Abstract

This work evaluates the application of Mytella falcata shells, discarded in large quantities in the state of Alagoas, Brazil, as adsorbent for methylene blue dye (MB). It was investigated how the amount of adsorbent (M), the average particle diameter (G), and the agitation speed (A) affected the adsorption. Kinetic and equilibrium studies were conducted, and the pseudo-second-order equation adequately represented the kinetic data and isotherms following Liu’s model (q max = 8.81 mg g−1 at 60 °C). The adsorption was spontaneous, favorable, and endothermic. Mytella falcata shell is a suitable adsorbent for MB and could potentially contribute to its removal from the environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The wastewater from textile industries contains considerable amounts of dyes that are not easily biodegradable in natural environments. The direct discharge of colored effluents containing toxic components is hazardous to the environment: they diminish sunlight penetration into water bodies, which harms the photosynthesis activity of plants and the growth of biota (Gad and El-Sayed 2009). Furthermore, synthetic dyes display toxic, mutagenic, and carcinogenic effects, which can affect the human life negatively (Carneiro et al. 2010). Several techniques such as coagulation, oxidation, biodegradation, photolysis, filtration, and adsorption can remove dyes from wastewater (Fernandez et al. 2010). In particular, adsorption is a simple process that relies on the availability of a wide range of adsorbents, which make this process an effective method to reduce the concentration of dissolved dyes in industrial effluents. Adsorption transfers the dyes present in an aqueous effluent to a solid phase, significantly decreasing the bioavailability of the dyes to living organisms (Treviño-Cordero et al. 2013; Wang and Li 2013; Zhang et al. 2013). Subsequently, the adsorbent can be regenerated or stored in a dry place without direct contact with the environment, and the decontaminated effluent can be released into the environment (Machado et al. 2011).

In this context, interest in alternative effective and inexpensive adsorbents for dye removal has increased. Babaçu coconut (Vieira et al. 2009), cupuaçu shell (Cardoso et al. 2011), sugarcane bagasse (Zhang et al. 2013), rice bran (Suzuki et al. 2007), papaya seeds (Paz et al. 2013; Weber et al. 2013), bottle gourd (Foletto et al. 2012), oyster shell (Asaoka et al. 2009), moringa aptera Gaertn (Matouq et al. 2015), Persian olive (Rahimdokht et al. 2016), Cyclosorus interruptus (Zhou et al. 2015), castor bean presscake (Magriotis et al. 2014), raw peach shell (Markovic et al. 2015), neem (Azadirachta indica) leaf powder (Bharali and Bhattacharyya 2015), shell dust of the snail Physa acuta (Hossain and Aditya 2013), untreated and mussel shell-treated granitic material (Otero et al. 2015), waste shell dust of fresh water mussel Lamellidens marginalis (Hossain et al. 2015), bivalve mollusk shell (Yousefi et al. 2015), biochar from biofuel residue (Yao et al. 2015), hickory and peanut hull hydrochars (Fang et al. 2016), un-amended and amended mussel shell (Garrido-Rodriguez et al. 2014), and calcined mussel shell (El Haddad et al. 2014) are examples of alternative adsorbents.

“Sururu” (Mytella falcata) is well known in the state of Alagoas (Brazil) and is even considered a symbol of the region. According to the Federation of Fishermen of Alagoas, 10,000 people survive on the collection of mussels, both for subsistence and for sale (OPAS 2015). Sururu collection is an activity that generates large amounts of waste. Irregular exploitation of mussels and incorrect waste disposal have caused several environmental problems. According to the Ministry of Fisheries and Aquaculture (Brazil) (MPA 2015), in 2011 mussels were the most captured species (3772.5 t) among clams, followed by sururu (2133.3 t) and octopus (2089.6 t). In the Alagoas area, “maçunim” (another mollusk species) was the most captured species (317.4 t), followed by sururu (217.9 t) and oyster (95.8 t).

