Abstract

Leather tanneries which produce significant amounts of solid waste, effluents, and emissions are a major contributor to industrial waste. A cleaner production program was launched by the government of Pakistan to implement the cleaner production measures for tanneries of Sialkot from 1999 to 2005. The main objective of this study is to identify the impact of a cleaner production program, along with other determinants of a cleaner production in the leather industry. The study analyses firm-level primary data collected from leather tanneries in Sialkot. The primary data were collected from tanneries in Sialkot. The econometric analysis is conducted using the Poisson regression analysis. Overall results show that there is no significant impact of cleaner production in 2015, while the panel data results indicate that the effect of cleaner production support by CPC on cleaner production practices diminished once the support came to an end. The other main factor is firm size, which indicates the financial position of the firm; international and regulator pressures are major determinants of the adoption of cleaner production measures. The analysis also indicates that there is higher probability of large firms adopting a cleaner production in comparison with small ones. Export orientation of firms is another important determinant of cleaner production. The enforcement of the environment compliance laws also has positive effect. The compliance with cleaner production measures is quite low, at 6.4 out of 19 cleaner production practice measures. There is a need to adopt measures that are environmentally friendly and are favorable towards both labor health and product quality, which are important for the sustainable growth of the tanning industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Leather products and supports goods of Pakistan are famous worldwide. For the FIFA World Cups of 1982, 2014, and 2018, the soccer balls (Tango and Brazuca, Telstar 18, respectively) were made in Pakistan (TDAP 2018). The leather industry’s contribution to value-added manufacturing as a percent of the GDP was 5% in 2015, with 2500 leather processing units providing employment to more than 500,000 people (Hashmi et al. 2017). The leather industry in Pakistan, with a 5% share in total export earnings, is one of the most dynamic as well as the second largest export-oriented sector after textiles (Siddiqui et al. 2016). The value of exports from the leather sector in the fiscal year 2013–14 was USD 1.27 billion, which was 10.5% higher than the previous year’s leather exports (World Bank 2011; Ghafoor and Zafar 2014).

Along significant contribution in economy, leather tanneries are major contributors to industrial waste, producing solid waste, effluents, and emissions, among which wastewater is the most significant threat to the environment (Tariq et al. 2010). The effluents of the tanning industry contain organic and inorganic matters which take the form of dissolved and suspended materials with toxic metal salt residues that severely affect the health of the habitants (Mahmood and Iqbal 1995; Tariq 2006; Garai 2014; Rabelo et al. 2018; Maqbool et al. 2018).

Tanneries, like many other small and medium enterprises, are often leading contributors to environmental degradation, especially when they are geographically clustered in urban localities.

There are many reasons for poor compliance with environmental regulations by the tanning industry in Pakistan, as in other developing countries. One reason is the limited body of environmental guidelines for tanneries with either weak or poorly enforced environmental laws. Many tanneries in Pakistan lack proper cleaner production equipment while water treatment plants are unavailable. Thus, international environmental standards are rarely implemented in Pakistan. Furthermore, conventional regulatory instruments are generally ineffective due to financial constraints, low education, and unavailability of technical assistance to owners (World Bank 2011). Another major factor is political influence which deflects efforts by local authorities to enforce environmental regulations and environmental compliance (Blackman and Kildegaard 2010).

The Government of Pakistan has made efforts to reduce the pollution associated with tanneries. A cleaner production program (CPP) was introduced during 1999–2005 by the Government with the cooperation of the Norwegian Agency for Development Cooperation (NORAD), Trade Development Authority of Pakistan (TDAP), and Pakistan Gloves Manufactures and Exporters Association (PGM&EA). Under this program, different measures were introduced in the leather sub-sectors in the cities of Sialkot, Lahore, and Karachi (World Bank 2011). Since it is difficult for financially constrained firms to obtain technical information about new technologies, this program sought to provide machinery as pilot project, technical assistance, and awareness raising to the tanneries. For the sustainable production of leather products in Pakistan, it is important to understand the factors that determine compliance with environmental regulations by the leather tanneries.

A number of studies have addressed factors affecting cleaner production in industries. Among the key factors, along with financial and technical support identified, are environmental regulations, international pressure, social activism, and firm-specific characteristics. The firm-specific characteristics include human capital, product and process, regulations, social, size, and financial position (Dasgupta et al. 2000; Anton et al. 2004; Anton 2005; Blackman 2008, 2010a, b; González del Rio 2009; Escobar and Chávez 2013; Lan and Munro 2013; Hemachandra 2015; Li and Hamblin 2016).

The main objective of this study is to understand the cleaner production program (CPP) and its implementation procedure and success rate as well as the challenges faced in its implementation at Sialkot. It also intends to identify the impact of the cleaner production program, along with other determinants of cleaner production in the leather industry. The study analyses firm-level primary data collected from leather tanneries in Sialkot. In the “Literature review” section, the study will therefore offer a review of literature on the cleaner production, environmental regulations in Pakistan. It also provides literature on factors affecting cleaner production. The “Research methods” section explains research methods to carry out this study. The “Leather industry in Pakistan” section gives an overview of the leather industry in Pakistan and its contribution to the economy. In the “Results and discussion” section, the study will examine whether support of the Cleaner Production Program to the leather industry is a significant determinant of the adoption of cleaner production measures. We offer conclusions and policy implications the “Conclusions and implications” section.

Literature review

Environmental regulation is one of the key factors of cleaner production. Therefore, to build a comprehensive understanding and highlight its importance, this section presents an overview of environmental regulations and cleaner production program in Pakistan. The literature on factors playing a role in adoption of cleaner production at firm level is also presented.

