Abstract

The heavy metal sources of large-scale raceway pond microalgae cultivation with flue gas were investigated to reduce heavy metal contents in microalgae during cultivation. The microalgae were cultivated with power plant flue gas (as C source) and circulating cooling seawater (added with N and P nutrients) for 6 days. The Pb, Cd, Hg, and As contents in microalgae were 0.91, 0.22, 0.08, and 0.28 ppm, respectively, which are nearly within the available national standard for food-grade microalgae. The heavy metal contents in microalgae with two membrane materials, namely, elastic polyethylene and random copolymer polypropylene, barely increased. The Hg, As, and Pb contents in microalgae cells cultivated with pure CO2 were 16.67%, 69.23%, and 70.33% that of cells cultivated with CO2 from flue gas. The Pb, As, and Hg contents in cells cultivated with fresh water were reduced by 38.46%, 15.38%, and 37.50%, respectively, compared with those cultivated with seawater. The heavy metal contents in microalgae were further reduced and controlled.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The prevention and remediation of heavy metal pollution have become a major research issue in recent years (Kim et al. 2013). The treatment of heavy metal–polluted water bodies via algal biosorption process has many advantages (Dekhil et al. 2011). Microalgae biomass can produce high value-added products and achieve high economic benefits (Maity et al. 2014). However, the concentration of heavy metals in water enriched with microalgae cells is high, resulting in overproof heavy metal contents in algae cells. The four heavy metals in microalgae biomass with a specified limit content in the international standard are Pb, Cd, Hg, and As.

Ibrahim (2011) studied the adsorption of heavy metal ions from water by using red algae. When the contact time of algae and heavy metal ions was 60 min, algal concentration was 10 g/L, the pH value was 5, and the maximum available metal ion adsorption capacity was 105.2 mg/g. Zhou et al. (2017) studied the performance characteristics of Cd2+ adsorption in water by living microalgae. The adsorption of Cd2+ by Scenedesmus quadricauda was high, whereas that by Spirulina platensis was low even though it exhibited strong affinity toward Cd2+. However, the adsorption of other heavy metals was not mentioned in the research. Zheng et al. (2019) studied the removal of four heavy metals through the growth of Nannochloropsis OZ-1. The result showed that the removal rate of Cd2+ by Nannochloropsis OZ-1 was up to 88.40%, and those of Pd2+, Hg2+, and As3+ were 80%, 80%, and 40.04%, respectively. Nevertheless, no large-scale microalgae cultivation experiment has been conducted; thus, outdoor cultivation of microalgae lacks guiding significance. Tao et al. (2018) explored research progress on the adsorption of environmental pollutants by marine microalgae and its oil production performance. Current research on the adsorption of pollutants by marine microalgae still has certain limitations. Most studies have focused on multiple aspects of influence on marine microalgae by a single heavy metal. To date, the physiological effects of marine microalgae have not been tested in combination with an actual outdoor environment on the basis of multiple environmental factors under multiple metal co-stresses. At present, research on heavy metals mostly adopts a few species of algae, such as S. platensis and Chlorella, with several practices on new algal varieties. Hence, the source analysis and control methods of heavy metals for large-scale outdoor cultivation of microalgae have rarely been reported in the existing literature. In the current work, the sources of heavy metals that may exist in microalgae cultivation with coal-fired power plant flue gas entering into a raceway pond and possible control measures are studied to provide a certain valuable solution to industrial production.

