Abstract

Highly porous biochar (BC) structures have been prepared from inexpensive biomasses like rice straw, bamboo, sugarcane waste, and corn cob via a slow pyrolysis technique in nitrogenous atmosphere. A surface engineering technique has been applied to enhance the surface-to-volume ratio of each biochar sample and finally compared its characteristics through standard surface and elemental characterization techniques, viz. CHN (carbon, hydrogen, and nitrogen), FTIR (Fourier transform infrared spectroscopy), BET (Brunauer–Emmett–Teller), and SEM (scanning electron microscopy). All the biochar samples were observed to be highly carbonized and aromatized. Exfoliated structures were found to contain more elemental carbon (34.14–77.32%) than its native form (30.92–74.46%). Aromatic hydrocarbon, aromatic C=C, aromatics, aliphatic C–O, aliphatic hydrocarbon, and H-bonded OH groups were found to predominate in the surface of biochar structures independent of their precursor composition and extent of exfoliation. SEM micrographic images clearly ensured about the unoriented sheets like the morphology of different biochar samples. Although no significant structural difference was found to exist depending on their precursor compositions, quantitative enhancement of porosity was found to be observed after exfoliation. Both native (240.65 m2/g) and exfoliated (712.89 m2/g) biochars derived from sugarcane wastes were observed to have a maximum surface area in comparison to the biochars derived from rice straw (native, 22.08 m2/g; exfoliated, 29.92 m2/g), bamboo (native, 42.08 m2/g; exfoliated, 248.38 m2/g), and corn cob (native, 136.62 m2/g; exfoliated, 221.71 m2/g). Exfoliated biochars were found to be consistently more potent in comparison to its native form as per our comparative characterizations performed so far.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amazon’s dark earth, terra preta do índio, has emerged as a rising star in the field of agriculture for its multidirectional application. The ancient settlers of the Amazonian Basin engineered a piece of fertile land which is being considered game changer in the history of soil fertility. Compared with the surrounding soil, terra preta (biochar) was enriched with three times more phosphorus and nitrogen as well as 18 times more carbon content (Marris 2006). Biochar is produced from a wide range of agricultural feedstock, and it has porous structure and negative surface functional groups (Yao et al. 2013). Biochars from plant material have high aromatic C content due to the presence of higher amount of lignin and cellulose, which gives the biochar high stability and resistance to microbial decomposition. Moreover, conversion of different feedstock into biochar reduces residue volume, improves the efficiency of nutrient use by crops, and generates products with high agronomic value (Domingues et al. 2017). As a result, much more efforts were invested to find out a sustainable way to produce biochars from inexpensive biomasses like wood chips, crop straws, crop husks, coconut shell, poultry litter, algae, sewage sludge, bamboo, and sawdusts. India produces 130 million tonnes of paddy straw, 280 million tonnes of sugarcane bagasse, 22.23 million tonnes corn cob, and 4.6 million tones bamboo (ICAR 2011). Although, initially, biochar was used only in agriculture, now it is being used in versatile fields like heavy metal remediation, global climate change mitigation, mine tailing, and environmental pollutant management (Egene et al. 2018; Wang et al. 2017; Zhang et al. 2018). Nowadays, manufacturing of biochar is not sufficient to manage its upgrowing demands in versatile fields. Surface engineering techniques are also attracting the burning attention to make these carbon particles more potent, sustainable, and user-friendly for its economically viable daily applications. Moreover, native biochar has lower adsorption capacity than exfoliated biochar (Tan et al. 2016). To increase the adsorption capacity of biochar and its application in different areas, different exfoliation methods have been developed and used in water contaminant removal and soil remediation. Exfoliation of biochar is done by physical, chemical, and biological methods, which can improve its different properties like specific surface area, porosity, cation exchange capacity, surface functional group, and pH. Exfoliation also can improve the adsorption capacity compared to native biochar (Yao et al. 2013).

In this study, porous exfoliated biochar derived from four easily available different biochar raw materials (rice straw, bamboo, sugarcane waste, and corn cob) through slow pyrolysis has been reported. Additionally, we have exfoliated it to enhance its surface-to-volume ratio and finally compared its characteristics through standard surface characterization techniques (Genovese et al. 2015). Although several precursors, conversion techniques, pyrolysis temperatures, and surface modification strategies have been applied for biochar preparation, this kind of comparative studies will be very effective for the characteristics specified for proper application of biochar in near future. Nowadays, these kinds of cost-effective, biodegradable, and environmentally benign carbon architecture could be very effective in the field of waste water remediation. The objective of this study was to evaluate the characteristics of biochars produced from different crop wastes and how it changes after exfoliation. Moreover, this study also can predict the potential to adsorb heavy metals from aqueous solutions.

