Abstract

Microplastics are widely recognized as a category of emergent pollutants that can cause complex ecotoxicological effects. Synthetic fibers released during the washing of textiles are a relevant source of microplastics, which reach aquatic ecosystems from sewer discharges, even when there is retention in wastewater treatment plants. In this paper, we determined microfiber emissions from washing of textiles in a domestic environment, by collecting wastewater from washings of a mix of clothing from a household of 4 people. It is the first time the characterization of microplastic emission from textiles washing is performed in real household conditions. Results estimated an average emission rate of 18,000,000 synthetic microfibers for a reference load of 6 kg of synthetic fibers. Only 7% of the synthetic fibers found were larger than 500 μm in length, 40% were between 100 and 500 μm, and 53% were between 50 and 100 μm.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the second half of the twentieth century, plastics production grew exponentially, existing today a wide variety of plastics, with multiple features that make it attractive to a multitude of sectors. However, these same characteristics also make plastic an environmental concern, given the great durability of the material in question (Cole et al. 2011). The study of environmental issues has focused on larger plastics, but the concern about the effects of smaller particles, usually described as microplastics (> 5 mm), has gained increased attention in recent years.

Microplastics are now considered a ubiquitous presence in aquatic environments (Wagner et al. 2014; Li et al. 2018a; Prata 2018) since their presence has been detected in both fresh- and salt-water environments all over the globe (Alison et al. 2015; Dris et al. 2018; Wagner and Lambert 2018).

To assess the effects of microplastics in aquatic environments, their size and count are two key variables. One of the entryways in the food chain is through ingestion by marine organisms and it has already been reported in lower levels of the food chain such as zooplankton, invertebrates, and echinoderm larvae (Cole et al. 2011). The adsorption of chemical pollutants to microplastics also represents a growing environmental concern due to the carrying capacity to aquatic biota (Bakir et al. 2014; Li et al. 2018b) where toxicological effects have been observed (Avio et al. 2015).

Wastewater treatment plants (WWTPs) are one of the transport routes of small polymers into the marine environment (Carr et al. 2016). In domestic wastewater, polyethylene, polypropylene, and polystyrene particles of primary origin prevail over other types of plastic and come from personal care products, cosmetics, and cleaning agents. Fibers as a result of the degradation of synthetic textile fabrics, such as polyester, acrylic, and polyamide during mechanical washing appear to be an important source of microplastics in wastewater (Browne et al. 2011; Sundt et al. 2014).

Most fibers are removed during the primary treatment, in the primary settling and mechanical treatment. However, the smaller the fibers are, the less efficient the treatment is. Although the removal efficiencies in WWTPs are high (65 to 99.9%), given the large volumes of treated wastewater, the net amount of synthetic fibers being discharged in the marine environment is significant (Murphy et al. 2016). Even if the removal were complete, there would be a risk of microfibers (MF) reaching the environment via biological sludge from WWTPs (Hartline et al. 2016). Natural fibers tend to be more efficiently removed than synthetic ones (Magnusson and Norén 2014).

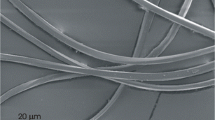

Although the existence of synthetic microfibers is known, the quantity and physical characteristics of those that are emitted by domestic textile washing are not yet fully understood. Several studies have analyzed different variables regarding their influence on microfiber release during washings, including temperature, detergents, and type of washing machine (Napper and Thompson 2016; Pirc et al. 2016; De Falco et al. 2017; Belzagui et al. 2019; Yang et al. 2019; Zambrano et al. 2019), but comparison between studies is not always possible given the different methods and units used to present results. Two main methods have been used to characterize MF emissions: direct methods, where a sample of the washing water is filtered, MF are counted using microscopy, and results are expressed as the number of MF released per unit volume of washing water or per weight load of the washing machine; and indirect methods where MF are retained in a filter and their mass is calculated, to determine a release rate per garment or per unit area of fabric. Some studies with indirect methods use mean MF length to determine the corresponding number of MF released. The method to determine the mean length usually consists of a visual observation by microscopy which is only performed in a short number of samples. Napper and Thompson (2016) adopted this method using scanning electron microscopy and reported a mean value of 4.99 mm for a polyester-cotton blend and 7.79 mm for polyester fibers while Pirc et al. (2016) also used scanning electron microscopy to observe recovered polyester microfibers from a filter with a 200-mm mesh and the mean size obtained was 5.3 mm. Studies using direct methods report values an order of magnitude lower: De Falco et al. (2017) obtained mean lengths between 0.339 and 0.478 mm for different materials. These values are close to the rage from 0.2 to 0.4 mm obtained by Belzagui et al. (2019) and from 0.1 to 0.8 mm obtained by Hernandez et al. (2017). Moreover, Hernandez et al. (2017) also concluded that the overall microplastic fiber length profile remained similar regardless of the washing conditions (with or without detergent or surfactant).

