Abstract

In this study, various food processing techniques, including high-temperature processes (pasteurization/sterilization and boiling), low-temperature processes (freezing), mechanical processing (peeling and juicing), and water-based processes (washing with tap water and ultrasonic washing) were used to identify the most effective way to remove contamination of 5 fungicides (cyprodinil, difenoconazole, fluopyram, tebuconazole, and fludioxonil). The most effective processes were juicing and freezing in the range between 63 and 100% and from 52 to almost 100%, respectively. Ultrasonic washing and boiling also significantly removed pesticide residues ranging from 79 to 84% and from 72 to 78%, respectively. The same trend was observed by peeling process where maximum reduction of 80% was achieved almost for all fungicides. Washing with tap water decreased the concentration levels in the range of 35–38%. This study demonstrated that the least effective and unpredictable method of decontamination of pesticides was sterilization and pasteurization, due to the large variation in pesticide levels during the process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

High quality of food is determined by the balanced composition, where components cannot contain artificial additives; they are only processed to the necessary extent and produced without the use of genetically modified organisms. They should not contain residues of agricultural chemistry too, i.e., pesticides.

Currently, pesticides are widely used in agriculture to ensure good yields and proper harvesting as well as minimal storage losses. Active substances of the applied pesticides have a diversified mode of action and contact with the plant. Systemic pesticides are absorbed by the tissues that cover the plants, and they circulate inside them and are transported through the vascular system inside the plant. On the other hand, contact pesticides are only used on the surface of plants; they are not absorbed by the plants and they do not move inside them; they protect the plant surface against the attack of pathogenic fungi and harmful insects connected with direct contact with the pest (Tano 2011). The correct use of pesticides and the allowed maximum residue levels (MRLs) of these substances in food are regulated by the law (Labels-instructions for use on plant protection products n.d., Register of plant protection products, Regulation (EC) No 396/2005 (n.d.; n.d.). However, it must be remembered that excessive and/or inappropriate use of pesticides may accumulate their active substances in the environment and may accumulate indirectly in plants. Pesticides are inherently toxic. Migration, durability, and synergistic effects make pesticides, as a result of long-term impact on the human body, contribute to internal organ damage and cancer, and lead to mutagenic and teratogenic changes (Makles and Domański 2008; Nowak et al. 2015).

People can enjoy eating apples almost all year round. In addition to being delicious and widely used in cooking, apples also rich in nutrients and perfectly nourish our entire body and they contribute to our health condition. Hence they are still an important component of our diet. Apples are known to be the main source of polyphenols (especially flavonoids) (Kschonsek et al. 2018) and antioxidants and dietary fiber (Boyer and Liu 2004; Gheyas et al. 1997); the source of vitamins C, E, and K; and the source of B-group vitamins, carotenoids, and other nutritional compositions (Lee 2012). In addition, the content of acid and sugar determines the attractiveness of the fruit. Many epidemiological studies on the health-promoting properties were done in order to reduce the risk of developing some chronic diseases (Boyer and Liu 2004) such as cardiovascular disease (Knekt et al. 2000; Sesso et al. 2003), cancer (Feskanich et al. 2000; Le Marchand et al. 2000), asthma (Woods et al. 2003), and diabetes (Knekt et al. 2002). Moreover, apple consumption was also positively associated with increased lung function (Tabak et al. 2001) and increased weight loss (de Oliviera et al. 2003).

However, apple growing is inextricably connected with the use of chemical plant protection products against several fungal diseases such as apple scab (Venturia inaequalis), apple powdery mildew (Podosphaera leucotricha), brown rot (Monilinia spp.), and the disease complex of flyspeck and sooty blotch (Holb 2009) as well as insect pests such as codling moth (Cydia pomonella L.) or leafrollers (Tortricidae) (Jones and Wiman 2008).

Knowledge about pesticide residues in apples and their potential impact on human health is very important for consumers nowadays. Over the last few years, numerous studies have described the occurrence of multiple and multiclass pesticide residues in apples (Lozowicka 2015; Mladenova and Shtereva 2009; Mutengwe et al. 2016; Poulsen et al. 2017; Szpyrka et al. 2013). An effective way to reduce exposure to toxic pesticides is to develop the efficient and low-cost methods for pesticide removal from commodities. One of the practicable solutions is the use of processing methods. Food processing techniques imply the set of methods and techniques used to transform raw ingredients into food or to transform food into other forms for consumption by humans or animals either at home or in the food processing industry (Kaushik et al. 2009).

Various food processing techniques such as washing, blanching, peeling, pasteurization, cooking, roasting, frying, boiling, and freezing at industrial or home level have been found in most food materials (Đorđević and Đurović-Pejčev 2016). In literature, we can find some information about changes of pesticide residue levels during these processes (Bajwa and Sandhu 2014; Kaushik et al. 2009; Tomer and Sangha 2013) in raw fruit (Bonnechère et al. 2012a, b; Lozowicka et al. 2016; Rawn et al. 2008; Shabeer et al. 2015) and vegetables (Bonnechère et al. 2012a, c). The authors show that the reduction in the content of pesticides is present in most techniques. Changes of pesticide residue levels are caused by processes such as the following: thermal degradation (decomposition), dissolving, hydrolysis, oxidation and reduction, photolysis, volatilization, enzymatic degradation, changes in pesticide residue levels due to weight changes and the partitioning properties of the pesticides (Đorđević and Đurović-Pejčev 2016).

The aim of the study was to evaluate the efficiency of seven processing methods for removal of five fungal pesticides in apples, determine processing factors, and explain the relationship between the properties of pesticides and the reduction of their concentration in fruit.

