Abstract

Wheat straw is an abundant agricultural waste that is rich in lignocellulose. However, its waxy surface, highly crystallized structure, and limited surface area make it difficult to be hydrolyzed and used efficiently by microorganisms. Liquid hot water (LHW) pretreatment was studied to explore the feasibility of improving the methane yield of wheat straw in anaerobic digestion (AD). The results showed that the crosslinking structure of wheat straw was broken by LHW pretreatment. Some pores and cracks appeared on the surface of the pretreated wheat straw, increasing the microbial attachment sites. Under different hydrothermal temperatures (150–225 °C) and retention times (5–60 min), the degradation of hemicellulose ranged from 27.69 to 99.07%. The maximum methane yield (201.81 mL CH4/g volatile solids) was achieved after LHW pretreatment at 175 °C for 30 min, which was a 62.9% increase compared with non-treated straw. LHW at high temperatures such as 225 °C was not suitable for the AD of wheat straw. Methane yield results were fitted with the first-order and modified Gompertz equations to evaluate the hydrolysis rate and inhibitory effects of the pretreated materials in AD.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bioenergy from renewable sources has been widely proposed as a solution for the depletion of fossil fuels and the pressures of greenhouse gas emissions. Lignocellulosic biomass can be used as renewable energy source due to its large scale, low cost, and wide availability (Alvira et al. 2010). Wheat straw is the second largest agricultural waste in the world and is also a major crop residue in north China (Qian et al. 2016). According to the data from the International Statistical Yearbook—2017, the wheat production is 131.69 million tons in China in 2016, and at the end of 2017, the yield of wheat straw reached 13.47 billion tons in China (China 2018). A small portion of wheat straw is used as animal feed or household fuel in the rural area, and the rest is usually left unused. This is a significant waste of biomass resources, and therefore, utilizing wheat straw for biofuel production has been increasingly encouraged (Menon and Rao 2012).

The treatment of biomass through anaerobic digestion (AD) has many advantages, such as a wide range of raw materials, diverse products (e.g., biomethane and organic fertilizer), environmental benefits, low-cost, and high-energy recovery efficiency (Chandra et al. 2012a). Because of these characters, the AD is widely supported by the Chinese government. The efficiency of biogas production from AD is affected by the characteristics of the raw materials. When lignocellulosic materials, such as wheat straw, are used as AD feedstock, their complex structure becomes the major barrier to acquire energy and improve degradation rates (Kumar et al. 2009). In order to break the recalcitrant structure that consisted of lignin, cellulose, and hemicellulose, and produce sugars that can be directly utilized by fermentation microorganisms, it is necessary to adopt efficient pretreatments on the lignocellulose-rich substrates before feeding them to the AD system (Sambusiti et al. 2013; Wang et al. 2018).

Nowadays, plenty of pretreatment methods have been investigated on lignocellulosic feedstock (Karagöz et al. 2012; Yi et al. 2014), including biological, chemical, physical processes, or a combination of them. Common methods include steam explosion (Gang et al. 2011), hydrothermal pretreatment (the liquid hot water method) (Yu-ting et al. 2016; Zi-mu et al. 2015), acid-base pretreatment (Chandra et al. 2012b; Ping et al. 2015), ionic liquid pretreatment (Lan et al. 2010; Sashina et al. 2016; Yihong et al. 2017), and bio-enzymatic hydrolysis (Zhong et al. 2011). Among them, liquid hot water pretreatment does not need the addition of chemicals, thus avoids the corrosion problems and decreases secondary pollution. What is more, it is easy to operate and is usually considered eco-friendly, green processing technologies (Bolado-Rodriguez et al. 2016).

There are many reports on using liquid hot water (LHW) pretreatment of lignocellulose to improve methane yield, and a variety of the lignocellulosic biomass has been studied, such as sunflower stalks, sugarcane bagasse, palm oil, and grass (Yi et al. 2014). Chandra et al. (2012b) heated wheat straw at the condition of 200 °C for 10 min by LHW, obtaining a 20% increase in methane productivity compared with the non-treated straw, but they did not explore other temperatures and retention times. According to Ferreira et al. (2013), the optimal pretreatment conditions for wheat straw was at 200 °C for 5 min, and the methane yield was increased by around 27% compared with the raw materials. Wang et al. (2018) observed that the methane potential was not significantly improved by heating the rice straw at different temperatures (90 °C, 150 °C, 180 °C, and 210 °C) for 15 min followed by the LHW pretreatments, and the methane yield was even reduced by 30% at 210 °C.

