Abstract

A Decentralized Wastewater Treatment System (DEWATS) provides an economically feasible and efficient wastewater treatment solution especially in developing countries. It has an enormous potential for developing a sustainable environmental sanitation system. In this study, the treatment efficiency of eight DEWATS plants was evaluated in the state of Maharashtra, India, for their performance in terms of selected physico-chemical parameters of the wastewater. Although the efficiency of some of the plants was lower than that reported in literature, the effluent quality of all the plants was within the permissible discharge limits of the Central Pollution Control Board for all the parameters. Comprehensive assessment of Plant I was carried in terms of its technical and socio-economic aspects. Moreover, LCA tool has been utilized to evaluate the environmental impacts of the operation stage of DEWATS. The midpoint, CML 2001 (April 2015) methodology was adopted, in which 11 impact categories were considered. From the life cycle impact assessment and interpretation, the main impacts are identified as releases of COD, P-PO43−, and N-NH4+ to water bodies and disposal of sludge. Due to negligible energy consumption, the operation stage was found to be less damaging to the environment. It was concluded that DEWATS can be a good alternative for treating wastewater with negligible energy and chemical consumption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In many developing countries, including India, providing extensive sewerage network and reliable and affordable wastewater treatment is a challenge (Singh et al. 2011). In India, out of the total quantity of the sewage generated, only 34.3% was getting treated in the year 1978; whereas, at present, 37.6% of it is getting treated (CSE 2011; Indiastat 2006). Centralized sewerage and wastewater treatment systems cover only a portion of larger urban areas, and on-site sanitation is often inappropriate in densely populated settlements. It has been observed that the collection of the wastewater and its treatment at a centralized treatment facility cannot be considered as an economically feasible and sustainable alternative as it relies on the sophisticated treatment technology and highly skilled technical expertise for its operation and maintenance (Massoud et al. 2009; Singh et al. 2009). In order to overcome this, Decentralized Wastewater Treatment System (DEWATS) can be implemented as beneficial intermediate and complementary solution, especially in developing countries as it comprises of treatment and discharge or reuse of wastewater close to its source of generation (WIN-SA 2014). It is an important component of the Community-Based Sanitation (CBS) framework that offers the possibility of relatively swift sanitation improvements in rural, near urban, and dense urban settlements (Water and Sanitation Program 2013). In developing countries, natural or advanced treatment systems like DEWATS are commonly used; whereas in the developed countries, common treatment systems installed include filtration using different membranes and batch reactors like sequencing batch reactor (Singh et al. 2009). In order to determine the location specific treatment system, an evaluation of site conditions needs to be performed before installing a particular treatment technology (EPA 2015). The Bremen Overseas Research and Development Association (BORDA) is a non-government organization (NGO) working for over four decades in the field of sanitation and urban development. Its main objective is to provide better living conditions to the underprivileged communities as well as to protect the environment by providing sanitation facilities in a decentralized manner. As a part of this work, they have developed decentralized wastewater treatment systems which are being installed at many locations in Asian subcontinent as well as in African region (Win-SA 2014; BORDA 2017a, b). DEWATS provides an economically feasible state of the technology as all the locally available construction material can be used Gutterer et al. 2009. Smaller plants especially designed for the wastewater of one residential area or industrial enterprise can thus be applied for more efficient wastewater treatment (Sönmez et al. 2012). According to Battilani et al. 2010, DEWATS technologies are raising interest among water stakeholders who are keenly interested in new single family, onsite and cluster technology, and advanced wastewater treatment to reduce the cost of centralized wastewater treatment which are governed by an expensive piping infrastructure. In the case of the decentralized wastewater sector, very little research has been done to establish the long-term performance of onsite or cluster systems, or the effect that various management approaches may have on by performance.

The main advantages of the DEWATS with extensive systems are as follows (Sassee 1998; Gutterer et al. 2009:

-

1.

Reliable, robust, and buffer shock loads.

-

2.

No (or very little) energy is required.

-

3.

Operation and maintenance (O &M) cost is very low and does not require highly skilled personnel.

-

4.

Limited sludge production.

-

5.

Reduces the risks associated with system failure.

-

6.

Provides a viable resource recovery option in terms of reuse of treated wastewater and biogas utilization.

-

7.

Facilitates multiple stakeholder network establishment to address water pollution problems.

Despite these distinct advantages and wide-scale implementation across the world, there are very few studies documenting the performance evaluation of DEWATS in terms of achieving compliance of the prescribed standards (WIN-SA 2014).

DEWATS provide treatment for both domestic and industrial sources with treatment level ranging for organic wastewater flows from 1 to 1000 m3/day. Without considering facilities for necessary chemical pretreatment of wastewater from industries, DEWATS applications are based on four basic technical treatment modules Gutterer et al. 2009:

-

1.

Primary treatment involves sedimentation and floatation. Settler functions as a sedimentation tank which retains the particles via settling mechanism over a period of time.

-

2.

Secondary anaerobic treatment in fixed-bed reactors consists of baffled upstream reactors or anaerobic filters. It works on the principle of anaerobic decomposition of solids (suspended and dissolved). This is achieved by mixing the fresh wastewater with already acclimatized active biomass in the sludge.

-

3.

Tertiary aerobic treatment in sub-surface flow filters results in the degradation of dissolved organic matter via aerobic and facultative microbial population.

-

4.

Tertiary aerobic treatment in polishing ponds.

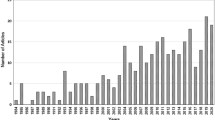

In India, 77 BORDA DEWATS plants have been installed until the year 2017 (BORDA 2017a, b). The details of all the plant locations along with the starting year of operation, funding agency, etc. are presented in Electronic Supplementary Material Table 1 (ESM 1). ESM Figure 1a depicts distribution of these plants according to the year of starting the operation. Out of the total plants, 11 and 56 plants have been funded by Government and Private organizations respectively. The categorization according to the project type is shown in ESM Figure 1b. According to the available data, only at 2 locations, prefabricated DEWATS units have been installed; whereas at remaining 73 locations, conventional DEWATS have been installed. In India, at none of the locations, a pretreatment in the form grease trap or screen has been installed. Only at FSTP in Leh, a screen has been installed. The settler followed by anaerobic baffled reactor (ABR) and anaerobic filter (AF) is the most common treatment module combination as can be seen from ESM Figure 1c. In terms of post treatment modules, horizontal gravel filter (HGF) seems to be the most preferred technology. The different types of post treatment technologies installed in DEWATS plants in India are represented in ESM Figure 1d. The categorization of these plants based on design treatment load is depicted in ESM Figure 1e with the maximum number of plants handling up to 50 m3/day hydraulic load. ESM Table 2 represents a concise literature review on DEWATS performance evaluation studies for the wastewater treatment.

The generation of wastewater is increasing because of the population growth and improved living standards. As a result, the required treatment capacity and the number of wastewater treatment plants (WWTPs) are also increasing in relation to this growth (Subramani and Jacangelo 2015). Thus, there is a need for comprehensive environmental assessments of a range of wastewater treatment (WWT) options to meet different treatment standards from a life cycle perspective that primarily focus on broader environmental consequences. In this context, LCA can determine what choices provide the best environmental performance (Castillo et al., 2016; Fang et al. 2016). LCA is a standardized and sophisticated tool to “compile and evaluate the inputs, outputs and the potential environmental impacts of a product/process/service system throughout its life cycle” (ISO 2006a).