Materials and methods

Samples

The field research was carried out in a commercial orchard with implementation of the principles of integrated production. The orchard of a land area of six hectares was located in Rzeszów (south-eastern Poland, administrative division of Podkarpackie Voivodeship). Two separate treatments were performed using the following preparations recommended in Poland for apple protection: combination of Score 250 EC (dose 0.2 L/ha, active substance—difenoconazole) and Switch 62.5 WG (dose 0.75 kg/ha, active substances—cyprodinil, fludioxonil) and the second treatment with Luna Experience 400 SC (dose 0.75 L/ha, active substances—tebuconazole, fluopyram). The choice of pesticides used by farmers was based on the highest utility in the orchard for farmers at that time. Apple samples (variety Gala) were collected the next day after application of formulations (ESM 1 contains data on pesticides which have been used in the experiment). Each sample consisted of apples randomly chosen from a row of apple trees. The weight of collected samples of ripe apples was ≥ 1 kg, as required by the national regulation (Regulation 2013). Samples were packed in polyethylene bags and transported to a laboratory.

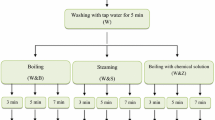

Analytical samples, respectively collected after each treatment, were divided into a few parts (subsample, depending on the number of processing techniques; Fig. 1 shows the processes used in the samples). One of them was not subjected to any process, but it was used to assess the initial concentrations of pesticide residues in the samples. Each sample was analyzed in three replicates.

Food processing techniques

The processing conditions of the samples were connected with the standard fruit processing conditions in households or food processing. Test samples were subjected to further steps depending on the type of processing:

Washing with tap water

In total, 250 g of apple samples was washed in running water for 1 min. Water temperature was 21 °C with hardness of 260 mg CaCO3/l and a flow rate of 5 l/min.

Ultrasonic washing

In total, 250 g of apple samples was washed in an Ultrasonic cleaner (Bandelin Sonorex RK 52, Germany) in 1 l of distilled water for 1, 5, and 15 min. Water temperature was 21 °C, ultrasonic frequency 35,000 Hz, and ultrasonic power 240 W.

Boiling

In total, 250 g of apple samples was immersed in 0.5 l of distilled water for 1, 5, and 15 min at the temperature of 100 °C.

Pasteurization and sterilization

In total, 250 g of apple samples was put into an incubator in a twisted glass jar (Binder GmbH, Germany) for 1, 5, and 15 min at the temperature of 120 °C.

Peeling

In total, 250 g of apple samples was peeled to a depth of 1–1.5 mm with a knife. Both peeled parts and skins were subjected to further testing.

Juicing

In total, 250 g of apple sample was subjected to pressing in order to obtain juice (Hurom, model HH 2G, rotational speed 40 rpm, power 150 W; South Korea).

Freezing

In total, 250 g of apple samples was put into a freezer and stored at − 25 °C with monitored conditions (Electrolux EUF2047AOW, Sweden).

Processed and unprocessed samples were extracted and cleaned with the use of multiresidue method (QuEChERS) and next analyzed with gas chromatography equipped with electron capture and nitrogen-phosphorus detection (GC-μECD/NPD).

Processing factor

Processing factors (PFs) for all processing methods were calculated as a ratio concentration of pesticide residues in processed and raw fruit, according to Eq. 1.

where

- Ca:

concentration of pesticide in processed apples (mg/kg)

- Cb:

concentration of pesticide in raw apples (mg/kg)

- PF < 1:

it means the reduction of pesticide concentration in apples

- PF > 1:

it means the increase of pesticide residue concentration in apples

Chemical and reagents

The analytical-grade acetonitrile and petroleum ether were purchased from Honeywell (Germany). The QuEChERS sorbent kits for sample preparation were supplied by Perlan Technologies (Poland).

Certified pesticide analytical standards were provided by LGC Standards (UK). Stock solutions and intermediate standards were prepared by dilution with acetone. Working standards were prepared by dilutions of the appropriate volumes of the intermediate standard with acetone and with blank sample extracts (containing 1 g of sample per 1 ml of petroleum ether solvent) to calibrate the GC-μECD/NPD system and to spike the apple samples in recovery experiments.

Sample preparation procedure

Preparation of apple sample was based on the QuEChERS procedure (Lehotay et al. 2010; PN-EN 15662 2008). However, in order to allow the final determination of pesticide residues with the use of selective detectors such as μECD and NPD, the procedure was modified by solvent exchanged to petroleum ether directly before GC analysis (Słowik-Borowiec and Szpyrka 2018). The analytical procedure of sample preparation is presented in Fig. 2.

GC-μECD/NPD analysis

The quantitative and qualitative analyses of apple samples were carried out with the use of the Agilent Technologies 7890A gas chromatograph (USA) equipped with a microelectron capture (μEC) and a nitrogen phosphorus (NP) detector. Details of chromatographic parameters are included in Table 1.

Method validation

Before the experiments, a number of quality control tests were carried out to ensure the reliability and robustness of the pesticide residue determination process. The following parameters were assessed: trueness, precision, selectivity, limits of quantification (LOQs), and measurement of uncertainty. The results of validation were interpreted according to the criteria adopted in Europe, recommended by the European Commission and published in document SANTE/11813/2017 (2017).

All analyses were done in an accredited laboratory according to the PN-EN ISO/IEC 17025 (2005) standard. There was used a multiresidue analytical method based on the extraction of organic solvent and further cleanup with the use of dispersive solid-phase extraction (Lehotay et al. 2010; PN-EN 15662 2008; Słowik-Borowiec and Szpyrka 2018) followed by GC/μECD/NPD detection techniques.