In previous studies, more attention was attributed to the pretreatment temperature, but the pretreatment time, which is another critical factor of LHW, has not been commonly studied (Ahmad et al. 2018). Few studies focused on the effects of LHW on the AD performance feeding with wheat straw, and the effect of retention time of LHW pretreatment on methane production was not clear. During the LHW pretreatment, various compounds could be produced and inhibit AD microbes. These inhibitors included organic acids, furan derivatives (furfural and 5-hydroxymethyl furfural (5-HMF)), and phenolic compounds (Bolado-Rodriguez et al. 2016; Fagbohungbe et al. 2017). Hence, it is necessary to examine the joint effects of pretreatment temperature and retention time on AD of wheat straw and identify the optimal pretreatment intensity with minimal inhibitors to AD.

This study investigated the effects of LHW with different temperatures and retention times on methanogenic performance of wheat straw-based AD. The effects of enhancement and inhibition were evaluated by the kinetic analysis. The suitable hydrothermal pretreatment conditions investigated in this study may provide a valuable reference for the application of AD of wheat straw.

Materials and methods

Materials

The wheat straw was collected from a farm near the Northwest Agricultural and Forestry University at that time (34° 56′ N, 107° 69′ E). It was first washed to remove particles and then dried in a blast drying oven at 37 °C. Based on the study of Ferreira et al. (2014), the dried wheat straw was ground by an agricultural crusher to particle size of 3–5 cm. Finally, the straw was stored in a self-sealed bag in a cool and dry warehouse. The inoculum used in this study was provided by a mesophilic (operation temperature 35 °C) biogas plant fed with slaughter wastewater, which is managed by the Peimin Company (Zhouzhi County, Shaanxi, China). The TS and VS concentrations of the inoculum were 1.01% and 0.72% (wet basis), respectively. The TS, VS, and carbon/nitrogen (C/N) ratio of the wheat straw were 93.06 ± 0.05%, 87.57 ± 0.01%, and 54.56 ± 0.31, respectively. The elemental composition of the wheat straw obtained was 42.01 ± 0.09% of carbon (C), 5.65 ± 0.12% of hydrogen (H), 40.14 ± 0.43% of oxygen (O), and 0.77 ± 0.22% of nitrogen (N).

Pretreatments

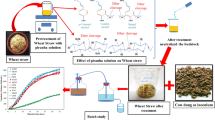

The LHW pretreatment were conducted in a set of 500 mL batch reactors assembled from 1/3-in. 304 stainless steel (Fig. 1). The pressure was 0.4~2.5 Mpa and the final temperature was in the range of 150~225 °C with a heating rate of 9 °C/min. Taking time and temperature as experimental variables, there were in total 14 treatments in this experiment, and each treatment had three replicates (Table 1). The mass ratio (straw/water) was set as 1:30. For the LHW pretreatment, wheat straw (5 g) with deionized water (150 g) was loaded into each reactor and then sealed with a cap; then, nitrogen gas was used to purge the headspace of the reactor for 3 min. After pretreatment, the microwave oven stopped immediately and cooled the material until room temperature (Fig. 1). The aqueous phase and solids were mixed and kept in the screw reagent bottle, and stored in the refrigerator at 4 °C before used for AD.

Biochemical methane potential tests

After the wheat straw had been pretreated, all liquid and solid materials were loaded in AD bottles (with an effective volume of 400 mL) and biochemical methane potential (BMP) tests were carried out in a thermostatic water bath at mesophilic temperature (36 ± 2 °C). The AD experimental setup is shown in Fig. 2. The inoculum mass fraction was 30% (based on wet weight) and the total solid (TS) content was 3.2%. Before starting the test, the bottles were sealed with caps which consisted of two-hole steel sheets and rubber gaskets. In order to ensure strict anaerobic environment in the bottles, the bottle headspace was purged by nitrogen gas inside the gas chamber for 2 min before the test started. A blank test was also conducted without substrate addition, aiming to check the methanogenic activity of the inoculum and obtain the real methane production from the straw. Raw substrate without pretreatment (the control test) was used to do AD under the same condition with the pretreatment tests. The biogas was collected directly by gas bags. The liquid samples (sampling 3 mL each time) were taken by injectors through part no. 7 in Fig. 2.

Schematic of AD device. (1) Constant temperature water bath shaker. (2) Temperature sensor. (3) Electronic temperature display. (4) Temperature sensor module. (5) AD reactor (the screw reagent bottle). (6) Water stop clamp. (7) Liquid sampling conduit. (8) Gas collection conduit. (9) Gas collecting bag. (10) Water stop clamp. (11) Gas bag with double pass valve

Analytical methods

TS, volatile solids (VS), and soluble chemical oxygen demands (CODs) were measured following the methods given in Standard Methods for Examination of Water and Wastewater (APHA et al. 2005). CODs were determined using closed digestion by method 5220D. The pH values were measured using a pH meter (DZS-706, LeiCi). The contents of hemicellulose, cellulose, and lignin were determined by ANKOM A220, and were calculated according to Van Soest method (Vansoest 1992). A scanning electron microscope (TM-300V, Hitachi, Japan) was used to determine the biomass structure after pretreatment. Biogas composition was measured by gas chromatograph (SHIMADZU GC-2014C). The temperatures of the TCD inlet and the oven were 100 °C and 90 °C, respectively, and the helium was used as the carrier gas with a flowrate of 30 mL/min.

