Abstract

This report gives a summary of the historic use, former management and current release of polychlorinated biphenyls (PCBs) in Germany and assesses the impact of the life cycle of PCBs on the contamination of the environment and of food products of animal origin. In Germany 60,000 t of PCBs were used in transformers, capacitors or as hydraulic oils. The use of PCB oils in these “closed applications”, has been banned in Germany in 2000. Thirty to 50% of these PCBs were not appropriately managed. In West Germany, 24,000 t of PCBs were used in open applications, mainly as additive (plasticiser, flame retardant) in sealants and paints in buildings and other construction. The continued use in open applications has not been banned, and in 2013, an estimated more than 12,000 t of PCBs were still present in buildings and other constructions. These open PCB applications continuously emit PCBs into the environment with an estimated release of 7–12 t per year. This amount is in agreement with deposition measurements (estimated to 18 t) and emission estimates for Switzerland. The atmospheric PCB releases still have an relevant impact on vegetation and livestock feed. In addition, PCBs in open applications on farms are still a sources of contamination for farmed animals. Furthermore, the historic production, use, recycling and disposal of PCBs have contaminated soils along the lifecycle. This legacy of contaminated soils and contaminated feed, individually or collectively, can lead to exceedance of maximum levels in food products from animals. In beef and chicken, soil levels of 5 ng PCB-TEQ/kg and for chicken with high soil exposure even 2 ng PCB-TEQ/kg can lead to exceedance of EU limits in meat and eggs. Areas at and around industries having produced or used or managed PCBs, or facilities and areas where PCBs were disposed need to be assessed in respect to potential contamination of food-producing animals. For a large share of impacted land, management measures applicable on farm level might be sufficient to continue with food production. Open PCB applications need to be inventoried and better managed. Other persistent and toxic chemicals used as alternatives to PCBs, e.g. short chain chlorinated paraffins (SCCPs), should be assessed in the life cycle for exposure of food-producing animals and humans.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction and background

Polychlorinated biphenyls (PCBs) are persistent organic pollutants (POPs) listed in the Stockholm Convention (http://chm.pops.int). The Stockholm Convention requests that remaining PCBs are phased out by 2025 and disposed by 2028 (Stockholm Convention 2017). From the approx. 1.3 to 2 million t of PCBs industrially produced in various countries from 1929 to the 1980s (Breivik et al. 2002; Fiedler 2001), approximately 21% have been used in open application. However, it is considered that these 21% of the PCBs were responsible for 50% of the releases to the environment (Breivik et al. 2007).

PCBs are also unintentionally formed in combustion in the presence of a chlorine source together with and through the same mechanism as the dioxins (polychlorinated dibenzo-p-dioxins (PCDD) and polychlorinated dibenzofurans (PCDF)) (Sakurai et al. 2003; Weber et al. 2001). PCBs are also unintentionally produced as by-products in the synthesis of organochlorine compounds, e.g. colour pigments (to be distinguished from PCB paints) (Anezaki et al. 2014; Hu and Hornbuckle 2010) or chlorinated paraffins (Takasuga et al. 2012).

There are 209 possible PCBs, referred to as “congeners”, which are defined by the number of chlorine atoms (from 1 to 10) and their position in the chemical structure. Only a subset of these congeners is generally present in various matrices. Due their differences in physicochemical properties, degradation, metabolism and bioaccumulation potentials, the congener composition in environmental media varies and shows some difference from respective sources.

Twelve PCB congeners have a similar planar structure to dioxins and have “dioxin-like toxicity”. They are referred to as dioxin-like PCBs (dl-PCBs). The term “dioxins” in principle refers to a group of 75 polychlorinated dibenzo-p-dioxin (PCDD) and 135 polychlorinated dibenzofuran (PCDF) congeners, but only 17 of these compounds (7 PCDDs and 10 PCDFs) exhibit dioxin-like toxicity.

The 17 dioxin-toxicity relevant PCDD/Fs and the 12 dl-PCBs have common mechanisms of action and similar toxicity profiles, but their potencies vary greatly. Toxic equivalency factors (TEFs) have been developed to compare the toxicity of the various congeners and to assess the combined effect of PCDDs, PCDFs and dl-PCBs. The TEF of each individual compound is expressed in terms of the “Seveso-dioxin” 2,3,7,8-tetrachlorodibenzo-p-dioxin (2,3,7,8-TCDD). The TEFs used in the European Union (EU) legislation, by the European Food Safety Authority (EFSA) and by a number of other authorities, are those set by the World Health Organization (WHO)Footnote 1 (Van den Berg et al. 2006).

In 2001, the EU set maximum levels for PCDD/Fs in foodstuffs (European Commission 2001). From a toxicological point of view, any limit value should include both dioxins and dl-PCBs. Therefore, in 2006, the EU established maximum levels for the sum of PCDD/Fs and dl-PCBs, but for a transitional period the levels for PCDD/Fs only should apply in addition to the newly set levels for the sum (European Commission 2006). The “dioxin content” of the PCDD/Fs, the dl-PCBs and the sum of PCDD/Fs and dl-PCBs are calculated as PCDD/F-TEQ, PCB-TEQ and PCDD/F-PCB-TEQ, respectively. In food, often dl-PCB contribute more than 50% of the TEQ. The TEQ reservoir of the worldwide produced PCB quantity can be estimated at 11000 to 16,000 kg PCB-TEQ1998 (Weber et al. 2008).

The other PCB congeners do not exhibit dioxin-like toxicities, but they have a different toxicological profile. They are termed non-dioxin-like PCBs (ndl-PCBs). Detailed full congener-specific measurements can be time-consuming and costly for large studies. As total PCB composition is generally dominated by only a few congeners, measurements using a subset of indicator PCBs are often considered appropriate. European monitoring and regulatory agencies have chosen six ndl-PCB indicator congeners (PCB-28, -52, -101, -138, -153 and -180) for risk assessment requirements and health protection guidelines. The six ndl-PCB indicators were found to represent around 50% of the sum of the ndl-PCBs which were measured in the food samples (EFSA 2012).

Both ndl-PCBs as well as dl-PCBs are usually found in industrial PCB mixtures, in the environment and in feed and food. The high proportion of indicator PCBs and the congener patterns of dl-PCBs found in environmental samples indicate that industrial produced PCB mixtures are the major source of the contamination of the environment and human exposure (Takasuga 2001; Kim et al. 2004). Inverse seasonal trends between emissions of PCBs/dl-PCBs and PCDD/Fs provide evidence that the source of present PCB emissions are technical PCB mixtures and not emissions from combustion processes (LfU 2006). Comparison of concentrations in indoor and outdoor air and of chiral signatures in outdoor air and soil indicates that the principal contemporary PCB emission is from remaining sources in existing buildings and other structures and not re-emission from soil (Jamshidi et al. 2007).

Due to the persistent nature of PCBs, they continue to be present in fish, meat, poultry, dairy products and breast milk. Dietary intake is an important pathway of exposure to PCBs. However, there is increasing evidence to suggest that the presence of PCBs in indoor dust and indoor air constitute a significant risk to some portion of the population (Harrad et al. 2009; Knobeloch et al. 2012; Lehmann et al. 2015).

Different organisations have undertaken risk assessments of dioxins/dl-PCBs and developed a range of health-based guidance values (HBGV) (European Commission 2001): in 1998, the WHO established a TDI for PCDD/Fs and dioxin-like PCBs of 1–4 pg TEQ/kg body weight (bw) per day (WHO 1998). In 2001, the Scientific Committee on Food (SCF) of the EU established a tolerable weekly intake (TWI) of 14 pg TEQ/kg bw per week. This TWI is in line with the provisional tolerable monthly intake (PTMI) of 70 pg TEQ/kg bw per month set by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) in 2001. For (total) PCBs the WHO derived a tolerable daily intake (TDI) of 20 ng PCB/kg bw per day in 2003 (WHO 2003).

With regard to dietary intake, it was shown that a part of the German adult population still exceeds the TWI of 14 pg TEQ/kg bw for the sum of PCDD/Fs and dl-PCBs, as well as the TDI for total PCBs of 20 ng/kg bw (BfR 2010). In children, PCB intake is about 2.5-fold and in breast-fed infants about 50 to 100 times the adult intake (BfR 2008).

In order to effectively reduce the presence of PCBs and dioxins in foodstuffs, in 2011, the EU set maximum levels for the sum of the six indicator PCB congeners, in addition to the maximum levels for the sum of PCDD/Fs and dl-PCBs which were set in 2006 (European Commission 2006, 2011). In Germany, food monitoring of dl-PCBs and indicator PCBs has been intensified, in order to ensure compliance with the limit values. In this context, it has been increasingly established that, in particular meat and animal products from extensive livestock farming (cattle, sheep, laying hens), partly exceed the EU maximum levels for the sum of PCDD/F and dl-PCBs, even without specific contamination of feedstuffs. In most cases, the excess levels are caused by dl-PCBs (Weber et al. 2015a).

Information on remaining PCBs and present PCB release and information on the historic release and related contamination is needed to define potential actions in respect to further management and mitigation measures.

