Abstract

One-pot synthesis of a new magnetic disinfectant was achieved through the polymerization of thiourea and formaldehyde in the presence of magnetite nanoparticles (MTUF). The obtained magnetic chelating resin was loaded with Ag(I) ions. This material was tested as a disinfectant for water pathogenic microorganism’s deactivation. The toxicity of MTUF before and after Ag(I) loading was estimated. The antimicrobial activity tests of MTUF-Ag were carried out against Escherichia coli, Salmonella Typhimurium, and Pseudomonas aeruginosa as examples of Gram-negative bacteria; Listeria monocytogenes, Staphylococcus aureus, Enterococcus faecalis, and Bacillus subtilis as examples of Gram-positive bacteria; and Candida albicans as representative for fungi. The results showed that the minimum inhibitory dosage (MID) of MTF-Ag against Escherichia coli, Salmonella Typhimurium, Listeria monocytogenes, Staphylococcus aureus, and mixed culture were 1.5, 2.0, 1.0, 1.5, and 1.5 mg/mL, respectively, after 40 min of contact time. While C. albicans was more resistant to the magnetic disinfectant, only three log reductions were done at 2.5 mg/mL. The studied MTUF-Ag was successfully tested for water and wastewater pathogenic microorganism’s deactivation. It can be concluded that MTUF-Ag could be a good candidate for water disinfection.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The discharging of untreated and/or partially treated wastewater into fresh, seawaters, and lakes is a major source of fecal pollution, including pathogenic microorganisms that able to cause waterborne diseases such as typhoid and cholera (WHO (World Health Organization), 2008; El-Lathy et al. 2009). As of 2012, it was estimated that 1.9 billion people in the world relied on fecally contaminated water for drinking. Infectious diarrheal diseases attributed to inadequate water are estimated to cause 502 thousands deaths a year, with the majority being children under age five (Prüss-Ustün et al. 2014). Conventional disinfectants for water treatments such as chlorine, chlorine derivatives, and ozonation can form harmful disinfection by-products which may provide an unintended health hazard (Sedlak and Gunten 2011; Jamil et al. 2015). UV irradiation as an alternative disinfectant method is safer, but it has non-residual effect and requires high energy (Darby et al. 1995). Recently, photocatalytic oxidations using TiO2, ZnS, ZnO doped with Ag, and BiOI have been used wide range of organic compounds and bacteria as pollutant disinfectants, but it still has some drawbacks; moreover, high energy is needed for visible light and/or UV (Bechambi et al. 2015; Khraisheh et al. 2015; Jamil et al. 2015). It is well known that the silver atom in non-ionized form has no antimicrobial effect, but when silver contacts with moisture, it leads to the release of their ions. Thus, all forms of silver or silver containing compounds have observed antimicrobial properties (Lok et al. 2007; Rai et al. 2009; Guldiren and Aydın 2017).

Thiourea-based polymeric ligands are versatile compounds that coordinate with metal ions either as neutral ligands or as protonated ligands (Elwakeel and Al-Bogami 2018). The bidentate nature of thiourea gives the advantage to synthesize TUF chelating sorbent, which have both sulfur and nitrogen as donor groups. The biological activities of the polymeric ligands are considered due to their ability to form polymer metal complexes with metal ions. This biological activity is different from their parental polymeric ligands due to the coordination with metal ions (Ahamad et al. 2009; Rivas et al. 2010; Hasnain et al. 2012).

Polymer metal complexes are a new and interesting class of materials that combine some of the mechanical properties of the organic polymer and some of those of the metal ions. A large number of such polymeric materials have been found to be of interest because of their biological applications such as antitumor (Ferreira et al. 2017), antibacterial (Fakhar et al. 2018), antiviral (Karakuş et al. 2009), and antifungal agents (Abbas et al. 2013; Ahamad and Alshehri 2013). Moreover, these materials have many practical applications in the fields of chemical analysis and environmental protection (Pan et al. 2006; Chen et al. 2007; Liu et al. 2018). For example, several chelating polymers with different functionalities were used for concentrating and retrieving of silver (I) from solutions (Donia et al. 2007; Yirikoglu and Gülfen 2008).

Thiourea formaldehyde (TUF) polymer has been shown ability to sorb heavy metals such Cr (III) and Cr (II) from water with efficient sorption capacity, good reusability, and high chemical stability (Panahi et al. 2009). Also, TUF polymer was used for separation several metal ions such as Au(III) from Cu(II), and Zn(II) ions (Ertan and Gülfen 2009). Moreover, Muslu and Gülfen (2011) used TF polymer for separation of Pd(II) from Fe(III), Co(II), Ni(II), and Cu(II) ions. Ahamad et al. (2006) evaluated antimicrobial activity of transition metal chelated TUF polymer; they studied Mn(II), Co(II), Ni(II), Cu(II), and Zn(II) as chelating metals with TUF polymer against many Gram-positive and Gram-negative bacteria and fungi. They reported that the polymeric ligand has varied antibacterial and antifungal activities, which were enhanced after metal ion chelation. Thiourea complexes showed significant antibacterial and antifungal activities and possess medicinal properties, which depend upon the chemical nature of the moiety attached to the C=S carbon atom (West et al., 1997). The potential biological activity of compounds containing nitrogen and sulfur may be of considerable interest (Ahamad et al. 2006). When the column dynamic mode is used for packing the disinfectant, the time limiting step is the large volume of water to load to the cartridge. The alternative to the column mode would be the static batch mode, but it is very difficult to separate the dispersed materials from aqueous media because of their little size (Zhang et al. 2012). To overcome these problems, a very interesting option is the new disinfection mode based on the use of magnetic nanoparticles (Fe3O4) which is known as magnetic disinfectant.