Regarding MF count, synthetic MF release rates obtained in controlled studies range from 140,000 MF/6 kg of washed clothes (Napper and Thompson 2016) up to 17,700,000 MF/5 kg of washed clothes (De Falco et al. 2017).

However, the large majority of the studies used new clothes, testing few pieces, and performed a limited number of washes. Given the different types of clothes and fabrics commonly used in a full load wash, the characterization of everyday washing conditions remains unstudied. It is therefore of extreme relevance to characterize real washing conditions in order to fully understand the extent and characteristics of MF household emissions.

This study provides an insight of the emission of microfibers resulting from regular household washings of common citizens, by analyzing wastewater from a washing machine from a family of 4 people during 2 months. The machine used has a front load and both liquid detergent and softener were used. Washes were performed at full capacity of the washing machine (in terms of volume) and with pieces with different materials in the same wash.

Materials and methods

Pieces used in the washes

Clothing and housing linens from a household of 4 people were used in the study in a total of 205 pieces. Clothes included shirts, trousers, shorts, sweaters, socks, cloths, underwear, and dresses. Housing linen included a duvet, sheets, pillowcases, rugs, and towels. Pieces had various materials in their composition, including cotton (the only natural fiber) and five types of synthetic fibers: polyester, polyamide, viscose, elastane, and acrylic. Eighty pieces (39%) were of a single type of material (cotton, polyester, or viscose) and the remaining were produced with two or more types of materials. All pieces washed were part of the everyday use of the residents and as such all were used items.

Washing set up

Clothing pieces and house linen were separated according to their color, into two groups, “light” and “dark,” to perform each washing from only one of the groups. Each piece was weighted, and color and composition of the fabric were recorded.

A total of 10 washings were carried out from May 1 to June 1, 2018. Two hundred five pieces were washed with the number of pieces per wash varying between 1 and 44. A frontal loading machine from BOSCH, model WAQ2448XEE/10, was used. The machine was in operation for 5 years and performed an average of 5 washes per week. Washes were performed using the program “Cotton” and spinning speed of 1000 rpm. Temperature varied between 20 and 60 °C, chosen according to the type of clothes. Washing time is automatically calculated by the washing machine, depending on the weight of the load. The water used was supplied by the public water supply network (SIMAR Loures/Odivelas). Common household liquid detergent brand (Persil) and softener (Quanto) were used in all washes, with doses of 120 mL or 150 mL per wash and 35 mL or 55 mL, respectively. Temperature selection, detergent, and softener dosing were selected by the household owner according to regular habits in order to monitor everyday household washings.

The wastewater discharge pipe of the machine was disconnected from the household drainage system and connected to a large polyethylene (PE) container to collect all the wastewater discharged in each wash. According to the manufacturer, all programs used 68 L of water per washing.

Filtration of the samples

An initial filtration of the raw washing water revealed a densely overlapping of fibers in the filter which prevented a proper counting. To overcome this situation, a dilution prior to filtration was adopted, similar to other studies such as Belzagui et al. (2019). A 20-mL sample of each wash was collected and diluted to 1:10 to produce a final volume of 200 mL. Each diluted sample was divided by 8 filters, each filtering 25 mL. After being placed into the filtration system, each filter was divided into quadrants with a needle to assist in the counting method. Filtration was performed with an inox filtration system connected to a vacuum pump, using nitrocellulose membrane filters with a 12-μm mesh (Whatman, WHA10400012).