Determination of kinetic parameters

The kinetics of the methane production was fitted to the first order model (Eq. (1)) and the modified Gompertz equation (Eq. (2)). The first-order kinetic equation had been successfully applied to simulate the AD process in some previous reports on anaerobic biodegradability tests (Wei et al. 2018). Therefore, the obtained first-order hydrolysis constant was used to judge whether the hydrolysis reaction was the rate-limiting step of the whole process (Ferreira et al. 2013). When an inhibitory behavior was observed in AD, the modified Gompertz model could describe the cumulative methane production in batch assays (Bolado-Rodriguez et al. 2016):

In these two equations, B is the cumulative methane production (mL CH4/g VS); B0 represents the methane production potential (mL CH4/g VS, related to the substrate biodegradability); KH is the hydrolysis rate coefficient (d-1); λ is the lag time (d); t is the time of the assay (d); and the maximum biogas production rate is Rm (mL CH4/g VS d). B0, Rm, and λ were used to evaluate the biogas production characteristics of the AD system.

Results and discussion

Effects of LHW pretreatments on the structure of wheat straw

Wheat straw is a complex mixture of cellulose, hemicellulose, and lignin. Cellulose and hemicellulose are macromolecular polysaccharide polymers that can be converted into sugars during hydrolysis (Prasad et al. 2007). Its waxy surface, highly crystallized stable structure, and limited available surface area made it difficult to get adhesion by microorganisms and be hydrolyzed (Feng 2010). It is impossible to decompose the dense thick-walled cell tissues by microbes in a short period of time, and thus, the lignocellulose cannot be effectively utilized.

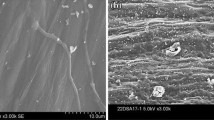

The internal appearance of the pretreated wheat straw under different hydrothermal conditions was examined by the scanning electron microscope, as shown in Fig. 3. The figure shows that under the same retention time, with the increase of hydrothermal temperature, the dense grid-like skeleton structure of wheat straw gradually cracked, and pores and cracks gradually appear on the surface of biomass. The dense skeletal structure of lignocellulose was broken, and the specific surface area increased by this mechanical fracture, which was more favorable for the microbes to adhere and the degradation rate of lignocellulose was increased. At the same temperature, the same phenomenon occurred with the extension of the retention time, and both temperature and retention time could affect the decomposition of lignocellulose. With the increasing temperature and the prolonging retention time, the cross-linking structure of wheat straw gradually collapsed. For example, the structure of the biomass in test H12 was seriously damaged and collapsed, and the grid-like structure could not be observed. Small spherical aggregates appeared on the surface of wheat straw at test H8. From test H8 to test H12, as the conditions changed, the number and volume of spherical aggregates increased. Selig et al. (2007) and Donohoe et al. (2008) also observed the spheroids on the surface of maize straw during the pretreated process. These spheroids were termed pseudo-lignin formed by lignin melting and transferring out of the cell wall under high-temperature conditions and then condensing during cooling (Donohoe et al. 2008; Ma et al. 2015; Shinde et al. 2018).

The changes of lignocellulose contents on wheat straw under different hydrothermal pretreatment conditions are shown in Table 2. The results showed that the hemicellulose degradation of the pretreated wheat straw was increased by 27.69–99.07% with the increases of temperature and retention time. At higher temperatures, water molecule was ionized and produced more H+ and OH−, and the H+ accelerate the hydrolysis rate of hemicellulose and part of cellulose, which made hemicellulose dissociate from original structure through decarboxylation reaction and formed acetate in the aqueous solution eventually. Acetates along with H+ promoted hemicellulose to convert into xylol oligosaccharides and xylose in turn. As is reported before, hemicellulose and some cellulose are hydrolyzed by catalysis of H+, causing the decarboxylation of hemicellulose to dissolve and overflow into aqueous solution to form acetic acid; then, H+ and acetic acid co-catalyze the hydrolysis of hemicellulose to xylooligosaccharides and xylose (Cara et al. 2007; Wan and Li 2011). So, the steric hindrance of cellulose to enzymes was eliminated, and the enzymatic efficiency was improved (Yu-ting et al. 2016), which might have a certain positive effect on AD.