This work aimed to evaluate the adsorptive capacity of M. falcata shells, a solid waste, widely generated that causes several environmental problems due to its inadequate management, for removal of methylene blue dye. Specific surface area (BET) measurements, scanning electron microscopy (SEM), infrared spectroscopy (FT-IR), X-ray diffraction (XRD), thermogravimetric analysis (TGA), and X-ray-dispersive energy spectroscopy (EDS) aided characterization of the material. To determine the applicability of the adsorbent, a 23 full experimental design was performed to investigate how the amount of adsorbent (M), the average particle diameter of the adsorbent (G), and the agitation speed affected the adsorption process. The pseudo-first-order and pseudo-second-order models were used to fit the kinetic data. The Langmuir, Freundlich, Liu, and Redlich-Peterson models were employed to fit the adsorption equilibrium data. Thermodynamic parameters like activation energy, standard enthalpy change, standard Gibbs energy change, and standard entropy change were determined.

Materials and methods

Chemicals

Methylene blue dye (MB) (Sigma-Aldrich, molecular formula = C16H18N3SCl, purity = 99%, molecular weight = 319.86, C. I. = 52,015) was used in this work (Ezzeddine et al. 2016; Samal et al. 2017). This cationic dye is common in paint and textile effluents. For the adsorption assays, all the solutions were prepared with distilled water, and all the reagents were of analytical grade. MB was quantified by a UV-visible spectrophotometer (Shimadzu, UVmini-1240, Japan) at 665 nm (Paz et al. 2013).

Adsorbent

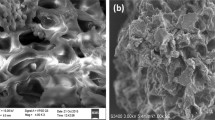

The M. falcata (mussels) shell was used as adsorbent. The raw material was collected in “Sururu de Capote” community (Maceió/Alagoas/Brazil). Figure 1 shows the discarded M. falcata shells. The shells were washed to remove the mud, and the material was placed in an oven at 60 °C for 8 h, to reduce the moisture content. The shells were then crushed in an industrial blender and classified by a Tyler series sieves. Figure 2a illustrates the shells without crushing. Figure 2b, c shows the shells with average particle sizes of 0.443 mm and smaller than 0.149 mm, respectively.

Adsorbent characterization

Specific surface area (BET) measurements, scanning electron microscopy (SEM), infrared spectroscopy (FT-IR), X-ray diffraction (XRD), thermogravimetric analysis (TGA), and X-ray-dispersive energy spectroscopy (EDS) were used to characterize the material with the smallest particle size (<0.149 mm). The functional groups of the shells were identified by FT-IR (Varian 660 IR). The thermal profile was obtained by TGA (Shimadzu/TGA 50 coupled to a thermal analyzer TA60WS). The crystal structure was determined by XRD (Shimadzu/XRD-6000). The surface morphology was analyzed by SEM (Shimadzu/SSX-550). The adsorbent was characterized by N2 adsorption-desorption isotherms at 77 K on Micromeritics ASAP 2020 equipment operating at relative pressure (P/Po) ranging from 0.01 to 0.99. Elements present in the material were qualitatively and quantitatively determined by EDS (Shimadzu/EDS 800HS) (Viriya-empikul et al. 2010).

Experimental design for batch experiments

A 23 experimental design was used to perform the batch experiments. To this end, 25 mL of MB dye solution at an initial concentration of 100 mg L−1 and the adsorbent were placed in flasks. The mixture (dye solution + adsorbent) was stirred in a shaker incubator at an average temperature of 25 °C and residence time of 60 min. After adsorption, an aliquot of the solution was withdrawn, and the final MB concentration in solution was determined by spectrophotometry.

The input variables were the amount of adsorbent (M), the average particle diameter of the adsorbent (G), and agitation speed (A). Table 2 presents the levels. The experiments were performed in duplicate, in random order. The adsorption capacity (q) was the considered response, given by Eq. 1:

where C 0 is the initial MB concentration (mg L−1), C f is the final MB concentration (mg L−1) at 60 min, V is the volume of the solution (L), and M is the amount of adsorbent (g).

Kinetic and equilibrium experiments

The kinetic curves were constructed in batch systems at 25 °C and 200 rpm in a shaker incubator. Briefly, 25 mL of MB solutions of different initial MB concentrations (25, 100, and 200 mg L−1) was added to the flasks containing 0.5 g of adsorbent with particle size <0.149 mm. After the predetermined time, an aliquot (without the presence of the adsorbent) was removed and quantified on a spectrophotometer.