Materials and methods

Manufacturing of biochar

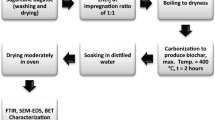

In a typical synthesis, 5–10-g precursor materials like rice straw, bamboo, sugarcane waste, and corn cob were pyrolyzed in a tubular furnace for 2 h with a heating rate of 5 °C min−1 in a nitrogen atmosphere to convert its native biochar without any pre- or post-treatment. In the case of exfoliated biochar, 10 g of precursors was crushed properly and soaked in 200 mL 1 M HNO3 at 75–80 °C for 4 h. The resultant components were recovered through filtration, dried, and pyrolyzed following the same procedure mentioned before. The carbonized materials were further placed in a muffle furnace for 30-s flash heat treatment at 950 °C in an air-limiting atmosphere for thermal exfoliation (Genovese et al. 2015). The final components were considered the exfoliated biochar sample.

Characterization

Carbon, hydrogen, and nitrogen abundances of the different biochar samples were determined by a CHN elemental analyzer (Carlo-Erba NA-1500) via high-temperature-catalyzed combustion followed by infrared detection of resulting CO2, H2, and NO2 gases. Surface functional groups were determined by Fourier transform infrared (FTIR) spectroscopy analysis on a PerkinElmer spectrum 2 FTIR spectrophotometer. Surface morphology and energy-dispersive X-ray (EDX) analysis was performed simultaneously by field emission scanning electron microscopy (JEOL JSM-7600F) in which the sample was prepared by deposition followed by spin coating on a glass slide. The Brunauer–Emmett–Teller (BET) surface areas and pore size distribution patterns were determined through nitrogen adsorption isotherms using a Quantachrome Autosorb 1-C surface area analyzer operated at 77 K (Lee et al. 2010).

Results and discussion

In this study, rice straw, bamboo, sugarcane waste, and corn cob have been used as precursors. The chemical constituents of rice are mainly cellulose, hemicellulose, and Klason lignin (Jin and Chen 2007). Likewise, the bamboo, sugarcane waste, and corn cob are contained with cellulose, hemicellulose, and lignin (Dorez et al. 2014). In the case of native biochar preparation, cellulose, hemicellulose, and lignin containing biomasses carbonized directly through pyrolysis in nitrogenous atmosphere. But, for the exfoliation technique, we used three sub-compartmentalized techniques: pre-treatment of lignocellulosic biomasses with mild acid to remove amorphous surroundings, slow pyrolysis of crystalline condensed cellulosic biomasses for proper carbonization at nitrogenous inert atmosphere, and thermal flash heat treatment for proper exfoliation as well as segregation of staged carbon structures into thinner carbon sheets (Genovese et al. 2015). The slow pyrolysis technique (450 °C for 2 h) has been used to enhance the ultimate mass of biochar. Increasing pyrolysis time and temperature decreases surface hydrophilicity and percentage of oxygen and indirectly enhances the degree aromaticity of the overall carbon structure. This additional aromaticity helps to enhance CO2 sequestration time and soil fertility (Peng et al. 2011).

Elemental analysis (C, H, and N % in w/w) clearly showed that exfoliated biochars were contained with much more elemental carbon than native biochar samples (supplementary Table 1). Removal of amorphous components (mainly hemicellulose and lignin) in the pre-acid treatment step was probably responsible for this carbon enrichment in exfoliated biochar samples (Genovese et al. 2015). All the biochar samples were found to be highly carbonized and aromatized as indicated by a very low atomic H/C ratio (i.e., 0.26 to 0.53) (Uchimiya et al. 2011). The H/C ratio value is an indicator of the basic and elemental structure of biochars, i.e., different pore size and surface areas (Crombie et al. 2013). The H/C ratio also reflects the aromaticity of biochars and for predicting the sorption of hydrophobic organic contaminants onto biochars (Leng et al. 2019). The ratio of H/C was used as carbonization indicators. Decreased H/C ratios of all the biochars made at the same temperatures indicated that they lost more water and O-containing functional groups, and formed more aromatic and graphic structure to condense C (Uchimiya et al. 2011). Supplementary table 1 shows that, under the same pyrolysis temperature, biochars derived from the bamboo had higher C contents than the rice straw. This is probably because the bamboo biomass has higher cellulose and lignin contents but lower hemicellulose content than herbaceous biomass. Lower H/C ratios in rice straw compared to bamboo biomass demonstrate an increased aromaticity caused by pyrolysis and therefore indicate higher stability of the material (Van Zwieten et al. 2010). The nitrogen (N) contents of the biochars were between 0.86 and 3%, which are also within the commonly observed value of previous studies (Sun et al. 2014).