Therefore, the aim of the present study is to develop a new magnetic disinfectant (the magnetic separation ability can play an important role in disinfectant recovery) for pathogenic microorganism deactivation by loading magnetic thiourea-formaldehyde polymer with silver ions.

Material and methods

Materials

Thiourea, formaldehyde solution (solution 37% w/w), ferric chloride, and ferrous sulfate were supplied by Sigma-Aldrich (Germany) as analytical grade reagents.

Magnetite nanoparticle synthesis

The synthesis of Fe3O4 nanoparticles was already described (Elwakeel et al. 2016, 2017). Fe3O4 particles were synthesized by co-precipitation of ferric and ferrous salts. Firstly, iron solutions of FeSO4·7H2O (3.334 g) and FeCl3·6H2O (6.480 g) are dissolved in 150 mL of deionized water. The iron mixture is heated up to 333 ± 1 K in a 250-mL flask being equipped with a reflux. The reaction solution is magnetically stirred under condition of N2 gas for 60 min. Then, NaOH (3 mol) solution is added to the mixture in a slowly and drop wise fashion, while the temperature is kept at 318 K until pH is reached to 12; then the reaction is continued for 300 min. The resulted particles are magnetically separated and washed repeatedly with deionized water and ethanol until the pH reaches 7. The products are then dried at 333 ± 1 K in vacuum for 300 min.

Magnetic disinfectant synthesis

Preparation of magnetic thiourea-formaldehyde polymer (MTUF)

In a 250-mL round flask equipped with a stirrer and condenser, 15.2 g (0.2 mol) of thiourea and 40 mL of distilled water were mixed. The flask was heated until thiourea was dissolved. Then, 7.6 g of Fe3O4 and 15 mL of formaldehyde (37% aqueous solution, containing 0.2 mol formaldehyde) were added, respectively. The acidity of the medium was performed by adding 2 mL of glacial acetic acid. The reaction was carried out for 6 h with heating at 368 K with stirring. The product was washed with dilute NaOH solution, distilled water, ethanol, and acetone in turn. The obtained black powder material was dried for 10 h and kept for use.

Loading of thiourea-formaldehyde polymer with Ag ions

MTUF polymer (3 g) was put in 1000-mL conical flask containing 500 mL of AgNO3 aqueous solution (0.11 mol/L), the pH was 4.6. The conical flask was wrapped with black paper to exclude light. The mixture was vibrated for 2 h after remaining motionless for 20 h and was then filtrated. The separated material was labeled MTUF-Ag.

Disinfectant morphology

The morphology of MTUF-Ag particles was determined using field emission scanning electron microscope FE-SEM, QUANTA FEG 250 (FEI, Japan) equipped with energy-dispersive X-ray micro analysis system (EDX) operated with an accelerating voltage of 20 kV and a working distances of 9.7 and 9.8 mm. Powder of MTUF-Ag polymer was spread on the holder, The specimens were examined at magnification power of ×500, ×1000, and ×4000. The magnetic properties of MTUF and MTUF-Ag disinfectant were measured on a vibrating-sample magnetometer (VSM) (Lake Shore 730T, Westerville OH, USA) at room temperature.

Measurement of Ag(I) sorption onto MTUF and toxicity test

The concentration of the silver ion solutions was determined before and after Ag(I) sorption onto MTUF polymer, and the measurements were done using Agilent atomic absorption spectrophotometer model FS240 (USA). Toxicity measurements of MTUF and MTUF-Ag were carried out using microtox analyzer 500.

Preparation of the microbial strains

Preparation of the inoculum was carried out 1 day before each test to determine the initial counts. Stock microbial strains with 10% glycerol in − 20 °C were inoculated in 10 mL Tryptic Soya Broth (TSB) (Merck, Germany). The tubes were incubated at 37 °C for 24 h. The counts between 105 and 106 CFU/mL were chosen by ten serial dilutions using pour plate method according to APHA (American Public Health Association) (2012). Briefly, 1 mL from suitable dilution was inoculated into plate count agar (Merck, Germany), and the plates were incubated at 37 °C for 24 h. The resulting colonies were counted and expressed as colony-forming unit (CFU/mL).

Impact of MTUF-Ag on pathogenic microorganisms

Impact of MTUF-Ag on pathogenic microorganisms was carried out using well and disc diffusion methods. Minimum inhibition dosages (MIMs) were also determined for each pathogen. Escherichia coli ATCC 25922, Salmonella enterica serovar Typhimurium ATCC 14028, Pseudomonas aeruginosa ATCC 10145 as a Gram-negative bacteria and Listeria monocytogenes ATCC 25152, Staphylococcus aureus ATCC 43300, Enterococcus faecalis ATCC 43845, and Bacillus subtilis as a Gram-positive bacteria and Candida albicans as fungus were used. Bacillus subtilis and Candida albicans were isolated from wastewater sample and confirmed using Biolog GEN III.

Well and disc diffusion methods

About 100 μg of the MTUF-Ag was weighted and then added to tubes containing 1 mL of DMSO solvent. Totally, 100 μL from each microbial pathogen strain suspension was spread onto Müller Hinton agar (BBL™, Germany) plates. The wells were dug in the media with the help of sterile tips. Then, 100 μL of each tested MTUF-Ag solution was inoculated into each well. Effect of MTUF-Ag on the pathogenic microorganisms was tested also using disc diffusion method according to Ayuba et al. (2014). Sterile discs of filter paper were soaked in prepared MTUF-Ag into DMSO solvent. The soaked discs were placed onto Müller Hinton agar plates. DMSO solvent and MTUF solution were inoculated as controls. All plates were incubated at 37 °C for 24 h. The inhibition zones were measured in millimeters.