The German Environment Agency (UBA) therefore commissioned a study in 2013 to elucidate the entry pathways of PCBs and PCDD/F in food and feed. It could be demonstrated that current PCB emissions from buildings and constructions and related deposition on grass as well as contaminated soils and sediments from historic releases are major causes for contamination of feed and food-producing animals. This paper summarises the most important results of this study with regard to the large amount of remaining PCBs in open applications and the historic releases (PCB contaminated sites) along the life cycle of PCBs in closed and open applications. The experience gained in Germany from cases of contaminated food of animal origin is complemented with international experience.

Results and discussion

PCB quantities used in Germany and management and fate of PCBs

Inventory of historic and present PCB use

To get an overview and to understand the relevance of a chemical group an inventory need to be developed and current and future releases need to be understood. The German Environment Agency (UBA) commissioned or conducted studies for the development of PCB inventories of former production and use in Germany and related former management (Detzel et al. 1998; Goßler and Höhlein 1992; Knetsch 2012).

In Germany, 85,000 t of PCBs were marketed in various applications, 72,500 t thereof in West Germany and 12,330 t in East Germany (Detzel et al. 1998; Knetsch 2012). The contained amount of PCB-TEQ can be estimated to be about 425 to 1000 kg TEQ. This shows the potential for the contamination of the environment and food with dl-PCB when compared, e.g. with the current release of PCDD/F in Germany of approx. 60 g TEQ/year.

In West Germany, 48,000 t of PCBs were used in closed applications mainly in capacitors (13,000 t), transformers (23,000 t) and other electrical equipment and hydraulic fluids (12,500 t) (Detzel et al. 1998). Twenty-four thousand tonnes of PCBs produced by Bayer (Clophen mixtures) were used in open applications, in sealants/caulking, but also in paints/varnishes, cable sheaths, adhesives and other products and as lubricating oil (Detzel et al. 1998). From this, 20,000 t were used as plasticiser in sealants in the construction sector by the Thiokol company (Goßler and Höhlein 1992). Since Thiokol had also imported Aroclor from Monsanto for sealant production, the total PCB amount in open applications must be even higher than 24,000 t (Goßler and Höhlein 1992). The quantity of PCBs used in paints and anticorrosion coatings is unknown, but it could be significant. The use of PCB-containing corrosion protection paints in the open has so far been little studied in Germany, in contrast to Switzerland (BAFU 2015).

In the former East Germany, about 11,000 t of PCBs were used in capacitors. One thousand tonnes of PCBs were added as plasticizers to PVC paints and PVC sheathing of power cables in open application (Detzel et al. 1998).

In 1996, an EU directive obliged the Member States to remove PCB-containing equipment and liquids as soon as possible, by the end of 2010 at the latest. In 2004, the German Federal Ministry for the Environment reported that the “PCB exit in Germany is almost complete” (BMU 2004). However, open PCB applications were not mentioned and not included in the EU Directive. Although approximately one third of the PCBs used in West Germany were used in open applications, their removal took little notice.

In West Germany, the per capita use of PCBs in open applications was particularly high: It was about 375 g/person (a total of 24,000 t PCB). While, in East Germany, it was at 60 g/person (a total of 1000 t of PCBs), in Sweden at 10 to 50 g/person (a total of 100 to 500 t of PCBs, Sundahl et al. (1999)) in Switzerland at 280 g/person (a total of 2000 t of PCB, BUWAL (2000a)) and in Denmark at 263 g/person (a total of 1500 t of PCB, Egsmose et al. (2016)). In West Germany, higher PCB concentrations were measured in indoor air than in any other country in the world (Bräuner et al. 2016).

PCB-containing sealants/caulking and paints are exceptionally stable and still fulfil their purpose today. The buildings from the 1960s and early 1970s are mostly still present, including most of the PCB-containing sealants and paint (estimated 50 to 80% or 12,000 to 19,000 t of PCBs) (Weber and Herold 2015). In Switzerland, the remaining PCBs in sealants in 2017 is estimated to 34% (Glüge et al. 2017). This estimate is close to the lower estimate for Germany in particular when considering that the Swiss estimate is made for 2017, and the German estimate was made for 2013 and currently buildings of the 1960s and early 1970s are renovated or demolished. In Scandinavia, where a main PCB use was sealing material in double-glazed windowpanes, the amount remaining today is lower and estimated to approx. 10%. In Norway, for example, an environmentally sound disposal system has been guaranteed in a controlled return system, and the majority has now been disposed of (PEN Magazine 2010; Waerner 2015).

Estimation of PCB emissions from open PCB applications

Estimation of PCB evaporation from open applications in use in Germany

In a Swedish study, the proportion of the PCB quantity released annually by evaporation from PCB-containing elastic sealant used in joints between concrete blocks was calculated to be 0.067% for an eight-storey residential block (Sundahl et al. 1999). For a ten-storey university building in Germany, it was estimated from indoor air concentrations and air exchange rate that 600 g PCBs were released annually with the contaminated indoor air to the air outdoors (Weber and Herold 2015). This is six times above reporting limits for the Pollution Release Transfer Register (PRTR) of 100 g of PCBs/year (E-PRTR VO 2006). In this university building, about 1000 kg of PCBs were present in joint sealants and paints (“Wilhelmi” ceiling tiles) (Weber and Herold 2015). The quantity of PCBs (600 g/year) emitted from indoor air to the environment corresponded therefore to approx. 0.06% of the installed inventory. A similar annual emission rate, namely 0.05%, calculated Csiszar et al. (2013) from the PCB inventory (440 t) and the annual PCB release from the buildings of Toronto (230 kg/year). Thus, all three studies measured/estimated similar release rates of 0.05–0.067% per year for the release of PCBs from buildings.

Considering the estimated stock of 12,000 to 19,000 t of PCBs in open application in Germany and an annual evaporation rate of 0.06% this results in an emission of 7 to 12 t PCB per year from the remaining PCBs in open applications. This emission estimate is in agreement with deposition measurement and other emission estimates:

The PCB deposition in background stations in Bavaria (South Germany) was determined to 200 ng PCBs per square meter and day (LfU 2006). From this deposition rate, an annual total of 18 t of PCB would be derived for the area of West Germany (249,000 km2). This quantity of deposited PCB is in the order of magnitude of the estimated 7 to 12 t from desorption.

By means of air measurements, Bogdal et al. (2014) calculated the PCB emissions for Switzerland to about 1.5 t per year. Recalculating to the population of West Germany, this would correspond to an annual PCB emission of approx. 11.4 t. Since the per capita consumption of PCBs in open applications in West Germany (375 g per person) was one third higher than in Switzerland (280 g/person), the actual West German PCB emissions would be expected slightly higher at about 15 t and also in the order of magnitude of estimated desorbed 7 to 12 t PCB per year.

In the official German PCB emission inventory, an emission of 220 kg PCB/year is given. (Karl et al. 2010). However, in this study only the release of unintentionally formed PCBs from combustion sources and other thermal sources has been taken into account. The actual amount of PCB released per year is 30 to 60 times higher than the official figure stated in the emissions inventory. In environmental matrices (soil, air and grass), almost exclusively congener profiles of industrially produced PCBs (Takasuga et al. 2001) and virtually no congeneric profiles of unintentional thermally formed PCBs (Sakurai et al.2003) are found. This confirms the strong dominance of releases from remaining industrial PCBs as a source of emissions and that this emission must be manifold over the 220 kg of thermally unintentional formed PCBs.

This is also in agreement with measurements from Western Europe and North America studies documenting that significant quantities of PCBs are released from cities. For the cities of Toronto/Canada, Chicago/USA and Birmingham/England it was shown that the PCB plume reaches many kilometres to the surrounding area. Measurements from Zurich/Switzerland, Toronto and Birmingham demonstrated that in particular open PCB applications are responsible for the current emission and therefore for the atmospheric load (Diefenbacher et al. 2015, 2016; Csiszar et al. 2013; Jamshidi et al. 2007). Csiszar et al. (2013) determined the PCB release from the buildings of Toronto to 230 kg/year from air measurements. Diefenbacher et al. (2016) estimated the release in Zurich with 65 kg PCB/year and Gasic et al. (2009) with several 100 kg PCB/year.

Increased PCB release during refurbishment and demolition work

Due to weathering and wear, repair and maintenance work are increasingly necessary on PCB-containing buildings and other constructions (e.g. bridges, swimming pools, pylons, pipelines, dams, ships) built in the 1950s to 1970s. If construction measures are not carried out in a professional manner, larger quantities of PCBs are released uncontrolled within a few days into the environment than in the previous decades by desorption. In particular when removing PCB-containing paint and anticorrosion coating or cleaning facades with joint sealants by abrasive blasting or other not appropriate removal, large amounts of PCBs can be released and contaminate soils, sediments, water bodies and plants (Astebro et al. 2000; BUWAL 2000a, b; Der Westen 2013; Jartun et al. 2009; Knechtenhofer 2009; Russ 2016; Schwartz et al. 2016; Weber and Herold 2015). This release might even be larger than the annual 7 to 12 t of desorbed PCBs (Weber and Herold 2015).

Contamination of the environment from PCB-containing construction materials

The direct or indirect PCB intake of livestockFootnote 2 via PCB-containing building materials or recycling materials in the barn or on pasture land also led to excess levels in food of animal origin. In particular, soils and the vicinity of PCB-contaminated stables and buildings can be highly contaminated (see as follows). The PCBs released into the atmosphere from buildings and other constructions are transported to the near and wider surroundings by wind. The released PCBs are deposited by different atmospheric mechanisms including dust precipitation, leaching by rain or adsorption by plant surfaces.

