Abstract

Traditional Fenton reagents are less effective for industrial wastewater treatment because they are active in a narrow pH range, precipitate and become inactive, and are difficult to recover. In this study, a heterogeneous Fenton catalyst, γ-Cu-Ce-Al2O3, was prepared by the sol-gel method and evaluated for the treatment of phenol-containing water. The optimal mix of γ-Cu-Ce-Al2O3 includes a Cu content of 5 wt% and a molar ratio between Cu and Ce of 2:1. The catalyst was prepared by continuously stirring the solution for 24 h and heating to 550 °C for 6 h. The Fenton catalyst was tested with hydrogen peroxide for phenol degradation. An initial phenol concentration of 100 mg/L was removed with 95% efficiency. Additionally, the catalyst was demonstrated to be effective for reuse up to five times with an overall removal rate of 72.3%. The test conditions were based on a catalyst dosage of 1.6 g/L, a hydrogen peroxide dosage of 200 mmol/L, a reaction temperature of 40 °C, an initial pH of 7.0 ± 0.05, and a reaction time of 120 min.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phenolic compounds are used to synthesize chemical materials in a variety of common industries including petrochemicals, pesticides, and dyes (Ocampo et al. 2011). The use of phenol for industrial chemical synthesis results in wastewater containing elevated concentrations of phenol and its derivatives (Zhu et al. 2011). Due to its persistence and toxicity, phenol and its derivatives are classified as priority organic pollutants (Rodrigues et al. 2010), and phenol-containing wastewater is a research priority (Ribeiro et al. 2016).

Although the classic Fenton reaction shows degradation of phenolic compounds at a pH of 3, challenges are encountered in practice including severe reaction conditions, the generation of large amount of iron sludge, recovery of spent catalyst, and potential secondary pollution (Descorme 2017). Currently, one of the solutions to the problems relies on the development of a heterogeneous catalyst that uses immobilized metal ion (Bautista et al. 2011; Xu and Wang 2011; Lv et al. 2015). The catalyst activity depends on the migration rate of surface electrons. In the classic Fenton reaction, the rate of reduction of Fe3+ to Fe2+ by hydrogen peroxide (H2O2) is much lower than that of Fe3+ formed by reaction with phenol. Another reaction competing with Fe3+ ions is precipitation with OH− when the pH is greater than 3.

Fenton catalysts use H2O2 as the primary reagent to produce hydroxyl radicals under neutral conditions without consuming equivalent amounts of Fe2+ (Navalon et al. 2010). Researchers have done considerable work fixing free metal ions on the appropriate carrier to create a heterogeneous Fenton catalyst system. Costa (Costa et al. 2008) prepared Fe0/Fe3O4 Fenton catalyst by treating Fe3O4 with the H2 programmed temperature-reduction method, which performed better than zero ferric iron or iron oxide alone. Hu and Lu (2010) found that doping trace copper can significantly promote the activity of Fe2O3/Al2O3 catalyst, because Cu has similar redox properties to iron but is active over a wider pH range. Moreover, Cu can accelerate electron migration between different valence states of the same element; for example, the rate of Fe3+ reduction to Fe2+ is 0.001–0.002 M−1S−1, while the rate of Cu2+ reduction to Cu+ is 460 M−1S−1 when applying the Fenton reaction. Therefore, researchers developed a series of single copper reaction center catalysts, including copper-doped mesoporous gamma alumina (γ-Cu-Al2O3) (Covinich et al. 2016) or copper-doped mesoporous silica (Cu-MsMs) nanoparticles (Lyu et al. 2015a). Rare-earth metals were also reported to promote catalysis and improve the degradation of organic matter when combined with transition metals by maintaining the integrity of the catalyst’s crystal structure. For example, Xu and Wang (2012) prepared a magnetic nanoscaled Fe3O4/CeO2 composite as an efficient Fenton-like heterogeneous catalyst for the degradation of 4-chlorophenol under acidic conditions and found that Ce accelerated the electron migration rate between Fe2+ and Fe3+ resulting in more hydroxyl radicals in the reaction solution. Zhang (Zhang et al. 2016) reported that the oxidation efficiency of phenol in water was enhanced by Ce3+ and Cu2+ in a Fenton system due to a synergistic effect.

Therefore, it is necessary to prepare a supported catalyst, which can be recycled easily, uses active components that are highly dispersed on the surface of the carrier, and contains rare-earth elements, transition metals, and oxide carriers. The stability of the catalyst is essential for practical application since stability minimizes the leaching of metal ions into aqueous solution. To improve the performance, mesoporous alumina prepared by the sol-gel method has been widely used due to the high specific surface area, narrow pore size distribution, and reliable thermal stability (Xu et al. 2006).

In this work, an innovative heterogeneous Fenton catalyst (γ-Cu-Ce-Al2O3) was synthesized using an optimized sol-gel method. The performance and mechanism of phenol removal were investigated by controlled experiments and surface characterization, respectively, and the results of the catalyst evaluation were compared with results from other heterogeneous Fenton catalyst studies.

