Abstract

The removal of perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) from aqueous solutions using agro-waste biomass of Vitis vinifera (grape) leaf litter was studied. Activated carbons were produced from the biomass and chemical activation achieved by using phosphoric acid (H3PO4) and potassium hydroxide (KOH) for the modification of the carbons’ surface morphology. Activated carbons were characterized using Fourier transform infrared spectroscopy, scanning electron microscopy and Brunauer–Emmett–Teller (BET) in order to understand removal mechanisms of the contaminants by activated carbons. The effect of solution concentration, pH, adsorbent dosage, contact time and temperature was evaluated to optimize the removal efficiency of activated carbons. Adsorption isotherm models were used to analyse the equilibrium data obtained, and kinetic models were applied to study sorption mechanisms. The results fitted well into Freundlich isotherm with both AC-KOH and AC-H3PO4 having high K f values. Maximum adsorption capacities for AC-H3PO4 were 78.90 and 75.13 mg/g for PFOA and PFOS, respectively. Equilibrium was reached before 60 min on both adsorbents, and thermodynamic studies indicated that the process was exothermic and spontaneous. Surface morphology showed the abundance of microspores (>60%) with BET total surface area of 295.488 and 158.67 m2/g for AC-H3PO4 and AC-KOH activated carbons, respectively. Removal efficiencies were 95 and 90% for PFOA using AC-H3PO4 and AC-KOH, respectively; corresponding values for PFOS were 94 and 88%. Adsorbents’ removal capacities depended on the physicochemical characteristics of adsorbents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent time, freshwater resources are faced with major pollution threats due to the intrusion of contaminants such as perfluorinated compounds (PFCs). PFCs are anionic surfactants with the high energy carbon–fluorine (C–F) bond that gives great stability; they also possess high surface activity and resistance to natural biodegradation (Castiglioni et al. 2015). These physicochemical characteristics allow PFCs to be highly persistent in nature, and hence bioaccumulative tendencies in the environment (Giesy and Kannan 2002). Extensive application of perfluoroalkyl substances in various manufacturing processes, such as pulp and paper, surface coating, textiles and pharmaceutical and petrochemical industries, have been identified as sources of these contaminants into the environment (Paul et al. 2008). Large volumes of industrial effluents with residues of various organic contaminants ultimately find their way into natural water bodies (Strynar et al. 2012). Pollution has led to the decline in natural regeneration capacity of the receiving water bodies hence increased the cost of water treatment. The presence of PFCs such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) in environmental water samples constitutes a potential threat to water quality (Castiglioni et al. 2015; Giesy and Kannan 2002). Both PFOA and PFOS belong to the group of emerging contaminants, and their occurrence in environmental and biological samples has received attention globally (Paul et al. 2008). Environmental and health risks associated with elevated levels of PFOA and PFOS in the aquatic system have also been established (So et al. 2007). Such risks include hepatotoxicity, developmental toxicity, immune toxicity, neurotoxicity, endocrine toxicity, gene toxicity and tumourigenic potential (Ericson et al. 2009). Therefore, the continuous application of PFOS and PFOA in production line could increase their burden s in the environment (Jiang et al. 2015). A major manufacturer (3M, USA) of perfluoroalkyl substances (PFAS) voluntarily suspended their production in North America due to the health implication of these chemicals (Benford et al. 2008). International environmental organizations and a few developed nations mobilized against the continuous production of PFCs and standard threshold limits were established for some PFCs in these nations. However, supply of products with PFAS as substituent into developing countries including all African countries continues unabatedly, due to poor legislation on use and discharge into the environment. In recent studies, presences of PFOA and PFOS in environmental samples were attributed to anthropogenic activities (Cui et al. 2009). The ingestion of PFCs via drinking of water and consumption of seafood is possible and may lead to serious health challenges even if at low concentrations (Ericson et al. 2009).

The development of an efficient method for the effective removal of PFOA and PFOS in water and other environmental matrices, therefore, becomes imperative. The removal of perfluorinated compounds from aqueous solutions has attracted lots of attention in recent times with pertinent attention to health and environmental safety (Cui et al. 2009). Various methods have been previously explored in literatures such as advanced oxidation, sonochemical decomposition, reverse osmosis membrane and adsorption techniques using activated carbons (Rattanaoudom et al. 2012). However, challenges of these methods were associated with their ineffective and incomplete removal of these organic pollutants with possible production of recalcitrant compounds during the water purification process (Wang and Shih 2011).