Equilibrium studies were performed in a finite bath system; 0.5 g of adsorbent (particle size <0.149 mm) was employed. The MB solutions (concentrations ranging from 10 to 600 mg L−1) were placed in contact with the adsorbent for 50 min under constant agitation of 200 rpm in a shaker incubator working at different temperatures (25, 40, 50, and 60 °C) (Chowdhury and Saha 2010). After 50 min, aliquots were withdrawn and quantified in a spectrophotometer. All the experiments were performed in duplicate.

Modeling

From the kinetic viewpoint, MB adsorption onto M. falcata (mussels) shells was investigated by using the pseudo-first-order (Lagergren 1898) (Eq. 2) and pseudo-second-order (Ho and Mckay 1998a, b, 1999) (Eq. 3) models:

where k 1 and k 2 are the rate constants of the pseudo-first-order and pseudo-second-order models (in min−1 and g mg−1 min−1, respectively), q 1 and q 2 are the theoretical values for the adsorption capacity (mg g−1), t is the time (min), and q t is the adsorption capacity determined by Eq. 4, where q t (mg g−1) is the quantity of adsorbed MB, C t (mg L−1) is the MB concentration in the liquid phase at any time, C 0 (mg L−1) is the initial dye concentration, V is the volume of the solution (L), and m is the amount of adsorbent (g).

Regarding the equilibrium, Langmuir (1918) (Eq. 5), Freundlich (1906) (Eq. 6), Liu et al. (2003) (Eq. 7), and Redlich-Peterson (Redlich and Peterson 1959) (Eq. 8) models were used:

where q e is the adsorption capacity in the equilibrium, calculated by Eq. 1, q m is the maximum adsorption capacity (mg g−1), K L is the Langmuir constant (L mg−1), K F is the Freundlich constant (mg g−1)(mg L−1)–1/nF, 1/n F is the heterogeneity factor, q S is the maximum adsorption capacity from the Liu model (mg g−1), K S is the Liu constant (L mg−1), m S is the exponent of the Liu model, and K RP (L mg−1) and a RP (L mg−1)β and β are the Redlich-Peterson constants.

Results

Adsorbent characterization

Figure 3 presents the FT-IR vibrational spectrum of the M. falcata shell. The main intense bands emerged at 3360, 2925, 2850, 2520, 1784, 1466, 1078, 854, and 705 cm−1. The FT-IR spectrum contained the characteristic bands of crystalline aragonite (CaCO3), which is typical of mollusk shells. The vibration modes at 705, 854, 1078, and 1466 cm−1 attested that the carbonate group was present in the shell. The band at 705 cm−1 corresponded to angular deformations in the OCO connection plane. The band at 854 cm−1 referred to angular deformations outside the connection plane of CO3. The band at 1078 cm−1 was attributed to symmetric stretching of the CO bond. The band at 1466 cm−1 was due to asymmetric stretching of the CO bond. The band at 2520 cm−1 indicated that resident radical HCO3 − existed in the material. The bands at 2850 and 2925 cm−1 were associated with the CH vibrational modes of various organic matter species present in the sample. The band near 3400 cm−1 corresponded to water OH stretching originating from moisture in the sample. The spectral data resembled the results reported by Li et al. (2012) and Silva et al. (2010).

Figure 4 depicts the X-ray diffractogram of the shell and confirmed its carbonaceous nature. The shell displayed high calcium concentration and contained carbon and oxygen. The XRD patterns revealed that the shell comprised the crystalline forms of calcium carbonate (CaCO3), aragonite, and calcite, which are the main constituents of shellfish shells. The percentage of aragonite and calcite phases may vary depending on the mollusk and the region where the species developed. According to Silva et al. (2010), crystallographic characterization of mollusk shells cannot always determine the proportions of the different calcium carbonate crystalline phases in shells because textures are different and the material may contain mixtures of other organic and amorphous impurities. The XRD results corroborated with the infrared data recorded for the M. falcata shell in Fig. 3.