During the hydrothermal pretreatment process, the lignin and cellulose of wheat straw were also degraded. For all the tests, the relative fraction of lignin increased probably because of the decreasing hemicellulose content. The degradation of lignin in four low-intensity tests (H1, H2, H4, and H5) was quite low (1.53–5.52%), indicating that hydrothermal pretreatment in low temperature and short retention time could not significantly remove lignin. For tests H7, H8, H9, H10, and H11, the degradation rate of lignin did not increase but decrease, and the reason might be mainly due to the formation of pseudo-lignin under severe conditions (high temperature and long retention time) (Brownell and Saddler 1987). This was consistent with the observation of microspheres shown in Fig. 3 by an electron microscope. Selig et al. (2007) believed that these attachments of microsphere could enhance the steric hindrance of cellulase and reduce the enzymatic efficiency. Although the cellulose content also increased partially, the degradation of cellulose reached 24.51–80.24%. The experimental results indicated that the hydrothermal pretreatment broke the compact structure of wheat straw and increased the surface porosity. The destroyed lignocellulose was more easily degraded into short-chain molecules, and this should have a positive effect on the AD process.

Effects of LHW pretreatments on the AD of wheat straw

Methane production

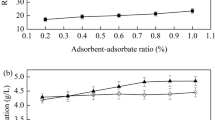

The overall effects of different pretreatment conditions on AD are summarized in Fig. 4. The experimental results showed that the methane productions of five tests which were conducted under high temperatures (H6, H9, H10, H11, and H12) were lower than that of the control, while methane productions of other groups were all higher than the control. Generally, the methane yield decreased with the increase of pretreatment time at all pretreatment temperatures, except for that with 30-min pretreatment time. The optimal methane yield was obtained at 175 °C, which was also the highest methane yield obtained within all treatments. With the relatively mild pretreatment temperature, the methane yield first increased with pretreatment temperature, then decreased after the time was longer than 30 min. However, at high temperatures of 200 °C and 225 °C, methane yield decreased with pretreatment time, probably due to the increasing production of inhibitors and pseudo-lignin.

Carbohydrates from lignocellulose hydrolysis can be easily degraded into inhibitors (such as furfural, hydroxymethylfurfural (HMF), and phenol) under a high-temperature condition, and the increase of temperature can enrich the types of inhibitors in the AD system (Brownell et al. 2010; Laser et al. 2002). What is more, these inhibitors could be further degraded into carbon-rich aromatic structures, which were viewed as the key intermediates to form pseudo-lignin (Shinde et al. 2018). Usually, the formation of pseudo-lignin is detrimental to enzymatic hydrolysis and biological conversion (Sannigrahi et al. 2011; Shinde et al. 2018; Zhuang et al. 2017); however, the methane yields of most pretreated groups were higher than the control. Among all tests, the optimum condition was test H5, which increased the methane yield by 62.9% (from 124.51 to 202.81 mL CH4/g VS). For tests H2, H1, H3, H4, H7, and H8, the LHW pretreatment enhanced methane production by 16.5–40.8%.

The dynamics of methane production was shown in Fig. 5. Changes of daily methane production from untreated and pretreated wheat straw by LHW are shown in Fig. 5a–c. The hydrothermally pretreated wheat straw started to produce methane on the first day, and all the teats had a peak period of methane production in the first 4 days. On the 6th day, the methane production in pretreatment tests was at a low ebb, and then came a small peak. It could be inferred that the methane production characteristics of treated wheat straw showed two stages: rapid biogas production and slow biogas production. This result was similar to the result reported by Qiao et al. (2018), who found that liquid part of chicken manure had a faster methane production than solid part. The reason for this phenomenon was that there were sugars and some organic acids in the liquid after pretreatment which can be directly utilized by microbes. The acidogenesis of sugars was faster, and acetic acid could be directly used by methanogens as substrates to produce methane. So, the substrate utilization efficiency of the microorganisms was improved. The lignocellulose degradation of the test H1 was the lowest, and the biogas production cycle was close to that of the control (42 days). Some tests (H2, H4, H6, H8, H9, and H11) ended on the 19th day, and the test H12 ended on the 16th day. Comparing with the control, the time of AD was shortened by 23 days and 26 days, respectively.

Methane production dynamics from wheat straw treated at different hydrothermal pretreatment conditions. a Daily methane production for 5-min treatment. b Cumulative methane production for 5-min treatment. c Daily methane production for 30-min treatment. d Cumulative methane production for 30-min treatment. e Daily methane yield production 60-min treatment. f Cumulative methane production for 60-min treatment

In all pretreatment test groups, the first peak of methanogenesis appeared in test H5 on day 2, which also was the only peak of the whole AD process. The second earliest peak appeared in H11 on the 12th day, probably because the microorganisms were inhibited from hydrolyzed intermediates of lignocellulosic at the early stage, and then the methanogenesis was increased due to the enhanced tolerance of microorganisms. Barakat et al. (2012) demonstrated the adaptability of microbial consortia to inhibitors. From the methane production fluctuations of all groups, the methanogenesis of H6, H9, and H12 was not active compared with other groups, probably due to the long pretreatment time (60 min).