A considerable amount of resources can be saved if LCA-based methodology is adopted in upgradation of existing WWT and management. LCA is an attractive way to be answering the question, “How can we make our processes more sustainable?” Further, LCA allows the expansion of system boundaries to include all impacts upon the environment, which helps to avoid the possibility of “problem transfer” (Guinée et al. 2001, 2011). The environmental impact of a given WWTP depends on the technological configuration because each specific technology has a characteristic consumption of resources, energy, and chemicals. It is a useful tool to quantify the environmental sustainability of the alternative options (Kalbar et al. 2016; Castillo et al. 2016).

Many researchers have considered LCA analysis as a best practice for the assessment of the environmental impacts of a complex group of processes such as those of WWTPs or urban water cycles (Pintilie et al. 2016). LCA as an optimization tool was first applied in the 1990s in the field of WWT. Since then, the number of internationally published LCA studies on WWT has increased sharply. During the last two decades, a considerable number of studies have been carried out worldwide on LCA of WWT technologies, sludge treatment technologies, and water recycling technologies. As applied in the field of WWT, LCA has been proven as a useful tool for evaluation and computation of the environmental footprint of a given WWT technology or WWTPs in both design and operation phases.

Emmerson et al. (1995) was the first to apply LCA in the field of wastewater treatment. The study focused on the inventory phase to evaluate different small-scale WWT technologies. With the advancements in LCA methodology and development of various impact categories, several studies applied LCA to identify the hotspots quantitatively evaluating the environmental impacts associated with WWTPs. Corominas et al. (2013) performed a critical review to describe the challenges for LCA applied to WWT and analyzed the reviewed studies following the LCA phases: goal and scope, inventory, impact assessment, and interpretation, in order to identify common elements and distinguishing aspects. Moreover, studies on LCA of sewage sludge were reviewed for their methodological and technological assumptions by Yoshida et al. (2013). LCA has often been used to compare conventional and natural WWT systems (Pan et al. 2011). In comparison with conventional technologies, eco-friendly technologies such as biological filters, constructed wetlands, soil biotechnology, and sand filtration system have been proposed as better alternatives with lower environmental impacts and reduced pollutant loads (Yildirim and Topkaya 2012; Garfi et al. 2017; Lutterbeck et al. 2017) as these technologies are highly efficient for heavy metal removal and have low energy demand. Till date, there are very few studies in Indian context dealing with LCA and wastewater treatment (Kalbar et al. 2012a; Kalbar et al. 2014; Kamble et al. 2017; Raghuvanshi et al. 2017; Singh et al., 2017a, b). The objective of this LCA study was to assess the environmental impacts of operation phase of the DEWATS. ESM Table 3 presents a brief review of studies on LCA applied to natural wastewater treatment systems.

The aim of the present study is to evaluate the wastewater treatment efficiency of BORDA DEWATS. Eight plants throughout India were analyzed for the environmental, socio, and economic parameters. These plants were located at Thane (1), Nagpur (4), and Pune (3). Table 1 represents details of eight BORDA DEWATS plants evaluated during the study period. These plants were categorized into two types, namely institutional and municipal. The periodic monitoring of these plants was carried out in order to assess the treatment efficiency of the BORDA DEWATS. Plant I was monitored with monthly frequency for the relevant physico-chemical and microbiological parameters along with the study of socio-economic aspects. For the first time, a detailed evaluation was performed for DEWATS plants receiving the effluents from different sources. The evaluation has been carried out not only in terms of treatment efficiency, but also in terms of socio-economic analysis of selected plants (two) and environmental impacts for the Plant I which was evaluated for the entire study period through LCA.

Materials and methods

Plant description

Plant I

Plant I is an institutional type of DEWATS plant situated in Pune with the treatment capacity of 0.035 Million Liter per Day (MLD). The wastewater from different sources is collected in decentralized septic tanks and the effluent from all the septic tanks is then collected in a common collection tank near the treatment system, which consists of the settler, baffled reactor, anaerobic filter, planted gravel filter, and collection tank. Table 2 gives treatment units, actual site photographs, and available dimensions of each unit.

Plant II

It is an institutional type of DEWATS plant situated in Pune with the treatment capacity of 0.0075 MLD. The wastewater from hostel toilets, kitchen area, and bathroom is collected in decentralized septic tanks. Wastewater treatment consists of two levels, primary and secondary. The treated water is used for gardening and farming.

Plant III

It is situated in Thane district and has the treatment capacity of 0.007 MLD. It mainly consists of an anaerobic baffled reactor (ABR) with biogas settler. Plant mainly recycles the blackwater from toilets and washbasins. Blackwater and greywater are first sent to a “biogas settler.” The effluent from the biogas settler flows by gravity to an anaerobic treatment system consisting of ABR and up-flow filter (UF). The treated water and urine, which are separately collected in a tank situated outside the toilets, are intended to be used for the proposed garden. The sludge generated from different treatment units like the biogas settler, baffled reactor, and UF is dewatered on sludge drying beds.

Plant IV

Plant IV is a municipal type of BORDA DEWATS plant located at Nagpur with a treatment capacity of 0.04 MLD. The plant treats blackwater and greywater from all the possible sources from the community in 2 phases. In Phase I, the wastewater streams from all the sources are collected in a common tank. The outflow is connected to the treatment system consisting of a settler and a rock bund. In Phase II, a regulated quantity of wastewater (40 m3) from the settler is diverted for further treatment modules—a baffle reactor, planted gravel filter, and collection tank.

Plant V

This BORDA DEWATS plant is situated in Nagpur and has the treatment capacity of 0.02 MLD. The wastewater from different buildings is collected in 8 septic tanks then collected in a common tank and conveyed to the DEWATS unit, which consists of a settler, baffled reactor, planted gravel filter, and collection tank.

Plant VI

Plant VI is a municipal type of BORDA DEWATS plant located at Nagpur with a treatment capacity of 0.012 MLD. The plant treats blackwater from pay and use public toilets. Initially, the wastewater streams are channeled from all the sources and are collected in a common register near the treatment system. It is then passed through a settler then subjected to anaerobic treatment in an anaerobic baffled reactor (ABR). The third unit process in this wastewater treatment plant consists of an anaerobic filter (AF).

Plant VII

Plant VII is an institutional type of BORDA DEWATS plant located at Pune with a treatment capacity of 0.024 MLD. The plant has been operating since 2005 and treats combined wastewater generated from school and pharmacy. In the primary treatment, the wastewater is allowed to pass through a settler. The settler is made as a sub-soil constructed tank with one partition wall. The sludge storage volume provided is for 18 to 24 months. Here, the minimal biological oxygen demand (BOD) reduction is between 20 and 25%. The wastewater is then treated in ABR. In the baffled reactor, up to 90%, BOD is reduced and the pathogen reduction ranges between 40 and 75%. The operation and maintenance of the system are simple. The spatial requirements for construction are compensated through pleasing landscapes. Finally, the treated effluent from PGF goes into a pond for effluent quality control. In the pond, further sedimentation or stabilization could take place (normally not needed). The treated wastewater is mainly stored in the pond to be reused for the irrigation of open areas.