Figure 5 shows the curve of the weight loss versus temperature (A) and the differential thermal analysis curve as a function of temperature (B). Based on curve (A), significant weight loss occurred between 650 and 800 °C due to calcium carbonate (CaCO3) decarbonation, and calcium oxide (CaO) formation. Differential thermal analysis (DrTGA) (B) evidenced a peak at approximately 785 °C, which indicated CaO formation (Silva et al. 2010). Figure 5, curve (A), illustrates how weight loss evolved from 30 to 900 °C. Organic content degradation took place around 200 °C, and the percentage of weight loss was about 9%. Total weight loss was approximately 43% around 650 °C. According to Mohamed et al. (2012), the results agreed with the theoretical decomposition of calcium carbonate, CaCO3 → CaO + CO2. Assuming that there were no impurities, CaCO3 degradation produced approximately 40 and 60%, by weight, of CaO and CO2, respectively.

Figure 6 brings the micrographs of the shells in different forms, cross section, and powder, obtained by SEM. Figure 6a, b shows the details of the cross section, revealing the overlapping lamellae that form the body of the M. falcata shell. Figure 6c, d displays the inner surface, where particle size distribution is more heterogeneous, and Fig. 6e, f shows the structure of the powder exhibiting smaller particles. Li et al. (2012) and Dauphin et al. (2013) also observed this morphological characteristic—lamellar structures—for bivalve mollusks.

The specific surface area, the total pore volume, and the average diameter of the pores were 65 m2/g, 0.0676 cm3/g, and 41 Ǻ, respectively, as determined by N2 adsorption/desorption (BET). The specific surface area was high as compared to other mollusks reported in the literature, such as the bivalve mollusk shell from beaches in India (3.6 m2/g) (Chowdhury and Saha 2010). Figure 7 corresponds to the N2 adsorption/desorption isotherm at 77 K and shows that the isotherm profile was type II, without hysteresis. According to the IUPAC classification, this profile is typical of non-porous solid. However, the absence of hysteresis does not mean porosity is absent because some kinds of pores may lead to adsorption and desorption (Webb and Orr 1997). The surface area analysis results confirmed the morphology viewed by the SEM technique (Fig. 6) and attested that the M. falcata shell was not porous, but lamellar.

EDS analyses afforded the elemental composition of the M. falcata shell as shown in Table 1. The material contained high concentration of calcium (Ca) and much smaller proportions of sodium (Na), phosphorus (P), sulfur (S), strontium (Sr), iron (Fe), silicon (Si), and chromium (Cr), corroborating the previous results.

Experimental design

Table 2 depicts the 23 experimental design matrix with the average values of q e in each combination of levels for the input variables. The results were fitted to a linear model, leading to an empirical correlation that described the adsorption capacity. Table 3 summarizes the effects calculated from the input variables on the response variable and provides the standard errors. The variable that influenced the adsorption process the most was the amount of adsorbent (M), followed by the average particle diameter of the adsorbent (G) and the effect of the interaction between the mass of adsorbent (M) and the average particle diameter of the adsorbent (G).

Equation 9 represents the empirical model obtained by linear regression of the experimental data:

where x M , x G , and x A are the amount of adsorbent, the average particle diameter of the adsorbent, and the agitation speed, respectively.

The second and the third terms in Eq. 9 influence the amount of adsorbed dye negatively. When the amount of adsorbent and the average particle diameter of the adsorbent increased, the response variable value (q e ) decreased. In contrast, according to the fourth term of Eq. 9, the variable agitation speed affected the response variable positively: increasing agitation increased the amount of adsorbed dye. The maximum amount of adsorbed MB was 3.11 mg g−1 under the following conditions: mass of adsorbent (M) = 0.5 g, particle diameter of adsorbent (G) <0.149 mm, and agitation speed (A) = 200 rpm. These optimal values were used in the subsequent tests.

The ANOVA table—analysis of variance—in Table 4 confirmed the adequacy of the empirical model represented by Eq. 9.

Comparison of the F tab (3.36, 95% of confidence) and F calc (39.7) values, with F calc > F tab, showed that the described model was valid. The coefficient of determination (R 2) was 0.99, close to unit, and the values of the lack of fit and pure error were low, indicating the model was well adjusted to the experimental data.

Kinetic and equilibrium studies

Figure 8 shows that MB adsorption onto the M. falcata shell was fast. Equilibrium was reached after 30 min, revealing good efficiency (Ruthven 1984). The time necessary for equilibrium to be reached did not depend on the studied concentrations. The experimental data fitted with non-linear pseudo-first-order and pseudo-second-order models (Russo et al. 2015). Table 5 contains data regarding the kinetic constants and the statistical values. The coefficients of determination were near unit (R 2 > 0.91) for the three studied concentrations. Furthermore, the q calc values were close to q exp values, enhancing the applicability of the pseudo-second-order model. El Haddad et al. (2014) and Chowdhury and Saha (2010) obtained similar results.