For the 5-min pretreatment, in the first 12 days of AD, the cumulative methane production of H1 was significantly lower than that in H7 and H4, but it began to catch up and surpass others from 14 days. The cumulative methane yield of the test H10 was the lowest. These indicated that the decomposition of lignocellulose at 150 °C (H1) was lower than the decomposition at high temperature with the pretreatment duration of 5 min. Therefore, the concentrations of sugars and acetic acid in the liquid phase were lower, causing a lower rate of methanogenesis at the early stage. Wheat straws pretreated at 175 °C and 200 °C were easy to be attacked and degraded by microorganisms and surely had a faster methane production rate, because the complex structures of lignocellulose were broken more thoroughly than at 150 °C. Under the 5-min treatment, compared with the other temperatures, the degradation of lignocellulose at 150 °C was the smallest, causing scarce inhibitors and less available organics. Although the hydrolysis and acidogenesis of the organics in the early stage were slow, the cumulative methane production was higher than other treatment groups. There were no significant differences in cumulative methane yield after the three treatment retention times in the range of 5–60 min at 150 °C, but the rate of methanogenesis was higher with longer treated time. Therefore, prolonging the retention time for lower temperature conditions was more conducive to the AD process.

Under the retention time of 30 min, the methane production of H5 was the highest. Except for H11, the cumulative methane productions of the other 3 experimental groups which were pretreated for 30 min were higher than those pretreated for 5 min under the same pretreatment condition. This result could be explained by the increased pretreatment time from 5 to 30 min, which increased the adsorption of water molecular of hydroxyl in amorphous areas of wheat straw, and resulting in the swelling in crystalline areas, and destroyed both the amorphous area and the crystalline area of wheat straw (Yuanfang et al. 2017). After pretreatment, lignocellulosic was easier to be converted into shorter chain organic molecules and was easy to be accessed by fermentation microorganisms (Ran et al. 2018), so more methane was produced.

Under the retention time of 60 min, the total methane production in each experimental group showed a decreasing trend with the increase of pretreatment temperature. Studies have shown that within 1 h under high-temperature conditions, the dissolved lignin re-adsorbed to the surface of the raw material and formed pseudo-lignin (Borrega et al. 2011; Mašura 1987). Pseudo-lignin increased the steric hindrance of cellulase and affected the enzymatic efficiency, thereby affecting AD efficiency, such as in the tests H6, H9, and H12. In addition, prolonging the retention time at high temperatures caused greater degree of degradation of xylan and increased the yield of furfural that inhibits the microbial activity. With the hydrothermal treatment at 180 °C for 20 min, a trace amount of furfural existed in the liquid, and by increasing temperature, 5-hydroxymethylfurfural (5-HMF) began to appear at 200 °C (Zi-mu et al. 2015). Barakat et al. (2012) suggested that the 5-HMF was easier to inhibit the microbial activity of AD than furfural was. Therefore, at 60 min, not only the concentrations of inhibitors increased with the increasing temperature, but also the types of inhibitors rose, which were not conducive to methanogenesis.

CODs and pH

CODs can be used to indicate the amount of organic matter in the solution. Figure 6 shows the changes in COD concentrations and pH of each AD test. Due to the different reaction rates, H2, H4, H6, H8, H9, and H11 stopped producing gas on the 19th day, and the test H12 ended at the 16th day.

In the first 4 days, COD concentrations showed a decreasing trend (Fig. 6a, c, e), which was in accordance to the pH drop (Fig. 6b, d, f) and methanogenesis (Fig. 5). This phenomenon indicated that organic matter was consumed in large quantities in the first 4 days. After that, the COD concentrations rose slightly, and then decreased slowly, probably due to the substrate decomposition, and the intermediates were then consumed by microorganisms. However, due to the absence of aerobic microorganisms in AD, the COD concentration in liquid was still at a high level (Fig. 6). During our experiment, the removal rate of COD concentration was only between 17.52 and 85.32%. In literature, Yong et al. (2017) used municipal solid waste as the substrate and achieved a removal rate of 93.42%. This high removal rate of CODs might be due to the different initial substrate concentrations and the exogenous additives.

During the AD process, the pH values of the solution of each test were first decreased and then increased subsequently, and the pH of the control (raw material without pretreatment) was higher than the pretreated group within the first 8 days. On the one hand, hemicellulose decomposed to sugars and acetic acid via hydrothermal pretreatment (Montané et al. 2006), and acetic acid made the initial pH of the pretreated groups lower than that of the control. On the other hand, the rapid hydrolysis of sugars caused the pH to drop, and the utilization rate of the acetic acid by the microorganism was lower than the rate it produced. However, no acidification during AD was observed, attributing to the low initial substrate loading. With the growth and metabolism of microorganisms, the concentration of organic acids in the liquid was reduced and the acid production rate was low (figure not shown), which could lead the pH to gradually increase until the end of the AD reaction.