Results and discussion

Method validation

A full validation study in terms of evaluation of linearity, recovery, and precision, as well as estimation of measurement uncertainty, was performed.

In validation experiments, blank apple samples were spiked at two fortification levels (in at least five repetitions, n = 5). These levels correspond to the lowest and highest concentrations of the linear range (ESM 2). The limits of quantification (LOQs) for each pesticide were set at the lowest spiking concentrations for which validation criteria in the term of recovery and precision were fulfilled. LOQs were within the range of 0.009–0.021 mg/kg. Precision was calculated from the recovery experiments, and it was expressed in terms of relative standard deviation (RSD) at each spiking level. For all pesticides, range percentage of mean recovery and RSD was acceptable and amounted to 83–110% and 2–11%, respectively. Selectivity of the method for all pesticides was assessed considering the lack of interfering peaks from co-extractives. For this purpose, extracts without pesticide were analyzed. In this study, there were no extracted matrix interferences, so the method could be considered selective. Linearity of calibration curves was studied over the concentration range between 0.009 and 2.096 μg/ml by the GC/μECD/NPD analysis of matrix-matched calibration standards (at five levels prepared in apple extract). For all tasted pesticides, over the studied concentration range, the linearity was highly satisfactory with coefficients of determination (R2) higher than 0.99 (details in ESM 2). According to SANTE/11813/2017 guide, a quantitative method for pesticide residues should provide mean recoveries within the range of 70–120% and relative standard deviations (RSD) ≤ 20% (SANTE/11813/2017 (2017)).

Method uncertainty (U) for each pesticide was assessed following the “top-down” approach using overall recovery and precision data (Medina-Pastor et al. 2011). The expanded uncertainty was calculated as twice the value of the uncertainty (k = 2, confidence level 95%) and ranged between 6 and 25%, with an average of 15% (ESM 2).

The values of characteristic parameters obtained in validation process confirmed that the method meets the requirements of the European Commission and it is suitable for the determination of pesticide residue in apples.

Processing effect

Changes of concentration of pesticide levels during food processing are determined by various factors, not only the type of technique which is used but also the type of food product and pesticide (their nature and chemical class and properties). Researches indicate that the effects of processing may be affected by the physical location of pesticide residues as well as physicochemical properties of pesticides such as solubility, volatility, hydrolytic rate constants, water-octanol partition coefficient, and thermal degradation (Keikotlhaile et al. 2010). Therefore, the main physicochemical properties and mode of action of the pesticides studied in our experiment are summarized in Table 2, and next discussed.

All processing conditions which were carried out in the laboratory are connected in terms of household and industrial processing. Evaluation of the behavior of pesticide residue levels in apples during processing is closely related with the calculation processing factor. For this purpose, initial concentration of five selected pesticides in raw and unprocessed fruit was determined. For majority processes, the achieved PFs were below 1; the exception was only the juicing (in extrudate) and apple peeling (in the skin) processes and two cases of pasteurization process. The results of analysis are presented in Table 3.

Washing with tap water

Washing with tap water is one of the simplest and the most common stages before consumption or further processing. In this study, washing was done with tap water for 1 min (Lozowicka et al. 2016). The removal effects for each individual fungicide are shown in Table 3. Significant reductions over 50% were found for tebuconazole (PF = 0.43) and fluopyram (PF = 0.44) while concentrations of cyprodinil (PF = 0.66), difenoconazole (PF = 0.62), and fludioxonil (PF = 0.65) in apples were reduced by 34%, 35%, and 38%, respectively.

The obtained data can be related to the physicochemical properties and the mode of action of these substances (Table 2). In the systemic mode of action, the active substances are absorbed into the system of a plant, which renders its parts (the roots, stems, and leaves), and then, they are poisonous to plant pests and pathogens (Bonnechère et al. 2012c). Therefore, we expected higher losses for fludioxonil, during simple washing operations, which is a non-systemic pesticide and remains on the plant’s surface. However, we have received only 35% of reduction. This is probably due to poor solubility in water (only 1.8; Table 2). Polar, water-soluble pesticides are easier to remove than low-polarity materials (Holland et al. 1994; Timme and Walz-Tylla 2004). Another important factor affecting the efficiency of the process is water-octanol partition coefficient, where according to available literature, substances with a lower octanol-water partition coefficient are more easily removed by washing (Zhao et al. 2014). Our results confirmed this relationship—fluopyram and tebuconazole with logP below 4 showed a greater reduction (56% and 57%, respectively) in contrast to logP above 4 for fludioxonil (35%), difenoconazole (38%), and cyprodinil (34%). Molecular mass g / mol of pesticides influences the percentage of removed pesticides (the higher molar mass, the greater removal efficiency). This was confirmed, except for difenoconazole (M = 406.26 g/mol with PF = 0.62, Table 2).

According to data published over past years, washing apples brought about 6–53% pesticide reduction (Mergnat et al. 1995; Rawn et al. 2008; Li et al. 2015). Similar results of decontamination using tap water by 47–53% were obtained for tomato (Vemuri et al. 2014) and a smaller drop value for strawberries between 6 and 33% (Lozowicka et al. 2016).

Ultrasonic washing

Ultrasonic cleaners can also be used for washing vegetables and fruit. The washer operates on the principle of microcavity induced by ultrasounds. High temperature, rapid pressure changes, and the formation and cracking of microbubbles ensure a continuous washing process and guarantee effective sterilization.

