Abstract

Indirect carbon emissions account for a large ratio of the total carbon emissions in processes to make the final products, and this implies indirect carbon emission flow across industries. Understanding these flows is crucial for allocating a carbon allowance for each industry. By combining input–output analysis and complex network theory, this study establishes an indirect carbon emission flow network (ICEFN) for 41 industries from 2005 to 2014 to investigate the interrelationships among different industries. The results show that the ICEFN was consistent with a small-world nature based on an analysis of the average path lengths and the clustering coefficients. Moreover, key industries in the ICEFN were identified using complex network theory on the basis of degree centrality and betweenness centrality. Furthermore, the 41 industries of the ICEFN were divided into four industrial subgroups that are related closely to one another. Finally, possible policy implications were provided based on the knowledge of the structure of the ICEFN and its trend.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Climate change continuously threatens the development of the human and ecological environment. As excessive greenhouse gas (GHG) emissions are not conducive to the preservation of the Earth’s climate and temperature, many national and international groups have made commitments to minimize the carbon footprint (Shuai et al. 2017). China is the world’s largest energy consumer and greenhouse gas emitter, and its energy intensity is twice that of the world average (Wang et al. 2011; Zhang et al. 2017). In this context, the Chinese government released a mitigation action plan to reduce the country’s carbon emission intensity by 40 to 45% in 2020 based on the 2005 level (Geng et al. 2013). In the 2014 US–China joint statement on climate change, China’s government further announced its plan to reach a national peak in carbon emissions by approximately 2030, and it has since pursued strategies to achieve this goal as early as possible (Wang et al. 2016).

Industries are the largest contributors to carbon emissions within a determinate national economy (Zhou et al. 2013). It is a common practice to assess the direct carbon emissions of industries. However, industries, when producing goods and services generate not only direct carbon emissions but also indirect carbon emissions (Nishimura et al. 1997; Chang 2015). The concept of indirect carbon emissions originated from “indirect energy requirements”, defined in terms of the energy consumption embodied in the goods and services required to create final products (Brown and Herendeen 1996; Zhu et al. 2012). By calculating Chinese economic data of this paper from 2005 to 2014, indirect carbon emissions of industries account for approximately 82% of the total carbon emissions of carbon emission in the processes to create final products (Fig. 1). Therefore, it is essential to study indirect carbon emissions in China. However, there is a complex carbon emissions relationship between industries because of the consumption and supply of products. Previous research has largely focused on the indirect carbon emissions of one industry, such as the construction industry (Li and Chen 2017; Han et al. 2013; Su and Zhang 2016), the tourism industry (Meng et al. 2016; Liu et al. 2011) or the transport industry (Han et al. 2017; Büchs and Schnepf 2013). These studies have failed to comprehensively reflect the linkages between the different industries and the effects of the industrial connections on carbon emissions. If government only focused on one industry when making carbon emission reduction policies, it may even result in mutually offsetting situations between different measures and it is detrimental for mitigating the carbon emissions of the whole economic system. Therefore, knowing the carbon emission relationship between different industries offers the prerequisite for coping with carbon emission related issues and thus for achieving a sustainable Chinese economic system.

Complex network theory is a useful tool to portray the structural properties of a system by analysing its components and linkages. It has been widely applied in the fields with strong interdependence within entities, including biology (Benevides et al. 2016; Góes-Neto et al. 2010), medicine (Zhang and Jin 2012) and communications (Li et al. 2014; Liu et al. 2016). Complex network theory has also been applied in the field of industrial ecology because it can simplify the operation of industrial symbiosis networks by combining the impact of both economic and environmental aspects and concentrating on the network structure morphology, interaction patterns and the influences on the results of the collaboration (Domenech and Davies 2011; Li et al. 2017). Moreover, complex network theory is not confined to study the linkage of industries on one industrial chain, which is more suitable for explore the diverse industrial chain relationships. Therefore, this paper applies complex network theory to analyse the indirect carbon emission flows among industries. It is helpful for showing the relationship between each part in a network and provides useful information regarding network composition and the power, role and impact of its underlying components.

Because no actual monitoring data support the construction of indirect transfer networks, scientists usually combine input–output analysis (IOA) and complex network theory together to construct and evaluate transfer networks. This combination has been used previously in various fields, including energy consumption (An et al. 2015; Sun et al. 2016; Chen and Chen 2015), raw material accounting (Ohno et al. 2016; Chen et al. 2016) and the energy-water nexus (Wang and Chen 2016; Chen and Chen 2016). These studies have already demonstrated the validity of IOA for recognizing the structural features of flows among industries. Thus, IOA can be used to measure indirect carbon emission flows among industries, and it can fundamentally support network analysis (Wang et al. 2017c). Indirect carbon emission flows that originate through trade could form a complex carbon emission transfer network. To analyse the pattern of the network of carbon emission flows across China’s industries, complex network theory provides a versatile and visible analytical framework to reveal the laws and features of such a network (Wang et al. 2017a;Wang et al. 2017b Hao et al. 2016; Huang and Ulanowicz 2014; Dai et al. 2012). By analysing this network structure, a better understanding of the essential characteristics of real systems can be achieved and thereby providing policymakers with various ideas for promulgating effective policies to help improve energy conservation, emissions reductions and low-carbon sustainable development. It would be very beneficial to investigate such networks to formulate effective policies.

The rest of the paper is structured as follows. After the “Introduction”, “Data and methods” is dedicated to describing the data and the methodology used in this study. “Empirical research” presents empirical results and analyses followed by discussion and policy implications in “Discussion and policy implications”. Finally, “Conclusion” provides the conclusions of the paper.

