Abstract

Currently, sustainable utilization, including recycling and valorization, is becoming increasingly popular in waste management. Black soldier fly larvae (BSFL) can convert the carbon (C) and nitrogen (N) from organic waste into biomass and improve properties of the substrate to reduce greenhouse gas and NH3 emissions. In this study, the recycling of C and N and the emissions of greenhouse gas and NH3 during BSFL bio-treatment of mixtures of pig manure and corncob were investigated under different C/N ratios. The results indicated that initial C/N ratios of feedstock are a crucial parameter affecting the biomass generation of larvae. The BSFL recycled approximately 4.17–6.61% of C and 17.45–23.73% of N from raw materials under different C/N ratios. Cumulative CO2, CH4, NH3, and N2O emissions at the different C/N ratios ranging from 15 to 35 were 107.92–151.68, 0.08–0.76, 0.14–1.17, and 0.91–1.18 mg kg−1, respectively. Compared with conventional composting, BSFL treatment could reduce the total greenhouse gas emissions by over 90%. The study showed that bio-treatment of mixtures of pig manure and corncob with a proper C/N ratio by BSFL could become an avenue to achieve higher nutrient recycling, which is an eco-friendly process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, the intensification of crop and livestock production has generated substantial levels of agricultural waste (Chang et al. 2019). Mismanagement of these bio-wastes might bring about many environmental challenges, such as odor nuisance, spreading of diseases, and air and groundwater pollution (Rehman et al. 2017a). In environmental management, composting is one of the most proper technologies for controlling livestock manure and crop residue, and it can diminish the volume and mass of bio-waste, destroy the weed seeds, as well as produce soil-amendment materials (Jiang et al. 2011; Peng et al. 2019). In China, it is reported that pig manure production had increased to about 490 million tons, and the total yield of corncobs is estimated to have reached over 20 million tons (Wang et al. 2018; Li et al. 2015). Nevertheless, recently, only 26.0% of the total amount of crop residues and 32.9% of manure were treated by composting (Chang et al. 2019). Moreover, the biodegradation of organic matter can result in substantial loss of valuable carbon (C) and nitrogen (N) during the long composting process, which both reduces the end-product quality and has a negative impact on the ecosphere. Many studies also confirmed that the loss of N caused by NH3 and N2O emission during composting could reach 9.6–46 and 0.2–6%, respectively (Luo et al. 2014). About 14–59% and 0.8–14% of initial total organic carbon (TOC) in organic wastes are lost in the form of CO2 and CH4, respectively (Chang et al. 2019; Luo et al. 2014). Under this circumstance, the development of ecologically green technique as an alternative for low-quality composting is extremely important.

Sustainable use of waste, including recycling and valorization, is the current trend in waste management (Sánchez et al. 2015). Waste valorization is usually conducted by biological processes, such as bioconversion of these wastes with larvae of insects. Black soldier fly (Hermetia illucens L.) larvae (BSFL), a bio-waste treatment, is an ecologically green technology as it could convert various wastes (e.g., swine manure, food waste, and sludge) and provide high-quality products compared with other waste treatment technologies, such as composting or anaerobic digestion (Cai et al. 2018; Pang et al. 2020; Lalander et al. 2019). In particular, BSFL farming can be used for converting agricultural waste as an ideal protein source for livestock to replace increasingly expensive commercial feed (Wang et al. 2019). Numerous researches highlighted the economic benefits of BSFL used as animal feed or biodiesel production and the residues produced as bio-fertilizer (Choi et al. 2009; Xiao et al. 2018; Quilliam et al. 2020). On the contrary, there are fewer studies generally focused on the environmental benefits of BSFL in terms of sustainability. Mertenat et al. (2019) and Ermolaev et al. (2019) found that BSFL treatment food waste has potential to decrease greenhouse gas (GHG) emissions compared with conventional composting. However, these researchers also expressed the need for further exploration based on various raw materials and process parameters which would undoubtedly be indispensable to studies on the direct GHG emissions and C and N conversion during BSFL conversion bio-waste process for evaluating its environmental impact.

To enhance the sustainability of BSFL conversion system, the search for more effective process parameter to shift toward a cleaner production process while maintaining the economic benefits, reducing the loss of gaseous C and N and increasing C and N recovery by BSFL, would be desirable. With this in view, the present study envisages adjusting the C/N ratio of the feeding substrates by mixing pig manure and corncob with complementary properties and optimize the BSFL conversion system, in that a suitable C/N ratio could reduce gaseous C and N losses, as well as enhance the efficiency of the BSFL biological process. Specifically, the flow direction of C and N in the following three parts would be monitored: direct GHG and NH3 emission, BSFL biomass, and nutrients of residues. This study aims to present data for life cycle assessment evaluation of BSFL treatment as a greener alternative and optimize C/N ratio of the mixtures of pig manure and corncob in BSFL treatment process.

Materials and methods

Raw materials

Wuhan strain of the BSFL (Hermetia illucens L.) was obtained from the State Key Laboratory of Agricultural Microbiology of Huazhong Agricultural University (HZAU), Wuhan, China. The fresh pig manure was collected from the National Pig Breeding Experimental Center at HZAU. The chopped corncob was from the experimental field of HZAU. The main physicochemical properties are shown in Table 1.