Plant VIII

Plant VIII is a municipal type of BORDA DEWATS plant located at Nagpur with a treatment capacity of 0.022 MLD. The plant has been functional since 2012 and treats combined wastewater generated from public toilet, slaughter house, and fish market. The wastewater generated from all sources gets collected in a common tank near the treatment system, which consists of following modules: the wastewater firstly goes to a biogas settler which is a sedimentation tank. Remaining wastewater goes to ABR. The wastewater is pumped into the next treatment module via a pump sump provided at the end of the baffle reactor. The tertiary treatment is provided by means of PGF. The treated effluent is finally stored in a collection tank and it can be reused for irrigation or for safe disposal.

The flow diagrams of the DEWATS under study are presented in ESM Figure 2 through ESM Figure 4. The common and abundantly available wetland plants at respective sites have been used in PGF. The available details of the dimensions of the treatment modules for selected plants are shown in ESM Table 4.

Physico-chemical analysis

To determine the efficiency of BORDA DEWATS system, Plant I was monitored for the period of 12 months. Composite samples were collected from influent and effluent locations in pre-sterilized containers. These samples were then analyzed for various physico-chemical parameters like pH, conductivity, color, total solids (TS), total suspended solids (TSS), volatile solids (VS), volatile suspended solids (VSS), alkalinity, oil and grease, chlorides, free ammonia, and dissolved oxygen (DO). The analysis of wastewater was carried out for parameters like chemical oxygen demand (COD) and biochemical oxygen demand (BOD) to estimate the organic load of influent. In terms of nutrients, the samples were analyzed for total ammoniacal nitrogen (TAN), total Kjeldahl nitrogen (TKN), phosphates, and nitrates. The wastewater samples were also analyzed for the presence of heavy metals like zinc, lead, copper, chromium, iron, and arsenic. All the parameters were analyzed as per Standard Methods for the Examination of Water and Wastewater (Clesceri et al. 2005).

Microbial analysis

The most probable number (MPN) method was used for enumerating the microbial load (fecal coliforms) in the collected wastewater samples. The discharge standards for coliforms can be developed only by carrying out the performance evaluation of the currently operating wastewater treatment plants. The Central Pollution Control Board (CPCB) has carried out such a study in the past (CPCB 2013).

Life cycle assessment

The LCA has been carried out with GaBi software (version6.0) provided by Thinkstep. The LCA methodology used in this study is in accordance with the international standards ISO 14040-44 series (ISO 2006a, b). There are four necessary phases for an LCA study: goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation of the results based on the system boundaries and assumptions that were considered. The four phases are described in detail below:

Goal and scope definition

It constitutes the first phase of an LCA and aims at defining the objective and boundaries of the study and the quality of data used. The goal of this LCA study was to evaluate and quantify the environmental impacts of DEWATS (Plant I). The objectives of this LCA were to perform a contribution analysis to identify the most significant impact category and to perform a contribution analysis to identify the processes that contribute most to the impact categories determined earlier.

Functional unit

A functional unit which represents the function of the system under study must be established in this phase. It is the base for the comparison in the life cycle inventory. In this study, the functional unit was defined as 1 m3 of treated wastewater. It is used in most of the studies and it adequately represents the system function when considering the final effluent quality (Fang et al. 2016; Ioannou-Ttofa et al. 2016; Hernandez-Padilla et al. 2017).

System boundaries

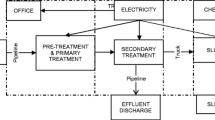

When identifying the parts of the system to be considered in the system boundaries of wastewater units, very different choices can be made and these choices will affect the results. System boundaries considered for LCA affect largely on the final results and hence shall be judiciously selected (Tillman et al. 1998). In this study, only operation phase (primary processes —treatment of wastewater, sludge treatment and disposal, emissions to air, water and soil from treatment plant) was considered. This approach is in agreement with similar LCA studies (Pasqualino et al. 2009; Foley et al. 2010; Kamble et al. 2017). The emphasis was put on the operation stage since it was considered the most relevant stage (Rodriguez-Garcia et al. 2011). The system boundary of this study is represented in Fig. 1.

The assumptions made in this study are listed below:

-

1.

The analysis was limited to the operation stage and no considerations were given to the construction and demolition phase, as these phases account for intensive data requirement (Lassaux et al. 2007; Hospido et al. 2012; García-Montoya et al. 2016).

-

2.

The influent BOD was assumed to be 200 mg/L, which is the average BOD5 value in India (Kalbar et al. 2012b; CPCB, 2016).

-

3.

The data for electricity consumption (primary data) for this LCA study was collected from plant operators, and the background data was used from the software to assess the environmental impacts.

-

4.

Electricity was assumed to be generated from hard coal, lignite, hydropower, nuclear, waste to energy, coal gases, natural gases, oil, wind, biomass, and solar. The energy process used for modeling in GaBi software was an Indian electricity grid mix, medium voltage.

-

5.

Indirect emissions due to electricity consumption were only considered. Direct process emissions which are biogenic in nature were excluded from the analyses due to lack of data.

-

6.

For transportation of sewage sludge to the landfill site, the distance of 50 km was assumed.

-

7.

The truck used for transportation was assumed to be a truck-trailer; diesel driven, Bharat stage IV, cargo; consumption mix; up to 28-ton gross weight/12.4 ton payload capacity. Diesel consumption was assumed to be based on type of truck used and distance in kilometers.

-

8.

For reuse scenario, the effluent reuse rate was considered to be 100%.

-

9.

The tap water production process is used from Gabi 6.0 software.

Life cycle inventory

In the second stage following the goal and scope definition, LCI is performed, which involves data collection and interpretation of inputs and outputs. The allocation procedure is also conducted during the LCI phase, which consists of distributing input and output flows among the process. For this study, the LCI consists of the following: inputs (electricity, influent, and diesel) and outputs (effluent, emissions to air, water, and soil, recycled water, and disposed sludge). Life cycle inventory data (input and output) of Plant I is reported in Table 3.

Life cycle impact assessment

Impact assessment is an important step in quantifying the environmental impacts. Its purpose is to convert LCI data into potential impacts associated with products and processes. In this study, a midpoint-based CML 2001 (April 2015) method was used for life cycle impact assessment (LCIA) as it gives a separate score for each type of environmental impact. CML 2001 (Guinéeet al. 2011) was the most favored and frequently used method for the quantification of impacts because of its extensive impact categories and accuracy proved by earlier studies (Lorenzo-Toja et al. 2016). Some studies generated similar LCA results showing no effect of LCA methods, whereas the results of other studies that demonstrated choice of methodologies did influence LCA results significantly. Selection of this method is in agreement with the published studies (Pennington et al. 2004; Hospido et al. 2012; Chen and Chen 2013; Rodriguez-Garcia et al. 2014).

Eleven potential impact categories, viz., abiotic depletion potential (ADP fossil, elements), acidification potential (AP), eutrophication potential (EP), freshwater aquatic ecotoxicity potential (FAETP), global warming potential (GWP), human toxicity potential (HTP), marine aquatic ecotoxicity potential (MAETP), ozone layer depletion potential (ODP), photochemical ozone creation potential (POCP), and terrestrial ecotoxicity potential (TETP), were considered in this study.

Socio-economic aspects

In addition to environmental and technological assessment, social and economic aspects of the wastewater treatment process should be studied. In terms of social aspects, data regarding details of sewer blockages, grievances with respect to the plant, employment generation due to this plant etc., was collected from concerned authorities by visiting the actual site. The capital cost and operation and maintenance (O & M) cost incurred, land area requirements were considered for studying the economic aspects of DEWATS plants (Plants I and II).