Minimum inhibition dosage (MIDs) test

The antimicrobial activity of MTUF-Ag polymer was tested against the selected pathogenic microorganisms according to Zhang et al. (2004). One hundred microliters of fresh pathogenic microorganisms broth was transferred to 10-mL sterilized distilled water tubes containing 0.5, 1.0, 1.5, 2.0, and 2.5 mg of MTUF-Ag. The same concentrations were used for MTUF as a control for each selected strain. The initial counts for each strain were determined by withdraw 100 μL before disinfectant addition. The antimicrobial activity of MTUF-Ag and MTUF was determined at zero contact time and after 40 min shaking at 250 rpm at room temperature (i.e., 25 ± 1 °C). The counts of pathogenic microorganisms after treatment with MTUF-Ag were determined using pour plate method according to APHA (2012). All the cultured plates were incubated at 37 °C for 24 h. The grown colonies were counted and the results were recorded as CFU/mL.

Transmission electron microscopy (TEM) examination of E. coli after treatment

Unstained cells of E. coli were used for examination of adhering particles, and the outer morphological changes by TEM. The bacterial suspension was diluted to a final concentration of 105 to 106 CFU/mL. The bacterial suspension (10 mL) was incubated with 1 mg/mL of MTUF-Ag at room temperature then shook at 250 rpm for 20 min. A drop of the mixture was placed on a glow-discharged formvar coated copper grid for 1 min. The excess liquid was drained off with a filter paper, and the preparation was air dried for 5 min. The specimen was examined using high-resolution transmission electron microscopy model JEM 2100-HRTEM (JEOL, USA, Inc.) operated at an accelerating voltage of 200 kV (Jung et al. 2008).

Application of MTUF-Ag for water disinfection

The sampling sites and water samples characterizations

The polluted water samples were treated using MTUF-Ag as a water disinfectant. Wastewater sample was collected from influent of New Cairo wastewater treatment plant (Orasqualia). Also, surface water sample was collected from the Nile river branch (Bahr Mourise branch, El-Sharkia Governorate). The presumptive E. coli, Salmonella sp., Staphylococcus sp., Listeria sp., and Candida sp. were also determined in the tested water samples before and after MTUF-Ag treatment by plating onto Rapid HiColiform agar, Improved Salmonella agar, Hicrome Aureus agar, Hicrom Listeria selective agar, and Candida agar, respectively. All the used chromogenic media were imported from HiMedia Co., India.

Water disinfection with MTUF-Ag

Disinfectant mass of 0.5 mg of MTUF-Ag was used to treat 50 mL of surface water sample, while mass of 2.5 mg of MTUF-Ag was used to treat 50 mL of influent wastewater sample. A disinfectant mass of 2.5 mg of MTUF was added also onto 50 mL of the tested water sample and used as a control. The flasks were kept at room temperature under shaking at 250 rpm. The previously selected microbes were determined as a function of time: zero, 15, 30, 45, 60, 120 min, and after 24 h. One hundred microliters from each flask was speared onto the previously prepared chromomeric agar medium. The inoculated plates were incubated at 37 °C for 24 h, and the grown colonies were counted as CFU/mL.

Results and discussion

Characterization of MTUF-Ag

MTUF-Ag disinfectant is a polymeric ligand bearing nitrogen and sulfur donor groups loaded with Ag(I) ions. The FTIR spectra of polychelates indicated that the metal ions were coordinated through the sulfur of the thionyl (C=S) groups and formed a covalent bond with the nitrogen of the NH groups (Ahamad et al. 2006). In the present study, the sorption capacity of MTUF for Ag(I) ions was 7.35 mmol/g. The EDX scanning results of MTUF-Ag polymer are shown in Fig. 1. The weight percent of Ag is 31.8%, while the weight percent % of C is 14.12%, N is 21.84%, O is 19.98%, and S is 12.24% of the net weight.

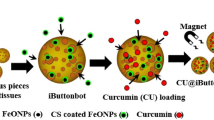

The VSM analysis of MTUF and MTUF-Ag shows the absence of coercivity and remanence, which confirms that the materials have super paramagnetic properties that make it separable from the aqueous medium by applying external magnetic field. The magnetization saturation of MTUF-Ag (31.57 emu g−1) is less than that of MTUF (45.54 emu g−1). The decrease in the magnetization of MTUF-Ag after Ag(I) sorption is another confirmation of the high sorption capacity of MTUF for non-magnetic Ag(I) ions. This decrease can be attributed to the increase in the mass of the non-magnetic material (due to Ag(I) loading) and the decrease in the relative mass percentage of magnetite in the sorbent (Fig. 2).

The SEM pictures of MTUF-Ag polymer are shown in Fig. 3. The cracks in some polymer particles may be related to the presence embedded magnetite particles inside the polymeric matrix. The ratio of formaldehyde and thiourea in this study was 1:1. Regarding to ratio of 1:2 will give higher sorbing capacity according to Ni et al. (2001). Also, the pH may affect the sorption capacity of the MTUF resin; in the present study, the sorption was carried out at 4.6 for Ag. In another study that involved recovery of Ag(I) on a chemically chitosan resin with magnetic properties (Donia et al. 2007), the effect of pH was studied. According to them for Ag, the uptake capacity increase till the pH reaches 6. For MTUF resin, the uptake capacity can be increased by increasing the ratio of the formaldehyde to thiourea and by shifting the pH of sorbing processes. Regarding to the toxicity results, the highest used disinfectant dosages (2.5 mg/mL) for both MTUF-Ag and MTUF were nontoxic against Vibrio fischeri strain using microtox analyzer 500. Guggenbichler et al. (1999) found that out of all the metals with antimicrobial properties, silver has the most effective antibacterial action and the least toxicity to animal cells.