Kinetics analysis

The relationship of microorganisms with the degradation of substrates and the metabolic intermediates could be studied by kinetic analysis (Donoso-Bravo et al. 2010; Li et al. 2018). In this paper, the modified Gompertz model and the first-order kinetic model were tested to fit the methane production experimental results. Table 3 shows the detailed kinetic parameters of the models.

The first-order kinetic equation was applicable to the hydrolysis stage of the AD process. The larger the KH value is, the faster the hydrolytic metabolism of the organic substrate by the microorganism will be (Li et al. 2015). Test H5 had the largest KH (0.330) and the maximum methane production in all tests. The KH from the control was only 0.027, confirming that the hydrolysis rate of AD was increased by hydrothermal pretreatment. It also indicated that the hydrolysis rate might have limited the AD of wheat straw, which was in accordance with the results from Ferreira et al. (2013) and Bolado-Rodríguez et al. (2016). The first-order rate constant of AD of wheat straw after hydrothermal pretreatment reached 0.330, which also demonstrated that hydrolysis is not the rate-limiting step in AD after hydrothermal pretreatment.

Good simulation results for AD of pretreated wheat straw were obtained from the modified Gompertz model, indicated by the high R2 values from 0.94 to 0.99. The value of λ reflected the speed of the start-up stage in the AD process and the degree of inhibition at the initial stage. The lower value means a shorter lag time and a faster rate of anaerobic degradation (Koch et al. 2015). Some λ values appeared to be negative, which was changed into zero in order to make it suitable to the reality. The short lag time indicated a very fast AD process, which is contributed by the effective pretreatment and the large amount of inoculum added. Tests H10~H12 had longer lag time than control (tests H10~H12 compared with the control by λ), indicating significant inhibitions compared with the control. The lag time of other tests was shorter than the control, which revealed that the AD process was accelerated, and the adaptability of microorganisms to AD was enhanced. The maximum methanogenic rate obtained by the test H5 was 49.2 mL/ (g VS day), which was the optimal level in this research. Therefore, the parameters obtained from test H5 can be recommended as the optimal pretreatment condition of LHW for wheat straw in AD.

According to the two kinetic models, all hydrothermal pretreatment conditions of wheat straw increased the hydrolysis rate of organic substrate and the maximum reaction rate (except for H10). However, it did not necessarily increase the yield of methane or reduce the lag phase time, probably due to the inhibitors produced during pretreatment.

Conclusions

The increasing intensity of LHW pretreatment (temperatures from 150 to 225 °C and retention times from 5 to 60 min) gradually broke the highly crystallized structure of wheat straw with holes and cracks appeared on the surface. At the same time, the degradation rate of hemicellulose increased by 27.69–99.07%. The AD of pretreated wheat straw was shortened after pretreatment, and thermal pretreatment between 150 and 200 °C and retention times between 5 and 60 min enhanced the methane production by 16.5–62.9%, with the optimum condition appeared at 175 °C and 30 min. The effect of LHW pretreatment at 225 °C was negative to AD at any pretreatment time. First-order model indicated that LHW pretreatment at all conditions increased the rate of hydrolysis in AD, and the modified Gompertz model successfully modeled the inhibitions occurred during AD.

References

Ahmad F, Silva EL, Varesche MBA (2018) Hydrothermal processing of biomass for anaerobic digestion – a review. Renew Sust Energ Rev 98:108–124

Alvira P, Tomas-Pejo E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861

APHA, AWWA, WPDF (2005) Standard methods for the examination of water and wastewater, 21st ed. American Public Health Association, Washington DC

Barakat A, Monlau F, Steyer JP, Carrere H (2012) Effect of lignin-derived and furan compounds found in lignocellulosic hydrolysates on biomethane production. Bioresour Technol 104(1):90–99

Bolado-Rodriguez S, Toquero C, Martin-Juarez J, Travaini R, Garcia-Encina PA (2016) Effect of thermal, acid, alkaline and alkaline-peroxide pretreatments on the biochemical methane potential and kinetics of the anaerobic digestion of wheat straw and sugarcane bagasse. Bioresour Technol 201:182–190

Borrega M, Nieminen K, Sixta H (2011) Degradation kinetics of the main carbohydrates in birch wood during hot water extraction in a batch reactor at elevated temperatures. Bioresour Technol 102(22):10724–10732

Brownell HH, Saddler JN (1987) Steam pretreatment of lignocellulosic material for enhanced enzymatic hydrolysis. Biotechnol Bioeng 29(2):228–235

Brownell HH, Yu EK, Saddler JN (2010) Steam-explosion pretreatment of wood: effect of chip size, acid, moisture content and pressure drop. Biotechnol Bioeng 28(6):792–801

Cara C, Moya M, Ballesteros I, Negro MJ, Gonzalez A, Ruiz E (2007) Influence of solid loading on enzymatic hydrolysis of steam exploded or liquid hot water pretreated olive tree biomass. Process Biochem 42(6):1003–1009