In our studies, this process was carried out for 1, 5, and 15 min and proved to be very effective. We found a great reduction of fluopyram and tebuconazole residues in a treated fruit, which increased with time. After 1 min, a decreased concentration for fluopyram (63%, PF = 0.37) and tebuconazole (64%, PF = 0.36) was observed. However, after 15 min, these levels were in range between 84% (fluopyram, PF = 0.16) and 79% (tebuconazole, PF = 0.21). Results are shown in Table 3. Both active substances belonging to the systemic group of pesticides, which were transported inside the plants, are contrasted with non-systemic chemicals remaining on the fruit surface. So, we were expecting a limited reduction. Nevertheless, they were easily removed by ultrasonic cleaning.

Comparing the obtained results, we can conclude that ultrasonic washing has proved to be more effective than using tap water. Similar results were obtained by other researchers in case of strawberries (Lozowicka et al. 2016).

Boiling

Boiling is the act of preparing food for eating with the use of hot water. Literature contains information about decontamination of pesticide residues when using this method (Randhawa et al. 2007; Rani et al. 2013; Walia et al. 2010). As it can be seen in Table 3, the concentration of pesticide residues in boiling is reduced in the first minute in the range of 49% and 55% and after further 15 min to 72% (PF = 0.28) and 78% (PF = 0.22) for fluopyram and tebuconazole, respectively. The results could be explained by the physicochemical properties of pesticides. Slightly greater decomposition was demonstrated by tebuconazole, with a solubility in water of 36 mg/l compared with fluopyram, where it was 16.0 mg/l. For both compounds, the octanol-water partition coefficient is sufficiently low to be water soluble (Table 2). However, in our experiment, no correlation was observed between degradation points (fluopyram is 300 °C, tebuconazole is 350 °C) and the disappearance of fungicides, which seems to be important from the point of view of thermal processes. Compared with previously described methods, boiling reduced the concentrations of fluopyram and tebuconazole to a higher extent than washing with tap water (56% and 57%), but slightly lower for ultrasonic cleaning (84% and 79%).

The authors of the publication show that the degree of pesticide reduction in this process also depends on the type of substance and its affiliation to the chemical group. Some of them found no decomposition or even an increase in the content of active substances in the processed products (Lozowicka et al. 2016; Rasmusssen et al. 2003).

Pasteurization and sterilization

The pasteurization and sterilization are common processes which were used to obtain shelf-stable products. Their conditions, in this study, were selected to be as close as possible in commercial repetition with a process temperature of 120 °C for 5, 15, 30, and 60 min. In our study, the distribution of pesticide residues was very varied. After the first 5 min, concentration of cyprodinil dropped by 22% (PF = 0.78), and after 60 min only by 16% (PF = 0.84) of the initial value, as well as fludioxonil, whose elimination decreased to 18% (PF = 0.82) and eventually to 14% (PF = 0.86). Fluopyram and tebuconazole after 5 min showed an increase in PF above 1, and finally, the decline content was equal to 1% and 3%, respectively. Only difenoconazole showed a decrease in concentration both after 5 and 60 min with a processing factor of 0.80 and 0.76, respectively (Table 3). Because this process took place without the presence of water, physicochemical properties such as solubility in water and logP are not significant. The effects of these thermal processes depend on the temperature and the degree of moisture loss. According to our expectations, contents of the most thermally stable compounds (Table 2) like tebuconazole (degradation point = 350 °C) and difenoconazole (degradation point = 337 °C) should be high. It confirms the assumption we received for this first component. In addition, an increase in concentration due to loss of moisture during the process was already observed at the beginning of the process for fluopyram (PF = 1.10) and tebuconazole (PF = 1.08) and gradually for cyprodinil (PF = 0.78 → 0.77 → 0.83 → 0.84) and fludioxonil (PF = 0.82 → 0.79 → 0.87 → 0.86). Open systems may result in water loss during heating by evaporation, thereby concentration of pesticide residues if they are not destroyed by heating (Keikotlhaile et al. 2010).

The results of our research indicate that the pasteurization and sterilization processes are the least effective way to remove pesticide residues from apples.

Literature describes the thermal processes in fruit and vegetables and indicates varied distribution of pesticides: from the total reduction (Severini et al. 2003) through partial elimination (Marudov et al. 1999) until no change observed in the concentration of active substances (Đorđević et al. 2013).

Peeling

Peeling is an important step to remove unwanted or indigestible parts of fruit and vegetables both in households and on industrial scales. Importantly, it is significant in eliminating pesticide residues from many plant products depending on the chemical nature of the pesticides and environmental conditions (Đorđević and Đurović-Pejčev 2016).

In case of this type of fruit processing, the mode of action of the pesticide will be the most important. Pesticides get into the fruit in the systemic interaction, while the contact remains on the surface of the skin. Four of our tested substances are systemic; only fludioxonil is a contact fungicide. The results show that the reduction of pesticide residues in peeled apples was for each substance: 81% for tebuconazole (PF = 0.19) and cyprodinil (PF = 0.19), 80% for fluopyram (PF = 0.20), 75% for fludioxonil (PF = 0.25), and 59% for difenoconazole (PF = 0.41). The coefficients for the processing of skins ranged from 3.69 (difenoconazole) to 5.85 (fludioxonil). All results are presented in Table 3. The experiment did not reveal any drastic differences between the studied substances related to their mode of action. These results can be explained by the presence of systemic pesticides which are still present on the skin (1 day before treatment), not absorbed inside; hence, they could be effectively removed in the peeling process.

This preparation method was found very effective in removing studied pesticide as well as ultrasonic washing.

Peeling had also a significant effect on pesticide elimination, according to literature in peaches (Balinova et al. 2006), potatoes, an eggplant (Randhawa et al. 2007), tomatoes (Kwon et al. 2015; Rani et al. 2013), apple (Rasmusssen et al. 2003), and cucumber (Cengiz et al. 2006).