Data and methods

In this study, IOA and complex network analysis are used to investigate industrial carbon emissions and linkages. First, a matrix of the indirect carbon emission flows was calculated by using IOA. Second, indirect carbon emission flow network (ICEFN) of industries were build. Then, the “small-world” theory, network density, degree centrality, betweenness centrality and block model are used as the key indicators for evaluating the linkages between different industries and their effects on the whole network. Finally, the industrial evolutionary features can be fully revealed by this model.

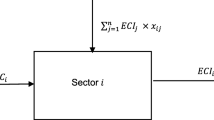

Calculation of indirect carbon emission flows

The carbon emissions in each industry can be considered from two perspectives. On the one hand, one industry needs raw materials and services from upstream industries; on the other hand, that industry’s products and services can be used as raw materials by downstream industries. The IOA recommended by Hendrickson et al. can measure the carbon emission flows among different industries (Hendrickson et al. 1998). Indirect carbon emission flows among industries are calculated based on direct carbon emissions and the I–O (input–output) table.

The calculation process of direct carbon emissions of industry i is conducted as follows:

where CDi denotes the direct carbon emissions of industry i; d is the type of energy (coal, coke, crude oil, gasoline, kerosene, diesel oil, fuel oil, natural gas, electricity); Ed,i represents the consumption of energy d of industry i, which is obtained from the provincial Statistical Yearbooks; NCVd represents the average lower-order calorific value of energy d, which is provided by the China Energy Statistical Yearbook; Ad is the carbon content per unit heat of energy d; Od represents the oxidation rate of energy d; and 44/12 is the molecular weight ratio of carbon emissions to carbon. The carbon content per unit heat and the oxidation rate of each fuel type are derived from The Guidelines to Make Provincial Lists of Greenhouse Gas Inventories.

Based on the direct carbon emissions, the carbon emission intensity can be calculated by the following:

where rci denotes the direct carbon emission intensity in industry i; GDPi refers to the added output values of industry i, which are provided by the China Statistical Yearbooks; and CDi represents the direct carbon emissions of industry i. R denotes the diagonal matrix of direct carbon emission intensity.

where X is the total output matrix of the industries; I is the unit matrix; A is the direct requirements coefficient, A = {aij}; (I − A)−1 is a Leontief inverse matrix that represents the demand that the horizontal industries have for the input industries’ products; and Y is a column vector of the ultimate demand industries in quadrant II of the input–output table, which comprised the final consumptions (government consumptions, urban household consumptions and rural household consumptions), gross capital formation (fixed capital formation and inventory increase) and gross imports and exports (interprovincial import, international import, interprovincial export and international export).

The indirect carbon emission flows among industries are calculated as follows:

where P is the indirect carbon emission intensity vector, i.e., the value of indirect carbon emission flows, P = {pij}; and R denotes the diagonal matrix of direct carbon emission intensity.

Network analysis

Network construction

In this study, the ICEFN of industries is constructed, in which the nodes are the industries, and the edges are the carbon emission flow relationships. First, the networks are built by adding all of the industries and their indirect carbon emission flows into the network. The original network had 41 nodes and 1640 edges. However, this network had many edges with minimal weights that were so insignificant that they could be safely ignored. To focus on the key flows, some edges were removed using the following process:

where eij is the indirect carbon emission flow relationship; Pij is the indirect carbon emission coefficient of industry j to i; and Pi is the average indirect carbon emission coefficient of industry i.

For the data analysis, graph-theoretic techniques were used applying UCINET 6.0 and Net Draw visualization software (Misra et al. 2017).

The small-world nature of an ICEFN

The small-world nature is defined as a network in which most nodes are not neighbours of one another, but where most nodes can be accessed from every other in a few steps (Carvalho 2014). In other words, a network with a high clustering coefficient and a short average path length between two nodes can be referred to as a “small-world network” (Sun et al. 2016; Watts and Strogatz 1998). The average path length is the average shortest path length between two nodes in the network, which can be used to assess the transmission efficiency (Luo 2005). The average path length can be calculated as follows:

where n is the number of nodes in the network, and bij is the shortest path length between node i and node j.

The clustering coefficient is divided into the node clustering coefficient and the network clustering coefficient (Li et al. 2017). The clustering coefficient of one node is defined as the ratio of actual edges between the node and its neighbours, accounting for the potential maximum number of edges. The clustering coefficient of a network represents the average clustering coefficient value of each node. The larger the clustering coefficient of a network is, the closer the connection within the network. These two indexes are used to present the subgroup integrated degree of the nodes in the network, which can be obtained as follows:

where Ci is the clustering coefficient of node i; C is the network clustering coefficient; V is the number of edges among the neighbours of node i; ki is the number of nodes adjacent to node i; and ki(ki − 1) is the potential maximum number of edges among the neighbours of node i.

Network density

Network density is used to evaluate the closeness among all of the nodes in a network. The higher the density is, the closer the relationship and higher the degree of linkage within the industrial network. The network density can be calculated as follows:

where D is the network density; M is the number of edges in the network; and n × (n − 1) is the potential maximum number of edges in the industry network.

Centrality

Centrality indicates the importance of one industry within the whole network. Generally, intensively connected industries are located in a strategic position and affect the entire network’s structure and systemic functions significantly. In this sense, the measurement of each industry’s centrality is vital to understanding the network comprehensively (Batallas and Yassine 2006). Centrality can be further classified into degree centrality and betweenness centrality.

