Abstract

The physical and mechanical properties of the dielectric materials mainly depend on shapes of particles in granular media. In order to reveal the differences of physical and mechanical properties between tailings and natural sands from the microscopic view, the usage of digital image processing techniques contributes to the quantification of shape descriptors (elongation, sphericity, convexity, and roughness) describing the shapes of particles. The comparison between four tailings (gold, tin, copper, and iron) and two natural sands (river sand and sea sand) is made in the current study. Results show that particle shape descriptors have great relationship with particle size. The decrement of particle size, on one hand, leads to the increase of the elongation of tailings and sea sand, and thus forming the needle-like or columnar shape of particles. The sphericity of tailings and river sand also increases and generates spherical shapes of particles. On the other hand, both of the convexity and roughness of tailings and sea sand grow with larger particle size. The remarkable difference can be observed on surface texture of particles between tailings and sea sand. Much higher angularity of tailings is also represented by comparing with that of sea sand and river sand.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

When loaded, granular materials consisting of individual particles interact with each other to resist the applied loading (Yang and Luo 2015). Typical granular materials in nature include rockfill, debris flow, and soil (Sun and Wang 2009). As far as granular materials are concerned, particle shape is probably as important as the particle size to describe particle characteristics (Das 2009; Ulusoy et al. 2003). Thus, the particle shape could also affect the physical and mechanical properties, including internal friction angle (Shinohara et al. 2000; Thomas and Prakash 2017; Chan and Page 1997), effective modulus and yield stress (Athanassiadis et al. 2014), small-strain shear modulus (Payan et al. 2016), shear band width (Zhuang et al. 2014), sintering behavior (Cutler and Henrichsen 2010), flow and packing behavior (Chan and Page 1997; Zou and Yu 1996; Carnavas and Page 1994), and hydraulic conductivity characteristics (Göktepe and Sezer 2010; Garcia et al. 2009). Hence, it is very beneficial to carry out analyses of the effect of particle shape.

Individual particles are manifested as irregular polygons that appear differently when analyzed in a two-dimensional plane (Tu and Wang 2004). Although the shape of particles is inherently a three-dimensional attribute, the collection of accurate data in three dimensions is considered problematic (Hentschel and Page 2003). Numerous studies have investigated the particle shape using two-dimensional image analysis technology and these methods have proven useful in describing particle shape (Hentschel and Page 2003; Persson 1998).

Particle shape is defined as “the envelope formed by all the points on the surface of the particle” (ISO 9276-6 2008). It could variously be described as a sphere, similar round, polygon, irregular, dendritic, fibrous and vesicular, etc. However, this type of description is solely a qualitative analysis. With the rapid development of image processing technology, the geometry of irregular particles can be quantified using various shape descriptors in the two-dimensional plane. For example, the elongation properties of the particles can be reflected by the aspect ratio or the extent of elongation. Sphericity is used to quantify the degree of similarity between a particle and a sphere. Convexity is closely related to angularity, and could be taken as a measurement of angularity. Roughness is used to characterize the fluctuation of the projected outline of particles (Yang and Luo 2015; Ulusoy et al. 2003; Hentschel and Page 2003; Rodriguez et al. 2012; Altuhafi et al. 2013; Mora and Kwan 2000; Liu et al. 2011).

Tailings are byproducts of mineral processing. The extraction of minerals from ore requires comminution. Therefore, tailings are also a type of granular material. Large-scale mining and mineral processing inevitably generates very large volumes of tailings worldwide (Yang et al. 2016). Most tailings are stored in surface tailings impoundments. Furthermore, statistics show that more than 12,000 tailings storage facilities have been constructed in China up to 2009 (Wei et al. 2013). Tailings pond failures may result in severe and sometimes catastrophic consequences (Rico et al. 2008a, b; Dixon-Hardy and Engels 2007). Therefore, the mining industry is paying more and more attention to the utilization of tailings as substitutes for natural sands in practice. For instance, Wang et al. (2016), Zheng et al. (2015), and Yang et al. (2014) evaluated the feasibility of utilizing tailings for production of construction materials. Li et al. (2009) discussed the feasibility of producing forsterite refractory which used tailings as raw materials. In view of the physical and mechanical properties that are influenced by the particle shape having a potentially significant impact on the stability of tailings dam and other tailings related products, a study focusing on the particle shape of tailings is necessary to improve the storage and utilization of tailings in practice.