Experimental design and operation

Pig manure and corncob were mixed at different mass ratios to initial C/N ratios of 15, 20, 25, 30, and 35, respectively, and hereafter labeled as E1–E5. The moisture content of the substrates was adjusted at 70 ± 2%. A total of 1.0 kg (wet weight) substrate was added in each 3 L cylindrical glass bottles with an enclosed lid. Based on preliminary trials, about 1600 3-day-old BSFL were inoculated onto the substrates. The experiment was terminated when the first prepupae appeared in the container of each replicate; the remaining larvae were separated from the residues and total weight of larvae and survival rate were recorded per bottle. All the treatments were incubated at 30 .0 ± 1.0 °C. All the experiments were replicated three times.

Measurements of gas emissions

The CO2, CH4, and N2O samples were detected daily. According to a method of Wu et al. (2018), on each sample day, the reactor was enclosed with the lid, and the headspace gas (30 mL) was collected with a 50-mL gastight syringe at 0 and 300 s. The bottles were kept open after gas is taken and gas sample was injected into pre-evacuated 20 ml screw-capped Exetainer® vials. The gas samples were analyzed using gas chromatograph (GC-7890A; Agilent Technologies, Santa Clara, CA, USA). The CO2 and CH4 concentrations were measured using a flame ionization detector, whereas N2O was measured using an electron capture detector. NH3 was trapped in a 0.01 mol/L H2SO4 solution and measured via titration with 0.02 mol/L NaOH (Komilis and Ham 2006).

Solid sample collection and analysis

Representative substrate samples were collected after gas sampling for the determination of some physiochemical properties. Total nitrogen (TN) and TOC were tested in the air-dried samples. TN was measured using the Kjeldahl method (Song et al. 2013). TOC in the mixtures was measured by K2Cr2O7 and H2SO4 (Chang et al. 2019). Solid sample inorganic N (ammonium-N and nitrate-N) was measured (sample: 2 mol L−1 KCl, 1:5 w/v ratio and shaken for 1 h) using the indophenol blue spectrophotometric method and ultraviolet spectrophotometry at 220 and 275 nm, respectively (UV-1800, SHIMADZU, Japan) (Wu et al. 2015). Dissolved organic carbon (DOC) in the substrate samples were measured using K2Cr2O7 oxidation (sample:water, 1:10 w/w ratio and shaken for 1 h) as described by Zhu et al. (2015). The moisture content was measured by drying the samples in an oven at 105 °C for 24 h.

Statistical analysis

The experiments and sample analyses for all important parameters in this study were performed in triplicates. Data were analyzed by one-way analysis of variance (ANOVA). Multiple comparisons between treatments were compared using the least significant difference test. SPSS 22 was used for all statistical analyses.

Results and discussions

Larval survival rate and yield

Table 2 displays the larval survival rates and their fresh weights. There were no significant differences between all treatments (F = 1.337, P = 0.322, df = 14) in larval survival rate and rather a high survival rate was found in E1–E5 (94.76–97.23%), which were similar to most published values. Oonincx et al. (2015) reported survival rates for chicken, pig, and cow manure in the range of 82.2–97.0%. Gold et al. (2020) found that the mean survival rates were 90–99% when using mill by-products, human feces, poultry slaughterhouse waste, and canteen waste as substrates. These results suggest that BSFL can develop on bio-wastes with a wide range of C/N ratio. Table 2 also shows that there was a significant difference (F = 11.775, P = 0.001, df = 14) in fresh larval weight among the five treatments of different C/N ratios. The highest larval yield was obtained in E3 treatment (79.47 ± 3.19 g), followed by E4 (73.65 ± 2.78 g), E2 (71.72 ± 3.05 g), E1 (65.64 ± 2.42 g), and E5 (61.71 ± 2.91 g). Lalander et al. (2019) indicated that volatile solids in substrate are likely the key element controlling the larval development. In the present study, the higher percentage of pig manure in the substrate contains less volatile solids and thereby slower larval growth. In contrast, corncob is rich in cellulose, hemicelluloses, and lignin and was difficult to degrade by BSFL, which tend to limit the treatment performance of the larvae. Therefore, adjusting the C/N ratio to balance the substrate nutrition will enhance BSFL ability to utilize the required nutrients to a higher degree. This is in agreement with the results obtained by Rehman et al. (2017a), who demonstrated that an appropriate C/N ratio enhances the BSFL production owing to a better nutrient balance, which is essential to establish positive synergism for biological growth. Overall, C/N ratio of 25 (E3) proved to be the best for BSFL biomass generation among the mixtures of pig manure and corncob.

