. (Ahmed et al. 2019; Chitte and Chaphalkar 2017; Rane et al. 2017). Among all these constituents, ellagic acid and baicalein are responsible for imparting reddish-brown color onto natural fabrics (Amutha and Sudhapriya 2020).

Recent advances in natural dyeing not only help to develop modern tools for inventing the new raw material but also give benefits for the production and application of natural dyes on textiles. Bio-mordants also increase the color shades and improve the adherence of natural dye to the fabric to enhance its colorfastness properties (Amanuel et al. 2019). Bio-mordants having excellent biological properties and medicinal importance are now gaining widespread fame due to their green application. After dyeing, the functional molecules acting as bio-mordants transfer their bio-medico properties into the fabrics, which are very useful for the community form health point of view. This work is showing the application of such plant-based extract which is not only excellent in their biological and medicinal properties but also making the dyeing process more soothing and sustainable with firm shades. From the sustainable point of view, textile researchers, traders, and other associated companies are trying to standardize the extraction process for getting stable and strong shades with high extraction yields (Kumar et al. 2021). For this purpose, modern techniques such as microwave, ultrasonic, ultraviolet, gamma, and plasma radiation (Haji 2019) are being introduced for saving time, labor cost, energy, and chemicals in textile processing which not only adds value in color addition using natural dye but also improves dye uptake ability of the fabric and color characteristics (Naebe et al. 2021; Yeong et al. 2021). Among all these techniques, ultrasonic-assisted extraction (UAE) is used to extract the natural colorants from natural sources as they can accelerate the mass transfer kinetics and increase the yield of extraction through homogeneous heating of the extracted (Fadil et al. 2021; Rodsamran and Sothornvit 2019). This method provides instant mixing for the frontier layer of liquid of fabric. In the ultrasound extraction method, the sonication mechanism produces two mechanisms of cavitation and heating as cavitation molecules strike at the surface of a solid substrate and generate strong waves leading to fast mixing of the modified layer (Baig et al. 2021; Martínez-Ramos et al. 2020). The molecules disperse thoroughly on the surface, and air is removed through cavitation. It increases the dye uptake by physically improving the surface of the fabric (Fomo et al. 2020; Chen et al. 2018). It ruptures the cell wall without physically damaging the physiological characteristic making the ultrasonic method more efficient, cost-saving, energy, and labor-efficient method (Sadeghi-Kiakhani et al. 2021).

The current study has aimed:

-

(i)

The advantages of bio-mordants for shade strength and US rays for isolation yield

-

(ii)

To explore the coloring behavior of Arjun bark colorant for fabric dye using optimum irradiation

-

(iii)

To isolate colorant in a suitable medium using an optimal level of US irradiation

-

(iv)

To get good color strength with excellent color characteristics

Collection of materials

Arjun bark (Terminalia arjuna) was purchased from the native market in Faisalabad, washed with tap water, dried, and ground finely to get crude powder. After sieving, up to 20 mesh, the uniform powder was saved in glass jars to use for further extraction and dyeing experiments. Cotton fabric (pre-treated) was obtained from the Faisalabad Textile market and washed with neutral soap at 60°C for 30 min. to make it ready for coloration. All the chemicals used in extraction and mordanting were of the commercial scale.

Extraction and irradiation process

For the extraction of functional biological components (natural colorant) from Arjun bark, the particular amount of powder (4g) was boiled with the acidified methanolic medium for 1 h, keeping powder amount to a medium ratio (P: A) of 1:25 (Adeel et al. 2021a). Extract after filtration and ready to dye cotton fabrics were ultrasonically irradiated for 15–60 min using Rohs US bath (70 kHz, 200 watts). Irradiated and un-irradiated obtained extracts were applied to dye irradiated and un-irradiated cotton fabrics at 70°C for 45min for obtaining extraction and irradiation condition.

Mordanting process for tint development

The bio-mordants such as Zeera (Cuminum cyminum), ilaichi (Elettaria cardamomum), Harmal (Peganum harmala), and neem (Azadirachta indica) were used. In this study, extracts of plants such as harmal, neem, zeera, and ilaichi as bio-mordants have been employed before, after and during dyeing at 60 °C for 45 min using fabric to the mordant ratio of 1:25. The extract of bio-mordants (1–10%) was prepared by following the already documented methods of Adeel et al. (2020b). After completion of the mordanting process, then mordanted fabrics were sent to the CIE Lab system for the evaluation of color strength and color coordinate values.