Tailings, which may often be considered as an artificial sand, differ from natural sands in shape. Recently, some experiments have been conducted to study the particle shape of natural sands (Yang and Luo 2015; Ulusoy et al. 2003). However, few publications on the particle shape of tailings are available. From the perspective of building materials, Wen et al. (2013) and Yin et al. (2011) studied the particle morphology and microstructure of sea sand, river sand, manufactured sand, and tailings sand. They found that the roundness of manufactured sand is the lowest, followed by tailings, and the manufactured sand and tailings sand show higher angularity and surface roughness than the other two sands.

In this paper, the particle shape of four tailings (gold, tin, copper, and iron) is studied using digital image processing technologies. Moreover, river sand and sea sand are selected as control materials to highlight the differences between tailings and natural sands. The experimental studies contribute to the establishment of a more fundamental understanding about tailings at the micro-level, and also provide basic data for exploring the differences in physical and mechanical properties of tailings and natural sands.

Experimental

Materials

Four tailings (gold, tin, copper, and iron) and two natural sands (river sand and sea sand) were selected in this study. Among them, four tailings (gold, tin, copper, and iron) were provided by Heqingbeiya Mining Co., Ltd. (Yunnan province, China); Yunnan Tin Group (Holding) Co., Ltd. (Yunnan province, China); Liangshan Mining Co., Ltd. (Sichuan province, China); and Lincang Mining Co., Ltd. (Yunnan province, China), respectively. And the river sand for building and sea sand were sampled respectively from Chongqing and Qingdao in China. It should be mentioned that the gold tailings, tin tailings, and copper tailings were byproducts of flotation, and the iron tailings were byproducts of magnetic separation and gravity separation.

Soil particles are divided into five classes, which are gravel particle, sand particle, silt particle, clay particle, and colloidal particle in terms of particle size (Chen et al. 1994). Among them, the sand particles are divided into very fine sand (particle sizes in 0.05–0.1 mm), fine sand (particle sizes in 0.1–0.25 mm), medium sand (particle sizes in 0.25–0.5 mm), and coarse sand (particle sizes in 0.5–2 mm). The fine sand, medium sand, and coarse sand were selected as the research objects. However, the very fine sand was excluded because it belongs to fine soil. In order to obtain a single particle, the test materials were sieved with different pore sizes, rinsed with water, and dried in the drying oven.

Test scheme and equipment

Based on the literature review on particle shape, the elongation, sphericity, convexity, and roughness were selected to quantify the shape of particles. And those particle shape descriptors were analyzed by image processing techniques. Table 1 represents the test schemes.

The particle digital images were captured by XPV–909E transreflective polarizing microscope and processed by ImageJ software. The ImageJ software is an open-source image processing software based on Java language, and the function of software can be extended through plugins. The surface texture of particles was observed by the TESCAN VEGA II LMU scanning electron microscopy.

Image analysis

Figure 1 shows the processing flow of particle image. In order to improve the image fidelity during the image processing process, firstly, the particle shape descriptors were stored as an array of pixels. Subsequently, the image was dimensioned using a micrometer with a precision of 10 μm to calculate the calibration factor which represents the actual size of each pixel in the digital image. Finally, the particle shape descriptors representing the actual size were calculated through calibration factor.

Description of particle shape

According to a comprehensive analysis of existing data of particles, a number of basic measurements of particles size were obtained from image analysis. Table 2 presents the physical meaning of those basic measurements. And the schematic diagrams of those basic measurements are shown in Fig. 2. Those basic measurements were used to form the shape descriptors through the mathematical operation. Particle shape characteristics could be described in terms of shape descriptors from four aspects. Four shape descriptors, namely, elongation, sphericity, convexity, and roughness can be determined by Eqs. (1)–(4). Elongation reflects the elongation properties. The degree of similarity between a particle and a sphere is determined by sphericity. Convexity and roughness indicate the angularity and the fluctuation of projected outline of particles, respectively.

Results and analysis

Relation between shape descriptors and particle size

For fine sand, medium sand, and coarse sand of research materials (four kinds of tailings and two kinds of natural sands), the elongation, sphericity, convexity, and roughness were statistically analyzed. The variation law of shape descriptors with particle size was studied. And the similarities and differences of particle shape between tailings and natural sands were also compared.