Changes in the physico-chemical properties of substrate during BSFL bioconversion process

Figure 1a shows the variation in temperature during the BSFL treatment process. BSFL is a temperate tropical and warm-season species, and the suitable temperature (27–30 °C) allows the BSFL to quickly transform organic wastes and shorten the growth cycle (Chen et al. 2019; Tomberlin et al. 2009). The temperature of all treatments was relatively steady at around 28 °C throughout the experiment almost approaching ambient temperature. This might be attributed to the feeding behavior of H. illucens, whereby they burrow and thus aerate the feeding medium (Ewusie et al. 2018), thereby maintaining temperature at the same level, indicating that BSFL waste treatment process is a mesophilic process. The moisture content showed variation and gradually decreased in the treatments studied (Fig. 1b). The moisture content of E1 and E2 decreased at a faster rate as compared with other treatments. The moisture content of E1–E5 was reduced from 71.06 to 54.23, 70.05 to 55.11, 71.03 to 61.54, 70.76 to 65.03, and 70.06 to 67.96%, respectively. During bioconversion, BSFL improves air circulation through continuous activity and digests the substrate, thus leading to evaporation and consumption of water. The differences in final moisture contents were possibly due to the addition of corncob which increased porosity and reduced the bulk density, improving water-holding capacity in raw materials.

The changes in ammonium-N (NH+ 4-N) and nitrate-N (NO− 3-N) were as shown in Fig. 1c and d, respectively. The initial NH+ 4 concentration of the treatments ranged between 1.17 and 5.06 g/kg owing to the differences in the composition of the different treatments. Organic N was firstly converted into NH+ 4via ammonification and subsequently oxidized into NO− 3 by nitrifying bacteria in the presence of O2 (Sánchez et al. 2015). In this study, a slowly decreasing tendency of NH+ 4-N concentration was found. However, NO− 3-N concentration of five treatments showed an initial decrease and then increase until relatively stable during the study period, whereas the content of NH+ 4-N was significantly higher than that of NO− 3-N content. These findings are inconsistent with the reporting of Wang et al. (2018) and Lv et al. (2018), who showed that with time, NH+ 4-N concentration decreased significantly while accumulation of NO− 3-N increased during composting. This phenomenon could be explained as the transformation of NH+ 4-N by nitrifying bacteria to NO− 3-N (Lv et al. 2018). In this present study, transformation of NH+ 4 to NH3 may be the main reason for the reduction in NH+ 4-N content during BSFL bio-waste treatment rather than nitrification. According to Yu et al. (2019), nitrification index (NH+ 4/NO− 3 ratio) reflects compost maturity and a value below 3 indicates mature compost. In our study, the nitrification index of final substrate from each treatment was above 3 except for E5, indicating that most of the resulting residues still required further degradation or curing. Besides, the DOC of the residues showed a trend of fluctuation without an apparent relationship to the C/N ratio (Fig. 1e). BSFL grow quickly and thus continuously utilize the most easily degradable C parts of the substrate which may result in a decrease in DOC concentration. After DOC cannot supply enough nutrients for BSFL, the formation of soluble organic matter by the degradation of solid polymeric material in the substrate may lead to increasing the DOC concentration (Lazcano et al. 2008). Therefore, a constantly fluctuating trend was observed during the composting.

CO2 and CH4 emissions during BSFL bioconversion process

CO2 emissions from the biodegradation process of organic matter are usually not considered in the evaluation of global warming potential due to the biogenic origin of CO2 (Sánchez et al. 2015). However, it is crucial for quantifying CO2 emissions to better understand C cycling in BSFL bio-waste treatment. Figure 2a shows the daily CO2 emissions during the bioconversion process. The CO2 evolution rate of E2 (16.56 g kg−1 day−1), E3 (16.98 g kg−1 day−1), and E4 (14.83 g kg−1 day−1) peaked by first day, while E5 (12.08 g kg−1 day−1) and E1 (12.08 g kg−1 day−1) peaked on 4th and 8th days, respectively. Thereafter, the CO2 evolution rate gradually dropped until the end of the experiment. Several studies indicated that large emission amounts of CO2 occurred at the initial stages of organic waste biodegradation (Lv et al. 2018; Santos et al. 2017; Barthod et al. 2018). The CO2 emission rate relates to BSFL and microbial activities and the stability of substrates during the conversion process (Lv et al. 2018). In the present study, CO2 emissions showed a trend of gradual reduction, suggesting stabilization of substrate by BSFL treatment.

The cumulative CO2 emission for the five treatments during the study is presented in Fig. 2b. The total CO2 emitted were 107.95, 126.91, 151.68, 148.84, and 124.26 g kg−1 for the E1–E5, respectively. Total CO2 emission in E1, E3, and E5 was significantly different (F = 66.794, P = 0.002, df = 8), whereas it did not differ significantly between E3 and E4 (F = 0.452, P = 0.693, df = 5) or between E2 and E5 (F = 0.193, P = 0.683, df = 5). The maximum cumulative CO2 emission was observed in E3 treatment, followed by E4, E3, E5, and E1. It is noteworthy that with the increase in larval output, cumulative CO2 emission increased, indicating BSFL respiration may be the main contribution to difference in total CO2 emissions from each treatment. A similar result was reported by Chen et al. (2019), who investigated the influences of different moisture contents on BSFL development, and they found that the tendency of total CO2 production was consistent with that of the yield of harvested BSFL. Lalander et al. (2019) and Rehman et al. (2017a) opined that a balanced nutrition (C/N ratio) enhances the BSFL process performance and helps with the biodegradation of substrate which cannot be well digested by BSFL. Consequently, a potential explanation might be that the suitable C/N ratio can accelerate the decomposition and bioconversion of organic materials by BSFL and thereby increasing CO2 loss through BSFL respiration from the treatment process. Overall, higher total cumulative CO2 emissions also show higher biodegradation and greater stability of the residue, which is of benefit to composting process (Chan et al. 2011).