-

(1)

Degree centrality

Degree centrality enables to count the number of connections directly related to a given node. If one node has more direct connections with individuals in the network, it usually has more opportunities to receive, exchange and transmit critical information and knowledge and thereby has a dominant position and competitive advantage in the network. That is, the larger the degree centrality of one industry, the more important it is. Degree centrality can be further separated into out-degree centrality and in-degree centrality. The in-degree centrality of industry i measures the material input from other industries to i; the out-degree centrality of industry i reflects the material output from industry i to other industries. In ICEFN, the larger one industry’s in-degree centrality is, the more indirect carbon emissions there is. And the greater one industry’s out-degree centrality is, the more indirect carbon emissions it supplies. The out-degree centrality and in-degree centrality of industry i are calculated as follows:

where xij is the connections from node i to j, and xji is the connections from node j to i.

-

(2)

Betweenness centrality

Betweenness centrality measures the number of shortest paths passing through the individual node. This type of impact is identified as an intermediate impact. If a node with high betweenness centrality changes its development direction or gets destroyed, the indirect connections passing through the node will break and a new geodesic path is hard to form in the short term. Thus, the network may collapse. Therefore, a higher betweenness centrality of an industry implies a larger intermediary impact on the whole network, which is similar to a bridge between two mountains that connect them by the shortest path. The formula employed for calculating betweenness centrality is as follows:

where Bi is the betweenness centrality of node i; gjk(ni) is the number of shortest paths between j and k through i; and gjk is the total number of shortest paths between j and k.

Block Model

A block modelling method is useful for a better understanding of an industrial cluster (Glückler and Panitz 2016). It is a valuable method for dividing a complex network into several subgroups (positions) and presenting the relations among the subgroups, and it can thereby depict the whole network in a simpler way. A subgroup can be generally described as a group of nodes that is tightly connected internally but sparsely connected externally (An et al. 2015). In our study, the nodes are the 41 industries, and the subgroups are clusters of industries. Relations between industries in the same subgroup are stronger than relations between industries in different subgroups. The CONCOR method in the program UCINET 6.0 is applied to split the industries into four subgroups.

Data

The basic I–O table is published every 5 years in China, and the newest one (the 2017 edition) has not been published yet. Hence, the basic I–O tables for the 2007 edition and the 2012 edition are used in this study. The 2007 edition is used for calculating the carbon emissions of industries from 2005 to 2009, and the 2012 edition is employed for 2010 to 2014. The basic I–O tables and original energy data used in this study are provided by the China Energy Statistical Yearbook from 2005 to 2014 and the China Statistical Yearbook from 2005 to 2014. Because the industry classifications in basic I–O tables are changing and are inconsistent with those in energy balance sheets, they are combined into a 41-industry table for data processing convenience without excluding important information. The industries are assigned ID numbers, and their descriptions are provided in the Appendix (Table 5).

Empirical research

Carbon emissions of the industries

Based on IOA, the indirect carbon emissions of each industry were calculated, as shown in Fig. 2. The results showed that indirect carbon emissions contributed the largest proportion to the total carbon emissions during the sample period. Compared with the industries’ direct carbon emissions, the contribution of indirect carbon emissions for most industries exceeded the direct carbon emissions and accounted for over 70% of the total carbon emissions. Furthermore, the indirect carbon emissions of manufacturing of general purpose machinery, manufacturing of transport equipment, manufacturing of electrical machinery and equipment and construction accounted for approximately 95% of the total carbon emissions, implying that these industries have a greater effect on the other industries.

Direct and indirect carbon emissions of each industry in 2005, 2008, 2011 and 2014. a Carbon emissions of industries 1–7. b Carbon emissions of industries 8–14. c Carbon emissions of industries 15–21. d Carbon emissions of industries 22–28. e Carbon emissions of industries 29–35. f Carbon emissions of industries 29–35

However, industries with low indirect carbon emissions may also have a larger scale impact on the others. For instance, manufacturing of articles for culture, education and sport activities and manufacturing of artwork and other manufacturing have low indirect carbon emissions but a high in-degree centrality (see Appendix Table 6 and Appendix Table 7). In other words, these industries have more input linkages to industries with lower indirect carbon emissions. Any small improvement in these industries would accelerate the resource use ratio of the whole system. Therefore, industries that have connections with more industries have larger-scale effects on the others. This demonstrates that IOA is more suited to carbon emissions accounting, whereas network analysis is more authoritative for identifying key industries in supply chains.

Comprehensive evaluation of the industrial network

The descriptive analysis of the network statistics (Table 1) presented the overall characteristics of the ICEFN, which have a short average distance, relatively large clustering coefficients and low network density. The average distance between different industries in China slightly increased from 1.473 to 1.546 during the research period, which indicated that one industry in the network could reach another by passing through 1.473–1.546 industries. The rapid development of eco-industrial parks, where products and waste produced in one factory can be utilized by another, is an important reason for the closer distances between industries. The clustering coefficient was relatively large and is getting closer increased from 0.642 to 0.645 from 2005 to 2014. This suggests that the relations between industries became increasingly closer and that the spread became easier. The density of the ICEFN was relatively low and showed a downward trend during the period from 2005 to 2014, which implies that the carbon emission relationships among industries were relatively loose during the research period.