The annual in West Germany emitted PCB quantity of 7–12 t (or more) demonstrates the potential relevance of open PCB applications for the contamination of the environment, especially in the vicinity of cities and urban areas. The higher contamination of grass/bioindicators in the surrounding of cities was shown by studies in permanent observation stations of Bavaria (Weber et al. 2017) and Baden-Württemberg (CVUA Freiburg 2013b). The mean dl-PCB concentration in grass, hay and silage in rural areas was 0.07 ng PCB-TEQ per kg dry matter (dm) and increased to above 0.1 ng PCB-TEQ/kg dm in sparsely populated areas and to 0.15 ng PCB-TEQ/kg dm in more populated areas (2005–2012) (CVUA Freiburg 2013b). In the monitoring station in Munich between 2002 and 2013, the average concentration in standardised grass cultures, which were exposed for 4 weeks, was 0.4 ng PCB-TEQ/kg dm (Weber et al. 2017). In the densely populated federal state North Rhine-Westphalia, the average content of grass is about 0.15 ng PCB-TEQ/kg dm (LANUV North Rhine-Westphalia 2010; Hembrock-Heger 2011). A content of 0.2 ng PCB-TEQ/kg dm and even slightly lower is already sufficient to exceed the EU maximum for total dioxin-like toxicity in meat from suckling calves (Fig. 1; see as follows).

Cumulative impact of grass and soil contaminated with dl-PCBs on exceedance of EU maximum levels for the sum of dioxins and dl-PCBs in beef and in veal from suckling calves. Concentrations above the solid line are critical for beef and concentrations above the dashed line can become critical for veal from suckling calves. (Weber et al. 2015a)

Pathways and sensitivity of food-producing animals for PCB exposure and critical levels

The relevance of contamination from an individual PCB source depends on the contamination of the surrounding. For livestock in particular, ingested contaminated feed and soil are relevant. The contamination of sediments has relevance for the exposure of fish, mussels and other aquatic food.

The sensitivity of livestock for PCBs depends on the intake of feed contaminated by pollutants from soil and atmosphere. An adequate evaluation is required of the contamination levels of grass and soil at which products of animal origin become contaminated above EU regulatory limits or above levels where consumption of meat or eggs leads to the exceedance of the tolerable daily intake for PCBs (Bell et al. 2016).

Sensitivity, risk and impact on beef

Cattle has been found particularly sensitive for PCBs (Hembrock-Heger 2011; Weber et al. 2015a). Cattle is taking up PCBs from feed (e.g. grass, grass silage or hay) and grazing cattle also from soil taken up during grazing. The amount of soil intake depends on the quality of the meadow/available amount of grass. For a high yielding meadow, a minimum share of 3% soil in ingested grass is considered. For meadows with short grass in dry season or dirty grass in muddy season, the proportion of soil might go up to 10% (BMU 2013; Bundesanzeiger 1999). A total intake of approx. 2 ng WHO-PCB-TEQ/day from both feed and soil might be critical regarding the risk for exceeding the maximum/upper limits for meat from beef (Fig. 1; Hoogenboom 2013). This is the case for beef and veal from suckler cow husbandry in particular when calves are suckling their mother’s milk for an extended period of several months to a year. Considering a normal consumption of 10 kg dm of grass/hay and the minimum soil content of approx. 3%, meat of these suckling calves can exceed the EU regulatory limits at relatively low soil levels (below 5 ng WHO-PCB-TEQ/kg dm; Fig. 1) in combination with grass/feed levels around 0.15 ng TEQ/kg dm. The critical grass levels are considerably below the EU regulatory limits for feed of plant origin of 1.25 ng TEQ/kg (moisture content of 12%) for the sum of PCDD/Fs and dl-PCBs.

This is observed on monitored flood plains in Germany with beef cow herds. Dl-PCB levels of soils varied between 2 and 5 ng WHO-PCB-TEQ/kg dm and in the feed in average between 0.13 and 0.17 ng WHO-PCB-TEQ/kg dm (below 0.2 ng WHO-PCB-TEQ/kg dm). The meat was above the EU regulatory limit of 4 pg TEQ/g fat for the sum of dioxins/furans and dl-PCB (Weber et al. 2015a). Also in other herds with dl-PCB levels resulting in exceedance of TEQ-limits in meat, where no point sources could be identified, relatively low soil levels (below 5 ng WHO-PCB-TEQ/kg dm) in combination with feed levels around 0.15 ng WHO-PCB-TEQ/kg dm seem to be responsible for the exceedance of EU limits for WHO-PCDD/F-PCB-TEQ in meat.

Sensitivity, risk and impact of chicken/eggs

Free-range laying hens and broilers ingest about 11 and up to 30 g soil per day (Hoogenboom et al. 2006; Waegeneers et al. 2009), and some recent studies have shown that dioxin and dl-PCB levels in eggs from free-range chickens frequently exceed EU food standards of 2.5 pg TEQ/g fat for PCDD/Fs or 5 pg TEQ/g fat for the sum of PCDD/Fs and dl-PCBs (Hoogenboom et al. 2016; Weber et al. 2015a, b) when soil concentrations are at levels around 2 to 4 ng PCDD/F-TEQ/kg (Kijlstra et al. 2007; Weber et al. 2015a, b). For chickens ingesting approx. 30 g soil per day, models indicate that soil levels around 2 ng TEQ/kg dl-PCB can be sufficiently high to reach or exceed the EU standards. This is particularly important for flocks of chickens spending a lot of time outside, as they have higher soil exposures and soil intake (Kijlstra et al. 2007).

The sensitivity of chicken in respect to PCB and PCDD/F exposure was already demonstrated by Hoogenboom in respect to feed where high transfer factors of around 50% for TEQ relevant PCBs and PCDD/Fs have been determined (Hoogenboom et al. 2006). Already a PCDD/F content of 0.4 ng PCDD/F-TEQ/kg feed resulted in exceedance of PCDD/F maximum level in egg (Hoogenboom et al. 2006). This demonstrated that the EU regulatory limit for feed (0.75 ng TEQ for PCDD/Fs and 1.25 ng TEQ for PCDD/F + dl-PCB) is not protective but should be lowered by a suggested factor of four (Hoogenboom et al. 2006).

A 4-year-old child weighing 16 kg would exceed the TWI (14 pg TEQ/kg/week) by consumption of a hen’s egg per day (avg. 7 g fat) even if the eggs complied with the EU regulatory food limit for the sum of dioxins and dl-PCBs (5 pg PCDD/F-PCB-TEQ/g fat). The current regulatory limit for soil for residential and recreational areas in Germany, for example, is 1000 ng PCDD/F-TEQ/kg dm (German BBodSchV 1999) (there is no limit for dl-PCBs). If chickens were kept on land with these levels of contamination, a typical ingestion of 11 g soil per day could result in eggs each containing approx. 800 pg TEQ/g fat. In this case, consumption of a single egg per day would lead to exceedance of the TWI for a 16 kg weighing child by approximately 175 times. It is clear, therefore, that consuming contaminated eggs can easily result in exceedances of health-based standards—especially for young children. Soil levels of > 5 ng TEQ/kg dm would certainly be too high and would require either that production be stopped or free-range access be restricted. It has therefore been suggested that the contamination levels in soil used for the production of free-range eggs should ideally be less than 2 ng TEQ/kg dm for PCDD/F and dl-PCBs. These maximum levels for establishing safe production of free-range eggs are below all current national soil standards and therefore present major challenges.

Consumption of eggs from free-range chickens kept in the vicinity of present and former PCB (and PCDD/F) emission sources is likely the most sensitive dioxin exposure pathway from soil to humans. Therefore, exposure assessments are needed for suspected contaminated sites and soils (Bell et al. 2016).

Sensitivity, risk and impact of other food-producing animal species

While there are estimates/assessments for chicken/egg and beef regarding soil and feed contamination levels that are critical for EU regulation limits (described previously), no similar detailed assessments on uptake of dioxins and PCBs have been conducted for other food-producing animals. Kamphues and Schulz (2006) categorised food-producing animals according their exposure risk to PCDD/F in soils which is similar to exposure to PCB from soils. They listed wild boars or pigs housed outdoors in the highest exposure category together with chicken.

High concentrations of PCDD/Fs and some dl-PCBs were detected in livers of mammals, but also in livers of birds and fish. It has been found that for more than 90% of the German sheep the TEQ levels in liver were above the former EU regulatory limit and liver was therefore not marketed (Basler 2009). PCDD/F and dl-PCB levels in liver of German deer and wild boar are high and are elevated in some meat (BfR 2011; Weber et al. 2015a). The EFSA Panel on Contaminants in the Food Chain (CONTAM Panel) concluded that “frequent consumption of deer liver, especially for high consumers may be of health concern” and that “frequent consumption of sheep liver, particularly by women of child-bearing age and children, may be a potential health concern” (EFSA 2011).