Figure 9 displays the adsorption isotherms. An increase in temperature favored MB adsorption, demonstrating that the process had endothermic characteristics. The Langmuir, Freundlich, Redlich-Peterson, and Liu isotherm models were evaluated. Table 6 lists the results. The Liu model was the best fit for all the evaluated temperatures, then was the most suitable to describe MB adsorption onto the M. falcata shell. The amount of adsorbed dye (q e ) is another parameter that can be used as adjusting evaluator of the models. The q max values obtained by the Liu model (3.01, 6.35, 7.77, and 9.53 mg g−1) were close to the q exp values (3.29, 6.11, 7.28, and 8.81 mg g−1) recorded at temperatures of 25, 40, 50, and 60 °C, respectively.

Thermodynamics

The Arrhenius equation (Eq. 10) afforded the activation energy (Ea)

where k is the constant of velocity, which was 0.866, 0.424, and 0.238 at 25, 40, and 60 °C, respectively; A is the Arrhenius constant, Ea is the activation energy (kJ mol−1), R is the constant of gases (8.314 J mol−1 K−1), and T is the temperature (K). The activation energy can be determined from the graph slope of ln k as a function of 1/T.

The thermodynamic parameters such as standard Gibbs free energy change (ΔG0), standard enthalpy change (ΔH0), and standard entropy change (ΔS0) were evaluated from the adsorption isotherms. Analysis of the thermodynamic parameters under equilibrium conditions provides significant information about the adsorption process. To obtain the thermodynamic parameters, it is necessary to determine the thermodynamic equilibrium constant (K e ), represented by Eq. 11, and to calculate the parameters using Eqs. 12 and 13 (Tan et al. 2008).

The slope and intercept coefficients of the diagram of ΔG0 (kJ mol−1) versus temperature (K) gave the values of ΔH0 and ΔS0, respectively. Table 7 summarizes the values of activation energy and thermodynamic parameters (ΔG0, ΔH0, and ΔS0).

Ea was 3.63 kJ mol−1, which provides an idea of the adsorption type. According to the literature, Ea lower than 40 kJ mol−1 generally indicates processes controlled by diffusion; higher Ea values represent processes that involve chemical reactions (Anirudhan and Radhakrishnan 2008). The Ea value calculated herein suggested that MB adsorption was controlled by diffusion, a physical adsorption process. The negative ΔG0 values achieved at all temperatures indicated that the process was viable and spontaneous. This parameter indicated that the process became more favorable as the temperature increased.

ΔH0 was positive, equivalent to 88.77 kJ mol−1. The standard entropy change gave the degree of disorder. The negative value of ΔS0 (−342.63 kJ mol−1 K−1) indicated that the system disorder decreased at the solid/solution interface during adsorption. According to Mohan and Singh (2002), the negative value of ΔS0 indicates that the internal structure of the adsorbent material did not change significantly during the adsorption process.

Conclusion

Mytella falcata shells are attractive wastes with potential application in the adsorption of dyes from textile effluents, which could reduce environmental liabilities and improve environmental conditions. The use of a process to activate the shells could increase their adsorptive capacity, adding value to this product and reducing environmental problems caused by their improper disposal. FT-IR and XRD analyses confirmed the presence of calcium carbonate (CaCO3) as aragonite and calcite in the shells. Thermal analysis (TGA) showed significant weight loss between 650 and 800 °C, a result of calcium carbonate decarbonation and calcium oxide formation. Morphological analysis evidenced the lamellar structure of the shells. The experimental design results demonstrated that the amount of adsorbent and the particle diameter of the adsorbent were the factors affecting adsorption the most. The best conditions to obtain maximum adsorption capacity were M = 0.5 g, G < 0.149 mm, and A = 200 rpm. According to the kinetic study, the adsorption equilibrium was reached in about 30 min, and the pseudo-second-order model was able to predict the kinetic data. The equilibrium studies revealed that adsorption followed the Liu model. The ΔG0 values were negative at all temperatures, indicating a viable and spontaneous process. The ΔH0 value was positive (32.16 kJ mol−1), suggesting an endothermic process. The negative value of ΔS0 confirmed a decreased disorder at the solid/solution interface during adsorption.