Materials and methods

Synthesis of the catalysts

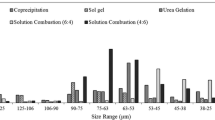

Three catalysts were prepared, including γ-Cu-Ce-Al2O3, γ-Cu-Al2O3, and γ-Ce-Al2O3, by the sol-gel method (Lyu et al. 2015b). The γ-Cu-Ce-Al2O3 was synthesized by dissolving 8.40 g of C9H21AlO3 (Shanghai Spectrum Vibration Biotechnology Co., AR), 0.40 g of CuCl2·2H2O (Shanghai Spectrum Vibration Biotechnology Co., AR), 0.27 g of CeCl3·7H2O (Shanghai Zhanyun Chemical Co., AR), and 7.20 g of glucose (Tianjin Komeo Reagent Co., AR) into 110 mL of deionized water, which was stirred for 3 h using a temperature-controlled magnetic stirrer (85-2A, Tianjin Sedleys Experimental Analytical Instrument Manufacturing Factory) at 40 °C. After 3 h, the pH value was adjusted to 5.5 by the addition of 0.10 mol/L hydrochloric acid (Sinopsin Group Chemical Reagent Co., 36.6%), and the mixture was stirred for another 24 h. Then, the water and volatile components were removed by evaporation by heating at 100 °C, and the remaining substances continued to be consolidated and calcinated at 600 °C for 6 h in a muffle furnace. The final solid catalyst was washed with deionized water to remove adsorbed ions and dried for another 6 h at 100 °C. The other two catalysts, γ-Cu-Al2O3 and γ-Ce-Al2O3, were obtained with the same method excluding CeCl3·7H2O and CuCl2·2H2O, respectively.

Inductively coupled plasma-atomic emission spectrometry (ICP-AES) was used to determine the abundance of copper after acid decomposition, which showed a Cu content of 5.1 wt% and a Cu to Ce molar ratio of approximately two to one.

Characterization of catalyst

The use of a scanning electron microscope (SEM) (FEI Quanta 400 FEG, FEI) was applied to the surface of synthesized catalyst, and energy-dispersive spectrometry (EDS) was carried out to investigate the distribution pattern of chemical elements on the surface of γ-Cu-Ce-Al2O3. The use of X-ray diffraction (XRD, SmartLab (3KW), Rigaku) was applied to γ-Cu-Al2O3 and initial and residual γ-Cu-Ce-Al2O3 catalyst after five test runs (γ-Cu-Ce-Al2O3-5) in order to evaluate the XRD patterns. The use of X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi, Thermo Fisher Scientific) was applied to evaluate the initial prepared catalyst and the spent catalyst or γ-Cu-Ce-Al2O3-5.

Phenol removal experiments

The phenol (China Pharmaceutical Group, AR) solutions were prepared with an initial concentration of 100 mg/L and a volume of 100 mL. Test runs were conducted with the catalyst for a period of 2 h on an 85-2A constant temperature magnetic stirrer with the initial pH adjusted by the addition of 0.10 mol/L of sodium hydroxide (Sinopsin Group Chemical Reagent Co., AR) and 0.10 mol/L of hydrochloric acid. After the reaction period was over, the concentration of phenol was determined by using the 4-aminoantipyrine (China Pharmaceutical Group Chemical Reagents Co., AR) spectrophotometry method (Kidder 1954; Tran and Paoli 2002). The experiment of reaction rate was to analyze the differences of catalyst performance between γ-Cu-Ce-Al2O3:γ-Cu-Al2O3 and γ-Cu-Ce-Al2O3:γ-Ce-Al2O3, resulted in the optimum test conditions that pH of 7.0 ± 0.05, reaction temperature controlled at 40 °C, 0.8 g/L dosage of γ-Cu-Ce-Al2O3, 10 mM of H2O2 (30%, China Pharmaceutical Group Chemical Reagents Co., AR), and 2 h of reaction.

Four conditions were tested including catalyst dosage, H2O2 dosage, temperature, and pH. The effect of catalyst dosage on the removal of phenol was tested by varying the mass of catalyst at 40 °C over a test period of 120 min with an initial pH of 7 ± 0.05 and a H2O2 dosage of 10 mM. The effect of H2O2 dosage was tested by changing the dose of H2O2 from 2 to 12 mM at a temperature of 40 °C with an initial pH of 7 ± 0.05 and a catalyst dosage of 0.8 g/L. The temperature effect was considered in the range from 25 to 50 °C. The effect of pH was investigated from pH value of 2 to 10.

The experiment was also carried out to analyze the activity and the stability of the catalyst after repeated use by evaluating efficiency and catalyst integrity after one to five test runs. After each reaction or test run, the leached copper ion concentration in the solution was measured by inductively coupled plasma (ICP, Optima2000, Shanghai PerkinElmer Instruments Co.). The solid catalyst used in the experiment was recovered, washed, and dried repeatedly with distilled water for three times. The test was then repeated using the same experimental conditions.

The last set of test runs were conducted with secondary effluent (COD = 50 mg/L and ammonia nitrogen = 5 mg/L) collected from the campus wastewater treatment plant and spiked with phenol to test initial concentrations from 1 to 125 mg/L (1 mg/L, 10 mg/L, 50 mg/L, 100 mg/L, and 125 mg/L). The test was conducted with 0.8 g/L of γ-Cu-Ce-Al2O3 catalyst at an H2O2 dosage of 10 mM, a temperature of 40 °C, an initial pH of 7 ± 0.05, and 2 h of reaction.

Results and discussion

Characterization of catalysts

SEM and EDS

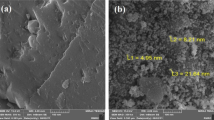

The surface of synthesized catalyst was scanned and the SEM micrographs are shown in Fig. 1.

Figure 1 shows that the surface of γ-Cu-Ce-Al2O3 has a non-porous structure and is smoother than the surfaces of γ-Al2O3 and γ-Cu-Al2O3. The structures shown in the micrograph suggest that the doping of Ce effectively improved the surface making it a more effective catalyst structure.