Environmental regulations

Environment improvement has long been a concern of the Government of Pakistan. However, the understanding of environmental issues, their relation to development, and their translation into action are yet to be approached in a systematic and effective manner. The first major consolidated environmental legislation, the Pakistan Environmental Protection Ordinance (PEPO), was passed and promulgated in 1983. Equally important was the National Conservation Strategy (NCS) prepared in 1992 which was a major step in setting goals for natural resource conservation. Furthermore, the Pakistan Environment Protection Commission (PEPC) approved the National Environment Quality Standards (NEQS) in 1993. These NEQS were uniform for industrial and municipal discharges. In 1996, the Environmental Standards Committee (ESC) was set up to suggest revisions to the NEQS where necessary. The Committee found some of the parameters to be more stringent than those for other countries in the region. Therefore, through consultations with stakeholders, the Pakistan Environmental Protection Act was promulgated in December 1997. The ESC proposed revised NEQS and recommended to the Pakistan Environmental Protection Council to endorse the revised NEQS in December 1999, which came to be known as NEQS 2000. In 2005, the National Environment Policy was issued which provides a framework for addressing the environmental issues of air, water, and waste management. It also addresses the environmental issues of conservation of forests, biodiversity, natural disasters, and climate change (Sial 2018). In 2012, the 1997 Act came to be changed after the 18th amendment to the Constitution, which designated “environment protection” as one of the devolved subjects to the provinces of Pakistan. Today, each province has a provincial Environment Protection Agency working under the provincial Environment Protection Act 2012 (The Pakistan Environmental Protection Act 1997 n.d.; The Punjab Environmental Protection Act 1997 n.d.; The Punjab Environmental Protection Act 2012 n.d.).

Cleaner production program

It was against the backdrop of the preparations for the 1992 United Nations Conference on Environment and Development (Rio Conference) that the realization came that if manufacturing goes global, cleaner production should follow suit as a global undertaking (OECD 2007). The United Nations Industrial Development Organization (UNIDO) and the United Nations Environment Program (UNEP) therefore initiated a program in 1989 with the aim of cleaner production by industries in advanced countries. They jointly therefore launched the National Cleaner Production Centers program in 1995 with the establishment of eight centers in developing and transitional countries (Luken and Navratil 2004).

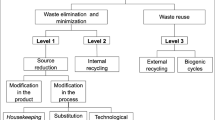

Owing to the role of the cleaner production program in increasing compliance with environment regulations, it is today accepted worldwide. Cleaner production is a voluntary approach focusing on environmental management for reduction in pollution. It is also helpful in reducing input use and improving quality. The application of cleaner production improves quality, reduces cost and health risks, and improves the environment. By 2002, 100 Cleaner Production Centers were functioning in over 40 countries and by 2015 the program had been extended to 58 countries (OECD 2007; WB 2011; UNIDO and UNEP 2015). These centers helped spread information, create skills, provide training, and initiate pilot projects. The Center essentially helps firms design and operate cleaner production processes and develop and produce eco-efficient products. The cleaner production process is one of the indicators of the Environment Management System (EMS). It is also helpful in meeting the requirements of the EMS and ISO-14001 certification. Cleaner production can also help in cost saving for developing countries given their energy deficiencies as well as extensive use of raw material (OECD 2007).

A cleaner production project (CPP) was initiated in 1999 by the Cleaner Production Centre (CPC) in Sialkot to reduce the environmental risks associated (World Bank 2011), the objective of the establishment of CPC being to convince the tanners to use cleaner practices. For this purpose, the CPP introduced different measures for cleaner production on a trial basis, one of them being the provision of display units to firms to practice cleaner production. The adoption of CP is environmentally friendly and cost effective in comparison with “end-of-pipe” treatmentFootnote 1 (Sarkis and Cordeiro 2001). As Dandira et al. (2012) have pointed out, the environmental benefits of Cleaner Production can be translated into market opportunities for ‘greener” products.

Cleaner Technologies for tanneries involve good housekeeping and process improvements, conservation of water through installation of water flow meters (for effluent load controls and measurements), control of air quality in the industry (via the installation of Dust Collectors on dry shavers and buffing machines), arresting of sludge from effluents tanneries (via the installation of Grit Chambers), control of indiscriminate discharge of potentially harmful liquids and hazardous solid wastes, control of high concentration of chloride in effluents (via the provision of de-dusting tables and related expertise), and recovery of chrome from spent chrome liquors (via the establishment of a chrome recovery plant) (World Bank 2011).

Factors affecting cleaner production

A number of studies have addressed factors affecting cleaner production in industries. The green process innovation rather than product innovation directly impacts cleaner production. There is need to promote process-oriented innovation and to build an environmentally friendly culture in order to be more active in cleaner production in the long-run (Li and Hamblin 2016). In their study, Frondel et al. (2007) have shown that cost saving tends to favor clean production while regulatory measures and stringent environmental regulations tend to be positively correlated with end-of-pipe technologies. Among other factors which support the implementation of cleaner production measures are general management systems and specific environmental management tools such as process control systems or environmental audits, which presumably the part of cleaner production (Luken and Navratil 2004).

The key driver of the adoption of cleaner production technologies is a firm’s human capital (Blackman and Kildegaard 2010). Firms with high human capital are more likely to have better environmental compliance (Lan and Munro 2013). This is because training of workers is a major factor of compliance with environmental regulations (Gangadharan 2006). Programs that promote more effective environmental management and training within the plants also lead to better compliance with industrial pollution control (Dasgupta et al. 2000). The training of workers is a major factor in compliance with environmental regulations (Gangadharan 2006). Environmental training is also important in green management (Teixeira et al. 2012). The programs that promote more effective environmental management and training within the plants enable the plants to arrive at a better compliance status with regard to industrial pollution control (Dasgupta et al. 2000; Teixeira et al. 2012). It is positively associated with the adoption of cleaner production (Blackman 2008, 2010a, b; González del Rio 2009).

The regulations have not always proven effective in reducing industrial pollution in the developing world (Anton et al. 2004; Blackman and Sisto 2005; Maxwell and Lyon 2000). Although there are firms that voluntarily adopt environment-friendly measures (Anton 2005; Uchida and Ferraro 2007; Florida and Davison 2001), evidence of the impact of voluntary regulatory policies on cleaner practices is far more mixed since non-regulatory pressures appear to have a very low impact on a firm’s environmental compliance in developing countries (Blackman 2008). One of the important reasons for the lack of compliance of a firm with environmental regulations is the poor enforcement of regulations (Schjolden 2000) as command and control instruments play a vital role in controlling industrial pollution (Dasgupta et al. 2000; Anton et al. 2004; Delmas and Toffel 2008; Priyadarshini and Gupta 2003). Close monitoring and stricter enforcement improves firms’ compliance behavior (Dasgupta et al. 2000; Escobar and Chávez 2013; Mudalige and Udagama 2013). The voluntary regulatory policies on industry compliance are mixed and indications are that non-regulatory pressures have a very low impact on a firm’s environmental compliance in developing countries (Blackman 2010b).