Results and discussions

Plant I

pH is one of the most critical parameters for the proper functioning of anaerobic treatment system. According to Nguyen et al. 2010, the optimum pH range for the methanogenic bacteria is in the range of 6 to 8. At higher pH values, the presence of free ammonia inhibits anaerobic metabolism and also can result in the accumulation of excess quantities of volatile acids which is not desirable for proper functioning of an anaerobic system. During the study period, the influent pH varied from 6.0 to 7.3, whereas that for effluent was in the range of 6.5 to 7.6, which is within the range of discharge standards. This pH provides suitable conditions for establishing active anaerobic microbial population, and in general indicates effective anaerobic treatment conditions (Batstone et al. 2002). During the study period, the conductivity of influent and effluent was varying from 215–1065 to 64–944 μS/cm respectively. There was a significant decrease in the turbidity of the treated effluent throughout the monitoring period except for the month of November. There was hardly any reduction in the concentration of TDS in the effluent. Similar results have been reported by Sutar and Kulkarni (2016) while evaluating TDS removal efficiency from kitchen wastewater by DEWATS. They reported TDS removal efficiency of 33% and 30% by ABR and HGF respectively. It has been reported that the microorganisms in biofilm of AF act as a substrate for attachment of suspended and dissolved solids and thereby reduces effluent TDS concentration Jamshidi et al. 2014. Dissolved oxygen in the effluent was found to increase than that in the influent during the sampling period.

The influent’s COD shows two peaks in August (251 mg/L) and September (239 mg/L) compared to the overall range of 76–227 mg/L of the rest of the studied period. Further, there is a highest peak in November of 472 mg/L which doubles the rest of the values. This outlier may suggest an experimental error during the laboratory analysis or could be related to specific characteristics of the wastewater. The effluent shows two COD peaks in August–September (95–99 mg/L) and April (97 mg/L), whereas the rest of the values vary between 15 and 57 mg/L. The efficiency varied from 51.7 to 94.9% with an average efficiency of 72.1%. These values indicate somewhat inconsistent performance of the plant in terms of COD removal. The lower COD removal efficiency could be attributed to low influent COD concentration. As reported in literature, in a study by Foxon et al. 2004, COD removal efficiency of about 65–90% can be achieved using ABR alone. AF could achieve approximate efficiency of 79.6–95.3% for COD removal (Sasse 1998). Singh et al. 2009 had reported the efficiency of DEWATS system consisting of ABR and hybrid constructed wetland to be capable of 90% COD removal.

The BOD of the influent varies between 25 and 63 mg/L except in December, with the peak concentration of 110 mg/L. The effluent BOD concentration varied from 4 to 15 mg/L except for the peak concentration in the post monsoon months of September and October and later in the month of April with a concentration of 26 mg/L. The average BOD removal performance of the plant was estimated to be 71.6%. Foxon et al. 2004 had reported BOD removal performance of ABR to be around 70–95%; whereas Sasse 1998 estimated that AF can remove BOD with 84.7–91% efficiency. ABRs enable biological degradation of organic matter by allowing the wastewater to flow through active sludge bed accumulated under the baffles. In the case of AF, biodegradation of organic material is accomplished by providing increased contact time between active microbial biomass settled on filter surface and the wastewater (Gutterer et al. 2009). Despite achieving lower performance than that reported in literature, the effluent concentration was within CPCB’s prescribed limit of 30 mg/L throughout the study period (CPCB 1986).

The TSS content of the inlet wastewater was varying between 58 and 143 mg/L. The effluent TSS concentration was in the range of 7 to 73 mg/L with an average removal efficiency of 68.9%. In a typical DEWATS system, AF plays an important role in removal of suspended solids by providing biofilm as a source of attachment Jamshidi et al. 2014. These are suitable for wastewaters with a low percentage of suspended solids (Gutterer et al. 2009). TSS concentration was found to be within the prescribed limit of 100 mg/L irrespective of the influent concentration and season. The VSS comprises 62–79% of the TSS, except in December, where the VSS content only accounts for 20% of the TSS. This may be due to the specific nature of the wastewater.

The TKN and ammonium content show a similar pattern, with the lower and higher peaks in October (TKN 15.7 mg N/L, ammoniacal nitrogen 12.3 mg N/L) and February (TKN 39.5 mg N/L, ammoniacal nitrogen 36.7 mg N/L) respectively. The rest of the values are contained within 21.8–30.8 mg N/L for the TKN, and 16.2–25.2 mg N/L for the ammoniacal nitrogen. The average removal efficiency was observed to be 28.1% and 35.2% for TKN and ammoniacal nitrogen respectively. The effluent concentrations of both these parameters were within their respective prescribed limits. Ellingsen 2010 could achieve overall ammoniacal nitrogen removal efficiency of 57% when ABR pretreatment was followed by constructed wetland. Jamshidi et al. 2014 treated the wastewater generated from small population using the combination of ABR and Bio-rack wetland planted with Phragmites sp. and Typha sp. The removal efficiency obtained for TN removal was 79% with an overall HRT of 21 h and 77% with 27 h HRT respectively.

The phosphate of the influent shows two peaks in July and October (3.5 mg P/L) and remains almost constant (0.7–1.5 mg P/L) during the rest of the period of operation of the plant. The effluent concentration ranges from 0.2 to 3.2 mg/L. The removal efficiency shows seasonal variation ranging from 9.7 to 71.6% with an average removal efficiency of 42.4%. This treatment system seems to perform better than other systems reported in literature. Hendriarianti and Karnaningroem 2016 reported only 2–13% PO4 removal efficiency with ABR treatment used in conjunction with stone media biofilter. Nguyen et al. 2010 have concluded that even though ABR is efficient to treat the low strength wastewater containing organic matter and suspended solids, the process is not effective in nutrient removal. ABR and Bio-rack wetland with Phragmites sp. and Typha sp. could achieve 21% and 14% PO4-P removal by 21% with HRT of 21 and 27 h respectively.

The average concentrations of significant physico-chemical and microbiological parameters for Plant I are shown in Table 4.

Heavy metal analysis

CPCB has stipulated standards for heavy metals in general discharge standards in effluents to be discharged in inland surface water. The concentration of heavy metals like copper (Cu), zinc (Zn), manganese (Mn), iron (Fe), and lead (Pb) in the influent and effluent of Plant I, during the study period, is shown in Table 4.

Microbial analysis

The microbial quality of the wastewater can be easily accessed by identifying the indicator organisms such as total and fecal coliforms in it (Kermani et al. 2008). This is due to the fact of the abundant presence of bacterial of fecal origins and enteric viruses in the untreated wastewater. According to Rodgers et al. 2003, the typical count of total and fecal coliforms in raw wastewater typically ranges from 107–109 to 106–108 per 100 ml respectively. The safe reuse for non potable purposes and disposal of wastewater in the water bodies or on land can be assured by the means of bacteriological examination of wastewater. The coliform count serves as an indicator for the possible presence of pathogens in treated effluent and is a very important consideration in deciding the best possible reuse. Coliform count in the influent was lower than 100 MPN/100 ml until September 2014, probably because of the monsoon season which dilutes the microbial load. In subsequent sampling, the coliform count was found to be 1600 MPN/100 ml. Salmonella and Shigella were not detected during the study period in influent as well as in effluent. The presence of Escherichia coli was detected in the months of November and December.