Experimental

Nannochloropsis OZ-1 was cultured in an open raceway pond with an area of 1191 m2 (length 120 m × width 10 m). Nannochloropsis belongs to Chlorophyta and Eustigmatophyceae. The suitable light intensity range was 5000–7000 lx, the appropriate temperature range was 0–30 °C, and the optimal pH value was 6.2–9.8 (Zheng et al. 2019). The environmental condition requirement for Nannochloropsis is low, its growth rate is fast, and it can adsorb many harmful substances. This material is ideal for the biosorption of many harmful substances. The Nannochloropsis OZ-1 cultivated in the experiments was algae preserved by Yantai Hailong Biotechnology Co., Ltd. The algal liquid volume was 310 m3 for an algal depth of 0.26 m. The cleaned flue gas (approximately 15% CO2) of the coal-fired power plant was treated and then allowed to enter the raceway pond to provide C source. The flue gas discharged from the power plant was treated to meet the national emission standard. The flue gas compositions were basically unchanged. During field testing, the flue gas in the cultivation ponds primarily contained 14.3–14.7% CO2, 40.3 mg/m3 NOX, 28.9 mg/m3 SO2, and 5.3 mg/m3 solid particles. In general, the flue gas temperature discharged into the atmosphere is 60–110 °C (Luo 2017). However, the microalgal cultivation ponds are built next to the power plant; thus, the flue gas should pass through a long pipeline to enter the cultivation ponds. Accordingly, the flue gas has been cooled to the environmental temperature when it reaches the microalgae cultivation ponds. Nutrient salt, such as N and P, was added to the seawater as culture medium. The raceway pond was subjected to 6 days of open cultivation after being accessed by algae, which would be harvested after algal density had doubled, thereby completing a cultivation cycle under standard condition. Five waterproof membrane materials, namely, elastic polyethylene (FPO), polyvinyl chloride (PVC), thermoplastic polyolefin (TPO1 and TPO2), and random copolymer polypropylene (PPR), were selected for the pavement on the bottom and the surroundings of five raceway ponds of the same size. The effects of the five membrane materials on the heavy metal contents in the harvested algae powder were investigated under the same cultivation conditions. Power plant flue gas and pure CO2 gas were allowed to enter the two raceway ponds of the same size to investigate the effect of power plant flue gas impurities on the heavy metal contents in algal powder. Nothing was added to the pure CO2 during the experiments because C, N, and P are the major nutrients required for microalgae growth. N and P were special N and P fertilizer additives, and C was provided by CO2, which was supplied by pure CO2 or CO2 in the power plant flue gas. CO2 in this experiment was only used to provide C elements, and no impurities or heavy metals were added to pure CO2. This approach prevented the impurities or heavy metals contained in pure CO2 from interfering with the influence of other culture condition changes on the heavy metal contents in microalgae in the experiment. Seawater and fresh water were allowed to enter the two raceway ponds of the same size to investigate the effects of different water qualities on the heavy metal contents in algal powder. A fully open raceway pond was compared with a raceway pond that was completely covered with a plastic house in terms of microalgae cultivation to examine the effect of the presence or absence of environmental dust on the heavy metal contents in algal powder. The raceway pond was open for 6 days after being accessed with algae to ensure that the algal powder harvested after algal density had redoubled could be compared with that harvested with high-density biomass after 9 days of continuous cultivation. In this manner, the effects of different algal cultivation time on the heavy metal contents in the algal powder could be investigated. Three raceway ponds of the same size were cleaned once after one, two, and three algae cultivation cycles (6 days per cycle) to investigate the effect of raceway pond cleaning frequency on the heavy metal contents in the algal powder. All the conducted experiments are provided in Table 1 in the Appendix to facilitate the comparisons of different experimental conditions.

First, the algae liquids obtained from the six sets of comparative tests were washed with MgSO4 solution with a concentration of 100 mM and water for salt leaching and then centrifuged to obtain dry algal powder. The algal powder was fully digested by adding algae powder to 8 mL of concentrated nitric acid and 2 mL of concentrated hydrochloric acid, followed by microwave power treatment of 1000 W for 45 min. The cooled liquid was then set to a constant volume of 25 mL for use (Domínguez-González et al. 2010). The contents of the four heavy metal components (HM), i.e., the contents M of Hg, As, Pb, and Cd, were measured using an inductively coupled plasma optical emission spectrometer (model iCAP6300, specification ABCZD10278, Thermo, USA).

Results and discussion

Effect of culture pond material on the heavy metal contents in microalgae

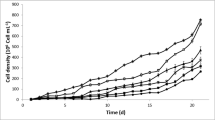

The effect of the materials required to pave the culture pond on the heavy metal contents in the harvested microalgae cells is investigated through Experiment Nos. 1–5 as shown in Table 1 in the Appendix. The results are presented in Fig. 1.

The figure shows that the optimal materials to pave the raceway pond for microalgae cultivation are FPO and PPR. When the two materials are used, the contents of Pb, Cd, Hg, and As in the microalgae cells can basically reach the national food grade standard for Spirulina (GB/T 16919-1997) (Pb < 2 ppm, Cd < 0.2 ppm, Hg < 0.05 ppm, and As < 0.5 ppm). Microalgae cultured with TPO1 and PVC waterproofing materials have a relatively high content of Pb, which is 1.25 and 3.29 times that of FPO cultivation and 1.30 and 3.41 times that of PPR cultivation. Thus, the content of Pb in microalgae cultured with TPO1 and PVC exceeds the national food grade standard for Spirulina. Microalgae cultured with TPO2 have high As and Pb contents. The As content is 1.84 and 1.79 times that of cultivation by FPO and PPR. The Pb content is 12.32 and 12.78 times that of cultivation by FPO and PPR.