Evaluation of dyed fabric

Color strength (K/S) of all dyed fabrics and shade quality parameters (L*, a*, b*) were determined using Kubelka Munk equation (K/S = (1–R)2/2R) which has been programmed in Spectra flash SF 600 (Data Color, USA).

Results and discussion

The role of ultrasonic radiation has been observed promising in every field of life. This is because waves having sustainable nature by the production of acoustic cavitation transfer energy into the matrix by rupturing its outer boundary (Baig et al. 2021; Kumar et al. 2021). After the collision of rays with matrix, the plant cell wall ruptures to enhance the transfer of mass (colorant) into solvent by penetrating deeply and thiskinetics gives promising interaction of powder with solvent to isolate functional bio-molecules (natural colorants) (Ojha et al. 2020). The same situation has been observed in our studies during isolation of colorant from Arjun bark for cotton dyeing. It has been found that unirradiated acidified methanolic extract of Arjun bark (NRE) has given high color yield (K/S=1.907) onto irradiated cotton (RC) after exposure up to 45 min as shown in Fig. 1, as compared to other modes applied (RE/RC, NRC/RE). The other important thing is the solvent, nature of colorant, as well as the nature of the fabric used. Irradiation of fabric has also added value in the coloration process by surface modification of fabric, where after treatment, the US rays cause scaling at fibers which enhances the uptake behavior of fabric.

Previously it has also been proved that these rays scratch the fibers, which results in an improvement in its dyeing behavior (Khatri et al. 2016). The color coordinates given in Table 1 reveal that all the dyed fabrics are brighter in shade with reddish and yellower in hue but the fabric dyed after given15 min. ultrasonic radiations exhibit brighter shade having reddish yellowish tone (L*= 74.89, a*=9.34, b*= 17.20). Dyeing of the fabric under ultrasonicrays for 30 min.(UAD) has also given more brighter shade but less redder and more yellowish tone (L*= 76.76, a*=7.69, b*= 19.11). Similarly, for 45 min, ultrasonic irradiation was employed onto fabric given much brighter less redder and less yellowish hues (L*= 86.21, a*=3.72, b*= 10.35). Overall it has been observed that the irradiation of the fabric for 60 min. has given more brighter shade having less redder but more yellower tone (L*= 82.62, a*=3.44, b*= 7.95). Hence, it is concluded that if an acidified methanolic medium is employed for isolation of colorant and for getting a high color yield, only fabric should be the US treated up to 60 min.

Mordanting in natural dyeing is an essential tool because it adds value in firm color development onto fabric but also gives excellent coordinates in the form of shade appearance (Hosseinnezhad et al. 2021). Previously chemical anchors are used, but owing to toxicity, these are under strict observation. Now bio-molecules (bio-mordants) of excellent biological characteristics have been introduced (Rani et al. 2020). It has been observed that the dyeing of ultrasonically treated extract (RE) onto cotton fabric after application of zeera (Cuminum cyminum), illaichi (Elettaria cardamomum), Harmal (Peganum harmala), neem (Azadirachta indica) leaves extract has given promising results. The results displayed in Fig. 2a reveal that 5% of zeera (Cuminum cyminum) extract, 7% of illaichi extract, and 1% of Harmal and neem extract have given color strength. But overall all, Harmal (Peganum harmala) and neem (Azadirachta indica) extracts have given excellent color depth. The application of 9% of zeera (Cuminum cyminum), 7% of illaichi, 7% of Harmal (Cuminum cyminum), and neem extracts after dyeing (post-mordanting) has given good color strength displayed in Fig. 2b.

a Pre-bio-mordanting for coloration of irradiated cotton fabric using acidified methanolic extract. b Post-bio-mordanting for coloration of irradiated cotton fabric using acidified methanolic extract. c Meta-bio-mordanting for coloration of irradiated cotton fabric using acidified methanolic extract

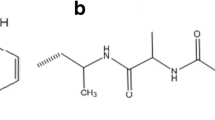

However, among bio-mordants, the utilization of Harmal (Peganum harmala) and Neem (Azadirachta indica) extracts has given excellent results. The addition of mordants during (meta) dyeing has given better results than pre-mordanting process. It has been found that 7% of zeera (Cuminum cyminum) extract, 3% of illaichi extract, and 5% of Harmal and neem extract have given good results as shown in Fig. 2c. Again it can be found that application of Harmal (Peganum harmala) and zeera (Cuminum cyminum) extract as meta-mordant has given excellent results. In the overall comparison, the application of mordants after dyeing has given excellent results (K/S and Lab values). This is because during bio-mordanting, the –OH of the functional moiety of bio-mordant has interacted with –OH of colorant from Arjun bark and -OH of cellulosic fabric via extra H-bonding (Adeel et al. 2021b). This extra H-bonding makes soothing and firm shades with new tints and high color strength (Jabar et al. 2020; Rani et al. 2020).