Environmental regulations have a significant effect on compliance when it comes to exports (Roy 2012) as buyers play an important role in demanding cleaner production. Firms that export their products to European countries need to comply with specific environment standards. Hence, in developing countries, export-oriented firms are found to display better compliance than those producing for the local market (Samad et al. 2015; Christmann and Taylor 2006; Roy 2012; Hemachandra 2015). According to Polinsky and Shavell (2000), among others, social activism is one of the factors affecting environmental compliance. The social activism by the community can play an influential role in enhancing compliance (Winter and May 2001).

The individual characteristics of the firm are also matters for adoption on cleaner production and environmental compliance. The age of a firm is represented by the number of years a firm has been in operation. It represents the level of technology and adherence to the conventional production process. The number of years that a firm has been in the production process is used as an indicator of the age of the tannery which is expected to negatively affect the choice of cleaner production (Hoogendoorn et al. 2014). Like firm age, firm size and type of operation of the firm also need to be controlled. Such differences in structural characteristics may influence a firm’s environmental attitude. The previous literature shows that firm size is an important determinant of environmental compliance behavior, as smaller firms may lack the necessary resources to invest in environmental activities, which matches the negative and significant relation (Bickerdyke and Lattimore 1997; Sáez-Martínez et al. 2014; Samad et al. 2015; Sáez-Martínez et al. 2016).

Finally, we can conclude that among the key factors identified are human capital, pecuniary and non-pecuniary support, regulations, social and international activism, and firms’ individual characteristics for adoption of cleaner production.

Research methods

In the present section, we provide a model that determines the impact of the cleaner production program on adoption of cleaner production including other determinants as control variables. It also describes about variables, study area, data, and its collection procedure.

Model

To investigate the impact of the cleaner production program (CPP) on cleaner production and determinants of cleaner production in the tanning industry, our study estimates a regression model using both cross-sectional data and panel data. The selection of the variables is based on studies discussed in literature review section (Gangadharan 2006; Blackman and Kildegaard 2010; Escobar and Chávez 2013). We provide a model that determines the impact of cleaner production program on adoption of cleaner production including other determinants as control variables. The control variables include firm characteristics as well as pressure from local and international community and government. The following equation presents the model for examining the determinants of the adoption of cleaner production measures:

where the dependent variable Y denotes the adoption of cleaner production measures while X1 is the vector representing pecuniary or non-pecuniary supports to firms, X2 is the vector of variables exerting pressure on firms to comply with cleaner production, and X3 is the vector of variables representing a firm’s characteristics.

Adoption of cleaner production measures (Y)

The dependent variable (Y) is a count variable, measuring the number of cleaner production measures adopted by a firm out of a total of 19 measures. As presented in Appendix 1 Table 8, there are 19 measures that a firm can adopt totally or partially. The present study estimates separate equations for overall measures of cleaner production as well as for each of three sub-categories, viz., environment, labor conditions, and quality. In addition, the dependent variable is also segregated on the basis of cost (i.e., low and high cost).

Support (X 1)

Support is also a count variable. It represents Cleaner Production Support for pecuniary or non-pecuniary measures (i.e., financial, technical, and training supports for adoption of cleaner production) for 19 measures from CPP. This variable is also segregated on the basis of cost (i.e., low and high cost).

The training of workers is a major factor in compliance with environmental regulations (Gangadharan 2006). Environmental training is also important in green management (Teixeira et al. 2012). The programs that promote more effective environmental management and training within the plants enable the plants to arrive at a better compliance status with regard to industrial pollution control (Dasgupta et al. 2000; Teixeira et al. 2012). It is positively associated with the adoption of cleaner production (Blackman 2008, 2010a, b; González del Rio 2009). The level of support that a firm obtains from the cleaner production program is an indicator of it.

Pressure (X 2)

The different types of pressure for compliance with cleaner production, such as pressure from the international community, environmental regulation enforcement agencies, and social actions (activism) by the community, are included in X2.

Regulations have not always proved effective in reducing industrial pollution in the developing world (Anton et al. 2004; Blackman and Sisto 2005; Maxwell and Lyon 2000). However, many firms voluntarily adopt environmentally friendly measures (Anton 2005; Uchida and Ferraro 2007). Nevertheless, the evidence on the impact of voluntary regulatory policies on industry compliance is mixed and indications are that non-regulatory pressures have a very low impact on a firm’s environmental compliance in developing countries (Blackman 2010b).

Environmental regulations have a far reaching impact on compliance when it comes to exports (Roy 2012). For export-oriented firm, there is a need to comply with specific environment standards. Hence, in developing countries, export-oriented firms are found to display better compliance than those producing for the local market (Samad et al. 2015; Christmann and Taylor 2006; Roy 2012; Hemachandra 2015). It is therefore a dummy variable and marked as 1 if a major portion of the firm’s production is exported. Technical assistance and awareness are also key factors given the cost of the technologies and need for awareness of quality benefits for compliance (Blackman 2010a, b; González del Rio 2009).

The second variable included in Pressure is Environmental Regulatory Pressure. One of the important reasons for lack of compliance of firms with environmental regulations is the poor enforcement of environment regulations (Schjolden 2000). Hence, in controlling industrial pollution, command and control instruments play a vital role (Dasgupta et al. 2000; Anton et al. 2004; Priyadarshini and Gupta 2003). Close monitoring and stricter enforcement improve a firm’s compliance behavior (Dasgupta et al. 2000; Escobar and Chávez 2013; Mudalige and Udagama 2013). It is expected that the more the number of inspections, the greater the adoption of cleaner production on the part of the firm (Dasgupta et al. 2000; Anton et al. 2004; Priyadarshini and Gupta 2003; Escobar and Chávez 2013; Mudalige and Udagama 2013). It is measured by the number of inspections in the last 2 years by the Environment Protection Authority.

The third indicator we have included is social activism by the community. It is expected that social activism can also affect the tannery’s choice of cleaner production measures. Tanneries facing more pressure by the community are more likely to adopt Cleaner Production. It is measured by the number of complaints by the community in a year.

Firm’s characteristics (X 3)

The individual characteristics of the firm are also important in adopting cleaner production measures. The years in operation, type of production process, scale of production, and human capital are included in the vector X3.

The age of a firm is represented by the number of years a firm has been in operation. It represents the level of technology and adherence to the conventional production process. The number of years that a firm has been in the production process is used as an indicator of the age of the tannery which is expected to negatively affect the choice of cleaner production.