Similar patterns in CH4 emission rate were observed in all treatments (Fig. 2c), which peaked in the first day, and decreased sharply, then approached zero after the 7th day. It is noteworthy that BSFL treatment of bio-waste had a lower emission rate and a shorter emission time compared with conventional compost (generally more than 15 days) (Luo et al. 2013; Yang et al. 2019; Jiang et al. 2011). CH4 is mainly generated through methanogenic bacteria breakdown of CO2/H2 and acetic acid in anaerobic microsites (Takai 1970). In the initial stages, the raw materials contain larger particles and BSFL activity range is insufficient to cover the entire substrate, thus part of feeding substrate internal area will be in an anaerobic state resulting in a considerable fraction of CH4 production. As the bioconversion process continued, BSFL improves air circulation and breakdown of larger particles through continuous turning and degrading of the substrate, thereby removing anaerobic conditions (Ermolaev et al. 2019).

The cumulative CH4 emitted were 0.76, 0.77, 0.49, 0.15, and 0.08 g/kg for treatments E1–E5, respectively, during the study (Fig. 2d). A significant difference (F = 167.226, P = 0.000, df = 11) in cumulative CH4 emission was observed among E1, E3, E4, and E5, whereas the difference between E1 and E2 was not significant (F = 0.057, P = 0.823, df = 5). According to Jiang et al. (2011), a higher C/N ratio (lower proportion of pig manure) caused lower CH4 emission by increasing the void space and reducing the easily degradable C sources. Nevertheless, several reports indicated that the cumulative CH4 emission is very low during BSFL bioconversion of food waste. The discrepancy could be attributed in part to the properties of the raw materials (Mertenat et al. 2019; Ermolaev et al. 2019). In the initial phase, the pH of food waste, being acidic, inhibits methanogen activity (Barthod et al. 2018), after which larval activity destroys the anaerobic activities. Thus, CH4 emissions remained at a low level during the study. In spite of this, compared with the results from previous studies (Table 3), the CH4 emissions of BSFL treatment were quite lower than those from conventional composting.

NH3 and N2O emissions during BSFL bioconversion process

NH3 is included in various environmental studies because it becomes imperative for the agricultural value of the end-product and protection of ecosystems (Sánchez et al. 2015). The NH3 volatilization is relatively stable throughout the BSFL conversion process except for E1 (Fig. 3a). This emission pattern is different from the thermophilic composting process, where an initial emission peak is generally found early in the biodegradation process, when easily available N source is transformed into inorganic nitrogen, such as NH+ 4-N by the microorganisms (Luo et al. 2014; Ermolaev et al. 2015; Wu et al. 2019). Previous research indicated that the significant factor of NH3 volatilization was high temperature in the biodegradation process, and temperatures above 45 °C speed up NH3 emissions (Chang et al. 2019; Nigussie et al. 2016). Higher temperatures (45–56 °C) during the active phase increase NH3 emissions resulting in higher N loss during composting (Nigussie et al. 2016). It was observed in this study that BSFL bioconversion of bio-waste was a mesophilic process, and the relatively constant temperature of 28 °C cannot stimulate further volatilization of NH3. Consequently, there is no significant fluctuation in the NH3 emission rate in the entire conversion process.

As shown in Fig. 3b, the cumulative NH3 emission curves present a good correlation between C/N ratio and NH3 emission. With the increase of C/N ratio, the cumulative emissions of NH3 were 1.17, 0.79, 0.57, 0.34, and 0.14 g kg−1 for treatments E1–E5, respectively. Obviously, the higher C/N ratio led to lower NH3 volatilization. Similar results were found by Jiang et al. (2011), who conducted composting of pig manure with corn stalk under different C/N ratios. Also, studies by Jiang et al. (2011) and Meng et al. (2016) suggested that the high C/N ratio of substrate improves microbial assimilation and thus reduces NH3 emissions. On the other hand, a higher proportion of corncob as part of the BSFL feedstock improves the water-holding capacity, therefore partly reducing NH3 volatilization. Figure 1b thus supports the above-mentioned conclusion. Furthermore, the initial NH+ 4concentrations of the substrates (Fig. 1c) may have contributed to the differences in NH3 emissions. Thus, the C/N ratio dominates the total NH3 emission in this system. It is noteworthy that BSFL bio-waste treatment showed more potential in mitigating NH3 emissions compared with composting in other research (Table 3). As previously commented, it appears that the relatively constant temperature of the system does not cause further loss of NH3. Besides, part of the available N in the raw materials is converted into larval biomass rather than being biodegraded by microorganisms and then volatilized in the form of NH3.