Chandra R, Takeuchi H, Hasegawa T (2012a) Methane production from lignocellulosic agricultural crop wastes: a review in context to second generation of biofuel production. Renew Sustain Energy Rev 16(3):1462–1476

Chandra R, Takeuchi H, Hasegawa T, Kumar R (2012b) Improving biodegradability and biogas production of wheat straw substrates using sodium hydroxide and hydrothermal pretreatments. Energy 43(1):273–282

China, N.B.o.S.o.P.s.R.o. (2018) International statistical yearbook–2017

Donohoe BS, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2008) Visualizing lignin coalescence and migration through maize cell walls following thermochemical pretreatment. Biotechnol Bioeng 101(5):913–925

Donoso-Bravo A, Pérez-Elvira SI, Fdz-Polanco F (2010) Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem Eng J 160(2):607–614

Fagbohungbe MO, Herbert BM, Hurst L, Ibeto CN, Li H, Usmani SQ, Semple KT (2017) The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Manag 61:236–249

Feng P (2010) Isolation, fraction, characterization and modification of hemicelluloses from agriculture and forestry biogass. South China University of Technology, Guangzhou

Ferreira LC, Donoso-Bravo A, Nilsen PJ, Fdz-Polanco F, Perez-Elvira SI (2013) Influence of thermal pretreatment on the biochemical methane potential of wheat straw. Bioresour Technol 143:251–257

Ferreira LC, Nilsen PJ, Fdz-Polanco F, Pérez-Elvira SI (2014) Biomethane potential of wheat straw: influence of particle size, water impregnation and thermal hydrolysis. Chem Eng J 242(8):254–259

Gang L, Dongliang L, Xutao W, Chao1 G (2011) Technology evaluation of steam exploded corn stalk anaerobic fermentation. Transactions of the Chinese Society of Agricultural Engineering

Karagöz P, Rocha IV, Özkan M, Angelidaki I (2012) Alkaline peroxide pretreatment of rapeseed straw for enhancing bioethanol production by same vessel saccharification and co-fermentation. Bioresour Technol 104(1):349–357

Koch K, Helmreich B, Drewes JE (2015) Co-digestion of food waste in municipal wastewater treatment plants: effect of different mixtures on methane yield and hydrolysis rate constant. Appl Energy 137:250–255

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48(8):3713–3729

Lan W, Liu CF, Yue FX, Sun RC (2010) Dissolution of cellulose in 1-butyl-3-methylimidazolium chloride ionic liquid assisted with ultrasonic irradiation. Research Progress in Paper Industry and Biorefinery (4th Isetpp), Vols 1-3, 177-180

Laser M, Schulman D, Allen SG, Lichwa J, Jr MJA, Lynd LR (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for bioconversion to ethanol. Bioresour Technol 43(4):243–244

Li K, Liu R, Sun C (2015) Comparison of anaerobic digestion characteristics and kinetics of four livestock manures with different substrate concentrations. Bioresour Technol 198:133–140

Li Y, Jin Y, Li H, Borrion A, Yu Z, Li J (2018) Kinetic studies on organic degradation and its impacts on improving methane production during anaerobic digestion of food waste. Appl Energy 213:136–147

Ma X, Yang X, Zheng X, Chen L, Huang L, Cao S, Akinosho H (2015) Toward a further understanding of hydrothermally pretreated holocellulose and isolated pseudo lignin. Cellulose 22(3):1687–1696

Mašura, M. (1987) Prehydrolysis of beechwood. Wood Sci Technol, 21(1), 89-100.

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38(4):522–550

Montané D, Nabarlatz D, Martorell A, Torné-Fernández V, Fierro V (2006) Removal of lignin and associated impurities from xylo-oligosaccharides by activated carbon adsorption. Ind Eng Chem Res 45(7), págs):2294–2302

Ping L, Hanwei L, Lihong G, Xiuli W, Tao J, Ke L, Maocun D (2015) Comparison of anaerobic digestion capability of rice straw with different pretreatment methods. Transactions of the Chinese Society of Agricultural Engineering

Prasad S, Singh A, Joshi HC (2007) Ethanol as an alternative fuel from agricultural, industrial and urban residues. Resour Conserv Recycl 50(1):1–39

Qian Y, Meiting J, Weizun L (2016) Review of methane production from straws anaerobic digestion.Trans. Chin. Soc. Agric. Eng. 32(14):232–242

Ran G, Li D, Zheng T, Liu X, Chen L, Cao Q, Yan Z (2018) Hydrothermal pretreatment on the anaerobic digestion of washed vinegar residue. Bioresour Technol 248:265–271

Sambusiti C, Ficara E, Malpei F, Steyer JP, Carrere H (2013) Effect of sodium hydroxide pretreatment on physical, chemical characteristics and methane production of five varieties of sorghum. Energy 55:449–456