The type of production process represents whether a firm is producing finished leather from raw hide or from wet blue.Footnote 2 Firms adopting the full process, i.e., producing leather from raw hide, are expected to adopt more measures of cleaner production. Dummy 1 is used if the firm produces leather from wet blue and zero otherwise.

Scale of production represents the size of the firm. Due to unavailability of data on financial position of the firm, the size is used here as proxy of financial position. The financial position of the firm matters for adoption of cleaner production. The better financial position of the firm, the more likely it is to adopt cleaner production (Samad et al. 2015).

In SMEs, the education of the owner as human capital is a vital factor with regard to compliance with environment regulations: the higher the human capital, the more positive is the effect on cleaner production adoption (Gangadharan 2006; Blackman and Kildegaard 2010; Lan and Munro 2013). Firms with high human capital are more likely to have better environmental compliance than those without (Lan and Munro 2013). The education of the owner in years is thus used as an indicator of human capital. The study uses three types of education for owners: Matric, FA, and BA, which are equivalent to 10, 12, and 14 (or higher) years of schooling.

Study area

Sialkot is one of the industrial cities of Pakistan. The city is famous for its industrial and export-related goods. There are more than 3221 industrial units producing sports goods, leather, surgical instruments, textiles, etc. Sialkot is the world’s largest producer of hand-sewn footballs, with local factories manufacturing more than 40 million footballs per year (Gordon and O’Connor 2010; TDAP 2018). For the FIFA World Cups of 1982, 2014, and 2018, the soccer balls (Tango and Brazuca, Telstar 18, respectively) were made in Sialkot (TDAP 2018). The city is also popular with regard to the production of surgical and medical instruments, sportswear and goods, and leather wear and products.

The Sialkot International Airport, which is the first-ever private sector airport in Pakistan, is managed by the Sialkot International Airport Limited (SIAL) consortium and boasts the longest runway in Pakistan. The Sialkot Dry Port has the distinction of being the first-ever private sector dry port in Asia (Nadvi 1999). It is controlled by the Sialkot Dry Port Trust. These two entities make easy transportation of exports to other countries. The value of exports from Sialkot was USD 1.2 billion in 2014.

The registered leather tanneries in Pakistan are more than 800 out of which around 250 are located in Sialkot (World Bank 2011; PTA 2018). The industry in general falls under the Small and Medium Enterprises (SMEs) category and uses a mix of old tanning techniques and clean production technologies (World Bank 2011). The chromium concentration in the ground water near the leather tanneries is higher than the WHO guideline (PCRWR 2007). The surface and groundwater of Sialkot have been degraded due to rapid industrialization while an estimated discharge of effluents from only the tanneries is approximately 1.1 million liters per day (Ullah et al. 2009). We selected Sialkot as the study area for data collection due to the negative effects of tanneries on the environment and the export orientation of their products.

Data and collection method

This study uses firm-level data collected by the World Bank (2011) and by the authors during the 2014–2015 period. The World Bank dataset had been collected in 2009. We collected second-round data from the same firms used in the World Bank study as well as data from an equal number of other firms that had not been included in the World Bank survey during 2014 and 2015 (referred to as the dataset of 2015).Footnote 3

We collected the data in two phases. In the first phase, we collected data from six tanneries for case studies (see Appendix 2 Table 9) which was a starting point for the purpose of determining whether further investigation was needed or not. These interviews with stakeholders were conducted to understand the underpinnings of the CPP.

Moreover, we analyzed World Bank data while developing methods to undertake the case studies. The case studies gave fruitful insights into determining whether it is necessary to collect data again or not and whether any extra information is required. This provided the basis for the second phase of the study which included a total of 78 firms out of which 39 had been part of the World Bank survey. However, it is noteworthy that all surveyed firms were a part of the CPP. This enabled us to formulate a cross-section of 78 tanneries and a panel of 39 tanneries.

A cleaner production project (CPP) was initiated in 1999 by the Cleaner Production Centre (CPC) in Sialkot to reduce the environmental risks associated with the tanning process at a total cost of PKR 100 million (World Bank 2011). The donors of the project were The Norwegian Agency for Development Cooperation (NORAD), the Trade Development Authority of Pakistan (TDAP), and the Pakistan Gloves Manufactures and Exporter Association (PGM&EA) (World Bank 2011), the objective of the establishment of CPC being to convince the tanners to use cleaner practices. For this purpose, the CPP introduced different measures for cleaner production on a trial basis, one of them being the provision of display units to firms to practice cleaner production. The adoption of CP is environmentally friendly and cost effective in comparison with “end-of-pipe” treatmentFootnote 4 (Sarkis and Cordeiro 2001). As Dandira et al. (2012) have pointed out, the environmental benefits of Cleaner Production can be translated into market opportunities for “greener” products.

Cleaner Technologies for tanneries involve good housekeeping and process improvements, conservation of water through installation of water flow meters (for effluent load controls and measurements), control of air quality in the industry (via the installation of Dust Collectors on dry shavers and buffing machines), arresting of sludge from effluents tanneries (via the installation of Grit Chambers), control of indiscriminate discharge of potentially harmful liquids and hazardous solid wastes, control of high concentration of chloride in effluents (via the provision of de-dusting tables and related expertise), and recovery of chrome from spent chrome liquors (via the establishment of a chrome recovery plant) (World Bank 2011). Appendix 1 Table 8 shows specific measures (and their benefits) that were introduced under CPP in Sialkot.

Leather industry in Pakistan

Today, Pakistan is the fourth largest exporter of leather garments in the world after China, Italy, and India, with tanned leather and leather apparel and clothing as the major contributors to leather exports with 43 and 32%, respectively. The major importers of tanned leather from Pakistan are Hong Kong, Italy, China, and Korea while the importers of leather garments are Germany, USA, France, and Spain with the USA, Germany, and Sweden as the main importers of leather gloves. Pakistan exports leather in the form of tanned leather, clothing and apparel, gloves, footwear, and other leather products. In recent years, the export of leather clothing, gloves, and footwear has been increasing rapidly in comparison with tanned leather (GoP 2015). The leather industry of Pakistan has its origins in Karachi and Lahore in the 1950s. It spread to Kasur, Hyderabad, Sahiwal, Sialkot, Peshawar, and Gujranwala in the 1960s and 1970s (PTA 2018). Presently, the leather processing units in Pakistan numbers approximately 2500, which includes both registered and unregistered entities. The tanning units have increased from 529 in the year 1999 to 800 in the year 2015.Footnote 5The technology used in the tanning industry was imported in the 1970s and 1980s while a few tanneries use machinery manufactured locally.