Variation law of elongation

The elongation can reflect the elongation properties of particles. The greater elongation leads to the generation of needle or columnar shaped particles. As shown in Fig. 3, the elongation of tailings decreases with the increment of the particle size, meaning that the shape of tailings tends to be needle-like or columnar with the decreases of particle size. The elongation of sea sand shows a similar pattern of variation law. For the river sand, the elongation of fine sand and coarse sand is larger than the elongation of medium particles. It indicates that the particle shape of fine sand and coarse sand tends to be needle-like or columnar.

Variation law of sphericity

Sphericity is the ratio between the perimeter of circle with the same area as particle outline and the particle perimeter. And it can quantify the degree of similarity between a particle and a sphere. The particle shape tends to be more sphere with larger sphericity. The variation law of sphericity of research materials is represented in Fig. 4. It indicates that the sphericity of tailings decreases with the increases of particle size, meaning that tailings tend to spherical shapes with the decrement of particle size. The sphericity of river sand shows a similar pattern of variation law. However, the sphericity of sea sand shows a reverse pattern of variation law. The sphericity of sea sand increases as the particle size grows; hence, the sea sand tends to form spherical shapes when the particle size grows large.

Variation law of convexity

Convexity is the ratio between the particle area and the area of the convex hull. And it can characterize the angularity of particles. The maximum value of the convexity is 1. If the angularity of particles is prominent, the value of convexity will be small. As shown in Fig. 5, the convexity of tailings increases with the increases of particle size, which indicates that the angularity of tailings decreases with the increases of particle size. The convexity of sea sand shows a similar pattern of variation law. The convexity of river sand increases firstly and then decreases with the increases of particle size.

Variation law of roughness

Roughness is used to characterize the fluctuation of projected outline of particles through the difference between the particle perimeter and the perimeter of convex hull. The larger roughness generates greater fluctuation of projected outline of particles. The variation law of roughness of research materials is shown in Fig. 6. The roughness of tailings increases with the increases of particle size. The roughness of sea sand and river sand shows a similar pattern of variation law.

Analysis of surface texture

For fine sand, medium sand, and coarse sand of copper tailings and sea sand, the similarities and differences of the surface texture among them are studied by scanning electron microscopy. The magnification of the particle images is 300 times and 2000 times, respectively.

Figure 7 shows that the difference of surface texture between the tailings particles and sea sand particles is very obvious. For the particle images which are magnified 300 times, the copper tailings particles show more angularity and the surface of particles is scaly. On the contrary, the surface of sea sand particles is smooth. For the particle images which are magnified 2000 times, the surface of copper tailings particles fluctuates greatly and has obvious local layered structure. The surface of the sea sand particles also fluctuates. Nevertheless, the fluctuation of surface is lower than that of the tailings particles. Furthermore, the sea sand particles also have corrosion pits.

Similarities and differences of particle shape analysis

During mineral processing, tailings are one of the products of separation operation. The tailings are excluded from the concentration plant, and then pumped into the tailings pond by hydraulic transportation. During the transportation process, the change of tailings particle shape is limited due to the short transportation distance. Thus, the shape of tailings particles is primarily determined by the progress of grinding and coarse crushing. The influence of the crushing process and grinding process has the same role on the particle size. However, the grinding process plays a dominant role on the particle shape.

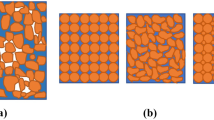

During the grinding process, the action mode applied to the particles could be divided into impacting and pressing action, cutting action, and grinding action (Wills and Napier-Munn 2006). The particles are subjected to difference action mode. Thus, the failure models are different. The failure model of particles could be divided into rupture, crush, and grind, respectively. Figure 8 represents the failure model of particles (Guyon and Troadec 1994). Rupture can break one particle into multiple particles with varying sizes. Crush and grind can make the small particles separated from the surface of large particle. However, the particle size of particles generated from grinding action is smaller than the particle size of particles generated from crushing.

At the beginning of the grinding process, the destruction is extended along the internal cracks of ore. This gives rise to more angularities and the shape is rough and sharp in tailings particles. For angular tailings particles, the prominent angular will be smoothed during the grinding process. The particle angular increases with the particle size. The larger the size of the particle, the more prone to be broken. Thus, the angularity of tailings decreases with the increases of the particle size. For strip tailings particles, the smaller the size of the strip particles, the harder it is to break. So, the shape of tailings tends to be needle-like or columnar with the decreases of the particle size.