Antimicrobial activity of MTUF-Ag disinfectant

The blank solvent (DEMSO) has no antimicrobial activity against the tested pathogenic microorganisms (Ce’liz et al. 2011). MTUF showed a limited clear zone with diameter of around 6–7 mm, while MTUF-Ag showed antimicrobial activity against the selected pathogenic microorganisms by using both disc and well diffusion methods. This means that the antimicrobial activity of MTUF increased after Ag chelation, and this is revealed to the polarity of the central metal ion by partial sharing of its positive charge with the donor groups (Ahamad et al. 2006). In this study, the clear zone diameters obtained from MTUF-Ag disinfectant using well diffusion method were wider than that obtained by using disc diffusion method. Regarding the results of disc diffusion method, the MTUF-Ag is the most effective deactivator against Bacillus subtilis producing clear zone of 18 mm. The lowest effect was against Listeria monocytogenes with clear zone of 8 mm. The clear zones were 10, 10, 11, 12, 12, and 12 mm against Salmonella Typhimurium, Candida albicans, Staphylococcus aureus, Escherichia coli, Pseudomonas aeruginosa, and Enterococcus faecalis, respectively. The order of MTUF-Ag activity against the tested microbes is Bacillus subtilis > E. coli = Pseudomonas aeruginosa = Enterococcus faecalis > Staphylococcus aureus > Salmonella Typhimurium = Candida albicans > Listeria monocytogenes (Fig. 4). Dong et al. (2014) investigated the antimicrobial activities of hybrids from cellulose, Ag, and AgCl against E. coli as the model Gram-negative bacteria and S. aureus as the model Gram-positive bacteria by the disc diffusion method. They reported that the inhibition zones of the hybrids synthesized by ultrasound agitation method for 10 min for E. coli and S. aureus were 2 and 3 mm, respectively. The inhibition zones of the hybrids from cellulose, AgCl and Ag synthesized by ultrasound agitation method for 30 min for E. coli and S. aureus were 2 and 2.5 mm, respectively. According to Dong et al. (2014), these results confirmed that the AgCl/Ag nanoparticles had good antimicrobial activities. Moreover, the antimicrobial activity against E. coli was lower than that against S. aureus, which might be assigned to the differences in cell walls between Gram-negative and Gram-positive bacteria.

In this study, the results of well diffusion method showed that the MTUF-Ag disinfectant has the highest deactivation against Bacillus subtilis producing a clear zone of 17 mm. The lowest activity is against Listeria monocytogenes with clear zone of 9 mm. From Fig. 4, the clear zones are 11, 11, 13, 14, 15, and 16 mm against Salmonella Typhimurium, Candida albicans, Staphylococcus aureus, Escherichia coli, Pseudomonas aeruginosa, and Enterococcus faecalis, respectively. The order of the activity of MTUF-Ag against tested microbes was Bacillus subtilis > Enterococcus faecalis > Pseudomonas aeruginosa > E. coli > Staphylococcus aureus > Salmonella Typhimurium = Candida albicans > Listeria monocytogenes (Fig. 4). Similarly, Ahamad et al. (2006) used well diffusion technique to test the antibacterial activity of MTUF-Mn(II), MTUF-Cu(II), MTUF-Co(II), MTUF-Ni(II), and MTUF-Zn(II) against Bacillus subtilis, Staphylococcus aureus, E. coli, Salmonella Typhi, Pseudomonas aeruginosa, Shigella boydii (as bacteria), and the antifungal activity against Candida albicans, Trichophyton spp., Aspergillus flavus, Aspergillus niger, Fusarium spp., Mucor spp., and Penicillium spp. (as filamentous fungi). Comparing to the results of Ahamad et al. (2006), the highest zone of inhibition was measured for MTUF-Cu(II) against E. coli and Salmonella Typhi, i.e., 25 mm. The lowest zone of inhibition was measured, i.e., 14 mm, against Pseudomonas aeruginosa in the case of MTUF-Co(II) and Shigella boydii in the case of MTUF-Mn(II)/Ni(II). The unloaded MTUF resin (free from metal ions) showed weak activity against tested organisms where zones of inhibition varied from 6 to 7 mm. Unlike Ahamad et al. (2006), hence, MTUF resin showed moderate activity, i.e., 12–16 mm against bacterial strains and significant activity, i.e., 18 mm against both Trichophyton spp. and Mucor spp. In well diffusion experiment, it was noticed that E. coli is more susceptible than Staphylococcus aureus, in consistence with Chamakura et al. (2011) and Feng et al. (2000) and unlike Dong et al. (2014) results, which stated that the antimicrobial activity against E. coli was lower than that of against S. aureus. Bindhu and Umadevi (2014) stated that S. aureus is more susceptible than P. aerugenosa. All of them explained their conclusion due to the differences in the cell wall between the Gram-negative and Gram-positive bacteria. In this study, it seems that there was no effect for the cell wall type either in Gram-positive or Gram-negative bacteria.