In the cities of Pakistan, the major contributors to environmental degradation are industries (Government of Pakistan 2015). In the industrial sector, the tanning industry is considered one of the most polluting among the Small and Medium Enterprises (SME), with compliance levels with environmental regulations very low (World Bank 2011). Industrial pollution is caused by the discharge of a variety of industrial pollutants in the form of gases, liquids, and solids which affect the physical, chemical, and biological compositions of the environment. Leather tanneries produce all three categories of waste: wastewater, solid waste, and air emissions. The inputs for leather in Pakistan are the raw hides of buffalos, cows, sheep, and goats. One ton of raw hide yields an average of 0.2 t leather, up to 0.6 t solid wastes and by-products, and about 50 m3 of effluents (UNEP 1996). Among the solid waste are salts, buffing materials, and raw and wet blue trimmings and shavings (Nazer et al. 2006). However, the discharge of wastewater is the most significant environmental challenge due to tanneries. The effluents of the tanning industry contain organic and inorganic matters which constitute dissolved and suspended materials with toxic metal salt residues (Tariq 2006). Additionally, ammonia is emitted during the washing of drums. A 2011 study by the World Bank has found that the tanning industry is neither efficient nor environmentally friendly (World Bank 2011).

The tanneries in Pakistan produce not only wet blue and crust but also fully finished leather and its products. The leather industry consists of six sub-sectors, namely tanning, footwear, garments, gloves, shoe uppers, and other leather goods. The share of leather exports as a percentage of total exports has increased from 4.68 in the fiscal year 2012–13 to 5.08 in 2013–2014 (Government of Pakistan 2015).

Results and discussion

The insights from the case studies provide rational for the need and importance of study. This section further includes descriptive statistics, correlation matrix, and regression results.

Insights from case studies

For that purpose, we conducted interviews with five stakeholders: the Project Director, two Ex-Chairmen of CPC, the Consultant of IMF, and the District Officer of the Punjab Environment Protection Authority. In the following paragraphs, we present and analyze the information obtained from these interviews. The objective in initiating cleaner production in the leather industry was to educate the firms on the importance of cleaner production. Hence, the CPP approached the industry through professional associations like the PTA, created awareness among industry professionals through seminars and workshops, demonstrated cleaner production technologies through pilot demonstrations; facilitated the conduct of environmental and energy audits, facilitated the identification and evaluation of specific CP options, provided training to the staff in tanneries, and calculated the environmental and financial benefits as a result of the implementation CP measures. This resulted in the systematic implementation of CP measures such as dust collector installation, chrome management, chrome recovery, and good housekeeping. Good housekeeping and process improvement received widespread acceptance as it involved little or no investment.

Among the major factors when it came to the non-adoption of some specific technology by a firm were the unavailability of modern CP technologies, the high costs of obtaining and installing these technologies, and lack of interest in research and development. Among the major hurdles in the way of implementation of CP measures were the rigid attitude of the owners, the lack of funds for the purchase of modern equipment, and the lack of education among workers. The implementation of CPP in the tanneries has been helpful to some extent in achieving the NEQS. However, full compliance with CPP will only be possible with the availability of effluent treatment facilities to the firms for this purpose (Appendix 1 Table 9)

Descriptive statistics

This section describes the descriptive statistics of data collected from 78 tanneries in Sialkot in 2015. Table 2 presents the summary statistics of the variables used in the regression model. The dependent variable is a count variable, measuring the number of cleaner production measures adopted by a firm out of a total of 19 measures. Appendix 1 Table 8 lists the 19 measures that a firm can adopt either partially or in full. Table 1 presents definitions of varibles used in this study. We group these 19 measures into three sub-categories, namely environment-, labor-, and quality-related measures based on their benefits. Measures which improve the environment by reduction in effluents and emissions from tanneries are characterized as environment-related measures. Those which affect the health and other work conditions of workers constitute labor-related measures. Measures that improve the quality of the leather either by proper use of materials or by use of proper materials are categorized as “quality” measures. Each sub-category is further divided into two categories based on the cost of adoption: low or high. The “overall” category is based on all the measures. As shown in Table 2, the overall average rate of adoption of cleaner production measures of tanneries in Sialkot is 6.4 (out of 19).

The tanneries received support for cleaner production between 1999 and 2005 by the CPP. Support is a count variable. It represents the Cleaner Production Support provided for either pecuniary or non-pecuniary aspects (i.e., financial, technical and training support enabling the adoption of cleaner production) of the 19 measures of CPP. The variable support is also segregated on the basis of sub-categories as well as in terms of low and high costs, as discussed above.

Table 2 shows that most tanneries export their final products (approximately 72%). It also shows that 41% of the owners are graduates while 42% have at least 12 years of education. According to the perception of the owners, 80% of the tanneries are either small or medium while big tanneries constitute only 20% of the sample. Figure 1 shows the adoption level of each measure of cleaner production adoption by tanneries in 2015 for each of the 19 measures. There are two bars for each measure. The first bar shows the adoption rate of each cleaner production measure by tanneries which were not supported by CPP while the second column presents the adoption of each measure by tanneries which were supported by CPP during 1999 to 2005 period. The figure indicates that, in most of the cases, the adoption rate is higher for tanneries which received support. However, in the case of some measures, there is not much difference between the two types of bars although in the case of others there is a significant difference. Note that this comparison does not control for other factors affecting adoption by tanneries, which are considered in the econometric analysis in the next subsection.

Correlation matrix

Correlates between the variable of 78 tanneries surveyed in 2015 are presented in Table 3. The correlation between support provided for cleaner production from 1999 to 2005 and adoption of cleaner production measures in 2015 is only 0.301, which is moderate and significant. The correlations between adoption of cleaner production and scale of production are strong and significant as these are 0.464 and 0.405, respectively. It is moderate for environmental regulations (0.379) and human capital (0.224), while for type of production process and social activism, insignificant. Moreover, correlation between independent variables is less than 0.7 so there is no issue of multicolinearity in the model.