Regulatory soil limits and critical concentration

The levels in feed at which beef or chicken meat/eggs can become contaminated above EU food limits is below the set limits for feed (Hoogenboom et al. 2006; Weber et al. 2015a, b). Furthermore, no limits for dl-PCBs in soils have been developed in Germany or elsewhere. For PCDD/F, it was assumed that 5 ng TEQ/kg is protective for all food-producing animals and is a target value (Bund/Länder-Arbeitsgruppe Dioxine 1992). The above compiled information show that for chicken and also for cattle soil, levels of 5 ng PCB-TEQ/kg dm are not protective in respect to EU food limits. For chicken, also PCDD/F levels in soils of 5 ng TEQ/kg are not protective and can lead to exceedance of EU limits in eggs and meat (Weber et al. 2015a, c).

This setting can result in the situation that chicken holders have dl-PCB-contaminated eggs/meat above regulatory limit, but the levels which are measured and evaluated by the authority do not indicate exceedance of regulatory limits in feed or soil. From a regulatory perspective, these levels in feed and soil are not considered as contamination. The polluter (e.g. the transformer factory or the metal smelter or the shredder plant) responsible for elevated levels in soil/feed is then not considered responsible for the contamination of the food-producing animal or the food product.

Therefore, regulatory limits for soils (and possibly feed) for PCBs (and PCDD/F) need to be updated so that limits in soil and feed are in agreement with regulatory limits for foods of animal origin.

Exposure to PCB along the life cycle and related knowledge gaps

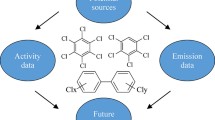

Food-producing animals and related products (meat, milk and eggs) can become PCB contaminated along the life cycle of PCBs (Weber et al. 2015a; Fig. 2). In this section, the PCB contamination of the environment and materials along the life cycle (production – use in production – product use – recycling – end of life; see Fig. 2) is described together with experiences of PCB food contamination in Germany and other countries.

Life cycle of PCBs and related releases to the environment and exposure to food-producing animals (Weber et al. 2015a)

PCB production sites and related contamination and exposure

PCB production sites were large emitters of PCBs with associated contamination of the production sites, the landfills and the wider environment including animals and population (ATSDR 2015; Kocan et al. 2001; Turrio-Baldassarri et al. 2009; Wimmerova et al. 2015). For the former PCB production site in Michalovce in eastern Slovakia, elevated human exposure was found up to 70 km in the prevailing wind direction from the plant with food-producing animals as likely major human exposure pathway (Wimmerová et al. 2015). Assessment of details of soil contamination in the larger surrounding of most production sites has not been conducted yet with the exemption of the Italian production site in Brescia where research projects were and are conducted. For some sites, no information on contamination was available at all. The East German PCB production site (Deutsche Solvay Werke, Westeregeln) where the factory was destroyed by a major fire 15 January 1961 (Heinisch et al. 2003; Berliner Zeitung 1994). The PCB and PCDF releases from this fire could have been substantial and contamination might be relevant but no assessment has been reported. Also for the large production of the Bayer Company in Leverkusen in West Germany, no documentation of associated pollution has been published (Weber et al. 2015a).

Considering the documented wide impact from the releases of the production facilities where assessment has been conducted like the Slovakian or Italian former PCB production sites, the contamination status of all production sites should be assessed.

PCB using industries and related contamination and exposure

Some production industries have used PCBs for the production of transformers, capacitors, paints, sealants, flooring, paper or textiles. Such companies have used PCBs in 100 to 1000 t scale with associated releases and contamination. In the two capacitor-producing factories in East Germany, about 580 t of PCBs from the 11,243 t used in production have been lost during handling.

In a recent study, the hens’ eggs (composite of 10 eggs) were sampled from two private chicken farmers (A and B) close to a factory in Teningen/West Germany where capacitors were produced from 1932 on, including PCB containing capacitors for some time. It was known that the groundwater below the former production site and below the associated dumping area is contaminated with PCBs and that a PCB plume contaminates the ground water of the nearby town (Weber et al. 2015b). The egg samples from chicken holder A were highly contaminated with dl-PCBs of 25 pg PCB-TEQ/g fat and a total TEQ of 36.4 pg TEQ/kg fat for the sum of dl-PCBs and PCDD/Fs. The levels in eggs from chicken farmer B had similarly high dl-PCB levels of 25.5 pg PCB-TEQ/g fat and a total TEQ of 31.9 pg TEQ/kg fat. The competent authority was then tested the soils in the area for dl-PCBs and PCDD/Fs and found 2.3 ng PCB-TEQ/kg (0–5 cm) and 3.3 ng PCB-TEQ/kg (5–10 cm) at farm A and 4.4 ng PCB-TEQ/kg (0–5 cm) and 3.8 ng PCB-TEQ/kg (5–10 cm) at farm B. Soil levels were significantly above German background levels of approx. 0.5 ng PCB-TEQ/kg (Bussian et al. 2013). However, soil ingestion with the average measured level of PCB could not explain this very high contamination of the eggs. Possibly, the upper layer of the soil had higher PCB levels. Furthermore, fish were analysed in the receiving water from the company which was used by the local fishing association. In an eel, a high dl-PCB level of 259 pg WHO-TEQ/g fresh weight was found (CVUA Freiburg 2013a). With a 200-g portion of the eel, an adult ingests a dioxin dose that is equal to his tolerable intake for 1 year, and for a child, a 100-g portion contains as much dioxin as can be tolerated for intake in 2.2 years. Although contamination potential from the factory was known and although direct receiving waters and close surrounding was used for food production, for more than 30 years, no assessment of food-producing animals has been conducted.

In Switzerland, another capacitor factory had disposed capacitors in a landfill. Leaking capacitors released PCBs over the decades and contaminated a river and associated fishes up to a distance of approx. 40-km downstream of the landfill (Zennegg et al. 2010a, b).

These cases highlight that factories having used tonnes of PCBs in the past need to be monitored in respect to current pollution situation and levels in food produced from animal in the surrounding.

Industries having used PCB containing equipment and related contamination and exposure

A range of industries have used PCB containing equipment or PCB oils. This includes, for example, high energy-consuming industries like metal industries or power companies. Normally, the largest share of PCBs is with the energy companies operating the electricity grit. Contaminations occur at the areas where transformers are operated or get maintenance and at storage areas of old transformers and other PCB containing equipment.

However, also the inventory of a steel work in Austria revealed that 106 t of PCBs have been used in transformers and capacitors at a single plant (Maderner and Hobiger 1996). For another large steel plant in Italy, 1000 transformers were in operation. Around the Italian steel plant, PCB (and PCDD/F) contamination of cattle above EU regulatory limits had been discovered and 1600 sheep/goats needed to be slaughtered. In a radius of 20 km around the steel plant, grazing cattle is now banned (Diletti et al. 2009; Esposito et al. 2010, 2014; Liberti 2014). The PCB contamination of the soil (average 3.3 ng PCB-TEQ/kg dm within the 5-skm zone; maximum 25 ng PCB-TEQ/kg dm) stems mainly from the historic fugitive PCB-emissions of the PCB-equipment on the site (Liberti 2014). PCB transformers have an average yearly leakage rate of 0.06 to 0.3 kg/t (EMEP/EEA 2009; UNEP 2013). A company demolishing PCB equipment was also located in the vicinity (Liberti 2014).

Metal industries have used PCB containing metal cutting oils (UNEP 1999). PCBs have been released from this open application and metal residues containing such oils have most likely ended up in sinter plants recovering such oily metal waste with associated releases.

A secondary metal smelter in Switzerland was responsible for the contamination of a river and associated fishes in Switzerland (Zennegg et al. 2010b). For secondary smelters, PCB release is not only from operating equipment but, in addition, can result from metal scrap containing PCB paints and anticorrosion coatings, (small) capacitors or other metal scrap contaminated with PCBs (see also as follows).

The egg monitoring of the International POPs Elimination Network (IPEN) detected high TEQ levels (dl-PCB and PCDD/F) in eggs around metal industries (Di Gangi and Petrlík 2005; Petrlik 2015). For such point sources, the extent of the pollution has been revealed and most eggs (> 90%) were above the EU TEQ limit (Di Gangi and Petrlík 2005; Petrlik 2015).

PCBs have also been used in military for different applications (hydraulic and transformer oils, paints for equipment/vehicles and sealants) (Fonnum et al. 1998; Krueger 2009; Jartun et al. 2009; Schaaffhausen Von and Gramenz 1993; Weber et al. 2015a). One of the contaminated beef herds in the German monitoring was from a rehabilitated military area. PCB soil levels on the area were in average 2 ng PCB-TEQ/kg dm with levels up to 5.6 ng PCB-TEQ/kg dm (Wahl et al. 2013) indicating the relevance of PCB contamination on (former) military areas in Germany. PCB contamination has also been reported from US/NATO bases indicating that this is an international issue (Fonnum et al. 1998; Krueger 2009).

PCB were also used in large volumes in the mining industry as hydraulic oil. In Germany from the approximately 12,500 t of PCB used in mining, only 5% has been managed appropriately (Deutscher Bundestag 1989) and the remaining has been released into the mines (Detzel et al. 1998). From pumped water, PCBs are leaking into rivers and in the German mining areas in North Rhine-Westphalia and Saarland high levels of PCBs in fish have been documented with eel unfit for human consumption (Guhl et al. 2014; IKMS 2005). In North Rhine-Westphalia, flood plains are contaminated with PCBs and grazing cattle exceed the EU food regulation limit (Hembrock-Heger 2011; Weber et al. 2015a). It needs to be stressed that, in addition to mining, the PCBs in sediments and flood plains in North Rhine-Westphalia originate also from other sources including large chemical industries (Heinisch et al. 2006, 2007) and most likely also metal industries and releases from open applications (Weber et al. 2015a).