The short average distance and relatively large clustering coefficients confirmed that the industrial network had a small-world nature, which provides information about the dynamics of the processes taking place on the networks. Changes in key industries will significantly affect the network’s systemic functions, indicating that the industrial network is very sensitive and fragile. On the one hand, this property means that a supply disturbance in key industries will spread very quickly to most of the other industries and thus may lead to turmoil for the overall network. On the other hand, cleaner production in key industries will significantly improve the level of cleanliness of the whole economy.

Centrality analysis of the industrial network

Centrality indicates the importance of one industry within the whole network. Figure 3 shows the industrial network structure pattern, with the structures in 2005 and 2014 serving as examples. The size of the nodes represents the industrial degree centrality trend in the network. The larger the node is, the larger the degree of centrality. The directional lines embody the edges between different industries and display the connection relationship between different industries and the carbon emission flow direction. As seen in Fig. 3, each node had more than one path that associates with the others, which made the structure of the industrial network complex. On the other hand, this type of multiple connectivities made the network stronger and reduced the risk of fragmentation.

Degree centrality analysis

Based on Eqs. (9) and (10), the out-degree centrality and in-degree centrality of industries are calculated. The results in Fig. 4 show that both the in-degree centrality and out-degree centrality fluctuated. As shown in Fig. 4a, the out-degree centrality values had slight differences among industries during our research period. The top 10 industries in out-degree centrality varied, while wholesale and retail trades, hotels and catering services and transport, storage and post were always ranked first and second carbon emissions exporting industries having high out-degrees, thus indicating that these two industries are basic industries in China. These industries provide materials to support the development of many other industries. Manufacturing of metal products remained in the top 10 from 2005 to 2014 because it provided indispensable metal materials for the construction industry and other important strategic industries. On the other hand, as shown in Fig. 4b, the in-degree centrality first increased before later decreasing. Only a few industries did not follow this pattern. For example, manufacturing of leather, fur, feather and related products, manufacturing of furniture and wholesale and retail trades, hotels and catering services grew from 2005 to 2014 because they received more products from other industries with the rapid development of China’s economy and society. In addition, it is notable that industry construction had its highest in-degree centrality values in 2005 and 2014, at 100, which was much higher than that of any other industry. This high value means that the construction industry received carbon emissions from every industry in the network. In other words, the development of the construction industry is based on the support of many other industries. This situation is quite relevant to the trend in China’s economic development. Beginning in 2002, the driver of China’s economic growth speeded up urbanization, which led to increasing demand for infrastructure and housing and increased material consumption by the construction industry; this accounts for the huge indirect carbon emissions flow to the construction industry. The manufacturing industry, including industries manufacturing of metal products, manufacturing of transport equipment, manufacturing of special purpose machinery, manufacturing of artwork and other manufacturing and manufacturing of electrical machinery and equipment, remained in high in-degree centrality throughout the period, indicating that these industries also had relationships with many other industries. While this may not be surprising as a general observation, the equipment manufacturing industry, as a core part of manufacturing, drives many other industries, resulting in other industries producing more carbon emissions. In general, industries such as the construction and equipment manufacturing industries, with high out-degree centrality, consume a large amount of materials from many other industries, which quickly increases economic development.

A comparison of the out-degree and in-degree centrality of one industry could help to clarify its role in the ICEFN. An industry with a higher in-degree centrality receives materials from more industries and enhances the development of other industries and is thereby defined as a controlling industry. Conversely, an industry with a higher out-degree centrality exports more carbon emissions to other industries, which means that the industry’s development depends more on other industries, and it is thereby defined as a dependent industry. There are four points in time, 2005, 2008, 2011 and 2014, displayed in Fig. 5 to show the out-degree and in-degree centrality of the industries. The horizontal axes of these scatter plots refer to the out-degree centrality of the industries, while the vertical axes refer to their in-degree centrality. The cross line is the average degree, which is 30.30, 32.20, 30.06 and 26.04 in 2005, 2008, 2011 and 2014, respectively.

The results of the degree scatter plots in 2005, 2008, 2011 and 2014 are reported in Table 2. Industries in each quadrant were relatively stable during the research period. Industries in quadrant I, such as manufacturing of articles for culture, education and sport activities, manufacturing of non-metallic mineral products, manufacturing of metal products, manufacturing of measuring instruments and machinery for cultural activities and office work and construction, with both high out-degree and in-degree centrality, were subject to greater demand from their upstream industries, resulting in a huge demand effect on the downstream industries. This means that these industries have more influence in the network. Industries in quadrant II, such as smelting and pressing of ferrous metals, manufacturing of electrical machinery and equipment and manufacturing of communication equipment, computers and other electronic equipment, with low out-degree but high in-degree centrality, received more materials from their upstream industries but only exported to a limited number of industries. These industries with more upstream than downstream connections play controlling roles. Industries in quadrant III, such as extraction of petroleum and natural gas; manufacturing of foods; manufacturing of textiles; manufacturing of leather, fur, feather and related products; processing of timber, manufacturing of wood, bamboo, rattan, palm and straw products; and manufacturing of paper and paper products, with both low out-degree and in-degree centrality, not only were subject to little demand from their upstream industries but also had a small demand effect on downstream industries. These industries have few connections with other industries. Industries in quadrant IV, such as agriculture, hunting, forestry and fishing; manufacturing of tobacco; processing of petroleum, coking and nuclear fuel; production and supply of electric power and heat power; production and supply of water; transport, storage and post; and wholesale and retail trades, hotels and catering services, with high out-degree but low in-degree centrality, exported more material downstream than they received from upstream industries, indicating that their carbon emissions were highly dependent on the downstream industries.