Comparing the tailings with natural sands washed by water for a long time or rubbed by self-rolling, the proportion of round particles of tailings is smaller. The angularity of tailings particles is higher than that of the natural sand particles generally. For different mineral types of tailings (such as gold tailings, copper tailings, and iron tailings), the mineral composition of ores, the strength of rock, etc. can also result in different shapes of tailings particles.

Conclusions

Based on digital image processing technologies, the elongation, sphericity, convexity, and roughness were selected to quantify the particle shape of tailings and natural sands. The surface texture of particles was also observed. The following conclusions could be drawn:

-

(1)

The elongation of tailings decreases with the increment of the particle size, which means the shape of tailings tends to be needle-like or columnar with the decreases of particle size. The elongation of sea sand shows a similar pattern of variation law. For the river sand, the elongation of fine sand and coarse sand is larger than that of medium particles. It indicates that the particle shape of fine sand and coarse sand tends to be needle-like or columnar.

-

(2)

The sphericity of tailings decreases with the increases of particle size, which means tailings tend to form spherical shapes with the decrement of particle size. The sphericity of river sand shows a similar pattern of variation law. However, the sphericity of sea sand increases as the particle size grows.

-

(3)

The convexity of tailings increases with the increases of particle size, which indicates that the angularity of tailings decreases with the increases of particle size. The convexity of sea sand shows a similar pattern of variation law. The convexity of river sand increases firstly and then decreases with the increases of particle size.

-

(4)

The roughness of tailings increases with the increases of particle size. The roughness of sea sand and river sand shows a similar pattern of variation law.

-

(5)

The surface of tailings particles is scaly and fluctuates greatly. The surface of the sea sand particles is relatively smooth.

References

Altuhafi F, O’sullivan C, Cavarretta I (2013) Analysis of an image-based method to quantify the size and shape of sand particles. J Geotech Geoenviron 139(8):1290–1307

Athanassiadis AG, Miskin MZ, Kaplan P, Rodenberg N, Lee SH, Merritt J, Brown E, Amend J, Lipsonb H, Jaeger HM (2014) Particle shape effects on the stress response of granular packings. Soft Matter 10:48–59

Carnavas PC, Page NW (1994) Particle shape factors and their relationship to flow and packing of bulk materials, International Mechanical Engineering Congress, Perth WA, 15 -19 May 1994, Preprints of Papers, The Institution of Engineers, Australia. 243 - 248.

Chan LCY, Page NW (1997) Particle fractal and load effects on internal friction in powders. Powder Technol 90:259–266

Chen ZY, Zhou JX, Wang HJ (1994) Soil mechanics. Tsinghua University Press, Beijing, pp 7–10 (in Chinese)

Cutler IB, Henrichsen RE (2010) Effect of particle shape on the kinetics of sintering of glass. J Am Ceram Soc 51:604–605

Das BM (2009) Principles of geotechnical engineering, 7th edn. Stamford, Cengage Learning

Dixon-Hardy DW, Engels JM (2007) Guidelines and recommendations for the safe operation of tailings management facilities. J Environ Eng Sci 24(5):625–637

Garcia X, Akanji LT, Blunt MJ, Matthai SK, Latham JP (2009) Numerical study of the effects of particle shape and polydispersity on permeability. Phys Rev E 80:021304

Göktepe AB, Sezer A (2010) Effect of particle shape on density and permeability of sands. Geotech Eng 163(6):307–320

Guyon E., Troadec J. P., 1994. Du sac de billes au tas de sable, Editions Odile Jacob.

Hentschel ML, Page NW (2003) Selection of descriptors for particle shape characterization. Part Part Syst Charact 20(1):25–38

ISO, ISO 9276-6 (2008) Representation of results of particle size analysis – part 6: descriptive and quantitative representation of particle shape and morphology. Geneva, Switzerland.