PCB use in open applications and related contamination and exposure

Direct exposure to PCBs in stables and on the farm

PCBs from “open applications” (paints, coatings and sealants) have been used also on farms. Already in the 1970s/1980s, it had been discovered that PCB paints used in fodder silos had contaminated cattle (Willett and Hess 1975; Deutscher Bundestag 1989). However, cases of meat or eggFootnote 3 contamination above EU regulatory limits caused by PCB paints on farms were recently discovered:

-

in Germany—paints on asbestos roof and in silos and PCBs in a rubber conveyor belt have contaminated chicken/eggs and beef (Weber et al. 2015a; Winkler 2015)

-

in Netherlands—paints on asbestos roof contaminated chicken/eggs (Hoogenboom et al. 2014)

-

in France—the paint on a metal surface has contaminated pork meat (Marchant 2017)

-

in Switzerland—paints on the wall of the stable contaminated a beef herd (Zennegg et al. 2014)

This demonstrates the contemporary relevance of PCBs in open applications for food-producing animals in particular paints present in stables and the surrounding area.

PCB release from open application to the wider environment and related contamination

PCB in open application can be released into the environment in large volumes in particular by abrasive (sand) blasting. In 2015, PCB contamination of the river Elbe was caused by the inappropriate removal of paints. Despite enclosure of the working area, approx. 330 kg PCBs were released into the river Elbe. PCB-contaminated sediments with related fish contamination potential moved towards the Port of Hamburg (distance of 500 km). Here every year, approximately 3 million m3 of sediments have to be removed from the waterway to secure access for seagoing vessels. PCB-contaminated sediments are not allowed to be dislocated into the open sea. Shipping traffic in the biggest German harbour was at risk to stop if the contaminated sediments were not removed in the upstream area (Schwartz et al. 2016).

In Norway, the sandblasting of PCB paint of the Puddefjordsbroen bridge released 1650-kg PCBs to the marine environment and contaminated the sediments under the bridge heavily (Jartun et al. 2009). Also, the blasting of paints from a dam in Switzerland has recently contaminated the river Spöl and related fishes (Russi 2016).

These releases to the aquatic environment reach partly the marine environment and add to the historic contamination of sediments and accumulate to the high contamination of marine top predators (mammals, fish, birds) which are partly at the risk of extinction (Stuart-Smith and Jepson 2017).

Releases from paints and sealants are also contaminating the terrestrial environment. The releases from buildings (Herrick et al. 2007; Weber and Herold 2015), pylons (LfU 2011) and road marking (Jartun et al. 2009) have also resulted in exposure of cattle (Weber et al. 2015a).

It needs to be highlighted that the Swiss experience revealed that even when the working area during removal of anticorrosive coatings was enclosed for secured removal, 5–10% of the coating were lost (BUWAL 2000a, b).

Recycling of PCB containing oils and wastes and related exposure

PCB containing oils in transformers and capacitors were not always properly handled and disposed. For Germany, it was estimated that 30 to 50% of the PCBs in closed applications were not appropriately managed (Detzel et al. 1998). PCB oil can enter oil recycling cycles and has in some cases contaminated feed and related meat and other animal products. The largest and most costly (approx. US$1 billion) PCB/Dioxin food scandal occurred in Belgium in 1999 where PCB oil was mixed with food fat impacting meat and eggs from more than 1500 farms (Fiedler et al. 2000; Van Larebeke et al. 2001). Another large meat contamination case with associated US$100 million damage cost resulted from use/recycling of PCB-contaminated oil for drying of animal feed. Irish pork/meat got contaminated and had to be recalled (Heres et al. 2010; Marnane 2012).

In Europe, the largest shares of PCBs in closed applications have been managed. But worldwide, in particular in developing countries, still 14 million t of PCB contaminated oil and equipment exist and need to be managed (UNEP 2017). Such oils are partly recycled in an uncontrolled manner (Wijegunasekara et al. 2015). However, almost no monitoring of PCBs in food is established in developing countries and meat or other food contamination is normally not discovered.

PCB exposure of food-producing animals from waste treatment and contaminated soils

At the end of life, considerable amounts of PCBs have been released and have contaminated the environment and especially soil (Detzel et al. 1998; UNEP 2013). In recent surveys in Germany, contaminations of beef meat from a range of sources mainly related to soil contamination were discovered (Weber et al. 2015a):

-

Application of sewage sludge from 1960s to 1970s

-

Contaminated sediment deposits on agricultural land

-

Construction debris scattered and incorporated into soil of a pasture area

-

Use of a PCB-contaminated former scrap yard as storage area for dung

-

Landfills where partly PCB-containing waste had been disposed

Application of sewage sludge

Sewage sludge, in particular in the1960s and 1970s, has been contaminated with PCBs.Footnote 4 Sites where such sludge has been disposed can have elevated PCB (and PCDD/F) levels (Umlauf et al. 2004). At a German reference site, sewage sludge has been yearly applied on soil since the 1950s. At the start in the 1950s, PCB levels were low (< 0.5 ng PCB-TEQ/kg dm). PCB-TEQ strongly increased at the end of the 1960s/early 1970s to around 4.5 ng PCB-TEQ/kg dm (Umlauf et al. 2004) when PCBs in open applications were at their peak use. At a German pasture land that had been amended with sewage sludge in the 1960/1970s, soil levels were 31 ng PCB-TEQ/kg dm and a sheep herd grazing on the meadow had meat levels above EU regulatory TEQ limits (Körner et al. 2011).

Sediment disposal

At another pasture land where sediments had been disposed in the past dl-PCB levels where 3.9 to 6.4 ng TEQ/kg dm and meat of a beef cattle herd grazing on the land was above EU regulatory limit (Wahl et al. 2013).

Shredder plants

The release of PCBs from metal shredders is still high. Biomonitoring with rye grass around three shredder plants in Bavaria/Germany showed high levels up to 85 ng TEQ/kg dm, and all measurements were considerably above EU regulatory limits for feed (1.25 ng TEQ/kg dm) and therefore unfit for food-producing animals (LfU 2009).

Scrap yards

Scrap yards are potentially PCB contaminated areas (MacKnight 1991). The highest contamination can be expected for sites used to store PCB equipment. However also “normal” scrap yards are impacted to some extent by PCB contaminated scrap and related releases. In a German study on the contamination of a cattle herd, it was found that PCBs had been transferred by horse dung stored on a former scrap yard and lead to PCB contamination on pasture land (Weber et al. 2015a).

Construction debris

Construction debris from buildings erected in the 1950 to 1970s can be contaminated with PCBs and is partly used for landscaping including areas of farms (for farm tracks) and has also been found to lead to contamination of cattle (Weber et al. 2015a).

Flood plains of rivers

In the past, PCBs and other POPs have been released to rivers as one mean of “waste management” with associated contamination of sediments (Forter 2000; Heinisch et al. 2006, 2007; Förstner et al. 2016). During flooding events, contaminated sediments are translocated to floodplains of the rivers. In recent years, flood plains of rivers with historic industrial inputs were discovered as possible exposure pathway of PCBs and PCDD/Fs for cattle in Germany and the UK (Hembrock-Heger et al. 2013; Lake et al. 2014; Schulz et al. 2005). Dl-PCB levels in soils of flood plains of several rivers in Germany were unfit for cattle grazing or for chicken/egg production (Fig. 3); and caused contamination of meat of beef and sheep (Hembrock-Heger et al. 2013; Weber et al. 2015a).

dl-PCB levels in soils of flood plains of rivers from three German federal states (federal states marked in different colours) (Weber et al. 2015a)

Landfills and dump sites

A considerable share of PCBs has been disposed to landfills in Germany and elsewhere. Also areas around landfills can have elevated PCB levels. Chicken eggs from two herds (each pooled egg samples) close to the hazardous landfill Eyller Berg had 10.4 and 8.7 pg TEQ/g fat. This is twice the regulatory limit. Major contribution was from dl-PCBs. The competent authority of the federal state had already conducted a soil screening for PCB and PCDD/F around the landfill in 2012. Dl-PCBs were between 3.1 und 6.6 ng WHO-PCB-TEQ/kg dm (LANUV 2012). This is about 6 to 10 times above background dl-PCB levels of soil of German pasture land (Bussian et al. 2013) and is sufficiently high to explain the contamination levels in the eggs (see previous section).

In the Campania region in Italy, large amount of wastes have been dumped and burned in the open. Concentrations of the six indicator PCBs in milk from sheep in the region are above the European maximum residue limit with associated health risk for humans (Ferrante et al. 2017).

Measures to control and reduce PCB contamination in food-producing animals

Inventory and related assessment of impact of individual (main) sources

A basis for the management of contaminated areas is an inventory of potentially contaminated sites on a national level. Then, it must be assessed if these areas are used for animal food production and if there is exposure of animals and related food contamination. In these assessments, the extent of contamination from individual emission sources in respect to critical PCB contamination in soil and levels in grass/feed need to be determined.