The NRCD’s prescribed limit for fecal coliform count is 1000 MPN/100 ml for discharge on land as well in receiving water bodies. The coliform count in the effluent is within these limits, except during the months of March and April in the year 2015. But, the average percent removal of coliform by the studied DEWATS systems was estimated to be only 36.1%. In contrast, in a study conducted by Jamshidi et al. 2014, very high (99%) reduction in total coliform was obtained. The log removal potential of Plant I was varying from 0.050 to 0.368 with an average of 0.217. However, high SD values reveal that the coliform inactivation in the treatment plant is very unstable. Ellingsen 2010 has reported that sorption is not a predominant bacterial removal mechanism. The more favored mechanism for it could be filtration and straining in regions where biofilm is properly developed in addition to other processes like die-out and predation.

Other plants

The performance evaluation result for all the eight DEWATS plants under study is presented in Table 5.

The highest BOD removal efficiency of 98% was observed for Plant V followed by Plant VII (96.8%). Similar results were reported by Sakthivel et al. 2012 when they evaluated 5 DEWATS plants at different locations. The BOD removal efficiency for all the plants was reported to be in the range of 90–93%. Among the plants evaluated in this study, the least efficient performance was reported for Plant VI (22.2%) and Plant III (41.4%). In terms of COD removal also, these plants perform poorly with 21.7% and 36.4% efficiency respectively. This low efficiency for organic matter removal could be attributed to lower influent load, intrusion of storm water, and loss/flushing out of microbial biomass (Pietruschka et al. 2015). The best COD removal performance was reported for Plant VII (98.3%) followed Plant V (97.8%). It has been also reported that ABR can treat the different types of wastewaters and its efficiency shows marked improvement with high organic load in the influent (Pietruschka et al. 2015).

In terms of TSS removal, the efficiency varied from as low as 7.9% for Plant III to as high as 94.9% for Plant V. ABR is one of the types of high-rate reactors with different hydraulic retention time (HRT) and Solid retention time (SRT) and thus facilitates the growth of the slow-growing anaerobic bacteria to be contained within the reactor irrespective of the flow of the wastewater (Nguyen et al. 2010). Sutar and Kulkarni 2016 have also highlighted the role of ABR in reducing suspended solids prior to further treatment by constructed wetland.

In this study, the highest ammoniacal nitrogen removal of 46.7% was reported for Plant VIII. The lowest removal efficiency of 2.8% was obtained for Plant VI. In the case of TKN removal, the highest removal of 68.1% was reported for Plant IV, whereas the worst performance was reported for Plant VI, with only 2% TKN removal.

The performance of different DEWATS plants was also studied for PO4 removal. The highest removal efficiency of 97.3% was reported for Plant VI. Plant I with only 36.9% was the worst performing plant in terms of phosphate removal.

The efficiency of nitrogen and phosphorus removal occurs due to the combination of the processes such as nitrification/denitrification along with their uptake by plants as nutrients respectively in planted gravel filter (Jamshidi et al. 2014). On the other hand, it has already been reported that post ABR treatment is very essential for reducing the nutrient concentration (Pillay et al. 2008; Nasr and Doma, 2009).

Life Cycle Assessment

It should be noted that WWTP-related LCA results are case specific. The results vary based on plant design, process selection, scale, wastewater quality, and other factors (Stokes and Horvath 2010). However, some general conclusions can still be obtained about the contributors of WWTPs to each impact category. Environmental impacts from the treatment facility are mainly caused by the use of electricity required to pump effluent for reuse purpose, sludge transportation, and its disposal to landfill site. Results with respect to all impact categories are discussed below.

Energy consumption

The total energy consumption over the life cycle of the plants has been found to be 0.131 (MJ/m3). It is in the range of the similar studies carried out in India (Singh and Kazmi 2017) and other countries (0.36 MJ/m3 to 5.4 MJ/m3). Research studies carried out such as Pasqualino et al. (2011) reported 0.34–2.16 MJ/m3, Rodriguez-Garcia et al. (2011) reported 0.36–3.24 MJ/m3, and Amores et al. (2013) and Niero et al. (2014) have reported the same values, i.e., 0.72–2.34 MJ. In terms of energy consumption, this plant has an advantage over conventional or other natural technologies.

Global warming potential

The energy consumption for the operation of the plant is found to be the largest contributing factor for CO2 emissions and GWP (0.0157 kg CO2 equiv). The global warming potential (GWP), due to transportation of sludge to landfill site, is found to be negligible, i.e., less than 1% of total impact, and can be neglected from the analysis. This finding is similar to previous studies carried out in India (Kamble et al. 2017).

Eutrophication potential

Due to the remaining nutrients, the effluent has been considered the most relevant environmental issue when performing environmental evaluation of WWTPs (Garrido-Baserba et al. 2014). In addition to the eutrophication potential (EP) that results from a plant’s direct emissions to the environment, there are also indirect emissions from upstream and downstream processes such as energy generation or chemical production that have the potential to cause eutrophication. The main factors are the total nitrogen (TN) and total phosphorus (TP) and to a lower extent COD contained in the effluent. DEWATS has an EP value (0.00098 kg phosphate equiv) which is lower as compared to other natural treatment systems (Kamble et al. 2017).

Acidification potential

Acidification potential (AP) is due to the contribution from substances that produce sulfuric acid when they are in contact with water. Emissions triggering acidification are mainly caused by electricity consumption. In this study, AP is found to be 0.000140616 kg SO2 equiv.

Abiotic depletion potential (ADP)

Abiotic depletion potential (ADP) is due to the contribution of the various emissions to the extraction of resources, including their availability, energy content, concentration, and rate of use. ADP (element) in WWT is a measure of a system’s non-renewable global resource consumption. Coal consumption also has a major contribution in ADP (fossil) category. In this study, ADP (element) is found to be 5.72E−10 kg sbequiv and ADP fossil is found to be 0.171 MJ.

Ozone depletion potential

Ozone depletion potential (ODP) mainly refers to the emission of gases that reduce the ozone layer (principally CFC-11, CFC-12, and Halon 1301) and these emissions are found to be minimal. The value for ODP is 3.66E−13 kg R11 equiv.

Photochemical ozone creation potential (POCP)

Photochemical ozone creation potential (POCP) is due to the contribution of the various emissions to the formation of photo-oxidant substances (particularly ozone and peroxyacetyl nitrate) through the photochemical oxidation of volatile organic substances and carbon monoxide. Energy production is the primary contributor to the POCP impact category. The value obtained for POCP in the current study is found to be 6.98E−06 kg ethene equiv.

Toxicity potentials (FAETP, MAETP, TETP, and HTP)

The main contributor to toxicity potential is the indirect emissions of metals associated with the production of electricity. This finding is in the same line with the previous research (Piao et al. 2016; Ioannou-Ttofa et al. 2016). On the other hand, direct emissions contributing to ecotoxicity are heavy metals discharged into the water and soil environments (Kalbar et al. 2013; Risch et al., 2014). Further, the disposal of sludge containing heavy metals contributed substantially to the ecotoxicity. TETP (0.000246848 kg DCB equiv) is dominated by the presence of heavy metals in the sludge being Zn (2.33E−008 kg), Pb (1.28E−009 kg), and Cu (8.55E−009 kg) as the main contributors. This impact category is directly proportional to the amount and quality of sludge produced by the treatment system. Concerning FAETP (0.0000429 kg DCB equiv), the emissions of metals that take place during electricity production dominate the impact. The discharge of treated water is the second element, mainly contributing to the release of Zn, Ni, and Cu to the aquatic environment (Hospido et al. 2012). MAETP (31.44 kg DCB equiv) was considered the most important category, since the characterization factors in this category (for energy consumption, sludge production, etc.) are generally higher than those of other impact categories. The results are in agreement with the results of earlier studies (Dikinya and Areola 2010; Kalbar et al. 2014; Zhao et al. 2015). HTP (0.0101 kg DCB equiv) is mainly because of the release of heavy metals in water, air, and the soil environment.