The N2O emission patterns of the BSFL composting were significantly different from conventional composting and vermicomposting that immediately had a relatively high N2O release in the initial stage of composting. During the entire BSFL conversion process, the daily N2O discharge did not follow any specific pattern regardless of C/N ratio (Fig. 3c), with almost undetectable N2O emissions in all the treatments. Cumulative N2O emission was not significantly different (F = 2.711, P = 0.092, df = 14) among E1–E5, and the total emissions were all less than 1.5 mg kg−1 (Fig. 3d). This should be a matter of great joy since N2O is a potent GHG, with a global warming potential of 298 times higher than that of CO2, and causes destruction of the ozone layer (Tsutsui et al. 2013; IPCC 2013). These results corresponded with research by Ermolaev et al. (2019), who reported that N2O concentrations in BSFL treatment of food waste do not differ significantly with the ambient air. The N2O production during biodegradation process is a complicated system since the formation of N2O is involved in different generated pathways (nitrification, nitrifier denitrification, and denitrification among others), which is regulated by the NH+ 4 and NO− 3 concentration, available C sources, O2 content, pH, and temperature in the substrate (Sánchez et al. 2015; Cayuela et al. 2012; Wang et al. 2018). BSFL activity could create a conducive aerobic environment that leads to inhibition of denitrification and thus limits the N2O production. Several composting research also indicated that poor aeration gives rise to higher N2O emissions (Hao et al. 2001; Awasthi et al. 2016; Tsutsui et al. 2013). Nevertheless, Lv et al. (2018) observed that the C/N ratio significantly affect N2O emission in vermicomposting of sewage sludge, probably due to denitrifying bacteria in the earthworm gut which produce measurable N2O fluxes. Larvae of Hermetia illucens have been shown to change the bacterial community of their feeding substrate (Jeon et al. 2011; Ermolaev et al. 2019). Moreover, Jiang et al.’s (2019) research found that BSFL gut microbiome could invade and interact with the substrate microorganisms, thus altering the microbial community structure, and the formation of a new intermediate habitat between the gut and medium. This intermediate habitat might be able to promote reproduction of bacteria beneficial to metabolism, thereby improving biodegradation (Jiang et al. 2019). The authors inferred that the influences of N2O production might be related to the establishment of symbiotic bacterial communities in BSFL gut and medium microorganisms. But the BSFL-microbe-waste system is a complicated system that still requires lots of experiments and data to support this hypothesis. In addition, this study shows that using BSFL to treat organic waste has a significant advantage over earthworms in reducing N2O emissions.

GHG emissions and C and N balance

Total GHG emissions are shown in Table 3. Although CO2 is one of the GHGs and originates from the biodegradation process, its global warming potential is the least (IPCC 2013; Sánchez et al. 2015). Hence, only CH4 and N2O were taken into account in calculating the total GHG emissions in this study. Taking the global warming potential of CO2 as 1, that of CH4 and N2O was 34 and 298, respectively (IPCC 2013). In this study, CH4 is a major contributor to GHG released from the system, which provided over 85% of total GHG emissions in all treatments. The results suggest that with increasing C/N ratio of the substrate, the total GHG emissions in BSFL biotransformation was decreased. The total GHG ranged from 3.12 to 26.52 g CO2-eq/kg, which does not exceed 10% of those from conventional composting. However, total GHG emission in this study was higher than those in previous BSFL treatment food waste studies (Mertenat et al. 2019; Ermolaev et al. 2019). The inconsistency between these studies may be ascribed to differences in the nature of raw materials. It is thus advised that measures are taken in the early stage of BSFL conversion process to mitigate CH4 generation.

The balance of C and N is presented in Table 4. The study is perhaps the first to evaluate the flow direction of C and N in BSFL bio-waste conversion process using C/N ratio as a variable. CO2 emissions were the major contributor to TOC losses (9.19–12.31%), resulting from BSFL and microbial metabolism in a natural process. The CH4 emission C loss was much lower than CO2 emissions C loss, which was only accounting for 0.01–0.19% of initial TOC. The TOC losses of all treatments ranged from 15.37 to 26.58% of initial TOC of raw materials. Perednia et al. (2017) observed a higher level (28.54%) of CO2-C and CH4-C loss when BSFL were used to treat rabbit manure. The main routes for the loss of total gaseous N were in the form of NH3 (0.97–5.32%), whereas initial TN of raw material lost is negligible due to N2O emission (< 0.01%). Although NH3 loss was enhanced at lower substrate of C/N ratio, the degree of enhancement was relatively lower compared with the TN in the raw materials. For all the treatments, the loss of TN ranged from 8.93 to 18.68% of the initial TN. The results of total C and N loss showed that high C/N ratio could reduce N loss but simultaneously increase C loss.