References

Anirudhan TS, Radhakrishnan PG (2008) Thermodynamics and kinetics of adsorption of Cu(II) from aqueous solutions onto a new cation exchanger derived from tamarind fruit shell. J Chem Thermodyn 40:702–709. doi:10.1016/j.jct.2007.10.005

Asaoka S, Yamamoto T, Kondo S, Hayakawa S (2009) Removal of hydrogen sulfide using crushed oyster shell from pore water to remediate organically enriched coastal marine sediments. Bioresour Technol 100:4127–4132. doi:10.1016/j.biortech.2009.03.075

Bharali RK, Bhattacharyya KG (2015) Biosorption of fluoride on neem (Azadirachta indica) leaf powder. J Environ Chem Eng 3:662–669. doi:10.1016/j.jece.2015.02.007

Cardoso NF, Lima EC, Pinto IS et al (2011) Application of cupuassu shell as biosorbent for the removal of textile dyes from aqueous solution. J Environ Manag 92:1237–1247. doi:10.1016/j.jenvman.2010.12.010

Carneiro PA, Umbuzeiro GA, Oliveira DP, Zanoni MVB (2010) Assessment of water contamination caused by a mutagenic textile effluent/dyehouse effluent bearing disperse dyes. J Hazard Mater 174:694–699. doi:10.1016/j.jhazmat.2009.09.106

Chowdhury S, Saha P (2010) Sea shell powder as a new adsorbent to remove Basic Green 4 (Malachite Green) from aqueous solutions: equilibrium, kinetic and thermodynamic studies. Chem Eng J 164:168–177. doi:10.1016/j.cej.2010.08.050

Dauphin Y, Ball AD, Castillo-michel H, Chevallard C (2013) In situ distribution and characterization of the organic content of the oyster shell Crassostrea gigas (Mollusca, Bivalvia). Micron 44:373–383

El Haddad M, Regti A, Laamari MR et al (2014) Calcined mussel shells as a new and eco-friendly biosorbent to remove textile dyes from aqueous solutions. J Taiwan Inst Chem Eng 45:533–540. doi:10.1016/j.jtice.2013.05.002

Ezzeddine Z, Batonneau-Gener I, Pouilloux Y, Hamad H (2016) Removal of methylene blue by mesoporous CMK-3: kinetics, isotherms and thermodynamics. J Mol Liq 223:763–770. doi:10.1016/j.molliq.2016.09.003

Fang J, Gao B, Zimmerman AR et al (2016) Physically (CO2) activated hydrochars from hickory and peanut hull: preparation, characterization, and sorption of methylene blue, lead, copper, and cadmium. RSC Adv 6:24906–24911. doi:10.1039/C6RA01644H

Fernandez C, Larrechi MS, Callao MP (2010) An analytical overview of processes for removing organic dyes from wastewater effluents. TrAC Trends Anal Chem 29:1202–1211. doi:10.1016/j.trac.2010.07.011

Foletto ELL, Weber CTT, Paz DSS et al (2012) Adsorption of leather dye onto activated carbon prepared from bottle gourd: equilibrium, kinetic and mechanism studies. Water Sci Technol 67:201–209. doi:10.2166/wst.2012.555

Freundlich H (1906) Over the adsorption in solution. J Phys Chem 57:358–471

Gad HMH, El-Sayed AA (2009) Activated carbon from agricultural by-products for the removal of Rhodamine-B from aqueous solution. J Hazard Mater 168:1070–1081. doi:10.1016/j.jhazmat.2009.02.155

Garrido-Rodriguez B, Cutillas-Barreiro L, Fernández-Calviño D et al (2014) Competitive adsorption and transport of Cd, Cu, Ni and Zn in a mine soil amended with mussel shell. Chemosphere 107:379–385. doi:10.1016/j.chemosphere.2013.12.097

Ho YS, Mckay G (1998a) Kinetic models for the sorption of dye from aqueous solution by wood. Process Saf Environ Prot 76:183–191. doi:10.1205/095758298529326