Adsorption has been identified and widely accepted as a better and versatile technique for the treatment of contaminated surface water, wastewaters, drinking water and irrigation water (Xu et al. 2015). Activated carbons generated from different precursors such as natural materials have been explored and reported to produce effective and efficient removal of some identified contaminants (Rattanaoudom et al. 2012). Biosorption is one of the focus areas in the adsorption technique whereby biomass from agricultural materials is used to generate activated carbons for possible removal of organic contaminants in the environmental matrices (Xu et al. 2015). Effective results from the application of activated carbons for contaminants’ removal were attributed to its well-developed surface morphology such as pore structure, pore volume and surface area of the materials (Sethia and Sayari 2016). Some of these activated carbons were found to possess relatively large pore volumes that could be exploited for the removal of large organic molecules. Hence, they are suitable for varieties of industrial applications such as solvent recovery, gas separation, catalysis and most importantly for clean-up and purification processes for purification of portable water (Ali and Asim 2012). Activated carbons derived from agricultural waste materials that have been previously investigated in some studies include waste from apricot, rubber seed coat, jute fibre and coconut husk, among others (Agarwal et al. 2016). Adsorptive capacities of these agro-based activated carbons have been attributed to their surface characteristics.

In this study, an agro-based biomass Vitis vinifera (grape) leaf litter was used to generate activated carbons with chemical modifications. The availability and affordability of V. vinifera leaf biomass in the Western Cape province of South Africa where wine making industry is prevalent were beneficial in terms of cost effectiveness. Limited information is available on the use of V. vinifera leaf biomass as an adsorbent; hence, this is the first investigation to explore the potential and possible relevance of an agro-waste leaf biomass as an adsorbent for water purification. The objective of this study is to produce activated carbons using V. vinifera leaf litter and to investigate the potentials of the activated carbons for removal of PFOA and PFOS at environmental occurrence levels from aqueous media using activated carbon prepared from agro base biomass. The adsorption capacities of the modified activated carbons were compared using adsorption isotherm models, and were characterized using BET, SEM and FTIR to provide information on the removal mechanisms.

Materials and methods

Standards and reagents

Analytical standards and reagents used in this study include the following: potassium hydroxide (KOH) (Merck Millipore, SA), phosphoric acid (H3PO4) (Merck Millipore, SA) (PFOS), heptadecafluorooctane sulfonic acid (Fluka Analytical), perfluorooctanoic acid (PFOA) (Alfa Aesar) and solid-phase extraction hydrophilic-lipophilic balance (SPE-HLB) cartridge (500 mg, 12 mL) supplied by Sulpeco, Sigma-Aldrich and Milli-Q water were obtained through the synthesis of distilled water by Milli-Q synthesis system integral with LC-Pack polisher from Merck Millipore, USA.

Preparation of activated carbon

The agro-waste leaf litter biomass of V. vinifera was collected from a wine farmland in Stellenbosch, South Africa, and was used as the raw material for the preparation of the adsorbent. The supporting information includes a detailed outline of the preparation of activated carbon or equivalent.

Characterization of adsorbents

The elemental composition of untreated leaf biomass and activated carbon (AC)-KOH and AC-H3PO4 activated carbons were determined using energy dispersive spectroscopy (EDS) on scanning electron microscope. The activated carbons and untreated biomass were characterized by Fourier transmittance infrared spectrometry (FTIR), Brunauer–Emmett–Teller (BET) surface area measurement and scanning electron microscopic (SEM) analysis.

FTIR

Infrared spectra of the activated carbons (AC-KOH, AC-H3PO4) and untreated biomass were obtained. Spectra pellet discs were prepared using the pressure disc technique at ratio 1:25 of adsorbent to potassium bromide (KBr) using PerkinElmer FTIR spectrometer (Spectrum 1000, USA) at ambient condition. The recorded spectra were within 4000–400/cm by average of five scans with resolution of 4/cm at constant velocity for the rotating mirror.

SEM

The surface morphology of the untreated biomass and the activated carbons (AC-KOH and AC-H3PO4) was determined before and after adsorption process, using the scanning electron microscope SEM (NOVA Nano SEM 230, USA). Samples were coated with a thin layer of gold using a gold sputtering device (JOEL, JFC-1600) to enhance the visibility of the surface morphology. The electric tension in the detector used was set at 25 kV at 5 mm.

BET

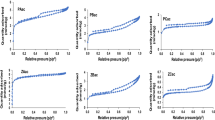

Surface morphologies such as pore area, pore volume and pore size distribution of the activated carbons were determined by nitrogen adsorption and desorption isotherms, using Automatic Adsorption Instrument (Quanta chrome Corp. Nova-1000 g gas sorption, USA). Prior to the measurement, samples were degassed at 170 °C for 13 h. Nitrogen adsorption and desorption data were recorded at liquid nitrogen temperature at 77 K. The surface area of the activated carbon was calculated using BET equation. The pore distribution of micropore and mesopore volumes was determined by the BJH method; the external surface area of the activated carbons was determined by t-plot method.

Sorption experiment

Batch experiments were conducted in triplicates using KOH and H3PO4 activated carbons as adsorbents. Laboratory-simulated wastewater containing a mixture PFOA and PFOS ranging between 0.125 and 1 mg/L was measured into 50-mL nalgene tubes, containing 30 mL Milli-Q water and 0.05 g of as adsorbent. Experimental details can be found in the supporting information at section. The percentage removal and amount of adsorbed at equilibrium, q e (mg/g) using the activated carbons were calculated by Eqs. 1 and 2, respectively.