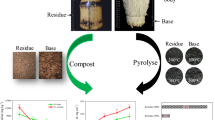

A diagram of the BSFL treatment system and the potential application of BSFL and residues in diverse fields are as shown in Fig. 4. In general, the quality of BSFL and residues relies on the nutritive contents of feedstock. In this study, the C and N in the substrate would be emitted into the atmosphere by microbial decomposition to cause environmental pollution without any treatment, while BSFL can recycle C and N in the substrate into stable and readily harvestable biomass, such as fat and protein. BSFL recycled 4.17–6.61% of C from organic waste into biomass. Although there was a significant difference (F = 7.677, P = 0.04, df = 14) in C recovery in BSFL among treatments E1–E5, probably due to the fact that the initial C in the feedstock was much higher than recovered by the larvae that resulted in the observed difference, which is not obvious. It is reported that TN over 90% in the form of organic N is first transformed into NH+ 4-N and subsequently easily volatilized as NH3 in the composting process (Chang et al. 2019). In this study, between 17.45 and 23.73% of initial TN could be recycled from organic waste to BSFL biomass of high value-added insect protein instead of being mineralized it into inorganic N by microbes and then emitted into the atmosphere. The results revealed high N recovery in larvae and residues, which agrees with the findings of Ermolaev et al. (2019). Currently, the commercial value of animal feeds primarily depends on its protein content (Lim et al. 2019). Hence, it is expected that enhancing yield of BSFL protein which correlates with the N content can lead to a lower price and thus being more competitive than fishmeal. Furthermore, the residues still contain 69.25–78.71% of C and 61.49–67.34% of N. These valuable nutrients potentially can further be converted to bioenergy (Win et al. 2018) or used as high-quality bio-fertilizer (Rehman et al. 2017b).

In terms of total GHG emissions, the addition of corncob to increase C/N ratio is a viable way to enable BSFL cope with mixtures of pig manure and corncob. From a practical application point of view, however, it is difficult to upscale to larger systems using a mixture with a high proportion of corncob, because the yield and environmental impact of pig manure are much higher than that of corncob, especially in China. Thus, based on the conversion of C and N from waste into BSFL biomass, mitigation of GHG emissions, and larval output, a C/N ratio of 25 is the most favorable condition for BSFL bioconversion of mixtures of pig manure and corncob.

Conclusions

The appropriate C/N ratio of BSFL feedstock comprising of a mixture of pig manure and corncobs can provide balanced nutrition and suitable properties of substrate and thus can lead to increased larval biomass, keep the environmental footprint low, and improve N recovery from waste. BSFL bioconversion of organic waste could reduce CH4, N2O, and NH3 emissions compared with conventional composting methods. Various analyses (C and N recovery, GHG emissions, larval biomass output, and practical application potential) indicated that C/N ratio of 25 is recommended for the bioconversion of mixtures of pig manure and corncob by BSFL. Overall, the findings of this study may contribute to improving the environmental and economic benefits of BSFL conversion system. Further studies on a large-scale production of biodiesel and animal feeds using BSFL should consider feedstock components that will enhance simultaneous C and N recovery.

References

Awasthi MK, Wang Q, Huang H, Ren X, Lahori AH, Mahar A, Ali A, Shen F, Li R, Zhang Z (2016) Influence of zeolite and lime as additives on greenhouse gas emissions and maturity evolution during sewage sludge composting. Bioresour Technol 216:172–181

Barthod J, Rumpel C, Calabi-Floody M, Mora ML, Bolan NS, Dignacd MF (2018) Adding worms during composting of organic waste with red mud and fly ash reduces CO2, emissions and increases plant available nutrient contents. J Environ Manag 222:207–215

Cai MM, Hu RQ, Zhang K, Ma ST, Zheng LY, Yu ZN, Zhang JB (2018) Resistance of black soldier fly (Diptera: Stratiomyidae) larvae to combined heavy metals and potential application in municipal sewage sludge treatment. Environ Sci Pollut Res 25:1559–1567

Cayuela ML, Sánchez-Monedero MA, Roig A, Sinicco T, Mondini C (2012) Biochemical changes and GHG emissions during composting of lignocellulosic residues with different N-rich by-products. Chemosphere 88(2):196–203

Chan YC, Sinha RK, Wang W (2011) Emission of greenhouse gases from home aerobic composting, anaerobic digestion and vermicomposting of household wastes in Brisbane (Australia). Waste Manage Res 29(5):540–548

Chang RX, Yao Y, Cao WC, Wang J, Wang X, Chen Q (2019) Effects of composting and carbon based materials on carbon and nitrogen loss in the arable land utilization of cow manure and corn stalks. J Environ Manag 233:283–290

Chen J, Hou D, Pang W, Nowar EE, Tomberlin JK, Hu R, Chen H, Xie J, Zhang J, Yu Z, Li Q (2019) Effect of moisture content on greenhouse gas and NH3 emissions from pig manure converted by black soldier fly. Sci Total Environ 697:133840

Choi YC, Choi JY, Kim JG, Kim MS, Kim WT, Park KH, Bae SW, Jeong GS (2009) Potential usage of food waste as a natural fertilizer after digestion by Hermetia illucens (Diptera: stratiomyidae). Int J Ind Entomol 19(1):171–174

Ermolaev E, Jarvis Å, Sundberg C, Smårs S, Pell M, Jönsson H (2015) Nitrous oxide and methane emissions from food waste composting at different temperatures. Waste Manag 46:113–119

Ermolaev E, Lalander C, Vinnerås B (2019) Greenhouse gas emissions from small-scale fly larvae composting with Hermetia illucens. Waste Manag 96(1):65–74

Ewusie EA, Kwapong PK, Ofosu-Budu G, Sandrock C, Akumah A, Nartey E, Teye-Gaga C, Agyarkwah SK, Adamtey N (2018) Development of black soldier fly, Hermetia illucens (Diptera: Stratiomyidae) in selected organic market waste fractions in Accra, Ghana. Asian J Biotechnol Bioresour Technol 4(1):1–16