The herbal based bio-anchors have excellent functional moieties which have biological activities beneficial for human. The presence of conjugation and availability of more –OH group form a new mode of bonding to given firm shades. The proposed interaction of mordanted fabric with colorant extracted from Arjun bark is given in Fig. 3.

The color coordinates given in Table 2 reveal that mostly the bio-mordants have produced much more brighter shades with reddish-yellow hue, but a fabric dyed during the application of 10% of Zeera (Cuminum cyminum) extract after US treatment using an acidified methanolic extract of Arjun bark give much more darker shade (L*=95.10) with reddish-yellow tone (a*=3.96; b*=14). Similarly, 3% Ilaichi extract during (meta) mordanting using optimal conditions exhibit darker shade (L*=90.72) with reddish-yellow tone (a*=6.58; b*=13.23). Correspondingly, among other bio-mordants that used 10% of Harmal extract during (meta) mordanting, the dyed fabric has shown a much brighter shade (L*=92.05) with a reddish-yellow tone (a*=5.89; b*=16.60). Likewise, using optimal mordanting conditions, 7% of Neem extract after (post) mordant has given much more darker shade (L*=91.74) with reddish-yellow tone (a*=5.40; b*=14.46). Hence bio-mordants have not modified the natural dyeing process by the development of new shades but also brighter shades with reddish-brown tones.

Conclusion

The environmental concerns and rising awareness among people about the hazardous effects of synthetic dyes have forced the manufacturer towards sustainable products such as natural dyes. Also, the use of bio-mordants is part of medication systems that add value to sustainability and give new scopes towards the eco-friendly approach of the natural dyeing process. Therefore, this study has been carried out to extract colorant from Arjun bark in the acidified medium used to dye 60 min. The US-treated extract exhibit a variety of shades. Furthermore, it has been found that ultrasonic radiations being an excellent sustainable heating source should be used for tuning fabric surfaces to achieve desirable bright tints. Hence it has been concluded that ultrasonic rays as isolation tool are cost, time, energy and labor effective tool for cotton dyeing. The newly introduced shade development process i-e., bio-mordanting should be employed for getting acceptable results for dyeing of natural fabrics using Arjun bark extract.

Availability of data and materials

The data presented here, is the part of M.Phil Thesis.

References

Adeel S, Rehman FU, Khosa MK, Anum T, Shahid M, Zia KM, Zuber M (2020a) Microwave assisted appraisal of neem bark based tannin natural dye and its application onto bio-mordanted cotton fabric. Iran J Chem Chem Eng 39(2):159–170

Adeel S, Habib N, Arif S, Rehman FU, Azeem M, Batool F, Amin N (2020b) Microwave-assisted eco-dyeing of bio mordanted silk fabric using cinnamon bark (Cinnamomumverum) based yellow natural dye. Sustain Chem Pharm 17:100306

Adeel S, Rehman FU, Khosa MK, Rajab S, Zia KM, Zuber M, Batool F (2021a) Eco-Friendly isolation of colorant from arjun bark for dyeing of biomordanted cotton fabric: short title: dyeing of bio-mordanted cotton with arjun bark colorant. J Nat Fiber, pp 1–12. https://doi.org/10.1080/15440478.2020.1870618

Adeel S, Rehman FU, Pervaiz M, Hussaan M, Amin N, Majeed A, Rehman H (2021b) Microwave assisted green isolation of laccaic acid from lac insect (Kerria lacca) for wool dyeing. Prog Color Color Coat 14(4):293–299

Ahmed M, Islam T, Karim MR (2019) Assessment of fastness properties of knitted cotton fabric dyed with natural dyes: a sustainable approach of textile coloration. J Text Eng Fashion Technol 5(3):177–182