Counting method/fiber characterization

Due to the large number of fibers released, fibers were counted in only one quadrant per filter. The first quadrant in the first filter of each washing was chosen randomly, then analysis was done for the next quadrant in the next filter, clockwise. Each selected quadrant was photographed using a stereomicroscope (Leica S9i) with a magnification of × 40. The entire quadrant area was scanned along consecutive “rows” so that contiguous photographs would slightly overlap. Each photo was analyzed individually, and fibers were visually identified and classified between natural and synthetic based on the guidelines outlined in previous studies (Canadian Conservation Institute 2010; Khan et al. 2017). Each fiber was classified in terms of length, by grouping into three classes: 50 to 100 μm, 100 to 500 μm, and > 500 μm. The counting of each quadrant was multiplied by 4 to obtain an estimate of the total fibers in each filter. The counting of each wash was obtained by the sum of the estimates of the corresponding 8 filters.

Statistical analysis was performed using SPSS 25.0, considering a significance level of α = 0.005.

Contamination control

Contamination was carefully controlled during sampling, filtering, and counting of the filters. Washing of the washing machine with clean water was not performed between washing cycles in order to simulate real household conditions.

For the sample collection procedure, the washing water collected in the large PE container was mixed using a wood rod and 5 to 7 L were transferred to a polyethylene terephthalate (PET) bottle to be transported to the laboratory. Both containers were thoroughly washed with water from the water supply network before each collection to avoid cross-contamination.

A white cotton laboratory coat was used during filtering and counting. Filtration of all samples was performed in a laminar flow chamber to avoid atmospheric contamination, using glass and metallic materials. All materials were thoroughly washed with Mili-Q water before using and between different sample processing. Control filtrations were conducted with Milli-Q water, using the same volume as for sample processing (25 mL). Immediately after filtration, each filter was individually stored in Petri dishes and stored until counting.

When observing filters in a stereoscope, contamination was controlled by placing two filters in Petri dishes on each side of the stereoscope. These remained uncovered as long as the observation of the stereoscope occurred. Counting of the fibers of the controls (both from control filtration and during counting) revealed a total of 235 contaminant fibers, representing 1.6% of the total fibers counted, which can be considered a low error level.

Results and discussion

Characterization of the washings

Table 1 presents the characterization of the pieces used in each washing cycle. The number of pieces per wash had a large variation due to the size of the pieces and density of the textiles (a full characterization of all pieces in each washing is provided in Table S1). This is to be expected in household washings due to the different types of clothing used in everyday life, e.g., washing #1 had only one piece corresponding to a single duvet while washing #5 had 44 pieces due to a large number of underwear (23 pieces). The average percentage of synthetics was 37%, with an average weight of 1160 g. It is also worth noting that the average total weight of the washings was 3847 g, significantly lower than the maximum load of the machine (8 kg). This is in accordance with previous studies developed in European countries, where it was reported that washing cycles in Germany were performed on average at 68% capacity for the “Cotton” program, which was also the program used in 68% of the cycles (Kruschwitz et al. 2014). The detergent used varied between 120 and 150 mL and the softener varied between 35 and 55 mL. The temperature varied between 20 °C (one washing) and 60 °C (2 washings), with most of the washings performed at 30 or 40 °C. The effects of temperature, detergent, and softener are not consensual in previous studies (Napper and Thompson 2016; Hernandez et al. 2017; Zambrano et al. 2019).

Figure 1 shows the weight distribution between different fabric types in each washing cycle. It can be observed that all washings except for #1 and #3 have more than 40% cotton. The largest synthetic component is polyester, with an average percentage across cycles of 24%, followed by polyamide and viscose (5% each) and elastane (2%).

Microfibers type and length distribution

Fibers release varied strongly between washes, especially for cotton where standard deviations exceed average (Table 2). The length distribution of MF showed that on average 79% of the fibers were in the range 50–100 μm, 17% was in the range 100–500 μm, and only 4% were larger than 500 μm. While cotton released most fibers in the 50–100-μm range (85%), 40% of the synthetic fibers released were in the range 100–500 μm and 53% in the range 50–100 μm, with only 7% of synthetic fibers being longer than 500 μm.