The comparison results show that the contents of four heavy metals in the microalgae cultured in the raceway pond paved by FPO and PPR materials can reach the national food grade standard for Spirulina. The microalgae in the case of TPO1 have high content of Cd, those in the case of PVC have high content of Pb, and those in the case of TPO2 have high contents of As, Cd, and Pb. FPO is an elastic polyethylene material. It is a new type of flexible polyolefin with a high melting point, low density, low crystallinity, high stretchability, and high elasticity. FPO was developed in 1994 by Rexene in Texas, USA (Mai and Xu 1997). This material is produced in accordance with the European Chemicals Regulations promulgated by the European Chemicals Agency, which imposes strict regulations on heavy metal contents. PVC exerts considerable influence on the Pb content in microalgae because the antiaging agent of PVC is Pb stearate (Mahmood and Qadeer 1994). This component of Pb salt will dissolve into the microalgae culture solution during microalgae cultivation. The solution is then absorbed by microalgae cells, causing excessive Pb accumulation in the microalgae cells. TPO1 and TPO2 are waterproof rolls. The national standards indicated that the limits of heavy metal dissolution in such materials require that Pb, Cd, and Hg concentrations to be < 10 ppm (Ministry of Environmental Protection 2009). However, the enrichment ability of microalgae cells for these heavy metals varies from 30 to 200 times (Cheng et al. 2015). Thus, the microalgae cultured in the raceway pond paved with the two materials have high contents of heavy metal accumulations.

Effects of flue gas, seawater, and dust on the metal contents in microalgae

The effect of power plant flue gas, seawater, and dust on the heavy metal contents in the harvested microalgae cells during microalgae cultivation is studied through Experiment Nos. 1 and 6–8 as shown in Table 1 in the Appendix. The results are presented in Fig. 2.

The figure shows that flue gas exerts the most important influence on Hg content in terms of change in heavy metal contents in microalgae cells. The Hg content in microalgae cultured with pure CO2 is 1/6 that in microalgae cultured using flue gas. The As and Pb contents are 69.23% and 70.33%, respectively, that in microalgae cultured in power plant flue gas. Therefore, the contents of various heavy metals in microalgae completely meet the national standards under this condition. If fresh water is used for microalgae cultivation, then the contents of Pb, As, and Hg in the cells are reduced by 38.46%, 15.38%, and 37.50%, respectively, compared with those in microalgae cells cultured in seawater. Hence, the heavy metal contents of microalgae basically reach the national standards under this condition.

The microalgae breeding plant is located near the coal yard of a coal-fired power plant. Consequently, serious dust pollution is experienced due to the coal conveyor and bulk cement truck in the coal-fired power plant. The dust in the surrounding environment falls into the microalgae culture pond. This situation considerably influences the heavy metal contents in the harvested microalgae cells. Pb is subjected to the greatest impact. The Pb content in microalgae cells when dust is absent is only 3.30% that when dust is present. The As content in microalgae when dust is absent is 42.3% that when dust is present. The contents of Hg and Cd in microalgae cells when dust is absent are also reduced by 25.00% and 19.18% compared with those when dust is present. Hence, the heavy metal contents of microalgae basically reach the national standard when dust is absent. The entry of power plant flue gas increases heavy metal contents in microalgae cells. This phenomenon may be attributed to the fine dust particles with diameters ranging from 2.5, 5, to 10 μm that are still present in the remaining power plant flue gas even though the flue gas has undergone a series of treatments. These dust particles can adsorb a large amount of heavy metal elements because of their small diameter and large specific surface area (Miller et al. 2002). Although the heavy metal contents vary depending on the type of coal, they generally contain a certain amount of As, Cd, Pb, and Hg. Field tests found that Pb, Cd, Hg, and As in the dust of coal-fired power plant flue gas entering the microalgae raceway pond had concentrations of 857.13, 20.17, 0.96, and 590.29 ppm, respectively. As shown in Fig. 2, Hg has the lowest concentration in power plant dust among the four heavy metals. However, Hg exerts the greatest impact of power plant flue gas entry on heavy metal contents in microalgae cells. This situation is attributed to Hg in coal that is mostly present in sulfide phase. Hg undergoes various forms of transformation after combustion in the pulverized coal boiler of the power plant. When the temperature of the flue gas is reduced to < 400 °C, Hg in the flue gas is largely HgCl2, and thus, it is easily absorbed by microalgae cells. Power plant dust has higher Hg concentration than seawater and dust. Therefore, the entry of power plant flue gas has the greatest impact on Hg content in microalgae cell biomass. Nevertheless, the heavy metal contents of microalgae cultured in power plant flue gas can still reach the national standard after it undergoes salt leaching. Moreover, CO2 with a concentration of 15% in power plant flue gas provides adequate C source for the growth of photosynthesis-accumulated biomass of microalgae (Cheng et al. 2013). Thus, the addition of C source nutrients during microalgae cultivation is completely eliminated. This phenomenon saves considerable production costs and improves economic benefits.