Betweenness centrality analysis

Betweenness centrality is calculated based on Eq. (11). As shown in Fig. 6, manufacturing of articles for culture, education and sport activities, manufacturing of raw chemical materials and chemical products, manufacturing of medicines, manufacturing of artwork and other manufacturing, construction and transport, storage and post were more dominant than the other industries in terms of betweenness centrality, which suggests that these industries are central to resource delivery and affect the whole industrial network. Shocks to these industries would likely lead to breaks in carbon emission flows between upstream industries and downstream industries and would therefore result in macroeconomic fluctuations. On the other hand, the sustainable development of these industries will greatly influence carbon emission flows by leading to decreased carbon emissions.

However, it is worth noting the bridge strength of construction in 2005 and mining and washing of coal in 2014. There was a significant difference in the betweenness centrality between the highest industry and the second-highest industry. In other words, this could be explained by that only the industry with the highest value controls the whole network, which is likely to result in a sensitive and fragile network.

Composition of the network

Using the block modelling method, the 41 industries considered were divided into four groups according to their connection patterns. Industries in each subgroup experienced minimal changes during the research period; thus, this study uses 2014 as the example year to discuss the industrial subgroups. To understand more about each subgroup, the industries in each subgroup are presented in Table 3.

There are 41 industries in the network; yellow represents industries in subgroup 1, green denotes industries in subgroup 2, red indicates industries in subgroup 3, and blue denotes industries in subgroup 4, and they consist of 8, 11, 10 and 12 industries, respectively (Fig. 7). To analyse the positions of the four industrial subgroups in the network, one must first analyse how each subgroup sends and receives relational ties in the block model. As shown in Table 4, there were 428 connections in the ICEFN in 2014. Furthermore, there were 149 connections within all subgroups, while there were 279 connections between subgroups. This means that there are larger carbon emission transmissions between subgroups. Based on a comparison of the connections between subgroups, as presented in Table 4, subgroup 3 received 156 relational ties from other subgroups, making it the largest receiving subgroup in the network. However, it is ranked last in sending relational ties, with only 39. In contrast, subgroup 4 received only 48 relational ties but sent 115 relational ties, ranking it first in that category as the largest sending subgroup in the network. Subgroup 1 had a relatively larger number of sending relational ties compared with its receiving relational ties. Subgroup 2 had approximately the same number of sending relational ties and receiving relational ties. Comparing the connections within each subgroup revealed that subgroups 1, 2, 3 and 4 contained 22, 34, 66 and 27 internal ties, respectively.

To clarify the position of each subgroup, a diagram was used to show the modular results of the ICEFN (Fig. 8), where the larger circles represent industrial subgroups and the size of the circle denotes the number of industries in the subgroup. The larger the circle is, the more industries the subgroup has. The size of each grey circle indicates how many internal connections the subgroup contains, and the number in grey indicates the number of internal connections. The lines between circles indicate the indirect carbon emission flows between subgroups, whereby wider lines indicate larger indirect carbon emission flows. The arrows denote the direction of the indirect carbon emission flows. As shown in Fig. 8, the subgroup in blue contained the most industries, followed by the red subgroup. The other subgroups have fewer industries. The pink subgroup imported a substantial amount of carbon emissions from the other subgroups, particularly from the blue subgroup.

Based on the information and analysis, some features of the subgroups of the industrial network can be identified. For example, first, subgroup 3 is the core of the whole network, even though it comprises only ten industries. Subgroup 3 is the largest receiver of carbon emissions in the network; in other words, it imports a large amount of embodied resources from the other subgroups, while it seldom exports embodied resources. Second, with the largest number of industries, subgroup 4 serves as a supplier in the network, as it exports a large amount of carbon emissions to the other subgroups. Similar to subgroup 4, subgroup 1 contains only a few industries, but it exports a large amount of carbon emissions to the other subgroups; thus, it is also a supplier in the network. Third, subgroup 2 acts as a carrier in the network; specifically, it imports and exports a balanced amount of carbon emissions in the network.

Discussion and policy implications

As the world’s largest energy consumer and carbon emitter, China has formulated many mitigation policies to reduce the country’s carbon emissions, most of which focus on energy- and carbon-intensive industries (Chen et al. 2017). However, those operation and policy orientations have ignored the linkages among different industries and the effects of these industrial connections on carbon emissions, which would undermine these environmental policies and even result in mutually offsetting situations between different measures. Although significant emissions intensity reduction in these heavy emission industries has been made, the total emissions from these industries may still increase due to the high demand of other related industries’ products (Chen et al. 2017). Therefore, to mitigate the carbon emissions of the whole economic system, future mitigation policies should place more emphasis on indirect carbon emission linkages between industries (Wang et al. 2017a; Sun et al. 2017). In this study, IOA and complex network theory are used to investigate industrial carbon emissions and the linkages among industries. Combining IOA and complex network theory, the pattern of the network of carbon emission flows across industries in China was analysed, thereby providing policymakers with various ideas for promulgating effective policies to help improve energy conservation, emission reductions and low-carbon sustainable development.

The industrial network displays a small-world nature, indicating that the impacts of one industry may spread extremely quickly to other industries in the ICEFN. Moreover, the industrial network has a relatively low density, which means that only a few industries have many connections while most industries have fewer connections. These two results prove that most industries can quickly connect with other industries through key industries. This result provides information for policymakers that the ICEFN can be easily tracked, especially where alterations in key industries may result in a systemic effect on ICEFN. Thus, industrial structure should be transformed from one of the independent operations to a cyclical network, such that most industries connect with others through varied supply chain relationships. For example, the redundant powder generated from slag in the iron-smelting process could be fully used in a cement factory, and burnable waste materials could be sent to a cement or iron factory or a thermal energy plant to produce more electricity (Dong et al. 2013).