EDS mapping was carried out to investigate the distribution pattern of Cu and Ce on the surface of γ-Cu-Ce-Al2O3 (Fig. 2). The images suggest that the distribution pattern of Cu (Fig. 2b) and Ce (Fig. 2c) elements was both well-dispersed on the γ-Cu-Ce-Al2O3 catalyst surface.

XRD

The XRD patterns of the γ-Cu-Ce-Al2O3 catalyst are shown in Fig. 3. The scanning range, voltage, and electric current were 10–90°, 40 kV, and 30 mA, respectively. Diffraction peaks for CuO corresponded to 27.3°, 33.6°, and 53.2°, and diffraction peaks of CeO2 were found at 42.1° and 45.9° at 2θ. The grain size of the CuO was calculated at 8.16 nm by the Scherrer equation (Lee et al. 2004; Patterson 1939), as follows:

where k is a constant (k = 0.943 for γ-Cu-Ce-Al2O3 catalyst as a crystalline material), λ is the XRD wavelength, β is the half-maximum width of diffraction peak, and θ is the diffraction angle.

Brunauer-Emmett-Teller specific surface area

The specific surface area (SSA), pore volume (PV), and porosity of catalysts were reported to directly impact on the catalytic performance (Rana et al. 2003). The Brunauer-Emmett-Teller (BET) values of bimetallic catalysts (γ-Cu-Ce-Al2O3) and monometallic catalysts (γ-Cu-Al2O3 or γ-Ce-Al2O3) were tested, and the results are presented as SSA, PV, and pore diameter (PD), which were 273.3643 m2g−1, 0.3965 cm3g−1, and 5.4834 nm, respectively, for γ-Cu-Ce-Al2O3; 250.4765 m2g−1, 0.4238 cm3g−1, and 6.8345 nm, respectively, for γ-Cu-Al2O3; and 257.1935 m2g−1, 0.4467 cm3g−1, and 6.2434 nm, respectively, for γ-Ce-Al2O3. Notably, the γ-Cu-Ce-Al2O3 catalyst demonstrated a higher SSA than the other two catalysts. Generally, higher SSA provides more contact opportunity with H2O2 in the reaction resulting in a higher concentration of hydroxyl radicals, thereby increasing the removal rate of phenol (Piumetti et al. 2016). The observed differences in SSA are consistent with the observed differences in phenol removal rates for the catalysts as demonstrated in the “Influential factors on phenol removal” section.

The N2 adsorption-desorption isotherms are shown in Fig. 4 and, according to the IUPAC classification, the isotherms corresponded to type IV adsorption with hysteresis loop type H2(b). This indicates that CuO-CeO2 (corresponding to the presence of copper and cerium in γ-Cu-Ce-Al2O3) catalyst belongs to mesoporous material with a larger SSA, a larger PD and PV, and higher adsorption capacity. These characteristics are further demonstrated by the interaction between γ-Cu-Ce-Al2O3, the adsorbed substances, and the interaction between molecules in the coagulation state. The hysteresis loop type H2(b) is usually associated with the blockage of the pores (Annie and Camille 2008), which could be explained by the fact that the active components, Cu and Ce, are loaded on the surface of γ-Al2O3 and occupy common pores. The hysteresis loop type H2(b) also corresponds to a complex pore structure, which results in a mesh structure capable of efficiently removing pollutants.

Influential factors on phenol removal

Dosage of catalysts

The catalyst dosage optimization experiment was carried out at pH of 7 ± 0.05, a reaction temperature of 40 °C, and an H2O2 dosage of 10 mM in 100 mL of phenol solution (concentration of 100 mg/L). The results are shown in Fig. 5a and reveal that 0.08 g of γ-Cu-Ce-Al2O3 resulted in the highest phenol degradation efficiency of 95.28% after the 2-h reaction period. The high degradation efficiency is attributed to the fact that increasing γ-Cu-Ce-Al2O3 created more active sites promoting the formation of hydroxyl radicals (Zhou and Zhu 2006). The use of higher catalyst dosages, e.g., 0.10 g and 0.12 g, results in coagulation of catalysts (Chen 2008), thereby reducing active sites and contact efficiency between catalyst and H2O2. Therefore, based on the test results, the optimum catalyst dosage was 0.08 g.

a Relative phenol removal ratio versus the dosage of γ-Cu-Ce-Al2O3 (initial pH = 7 ± 0.05, 40 °C, 10 mM H2O2, and 100 mg/L phenol). b Relative phenol removal ratio versus the dosage of H2O2 (initial pH = 7 ± 0.05, 40 °C, 0.8 g/L of catalyst, and 100 mg/L phenol). c Relative phenol removal ratio versus the temperature variation (initial pH = 7 ± 0.05, 10 mM H2O2, 0.8 g/L of catalyst, and 100 mg/L phenol). d Relative phenol removal ratio versus the pH variation (40 °C, 10 mM H2O2, 0.8 g/L of catalyst, and 100 mg/L phenol). e Relative phenol removal ratio versus the different catalysts (initial pH = 7 ± 0.05, 40 °C, 2 h, 10 mM H2O2, and 0.8 g/L of catalyst). f Frequency of catalyst used in the test

Dosage of H2O2

Hydroxyl radicals, the main oxidative active substances in Fenton-like reactions, are generated by reacting H2O2 with the surface of catalyst. The dosage of H2O2 is crucial to the Fenton-like reaction (Pereira et al. 2012), and the results are shown in Fig. 5b as a function of the H2O2 dosage.