Inventories are needed for PCBs in open applications so that they can be appropriately controlled and managed.

In the frame of the Stockholm Convention, inventories for PCBs in closed applications are developed indicating that still 14 million t of PCB-contaminated oils and equipment exist and need to be managed. PCB in open applications have been acknowledged as relevant sources but have not yet been included in inventories due to the lack of guidance documents. Therefore, guidance documents are needed for assessment and inventory of PCBs in open applications to assess and clarify the relevance of PCBs in open applications for countries and regions.

For PCB/POP-contaminated sites, international guidance documents have been developed, e.g. by UNIDO and by UNEP (UNIDO 2011; UNEP 2013). The BAT/BEP and Dioxin toolkit group has recently highlighted the need to assess POP-contaminated sites in respect to food safety (Bell et al. 2016). Within national implementation plans (NIPs), the 181 Parties/countries to the Stockholm Convention also address POPs contaminated sites and preliminary inventories with potentially contaminated sites have often been developed. However, in most developing countries, no monitoring capacity is available to verify contamination. Here, further information and global support are necessary. The current compilation on PCB contaminated sites along the life cycle in this publication might be a useful information for a structured list of potentially PCB contaminated sites.

Management measures and support for farmers

In the German survey, beef meat not complying with the maximum level for PCBs was in most cases only slightly above the regulatory limit (Weber et al. 2015a). Therefore, management measures to reduce exposure in impacted areas might be sufficient for further use by food-producing animals. For example, it has been found for a herd of suckling cows that the TEQ values in the meat decrease after weaning. Extending the duration between weaning and slaughtering might therefore be a relevant factor for reducing the PCB levels in meat (Fig. 4; Wahl et al. 2013).

Studies have shown that it is possible to decrease levels for PCDD/F in beef by feeding non-contaminated feed in the fattening phase before slaughtering (Ungemach 2013). A similar way was found for reducing PCBs in pigs (Marchant 2017). This reduction is mainly due to accretion of body mass diluting the earlier load from the higher PCB intake when suckling milk (Fig. 4) or from high exposure to PCDD/F on contaminated land before fattening in the stable (Ungemach 2013).

The selection of appropriate feed for production on an impacted areas can reduce exposure. For example, it is possible to grow maize (whole plant; high cut technique) on contaminated soils with low transfer of pollutants to the feed (Kamphues and Schulz 2006). Also optimising harvesting technique (e.g. cutting heights) of fodder on contaminated soils can result in a reduction of dioxin contamination on grass/green fodder from soil (Kamphues and Schulz 2006).

For reducing the impact of PCB contamination from atmospheric deposition, the PCB sources need to be better controlled and eliminated. Here, the remaining PCBs in open application need to be appropriately removed, when constructions reach end of life or are being renovated. The removal of paints and anticorrosion coatings needs particular care considering available guidance documents (currently only in German). The remaining open application of PCBs on farms (PCB coated silos, PCB painted asbestos roofs and PCB paints in stables) needs to be assessed and removed in an environmentally sound manner.

It needs to be mentioned that after the PCB ban, PCBs in PVC coatings and related paints have often been substituted by chlorinated paraffins which likely result in exposure today.

The measures mentioned show that there are options to control PCB pollution. The objective is to ensure that food products of animal origin stay or can be reduced below maximum PCB (and PCDD/F) levels. More research is needed on management and control options and their effectiveness and limitations (Weber et al. 2015c). Also, further research is needed to conclude on the suggested critical dl-PCB (and PCDD/F) levels in soil and feed with regard to resulting levels in meat and other animal products. Some initial assessment for sheep/goat have been made (Hoogenboom et al. 2015; Ounnas et al. 2010) but is completely missing for pigs in this respect. It should be examined if there are species or breeds with lower soil uptake or high metabolism capacity. A different elimination capacity after treatment of TCDD, 4-PeCDF and PCB-153 in genetically different strains of mice was shown by Diliberto et al. (1999). Robust knowledge has to be established at what soil and feed level what type of food-producing animals reaches critical levels in food products (meat, eggs, milk) and what management measures for intervention are available for the farmers.

The topic of PCB (and PCDD/F) contamination of the environment and farms in respect to food safety is complex and farmers with impacted food-producing animals need support from experts for solving contamination problems. Appropriate knowledge and capacity need to be built in agricultural ministries and related institutions. The federal state of Niedersachsen/Germany and Netherlands (RIKILT) have established a competence team to assess causes of contamination on farms and to give advice to farmers. Here, experience should be compiled and possible fed into international guidance documents (see the following section).

Available guidance documents and potential to minimise exposure

To support and ensure safe food production and to avoid PCB and PCDD/F contamination of food of animal origin (meat, milk and eggs), some international and governmental institutions have published guidance documents/recommendations. On an international level, the “Code of Practice for the Prevention and Reduction of Dioxin and Dioxin-like PCB Contamination in Food and Feeds” has been published in 2006 (FAO 2006). Several documents were published on EU level, e.g. “Evaluation of the Occurrence of PCDD/PCDF and POPs in Wastes and Their Potential to Enter the Food Chain” (Fiedler 2001) or “Guidelines for the enforcement of provisions on dioxins in the event non-compliance with the maximum levels for dioxins in food” (DG Sanco 2004). These international documents might need an update in respect to the concentration levels of soil and feed at which certain food-producing animals can become contaminated above levels of exposure concern and regulatory limits. Findings on the PCB life cycle and related risk of exposure could be a valuable information for guidance documents to be considered within an update.

In Germany, guidance documents have been developed on national level and on federal state level. For the example, the German Environmental Ministry has published a guidance on “Environmental protection—pillar for food safety to avoiding dioxin and PCB entry” (BMU 2013). The Chamber of Agriculture of the federal state of Lower Saxony published a leaflet for beef and milk producing farmers to control dioxin and PCB entry, and there is information on cultivation/feed production on contaminated land (Landwirtschaftskammer Niedersachsen 2011, 2014). These documents already include some details on sources and their control and also some management measures. This information might be useful additions for international guidance documents and helpful to implement precautionary measures and finally to raise awareness.

Consideration and control of persistent and toxic substitution products to PCBs

PCBs have been substituted by chlorinated terphenyls, tetrachlorobenzyltoluenes (Ugilec), PCNs, chlorinated paraffins and other non-halogenated alternatives (e.g. mineral oils; silicones). The structural similar alternatives (chlorinated terphenyls; Ugilec; PCNs) were also similarly persistent and toxic (Filyk 2004; Jakobsson and Asplund 2000; Murk et al. 1991) and can be considered regrettable alternatives (Fantke et al. 2015). Therefore, chlorinated terphenyls, PCNs and Ugilec were used only shortly longer as alternatives and the uses have also stopped in the 1980s. The last use of PCNs has been recorded around 2000 (Filyk 2004; Secretariat of the Stockholm Convention 2017). However, chlorinated paraffins are still primarily used in open applications (Glüge et al. 2016) even in baking ovens and kitchen blenders (Gallistl et al. 2018; Yuan et al. 2017). Recently also short chain chlorinated paraffins have been listed as POPs in the Stockholm Convention with a wide range of exempted uses and will be likely used further in high amounts. It is estimated that today, approx. 165,000 t of SCCP are still produced and used and even higher amounts of MCCPs (Glüge et al. 2016). SCCP and MCCP are also bioaccumulate in (food) animals (Ueberschär and Matthes 2004; Zeng et al. 2015) and humans (Xia et al. 2017). Their exposure pathways should be assessed along the life cycle similarly to PCBs (Fig. 2). Use should be controlled to minimise exposure and contamination of food-producing animal as well as human contamination. When assessing potential PCB contaminated sites and buildings also these PCB alternatives should be assessed for their potential relevance.

Further evaluation of human toxicity

The major dl-PCB TEQ-contribution in feed and food stems from PCB 126 (normally > 80 to 97%). Results from human cell systems in an EU-Project (EU-SYSTEQ) indicated a re-evaluation of the WHO-TEF of PCB-126, since the human cell lines had 10 to 100 lower dioxin-like activity compared to the current WHO-TEF of 0.1 (European Commission 2014). On the other hand, PCBs have been listed as carcinogen class 1 by the International Agency for Research on Cancer in 2013 (IARC 2015) and therefore PCB exposure needs to be minimised.

Conclusions

The assessment of the life cycle of PCBs demonstrates the generation of contaminated sites along all life cycle stations. Even for an industrial country like Germany, where PCBs have been widely used and monitoring capacity exist, the contamination of food products of animal origin for human consumption is rather detected by chance and not by systematic assessment.

Furthermore, soil levels which have hitherto been considered as low (below 5 ng TEQ/kg dm) can contaminate food products of exposure sensitive animal above EU regulatory limits. EU maximum levels for feed and food were set according to the principle “strict but feasible”, i.e. they are based on actual levels reported by member states. Therefore, maximum levels are not necessarily protective. In fact, levels of dl-PCBs (and dioxins) in feed, which are below the maximum limits for dioxins and dl-PCBs, may lead to the exceedance of the limit in meat.

Chickens and egg are likely to be the most sensitive exposure pathways for human exposure via contaminated soils and should be used to define soil limits.