The average concentration of total microfibers in the washing water was 297,400 MF/L, with 83% from cotton fibers. Synthetic fibers had an average concentration of 56,911 MF/L, representing only 19% of the total fibers identified (Table 2). Since synthetic clothing represented 37% on average of the total washed load (Table 1), the relation between washed synthetics and cotton is different from the relation between synthetic MF and cotton fibers being released. This results from the different shedding characteristics of different materials and the fabric construction, as previously reported in other studies (Sillanpää and Sainio 2017; Almroth et al. 2018; Belzagui et al. 2019; Yang et al. 2019).

The wide range of total MF emissions in each washing can be observed in Fig. 2. Cotton shows the largest variation, especially for MF in the 50–100-μm range, with washes 9 and 10 reaching 700,000 MF/L (not plotted). The large release of cotton in these two washes was probably due to the large number of jeans which were not washed in any other cycle. Synthetic fibers had the largest variation in emissions also in the lower size range but with a much short interquartile range (IQR). On the other hand, synthetic fibers had a larger variation than cotton in the 100–500-μm range.

Synthetic microfiber characterization

Length

Table 3 includes the main characteristics of studies on synthetic MF release and compares with present work. Mean fiber length in the present study was calculated by a weighted average of the number of fibers from the size classes 50–100 μm and 100 to 500 μm, considering the average length in each class. Fibers longer than 500 μm were not considered given the absence of information regarding the maximum size but given its lower percentage of the total synthetic fiber count (< 7%), its influence was considered not representative.

The mean fiber length obtained in the present study for synthetic MF was 170 μm. This value is 30 to 40 times lower than the values reported by Pirc et al. (2016) and Napper and Thompson (2016), respectively, which used indirect methods to estimate the total number of MF release.

The length obtained in the present study is also 2 to 5 times lower than the values reported by De Falco et al. (2017) and Belzagui et al. (2019), where direct (visual) counting methods were used. This seems to indicate that length characterization during direct counting methods provides a more accurate estimate of synthetic MF length.

It is also worth noting that the previous studies were performed with new clothes, despite including 5 to 10 initial washings to stabilize MF release. Since less than 7% of the fibers identified in the present study were longer than 500 μm and over 50% were shorter than 100 μm, the present work results can also indicate that fabrics with real aging and use can produce synthetic fibers smaller than new clothes. This result tends also to refute the claim of Pirc et al. (2016) that the installation of a filter with a 0.2 × 0.2-mm opening size could prevent most of the emissions.

Release rates

The total count of synthetic fibers in the washing water was plotted against the total weight of synthetic fibers in each washing cycle, as presented in Fig. 3. As could be expected, results suggest a strong correlation (R2 = 0.69, p = 0.006) between synthetic MF release and the total weight of the synthetic fibers being washed, especially for washing weights up to 2000 g.

Considering the total number of synthetic MF identified in each individual wash, the release rate varied between 1842 and 6259 MF/g, with an average of 3170 MF/g and a standard deviation of 1500 MF/g synthetic fibers.

Given the different units used in other MF detachment studies, a wider comparison with other literature studies was only possible considering a wash load of 6 kg of synthetic fibers. Several studies have reported a range of synthetic MF released for a wash load of 6 kg extrapolated from single piece washings (Table 3). In the present study, the regression equation for MF release as a function of the weight of synthetic fibers washed (Fig. 3) was used to estimate synthetic MF release for a wash load of 6 kg, resulting in 18,000,000 MF/6 kg of synthetic fibers. This value is significantly higher than one of the first estimates of 140,000 MF/6 kg obtained by Napper and Thompson (2016). The results of the present study are only comparable with the ones obtained by De Falco et al. (2017), where the highest estimated release rate for a 6-kg load of synthetic fibers reached 21,000,000 MF.