The experiment was carried out at a pH of 7.0 ± 0.05, a reaction temperature of 40 °C, and a catalyst dosage of 0.08 g in 100 mL of phenol solution (concentration of 100 mg/L). The removal rates of phenol were found to be similar at 20 min for all the dosages; but at 120 min, only 60.42% was removed with 2 mM H2O2 added, compared with 98.94% with 10 mM H2O2 added. Larger amounts of H2O2 generated more hydroxyl radicals in the solution (Dantas et al. 2006; Pouran et al. 2013), because H2O2 was the limiting reagent until it was dosed in excess. For instance, in this case, 12 mM H2O2 failed to improve the phenol removal rate compared to 10 mM dosage. Excess H2O2 actually leads to a cavitation phenomenon producing O2 or intermediate of ·O2H, which adversely affects phenol removal by consuming hydroxyl radicals (Ma et al. 2005). Therefore, the optimal concentration of hydrogen peroxide in this experiment was found to be 10 mM.

Temperature

The temperature effect on phenol removal was tested at temperatures ranging from 2 to 50 °C. The test was performed at pH of 7.0 ± 0.05, a 10-mM dosage of H2O2, and a 0.08-g dosage of catalyst in 100 mL of phenol solution (concentration of 100 mg/L). The phenol removal variation with temperature is shown in Fig. 5c. The phenol removal rate increased as the temperature increased from 25 to 40 °C, but declined for 50 °C. With the higher temperature, a longer reaction time impaired the performance of catalyst; for instance, the removal efficiency at 45 or 50 °C was lower than that at 40 °C after 80 min. The drop-in efficiency is attributed to accelerated decomposition of H2O2 at higher temperatures (Zou et al. 2014). Based on the results, the optimum temperature for phenol removal was found to be 40 °C.

pH

In order to evaluate the balance between stability and activity of catalyst as a function of pH, phenol degradation tests were carried out to establish the optimum conditions for γ-Cu-Ce-Al2O3 and γ-Cu-Al2O3 catalysts. The experiment was conducted at pH values ranging from 2 to 10 with results measured based on phenol removal efficiency. The test was performed at temperature of 40 °C, a 10-mM dosage of H2O2, and a 0.08-g dosage of catalyst in 100 mL of phenol solution (concentration of 100 mg/L).

Surface charges and activity of the catalyst are affected by the pH of the reaction solution (Luo et al. 2014). As a result, phenol removal varies as pH increases as shown in Fig. 5d. The results show that pH of 7 was optimum for phenol degradation by the γ-Cu-Ce-Al2O3 and γ-Cu-Al2O3 catalysts prepared in this research. The performance of the γ-Cu-Ce-Al2O3 catalyst was demonstrated to be better than the γ-Cu-Al2O3 catalyst, which could result from the synergetic effect between Cu and Ce (Zou et al. 2014). The metal species doped in γ-Cu-Ce-Al2O3 formed a Cu-O-Ce and Cu-O-Al complexes, which resulted in greater exposure of the active components on the surface of the catalyst allowing for higher surface activity. The classic Fenton reactions usually reach maximum efficiency at strong acid conditions (close to pH = 3), because H2O2 is more readily protonated to form H3O2+ in acidic conditions, followed by reaction of the catalyst to generate the hydroxyl radicals (Xia et al. 2017). However, researchers (Cruz et al. 2013) reported that photo-Fenton reactions could perform high catalytic activity at neutral pH while Fe3+ underwent precipitation. Unfortunately, the introduction of light requires additional investment. In our study, the solid-state bimetallic catalyst is an alternative solution to this problem without a light source.

Inductively coupled plasma mass spectrometry (ICP-MS) was used to detect the leaching Cu2+ and the results are shown in Table 1.

The results show that copper ions more easily dissociate from the catalysts under acidic conditions, or conversely, and a higher pH value increases the stability of the catalysts. The γ-Cu-Ce-Al2O3 performed better than γ-Cu-Al2O3 based on copper leaching results with γ-Cu-Ce-Al2O3 releasing less copper than γ-Cu-Al2O3. The difference in removal efficiencies shown in Fig. 5d at low pH may be related to the observed leaching. However, at pH values above 7, the removal rate of phenol decreased despite undetectable copper ions leaching from the γ-Cu-Ce-Al2O3. Reduced efficiency at higher pH is due to lower H2O2 protonation and reduced production of hydroxyl radicals at alkaline conditions (Zhang et al. 2010). Generally, the heterogeneous Fenton system composed of γ-Cu-Ce-Al2O3 catalyst and H2O2 can maintain maximum activity under neutral conditions with low leaching translating to effective practical application.

Performance and mechanism on phenol removal

Reaction rate

Reaction rates were evaluated at the optimum or practical conditions identified previously: a temperature of 40 °C, a 0.8 g/L dosage of catalyst, a 10-mM dosage of H2O2, a 2-h reaction time, and a pH of 7.0 ± 0.05. The specific phenol removal rate was calculated by the following Eq. (2):

where C0 is the initial phenol concentration, Ct is the residual phenol after reaction, mcat is the dosage of catalyst, and t is the reaction time.

The reaction rates for phenol degradation by H2O2 using γ-Cu-Ce-Al2O3, γ-Cu-Al2O3, and γ-Ce-Al2O3 were 0.21, 0.11, and 0.10 mgphenol/gcat•min, respectively. Compared with some similar catalysts, Fe2O3-ZrO2 (0.16 mgphenol/gcat•min) (Gao et al. 2018), and BiFeO3 (0.15 mgphenol/gcat•min) (Rusevova et al. 2014), the reaction rate of γ-Cu-Ce-Al2O3 demonstrated higher phenol removal rates with increased activity and selectivity.