Regression results

This section provides the empirical results of the study. We collected data on cleaner production measures and other characteristics of the firms from 78 tanneries in Sialkot. It presents two types of econometric analysis. The first is a cross-section analysis of the data for 78 tanneries collected in 2015while the other is a panel data analysis for 39 tanneries for which data is available for 2009 and 2015. The estimation technique is always based on characteristics of the variables. Ordinary least squares regression assumes normally distributed data which can take any real value. The logistic regression is only used for dichotomous variables that are 0–1 valued while Poisson regression is applied for count data. In this study, the dependent variable, in all regressions, consists of count data. Therefore, we use Poisson regression for estimation.

Regression results from cross-sectional data

Tables 4 and 5 present the Poisson regression results. The dependent variable is a count variable, measuring the number of cleaner production measures adopted by a firm. Table 4 presents results for both overall compliance and compliance broken down by sub-categories, with cleaner production measures as the dependent variable. Table 5 presents the results for each of these categories as low-cost and high-cost measures. The explanatory variables include CPP support for adoption of each measure, international pressure (whether the firm sells a major part of its final product in the domestic or international market), pressure from regulatory authorities in terms of the number of inspections by PEPA, social pressure in terms of complaints by community, and firm characteristics such as the number of years in operation, type of tanning process, size of the firm, and education of the owner.

In independent variables, overall support indicates the number of measures that the Cleaner Protection Program (CPP) had supported. Results in Table 4 show that overall support from CPP to a firm is not significant. Thus, the major role in the adoption of overall CP measures was played by international pressure, firm size, type of production, and education of the owner. Table 5 which presents the same measures bifurcated into low- and high-cost measures gives similar results except that human capital and type of production which are high-cost measures become insignificant. Thus, when it comes to the adoption of environment-related measures, only the size of the firm, international pressure, and type of production process have significant effects while in bifurcated results mainly size matters. However, both tables confirm that support from CPC has not affected the decision to adopt environment-friendly measures.

Cleaner production measures which improve labor conditions are mostly those which improve the internal conditions of the tannery and are important for the health of workers, such as dust collectors and personal protective equipment. The results presented in Tables 4 and 5 show that big tanneries are more likely to adopt health-related cleaner production (CP) measures that are both low and high cost. It is important to note here that support of CPC has no significant impact on the adoption of either high- or low-cost labor condition measures. Only the size of the firm is significant for the adoption of overall and low-cost health measures. There is no variable that significantly affects high-cost labor condition measures.

Measures which reduce cost or improve quality with regard to overall adoption are significantly affected by size, international pressure, and type of production process. However, with regard to low-cost quality measures, the size of the firm and type of process are important whereas for high-cost quality measures there are no significant determinants.

Regression results from panel data

Tables 6 and 7 present Poisson regression results based on panel data. These panel data models have been estimated using fixed effects to control for firm-level heterogeneity across tanneries. Table 6 presents results for both overall conditions and environment-, labor-, and quality-related sub-categories with cleaner production measures as the dependent variable while Table 7 presents the results for each of these categories divided into low-cost and high-cost measures.

While the CPP support was provided between 1999 and 2005, the panel data is for the 2 years, 2009 and 2015. Thus, the variable is the same for both years and its coefficient estimate cannot be estimated with fixed effects. We therefore estimate the model using its interaction with the year (time). The results show that the coefficients of the time interaction term is statistically significant and negative in most of the estimated models, indicating the diminishing effect of cleaner production support over time. Furthermore, the results show that environmental regulatory pressure and the size of the firm have a significant effect on the adoption of overall and environment-friendly measures. It is interesting to note that environmental regulatory pressure has a significant effect on the adoption of cleaner production. It is worth noting in Table 6 that the time interaction term with CPP is significant for all types of low-cost measures while insignificant for all high-cost measures. This may be because the firm does not try to maintain or reinstall a high-cost measure, when it depreciates with time, due to financial constraints. It could also be that, prior to 1999, the firm did not adopt many high-cost measures.

Conclusions and implications

Our study attempted to understand the factors that determine compliance with cleaner production practices in the case of the tanning industry in Pakistan. For that purpose, it analyses firm-level primary data collected from leather tanneries in Sialkot. We find that firm size, which indicates the financial position of the firm, is a major determinant of the adoption of cleaner production measures. The analysis also indicates that there is a higher probability for large firms to adopt cleaner production measures in comparison with small ones. International pressure which is measured by the export orientation of the firm is another important determinant of cleaner production. Results show that international pressure affects all types of measures except labor condition measures. Type of production is another important measure, and its significance is understandable given that more measures are needed in the full tanning process (from raw hide to leather)in comparison with half-tanning processes(i.e., from raw hide to wet blue and wet blue to leather). It can be concluded from the analysis that labor conditions do not rank high among either the firms or the international community, the concern being more with the end product of the firm. The human capital of the firm as measured by the education of owners has a significant effect on overall adoption. The results show that, after controlling for other factors, support from the cleaner production program (CPP) is not a significant determinant of the adoption of cleaner production measures, in either the overall or segregated analysis.

The assessment of cleaner production support overtime indicates that the adoption of cleaner production measures by tanneries supported by the CPP was higher in 2009 than in 2015, which shows that it has diminished overtime. We find evidence for greater adoption of low-cost measures perhaps because the tanners are financially constrained, which makes adopting, sustaining, and maintaining higher cost measures difficult. Moreover, tanners seek permanent support while the support available was only partial, transitory, and demonstrational. For example, the solid waste management system stopped functioning during the closing stages of the CPP project. Moreover, not only was the adoption of these measures voluntary but there was no review process after the implementation of the program. Hence, the tanners abandoned these measures when the support came to an end. But the results reveal that environmental regulatory pressure has a significant effect on the adoption of overall as well as environment-friendly production measures.

One of the reasons for the ineffectiveness of social activism is the negligible complaints from those living in the vicinity of the firms. One reason for the paucity of complaints could be that firms normally hire workers from households in the vicinity so that they are unable to complain about bad environmental conditions. Moreover, after some time, people in the vicinity of the firms would get used to the smell and the prevailing environment so that they would no longer regard the smell as a problem. Another hurdle in the way of implementation of cleaner production measures is a perception among employees that such measures would reduce their efficiency. For them, the unheeding of cleaner production measures is a risk worth taking.