Microalgae cultured in fresh water have lower heavy metal contents than those cultured in seawater due to the presence of a certain amount of heavy metals in seawater. The contents of Pb, Cd, Hg, and As in seawater were measured at 0.8, 0.01, 0.1, and 1.1 ppb, respectively, through sampling from the microalgae cultivation site. The contents of Pb and As in microalgae cultured in fresh water were 0.05 ppb and 0.8 ppb, respectively. Cd was not detected. The contents of the four heavy metals were slightly lower than those in seawater. Therefore, the heavy metal contents are lower in microalgae cultured using fresh water than those cultured in seawater. However, the heavy metal contents in microalgae cultured in seawater can still meet the national standards after salt leaching. Microalgae cultivation in seawater saves water cost compared with microalgae cultivation in fresh water. The trace elements in seawater (Zhang et al. 2014) eliminate the addition of trace elements during microalgae growth, saving costs in microalgae cultivation.

Dust exerts an evident effect on the heavy metal contents in microalgae cells. The analysis result of dust collected from the site found that the contents of Pb, Cd, Hg, and As were 53.96, 1.26, 0.63, and 50.41 ppm, respectively. The ultrahigh contents of Pb and As indicate the huge impact of dust on the contents of these heavy metals in microalgae cells. Hence, dust is an important factor that threatens the heavy metal contents in microalgae cells. Dust can be prevented from falling into the culture pond by setting up a glass or plastic house that can block the dust above the open microalgae culture pond. Consequently, the heavy metal hazard brought by dust in microalgae cultivation is avoided. Moreover, the accumulation of heavy metals in microalgae caused by dust is reduced.

Effect of culture cycle on the heavy metal contents in microalgae

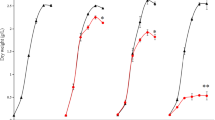

The algae powder harvested with redoubled algae density 6 days after algae entered into the raceway pond was compared with the algae powder harvested with high-density biomass after 9 days of continuous cultivation, such as in Experiment Nos. 1 and 9 as shown in Table 1 in the Appendix. The effect of different algae cultivation periods on the heavy metal contents in the harvested microalgae cells was examined as shown in Fig. 3.

The contents of heavy metals in algae cells harvested after 6 days of cultivation were lower than those of algae cells harvested after 9 days of cultivation. The contents of Cd and Pb decreased by 39.48% and 37.96%, respectively. Meanwhile, the contents of Hg and As decreased by 10.00% and 3.69%, respectively. Cultivation time mostly affects the contents of Pb and Cd in microalgae, followed by Hg and As. With the prolongation of microalgae cultivation time, the contents of Pb and Cd increased significantly in microalgae cells. This change may be attributed to the presence of additional possible sources of heavy metals with the prolongation of cultivation time, increasing the accumulation of heavy metals in algae cells. Microalgae cells have high absorption and enrichment capacity for Pb and Cd, which can reach 439.4 mg/g algae and 116.72 mg/g algae, respectively (Barange et al. 2014), considerably exceeding the Pb and Cd contents in this experiment. Therefore, algae cells cultured for 9 days have significantly higher Pb and Cd contents than those cultured for 6 days. Liu et al. (2019) studied the effect of replacement rate on the growth and quality accumulation of Chlorella. They found that high microalgae biomass and oil yield could be obtained by adjusting the replacement rate. Therefore, selecting the appropriate cultivation time and method offers important practical significance for large-scale algae cultivation. Thus, the detention of algae cells in a culture pond for a prolonged period should be avoided to avoid excessive accumulation of heavy metals in microalgae during cultivation. The pollution of algae cells in a culture pond by the external environment must be prevented.