Different industries display various features in the ICEFN. The direct impact and intermediate impact of each industry are analysed based on the degree centrality and betweenness centrality, respectively, and at the same time, key industries are identified from two perspectives.

First, the direct impacts are analysed based on the results of in-degree centrality and out-degree centrality measures. The results showed that wholesale and retail trades, hotels and catering services, transport, storage and post and manufacturing of metal products have high out-degree centrality and were the largest net carbon exporters, while construction and the equipment manufacturing industry have high in-degree centrality and imported a large amount of carbon emissions. These industries with high in-degree centrality are located in the central position of the ICEFN and have larger impacts on other industries, which indicate that more efforts in formulating policies should be exerted for these industries so that carbon emissions in the whole network can be reduced. For example, considering that the construction as a key industry has more influence in the network, there is an urgent need to increase technology investments in green building materials and low-carbon cement and thereby reduce the indirect carbon emissions coming from relevant industries.

Furthermore, the comparison of the out-degree and in-degree centrality of one industry could help to clarify the role of the industry in the ICEFN and provide policymakers with different ideas to create effective policies. For example, controlling industries with higher in-degree than out-degree centrality significantly influenced the carbon flows of other industries with which they were connected, such as smelting and pressing of ferrous metals, manufacturing of electrical machinery and equipment and manufacturing of communication equipment, computers and other electronic equipment. Therefore, regulations and policies should be promulgated for these industries to reduce excessive industrial capacity as well as improve energy efficiency. This might significantly influence overall carbon emissions in China by not only reducing the direct emissions from these industries but also decreasing the emissions of closely connected industries. Dependent industries with higher out-degree than in-degree centrality were the largest net carbon exporters, such as transport, storage and post, wholesale and retail trades, hotels and catering services and production and supply of water. Because the other industries in the system rely on the resources of these industries, any small improvement in these industries would increase the resource use of the whole system. Therefore, it is important to improve the energy efficiency and decrease the consumption of products from these industries by the controlling industry to make the system more sustainable and environmentally friendly.

Second, intermediate impacts were analysed based on betweenness centrality. This indicator showed that manufacturing of articles for cultural, education and sport activities, manufacturing of medicines and construction have large betweenness centrality, indicating that these industries play the intermediary role in the network. Similar to viral transmissions, one must not only control the virus’ source but also block transmissions by controlling the medium. Therefore, through adjustments in these intermediary industries, China could effectively limit the spread of negative influences (such as air pollution). Furthermore, benefits can be obtained by using incentives in these intermediary industries.

The original industries were used to build the ICEFN, and then the structure of the whole network was evaluated using block modelling. The block modelling method found that there are four clusters in ICEFN of China. The block modelling method in complex network theory recognizes groups of industries based on the connections between them. Industries with high carbon emission flow relationships are grouped together. This approach shows the industrial structure from the perspective of indirect carbon emission flows and can be treated as supporting information or a new idea for grouping industries in a system. For example, subgroup 3 serves as a receiver in the network, as it imports a large amount of embodied resources from the other subgroups; thus, in those subgroups, energy structure optimization should be considered by balancing the development of light and heavy industries. Subgroup 2 serves as a carrier in the network; thus, exchanges and cooperation of carbon emission reductions could be strengthened through improvements in the flow and diffusion of resources, low-carbon technology, capital and other similar elements, and lessons can be drawn from the experience of the low-carbon agglomeration subgroups as an example for the high-carbon agglomeration subgroups. Subgroup 4 and subgroup 1 serve as a supplier in the network, transferring a large amount of carbon emissions to the other subgroups. In these subgroups, some industries with low resource utilization and heavy environmental pollution should be shut down, and industries should be encouraged to manufacture a certain amount of high value-added products using fewer resources and employing more advanced, modern techniques.

This study has some limitations. First, only the main features of the network were analysed. There are many other questions that need to be addressed concerning issues such as the main indirect carbon emission flow chain and the indirect carbon emission efficiencies of each industry. Moreover, because of the obvious regional disparities among carbon emissions and economic development in China, the same industry in different areas likely has different characteristics in a network; thus, regional factors should be considered in further research.

Conclusion

The flow of carbon emissions among industries in China is analysed based on input–output theory and complex network theory. Some meaningful conclusions are as follows:

-

(1)

Indirect carbon emissions contributed the largest proportion to the total carbon emissions, and for most industries, indirect emissions accounted for over 70% of the total. Therefore, there should be more attention paid to indirect carbon emissions.

-

(2)

ICEFN have a small-world nature; thus, a supply disturbance in key industries will spread rapidly to most of the other industries. According to the analysis of the clustering coefficients and the average path lengths, which are properties of a small-world nature, the former increased from 0.642 to 0.645 from 2005 to 2014, which indicates that the relations between industries grew closer. The latter increased from 1.473 to 1.546, which indicates that it takes only 1.473–1.546 steps to transmit carbon emissions from one industry to another in the ICEFN.