Ahsan R, Masood A, Sherwani R, Khushbakhat H (2020) Extraction and application of natural dyes on natural fibers: an eco-friendly perspective. Rev Edu Admin LAW 3(1):63–75

Amalraj A, Gopi S (2017) Medicinal properties of Terminalia arjuna (Roxb.) Wight and Arn.: a review. J Tradit Complement Med 7(1):65–78

Amanuel L, Adefris D, Ajaw E, Bekele N, Abinet A (2019) Dye extraction and cotton dyeing from peach leaf. Curr Trends Fashion Technol Text Eng 5(3):68–74

Amutha K, Sudhapriya N (2020) Dyeing of textiles with natural dyes extracted from Terminalia arjuna and Thespesia populnea fruits. Ind Crop Prod 148:112303

Baig U, Khatri A, Ali S, Sanbhal N, Ishaque F, Junejo N (2021) Ultrasound-assisted dyeing of cotton fabric with natural dye extracted from marigold flower. J Text Inst 112(5):801–808.

Bhatia D, Sharma NR, Singh J, Kanwar RS (2017) Biological methods for textile dye removal from wastewater: a review. Crit Rev Environ Sci Technol 47(19):1836–1876

Chen G, Bu F, Chen X, Li C, Wang S, Kan J (2018) Ultrasonic extraction, structural characterization, physicochemical properties and antioxidant activities of polysaccharides from bamboo shoots (Chimonobambusa quadrangularis) processing by-products. Int J Biol Macromol 112:656–666

Chitte R, Chaphalkar S (2017) The world of proteases across microbes, insects, and medicinal trees. (Ch. 24). Proteases in Physiology and Pathology. Springer Nature, Singapore, pp 517–526

Devi OR, Bains S, Grewal S (2020) Comparative study of ultrasonic and conventional dyeing of cotton and wool with natural dye Arjun (Terminalia arjuna) bark. Int J Chem Stud 8(4):18–23

Fadil M, Bousta D, El Ouali LA, Lachkar M, Farah A (2021) Ultrasound-assisted extraction of phenolic compounds from Moroccan Lavandula stoechas L.: optimization using response surface methodology. J Chem. https://doi.org/10.1155/2021/8830902

Fomo G, Madzimbamuto TN, Ojumu TV (2020) Applications of nonconventional green extraction technologies in process industries: challenges, limitations and perspectives. Sustain 12:1–21

Haji A (2019) Dyeing of cotton fabric with natural dyes improved by mordants and plasma treatment. Prog Color Color Coat 12(3):145–153

Hosseinnezhad M, Gharanjig K, Jafari R, Imani H (2021) Green dyeing of woolen yarns with weld and madder natural dyes in the presences of bio-mordant. Prog Color Color Coat 14(1):35–45

Hynes NRJ, Kumar JS, Kamyab H, Sujana JAJ, Al-Khashman OA, Kuslu Y, Ene A, Kumar BS (2020) Modern enabling techniques and adsorbents based dye removal with sustainability concerns in textile industrial sector -A comprehensive review. J Clean Prod 272(1):122636. https://doi.org/10.1016/j.jclepro.2020.122636

Iyer VV (2018) Embrace a gift of nature: a proposal for commercializing natural eco-dyes for the textile industry. Geo Envtl L Rev 31:725

Jabar JM, Ogunmokun AI, Taleat TAA (2020) Color and fastness properties of mordanted Bridelia ferruginea B dyed cellulosic fabric. Fashion Text 7(1):1–13

Khaliq F, Fahim M (2018) Role of Terminalia arjuna in improving cardiovascular functions: a review. Indian J Physiol Pharmacol 62(1):8–19

Khatri M, Ahmed F, Jatoi AW, Mahar RB, Khatri Z, Kim IS (2016) Ultrasonic dyeing of cellulose nanofibers. Ultrason Sonochem 31:350–354

Kumar K, Srivastav S, Sharanagat VS (2021) Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing byproducts: A review. Ultras Sonochem 70:105325. https://doi.org/10.1016/j.ultsonch.2020.105325

Mahdi MM, Tuj-zohra F, Ahmed S (2021) Dyeing of shoe upper leather with extracted dye from Acacia nilotica Plant Bark: an ecofriendly initiative. Prog Color Color Coat 14(4):241–258