Gold M, Cassar CM, Zurbrügg C, Kreuzer M, Boulos S, Diener S, Mathys A (2020) Biowaste treatment with black soldier fly larvae: increasing performance through the formulation of biowastes based on protein and carbohydrates. Waste Manag 102:319–329

Hao X, Chang C, Larney FJ, Travis GR (2001) Greenhouse gas emissions during cattle feedlot manure composting. J Environ Qual 30:376–386

IPCC (2013) Climate change 2013: the physical science basis. In: Contribution of working group I to the fifth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA. https://doi.org/10.1017/CBO9781107415324

Jeon H, Park S, Choi J, Jeong G, Lee SB, Choi Y, Lee SJ (2011) The intestinal bacterial community in the food waste-reducing larvae of Hermetia illucens. Curr Microbiol 62(5):1390–1399

Jiang T, Schuchardt F, Li G, Guo R, Zhao Y (2011) Effect of C/N ratio, aeration rate and moisture content on ammonia and greenhouse gas emission during the composting. J Environ Sci 23(10):1754–1760

Jiang CL, Jin WZ, Tao XH, Zhang Q, Zhu J, Feng SY, Xu XH, Li HY, Wang ZH, Zhang ZJ (2019) Black soldier fly larvae (Hermetia illucens) strengthen the metabolic function of food waste biodegradation by gut microbiome. Microb Biotechnol 12:528–543

Komilis DP, Ham RK (2006) Carbon dioxide and ammonia emissions during composting of mixed paper, yard waste and food waste. Waste Manag 26(1):62–70

Lalander C, Diener S, Zurbrügg C, Vinnerås B (2019) Effects of feedstock on larval development and process efficiency in waste treatment with black soldier fly (Hermetia illucens). J Clean Prod 208(20):211–219

Lazcano C, Gómez-Brandón M, Domínguez J (2008) Comparison of the effectiveness of composting and vermicomposting for the biological stabilization of cattle manure. Chemosphere 72(7):1013–1019

Li W, Li Q, Zheng L, Wang Y, Zhang J, Yu Z, Zhang Y (2015) Potential biodiesel and biogas production from corncob by anaerobic fermentation and black soldier fly. Bioresour Technol 194:276–282

Lim JW, Mohd-Noor SN, Wong CY, Lam MK, Goh PS, Beniers JJA, Oh WD, Jumbri K, Ghani NA (2019) Palatability of black soldier fly larvae in valorizing mixed waste coconut endosperm and soybean curd residue into larval lipid and protein sources. J Environ Manag 231:129–136

Luo Y, Li G, Luo W, Schuchardt F, Jiang T, Xu D (2013) Effect of phosphogypsum and dicyandiamide as additives on NH3, N2O and CH4 emissions during composting. J Environ Sci 25(7):1338–1345

Luo WH, Yuan J, Luo YM, Li GX, Nghiem LD, Price WE (2014) Effects of mixing and covering with mature compost on gaseous emissions during composting. Chemosphere 117:14–19

Lv BY, Zhang D, Cui YX, Yin F (2018) Effects of C/N ratio and earthworms on greenhouse gas emissions during vermicomposting of sewage sludge. Bioresour Technol 268:408–414

Meng L, Li W, Zhang S, Wu C, Wang K (2016) Effects of sucrose amendment on ammonia assimilation during sewage sludge composting. Bioresour Technol 210:160–166

Mertenat A, Diener S, Zurbrugg C (2019) Black soldier fly biowaste treatment—assessment of global warming potential. Waste Manag 84:173–181

Nigussie A, Kuyper TW, Bruun S, Neergaard AD (2016) Vermicomposting as a technology for reducing nitrogen losses and greenhouse gas emissions from small-scale composting. J Clean Prod 139(15):429–439

Oonincx DGAB, van Broekhoven S, van Huis A, van Loon JJA (2015) Feed conversion, survival and development, and composition of four insect species on diets composed of food by-products. PLoS One 10(12):e0144601

Pang WC, Hou DJ, Ke JW, Chen JS, Holtzapple MT, Tomberlin JK, Chen HC, Zhang JB, Li Q (2020) Production of biodiesel from CO2 and organic wastes by fermentation and black soldier fly. Renew Energ 149:1174–1181

Peng S, Li H, Xu Q, Lin X, Wang Y (2019) Addition of zeolite and superphosphate to windrow composting of chicken manure improves fertilizer efficiency and reduces greenhouse gas emission. Environ Sci Pollut Res 26:36845–36856

Perednia DA, Anderson J, Rice A (2017) A comparison of the greenhouse gas production of black soldier fly larvae versus aerobic microbial decomposition of an organic feed material. Res Rev J Ecol Environ Sci 5:10–16

Quilliam RS, Nuku-Adeku C, Maquart P, Little F, Newton R, Murray F (2020) Integrating insect frass biofertilisers into sustainable peri-urban agro-food systems. J Insects Food Feed 6:315–322. https://doi.org/10.3920/JIFF2019.0049