Juicing

Juicing is currently one of the most popular methods for processing fruit and vegetables and can be carried out using a variety of tools. Many of the available publications maintain that juice extrusion has the benefit of reducing the occurrence of pesticides in processed objects. High reduction of over 60% related to fluopyram and tebuconazole, while the remaining fungicides were completely removed from apple juice (difenoconazole and fludioxonil were not detected, and PF for cyprodinil was 0.04). Residues of pesticides persisted in apple extrudate as confirmed by high processing rates above 1 for each active substance tested (data are included in Table 3). Reducing the levels of pesticide residues during this process depends largely on the partitioning properties of the pesticide between the fruit/pulp and the juice. We can assume that highly lipophilic pesticide (with logP above 4) was found in the pulp or pomace after juice making (Kaushik et al. 2009) and following steps such as clarification can further reduce the pesticide content.

Comparing our results with data present in literature, we can confirm high efficacy in decontamination of apples. Lipowska et al. (1998), as well as Zabik et al. (2000), Rasmusssen et al. (2003), and Li et al. (2015), showed a decrease in the concentration of pesticides in apple juice in more than 90%, 78–100%, and 85–95%, respectively.

Thus, we can conclude that the method of juicing is very simple and the most effective among the investigated methods of eliminations of pesticide residues.

Freezing

In our study, apples were stored at a temperature below − 25 °C for 120 days and samples were taken regularly every 30 days. We found that contaminations of apple during freezing were gradually decreased for all test compounds. After the first 30 days, reduction for cyprodinil and fludioxonil by 30% from the initial value was noted, and after 120 days almost the total reduction (PF = 0.05 and 0.07, respectively), while for difenoconazole by only 17% after 30 days and then 52% after ending of freezing (Table 3). Nevertheless, it should be emphasized here that a significant disadvantage of this method is time-consuming.

Previously, methods of heat treatment using high temperatures were described, but according to our research, freezing can also cause a significant reduction of pesticide contamination. Nevertheless, these methods are not widely described in literature. Just Abou-Arab (1999) designated the effects of freezing at − 10 °C and storage of tomatoes within 12 days and their impact on some pesticides.

Conclusions

Apples are widely grown and eagerly consumed, both in a fresh and processed form. In agricultural practice, for economic reasons, chemical protection is used during the growing season. However, there is a problem of contamination of residues of these substances in apples. Taking along with food, inherently toxic pesticides are linked to a wide spectrum of human health hazards.

In this study, the following various food processing techniques have been used including high-temperature processes (pasteurization/sterilization and boiling), low-temperature processes (freezing), mechanical processing (peeling and juicing), and water-based processes (washing with tap water and ultrasonic washing), which were used to identify the most effective way to remove contamination of five fungicides from apples. Figure 3 shows the impact of individual apple processing on concentration of active substances.

The most effective procedure for removing all pesticides from raw apples turned out to be juicing in the range between 63 and 100%, similarly freezing within 52% and almost 100% for studied compounds (a significant limitation of the freezing process is long duration). Peeling of fruit was also the sufficient way of decreasing the content of almost all pesticides in apples by about 80%; the exception was difenoconazole with PF = 0.41. Instead, washing in tap water caused a decreased content of active substances to a less extent, by about 38% and 35%.

The decomposition of pesticide residues for some processing techniques such as boiling, sterilization/pasteurization, and ultrasonic washing was analyzed systematically during their lasting to obtain information about behavior of the tested substances. Ultrasonic washing and boiling removed different portions of pesticide residues in the range between 79 and 84% and between 72 and 78%, respectively. Decreasing amounts of pesticide residues during apple processing could be coherent to their distribution by heat, adsorption of pesticides to plant tissues, and the solubility of water (Holland et al. 1994). The exception was sterilization/pasteurization, where some increase was observed, from the initial increase in concentration level for fluopyram and tebuconazole (for both PF above 1), followed by slightly reduction by 1 and 3%, respectively. While for the other substances, an initial drop in content was noted, followed by concentrations for cyprodinil (PF = 0.84) and fludioxonil (PF = 0.86). This is probably due to evaporation of water from the sample at high temperature during sterilization and consequently is the least efficient process in eliminating pesticides in apples.

In our study, it was estimated that the residue reduction level was not always correlated with physicochemical properties of pesticides, including structure and belonging to the chemical group, water solubility, logP, and degradation point of the pesticides as well as mode of action. Some pesticides have demonstrated a specific behavior for each process. In conclusion, we are certain and we can confirm that the data obtained in the experiments indicate that both water treatment and mechanical and thermal processing of apples lead to the removal of pesticide residues suitable for home and industry processing.