Effect of culture pond cleaning on the heavy metal contents in microalgae

The effect of raceway pond cleaning frequency on the heavy metal contents in the harvested microalgae cells is investigated through Experiment Nos. 1 and 10–11 as shown in Table 1 in the Appendix. The results are presented in Fig. 4.

The figure shows that cleaning the microalgae raceway pond exerts a considerable influence on the heavy metal contents in the microalgae during their large-scale outdoor cultivation. The content of Pb in the microalgae cells harvested after cleaning the raceway pond once per 6 days is only 0.91 ppm. However, the content is increased to 2.1 ppm for algae cells harvested after cleaning the raceway pond once per 2 cycles (12 days), i.e., an increase of 131%. This content exceeds the national food grade standard for Spirulina. The content of Hg in the microalgae also changes significantly with a change in raceway pond cleaning frequency. The content of Hg in the microalgae harvested after raceway pond cleaning of once per 6 days is only 0.08 ppm. The content is increased by 93% and 138% when the raceway pond is cleaned once every 12 days and 18 days, respectively. The aforementioned phenomenon is attributed to a certain amount of impurities that accumulate at the bottom of the microalgae raceway pond after the end of one cycle of microalgae cultivation for 6 days. The composition mostly includes dust falling into the microalgae culture pond from the surrounding environment. Such dust is not dissolved in the microalgae culture medium or adsorbed by microalgae cells. A small proportion of microalgae cells remaining at the bottom of the raceway pond during harvest, corpses of flagellates and bacteria during the microalgae cultivation process, and a small amount of residual culture solution are found. If the raceway pond is not cleaned after microalgae harvest, then these impurities will continue to enter the microalgae growth environment during the next culture cycle, causing the accumulation of heavy metals in microalgae cells. Therefore, regular raceway pond cleaning is necessary to reduce heavy metal contents in microalgae cells.

In general, the mechanism for metal ion biosorption includes adsorption or complexation on cell wall surfaces and accumulation in the cell interior (Singh et al. 2017). Heavy metal ions are trapped in the structures of cell wall surfaces and then adsorbed onto the binding site of cell wall surfaces. This process is called “adsorption” or “passive absorption.” These heavy metal ions can also enter the cell interior and the metabolism cycle of microalgae cells through cell growth. This process is called “active absorption.” “Passive absorption” and “active absorption” are also called “bioaccumulation” or “enrichment.” When the surface adsorption or intracellular accumulation of heavy metals in the microalgae cultivation process can be controlled, the heavy metal contents in the harvested microalgae biomass can be managed. This condition is instructive for practice.

Conclusions

Algae inoculation was cultivated by adding nutrients, such as N and P, to seawater and allowing power plant flue gas to enter the raceway pond to provide a C source. After 6 days of open culture, algae density was doubled, and the contents of heavy metals, such as Pb, Cd, Hg, and As, in the algae powder reached the national standard of the existing food grade algae powder. The use of FPO or PPR membrane to pave the outdoor raceway pond did not increase the heavy metal contents in the microalgae powder. The contents of Hg, As, and Pb in pure CO2-cultured microalgae were 16.67–70.33% that in flue gas-cultured algae. The contents of Pb, As, and Hg in fresh water algae were 15.38–38.46% lower than that in seawater algae. Thus, the contents of various heavy metals in algae powder can be further reduced and controlled. Dust is an unfavorable factor during microalgae cultivation. Dust hazard can be effectively reduced by setting up a glass or plastic house. Shortening the culture time and timely cleaning of the raceway pond can control the accumulation of heavy metals in microalgae.

References

Barange M, Srivastava A, Srivastava J, Palsania J (2014) Biosorption of heavy metals from wastewater by using microalgae. Int J Chem Phys Sci 3(6):67–81. http://www.ijcps.org/admin/php/uploads/160_pdf.pdf

Cheng J, Huang Y, Feng J, Sun J, Zhou J, Cen K (2013) Mutate Chlorella sp. by nuclear irradiation to fix high concentrations of CO2. Bioresour Technol 136:496–501. https://doi.org/10.1016/j.biortech.2013.03.072

Cheng J, Xu J, Huang Y, Li Y, Zhou J, Cen K (2015) Growth optimisation of microalga mutant at high CO2 concentration to purify undiluted anaerobic digestion effluent of swine manure. Bioresour Technol 177:240–246. https://doi.org/10.1016/j.biortech.2014.11.099