Rehman KU, Rehman A, Cai M, Zheng L, Xiao XP, Somroo AA, Wang H, Li W, Yu ZN, Zhang JB (2017a) Conversion of mixtures of dairy manure and soybean curd residue by black soldier fly larvae (Hermetia illucens, L.). J Clean Prod 154:366–373

Rehman KU, Cai MM, Xiao XP, Zheng LY, Wang H, Soomro AA, Zhou YS, Li W, Yu ZN, Zhang JB (2017b) Cellulose decomposition and larval biomass production from the co-digestion of dairy manure and chicken manure by mini-livestock (Hermetia illucens, L.). J Environ Manag 196:458–465

Sánchez A, Artola A, Font X, Gea T, Barrena R, Gabriel D, Sánchez-Monedero MA, Roig A, Cayuela ARML, Mondini C (2015) Greenhouse gas emissions from organic waste composting. Environ Chem Lett 13(3):223–238

Santos C, Fonseca J, Aires A, Coutinho J, Trindade H (2017) Effect of different rates of spent coffee grounds (SCG) on composting process, gaseous emissions and quality of end-product. Waste Manag 59:37–47

Song Y, Song CC, Li YC, Hou CC, Yang GS, Zhu XY (2013) Short-term effects of nitrogen addition and vegetation removal on soil chemical and biological properties in a freshwater marsh in Sanjiang Plain, Northeast China. Catena 104:265–271

Takai K (1970) The mechanism of methane formation in flooded paddy soil. Soil Sci Plant Nutr 16:238–241

Tomberlin JK, Adler PH, Myers HM (2009) Development of the black soldier fly (Diptera: stratiomyidae) in relation to temperature. Environ Entomol 38:930–934

Tsutsui H, Fujiwara T, Matsukawa K, Funamizu N (2013) Nitrous oxide emission mechanisms during intermittently aerated composting of cattle manure. Bioresour Technol 141(7):205–211

Wang Q, Awasthi MK, Ren XN, Zhao JC, Li RH, Wang Z, Wang MJ, Chen HY, Zhang ZQ (2018) Combining biochar, zeolite and wood vinegar for composting of pig manure: the effect on greenhouse gas emission and nitrogen conservation. Waste Manag 74:221–230

Wang GX, Peng K, Hu JR, Yi CJ, Chen XY, Wu HM, Huang YH (2019) Evaluation of defatted black soldier fly (Hermetia illucens L.) larvae meal as an alternative protein ingredient for juvenile Japanese seabass (Lateolabrax japonicus) diets. Aquaculture 507:144–154

Win SS, Ebner JH, Brownell SA, Pagano SS, Cruz-Diloné P, Trabold TA (2018) Anaerobic digestion of black solider fly larvae (BSFL) biomass as part of an integrated biorefinery. Renew Energ 127:705–712

Wu YP, Shaaban M, Zhao JS, Hao R, Hu RG (2015) Effect of the earthworm gut-stimulated denitrifiers on soil nitrous oxide emissions. Eur J Soil Biol 70:104–110

Wu YP, Shaaban M, Peng QA, Zhou AQ, Hu RG (2018) Impacts of earthworm activity on the fate of straw carbon in soil: a microcosm experiment. Environ Sci Pollut Res 25(11):11054–11062

Wu J, He SZ, Li GX, Zhao ZH, Wei YQ, Lin Z, Tao D (2019) Reducing ammonia and greenhouse gas emission with adding high levels of superphosphate fertilizer during composting. Environ Sci Pollut Res 26:30921–30929

Xiao XP, Mazza L, Yu YQ, Cai MM, Zheng LY, Tomberlin JK, Yu J, Huis AV, Yu ZN, Fasulo S, Zhang JB (2018) Efficient co-conversion process of chicken manure into protein feed and organic fertilizer by Hermetia illucens L. (Diptera: Stratiomyidae) larvae and functional bacteria. J Environ Manag 217:668–676

Yang B, Ma Y, Xiong Z (2019) Effects of different composting strategies on methane, nitrous oxide, and carbon dioxide emissions and nutrient loss during small-scale anaerobic composting. Environ Sci Pollut Res 26:446–455

Yu H, Xie B, Khan R, Shen G (2019) The changes in carbon, nitrogen components and humic substances during organic-inorganic aerobic co-composting. Bioresour Technol 271:228–235

Zhu FX, Yao YL, Wang SJ, Du RG, Wang WP, Chen XY, Hong CL, Li B, Xue ZY, Yang HQ (2015) Housefly maggot-treated composting as sustainable option for pig manure management. Waste Manag 35:62–67

Acknowledgments

This study was financially supported by the National Key Research and Development Program of China (Project No. 2018YFD0500203), Fundamental Research Funds for the Central Universities (Project No. 2662017JC045), and the open funds of the State Key Laboratory of Agricultural Microbiology (Project No. AMLKF201901).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they do not have any possible conflicts of interest.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pang, W., Hou, D., Nowar, E.E. et al. The influence on carbon, nitrogen recycling, and greenhouse gas emissions under different C/N ratios by black soldier fly. Environ Sci Pollut Res 27, 42767–42777 (2020). https://doi.org/10.1007/s11356-020-09909-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09909-4