The minimum inhibition dosage (MID)

The minimum inhibitory dosage (MID) test results of MTUF-Ag disinfectant against the selected pathogenic microorganisms at zero contact time are shown in Fig. 5. The initial concentrations of microbial suspensions of E. coli, Salmonella Typhimurium, Staphylococcus aureus, Listeria monocytogenes, and Candida albicans were 6.0 × 105, 1.8 × 105, 3.2 × 105, 4.0 × 105, and 3.7 × 105 CFU/mL, respectively. A series of 0.5, 1.0, 1.5, 2.0, and 2.5 mg/mL of MTUF-Ag was used to determine the MID for each tested pathogenic microorganisms. The results showed that there is no observed deactivation effect for the MTUF against the tested pathogenic microorganisms, while complete eradication (100%) was observed for Listeria monocytogenes and pathogenic mixture for MTUF-Ag (Fig. 5d, f) at a minimum disinfectant dosage of 1.5 mg/mL. Moreover, complete deactivation for both E. coli and Staphylococcus aureus was occurred at minimum disinfectant dosage of 2.0 mg/mL (Fig. 5a, c). Three log reductions were reached for Salmonella Typhimurium and Candida albicans (Fig. 5b, e) at the studied highest disinfectant dosage (2.5 mg/mL). Statistically, the regression coefficient (R2) between MTUF-Ag dosage and log reductions of E. coli, Salmonella Typhimurium, Staphylococcus aureus, Listeria monocytogenes, and Candida albicans was 0.478, 0.928, 0.944, 0.808, and 0.919, respectively. This indicates the good linear relationship between microorganism’s reductions with increasing disinfectant dosage. The MID test of MTUF-Ag disinfectant against the selected strains after 40 min of contact time is shown in Fig. 6. The initial counts of tested strains are 4.7 × 105, 4.3 × 105, 3.3 × 105, 2.1 × 105, and 2.4 × 105 CFU/mL for E. coli, Salmonella Typhimurium, Staphylococcus aureus, Listeria monocytogenes, and Candida albicans, respectively. From the results, it was found that the pathogen deactivations are elevated by increasing the contact time with MTUF-Ag. Complete deactivation of E. coli, Staphylococcus aureus, and pathogens mixture was occurred at MID of 1.5 mg/mL for MTUF-Ag disinfectant (Fig. 6a, c, e). The MID of Listeria monocytogenes and Salmonella Typhimurium was observed at 1.0 and 2.0 mg/mL, respectively (Fig. 6b, d). MTUF-Ag deactivates all the tested pathogenic microorganisms after 40 min of exposure time. Except for Candida albicans, 40 min of shaking was enough to inhibit the growth of organisms that showed resistance at zero contact time. The removal percentage varied from 99.90 to 100% for the highest concentration used (2.5 mg/L) (Fig. 6e). This is revealed to the fact that C. albicans is an important opportunistic pathogenic fungus and resistance to antimicrobial materials. It is able to infect mucosal membranes (Kalinowska-Lis et al. 2014). The mixed suspension strains showed MIDs 1.5, 1 mg/mL of MTUF-Ag(I) at zero and after 40 min of contact time. Isab et al. (2010) reported that mixed ligand Ag(I) complexes of triphenylphosphine and thioureas showed significance activity against E. coli. According to them, the antibacterial activities of the complexes are due to a direct interaction of the metal ions with biological ligands such as proteins, enzymes, and membranes. Many studies found that Gram-positive Staphylococcus aureus was more resistant than Gram-negative E. coli by exposure to Ag ions or Ag-NPs. This decreased susceptibility can simply be explained by the fact that the cell wall of Gram-positive bacteria is thicker than that of Gram-negative one, resulting in trapping more silver by peptidoglycan molecules in the cell wall (Chamakura et al. 2011; Baheiraei et al. 2012; Jang et al. 2014). Statistically of this work, the regression coefficient (R2) between MTUF-Ag dosages and log reduction of E. coli, Salmonella Typhimurium, Staphylococcus aureus, Listeria monocytogenes, and Candida albicans after 40 min contact time was 0.833, 0.921, 0.848, 0.550, and 0.799, respectively. This again reflects the linear increase of microorganism’s reduction with increasing disinfectant dosage.

Transmission electron microscopy (TEM) examination of E. coli after treatment with MTUF-Ag

E. coli strain was exposed to MTUF-Ag in sterilized distilled water for 20 min at 250 rpm. The treated cells were examined using the transmission electron photomicrograph (TEM). E. coli cells were completely destroyed after the treatment with MTUF-Ag. Figure 7 shows the MTUF-Ag particle adhesion to E. coli cell and the ruptured cell wall of E. coli. E. coli cytoplasm was exposed by MTUF-Ag (Fig. 7c).

The application of MTUF-Ag disinfectant

Chlorine and chlorine derivatives are still the most widely used as water disinfection overall the world. While they are effective against most pathogenic microorganisms, economical, and easy to use, but, one of their drawbacks is that chlorine interacts readily with natural organic matter (NOM) present in all source surface waters to generate numerous disinfection by-products (DBPs) (Sedlak and Gunten 2011). In biological applications, silver (Ag) ions gained the significant attention due to their unique electrical and optical properties. The use of chemical disinfectants or sunlight to sterilize drinking water is well established. Ancient civilizations practiced a number of techniques such as boiling water, leaving water in sun light, or storing water in silver jugs, as methods to make it sterile (Chamakura et al. 2011). Although there is several attempts for using MTUF as antimicrobials, but, using these metal resins as water disinfectants is still limited (Ahamad et al. 2006, 2009; Nishat et al. 2011). The application experiment of MTUF-Ag(I) was used as water disinfectant against pathogenic microorganisms. Surface water and wastewater samples were used to evaluate their efficiency in the treatment. The lowest used concentrations in the MID test (0.5 mg/ml of MTUF-Ag(I)) was used in the treatment test. Table 1 reports the physico-chemical and microbiological characteristics of the two tested water samples. The disinfectant dosage of 0.5 mg/mL was used to treat surface and wastewater samples at different contact time intervals (zero, 15, 30, 60, and 120 min). The result of the treatment of surface water sample using MTUF-Ag is illustrated in Fig. 8. Fifteen minutes and disinfectant dosage of 0.5 mg/mL were enough to complete eradication of E. coli and Salmonella sp., while Staphylococci sp. and Listeria sp. took 60 and 120 min, respectively, for complete eradication. Candida sp. showed no complete deactivation although their percentage of reduction reached 97.87% (Fig. 8). The differences between the application test and the MID test such as the resistance of the Salmonella Typhimurium to MTUF-Ag(I) even at 2.5 mg/L at zero time of exposure where it shows no growth at 0.5 mg/L at zero time can be explained by the proportional ratio between bacteria number and the concentration of silver. Likely, Nawaz et al. (2012) studied the inactivation of two microorganisms in roof harvested rainwater, namely P. aeruginosa and E. coli by treating with silver at different concentrations in addition to re-growth phenomenon and inactivation rate constant calculations. At higher concentrations of silver (0.08–0.1 mg/L), both P. aeruginosa and E. coli were effectively inactivated in lesser time (about 10 h) with high residual effect of silver as compared to the inactivation at lower concentrations of silver (0.01–0.04 mg/L), where the inactivation time increased to about 14 and 24 h for P. aeruginosa and E. coli, respectively. Moreover, the inactivation was also not completed at lower concentration of silver for either P. aeruginosa or E. coli except at 0.04 mg/L of silver for E. coli inactivation. No re-growth was seen in either P. aeruginosa or E. coli when disinfected with silver at higher concentrations.