Catalyst reuse

In homogeneous Fenton, the Fe2+ ions are oxidized by H2O2 resulting in significant precipitation with OH− making reuse impractical. Therefore, the classic Fenton reaction requires continuous Fe2+ addition to the solution, which leads to an increase in the chroma and conductivity of the solution, and enhances the difficulty and cost of subsequent treatment. In order to solve this problem, the researchers fixed the free metal ions onto carriers, which results in a multiphase Fenton catalyst system (Fayazi et al. 2016; Wang et al. 2016). By using this approach, the generation of multiphase Fenton makes the recovery of catalyst possible (Hou et al. 2016).

As part of this research work, the catalyst was tested. The catalyst was recovered, washed and dried repeatedly, rinsed with distilled water, dried, and retested for phenol removal efficiency. The optimum experimental conditions were applied to study the catalytic activity and stability of the catalyst after repeated use for one to five times. After each test reaction, phenol removal efficiency and copper ion leaching were measured.

As shown in Fig. 5f, the phenol removal efficiency declined from 96.73 to 72.33% after subsequent reuses, and the leached copper concentrations increased from 0.11 to 0.34 mg/L. These results suggest incomplete recovery of reacted catalyst, fouled surface, or structure/crystallization damage may contribute to the observed reduced efficiency during reuse tests.

The XRD patterns of spent γ-Cu-Ce-Al2O3 were evaluated and compared after five cycles (γ-Cu-Ce-Al2O3-5).

As shown in Fig. 6, there is a small difference in the diffraction peak height between γ-Cu-Ce-Al2O3-5 and the initially prepared catalyst, but no changes in the crystal structure of the catalyst. This supports the hypothesis of better stability of γ-Cu-Ce-Al2O3 in a heterogeneous Fenton reaction system.

The initial catalyst and recycled catalyst, γ-Cu-Ce-Al2O3-5, were also measured and compared with XPS. Results show that the Cu2p peaks of γ-Cu-Ce-Al2O3 and γ-Cu-Ce-Al2O3-5 are 932.9 eV and 933.4 eV, respectively, and the O1s binding energies of γ-Cu-Ce-Al2O3 and γ-Cu-Ce-Al2O3-5 are 530.69 eV and 530.87 eV, respectively. Based on the XPS test results, the γ-Cu-Ce-Al2O3-5 predominantly exists as Cu2+ instead of Cu+, which may partly explain impact on catalyst activity.

Catalytic mechanism

The hydroxyl radicals produced in Fenton reaction are thought to be the major active component in organic removal with the Fenton reaction (Zhang et al. 2006). Tert-butanol, an efficient eliminator of OH radicals, is used to calculate the production of OH radicals in the reaction. The experimental results are shown in Fig. 7a.

a The catalytic mechanism of γ-Cu-Ce-Al2O3. b Catalytic activity of soluble copper ions (initial pH = 7 ± 0.05, 40 °C, 2 h of reaction time, 10 mM H2O2, 100 mg/L phenol, and no catalyst added). c Relative phenol removal ratio versus the different concentrations of phenol in secondary effluent (initial pH = 7 ± 0.05, 40 °C, 2 h of reaction time, 10 mM H2O2, and 0.8 g/L of catalyst). d γ-Cu-Ce-Al2O3 removal capacity for phenol after 5 cycles (initial pH = 7 ± 0.05, 40 °C, 2 h, 10 mM H2O2, and 0.8 g/L of catalyst)

The removal efficiency of phenol dropped significantly in the presence of tert-butanol (97.64% vs. 26.52%). The results suggested that the OH radicals are formed by γ-Cu-Ce-Al2O3 catalyst and H2O2 and are the key mechanism for phenol removal, consistent with previous literature (Dhakshinamoorthy et al. 2012; Sobańska et al. 2017).

In the heterogeneous Fenton reaction, the generation of OH radical has been widely proposed and accepted as the oxidation mechanism (Neyens et al. 2003). As shown in Fig. 5e, the bimetallic catalyst γ-Cu-Ce-Al2O3 was found to perform better than monometallic catalyst γ-Cu-Al2O3 or γ-Ce-Al2O3. The improved performance shows a synergetic effect with the addition of rare-earth element, Ce changing the activity and selectivity of Cu-containing catalyst, as well as improving the stability (Lyu and Hu 2017). The proposed pathway of the H2O2 activation by γ-Cu-Ce-Al2O3 is as follows: first, OH is produced by Cu+ reacting with H2O2 (Eq. 3); next, Cu2+ is reduced to Cu+ by reaction with H2O2 and HO2 (Eqs. 4 and 5); then, cerium produces OH with H2O2 (Eqs. 6, 7, and 8), which is similar to iron in a Fenton-like reaction (Heckert et al. 2008); finally, electrons transfer from Cu+ to Ce4+ (Eq. 9) based on achieving the most thermodynamically favorable state since the standard redox potential of Ce4+/Ce3+ (1.44 V) is larger than the standard redox potential of Cu2+/Cu (0.15 V).

In the Fenton reaction, electron migration between different valence states of the same element can be accelerated by substituting iron with copper, since the rate of Fe3+ reduction to Fe2+ (0.001–0.002 M−1S−1) is lower than the rate of Cu2+ reduction to Cu+ (460 M−1S−1) (Lyu and Hu 2017). To demonstrate the performance of the γ-Cu-Ce-Al2O3 catalyst requires the complex heterogeneous structure; a control reaction has been carried out to measure the catalytic activity of soluble copper ions with concentrations ranging from 0.1 to 2 mg/L (Fig. 7b). The results show that copper ions are less effective for phenol removal than the γ-Cu-Ce-Al2O3 catalyst.