The wastewater treatment system arose as a toxicity removal process instead of being a toxicity generator. In addition, it is also necessary to assess the toxic impacts of heavy metals and metalloids, organic micro-pollutants, pharmaceuticals and personal care products (PPCPs), and pathogen-related issues, as these studies have not been undertaken with the required vigor and frequency. Future studies should assess toxicity and the potential of pathogen risks in an LCA.

LCIA results for chosen impact categories are shown in ESM Table 5. LCIA results for various impact categories for Plant I derived using CML 2001 for April 2015 are depicted Fig. 2.

Evaluation of benefit from reuse of the treated effluent

In order to cope with water scarcity, wastewater reuse and resource recovery are one of the promising areas where technology is responding to the need for pollution prevention and resource efficiency. In the current study, tertiary effluent was used to replace tap (fresh) water, and the benefits are gained from water saving. Such kind of benefits are considered to be equivalent to a saving of energy that otherwise would be consumed for the production of the same quantity of tap water or use of freshwater (Singh et al. 2018). ESM Table 6 represents LCIA results of Plant I for two different scenarios (No reuse and Reuse).

Socio-economic aspects

It focuses on information related to the social acceptance of DEWATS technology in addition to its economic aspects. The criteria for selecting a technology should not be only based on its implementation cost but also should take into consideration the cost of operation and maintenance along with its benefits like reuse of treated wastewater. Table 6 represents socio-economic aspects of Plant I and Plant II under study. Some of the conventional sewage treatment technologies like Up-flow Anaerobic Sludge Blanket (UASB) has significant land requirement but has the least energy requirement. The capital cost for UASB is Rs. 68 lacs per MLD. Activated sludge plant (ASP) requires land area of 450 m2/MLD with similar capital cost as UASB. The power consumption by ASP is significant (180 kwh/day/MLD) as compared to UASB. Membrane bioreactor (MBR) and sequential batch reactor (SBR) have the least land requirement, but on the other hand require highest amount of energy among these technologies. Additional investment is required in terms of chemicals to be used and hiring skilled manpower for operating these conventional treatment technologies (CPCB 2013).

DEWATS has higher land requirement than treatment technologies like MBR and natural treatment technologies like Reed bed system. It has the same land requirement as SBR and lower land requirement than stabilization pond (SP). In terms of capital expenditure, DEWATS is economically feasible than MBR and SP. One of the biggest advantages of DEWATS technology is the very affordable requirement of operation and maintenance cost (CDD 2017).

Conclusion

Most of the Indian cities depend on the centralized systems for domestic wastewater treatment which not only require high capital cost but also have high O and M costs. With the rapid rate of urbanization, introducing a decentralized wastewater management system could prove as an effective solution to minimize the pollution load. During the study, DEWATS’s sustainability aspect was assessed from the point of view of its technical as well as its economic feasibility and its environmental impacts. Although no health issues have been reported till date, further treatment like conditioning pond would be required to promote safe reuse of treated wastewater. It is one of the most promising technologies to treat wastewater. As compared to other conventional or natural wastewater treatment systems, this technology has environmental benefits, due to its low cost, less energy demand, and simple operation. The results obtained from LCA can be utilized to identify environmental hot spots and optimize the process. However, the application of LCA is limited to the evaluation of the environmental sustainability of processes. Hence, additional indicators introducing economic and social dimensions considering regional and local priorities are needed to measure the sustainability of WWT technologies. There is a clear need for a paradigm shift in the selection of the wastewater treatment processes. In addition to the technical and economic issues, the environmental and social aspects should also be considered in the decision making process.

References

Amores MJ, Meneses M, Pasqualino J, Antón A, Castells F (2013) Environmental assessment of urban water cycle on Mediterranean conditions by LCA approach. J Clean Prod 43(1):84-92

Batstone DJ, Keller J, Angelidaki I, Kalyuzhnyi S, Pavlostathis SG, Rozzi A, Sanders W, Siegrist H, Vavilin V (2002) The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci Technol 45(1):65–73

Battilani A, Steiner M, Andersen M, Back SN, Lorenzen J, Schweitzer A, Dalsgaard A, Forslund A, Gola S, Klopmann W (2010) Decentralised water and wastewater treatment technologies to produce functional water for irrigation. Agric Water Manag 98(3):385–402

Bremen Overseas Research and Development Association [BORDA] (2015) Demand-based technicalsolutions to reduce waterpollutionby small and mediumenterprises and settlementsin densely populated areas. https://www.borda.de/content/uploads/2015/08/Dewats_2010_Sept_web.pdf Accessed 20 April 2017

Bremen Overseas Research and Development Association [BORDA] (2017a) DEWATS implementationby BORDA. http://en.borda.de/content/uploads/sites/2/2018/02/DEWATS_Inventory_2017.pdf Accessed 25 April 2018

Bremen Overseas Research and Development Association [BORDA] (2017b) DEWATS implementationby BORDA. https://portal.mwater.co/#/maps/8ccbb9c9dbef4cebb3e029e48a9819ed?share=a729464249d54650a1785f17538e25ed Accessed 25 April 2018

Castillo A, Porro J, Garrido-Baserba M, Rosso D, Renzi D, Fatone F et al (2016) Validation of a decision support tool for wastewater treatment selection. J Environ Manag 184(1):409–418

Central Pollution Control Board, Government of India (1986) General Standards for Discharge of Environmental Pollutants Part-A: Effluents, . https://cpcb.nic.in/GeneralStandards.pdf Accessed 2 November 2018

Central Pollution Control Board [CPCB] (2013) Performance evaluation of sewage treatment plants under NRCD. Ministry of Environment and Forest. https://cpcb.nic.in/openpdffile.php?id=UmVwb3J0RmlsZXMvMjlfMTQ1ODExMDk5Ml9OZXdJdGVtXzE5NV9TVFBfUkVQT1JULnBkZg Accessed 20 March 2018

Central Pollution Control Board [CPCB] (2016) CPCB bulletin, Ministry of Environment and Forests, Govt. of India. Available at: https://cpcb.nic.in/. Accessed on 10 March 2018.