On the other hand, the result of the treatment of wastewater sample with MTUF-Ag disinfectant is illustrated in Fig. 9. All the tested microorganisms showed no complete deactivation using disinfectant dosage of 0.5 mg/mL even after 120 min of contact time. The percentage of reduction is promised for most of targeted organisms, where it varied from 93.75 to 99.5% after 120 min of contact time for E. coli and Salmonella sp., respectively. The percentages of reduction were 97.22, 98.0, and 98.18% for Candida sp., Listeria sp., and Staphylococcus sp., respectively (Fig. 9). The results showed that all the targeted organisms showed resistance against both metal-chelated resins at the used concentration (0.5 mg/L) even after 120 min of exposure and this result different with the turbid drinking water test result. Although there is no strain that showed complete inhibition of growth, in this context, the percentages of removal were significance, they varied from 93 to 99.5% for MTUF-Ag(I) against E. coli and Listeria sp., respectively, after 120 min of exposure time. The result of the wastewater treatment application test showed that MTUF-Ag(I) have significant bactericidal effect in the treatment field of the wastewater. The findings of the present work can be confirmed by Nawaz et al. (2012) findings. From the previous results, it is concluded that MTUF-Ag(I) provide new opportunities for water treatment, similar to Chamakura et al. (2011) who reported that the Ag nanoparticles may provide new opportunities for water treatment.

Microorganism’s deactivation mechanism

The exact mechanism of antimicrobial action of MTUF loaded with Ag(I) ions is not clearly known, but studies proposed that the polymeric complexes of thiourea-formaldehyde with Ag(I) ions have the ability to kill bacteria by (i) damaging cell membrane via direct contact of amino and/or thiol groups on the thiourea moiety, and (ii) releasing silver ions from coordinated Ag(I) TUF complex into cell membrane. This can be attributed to the fact that the coordination of Ag(I) ions with amino and/or thiol groups reduces its polarity by partial sharing of its positive charge with the donor atoms (i.e., N and S on thiourea moiety) (Ahamad and Alshehri 2013). This process increases the lipophilic nature of the Ag(I) ions, which in turn favors its permeation to the lipid layer of the membrane. Furthermore, the cell wall of living microorganisms contains some chelating sites such as (N, O, P) that enable microorganism to accumulate metal ions (Elwakeel et al. 2012).

Conclusions

Magnetic thiourea-formaldehyde polymer (MTUF) was prepared by the reaction of thiourea and formaldehyde in the presence of Fe3O4 nanoparticles. The prepared disinfectant was loaded with Ag(I) ions. It was observed that the attachment of the silver ion to the polymeric backbone enhances its antimicrobial activity. MTUF-Ag has been studied as antibacterial and antifungal against Gram-negative, Gram-positive, and Candida albicans. The MID of MTUF-Ag disinfectant against the tested pathogenic microorganisms was ranged between 1.0 and 2.0 mg/mL after 40 min of contact time. Three log reductions of Candida albicans counts were done at 2.5 mg/mL of MTUF-Ag disinfectant. Therefore, MTUF-Ag provides a promising disinfectant activity against microbial pathogens in the studied water and wastewater samples with high magnetic separation ability.

References

Abbas SY, El-Sharief MAMS, Basyouni WM, Fakhr IMI, El-Gamma EW (2013) Thiourea derivatives incorporating a hippuric acid moiety: synthesis and evaluation of antibacterial and antifungal activities. Eur J Med Chem 64:111–120

Ahamad T, Alshehri SM (2013) Physiochemical characterization and antimicrobial evaluation of phenylthiourea–formaldehyde polymer (PTF) based polymeric ligand and its polymer metal complexes. Spectrochim Acta A Mol Biomol Spectrosc 108:26–31

Ahamad T, Kumar V, Nishat N (2006) Synthesis, characterization and antimicrobial activity of transition metal chelated thiourea-formaldehyde resin. J Polym Int 55:1398–1406

Ahamad T, Kumar V, Nishat N (2009) New class of anti-microbial agents: synthesis, characterization, and anti-microbial activities of metal chelated polyurea. J Biomed Mater Res A 88:288–294

APHA (American Public Health Association) (2012) Standard methods for the examination of water and wastewater, 22nd ed. Washington, D.C.