References

Abou-Arab AAK (1999) Behavior of pesticides in tomatoes during commercial and home preparation. Food Chem 59:115–119. https://doi.org/10.1016/S0308-8146(98)00231-3

Bajwa U, Sandhu KS (2014) Effect of handling and processing on pesticide residues in food-a review. J Food Sci Technol 51(2):201–220. https://doi.org/10.1007/s13197-011-0499-5

Balinova AM, Mladenova RI, Shtereva DD (2006) Effects of processing on pesticide residues in peaches intended for baby food. Food Addit Contam 23:895–901. https://doi.org/10.1080/02652030600771715

Bonnechère A, Hanot V, Jolie R, Hendrickx M, Bragard C, Bedoret T, Loco J (2012a) Processing factors of several pesticides and degradation products in carrots by household and industrial processing. J Food Res 1:68–83. https://doi.org/10.5539/jfr.v1n3p68

Bonnechère A, Hanot V, Bragard C, Bedoret T, van Loco J (2012b) Effect of household and industrial processing on the levels of pesticide residues and degradation products in melons. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 29:1058–1066. https://doi.org/10.1080/19440049.2012.672339

Bonnechère A, Hanot V, Jolie R, Hendrickx M, Bragard C, Bedoret T, van Loco J (2012c) Effect of household and industrial processing on levels of five pesticide residues and two degradation products in spinach. Food Control 25:397–406. https://doi.org/10.1016/j.foodcont.2011.11.010

Boyer J, Liu RH (2004) Apple phytochemicals and their health benefits. Nutr J 3:5. https://doi.org/10.1186/1475-2891-3-5

Cengiz MF, Certel M, Karakas B, Gocmen H (2006) Residue contents of DDVP (dichlorvos) and diazinon applied on cucumbers grown in greenhouses and their reduction by duration of a pre-harvest interval and post-harvest culinary applications. Food Chem 98:127–135. https://doi.org/10.1016/j.foodchem.2005.05.064

de Oliviera M, Sichieri R, Moura A (2003) Weight loss associated with a daily intake of three apples or three pears among overweight women. Nutrition 19:253–256. https://doi.org/10.1016/S0899-9007(02)00850-X

Đorđević T, Đurović-Pejčev R (2016) Food processing as a means for pesticide residue dissipation. Pestic Phytomed 31(3–4):89–105. https://doi.org/10.2298/PIF1604089D

Đorđević T, Šiler-Marinković S, Đurović R, Dimitrijević-Branković S, Gajić Umiljendić J (2013) Stability of the pyrethroid pesticide bifenthrin in milled wheat during thermal processing, yeast and lactic acid fermentation, and storage. J Sci Food Agric 93:3377–3383. https://doi.org/10.1002/jsfa.6188

Feskanich D, Ziegler R, Michaud D, Giovannucci E, Speizer F, Willett W, Colditz G (2000) Prospective study of fruit and vegetable consumption and risk of lung cancer among men and women. J Natl Cancer Inst 92:1812–1823. https://doi.org/10.1093/jnci/92.22.1812

Gheyas F, Blankenship SM, Young E, McFeeters R (1997) Dietary fibre content of thirteen apple cultivars. J Sci Food Agric 75(3):333–340. https://doi.org/10.1002/(SICI)1097-0010(199711)75:3<333::AID-JSFA883>3.0.CO;2-R

Holb IJ (2009) Fungal disease management in environmentally friendly apple production – a review. In: Lichtfouse E (ed) Climate change, intercropping, pest control and beneficial microorganisms chapter 10. Springer, Netherlands, pp 219–292 https://springerlink.bibliotecabuap.elogim.com/chapter/10.1007/978-90-481-2716-0_10. Accessed December 2018

Holland PT, Hamilton D, Ohlin B, Skidmore MW (1994) Effects of storage and processing on pesticide residues in plant products. Pure Appl Chem 66:335–356. https://doi.org/10.1351/pac199466020335

Jones VP, Wiman NG (2008) Longevity of the adult codling moth, Cydia pomonella, and the obliquebanded leafroller, Choristoneura rosaceana, in Washington apple orchards. J Insect Sci 8:14. https://doi.org/10.1673/031.008.140110pp

Kaushik G, Satya S, Naik SN (2009) Food processing a tool to pesticide residue dissipation – a review. Food Res Int 42(1):26–40. https://doi.org/10.1016/j.foodres.2008.09.009

Keikotlhaile BM, Spanoghe P, Steurbaut W (2010) Effects of food processing on pesticide residues in fruits and vegetables: a meta-analysis approach. Food Chem Toxicol 48:1–6. https://doi.org/10.1016/j.fct.2009.10.031

Knekt P, Isotupa S, Rissanen H, Heliovaara M, Jarvinen R, Hakkinen R, Aromaa A, Reunanen A (2000) Quercetin intake and the incidence of cerebrovascular disease. Eur J Clin Nutr 54:415–417. https://doi.org/10.1038/sj.ejcn.1600974

Knekt P, Kumpulainen J, Jarvinen R, Rissanen H, Heliovaara M, Reunanen A, Hakulinen T, Aromaa A (2002) Flavonoid intake and risk of chronic diseases. Am J Clin Nutr 76:560–568. https://doi.org/10.1093/ajcn/76.3.560

Kschonsek J, Wolfram T, Stöckl A, Böhm V (2018) Polyphenolic compounds analysis of old and new apple cultivars and contribution of polyphenolic profile to the in vitro antioxidant capacity. Antioxidants (Basel) 7(1):20. https://doi.org/10.3390/antiox7010020

Kwon H, Kim TK, Hong SM, Se EK, Cho NJ, Kyung KS (2015) Effect of household processing on pesticide residues in field-sprayed tomatoes. Food Sci Biotechnol 24(1):1–6. https://doi.org/10.1007/s10068-015-0001-7

Labels-instructions for use on plant protection products (n.d.). Labels-instructions for use on plant protection products approved for marketing and application with a permit of the Ministry of Agriculture and Rural Development. Available at https://bip.minrol.gov.pl/Informacje-Branzowe/Produkcja-Roslinna/Ochrona-Roslin/Etykiety-Srodkow-Ochrony-Roslin?%2FInformacje-Branzowe%2FProdukcja-Roslinna%2FOchrona-Roslin%2FEtykiety-Instrukcji-Stosowania-Srodkow-Ochrony-Roslin. /Accessed December 2018