Centre for Science and Environment [CSE] (2011) Policy Paper on Septage Management in India. https://moud.gov.in/upload/uploadfiles/files/SeptagePolicyPaper.pdf Accessed 22 June 2017

Chen S and Chen B (2013) Net energy production and emissions mitigation of domestic wastewater treatment system: A comparison of different biogas-sludge use alternatives. Bioresource Technol 144(1):296-303

Clesceri LS, Greenberg AE, Eaton AD [Eds] (2005) Standard Methods for the Examination of Water and Wastewater. American Public Health Association, American Water Works Association, Water Environment Federation, USA

Consortium for DEWATS Dissemination Society [CDD] (2017) https://www.cddindia.org/dewats Accessed 4 May 2018

Corominas L, Foley J, Guest JS, Hospido A, Larsen HF, Morera S, Shaw A (2013) Life cycle assessment applied to wastewater treatment: state of the art. Water Res 47(15):5480–5492

Ellingsen M (2010) Sustainability of a decentralized wastewater treatment system in Kathmandu Valley, Nepal - technical and social challenges. Dissertation, Norwegian University of Life Sciences. Available at: https://nmbu.brage.unit.no/nmbuxmlui/bitstream/handle/11250/189419/monaEllingsen.pdf?sequence=1&isAllowed=y. Accessed on 24 April 2018

Emmerson RHC, Morse GK, Lester JN, Edge DR (1995) The life-cycle analysis of small-scale sewage-treatment processes. Water Environ J 9(3):317–325

Fang LL, Valverde-Pérez B, Damgaard A, Plósz BG, Rygaard M (2016) Life cycle assessment as development and decision support tool for wastewater resource recovery technology. Water Res 88:538–549

Foley JM, De Haas D, Hartley K, Lant P (2010) Comprehensive life cycle inventories of alternative wastewater treatment systems. Water Res 44(5):1654–1666

Foxon KM, Pillay S, Lalbahadur T, Rodda N, Holder F, Buckley CA (2004) The anaerobic baffled reactor (ABR) - an appropriate technology for on-site sanitation. Water SA 30(5):44–50

García-Montoya M, Sengupta D, Nápoles-Rivera F, Ponce-Ortega JM, El-Halwagi MM (2016) Environmental and economic analysis for the optimal reuse of water in a residential complex. J Clean Prod 130(1):82-91

Garfi M, Flores L, Ferrer I (2017) Life cycle assessment of wastewater treatment systems for small communities: activated sludge, constructed wetlands and high rate algal ponds. J Clean Prod 161(1):211–219

Garrido-Baserba M, Hospido A, Reif R, Molinos-Senante M, Comas J, Poch M (2014) Including the environmental criteria when selecting a wastewater treatment plant. Environ Model Softw 56(1):74–82

Guinée JB, Huppes G, Heijungs R (2001) Developing an LCA guide for decision support. Environ Manag Health 12(3):301–311

Guinée JB, Heijungs R, Huppes G, Zamagni A, Masoni P, Buonamici R et al (2011) Life cycle assessment: past, present, and future. Environ Sci Technol 45(1):90–96

Gutterer B, Sasse L, Panzerbieter T, Reckerzügel T (2009) Decentralised Wastewater Treatment Systems (DEWATS) and sanitation in developing countries – a practical guide. https://www.sswm.info/sites/default/files/reference_attachments/DEWATS_Guidebook_small.pdf Accessed on 1 May 2018

Hendriarianti E, Karnaningroem N (2016) Evaluation of communal wastewater treatment plant operating anaerobic baffled reactor and biofilter. Waste Technol 4(1):7–12

Hernández-Padilla F, Margni M, Noyola A, Guereca-Hernandez L, Bulle C (2017) Assessing wastewater treatment in Latin America and the Caribbean: enhancing life cycle assessment interpretation by regionalization and impact assessment sensibility. J Clean Prod 142:2140–2153

Hospido A, Sanchez I, Rodriguez-Garcia G, Iglesias A, Buntner D, Reif R et al (2012) Are all membrane reactors equal from an environmental point of view? Desalination 285(1):263–270

Indiastat (2016). State-wise quantum sewage generation and treatment capacity of urban population of India (As on 02.08.2016). Available at:https://www.indiastat.com/table/environmentandpollution/11/%201055%20waterpollution/294/967874/data.aspx Accessed on 8 October 2017

International Organization for Standardization (ISO) (2006a) Environmental management. Life cycle assessment. Principle and framework. ISO14040:2006. International Organization for Standardisation, Geneva

International Organization for Standardization (ISO) (2006b) Environmental management. Life cycle assessment. Requirements and guidelines. ISO 14044:2006. International organization for standardisation (ISO), Geneva

Ioannou-Ttofa L, Foteinis S, Chatzisymeon E, Fatta-Kassinos D (2016) The environmental footprint of a membrane bioreactor treatment process through life cycle analysis. Sci Total Environ 568(1):306–318

Jamshidi S, Akbarzadeh A, Woo KS, Valipour A (2014) Wastewater treatment using integrated anaerobicbaffled reactor and Bio-rack wetland planted withPhragmites sp. and Typha sp. J Environ Health Sci Eng 12:131–142

Kalbar PP, Karmakar S and Asolekar SR (2012a) Selection of an appropriate wastewater treatment technology: A scenario-based multiple-attribute decision-making approach. J Environ Manage 113(1): 158-169.

Kalbar PP, Karmakar S, Asolekar SR (2012b) Estimation of environmental footprint of municipal wastewater treatment in India: life cycle approach. In Proceedings of International Conference on Environmental Science and Technology (Vol. 30, pp. 30-34), IACSIT Press, Singapore.

Kalbar PP, Karmakar S, Asolekar SR (2013) Assessment of wastewater treatment technologies: life cycle approach. Water Environ J 27(2):261–268

Kalbar PP, Karmakar S, Asolekar SR (2014) Life cycle-based environmental assessment of municipal wastewater treatment plant in India. Int J Environ Waste Manag 14(1):84–98

Kalbar PP, Karmakar S, Asolekar SR (2016) Life cycle-based decision support tool for selection of wastewater treatment alternatives. J Clean Prod 117(1):64–72

Kamble SJ, Chakravarthy Y, Singh A, Chubilleau C, Starkl M, Bawa I (2017) A soil biotechnology system for wastewater treatment: technical, hygiene, environmental LCA and economic aspects. Environ Sci Pollut Res 24:13315–13334

Kermani M, Bina B, Movahedian H, Amin MM, Nikaein M (2008) Application of moving bed biofilm process for biological organics and nutrients removal from municipal wastewater. Am J Environ Sci 4(6):675

Lassaux S, Renzoni R, Germain A (2007) Life cycle assessment of water from the pumping station to the wastewater treatment plant. Int J Life Cycle Assess 12(2):118-126

Lorenzo-Toja Y, Vázquez-Rowe I, Amores MJ, Termes-Rifé M, Marin-Navarro D, Moreira MT, Feijoo G (2016) Benchmarking wastewater treatment plants under an ecoefficiency perspective. Sci Total Environ 566(1):468-479

Lutterbeck CA, Kist LT, Lopez DR, Zerwes FV, Machado ÊL (2017) Life cycle assessment of integrated wastewater treatment systems with constructed wetlands in rural areas. J Clean Prod 148(1):527–536

Massoud MA, Tarhini A, Nasr JA (2009) Decentralized approaches to wastewater treatment and management: applicability in developing countries. J Environ Manag 90:652–659

Nasr FA, Doma HS (2009) Treatment of domestic wastewater using an anaerobic baffled reactor followed by a duckweed pond for agricultural purposes. Environmentalist 29:270–279

Nguyen H, Turgeon S, Matte J (2010) The anaerobic baffled reactor - a study of the wastewater treatment process using the anaerobic baffled reactor. https://pdfs.semanticscholar.org/b697/ea62a268121621a71c7363925d5c1c3dc5f9.pdf. Accessed 27 April 2018

Niero M, Pizzol M, Bruun HG, Thomsen M (2014) Comparative life cycle assessment of wastewater treatment in Denmark including sensitivity and uncertainty analysis. J Clean Prod 68(1):25-35

Pan T, Zhu XD, Ye YP (2011) Estimate of life-cycle greenhouse gas emissions from a vertical subsurface flow constructed wetland and conventional wastewater treatment plants: a case study in China. Ecol Eng 37(2):248–254