It can be concluded from the above that compliance with cleaner production measures in the tanning industry in Sialkot, Pakistan, is quite low. As a statistical measure, it is 6.4 out 19 on average. Thus, there is an urgent need to improve compliance with, as well as the adoption of, measures that are environmentally friendly and favorable for workers as well as for the quality of products, which will ensure the sustainable growth of the tanning industry in Pakistan. This is an aspect that policy makers and those concerned about cleaner production practices and better working conditions for workers should look into on an immediate basis.

Notes

Cleaner production intends to minimize waste and emissions during the production process while end-of-pipe treatment removes already formed contaminants from a stream of air, water, or waste. The end-of-pipe treatment is normally implemented as the last stage of a process before the stream is disposed of or delivered.

The raw hide which is extracted from the animal is converted first into wet blue and then into finished leather via the tanning process. In our sample, while some tanneries produced finished leather from raw hide, others produce finished leather from wet blue. Wet blue refers to a stage in the tanning process (which is not the final finished leather) in which the color of the leather becomes a pale blue color due to use of chromium.

Data are available with authors and can be provided on request.

Cleaner production intends to minimize waste and emissions during the production process while end-of-pipe treatment removes already formed contaminants from a stream of air, water, or waste. The end-of-pipe treatment is normally implemented as the last stage of a process before the stream is disposed of or delivered.

Tanning units are tanneries that only produce leather from raw hide while leather processing units include tanneries as well as sections for the production of clothing and apparel, gloves, footwear, and other leather manufacturing.

References

Anton WR (2005) The choice of management practices: what determines the design of an Environmental Management System? Annual Meeting of the American Agricultural Economics Association, July 24–27, 2005, Providence, Rhode Island

Anton WRQ, Deltas G, Khanna M (2004) Incentives for environmental self-regulation and implications for environmental performance. J Environ Econ Manag 48(1):632–654

Bickerdyke I, Lattimore R (1997) Reducing the regulatory burden: does firm size matter? Industry Commission, AGPS, Canberra

Blackman A (2008) Can voluntary environmental regulation work in developing countries? Lessons from case studies. Policy Stud J 36(1):119–141

Blackman A (2010a) Adoption of clean leather-tanning technologies in Mexico. Environ Econ Policy Stud 12(3):115–132

Blackman A (2010b) Alternative pollution control policies in developing countries. Rev Environ Econ Policy 4(2):234–253

Blackman A, Kildegaard A (2010) Clean technological change in developing-country industrial clusters: Mexican leather tanning. Environ Econ Policy Stud 12:115–132

Blackman A Sisto N (2005) Muddling through while environmental regulatory capacity evolves: What role for voluntary agreements? Discussion Paper 05–16, Resources for the Future,Washing DC

Christmann P, Taylor G (2006) Firm self-regulation through international certifiable standards: determinants of symbolic versus substantive implementation. J Int Bus Stud 37(6):863–878

Dandira V, Mugwindiri K, Chikuku T (2012) A cleaner production exercise of a leather manufacturing company: a Zimbabwean experience. Int J Sci Technol Res 1(11):97–101

Dasgupta S, Hettige H, Wheeler D (2000) What improves environmental compliance? Evidence from Mexican industry. J Environ Econ Manag 39(1):39–66

Delmas MA, Toffel MW (2008) Organizational responses to environmental demands: opening the black box. Strateg Manag J 29(10):1027–1055

Escobar N, Chávez C (2013) Monitoring, firms’ compliance and imposition of fines: evidence from the Federal Industrial Inspection Program in Mexico City. Environ Dev Econ 18(6):723–748

Florida R, Davison D (2001) Gaining from green management: environmental management systems inside and outside the factory. Calif Manag Rev 43(3):64–84

Frondel M, Horbach J, Rennings K (2007) End-of-pipe or cleaner production? An empirical comparison of environmental innovation decisions across OECD countries. Bus Strateg Environ 16(8):571–584

Gangadharan L (2006) Environmental compliance by firms in the manufacturing sector in Mexico. Ecol Econ 59(4):477–486

Garai J (2014) Environmental aspects and health risks of leather tanning industry: a study in the Hazaribag area. Chinese Journal of Population Resources and Environment 12(3):278–282

Ghafoor A, Zafar M (2014) Determinants of leather exports from Pakistan: a time series analysis. VFAST Transactions on Education and Social Sciences 5(2):77–86

González del Rio P (2009) The empirical analysis of the determinants for environmental technological change: a research agenda. Ecol Econ 68:861–878

Gordon K, O’Connor K (2010) Playing fair? Ethos 18(3):9

Government of Pakistan (2015) Pakistan economic survey 2014–2015. Ministry of Finance, Islamabad

Hashmi GJ, Dastageer G, Sajid MS, Ali Z, Malik MF, Liaqat I (2017) Leather industry and environment: Pakistan scenario. Int J Appl Biol Forensic 1(2):20–25

Hemachandra DWK (2015) Adoption of voluntary environmental practices: evidence from the textile and apparel industry in Sri Lanka, SANDEE Working Paper No. 93–15, South Asian Network for Development and Environmental Economics (SANDEE), Kathmandu, Nepal

Hoogendoorn B, Guerra D, van der Zwan P (2014) What drives environmental practices of SMEs? Small Bus Econ 44:759–781

Lan J, Munro A (2013) Environmental compliance and human capital: evidence from Chinese industrial firms. Resour Energy Econ 35(4):534–557

Li X, Hamblin D (2016) Factors impacting on cleaner production: case studies of Chinese pharmaceutical manufacturers in Tianjin, China. J Clean Prod 131:121–132

Luken R, Navratil J (2004) A programmatic review of UNIDO/UNEP national cleaner Production centres. J Clean Prod 12:195–205

Mahmood T, Iqbal ZM (1995) Vegetation and soil characteristics of the wasteland of Valika chemical industries near Manghopir, Karachi. J Arid Environ 30:453–462

Maqbool A, Ali S, Rizwan M, Ishaque W, Rasool N, Rehman MZ, Bashir A, Abid M, Wu L (2018) Management of tannery wastewater for improving growth attributes and reducing chromium uptake in spinach through citric acid application. Environ Sci Pollut Res 25:10848–10856. https://doi.org/10.1007/s11356-018-1352-4

Maxwell JW, Lyon TP (2000) Self regulation and social welfare: the political economy of corporate environmentalism. J Law Econ 43:583–619