The comparison of release rates with other studies needs to be performed carefully given the different methods used. Studies that used indirect methods most likely overestimate mean fiber length, which leads to an underestimation of the total number of MF released. This is consistent with MF release rate below 1,000,000 MF/6-kg synthetic fibers in studies using indirect methods (Napper and Thompson 2016; Pirc et al. 2016), which contrasts with MF release rates higher than this value in studies where a direct count was used (De Falco et al. 2017; Sillanpää and Sainio 2017; Belzagui et al. 2019).

Conclusions

To the knowledge of the authors, the approach of analyzing washings of clothes from everyday household use to assess the release of MF to the environment is the first of its kind. More than 90% of the synthetic MF had a length lower than 500 μm, with 50% being smaller than 100 μm. These results are in contrast with most studies where average length ranges from 200 μm to > 5 mm. The estimated number of synthetic MF released for a reference load of 6 kg of synthetic fibers is of 18,000,000 MF. This value is 3 to 130 times higher than estimates from previous studies, where new clothes or fabrics were used. Both the length range and the number of synthetic MF estimated for a 6-kg reference load provide the first evidence that real household emissions with worn clothes can have higher emission rates than most current estimates. This information is of undeniable value to the definition and design of mitigation strategies, especially those based on MF capture at the source, such as filtering systems coupled to washing machines.

A significant correlation between the weight of synthetics in each washing and the number of synthetic MF released was observed. However, for loads higher than 2000 g, the correlation was weaker, which should be explored in future studies. Future studies should also explore MF emissions from household washings in different times of the year given clothing changes with seasons. The fate of these emissions should also be investigated throughout the sewage drainage network and wastewater treatment plants, down to aquatic systems. These studies will help to understand potential length changes of MF over the urban water cycle, so that the significance of domestic sources can be established and its impacts analyzed.

References

Alison A, Hidalgo-ruz V, Andrady AL, Peter JK (2015) Sources, fate and effects of microplastics in the marine environment: a global assessment

Almroth BM, Åström L, Roslund S et al (2018) Quantifying shedding of synthetic fibers from textiles: a source of microplastics released into the environment. Environ Sci Pollut Res 25:1191–1199. https://doi.org/10.1007/s11356-017-0528-7

Avio CG, Gorbi S, Milan M, Benedetti M, Fattorini D, d’Errico G, Pauletto M, Bargelloni L, Regoli F (2015) Pollutants bioavailability and toxicological risk from microplastics to marine mussels. Environ Pollut 198:211–222. https://doi.org/10.1016/j.envpol.2014.12.021

Bakir A, Rowland SJ, Thompson RC (2014) Enhanced desorption of persistent organic pollutants from microplastics under simulated physiological conditions. Environ Pollut 185:16–23. https://doi.org/10.1016/j.envpol.2013.10.007

Belzagui F, Crespi M, Álvarez A et al (2019) Microplastics’ emissions: microfibers’ detachment from textile garments. Environ Pollut 248:1028–1035. https://doi.org/10.1016/j.envpol.2019.02.059

Browne MA, Crump P, Niven SJ, Teuten E, Tonkin A, Galloway T, Thompson R (2011) Accumulation of microplastic on shorelines woldwide: sources and sinks. Environ Sci Technol 45:9175–9179. https://doi.org/10.1021/es201811s

Canadian Conservation Institute (2010) The Identification of Natural Fibers - CCI Notes:13/18

Carr SA, Liu J, Tesoro AG (2016) Transport and fate of microplastic particles in wastewater treatment plants. Water Res 91:174–182. https://doi.org/10.1016/j.watres.2016.01.002

Cole M, Lindeque P, Halsband C, Galloway TS (2011) Microplastics as contaminants in the marine environment: a review. Mar Pollut Bull 62:2588–2597. https://doi.org/10.1016/j.marpolbul.2011.09.025

De Falco F, Pia M, Gentile G et al (2017) Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ Pollut 236:916–925. https://doi.org/10.1016/j.envpol.2017.10.057

Dris R, Gasperi J, Rocher V, Tassin B (2018) Synthetic and non-synthetic anthropogenic fibers in a river under the impact of Paris Megacity: sampling methodological aspects and flux estimations. Sci Total Environ 618:157–164. https://doi.org/10.1016/j.scitotenv.2017.11.009