Pasqualino JC, Meneses M, Abella M, Castells F (2009) LCA as a decision support tool for the environmental improvement of the operation of a municipal wastewater treatment plant. Environ Sci Technol 43(9):3300–3307

Pasqualino JC, Meneses M, Castells F (2011) Life cycle assessment of urban wastewater reclamation and reuse alternatives. J Ind Ecol 15(1):49-63

Pennington DW, Potting J, Finnveden G, Lindeijer E, Jolliet O, Rydberg T, Rebitzer G (2004) Life cycle assessment Part 2: Current impact assessment practice. Environ Int 30(5):721-739

Piao W, Kim Y, Kim H, Kim M, Kim C (2016) Life cycle assessment and economic efficiency analysis of integrated management of wastewater treatment plants. J Clean Prod 113(1):325–337

Pietruschka B, Buckley CA, Campbell A (2015) DEWATS systems as a low cost solution for School Based Sanitation in Cambodia. Poster presented in IWA-Water and Development Congress & Exhibition, Jordan

Pillay S, Foxon KM, Buckley CA (2008) An anaerobic baffled reactor/membrane bioreactor (ABR/MBR)for on-site sanitation in low income areas. Desalination 231:91–98

Pintilie L, Torres CM, Teodosiu C, Castells F (2016) Urban wastewater reclamation for industrial reuse: an LCA case study. J Clean Prod 139(1):1–14

Padilla-Rivera A, Morgan-Sagastume JM, Noyola A, Güereca LP (2016) Addressing social aspects associated with wastewater treatment facilities. Environ Impact Assess Rev 57(1):101–113

Raghuvanshi S, Bhakar V, Sowmya C, Sangwan KS (2017) Waste water treatment plant life cycle assessment: treatment process to reuse of water. Procedia CIRP 61:761-766

Risch E, Loubet P, Núñez M, Roux P (2014) How environmentally significant is water consumption during wastewater treatment?:application of recent developments in LCA to WWT technologies used at 3 contrasted geographical locations. Water Res 57(1):20–30

Rodgers M, Zhan XM, Gallagher B (2003) A pilot plant study using vertically moving biofilm process to treat municipal wastewater. Bioresour Technol 89(2):139–143

Rodriguez-Garcia G, Molinos-Senante M, Hospido A, Hernandez-Sancho F, Moreira MT, Feijoo G (2011) Environmental and economic profile of six typologies of wastewater treatment plants. Water Res 45(18):5997–6010

Rodriguez-Garcia G, Frison N, Vázquez-Padín JR, Hospido A, Garrido JM, Fatone F, Feijoo G (2014) Life cycle assessment of nutrient removal technologies for the treatment of anaerobic digestion supernatant and its integration in a wastewater treatment plant. Sci Total Environ 490(1):871-879

Sakthivel SR, Seshadri A, Rahman MA, Chariar V (2012) Standardisation of design and maintenance of DEWATS plants in India. Paper presented in IWA Conference

Sasse L (1998) DEWATS – decentralised wastewater treatmentin developing countries. Bremen overseas research and development association (BORDA), Bremen

Singh A, Kamble SJ, Sawant M, Chakravarthy Y, Kazmi A, Aymerich E, Philip L (2017a) Technical, hygiene, economic, and life cycle assessment of full-scale moving bed biofilm reactors for wastewater treatment in India. Environ Sci Pollut Res 25:2552–2569

Singh NK, Singh RP, Kazmi AA (2017b) Environmental impact assessment of a package type IFAS reactor during construction and operational phases: a life cycle approach. Water Sci Technol 75(10):2246–2256

Singh S, Haberl R, Moog O, Shrestha RR, Shrestha P, Shreshta R (2009) Performance of an anaerobic baffled reactor and hybrid constructed wetland treating high-strength wastewater in Nepal—a model for DEWATS. Ecol Eng 35:654–660

Singh S, Raju NJ, Sagar G (2011) Process design for decentralized sewage treatment system with total natural resource management. Int J Water Res Environ Eng Commun 3(11):233–237

Singh NK and Kazmi AA (2017) Performance and Cost Analysis of Decentralized Wastewater Treatment Plants in Northern India: Case Study. J Water Res Plan Man 144(3):05017024

Singh A, Kamble SJ, Sawant M, Chakravarthy Y, Kazmi A, Aymerich E ...and Philip L (2018). Technical, hygiene, economic, and life cycle assessment of full-scale moving bed biofilm reactors for wastewater treatment in India. Environ Sci Pollut Res 25(3):2552-2569

Sönmez N, Tengnäs A, McGrath V (2012) Design of sustainable sanitation systems for IDPA corail camp in Haiti. J Environ Manag 94:61–68

Stokes JR and Horvath A (2010) Supply-chain environmental effects of wastewater utilities. Environ Res Lett 5(1):014015 (1-7)

Subramani A, Jacangelo JG (2015) Emerging desalination technologies for water treatment: a critical review. Water Res 75(1):164–187

Sutar SA, Kulkarni GS (2016) Development of decentralized wastewater treatment system for kitchen wastewater. Int J Innov Res Creative Technol 2(2):51–53

Tillman AM, Svingby M, Lundstrom H (1998) Life cycle assessment of municipal wastewater systems. Int J Life Cycle Assess 3(3):145–157

United States Environment Protection Agency [US EPA] (2015) https://www.epa.gov/sites/production/files/2015-06/documents/mou-intro-paper-081712-pdf-adobe-acrobat-pro.pdf Accessed 14 January 2018

Water and Sanitation Program (2013) Water and sanitation program end of year report, Fiscal Year 2013. https://wsp.org/sites/wsp.org/files/publications/WSP-End-Year-Report-FY13.pdf Accessed 15 December 2017

Water Information Network South Africa [WIN-SA] (2014) DEWATS process for decentralized wastewater treatment. Technical lessons from Ethekwini municipality. https://www.susana.org/_resources/documents/default/2-2039-dewats-processfor-decentralised-wastewater-treatmentlessonv9.pdf Accessed 27 April 2018

Yıldırım M, Topkaya B (2012) Assessing environmental impacts of wastewater treatment alternatives for small-scale communities. CLEAN-Soil, Air, Water 40(2):171–178

Yoshida H, Christensen TH, Scheutz C (2013) Life cycle assessment of sewage sludge management: a review. Waste Manag Res 31(11):1083–1101

Zhao C, Zhang Y, Liang K, Li J (2015) Environmental impact analysis of wastewater treatment process based on life cycle assessment. In International Conference on Education,Management and Computing Technology (Vol. 16, pp. 1614-1617), Atlantis Press

Acknowledgments

With funding from The Government of India [Department of Science and Technology, File DST/IMRCD/SARASWATI/2012/(G)/II] is gratefully acknowledged. The cooperation of the plant management teams extended during the study period is highly appreciated.

Funding

The research was conducted under the collaborative project “Supporting consolidation, replication and up-scaling of sustainable wastewater treatment and reuse technologies for India (SARASWATI)” and co-funding from the European Commission within the Seventh Framework Programme (grant agreement number 308672).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Loubet

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, A., Sawant, M., Kamble, S.J. et al. Performance evaluation of a decentralized wastewater treatment system in India. Environ Sci Pollut Res 26, 21172–21188 (2019). https://doi.org/10.1007/s11356-019-05444-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-05444-z