Ho YS, McKay G (1998b) Sorption of dye from aqueous solution by peat. Chem Eng J 70:115–124. doi:10.1016/S1385-8947(98)00076-X

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. doi:10.1016/S0032-9592(98)00112-5

Hossain A, Aditya G (2013) Cadmium biosorption potential of shell dust of the fresh water invasive snail Physa acuta. J Environ Chem Eng 1:574–580. doi:10.1016/j.jece.2013.06.030

Hossain A, Bhattacharyya SR, Aditya G (2015) Biosorption of cadmium by waste shell dust of fresh water mussel Lamellidens marginalis: implications for metal bioremediation. ACS Sustain Chem Eng 3:1–8

Lagergren S (1898) About the theory of so-called adsorption of soluble substances. K Sven Vetenskapsakademiens 24:1–39

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403. doi:10.1021/ja02242a004

Li H-Y, Tan Y-Q, Zhang L et al (2012) Bio-filler from waste shellfish shell: preparation, characterization, and its effect on the mechanical properties on polypropylene composites. J Hazard Mater 217–218:256–262. doi:10.1016/j.jhazmat.2012.03.028

Liu Y, Xu H, Yang SF, Tay JH (2003) A general model for biosorption of Cd2+, Cu2+ and Zn2+ by aerobic granules. J Biotechnol 102:233–239. doi:10.1016/S0168-1656(03)00030-0

Machado FM, Bergmann CP, Fernandes THM et al (2011) Adsorption of Reactive Red M-2BE dye from water solutions by multi-walled carbon nanotubes and activated carbon. J Hazard Mater 192:1122–1131. doi:10.1016/j.jhazmat.2011.06.020

Magriotis ZM, Carvalho MZ, De Sales PF et al (2014) Castor bean (Ricinus communis L.) presscake from biodiesel production: an efficient low cost adsorbent for removal of textile dyes. J Environ Chem Eng 2:1731–1740. doi:10.1016/j.jece.2014.07.005

Markovic S, Stankovic A, Lopicic Z et al (2015) Application of raw peach shell particles for removal of methylene blue. J Environ Chem Eng 3:716–724. doi:10.1016/j.jece.2015.04.002

Matouq M, Jildeh N, Qtaishat M et al (2015) The adsorption kinetics and modeling for heavy metals removal from wastewater by Moringa pods. J Environ Chem Eng 3:775–784. doi:10.1016/j.jece.2015.03.027

Mohamed M, Yousuf S, Maitra S (2012) Decomposition study of calcium carbonate in cockle shell. J Eng Sci Technol 7:1–10. doi:10.1007/s11440-013-0278-8

Mohan D, Singh KP (2002) Single- and multi-component adsorption of cadmium and zinc using activated carbon derived from bagasse—an agricultural waste. Water Res 36:2304–2318. doi:10.1016/S0043-1354(01)00447-X

MPA (2015) Ministério da Pesca e Aquicultura http://www.icmbio.gov.br/cepsul/images/stories/biblioteca/download/estatistica/est_2011_bol__bra.pdf. Accessed 7 Oct 2015

OPAS (2015) Organização Pan-Americana da Saúde http://bvs.panalimentos.org/local/File/Guias_para_gerenciamento_riscos_sanitarios_em_alimentos.pdf. Accessed 8 Oct 2015

Otero M, Cutillas-Barreiro L, Nóvoa-Muñoz JC, Arias-Estévez M, Fernández-Sanjurjo MJ, Álvarez-Rodríguez E, Núñez-Delgado A (2015) Cr(VI) sorption/desorption on untreated and mussel-shell-treated soil materials: fractionation and effects of pH and chromium concentration. Solid Earth 6:337–346

Paz DS, Baiotto A, Schwaab M et al (2013) Use of papaya seeds as a biosorbent of methylene blue from aqueous solution. Water Sci Technol 68:441–447. doi:10.2166/wst.2013.185

Rahimdokht M, Pajootan E, Arami M (2016) Central composite methodology for methylene blue removal by Elaeagnus angustifolia as a novel biosorbent. J Environ Chem Eng 4:1407–1416. doi:10.1016/j.jece.2016.02.006