According to the proposed reaction mechanism of γ-Cu-Ce-Al2O3, the reaction process can be roughly divided into two steps: the reaction on the catalyst and the reaction in the solution. Under the combined action of Cu+ and Ce3+, the catalyst accelerated H2O2 decomposition into OH, and Cu+/Cu2+ and Ce3+/Ce4+ on the catalyst can be regenerated due to thermodynamic potential for electron transfer.

Performance on phenol removal in the secondary effluent

Removal efficiency

The phenol removal efficiencies in secondary effluent with different initial phenol concentrations are shown in Fig. 7c. The catalyst effectively removes phenol, and the phenol removal rate at the concentration of 1 mg/L is lower than the other initial test concentrations. The difference may result from the fact that low initial concentration decreases the contact between phenol and the catalyst since other organic compounds in the solution compete for reaction sites on the surface of the catalyst (Cong et al. 2010). This hypothesis is supported by the fact that over 98% of phenol in distilled water was degraded (shown in Fig. 5a–e, 0.8 g/L of catalyst within 120 min under conditions of 10 mM H2O2, initial pH = 7 ± 0.05, and 40 °C), which was higher than the average removal rate in all concentrations (93%) of phenol in secondary effluent.

Reusability

As shown in Fig. 7d, the catalyst showed a slight decrease in removal performance after five-cycle experiments; the efficiency declined from 95.73 to 70.15%. The results mean that γ-Cu-Ce-Al2O3 was able to be reused for at least five cycles and exhibited no significant loss of activity. As shown in Fig. 5f, the catalyst retained 72% phenol degradation efficiency in the prepared phenol solution after five cycles. The decrease in removal efficiency might be caused by incomplete recovery of reacted catalyst, carbon deposit on catalyst surface (Sun 2006), or structure/crystallization damage (Tang et al. 2006).

Conclusions

Using Cu instead of Fe, the γ-Cu-Ce-Al2O3 catalyst prepared by the sol-gel method had higher SSA and purity. The surface characterization demonstrated that Ce reduced the particle size of the catalyst and inhibited the formation of CuO during preparation to increase the SSA and accelerate the phenol oxidation reaction. Furthermore, the introduction of Ce also changed the crystal structure, resulting in the better performance of γ-Cu-Ce-Al2O3 than γ-Cu-Al2O3, and γ-Cu-Ce-Al2O3 has better stability than γ-Cu-Al2O3 and γ-Ce-Al2O3. The experiment with phenol-containing solution demonstrated that the γ-Cu-Ce-Al2O3 catalyst acts to generate hydroxyl radicals from H2O2 effectively, which removes phenol successfully under neutral pH conditions. Although small amounts of Cu leached into solution, the catalyst has the potential to be recycled. The dosage of catalyst and hydrogen peroxide affected the removal effect of phenol, but the reaction was more sensitive to temperature and initial solution pH. Moreover, γ-Cu-Ce-Al2O3 performed well for phenol removal and successive recycling under the secondary effluent.

References

Annie G, Camille O (2008) Capillary condensation in porous materials. Hysteresis and interaction mechanism without pore blocking/percolation process. Langmuir 24(8):3977–3986. https://doi.org/10.1021/la703978v

Bautista P, Mohedano AF, Casas JA, Zazo JA, Rodriguez JJ (2011) Highly stable Fe/γ-Al2O3 catalyst for catalytic wet peroxide oxidation. J Chem Technol Biotechnol 86(4):497–504. https://doi.org/10.1002/jctb.2538

Chen YJ (2008) Influence of pore size and surface area of activated carbon on the performance of TiO2/AC photocatalyst. Acta Phys -Chim Sin 24(9):1589–1596

Cong YQ, Fu FX, Ma XJ, Huang WY, Ren HH, Ding MJ, Zhang RR (2010) Treatment and kinetics of phenol wastewater by combined electrocatalysis and adsorption. J Chem Ind Eng 61(11):2971–2977 (in Chinese)

Costa RC, Moura FC, Ardison JD, Fabris JD (2008) Highly active heterogeneous Fenton-like systems based on Fe0/Fe3O4 composites prepared by controlled reduction of iron oxides. Appl Catal B 83(1):131–139. https://doi.org/10.1016/j.apcatb.2008.01.039

Covinich LG, Massa P, Fenoglio R, Area MC (2016) Oxidation of hazardous compounds by heterogeneous catalysis based on Cu/Al2O3 system in Fenton-type reactions. Crit Rev Environ Sci Technol 46(22–23):1745–1781. https://doi.org/10.1080/10643389.2016.1267449

Cruz ND, Esquius L, Grandjean D, Magnet A, Tunglar A, Alencastro LF, Pulgarin C (2013) Degradation of emergent contaminants by UV, UV/H2O2 and neutral photo-Fenton at pilot scale in a domestic wastewater treatment plant. Water Res 47(15):5836–5845. https://doi.org/10.1016/j.watres.2013.07.005

Dantas TL, Mendonça VP, José HJ, Rodrigues AE, Moreira R (2006) Treatment of textile wastewater by heterogeneous Fenton process using a new composite Fe2O3/carbon. Chem Eng J 118(s1–2):77–82. https://doi.org/10.1016/j.cej.2006.01.016

Descorme C (2017) Catalytic wastewater treatment: oxidation and reduction processes. Recent studies on chlorophenols. Catal Today. https://doi.org/10.1016/j.cattod.2017.03.039

Dhakshinamoorthy A, Navalon S, Alvaro M, Garcia H (2012) Metal nanoparticles as heterogeneous Fenton catalysts. ChemSusChem 5(1):46–64. https://doi.org/10.1002/cssc.201100517