Li J, Qi W, Liu JH, Li P (2009) Synthesis process of forsterite refractory by iron ore tailings. J Environ Sci 21:S92–S95

Liu QB, Xiang W, Budhu M, Cui DS (2011) Study of particle shape quantification and effect on mechanical property of sand. Rock Soil Mech 32:190–197 (in Chinese)

Mora CF, Kwan AKH (2000) Sphericity, shape factor, and convexity measurement of coarse aggregate for concrete using digital image processing. Cem Concr Res 30:351–358

Payan M, Khoshghalb A, Senetakis K, Khalili N (2016) Effect of particle shape and validity of Gmax models for sand: a critical review and a new expression. Comput Geotech 72:28–41

Persson AL (1998) Image analysis of shape and size of fine aggregates. Eng Geol 50:177–186

Rico M, Benito G, Diez-Herrero A (2008a) Floods from tailings dam failures. J Hazard Mater (154):79–87

Rico M, Benito G, Salgueiro AR, Diez-Herrero A, Pereira HG (2008b) Reported tailings dam failures- a review of the European incidents in the worldwide context. J Hazard Mater 152:846–852

Rodriguez JM, Johansson JMA, Edeskär T (2012) Particle shape determination by two-dimensional image analysis in geotechnical engineering. Proceedings of Nordic Conference on Soil Mechanics and Geotechnical NGM, Copenhagen, Danish Geotechnical Society. 207-218.

Shinohara K, Oida M, Golman B (2000) Effect of particle shape on angle of internal friction by triaxial compression test. Powder Technol 107:131–136

Sun QC, Wang GQ (2009) An introduction to granular material mechanics. Science Press, Beijing (in Chinese)

Thomas KS, Prakash VM (2017) Effect of particle shape on sand-geosynthetic interfaces. Int Res J Eng Technol 04(04):1899–1904

Tu XB, Wang SJ (2004) Particle shape descriptor in digital image analysis. Chin J Geotech Eng 26(5):659 inese Journal of G

Ulusoy U, Yekeler M, Hiçyılmaz C (2003) Determination of the shape, morphological and wettability properties of quartz and their correlations. Miner Eng 16(10):951–964

Wang ZJ, Xu C, Wang S, Gao J, Ai T (2016) Utilization of magnetite tailings as aggregates in asphalt mixtures. J Constr Build Mater 114:392–399

Wei ZA, Yin GZ, Wang JG, Wan L, Li GZ (2013) Design, construction and management of tailings storage facilities for surface disposal in China: case studies of failures. Waste Manag Res 31(1):106–112

Wen XL, Ouyang D, Li JY (2013) Research of particle morphology, microscopic structure and microstructure of fine aggregate. Concrete 284:62ncrete. 284ructure

Wills BA, Napier-Munn T (2006) Will’s mineral processing technology – an introduction to the practical aspects of ore treatment and mineral recovery, 7th edn. Elsevier, Amsterdam, The Netherlands

Yang J, Luo XD (2015) Exploring the relationship between critical state and particle shape for granular materials. J Mech Phys Solids 84:196–213

Yang CM, Cui C, Qin J, Cui XY (2014) Characteristics of the fired bricks with low-silicon iron tailings. J Constr Build Mater 70:36–42

Yang YH, Wei ZA, Yin GZ, Wang JG, Wang WS, Chen YL (2016) Uniaxial compression test of frozen tailings. J Cold Reg Sci Technol 129:60–68

Yin FL, Ouyang D, Wen XL, Huang HX (2011) Comparative study of sea sand, river sand and tailing sand which using as building sand. Concrete 266:73ncrete, 266 taili

Zheng KR, Zhou J, Gbozee M (2015) Influences of phosphate tailings on hydration and properties of Portland cement. J. Constr Build Mater 98:593–601

Zhuang L, Nakata Y, Kim UG, Kim D (2014) Influence of relative density, particle shape, and stress path on the plane strain compression behavior of granular materials. Acta Geotech 9:241–255

Zou RP, Yu AB (1996) Evaluation of the packing characteristics of mono-sized non-spherical particles. Powder Technol 88:71–79

Acknowledgments

The authors are very grateful to Dr. Yun Chen and anonymous reviewers for their valuable comments and suggestions.

Funding

This research was funded by the National Key Research and Development Program of China (No. 2017YFC0804609), National Natural Science Foundation of China (No. 51804178), and the China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Y., Wei, Z., Fourie, A. et al. Particle shape analysis of tailings using digital image processing. Environ Sci Pollut Res 26, 26397–26403 (2019). https://doi.org/10.1007/s11356-019-05974-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-05974-6