-

(3)

The degree centrality analysis of each industry shows that the degree centrality fluctuated, and transport, storage and post; wholesale and retail trades, hotels and catering services; and manufacturing of metal products have higher out-degree centrality, thus indicating that they provide materials to support the development of many other industries. Industries such as construction and equipment manufacturing industries have higher in-degree centrality, indicating that they imported a large amount of carbon emissions from many other industries. Manufacturing of articles for culture, education and sport activities, manufacturing of non-metallic mineral products, manufacturing of metal products, manufacturing of measuring instruments and machinery for cultural activities and office work and construction have high out-degree and in-degree centrality, indicating that they have more impact in the network. Smelting and pressing of ferrous metals, manufacturing of electrical machinery and equipment and manufacturing of communication equipment, computers and other electronic equipment have low out-degree but high in-degree centrality, thus indicating that they are controlling industries. Agriculture, hunting, forestry and fishing; manufacturing of tobacco; processing of petroleum, coking and nuclear fuel; production and supply of electric power and heat power; production and supply of water; transport, storage and post; and wholesale and retail trades, hotels and catering services have high out-degree but low in-degree centrality, indicating that their carbon emissions are highly dependent on their downstream industries.

-

(4)

Industries such as manufacturing of articles for culture, education and sport activities, manufacturing of raw chemical materials and chemical products, manufacturing of medicines, manufacturing of artwork and other manufacturing, construction and transport, storage and post have high betweenness centrality, indicating that they are key intermediaries in the network. If the indirect carbon emission flows related to these industries are constrained for some reason, the ICEFN will be greatly affected because some industries may become disconnected from other industries.

-

(5)

A block modelling method was used to divide the network into subgroups. Four subgroups were defined, and the results showed that the network of carbon emission flows among Chinese industries has the following features: subgroup 3 is the core of the entire network, as it imports a large amount of embodied resources from the other subgroups, but it seldom exports embodied resources. Subgroup 4 and subgroup 1 serve as a supplier in the network by transferring a large amount of carbon emissions to the other subgroups. Subgroup 2 serves as a carrier that imports and exports a balanced amount of carbon emissions in the network.

References

An Q, An HZ, Wang L, Gao XY, Lv N (2015) Analysis of embodied exergy flow between Chinese industries based on network theory. Ecol Model 318:26–35

Batallas D, Yassine A (2006) Information leaders in product development organizational networks: social network analysis of the design structure matrix. IEEE T Eng Manage 53:570–582

Benevides LJ, Carvalho DS, Andrade RF, Bomfim GC, Fernandes FM (2016) Evolutionary analysis of apolipoprotein e by maximum likelihood and complex network methods. Genet Mol Biol 39(4):665–673

Brown MT, Herendeen RA (1996) Embodied energy analysis and energy analysis, a comparative view. Ecol Econ 19:219–235

Büchs M, Schnepf SV (2013) Who emits most? Associations between socio-economic factors and UK households’ home energy, transport, indirect and total CO2 emissions. Ecol Econ 90:114–123

Carvalho VM (2014) From micro to macro via production networks. J Econ Perspect 28:23–47

Chang N (2015) Changing industrial structure to reduce carbon dioxide emissions: a Chinese application. J Clean Prod 103:40–48

Chen SQ, Chen B (2015) Urban energy consumption: different insights from energy flow analysis, input–output analysis and ecological network analysis. Appl Energy 138:99–107

Chen SQ, Chen B (2016) Urban energy–water nexus: a network perspective. Appl Energy 184:905–914

Chen WQ, Graedel TE, Nuss P, Ohno H (2016) Building the material flow networks of aluminum in the 2007 U.S. Economy. Environ Sci Technol 50(7):3905–3912

Chen WD, Wu FY, Geng WX, Yu GY (2017) Carbon emissions in china’s industrial sectors. Resour Conserv Recycl 117

Dai J, Fath B, Chen B (2012) Constructing a network of the social-economic consumption system of China using extended exergy analysis. Renew Sust Energ Rev 16(7):4796–4808

Domenech T, Davies M (2011) Structure and morphology of industrial symbiosis networks: the case of Kalundborg. Proced Soc Behav Sci 10(1):79–89

Dong L, Zhang H, Fujita T, Ohnishi S, Li H, Fujii M, Dong H (2013) Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J Clean Prod 59(226):238

Geng Y, Zhao HY, Liu Z, Xue B, Fujita T, Xi FM (2013) Exploring driving factors of energy-related CO2 emissions in Chinese provinces: a case of Liaoning. Energy Policy 60:820–826

Glückler J, Panitz R (2016) Unpacking social divisions of labor in markets: generalized blockmodeling and the network boom in stock photography. Soc Networks 47:156–166

Góes-Neto A, Diniz MVC, Santos LBL, Pinho STR, Miranda JGV, Lobao TP et al (2010) Comparative protein analysis of the chitin metabolic pathway in extant organisms: a complex network approach. Bio Systems 101(1):59–66

Han MY, Chen GQ, Shao L, Alsaedi A, Ahmad B, Guo S (2013) Embodied energy consumption of building construction engineering: case study in E-town, Beijing. Energy Buildings 64:62–72

Han R, Yu BY, Tang BJ, Liao H, Wei YM (2017) Carbon emissions quotas in the Chinese road transport sector: a carbon trading perspective. Energy Policy 106:298–309

Hao XQ, An HZ, Qi H, Guo XY (2016) Evolution of the exergy flow network embodied in the global fossil energy trade: based on complex network. Appl Energy 162:1515–1522

Hendrickson C, Horvath A, Joshi S, Lave L (1998) Economic input-output modes for environmental life-cycle assessment. Environ Sci Technol 32:184–191