Fayazi M, Taher MA, Afzali D, Mostafavi A (2016) Enhanced Fenton-like degradation of methylene blue by magnetically activated carbon/hydrogen peroxide with hydroxylamine as Fenton enhancer. J Mol Liq 216:781–787. https://doi.org/10.1016/j.molliq.2016.01.093

Gao P, Song Y, Hao MJ, Zhu A, Yang HW, Yang SH (2018) An effective and magnetic Fe2O3 -ZrO2 catalyst for phenol degradation under neutral pH in the heterogeneous Fenton-like reaction. Sep Purif Technol 201:238–243. https://doi.org/10.1016/j.sepur.2018.03.017

Heckert EG, Seal S, Self WT (2008) Fenton-like reaction catalyzed by the rare earth inner transition metal cerium. Environ Sci Technol 42(13):5014–5019. https://doi.org/10.1021/es8001508

Hou LW, Wang LG, Royer S, Zhang H (2016) Ultrasound-assisted heterogeneous Fenton-like degradation of tetracycline over a magnetite catalyst. J Hazard Mater 302:458–467. https://doi.org/10.1016/j.jhazmat.2015.09.033

Hu Y, Lu SX (2010) Heterogeneous catalytic degradation of polyacrylamide solution. Int J Eng Sci Technol. https://doi.org/10.4314/ijest.v2i7.63750

Kidder GA (1954) Determination of yellow color in raw rubber latex films and crepes. Anal Chem 26(2):311–315. https://doi.org/10.1021/ac60086a014

Lee HJ, Soles CL, Liu DW, Bauer BJ, Lin EK, Wu WL, Grill A (2004) Structural characterization of porous low-k thin films prepared by different techniques using x-ray porosimetry. J Appl Phys 95(5):2355–2359. https://doi.org/10.1063/1.1641955

Luo M, Yuan SH, Tong M, Liao P, Xie W, Xu X (2014) An integrated catalyst of Pd supported on magnetic Fe3O4 nanoparticles: simultaneous production of H2O2 and Fe2+ for efficient electro-Fenton degradation of organic contaminants. Water Res 48(1):190–199. https://doi.org/10.1016/j.watres.2013.09.029

Lv HL, Zhao HY, Cao TC, Lin Q, Wang YB, Zhao GH (2015) Efficient degradation of high concentration azo-dye wastewater by heterogeneous Fenton process with iron-based metal-organic framework. J Mol Catal A Chem 400:81–89. https://doi.org/10.1016/j.molcata.2015.02.007

Lyu L, Hu C (2017) Heterogeneous Fenton catalytic water treatment technology and mechanism. Prog Chem 29(9):981–999

Lyu L, Zhang LL, Hu C (2015a) Enhanced Fenton-like degradation of pharmaceuticals over framework copper species in copper-doped mesoporous silica microspheres. Chem Eng J 274:298–306. https://doi.org/10.1016/j.cej.2015.03.137

Lyu L, Zhang LL, Wang QY, Nie YL, Hu C (2015b) Enhanced Fenton catalytic efficiency of γ-Cu-Al2O3 by σ-Cu2+-ligand complexes from aromatic pollutant degradation. Environ Sci Technol 49(14):8639–8647. https://doi.org/10.1021/acs.est.5b00445

Ma JH, Song WJ, Chen CC, Ma WH, Zhao JC, Tang YL (2005) Fenton degradation of organic compounds promoted by dyes under visible irradiation. Environ Sci Technol 39(15):5810–5815. https://doi.org/10.1021/es050001x

Navalon S, Alvaro M, Garcia H (2010) Heterogeneous Fenton catalysts based on clays, silicas and zeolites. Appl Catal B 99(1):1–26. https://doi.org/10.1016/j.apcatb.2010.07.006

Neyens E, Baeyens J, Creemers C (2003) Alkaline thermal sludge hydrolysis. J Hazard Mater 97(1–3):295–314. https://doi.org/10.1016/s0304-3894(02)00286-8

Ocampo R, Ramos RL, Mendoza-Barron J, Guerrero-Coronado RM (2011) Adsorption rate of phenol from aqueous solution onto organobentonite: surface diffusion and kinetic models. J Colloid Interface Sci 364(1):195–204. https://doi.org/10.1016/j.jcis.2011.08.032

Patterson AL (1939) The Scherrer formula for X-ray particle size determination. Phys Rev 56(10):978–982

Pereira MC, Oliveira LC, Murad E (2012) Iron oxide catalysts: Fenton and Fenton-like reactions - a review. Clay Miner 47(3):285–302. https://doi.org/10.1180/claymin.2012.047.3.01

Piumetti M, Freyria FS, Armandi M, Saracco G, Garrone E, Gonzalez GE, Bonelli B (2016) Catalytic degradation of Acid Orange 7 by H2O2 as promoted by either bare or V-loaded titania under UV light, in dark conditions, and after incubating the catalysts in ascorbic acid. Catal Struct React. https://doi.org/10.1080/2055074X.2015.1105618

Pouran SR, Raman AA, Daud WM (2013) Review on the application of modified iron oxides as heterogeneous catalysts in Fenton reactions. J Clean Prod 64(2):1–12. https://doi.org/10.1016/j.jclepro.2013.09.013

Rana MS, Maity SK, Ancheyta J (2003) TiO2–SiO2 supported hydrotreating catalysts: physico-chemical characterization and activities. Appl Catal A 253(1):165–176. https://doi.org/10.1016/S0926-860X(03)00502-7