Hartline NL, Bruce NJ, Karba SN, Ruff EO, Sonar SU, Holden PA (2016) Microfiber masses recovered from conventional machine washing of new or aged garments. Environ Sci Technol 50:11532–11538. https://doi.org/10.1021/acs.est.6b03045

Hernandez E, Nowack B, Mitrano DM (2017) Polyester textiles as a source of microplastics from households: a mechanistic study to understand microfiber release during washing. Environ Sci Technol 51:7036–7046. https://doi.org/10.1021/acs.est.7b01750

Khan PDEAN, Abir N, Rakib MAN et al (2017) A review paper on textile fiber identification. IOSR J Polym Text Eng 04:14–20. https://doi.org/10.9790/019x-04021420

Kruschwitz A, Karle A, Schmitz A, Stamminger R (2014) Consumer laundry practices in Germany. Int J Consum Stud 38:265–277. https://doi.org/10.1111/ijcs.12091

Li J, Liu H, Chen JP (2018a) Microplastics in freshwater systems: a review on occurrence, environmental effects, and methods for microplastics detection. Water Res 137:362–374. https://doi.org/10.1016/j.watres.2017.12.056

Li J, Zhang K, Zhang H (2018b) Adsorption of antibiotics on microplastics. Environ Pollut 237:460–467. https://doi.org/10.1016/j.envpol.2018.02.050

Magnusson K, Norén F (2014) Screening of microplastic particles in and down-stream a wastewater treatment plant. IVL Swedish Environ Res Inst C 55:22

Murphy F, Ewins C, Carbonnier F, Quinn B (2016) Wastewater treatment works (WwTW) as a source of microplastics in the aquatic environment. Environ Sci Technol 50:5800–5808. https://doi.org/10.1021/acs.est.5b05416

Napper IE, Thompson RC (2016) Release of synthetic microplastic plastic fibres from domestic washing machines: effects of fabric type and washing conditions. Mar Pollut Bull 112:39–45. https://doi.org/10.1016/j.marpolbul.2016.09.025

Pirc U, Vidmar M, Mozer A, Kržan A (2016) Emissions of microplastic fibers from microfiber fleece during domestic washing. Environ Sci Pollut Res 23:22206–22211. https://doi.org/10.1007/s11356-016-7703-0

Prata JC (2018) Microplastics in wastewater: state of the knowledge on sources, fate and solutions. Mar Pollut Bull 129:262–265. https://doi.org/10.1016/j.marpolbul.2018.02.046

Sillanpää M, Sainio P (2017) Release of polyester and cotton fibers from textiles in machine washings. Environ Sci Pollut Res 24:19313–19321. https://doi.org/10.1007/s11356-017-9621-1

Sundt P, Schulze P-E, Syversen F (2014) Sources of microplastic- pollution to the marine environment project report

Wagner M, Lambert S (eds) (2018) Freshwater microplastics. Springer Open

Wagner M, Scherer C, Alvarez-Muñoz D et al (2014) Microplastics in freshwater ecosystems: what we know and what we need to know. Environ Sci Eur 26:1–9. https://doi.org/10.1186/s12302-014-0012-7

Yang L, Qiao F, Lei K, Li H, Kang Y, Cui S, An L (2019) Microfiber release from different fabrics during washing. Environ Pollut 249:136–143. https://doi.org/10.1016/j.envpol.2019.03.011

Zambrano MC, Pawlak JJ, Daystar J et al (2019) Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar Pollut Bull 142:394–407. https://doi.org/10.1016/j.marpolbul.2019.02.062

Acknowledgments

The authors thank Maria Teresa Fonseca for her support in statistical analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(XLSX 19 kb)

Rights and permissions

About this article

Cite this article

Galvão, A., Aleixo, M., De Pablo, H. et al. Microplastics in wastewater: microfiber emissions from common household laundry. Environ Sci Pollut Res 27, 26643–26649 (2020). https://doi.org/10.1007/s11356-020-08765-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08765-6