Dekhil A, Hannachi Y, Ghorbel A, Boubarker T (2011) Removal of lead and cadmium ions from aqueous solutions using the macroalga Caulerpa racemosa. Chem Ecol 27(3):221–234. https://doi.org/10.1080/02757540.2010.529077

Domínguez-González R, Romarís-Hortas V, García-Sartal C, Moreda-Piñeiro A, Barciela-Alonso M, Bermejo-Barrera P (2010) Evaluation of an in vitro method to estimate trace elements bioavailability in edible seaweeds. Talanta 82(5):1668–1673. https://doi.org/10.1016/j.talanta.2010.07.043

Ibrahim WM (2011) Biosorption of heavy metal ions from aqueous solution by red macroalgae. J Hazard Mater 192(3):1827–1835. https://doi.org/10.1016/j.jhazmat.2011.07.019

Kim K, Keller A, Yang J (2013) Removal of heavy metals from aqueous solution using a novel composite of recycled materials. Colloids Surf A Physicochem Eng Asp 425:6–14. https://doi.org/10.1016/j.colsurfa.2013.02.044

Liu X, Hong Y, Zhan J, Yan R (2019) Effects of renewal rates on the growth and lipid accumulation of Chlorella under semi-continuous cultivation. Environ Sci Technol 42(5):1–6. https://doi.org/10.19672/j.cnki.1003-6504.2019.05.001

Luo Q (2017) The application study of low temperature flue gas waste heat recovery in power plant. J Eng Therm Energy Power 32(08):1–4. https://doi.org/10.16146/j.cnki.rndlgc.2017.08.001

Mahmood F, Qadeer R (1994) Effects of alkaline-earth metal stearates on the dehydrochlorination of poly(VINYL CHLORIDE). J Therm Anal 42(6):1167–1173. https://doi.org/10.1007/BF02546926

Mai K, Xu J (1997) Toughening of thermoplastics. In: Olagoke O (ed) Handbook of thermoplastics, 2nd edn. Marcel Dekker Inc, New York, p 727

Maity JP, Bundschuh J, Chen C, Bhattacharya P (2014) Microalgae for third generation biofuel production, mitigation of greenhouse gas emissions and wastewater treatment: present and future perspectives–a mini review. Energy 78:104–113. https://doi.org/10.1016/j.energy.2014.04.003

Miller C, Srivastava R, Sedman C (2002) Advances in control Of PM2.5 and PM2.5 precursors generated by the combustion of pulverized coal. Int J Environ Pollut 17(1–2):143–156. https://doi.org/10.1504/ijep.2002.000663

Ministry of Environmental Protection (2009) Technical requirements for environmental sign products-water proof roll (HJ455-2009). China Environment Publishing Group, Bejing

Singh M, Pant G, Hossain K, Bhatia AK (2017) Green remediation. Tool for safe and sustainable environment: a review. Appl Water Sci 7:2629–2635. https://doi.org/10.1007/s13201-016-0461-9

Tao A, Meng R, Liu Y, Liang J, Dou X, Kong L, Liu J (2018) Research progress on adsorption of environmental pollutants and oil production properties of marine microalgae. Farm Prod Process 12:70–75. https://doi.org/10.16693/j.cnki.1671-9646(X).2018.12.019

Zhang E, Huang F, Wang Z, Li Q, Sun Y (2014) Characteristics of trace elements in freshwater and seawater cultured pearls. Spectrosc Spectr Anal 34(9):2544–2547. https://doi.org/10.3964/j.issn.1000-0593(2014)09-2544-04

Zheng K, Li Y, Wu D, Qian G, Liu J, Gong D, Ji X (2019) Effects of the growth of Nannochloropsis XJ006 on the removal efficiency of four heavy metals. J Biol 36(3):47–50. https://doi.org/10.3969/j.issn.2095-1736.2019.03.047

Zhou X, Li C, Gao P, Jiang X, Zhao Z, Han W (2017) Adsorption of Cd 2+ in water by living microalgae. Microbiol China 44(5):1182–1188. https://doi.org/10.13344/j.microbiol.china.160556

Funding

This research was supported by the National Key Research and Development Program of China (2016YFB0601003) and Zhejiang Provincial Natural Science Foundation (LQ19E060003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 14 kb)

Rights and permissions

About this article

Cite this article

Sun, J., Cheng, J., Yang, Z. et al. Heavy metal control in microalgae cultivation with power plant flue gas entering into raceway pond. Environ Sci Pollut Res 27, 37357–37362 (2020). https://doi.org/10.1007/s11356-020-08220-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08220-6