Martínez-Ramos T, Benedito-Fort J, Watson NJ, Ruiz-López II, Che-Galicia G, Corona-Jiménez E (2020) Effect of solvent composition and its interaction with ultrasonic energy on the ultrasound-assisted extraction of phenolic compounds from mango peels (Mangifera indica L.). Food Bioprod Process 122:41–54

Naebe M, Haque ANMA, Haji A (2021) The effect of plasma treatment on dyeing of natural fibers. InnovEmergTechnolo Text Dye Finish 191–212

Ojha KS, Aznar R, Donnell C, Tiwari BK (2020) Ultrasound technology for the extraction of biologically active molecules from plant, animal and marine sources. TrAC Trends Anal Chem 122:115663

Rane S, Hate M, Hande P, Ajitkumar BS, Datar A (2017) Dyeing of cotton with Tectonagrandis leaves and Terminalia arjuna bark extracts. Int J Text Sci 6(2):72–77

Rani M, Shanker U (2021) Insight in to sunlight-driven rapid photocatalytic degradation of organic dyes by hexacyanoferrate-based nanoparticles. Environ Sci Pollut Res 28(5):5637–5650

Rani N, Jajpura L, Butola BS (2020) Ecological dyeing of protein fabrics with Carica papaya L. leaf natural extract in the presence of bio-mordants as an alternative copartner to metal mordants. J InstEng (India): Series E:1–13

Rashdi SY, Naveed T, Sanbhal N, Almani S, Lin P, Wei W (2020) Lyocell fabric dyed with natural dye extracted from marigold flower using metallic salts. AUTEX Res J 20(3):352–358

Reck IM, Baptista ATA, Paixão RM, Bergamasco R, Vieira MF, Vieira AMS (2020) Application of magnetic coagulant based on fractionated protein of Moringa oleifera Lam. seeds for aqueous solutions treatment containing synthetic dyes. Environ Sci Pollut Res 27(11):12192–12201

Rodsamran P, Sothornvit R (2019) Extraction of phenolic compounds from lime peel waste using ultrasonic-assisted and microwave-assisted extractions. Food Biosci 28:66–73

Sadeghi-Kiakhani M, Tehrani-Bagha AR, Safapour S, Eshaghloo-Galugahi S, Etezad SM (2021). Ultrasound-assisted extraction of natural dyes from Hawthorn fruits for dyeing polyamide fabric and study its fastness, antimicrobial, and antioxidant properties. Environ Dev Sustain 23:9163–9180. https://doi.org/10.1007/s10668-020-01017-0

Saivaraj S, Chandramohan G (2018) Antimicrobial activity of natural dyes obtained from Terminalia arjuna (Roxb.) Wight and Arn barks. World Sci News 98(4):221–227

Silva PMS, Fiaschitello TR, Queiroz RS, Freeman HS, Costa SA, Leo P, Montemor AF, Costa SM (2020) Natural dye from Croton urucuranaBaill. bark: extraction, physicochemical characterization, textile dyeing and color fastness properties. Dyes Pigments 173:1–14

Yeong YL, Pang SF, Putranto A, Gimbun J (2021) Optimisation of microwave-assisted extraction (MAE) of anthraquinone and flavonoids from Senna alata (L.) Roxb. Nat Prod Res, pp 1–5. https://doi.org/10.1080/14786419.2021.1881096

Yılmaz F, Bahtiyari Mİ (2020) Antibacterial finishing of cotton fabrics by dyeing with olive tree leaves fallen during olive harvesting. J Clean Prod 270:122068

Author information

Authors and Affiliations

Contributions

Dr Noman Habib is the supervisor, while Dr Shahid Adeel is co-supervisor of the work in which lab practical work has been done. Mr Farhan Ali and Ms. Nimra Amin have jointly conducted the experiments, whereas Mr Shahid Rehman Khan has analyzed the data of the work critically and technically for smooth running of experiments.

Corresponding authors

Ethics declarations

Ethical approval

We approved that this manuscript is part of M.Phil studies.

Consent to participate and publish

We give consent to publish our work of M.Phil studies and is jointly contributed by all authors.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Habib, N., Adeel, S., Ali, F. et al. Environmental friendly sustainable application of plant-based mordants for cotton dyeing using Arjun bark-based natural colorant. Environ Sci Pollut Res 28, 54041–54047 (2021). https://doi.org/10.1007/s11356-021-14536-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-14536-8