Specific surface area and pore size distribution of different biochar samples were determined by Barrett–Joyner–Halenda (BJH) pore size distribution pattern analysis (Fig. 1). Surface area is one of the most significant factors which control a material’s ability to adsorb chemical compounds. Biochar having larger surface area is considered to be more porous and more useful for water treatment or environmental remediation (Sun et al. 2014; Chen et al. 2018). Proper exfoliation resulted in significant increase in surface area, micropore area, and micropore volume in all four types of biochar precursors. Biochars from sugarcane waste were found to have significantly higher surface area in comparison to the biochars from other sources (rice, bamboo, and corn cob) (Lu et al. 2014; Sun et al. 2014; Leng et al. 2019). Although both micro- and mesopores were found to be present in all the biochar samples (size of the pores ranged from 1.55 to 4.52 nm), pore size distribution patterns were completely different from each other. Even the pore size distribution pattern of native and exfoliated biochars was found to be significantly different, although the precursors were the same (Fig. 1). A detailed clear picture about the surface functional groups in different biochar samples was further determined by FTIR pattern analysis (supplementary Fig. 1). The adsorption peaks at 786 cm−1, 1088 cm−1, 1420 cm−1, 1636 cm−1, and 3437 cm−1 were assigned to aromatic hydrocarbon, aliphatic C–O, aromatics, aromatic C=C, and H-bonded OH groups respectively in the case of native biochar samples from rice straw, whereas in exfoliated biochar from rice straw, the adsorption peaks around 782 cm−1, 1097 cm−1, 1630 cm−1, 2920 cm−1, and 3435 cm−1 were assigned to aromatic hydrocarbon, aliphatic C–O, aromatic C=C, aliphatic hydrocarbon, and H-bonded OH groups respectively (supplementary Table 2). Aromatic hydrocarbon, aliphatic C–O, aromatics, aromatic C=C, and H-bonded OH groups were found to be common in both native and exfoliated biochars from bamboo (supplementary Table 2). Likewise, in the case of biochars from sugarcane waste and corn cob, no significant changes were found in peak positioning between native and exfoliated forms. In the case of biochars from sugarcane waste, aromatic hydrocarbon, aliphatic C–O, aromatic C=C, aliphatic hydrocarbons, and H-bonded OH groups were found to be common in both of their native and exfoliated forms, whereas aromatic hydrocarbon, aliphatic C–O, aromatic C=C, and H-bonded OH groups were found in both native and exfoliated forms of biochars from corn cob (supplementary Table 2). The surface morphologies of different carbon structures were further examined through scanning electron microscopy (SEM) analysis. Figure 2 illustrates SEM micrographs of different biochar samples where multiple unoriented sheet-like structures were found to be noticed in the case of both native and exfoliated forms of biochars from rice straw, bamboo, sugarcane waste, and corn cob. Although no significant morphological differences were found between the native and exfoliated forms of biochars from rice straw and sugarcane waste, qualitative indications of increased porosity due to the exfoliation procedure were clearly noticed in the SEM micrographs of bamboo- and corn cob-derived biochars. The conversion of rough surfaces to highly porous structures might facilitate the adsorption of heavy metals by increasing the surface area of the exfoliated biochar (Mubarik et al. 2016). Probably, the pre-treatment step was responsible to removing the lignin, hemicellulose, and other impurities from the surfaces of individual biochar sheets. As a result after carbonization and post carbonization flash heat treatment, more porous and smoother carbon structures were found to appear in the case of exfoliated biochar samples (Genovese et al. 2015).

In this study, we have manufactured biochars from four different agricultural wastes, i.e., rice straw, bamboo, sugarcane waste, and corn cob. We further exfoliated it to enhance its surface-to-volume area for making it superior in comparison to its native form. We characterized it through CHN analysis, XRD, BET surface area analysis, FTIR, and SEM and further compared the results to find out the basic characteristic difference between different biochar samples. All the carbon samples were found to be highly carbonized and aromatized. Exfoliated biochars were found to have more carbon content in comparison to its native form. Carbon architectures were found to have some basic sheet-like morphologies, but appearance of additional porosity made exfoliated biochars superior in terms of qualitative surface morphological characteristics. BET surface area and pore size distribution pattern analysis results were proven to be most conclusive among all the characterization techniques mentioned before. Both micro- and mesopores were found to be present in the surface of different biochar structures. Biochars derived from sugarcane waste were found to have maximum BET surface area in comparison to biochars derived from rice straw, bamboo, and corn cob.

Conclusions

Exfoliated biochars were found to be consistently more potent in comparison to its native form as per our comparative characterizations explained earlier. Likewise, sugarcane waste–derived biochars were found to be superior in comparison to the other precursor-derived biochars that had been analyzed in our experiment and had greater potential to adsorb heavy metals from waste water.