Ayuba SB, Mallikarjuna RP, Vasantha KN, Kavitha M (2014) In vitro antibacterial effects of Cinnamomum extracts on common bacteria found in wound infections with emphasis on methicillin-resistant Staphylococcus aureus. J Ethnopharmacol 153:587–595

Baheiraei N, Moztarzadeh F, Hedayati M (2012) Preparation and antibacterial activity of Ag/SiO2 thin film on glazed ceramic tiles by sol–gel method. Ceram Int 38:2921–2925

Bechambi O, Chalbi M, Najjar W, Sayadi S (2015) Photocatalytic activity of ZnO doped with Ag on the degradation of endocrine disrupting under UV irradiation and the investigation of it santibacterial activity. Appl Surf Sci 347:414–420

Bindhu MR, Umadevi M (2014) Silver and gold nanoparticles for sensor and antibacterial applications. Spectrochim Acta A Mol Biomol Spectrosc 128:37–45

Ce’liz G, Daz M, Audisio MC (2011) Antibacterial activity of naringin derivatives against pathogenic strains. J Appl Microbiol 111:731–738

Chamakura K, Perez-Ballestero R, Luo Z, Bashir S, Liu J (2011) Comparison of bactericidal activities of silver nanoparticles with common chemical disinfectants. Colloids Surf B Biointerfaces 84:88–96

Chen C, Chiang C, Chen C (2007) Removal of heavy metal ions by a chelating resin containing glycine as chelating groups. Sep Purif Technol 54:396–403

Darby J, Heath M, Jacangelo J, Loge F, Swaim P, Tchobanoglous G (1995) Comparison of UV irradiation to chlorination: guidance for achieving optimal UV performance. Water Environment Research Foundation, Alexandria, Virginia

Dong Y-Y, Deng F, Zhao J-J, He J, Ma MG, Xu F, Sun R-C (2014) Environmentally friendly ultrasound synthesis and antibacterial activity of cellulose/Ag/AgCl hybrids. Carbohydr Polym 99:166–172

Donia AM, Atia AA, Elwakeel KZ (2007) Recovery of gold(III) and silver(I) on a chemically modified chitosan with magnetic properties. Hydrometallurgy 87:197–206

El-Lathy MA, El-Taweel GE, El-Sonosy WM, Samhan FA, Moussa TA (2009) Determination of pathogenic bacteria in wastewater using conventional and PCR techniques. Environ Biotechnol 5:73–80

Elwakeel KZ, Al-Bogami AS (2018) Influence of Mo(VI) immobilization and temperature on As(V) sorption onto magnetic separable poly p-phenylenediamine-thiourea-formaldehyde condensate. J Hazard Mater 342:335–346

Elwakeel KZ, El-Sadik HA, Abdel-Razek AS, Beheary MS (2012) Environmental remediation of thorium(IV) from aqueous medium onto Cellulosimicrobium cellulans isolated from radioactive wastewater. Desalin Water Treat 46:1–9

Elwakeel KZ, El-Bindary AA, El-Sonbati AZ, Hawas AR (2016) Adsorption of toxic acidic dye from aqueous solution onto diethylenetriamine functionalized magnetic glycidyl methacrylate-N, N′-methylenebisacrylamide. RSC Adv 6:335–3361

Elwakeel KZ, Daher AM, Abd El-Fatah AIL, Abd El Monem H, Khalil MMH (2017) Biosorption of lanthanum from aqueous solutions using magnetic alginate beads. J Disper Sci Technol 38:145–151

Ertan E, Gülfen M (2009) Separation of gold(III) ions from copper(II) and zinc(II) ions using thiourea–formaldehyde or urea–formaldehyde chelating resins. J Appl Polym Sci 111:2798–2805

Fakhar I, Hussien NJ, Sapari S, Bloh AH, Yusoff SFM, Hasbullah SA, Yamin BM, Mutalib SA, Shihab MS, Yousif E (2018) Synthesis, X-ray diffraction, theoretical and anti-bacterial studies of bis-thiourea secondary amine. J Mol Struct 1159:96–102

Feng Q L, Wu J, Chen GQ, Cui FZ, Kim TN, Kim JO (2000) A mechanistic study of the antibacterial effect of silver ions on Escherichia coli and Staphylococcus aureus. J Biomed Mater Res 52:662–668

Ferreira M, Assunçao LS, Silva AH, Filippin-Monteiro FB, Creczynski-Pasa TB, Sa MM (2017) Allylic isothiouronium salts: the discovery of a novel class of thiourea analogues with antitumor activity. Eur J Med Chem 129:151–158

Guggenbichler JP, Boswald M, Lugauer S, Krall T (1999) A new technology of microdispersed silver in polyurethane induces antimicrobial activity in central venous catheters. Infection 27:16–23

Guldiren D, Aydın S (2017) Antimicrobial property of silver, silver-zinc and silver-copper incorporated soda lime glass prepared by ion exchange. Mater Sci Eng C 78:826–832

Hasnain S, Zulfequar M, Nishat N (2012) Adsorption properties of thermally stable and biologically active polyurea: its synthesis and spectral aspects. Polym Adv Technol 23:1002–1010

Isab AA, Nawaz S, Saleem M, Altaf M, Monim-ul-Mehboob M, Ahmad S, Evans HS (2010) Synthesis, characterization and antimicrobial studies of mixed ligand silver (I) complexes of thioureas and triphenylphosphine; crystal structure of {[Ag (PPh3)(thiourea)(NO3)]2·[Ag (PPh3)(thiourea)]2 (NO3)2}. Polyhedron 29(4):1251–1256