Redlich O, Peterson DL (1959) A useful adsorption isotherm. J Phys Chem 63:1024

Russo V, Tesser R, Trifuoggi M et al (2015) A dynamic intraparticle model for fluid-solid adsorption kinetics. Comput Chem Eng 74:66–74. doi:10.1016/j.compchemeng.2015.01.001

Ruthven DM (1984) Principles of adsorption and adsorption processes, 7th edn. Springer, Berlin

Samal K, Das C, Mohanty K (2017) Eco-friendly biosurfactant saponin for the solubilization of cationic and anionic dyes in aqueous system. Dyes Pigments 140:100–108. doi:10.1016/j.dyepig.2017.01.031

Silva D, Debacher NA, Junior ABC, Rohers F (2010) Caracterização físico-química e microestrutural de conchas de moluscos bivalves provenientes de cultivos da região litorânea da ilha de Santa Catarina. Quim Nova 33:1053–1058

Suzuki RM, Andrade AD, Sousa JC, Rollemberg MC (2007) Preparation and characterization of activated carbon from rice bran. Bioresour Technol 98:1985–1991. doi:10.1016/j.biortech.2006.08.001

Tan IAW, Ahmad AL, Hameed BH (2008) Adsorption of basic dye using activated carbon prepared from oil palm shell: batch and fixed bed studies. Desalination 225:13–28. doi:10.1016/j.desal.2007.07.005

Treviño-Cordero H, Juárez-Aguilar LG, Mendoza-Castillo DI et al (2013) Synthesis and adsorption properties of activated carbons from biomass of Prunus domestica and Jacaranda mimosifolia for the removal of heavy metals and dyes from water. Ind Crop Prod 42:315–323. doi:10.1016/j.indcrop.2012.05.029

Vieira AP, Santana SAA, Bezerra CWB et al (2009) Kinetics and thermodynamics of textile dye adsorption from aqueous solutions using babassu coconut mesocarp. J Hazard Mater 166:1272–1278. doi:10.1016/j.jhazmat.2008.12.043

Viriya-empikul N, Krasae P, Puttasawat B et al (2010) Waste shells of mollusk and egg as biodiesel production catalysts. Bioresour Technol 101:3765–3767. doi:10.1016/j.biortech.2009.12.079

Wang L, Li J (2013) Adsorption of C.I. Reactive Red 228 dye from aqueous solution by modified cellulose from flax shive: kinetics, equilibrium, and thermodynamics. Ind Crop Prod 42:153–158. doi:10.1016/j.indcrop.2012.05.031

Webb PA, Orr C (1997) Analytical methods in fine particle technology. Micromeritics Instrument Corporation, Norcross

Weber CT, Foletto EL, Meili L (2013) Removal of tannery dye from aqueous solution using papaya seed as an efficient natural biosorbent. Water Air Soil Pollut. doi:10.1007/s11270-012-1427-7

Yao Y, Gao B, Wu F et al (2015) Engineered biochar from biofuel residue: characterization and its silver removal potential. ACS Appl Mater Interfaces 7:10634–10640. doi:10.1021/acsami.5b03131

Yousefi Z, Mashayekh-Salehi A, Mohammadpour Tahmtan RA (2015) Biosorption of chromium in aqueous solutions using bivalve mollusk shells through central composite design (CCD) model. Desalin Water Treat:1–13. doi:10.1080/19443994.2015.1106342

Zhang Z, O’Hara IM, Kent GA, Doherty WOS (2013) Comparative study on adsorption of two cationic dyes by milled sugarcane bagasse. Ind Crop Prod 42:41–49. doi:10.1016/j.indcrop.2012.05.008

Zhou K, Yang Z, Liu Y, Kong X (2015) Kinetics and equilibrium studies on biosorption of Pb(II) from aqueous solution by a novel biosorbent: Cyclosorus interruptus. J Environ Chem Eng 3:2219–2228. doi:10.1016/j.jece.2015.08.002

Acknowledgments

The authors thank Capes, CNPq, FAPEAL, and UFAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Silva, T.S., Meili, L., Carvalho, S.H.V. et al. Kinetics, isotherm, and thermodynamic studies of methylene blue adsorption from water by Mytella falcata waste. Environ Sci Pollut Res 24, 19927–19937 (2017). https://doi.org/10.1007/s11356-017-9645-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9645-6