Sannigrahi P, Kim DH, Jung S, Ragauskas AJ (2011) Pseudo-lignin and pretreatment chemistry. Energy Environ Sci 4(4):1306–1310

Sashina ES, Kashirskii DA, Busygin KN (2016) Dissolution of cellulose with pyridinium-based ionic liquids: effect of chemical structure and interaction mechanism. Cellul Chem Technol 50(2):199–211

Selig MJ, Viamajala S, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2007) Deposition of lignin droplets produced during dilute acid pretreatment of maize stems retards enzymatic hydrolysis of cellulose. Biotechnol Prog 23(6):1333–1339

Shinde SD, Meng X, Kumar R, Ragauskas AJ (2018) Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chem. https://doi.org/10.1039/C8GC00353J

Vansoest PJ (1992) Fiber in the diets of animals and man - a citation-classic commentary on use of detergents in the analysis of fibrous feeds .4. Determination of plant cell-wall constituents by Vansoest,P.J. and Wine,R.H. and Development of a comprehensive system of feed analyses and its application to forages and nutritional ecology of the ruminant by Vansoest,PJ Current Contents/Agriculture Biology & Environmental Sciences(26), 8-8.

Wan CX, Li YB (2011) Effect of hot water extraction and liquid hot water pretreatment on the fungal degradation of biomass feedstocks. Bioresour Technol 102(20):9788–9793

Wang D, Shen F, Yang G, Zhang YZ, Deng SH, Zhang J, Zeng YM, Luo T, Mei ZL (2018) Can hydrothermal pretreatment improve anaerobic digestion for biogas from lignocellulosic biomass? Bioresour Technol 249:117–124

Wei Q, Shaojie B, Dongmei Y, Mengmeng J, Algapani E, Renjie D (2018) Biogas production potential and kinetics of chicken manure methane fermentation under mesophilic and thermophilic conditions. China Environ Sci 38(1):234–243

Yi Z, Jia Z, Xu F, Li Y (2014) Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog Energy Combust Sci 42(1):35–53

Yihong G, Ling Q, Shihai L, Shanshan L, Xiunan Y, Xiaohui G (2017) Effect of ionic liquids pretreatment on anaerobic digestion of potato stem leaves. Transactions of the Chinese Society for Agricultural Machinery

Yong Q, Wang H, Li X, Cheng JJ, Wu W (2017) Improving methane yield from organic fraction of municipal solid waste (OFMSW) with magnetic rice-straw biochar. Bioresour Technol 245(Pt A:S0960852417315961

Yuanfang D, Ling Q, Yajun W, Benling D, Jiming X (2017) Effect of freeze-thaw and enzymatic pretreatment of rice straw on biogas production by anaerobic digestion transactions of the Chinese Society for Agricultural Machinery

Yu-ting Q, Jing D, Guang-yin C, Hong-ying H, Hong-mei J, Yong-lan X, Yue-ding X, Zhi-zhou C (2016) Optimization of conditions for promoting biogas production with hydrothermal pretreatment for straw. China Environ Sci

Zhong WZ, Zhang ZZ, Luo YJ, Sun SS, Qiao W, Xiao M (2011) Effect of biological pretreatments in enhancing corn straw biogas production. Bioresour Technol 102(24):11177–11182

Zhuang J, Wang X, Xu J, Wang Z, Qin M (2016) Formation and deposition of pseudo-lignin on liquid-hot-water-treated wood during cooling process. Wood Sci Technol 51:165–174

Zi-mu L, Yan-ling Y, Gui-hong Z, Jia-xing S, Dong-mei L, Yu-dong H, Yu-jie F 2015 Enhancement of enzymatic hydrolysis of corn stover by liquid hot water pretreatment and ethanol extraction. J Agro-Environ Sci

Funding

The authors are also grateful for the support of the Agricultural Public Welfare Industry Research of China’s Ministry of agriculture (201503135-18), the National Foundation of Natural Science (51576167), Special Agricultural Program of Shaanxi Province (2017-136), and the Postgraduate Scholarship Project of China Scholarship Council.

Author information

Authors and Affiliations

Contributions

Gaoyuan Shang, Congguang Zhang, and Fei Wang designed and carried out the experiment. Gaoyuan Shang and Congguang Zhang prepared the manuscript. Xiaohui Guo and Fuqing Xu analyzed the data and summarized the discussion. Ling Qiu and Fuqing Xu revised the manuscript and provided the supervision and funding.

Corresponding authors

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shang, G., Zhang, C., Wang, F. et al. Liquid hot water pretreatment to enhance the anaerobic digestion of wheat straw—effects of temperature and retention time. Environ Sci Pollut Res 26, 29424–29434 (2019). https://doi.org/10.1007/s11356-019-06111-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-06111-z