Huang J, Ulanowicz RE (2014) Ecological network analysis for economic systems: growth and development and implications for sustainable development. PLoS One 9(6):e100923

Li LJ, Chen KH (2017) Quantitative assessment of carbon dioxide emissions in construction projects: a case study in Shenzhen. J Clean Prod 141:394–408

Li ZL, Sun L, Geng Y, Dong HJ, Ren JZ, Liu Z, Tian X, Yabar H, Higano Y (2017) Examining industrial structure changes and corresponding carbon emissions reduction effect by combining input-output analysis and social network analysis: a comparison study of China and Japan. J Clean Prod 162:61–70

Li WH, Tang ST, Pei S, Yan S, Jiang SJ, Teng X, Zheng ZM (2014) The rumor diffusion process with emerging independent spreaders in complex networks. Physica A 397(3):121–128

Liu J, Feng TT, Yang X (2011) The energy requirements and carbon dioxide emissions of tourism industry of Western China: a case of Chengdu city. Renew Sust Energ Rev 15(6):2887–2894

Liu NR, An HZ, Gao XY, Li HJ, Hao XQ (2016) Breaking news dissemination in the media via propagation behavior based on complex network theory. Physica A 453:44–54

Luo J (2005) Social network analysis, first edn. Social Sciences Academic Press, Beijing (in Chines)

Meng WQ, Xu LY, Hu BB, Zhou J, Wang ZL (2016) Quantifying direct and indirect carbon dioxide emissions of the Chinese tourism industry. J Clean Prod 126:586–594

Misra S, Goswami R, Mondal T, Jana B (2017) Social networks in the context of community response to disaster: study of a cyclone-affected community in Coastal West Bengal, India. Int J Disast Risk Re 22:281–296

Nishimura K, Hondo H, Uchiyama Y (1997) Estimating the embodied carbon emissions from the material content. Energy Convers Manag 38:S589–S594

Ohno H, Nuss P, Chen WQ, Graedel TE (2016) Deriving the metal and alloy networks of modern technology. Environ Sci Technol 50(7):4082–4090

Shuai CY, Shen LY, Jiao LD, Wu Y, Tan YT (2017) Identifying key impact factors on carbon emissions: evidences from panel and time-series data of 125 countries from 1990 to 2011. Appl Energy 187:310–325

Su X, Zhang X (2016) A detailed analysis of the embodied energy and carbon emissions of steel-construction residential buildings in China. Energy Buildings 119:323–330

Sun LC, Wang QW, Zhang JJ (2017) Inter-industrial carbon emission transfers in China: economic effect and optimization strategy. Ecol Econ 132:55–62

Sun XQ, An HZ, Gao XY, Jia XL, Liu XJ (2016) Indirect energy flow between industrial sectors in China: a complex network approach. Energy 94:195–205

Wang J, Zhao T, Wang YN (2016) How to achieve the 2020 and 2030 emissions targets of China: evidence from high, mid and low energy-consumption industrial sub-sectors. Atmos Environ 145:280–292

Wang SG, Chen B (2016) Energy–water nexus of urban agglomeration based on multiregional input–output tables and ecological network analysis: a case study of the Beijing–Tianjin–Hebei region. Appl Energy 178:773–783

Wang SS, Zhou DQ, Zhou P, Wang QW (2011) CO2 emissions, energy consumption and economic growth in China: a panel data analysis. Energy Policy 39(9):4870–4875

Wang CJ, Wang F, Zhang XL, Deng HJ (2017a) Analysis of influence mechanism of energy-related carbon emissions in Guangdong: evidence from regional China based on the input-output and structural decomposition analysis. Environ Sci Pollut R 24(32):1–14

Wang XB, Wei WD, Ge JP, Wu B, Bu W, Li JH, Yao MT, Guan Q (2017b) Embodied rare earths flow between industrial sectors in China: a complex network approach. Resour Conserv Recycl 125:363–374

Wang Z, Xiao CM, Niu BB, Deng LC, Liu Y (2017c) Identify sectors’ role on the embedded CO2 transfer networks through China’s regional trade. Ecol Indic 80:114–123

Watts DJ, Strogatz SH (1998) Collective dynamics of ‘small-world’ networks. Nature 393:440–442

Zhang JP, Jin Z (2012) Epidemic spreading on complex networks with community structure. Appl Math Comput 219(6):2829–2838

Zhang YJ, Peng YL, Ma CQ, She B (2017) Can environmental innovation facilitate carbon emissions reduction? Evidence from China. Energy Policy 100:18–28

Zhou S, Kyle GP, Yu S, Clarke LE, Eom J, Luckow P, Chaturvedi V, Zhang XL, Edmonds JA (2013) Energy use and CO2 emissions of China’s industrial sector from a global perspective. Energy Policy 58:284–294

Zhu Q, Peng X, Wu KY (2012) Calculation and decomposition of indirect carbon emissions from residential consumption in China based on the input–output model. Energy Policy 48:618–626

Funding

The research work was supported by the National Social Science Foundation of China [Grant No. 16CJY028]. Humanity and Social Science Program Foundation of the Ministry of Education of China [Grant No. 15YJC790015]. The Fundamental Research Funds for the Central Universities [Grant No. 300102238620, 300102238303].

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Du, Q., Xu, Y., Wu, M. et al. A network analysis of indirect carbon emission flows among different industries in China. Environ Sci Pollut Res 25, 24469–24487 (2018). https://doi.org/10.1007/s11356-018-2533-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2533-x