The PCB-TEQ is higher than the PCDD/F-TEQ in most food products of animal origin. Levels in eggs and in meat/milk can make a large contribution to the TWI and can even surpass it, in particular for children, and especially for breast-fed infants. Levels of PCBs and/or levels of dioxins and dl-PCBs in fish and in animal liver are generally high (EFSA 2012) and with one single meal the respective TDI and/or TWI can be exceeded by far. This causes concern, considering that the TWI for dioxins and dl-PCBs has been derived from adverse effects in animals with an uncertainty factor of only 10 (EFSA 2015).

Emissions from PCB sources will have to be reduced if the TDI/TWI is to be met.

Feed and food safety can be improved by

-

Development of inventories of PCB (and other POPs) contaminated sites and their securing and, where feasible, remediation.

-

Development of the inventory and management of PCBs and other persistent and toxic alternatives (e.g. chlorinated paraffins) in open applications.

-

Improvement of the management of PCBs in open applications at the end of life (e.g. removal of paints, coatings and sealants when buildings are renovated or demolished).

-

Assessment and management of open PCB applications on farms, and guidance how to handle paints and other contaminated materials.

-

Implementation of management measures for the exposure reduction for farm animals.

-

Assessment of current soil standards for PCBs (and for PCDD/Fs) and a related update for the use of land for food-producing animals foraging outside.

For most of the areas with relative low PCB contamination, the implementation of management measures can likely result in a continued use of these areas for food production and improve feed and food safety. The German R&D project (Weber et al. 2015a) has demonstrated that cooperation and a systematic approach between the agricultural ministry/authorities and environmental ministry/authorities is necessary to tackle this complex issue of exposure of food-producing animals to PCB/POPs pollution. In the German law for food and feed (LFGB 2013), the official control of the competent authority already requires to consider the environment (soil, air, water) and therefore requires this joint responsibility.

The relevance of PCB-contaminated sites and of PCB emissions on the food safety gives one more reason to accelerate the management of the remaining approximately 14 million t of the PCB-contaminated oil and equipment globally. This can contribute to several Sustainable Development Goals (SDGs), in particular, Goal 2: end hunger, achieve food security and promote sustainable agriculture; Goal 3: ensure healthy lives; Goal 11: make cities and human settlements inclusive, safe, resilient and sustainable; Goal 12: ensure sustainable consumption and production patterns and Goal 15: protect, restore and promote sustainable use of terrestrial ecosystems (Bell et al. 2016).

Notes

including poultry

If an egg is above the EU regulatory limit, also the chicken meat is above the regulatory limit.

References

Anezaki K, Kannan N, Nakano T (2014) Polychlorinated biphenyl contamination of paints containing polycyclic- and Naphthol AS-type pigments. Environ Sci Pollut Res Int. https://doi.org/10.1007/s11356-014-2985-2986

Astebro A, Jansson B, Bergström U (2000) Emissions during replacement of PCB containing sealants—a case study, Organohalogen Compd 46. http://www.dioxin20xx.org/pdfs/2000/00-21.pdf

ATSDR (Agency for Toxic Substances & Disease Registry) 2015 Anniston Community Health Survey. https://www.atsdr.cdc.gov/sites/anniston_community_health_survey/overview.html

BAFU (2015) PCB in Korrosionsschutzbeschichtungen, Schweizer Bundesamt für Umwelt. https://www.bafu.admin.ch/bafu/de/home/themen/chemikalien/fachinformationen/chemikalien--bestimmungen-und-verfahren/pcb/pcb-in-korrosionsschutzbeschichtungen.html

BaslerA (2009) Evaluierung des Forschungsbedarfs zur Ursachenaufklärung der Kontamination bestimmter Lebensmittel mit Dioxinen und PCB. Förderkennzeichen (UFOPLAN) 370963224

Bell L, Weber R, De Borst B, PaunMC, HoloubekI, WatsonA, Vijgen J (2016) Assessment of POPs contaminated sites and the need for stringent soil standards for food and feed safety. Working document for UNEP Dioxin Toolkit and BAT/BEP group. October2016

Berliner Zeitung (1994) Brände und Explosionen brachten Gift und Tod. Ausgabe02.03.1994

BfR German Federal Institute for Risk Assessment (2008) Vorgeschlagene EU-Höchstgehalte für nicht dioxinähnliche polychlorierte Biphenyle (ndl-PCB) sind noch immer zu hoch, Aktualisierte Stellungnahme Nr. 029/2008 des Bundesinstituts für Risikobewertung (BfR). http://www.bfr.bund.de/cm/343/vorgeschlagene_eu_hoechstgehalte_fuer_nicht_dioxinaehnliche_polychlorierte_biphenyle_nd_pcb_sind_noch_immer_zu_hoch.pdf

BfR German Federal Institute for Risk Assessment (2010) Aufnahme von Umweltkontaminanten über Lebensmittel, Ergebnisse des Forschungsprojektes LExUKon, Bundesinstitut für Risikobewertung (BfR), 2010. http://www.bfr.bund.de/cm/350/aufnahme_von_umweltkontaminanten_ueber_lebensmittel.pdf

BfR German Federal Institute for Risk Assessment (2011) Dioxin- und PCB-Gehalte in Wild stellen keine Gesundheitsgefahr dar, Stellungnahme Nr. 048/2011 des BfR vom 16. Mai 2011, http://www.bfr.bund.de/cm/343/dioxin-und-pcb-gehalte-in-wild-stellen-keinegesundheitsgefahr-dar.pdf

BMU (2004) PCB-Ausstieg in Deutschland fast abgeschlossen, Pressemitteilung 174/04, ehemaliges Bundesministerium für Umwelt, Naturschutz und Reaktorsicherheit. http://www.bmub.bund.de/pressemitteilung/pcb-ausstieg-in-deutschland-fast-abgeschlossen

BMU (Bundesministerium für Umwelt, Naturschutz, und Reaktorsicherheit)2013Umweltschutz—Standbein der Lebensmittelsicherheit—Dioxin- und PCB-Einträge vermeiden. 5. aktualisierte Auflage, Januar 2013

Bogdal C, Müller CE, Buser AM, Wang Z, Scheringer M, Gerecke AC, Schmid P, Zennegg M, MacLeod M, Hungerbühler K (2014) Emissions of polychlorinated biphenyls, polychlorinated dibenzo-p-dioxins, and polychlorinated dibenzofurans during 2010 and 2011 in Zurich, Switzerland. Environ Sci Technol 48:482–490

Bräuner EV, Andersen ZJ, Frederiksen M, Specht IO, Hougaard KS, Ebbehøj N et al (2016) Health Effects of PCBs in Residences and Schools (HESPERUS): PCB–health cohort profile. Sci Rep 6

Breivik K, Sweetman A, Pacyna JM, Jones KC (2002) Towards a global historical emission inventory for selected PCB congeners—a mass balance approach: 2. Emissions. Sci Total Environ 290(1):199–224

Breivik K, Sweetman A, Pacyna JM, Jones KC (2007) Towards a global historical emission inventory for selected PCB congeners—a mass balance approach: 3. An update. Sci Total Environ 377(2):296–307

Bund/Länder-Arbeitsgruppe Dioxine (1992) Umweltpolitik—Eine Information des Bundesumweltministers. Rechtsnormen, Richtwerte, Handlungsempfehlungen, Messprogramme, Messwerte und Forschungsprogramme

Bundesanzeiger (1999) Bekanntmachung über Methoden und Maßstäbe für die Ableitung der Prüf- und Maßnahmenwerte nach der Bundes-Bodenschutz- und Altlastenverordnung (BBodSchV) von 18 Juni 1999. Bundesanzeiger Nr. 161a v. 28/8/99

BussianB, SchmidtS, UtermannJ (2013) Typische Gehalte von Dioxinen und dl-PCB in Böden, Fachgespräch „Dioxine und PCB: Bessere Daten—Schnellere Aufklärung“ Bonn 28.10.2013

BUWAL (2000a) Praxishilfe. PCB-Emissionen beim Korrosionsschutz, Schweizer Bundesamt für Umwelt, Wald und Landschaft 2000

BUWAL (2000b) BUWAL warnt vor nicht fachgerechten Sanierungen: PCB-Altlasten bilden ein Risiko für Mensch und Umwelt, Schweizer Bundesamt für Umwelt, Wald und Landschaft

Csiszar SA, Daggupaty SM, Verkoeyen S, Giang A, Diamond ML (2013) SO-MUM: a coupled atmospheric transport and multimedia model used to predict intraurban-scale PCB and PBDE emissions and fate. Environ Sci Technol 47:436–445

CVUA Freiburg (2013a)Untersuchungsergebnisse zu Dioxinen und PCB— Email des Landratsamtes Emmendingen, Amt für Wasserwirtschaft und Bodenschutz vom 23.07.2013 mit der Bitte um Untersuchung von drei Fischproben aus dem Dammgraben der Elz im Rahmen der Amtshilfe

CVUA Freiburg (2013b) Grasreferenzmessprogramm Baden-Württemberg. Bestimmung von PCB in Gras Heu- und Grassilageproben 9.8.2013

Der Westen (2013) Komplette Freibad-Saison 2013 nach PCB-Fund bei „Hesse“ in Essen in Gefahr 20.03.2013. http://www.derwesten.de/staedte/essen/komplette-freibad-saison-2013-nachpcb-fund-bei-hessein-essen-in-gefahr-id7746360.html