References

Chen Z, Liu T, Tang J, Zheng Z, Wang H, Shao Q, Chen G, Li Z, Chen Y, Zhu J, Feng T (2018) Characteristics and mechanisms of cadmium adsorption from aqueous solution using lotus seedpod-derived biochar at two pyrolytic temperatures. Environ Sci Pollut Res 25:11854–11866

Crombie K, Masek O, Sohi SP, Brownsort P, Cross A (2013) The effect of pyrolysis conditions on biochar stability as determined by three methods. Glob Change Biol Bioenergy 5:122–131

Domingues RR, Trugilho PF, Silva CA, de Melo ICNA, Melo LCA, Magriotis ZM, SaÂnchez-Monedero MA (2017) Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS One 12(5):e0176884

Dorez G, Ferry L, Sonnier R, Taguet A, Lopez-Cuesta JM (2014) Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J Anal Appl Pyrol 107:323–331

Egene CE, Van Poucke R, Ok YS, Meers E, Tack FMG (2018) Impact of organic amendments (biochar, compost and peat) on Cd and Zn mobility and solubility in contaminated soil of the Campine region after three years. Sci Total Environ 626:195–202

Genovese M, Jiang J, Lian K, Holm N (2015) High capacitive performance of exfoliated biochar nanosheets from biomass waste corn cob. J Mater Chem A 3:2903–2913

ICAR (2011) Hand book of agriculture, 6th edn. Indian Council of Agricultural Research, New Delhi

Jin S, Chen H (2007) Near-infrared analysis of the chemical composition of rice straw. Ind Crop Prod 26:207–211

Lee JW, Kidder M, Evans BR, Paik S, Buchanan AC, Garten CT, Brown RC (2010) Characterization of biochars produced from cornstovers for soil amendment. Environ Sci Technol 44:7970–7974

Leng L, Huang H, Li H, Li J, Zhou Z (2019) Biochar stability assessment methods: a review. Sci Total Environ 647:210–222

Lu K, Yang X, Shen J, Robinson B, Huang H, Liu D, Bolan N, Pei J, Wang H (2014) Effect of bamboo and rice straw biochars on the bioavailability of Cd, Cu, Pb and Zn to Sedum plumbizincicola. Agric Ecosyst Environ 191:124–132

Marris E (2006) Black is the new green. Nature 442:624–626

Mubarik S, Saeed A, Athar MM, Iqbal M (2016) Characterization and mechanism of the adsorptive removal of 2, 4, 6-trichlorophenol by biochar prepared from sugarcane baggase. J Ind Eng Chem 33:115–121

Peng XYLL, Ye LL, Wang CH, Zhou H, Sun B (2011) Temperature-and duration-dependent rice straw-derived biochar: characteristics and its effects on soil properties of an Ultisol in southern China. Soil Tillage Res 112:159–166

Sun Y, Gao B, Yao Y, Fang J, Zhang M, Zhou Y, Chen H, Yang L (2014) Effects of feedstock type, production method, and pyrolysis temperature on biochar and hydrochar properties. Chem Eng J 240:574–578

Tan XF, Liu YG, Gu YL, Xu Y, Zeng GM, Hu XJ, Liu SB, Wang X, Liu SM, Li J (2016) Biochar-based nano-composites for the decontamination of wastewater: a review. Bioresour Technol 212:318–333

Uchimiya M, Wartelle LH, Klasson KT, Fortier CA, Lima IM (2011) Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J Agric Food Chem 59:2501–2510

Van Zwieten L, Kimber S, Morris J, Chan K, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327:235–246

Wang B, Gao B, Fang J (2017) Recent advances in engineered biochar productions and applications. Crit Rev Environ Sci Technol 47:2158–2207

Yao Y, Gao B, Chen J, Zhang M, Inyang M, Li Y, Alva A, Yang L (2013) Engineered carbon (biochar) prepared by direct pyrolysis of Mg-accumulated tomato tissues: characterization and phosphate removal potential. Bioresour Technol 138:8–13

Zhang C, Liu L, Zhao M, Rong H, Xu T (2018) The environmental characteristics and applications of biochar. Environ Sci Pollut Res 25:21525–21534

Funding

Shuvrodeb Roy is thankful to the Ministry of Social Justice and Empowerment, Govt. of India and University Grants Commission (UGC) for providing him fellowship. The authors are thankful to the Indian Statistical Institute for providing financial assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOC 328 kb)

Rights and permissions

About this article

Cite this article

Roy, S., Kumar, U. & Bhattacharyya, P. Synthesis and characterization of exfoliated biochar from four agricultural feedstock. Environ Sci Pollut Res 26, 7272–7276 (2019). https://doi.org/10.1007/s11356-018-04117-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-018-04117-7