Jamil TS, Mansor ES, El-Liethy MA (2015) Photocatalytic inactivation of E. coli using nano-size bismuth oxyiodide photocatalysts under visible light. J Environ Chem Eng 3:2463–2471

Jang KH, Yu YJ, Lee YH, Kang YO, Park OH (2014) Antimicrobial activity of cellulose-based nanofibers with different Ag phases. Mater Lett 16:146–149

Jung WK, Koo HC, Kim KW, Shin S, Kim SH, Park YH (2008) Antibacterial activity and mechanism of action of the silver ion in Staphylococcus aureus and Escherichia coli. Appl Environ Microbiol 74(7):2171–2178

Kalinowska-Lis U, Felczak A, Chęcińska L, Lisowska K, Ochocki J (2014) Synthesis, characterization and antimicrobial activity of silver(I) complexes of hydroxymethyl derivatives of pyridine and benzimidazole. J Organomet Chem 749:394–399

Karakuş S, Güniz Küçükgüzel S, Küçükgüzel I, De Clercq E, Pannecouque C, Andrei G, Snoeck R, Sahin F, Bayrak OF (2009) Synthesis, antiviral and anticancer activity of some novel thioureas derived from N-(4-nitro-2-phenoxyphenyl)-methanesulfonamide. Eur J Med Chem 44(2009):3591–3595

Khraisheh M, Wu L, Al-Muhtaseb AH, Al-Ghouti MA (2015) Photocatalytic disinfection of Escherichia coli using TiO2 P25 and Cu-doped TiO2. J Ind Eng Chem 28:369–376

Liu S-J, Jiang J-Y, Wang S, Guo Y-P, Ding H (2018) Assessment of water-soluble thiourea-formaldehyde (WTF) resin for stabilization/solidification (S/S) of heavy metal contaminated soils. J Hazard Mater 346:167–173

Lok CN, Ho CM, Chen R, He QY, Yu WY, Sun H, Tam PK, Chiu JF, Che CM (2007) Silver nanoparticles: partial oxidation and antibacterial activities. J Biol Inorg Chem 12(4):527–534

Muslu N, Gülfen M (2011) Selective separation and concentration of Pd(II) from Fe(III), Co(II), Ni(II), and Cu(II) ions using thiourea-formaldehyde resin. J Appl Polym Sci 120(6):3316–3324

Nawaz M, Han MY, Kim T, Manzoor U, Amin MT (2012) Silver disinfection of Pseudomonas aeruginosa and E. coli in rooftop harvested rainwater for potable purposes. Sci Total Environ 431:20–25

Ni C, Yi C, Feng Z (2001) Studies of syntheses and adsorption properties of chelating resin from thiourea and formaldehyde. J Appl Polym Sci 82(13):3127–3132

Nishat N, Rasool R, Khan SA, and Parveen S (2011) Synthesis and characterization of metal-incorporated aniline formaldehyde resin modified by amino acid for antimicrobial applications. J Coord Chem 64:4054–4065

Pan J, Wang S, Zhang R (2006) Preparation and modification of macroporous epoxy-triethylenetetramine resin for preconcentration and removal of Hg(II) in aqueous solution. J Appl Polym Sci 102:2372–2378

Panahi HA, Sharif AAM, Bigonah M, Moniri E (2009) Preconcentration and determination of chromium in water with flame atomic absorption spectrometry by thiourea-formaldehyde as chelating resin. Korean J Chem Eng 26:1723–1728

Prüss-Ustün A, Bartram J, Clasen T, Colford JM, Cumming O, Curtis V, Bonjour S et al (2014) Burden of disease from inadequate water, sanitation and hygiene in low- and middle- income settings: a retrospective analysis of data from 145 countries. Tropical Med Int Health 19:894–905

Rai M, Yadav A, Gade A (2009) Silver nanoparticles as a new generation of antimicrobials. Biotechnol Adv 27:76–83

Rivas BL, Maureira AN, Guzmán CS (2010) Water-soluble polymers and their polymer-metal ion-complexes as antibacterial agents. Macromol Symp 287:69–79

Sedlak DL, Gunten UV (2011) The chlorine dilemma. Science 331:42–43

West DX, Sallberg MM, Bain GA, Liberta AE (1997) Nickel (II) and copper (II) complexes of 5-substituted-salicylaldehyde thiosemicarbazones. Transit Met Chem 22(2):180–184

WHO (World Health Organization) (2008) Guideline for drinking–water quality. Incorporating 1st and 2nd addenda, volume 1, recommendations, 3rd Ed; WHO: Geneva

Yirikoglu H, Gülfen M (2008) Separation and recovery of silver(I) ions from base metal ions by melamine–formaldehyde–thiourea (MFT) chelating resin. Sep Sci Technol 43:376–388

Zhang S, Fu R, Wu D, Xu BW, Ye Q, Chen Z (2004) Preparation and characterization of antibacterial silver-dispersed activated carbon aerogels. Carbon 42:3209–3216

Zhang C, Sui J, Li J, Tang Y, Cai W (2012) Efficient removal of heavy metal ions by thiol-functionalized superparamagnetic carbon nanotubes. Chem Eng J 210:45–52

Acknowledgments

The authors would like to say thanks to the Virus Consulting Unit, National Research Centre, Egypt, for proving facilities for carrying out this research work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors have not declared any conflict of interests.

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(DOCX 656 kb)

Rights and permissions

About this article

Cite this article

Elwakeel, K.Z., El-Liethy, M.A., Ahmed, M.S. et al. Facile synthesis of magnetic disinfectant immobilized with silver ions for water pathogenic microorganism’s deactivation. Environ Sci Pollut Res 25, 22797–22809 (2018). https://doi.org/10.1007/s11356-018-2071-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-2071-6