DetzelA, PatykA, FehrenbachH, Franke et al. (1998) Ermittlung von Emissionen und Minderungsmaßnahmen für persistente organische Schadstoffe in der Bundesrepublik Deutschland. FuE-Vorhaben 360 12 008, im Auftrag des Umweltbundesamtes. UBA-Texte 74/98. Berlin

Deutscher Bundestag (1989) Antwort der Bundesregierung auf die Kleine Anfrage der Abgeordneten Frau Teubner, Frau Flinner, Frau Garbe, Kreuzeder und der Fraktion DIE GRÜNEN. Drucksache 1114276 —Drucksache 11/4352; 14.04.1989

DG Sanco (2004) Guidelines for the enforcement of provisions on dioxins in the event non-compliance with the maximum levels for dioxins in food. https://www.fsai.ie/uploadedFiles/ECguidelines-july_2004.pdf

Di Gangi J, PetrlíkJ (2005) The egg report—keep the promise eliminate POPs report. IPEN

Diefenbacher PS, Bogdal C, Gerecke AC, Glüge J, Schmid P, Scheringer M, Hungerbühler K (2015) Emissions of polychlorinated biphenyls in Switzerland: a combination of long-term measurements and modeling. Environ Sci Technol 49(4):2199–2206

Diefenbacher PS, Gerecke AC, Bogdal C, Hungerbühler K (2016) Spatial distribution of atmospheric PCBs in Zurich, Switzerland: do joint sealants still matter? Environ Sci Technol 50(1):232–239

Diletti G, Ceci R, Scortichini G, Migliorati G (2009) Dioxin levels in lifestock and grassland near a large industrial area in Taranto (Italy). Organohalogen Compds 71:2344–2348

Diliberto JJ, Burgin DE, Birnbaum LS (1999) Effects of CYP1A2 on disposition of 2,3,7, 8-tetrachlorodibenzo-p-dioxin, 2,3,4,7,8-pentachlorodibenzofuran, and 2,2',4,4',5,5'-hexachlorobiphenyl in CYP1A2 knockout and parental (C57BL/6N and 129/Sv) strains of mice. Toxicol Appl Pharmacol 159(1):52–64

EFSA European Food Safety Authority (2012) Update of the monitoring of levels of dioxins and PCBs in food and feed, European Food Safety Authority. EFSA J 10(7):2832. https://doi.org/10.2903/j.efsa.2012.2832

EFSA European Food Safety Authority (2015) Scientific statement on the health-based guidance values for dioxins and dioxin-like PCBs, European Food Safety Authority. EFSA J 13(5):4124. https://doi.org/10.2903/j.efsa.2015.4124

Egsmose E, Bräuner EV, Frederiksen M, Mørck TA, Siersma VD, Hansen PW et al (2016) Associations between plasma concentrations of PCB 28 and possible indoor exposure sources in Danish school children and mothers. Environ Int 87:13–19

EMEP/EEA (2009) Atmospheric Emission Inventory Guidebook. http://www.eea.europa.eu/publications/emep-eea-emission-inventory-guidebook-2009

E-PRTR (2006) Europäisches Schadstofffreisetzungs- und -verbringungsregister, Verordnung Anhang II. http://www.thru.de/fileadmin/SITE_MASTER/content/Dokumente/Downloads/E_PRTR_VO_Anhang_II.pdf

Esposito V, Maffei A, Castellano G, Martinelli W, Conversano M, Assenato G (2010) Dioxin levels in grazing land and groundwater in the surrounding of a large industrial area in Taranto (Italy). Organohalgen Compd 72:736–739

Esposito V, Maffei A, Bruno D, Castellano G, Varvaglione B, Ficoceli S, Capoccia C, Spartera M, Giua R, Blonda M, Assenato G (2014) POPs Emission from a large sinter plant in Taranto (Italy) over a five-year period following enforcement of new legislation. Sci Total Environ 491–492, 118–122

European Commission (2001) Communication from the Commission to the Council, the European Parliament and the Economic and Social Committee. Community Strategy for Dioxins, Furans and Polychlorinated Biphenyls, COM 593

European Commission (2006) Commission Regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Off J Eur Union L364:5

European Commission (2011) Commission Regulation (EU) No 1259/2011 of 2 December 2011 amending Regulation (EC) No 1881/2006 as regards maximum levels for dioxins, dioxin-like PCBs and non dioxin-like PCBs in foodstuffs. Off J Eur Union L320:18–23

European Commission (2014) Final Report Summary—SYSTEQ (the development, validation and implementation of human systemic Toxic Equivalencies (TEQs) as biomarkers for dioxin-like compounds). Project reference 226694

Fantke P, Weber R, Scheringer M (2015) From incremental to fundamental substitution in chemical alternatives assessment. Sustain Chem Pharm 1:1–8

FAO (2006) Code of Practice for the Prevention and Reduction of Dioxin and Dioxin-like PCB Contamination in Food and Feeds. 1st ed. http://www.fao.org/ag/againfo/home/en/news_archive/2009_IN_dioxin.html

Ferrante MC, Fusco G, Monnolo A, Saggiomo F, Guccione J, Mercogliano R, Clausi MT (2017) Food contamination by PCBs and waste disposal crisis: evidence from goat milk in Campania (Italy). Chemosphere 186:396–404

Fiedler H (2001) Existierende Dioxininventare weltweit und neue Methodik zur Erstellung von vergleichbaren und vollständigen Emissionsinventaren. Umweltwiss Schadst Forsch 13(2):88–94

Fiedler H, Hutzinger O, Welsch-Pausch K, Schmiedinger A (2000) Evaluation of the occurrence of PCDD/F and POPs in wastes and their potential to enter the foodchain. Study on behalf of the European Commission, DG Environment, 30. September 2000

FilykG (2004) Information dossier for the reassessment of production and use of polychlorinated terphenyls (PCTs) under the United National Economic Commission for Europe protocol on persistent organic pollutants (POPs). http://www.unece.org/fileadmin/DAM/env/lrtap/TaskForce/popsxg/2004/Dossier_PCT.pdf

Fonnum F, Paukstys B, Zeeb BA, Reimer KJ (1998) Environmental contamination and remediation practices at former and present military bases. Nato Science Partnership Subseries: 2. https://doi.org/10.1007/978-94-011-5304-1

Förstner U, Hollert H, Brinkmann M, Eichbaum K, Weber R, Salomons W (2016) Dioxin in the Elbe river basin: policy and science under the water framework directive 2000–2015 and toward 2021. Environ Sci Eur 28(1):9

Forter M (2000) Farbenspiel—ein Jahrhundert Umweltnutzung durch die Basler chemische Industrie. Chronos-Verlag, Zürich

Gallistl C, Sprengel J, Vetter W (2018) High levels of medium-chain chlorinated paraffins and polybrominated diphenyl ethers on the inside of several household baking oven doors. Sci Total Environ 615:1019–1027

Gasic B, Moeckel C, MacLeod M, Brunner J, Scheringer M, Jones KC, Hungerbühler K (2009) Measuring and modeling short-term variability of PCBs in air and characterization of urban source strength in Zurich, Switzerland. Environ Sci Technol 43:769–776

German BBodSchV (1999) German Federal Soil Protection Regulation (Bundes-Bodenschutz- und Altlastenverordnung), Bundesgesetzblatt. Jahrgang 1999 Teil I Nr.36, S. 1554 pp, Bonn, 16. Juli 1999

Glüge J, Wang Z, Bogdal C, Scheringer M, Hungerbühler K (2016) Global production, use, and emission volumes of short-chain chlorinated paraffins—a minimum scenario. Sci Total Environ 573:1132–1146

Glüge J, Steinlin C, Schalles S, Wegmann L, Tremp J, Breivik K, Hungerbühler K, Bogdal C (2017) Import, use, and emissions of PCBs in Switzerland from 1930 to 2100. PLoS One 12(10):e0183768

GoßlerK, Höhlein T (1992) Schlussbericht zum Forschungsvorhaben „Quantifizierung der Ausgasung von polychlorierten Biphenylen aus Fugendichtmassen“, T 2454, Landesgewerbeanstalt Bayern, Nürnberg

Guhl B, Stürenberg F-J, Santora G (2014) Contaminant levels and parasite infection in the European eel (Anguilla anguilla) in North Rhine-Westfalian rivers. Environ Sci Eur 26:26

Harrad S, Ibarra C, Robson M, Melymuk L, Zhang X, Diamond M, Douwes J (2009) Polychlorinated biphenyls in domestic dust from Canada, New Zealand, United Kingdom and United States: implications for human exposure. Chemosphere 76(2):232–238

Heinisch E, Kettrup A, Bergheim W, Holoubek I, Wenzel S (2003) PCB in aquatic ecosystems of the river Elbe and Berlin waters—source oriented monitoring. Fresenius Environ Bull 12:103–110

Heinisch E, Kettrup A, Bergheim W, Martens D, Wenzel S (2006) Persistent chlorinated hydrocarbons, source-oriented monitoring in aquatic media. 5. The polychlorinated biphenyls (PCBs). Fresenius Environ Bull 15:1344–1362