Mudalige UKJ, Udagama JMM (2013) Role of regulation for firms to adopt environmental controls: an analysis based on panel data solid waste management in agri-food processing sector in Sri Lanka. Journal of Environmental Professionals Sri Lanka 2(1):65–82

Nadvi K (1999) The cutting edge: collective efficiency and international competitiveness in Pakistan. Oxf Dev Stud 27(1):81–107

Nazer DW, Al-Sa'ed RM, Siebel MA (2006) Reducing the environmental impact of the unhairing-liming process in the leather tanning industry. J Clean Prod 14(1):65–74

OECD (2007) Small businesses and environmental compliance: review and possible application of international experience in Georgia. OECD, Paris

Pakistan Tanners Association (PTA) (2018). Available on http://www.pakistantanners.org/. Accessed 30 Sept 2018

PCRWR (2007) Water quality report 2003–2004. Available at: http://www.pakistantanners.org/industrial_statistics.html [Accessed in 2017]

Polinsky AM, Shavell S (2000) The economic theory of public enforcement of law. J Econ Lit 36:45–76

Priyadarshini K, Gupta OK (2003) Compliance to environmental regulations: the Indian context. Int J Bus Econ 2(1):9–28

Rabelo LM, Guimarães ATB, de Souza JM, da Silva WAM, de Oliveira Mendes B, de Oliveira Ferreira R, de Lima Rodrigues AS, Malafaia G (2018) Correction to: histological liver chances in Swiss mice caused by tannery effluent. Environ Sci Pollut Res 25:16267–16268. https://doi.org/10.1007/s11356-018-1805-9

Roy C (2012) A study on environmental compliance of Indian leather industry and its far-reaching impact on leather exports. Foreign Trade Review 47(2):3–36

Sáez-Martínez F, González-Moreno A, Hogan T (2014) The role of university in eco-entrepreneurship: evidence from the Eurobarometer Survey on attitudes of European entrepreneurs towards eco-innovation. Environ Eng Manag J 10:2541–2549

Sáez-Martínez F, Díaz-García C, González-Moreno Á (2016) Factors promoting environmental responsibility in European SMEs: the effect on performance. Sustainability 8:898

Samad G, Gulzar W, Ahmad V (2015) Environmental regulations and compliance in the textile processing sector in Pakistan: empirical evidence. SANDEE Working Paper No. 98–15, South Asian Network for Development and Environmental Economics (SANDEE), Kathmandu, Nepal

Sarkis J, Cordeiro JJ (2001) An empirical evaluation of environmental efficiencies and firm performance: pollution prevention versus end-of-pipe practice. Eur J Oper Res 135(1):102–113

Schjolden A (2000) Leather tanning in India: environmental regulations and firms’ compliance, FIL Working Papers, No. 21, Forurensende Industri-Lokalisering, Oslo, Norway

Sial SA (2018) Review of existing environmental laws and regulations in Pakistan. WWF-Pakistan. Available at https://wwfpak.org/consultancy/images/10517_environmentallaws.pdf

Siddiqui A, Uroos A, Nadeem F (2016) Sectoral competitiveness and value chain analysis: leather gloves value chain analysis in Pakistan. Trade development authority of Pakistan. Available at http://trtapakistan.org/wp-content/uploads/2016/05/leather-final-report.pdf

Tariq SR (2006) Correlation studies on trade trace metal levels in effluents in relation to soil and water in proximity of tanneries, Pakistan, PhD Thesis, Quid-e-Azam University, Islamabad

Tariq SR, Shaheen N, Khalique A, Shah MH (2010) Distribution, correlation, and source apportionment of selected metals in tannery effluents, related soils, and groundwater—a case study from Multan, Pakistan. Environ Monit Assess 166(1–4):303–312

TDAP (2018) Football Diplomacy of Pakistan, retrived on 2018-09-30 from https://www.tdap.gov.pk/pdf/Press-Release-Football-Diplomacy.pdf

Teixeira AA, Jabbour CJC, Jabbour ABLS (2012) Relationship between green management and environmental training in companies located in Brazil: a theoretical framework and case studies. Int J Prod Econ 140(1):318–329

The Pakistan Environmental Protection Act 1997 (n.d.) http://www.na.gov.pk/uploads/documents/Pakistan=Environmental-Protection-Act-1997.pdf

The Punjab Environmental Protection Act 1997 (n.d.) http://punjablaws.gov.pk/laws/2192a.html

The Punjab environmental protection Act 2012 (n.d.) (XXXV of 2012) available at http://www.punjabcode.punjab.gov.pk/ available on: 10-05-2018

Uchida T, Ferraro PJ (2007) Voluntary development of environmental management systems: motivations and regulatory implications. J Regul Econ 32(1):37–66

Ullah R, Malik RN, Qadir A (2009) Assessment of groundwater contamination in an industrial city, Sialkot, Pakistan. Afr J Environ Sci Technol 3(12):429–446

UNEP (1996) Cleaner production in leather industry: a workbook for trainers. Division of Technology, Industry and Economics, Paris

UNIDO and UNEP (2015) National cleaner production centres: 20 years of achievement: towards decoupling resource use and environmental impact from manufacturing growth. Division of Technology, Industry and Economics, Paris

Winter SC, May PJ (2001) Motivation for compliance with environmental regulations. J Policy Anal Manage 20(4):675–698

World Bank (2011) Implementable recommendations for cleaner production programs in Pakistan, Consultant report prepared for non-lending technical assistance for Ministry of Industries and Production, Government of Pakistan. World Bank, Washington D.C

Acknowledgements

This study has been undertaken with the financial support provided by the South Asian Network for Development and Environmental Economics (SANDEE). We are indebted to Jean Marie Baland for his invaluable guidance. His contribution to bring the study to into its present shape was considerable. We are also thankful to Priya Shyamsundar for help with proposal development and encouragement at every stage of the study. We are also indebted to Eswaran Somanathan, Enamul Haq, Celine Nauges, Heman Lohano and Mani Nepal for their invaluable guidance and support during the course of research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Padda, I.U.H., Asim, M. What determines compliance with cleaner production? An appraisal of the tanning industry in Sialkot, Pakistan. Environ Sci Pollut Res 26, 1733–1750 (2019). https://doi.org/10.1007/s11356-018-3717-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-3717-0