Le Marchand L, Murphy S, Hankin J, Wilkens L, Kolonel L (2000) Intake of flavonoids and lung cancer. J Natl Cancer Inst 92:154–160. https://doi.org/10.1093/jnci/92.2.154

Lee CY (2012) Common nutrients and nutraceutical quality of apples. New York Fruit Quarterly 20(3):1–8 Available at http://nyshs.org/wp-content/uploads/2016/10/1.Common-Nutrients-and-Nutraceutical-Quality-of-Apples.pdf. Accessed December 2018

Lehotay SJ, Son KA, Kwon H, Koesukwiwat UFW, Mastovska K, Hoh E, Leepipatpiboon N (2010) Comparison of QuEChERS sample preparation methods for the analysis of pesticide residues in fruits and vegetables. J Chromatogr A 1217:2548–25602. https://doi.org/10.1016/j.chroma.2010.01.044

Li M, Liu Y, Fan B, Lu J, He Y, Kong Z, Wang F (2015) A chemometric processing-factor-based approach to the determination of the fates of five pesticides during apple processing. LWT - J Food Sci Technol 63:1102–1109. https://doi.org/10.1016/j.lwt.2015.03.105

Lipowska T, Szymczyk K, Danielewska B, Szteke B (1998) Influence of technological process on fenitrothion residues during production of concentrated apple juice - short report. Pol J Food Nutr Sci 7:293–297

Lozowicka B (2015) Health risk for children and adults consuming apples with pesticide residue. Sci Total Environ 502:184–198. https://doi.org/10.1016/j.scitotenv.2014.09.026

Lozowicka B, Jankowska M, Hrynko I, Kaczynski P (2016) Removal of 16 pesticide residues from strawberries by washing with tap and ozone water, ultrasonic cleaning and boiling. Environ Monit Assess 188(1):51 https://springerlink.bibliotecabuap.elogim.com/article/10.1007/s10661-015-4850-6. Accessed December 2018

Makles Z, Domański W (2008) Ślady pestycydów - niebezpieczne dla człowieka i środowiska. Bezpieczeństwo Pracy 1:5–9 [in Polish]

Marudov G, Radeva S, Pietrowska E, Nikolov I (1999) Influence of processing peaches into puree and nectar on contents of pesticides residues. Fluessiges-Obst 66:171–172

Medina-Pastor P, Valverde A, Pihlsotrm T, Masselter S, Gamon M, Mezcua M, Rodriguez-Torreblanca C, Fernandez-Alba AR (2011) Comparative study of the main top-down approaches for the estimation of measurement uncertainty in multiresidue analysis of pesticides in fruits and vegetables. J Agric Food Chem 59(14):7609–7619. https://doi.org/10.1021/jf104060h

Mergnat T, Fritsch P, Saint-Joly C, Truchot E, Saint-Blanquat G (1995) Reduction of phosalone residue levels during industrial dehydration of apples. Food Addit Contam 12:759–767. https://doi.org/10.1080/02652039509374368

Mladenova R, Shtereva D (2009) Pesticide residues in apples grown under a conventional and integrated pest management system. Food Addit Contam Part A Chem Anal Control Expo Risk Assess 26(6):854–858. https://doi.org/10.1080/02652030902726060

Mutengwe MT, Chidamba L, Korsten L (2016) Pesticide residue monitoring on South African fresh produce exported over a 6-year period. J Food Prot 79(10):1759–1766. https://doi.org/10.4315/0362-028X.JFP-16-022

Nowak R, Włodarczyk-Makuła M, Mamzer E (2015) Ryzyko środowiskowe i zdrowotne wynikające ze stosowania środków ochrony roślin (Environmental and health risk resulting from applying plant protection products). Zeszyty Naukowe Wyższej Szkoły Zarządzania Ochroną Pracy w Katowicach 1(11):51–63 [in Polish]

PN-EN 15662, (2008). PN-EN 15662:2008 (2008) Foods of plant origin. Determination of pesticide residues using GC-MS and/or LC-MS/MS following acetonitrile extraction/partitioning and clean-up by dispersive SPE. QuEChERS-method. Polski Komitet Normalizacyjny, Warszawa, 81 pp.

PN-EN ISO/IEC 17025 (2005). PN-EN ISO/IEC 17025 (2005) General requirements for the competence of testing and calibration laboratories, 42 pp.

Poulsen ME, Andersen JH, Petersen A, Jensen BH (2017) Results from the Danish monitoring programme for pesticide residues from the period 2004–2011. Food Control 74:25–33. https://doi.org/10.1016/j.foodcont.2016.11.022

Randhawa MA, Muhammad Anjum F, Ahmed A, Saqib Randhawa M (2007) Field incurred chlorpyrifos and 3,5,6-trichloro-2-pyridinol residues in fresh and processed vegetables. Food Chem 103:1016–1023. https://doi.org/10.1016/j.foodchem.2006.10.001

Rani M, Saini S, Kumari B (2013) Persistence and effect of processing on chlorpyriphos residues in tomato (Lycopersicon esculantum Mill.). Ecotox Environ Safe 95:247–252. https://doi.org/10.1016/j.ecoenv.2013.04.028

Rasmusssen RR, Poulsen ME, Hansen HCB (2003) Distribution of multiple pesticide residues in apple segments after home processing. Food Addit Contam 20:1044–1063. https://doi.org/10.1080/02652030310001615221

Rawn DFK, Quade SC, Sun W, Fouguet A, Belanger A, Smith M (2008) Captan residue reduction in apples as a result of rinsing and peeling. Food Chem 109:790–796. https://doi.org/10.1016/j.foodchem.2008.01.061