Ribeiro RS, Silva AM, Figueiredo JL, Faria JL, Gomes HT (2016) Catalytic wet peroxide oxidation: a route towards the application of hybrid magnetic carbon nanocomposites for the degradation of organic pollutants. A review. Appl Catal B 187:428–460. https://doi.org/10.1016/j.apcatb.2016.01.033

Rodrigues GD, Lemos LR, Silva LH, Minim L, Coimbra JS (2010) A green and sensitive method to determine phenols in water and wastewater samples using an aqueous two-phase system. Talanta 80(3):1139–1144. https://doi.org/10.1016/j.talanta.2009.08.039

Rusevova K, Köferstein R, Rosell M, Richnow HH, Kopinke FD, Georgi A (2014) LaFeO3 and BiFeO3 perovskites as nanocatalysts for contaminant degradation in heterogeneous Fenton-like reactions. Chem Eng J 239:322–331. https://doi.org/10.1016/j.cej.2013.11.025

Sobańska K, Pietrzyk P, Sojka Z (2017) Generation of reactive oxygen species via electroprotic interaction of H2O2 with ZrO2 gel: ionic sponge effect and pH-switchable peroxidase- and catalase-like activity. ACS Catal 7(4):2935–2947. https://doi.org/10.1021/acscatal.7b00189

Sun JY (2006) Deactivation and regeneration of industrial catalysts. Chemical Industry Press, Beijing

Tang WW, Zeng XP, Zhao JF, Gu GW (2006) Study on stability and application of loaded catalyst in catalytic wet air oxidation. Tech Equip Environ Pollut Control 7(12):132–134,140

Tran CD, Paoli SH (2002) Determination of binding constants of cyclodextrins in room-temperature ionic liquids by near-infrared spectrometry. Anal Chem 74(20):5337–5341. https://doi.org/10.1021/ac020320w

Wang NN, Zheng T, Zhang GS, Wang P (2016) A review on Fenton-like processes for organic wastewater treatment. J Environ Chem Eng 4(1):762–787. https://doi.org/10.1016/j.jece.2015.12.016

Xia QX, Jiang ZH, Wang JK, Yao ZP (2017) A facile preparation of hierarchical dendritic zero-valent iron for Fenton-like degradation of phenol. Catal Commun 100:57–61. https://doi.org/10.1016/j.catcom.2017.06.017

Xu LJ, Wang JL (2011) A heterogeneous Fenton-like system with nanoparticulate zero-valent iron for removal of 4-chloro-3-methyl phenol. J Hazard Mater 186(1):256–264. https://doi.org/10.1016/j.jhazmat.2010.10.116

Xu L, Wang J (2012) Magnetic nanoscaled Fe3O4/CeO2 composite as an efficient Fenton-like heterogeneous catalyst for degradation of 4-chlorophenol. Environ Sci Technol 46(18):10145–10153. https://doi.org/10.1021/es300303f

Xu BJ, Xiao TC, Yan ZF, Sun X, Sloan J, González-Cortés SL, Alshahrani F, Green ML (2006) Synthesis of mesoporous alumina with highly thermal stability using glucose template in aqueous system. Microporous Mesoporous Mater 91(1–3):293–295. https://doi.org/10.1016/j.micromeso.2005.12.007

Zhang DL, Huang TP, Luo GF (2006) Research progress of Fenton and photo-Fenton reaction. Environ Chem 25(2):121–127

Zhang Q, Ying CY, Yu KN, Gu DH, Xiao HH, Wu JY (2010) Study on decomposition rate and stability of hydrogen peroxide. J Jiaxing Univ 3:53–55 (in Chinese)

Zhang JQ, Chi HZ, Song Y, Luo CW, Jiang J, Ma J (2016) Synergistic enhancement on oxidation of phenol by Fenton processes by adding Ce3+ and Cu2+ ions. Environ Sci 37(8):3067–3072. https://doi.org/10.13227/j.hjkx.2016.08.030

Zhou YR, Zhu WP (2006) Catalytic oxidation of dimethyl phthalate in aqueous solution by aluminum oxide. Environ Sci 27(1):51–56. https://doi.org/10.1016/S1872-2040(06)60041-8

Zhu LL, Deng YF, Zhang JP, Chen J (2011) Adsorption of phenol from water by N-butylimidazolium functionalized strongly basic anion exchange resin. J Colloid Interface Sci 364(2):462–468. https://doi.org/10.1016/j.jcis.2011.08.068

Zou XL, Tao Z, Mao J, Wu XH (2014) Synergistic degradation of antibiotic sulfadiazine in a heterogeneous ultrasound-enhanced Fe0/persulfate Fenton-like system. Chem Eng J 257:36–44. https://doi.org/10.1016/j.cej.2014.07.048

Acknowledgments

We thank Dr. Eric Evans, from HDR Engineering, for assistance with academic writing and comments that greatly improved the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51878394), the State Key Laboratory of Environmental Chemistry and Ecotoxicology, the Research Center for Eco-Environmental Sciences, Chinese Academy of Sciences (Grant No. KF2018-12), the Major State Basic Research Development Program of Shandong (Grant No. 2018GSF117003), and the Shandong Key Laboratory of Water Pollution Control and Resource Reuse (Grant No. 2019KF14).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Vítor Pais Vilar

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, M., Gao, X., Liu, H. et al. Preparation of heterogeneous Fenton catalyst γ-Cu-Ce-Al2O3 and the evaluation on degradation of phenol. Environ Sci Pollut Res 27, 21476–21486 (2020). https://doi.org/10.1007/s11356-020-08648-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08648-w