Register of plant protection products (n.d.). Register of plant protection products approved for marketing and application. Available at https://bip.minrol.gov.pl/Informacje-Branzowe/Produkcja-Roslinna/Ochrona-Roslin/Rejestr-Srodkow-Ochrony-Roslin/ Accessed December 2018

Regulation (2013). Regulation of the Minister of Agriculture and Rural Development from 27 November 2013 on the sampling of plants, plant products or other objects to test for the presence residues of plant protection products. Dz.U. z 2013 r. Nr 00, poz. 1549. Available at http://isap.sejm.gov.pl/DetailsServlet?id=WDU20130001549/Accessed December 2018

Regulation (EC) No 396/2005 (n.d.). Regulation (EC) No 396/2005 of the European Parliament and of the Council of 23 February 2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending Council Directive 91/414/EEC. Off. J. L 70, with later amendments. 16 pp. http://ec.europa.eu/sanco_pesticides/public/?event=product.resultat&language=PL&selectedID=169 / Accessed December 2018

SANTE/11813/2017 (2017). European Commission Directorate General for Health and Food Safety SANTE/11813/2017. Guidance document on analytical quality control and method validation procedures for pesticide residues and analysis in food and feed, 46 pp. https://ec.europa.eu/food/sites/food/files/plant/docs/pesticides_mrl_guidelines_wrkdoc_2017-11813.pdf. / Accessed December 2018

Sesso H, Gaziano JM, Liu S, Buring J (2003) Flavonoid intake and risk of cardiovascular disease in women. Am J Clin Nutr 77:1400–1408. https://doi.org/10.1093/ajcn/77.6.1400

Severini C, de Pilli T, Petruccelli A, Baiano A, Scapicchio P (2003) Effects of technological processes on pesticide residues in canned tomatoes. Ind Aliment 42:487–495

Shabeer ATP, Kaushik B, Manjusha J, Rushali G, Sagar U, Sandip H, Dasharath O (2015) Residue dissipation and processing factor for dimethomorph, famoxadone and cymoxanil during raisin preparation. Food Chem 170:180–185. https://doi.org/10.1016/j.foodchem.2014.08.008

Słowik-Borowiec M, Szpyrka E (2018) Multiresidue analysis of pesticides in wine and grape using gas chromatography with microelectron capture and nitrogen–phosphorus detection. Food Anal Method 11:3516–3530. https://doi.org/10.1007/s12161-018-1329-4

Szpyrka E, Kurdziel A, Słowik-Borowiec M, Grzegorzak M, Matyaszek A (2013) Consumer exposure to pesticide residues in apples from the region of south-eastern Poland. Environ Monit Assess 185:8873–8878. https://doi.org/10.1007/s10661-013-3219-y

Tabak C, Arts I, Smit H, Heederik D, Kromhout D (2001) Chronic obstructive pulmonary disease and intake of catechins, flavonols, and flavones. Am J Resp Crit Care Med 164:61–64. https://doi.org/10.1164/ajrccm.164.1.2010025

Tano ZJ (2011) Pesticides in the modern world – trends in pesticides analysis. Stoytcheva, M. (ed.) Identity, physical and chemical properties of pesticides InTech, United Kindom, Chapter 1, pp. 3–21. Available at http://www.intechopen.com/books/show/title/pesticides-in-the-modern-world-trends-in-pesticidesanalysis. Accessed December 2018

Timme G, Walz-Tylla B (2004) Effects of food preparation and processing on pesticide residues in commodities of plant origin. In: Hamilton D, Crossley S (eds) Pesticides residues in food and drinking water: human exposure and risks. Wiley, New Jersey, pp 12–148. https://doi.org/10.1002/0470091614.ch4

Tomer V, Sangha JK (2013) Vegetable processing at household level: effective tool against pesticide residue exposure. IOSR J Environ Sci Toxicol Food Technol 6(2):43–53. https://doi.org/10.9790/2402-0624353

Vemuri SB, Rao CS, Darsi R, Reddy AH, Aruna M, Ramesh B, Swarupa S (2014) Methods for removal of pesticide residues in tomato. J Food Sci Technol 2(5):64–68. https://doi.org/10.13189/fst.2014.020502

Walia S, Boora P, Kumari B (2010) Effect of processing on dislodging of cypermethrin residues on brinjal. Bull Environ Contam Toxicol 84:465–468. https://doi.org/10.1007/s00128-010-9952-9

Woods R, Walters H, Raven J, Wolfe R, Ireland P, Thien F, Abramson M (2003) Food and nutrient intakes and asthma risk in young adults. Am J Clin Nutr 78:414–421. https://doi.org/10.1093/ajcn/78.3.414

Zabik MJ, El-Hadidi MFA, Cash JN, Zabik ME, Jones AL (2000) Reduction of azinphos-methyl, chlorpyrifos, esfenvalerate and methomyl residues in processed apples. J Agric Food Chem 48:4199–4203. https://doi.org/10.1021/jf9913559

Zhao L, Ge J, Liu F, Jiang N (2014) Effects of storage and processing on residue levels of chlorpyrifos in soybeans. Food Chem 150:182–186. https://doi.org/10.1016/j.foodchem.2013.10.124

Funding

This study was supported by Polish Ministry of Science and Higher Education (Ministerstwo Nauki i Szkolnictwa Wyższego, project ID: SRZ-08).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Słowik-Borowiec, M., Szpyrka, E. Selected food processing techniques as a factor for pesticide residue removal in apple fruit. Environ Sci Pollut Res 27, 2361–2373 (2020). https://doi.org/10.1007/s11356-019-06943-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-06943-9