In the equation, C o and C e are initial concentration and equilibrium concentration (mg/L), respectively, y is the percentage removed, v is the volume of solution (L) and w (gramme) represents the weight of activated carbons.

Kinetic studies were carried out to investigate the adsorption rate and the interaction of the adsorbents.

Activated carbons (0.05 g) were accurately weighed into 50-mL Nalgene tubes containing 30 mL solution of simulated wastewater (a mixture of 0.5 mg/L of PFOS and PFOA). Supernatants were collected at a predetermined time interval ranging from 5 to 120 min. The concentrations of the analytes in the Nalgene tubes were determined, and the quantity of PFOS and PFOA adsorbed q t (mg/g) after adsorption was calculated from Eq. 3.

In the above equation, C o and C t (mg/g) were the liquid-phase concentrations at initial and at time intervals, M is the mass of adsorbent (g) and V is the volume (L) of the solution. Control sample was run simultaneously with the experimental samples to account for possible deviations that may occur during adsorption process.

There were three stages involved in PFOS adsorption. During the first stage, there was gradual adsorption of analytes before 20 min, followed by rapid second stage (less than 3 min), and the third stage which represented the equilibrium state of the adsorption process.

Analytical determination LC-MS/QTOF

The concentrations of PFOS and PFOA in aqueous solutions before and after adsorption experiment were quantified by liquid chromatography (LC) system coupled to quadruples mass spectrometry. Mass spectral was monitored by mass spectrometry fitted with electrospray ionization (ESI), operated in the negative ionization mode. The spectral was recorded using a multiple reaction monitoring mode (MRM).

Result and discussion

Production of activated carbons

The carbonization process reduced an initial biomass of the leaf of 25.0 to 12.9, 8.51, 6.94 and 6.19 g at temperatures 450, 600, 750 and 900 °C, respectively. Xu et al. (2015) reported that the reduction in weight of the carbonization process above 600 °C was due to an increase of the aromatization process of the biochar. Our reported weight reduction increased only from 72 to 75% on going from 750 to 900 °C. In another study (Komkiene and Baltrenaite 2016), it was reported that carbonization at 700 ± 5 °C for 45 min produced a well-developed pore structure on the surface of the activated carbons. Therefore, we concluded that the optimal carbonization process in our experiment is charring at 750 °C for 2 h.

Chemical activation of the charcoal was optimized at 0.5, 1.0 and 3.0 M with both KOH and H3PO4; these results can be found in the supporting information. Maximum concentration of 3.0 M chemical impregnation and a shining black charcoal was produced. This suggested well-developed pore structures with an abundance of micropore and mesopores on the surface of the activated carbon; this observation is consistent with a study reported by Izquierdo et al. (2003). The produced AC-H3PO4 had the highest maximum carbon content of 62.13% compared to AC-KOH (57.29%), untreated charcoal (54.06%) and untreated V. vinifera leaf litter biomass (38.35%). AC-H3PO4 had the maximum carbon content with (62.13%) when compared to AC-KOH (57.29%), untreated charcoal (54.06%) and untreated V. vinifera leaf litter biomass (38.35%).

Characterization of the activated carbons

In this study, chemical activation with H3PO4 increases the pH of the solution with the possible tendency to enhance adsorption process. In literature, phosphoric acid (H3PO4) has been reported as an efficient and excellent chemical activation agent for lignocellulose materials at room temperature (Hameed et al. 2008). This is due to its potential to activate the cleavage of bonds between cellulose and lignin. Studies also reveal that phosphoric acid could enhance formation of phosphate linkage between the fragment of biopolymers pyrolytic (Ghasemian and Palizban 2016). And, chemical activation with KOH reduces the pH of the solution; hence, the basic group on the surface of the activated carbons enhances the electrostatic interactions (Bedin et al. 2016). Raw grape leaf litter biomass and untreated char were generally neutral.

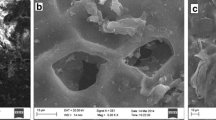

SEM images of untreated V. vinifera biomass and AC-KOH and AC-H3PO4 before and after adsorption are presented in Fig. 1. Micrograph images of the adsorbents were viewed at 10 μm magnification to have a visible surface morphology of the activated carbons. SEM images showed well-developed pore structures on both AC-KOH and AC-H3PO4. The surface texture of untreated biomass was poorly developed and there were no visible blurry changes in the surface morphology. However, the surface texture of the adsorbents AC-KOH and AC-H3PO4 were altered after adsorption; this appearance was suspected to be as a result accumulation of analytes after adsorption process. Remarkable blurry images of activated carbons after adsorption were due to changes in the external and internal surface areas and the degree of porosity of the activated carbons. Apparently, organic compounds with large molecular weights such as PFOA and PFOS could penetrate into the developed inner pores of the adsorbents. It was also assumed that adsorbed analytes could replace the existing molecules on the surface of the modified activated carbons during the adsorption process (Zhang et al. 2014).

SEM image for H3PO4-treated activated carbon before adsorption (Ai), H3PO4-treated activated carbon after adsorption (Aii), KOH-treated activated carbon before adsorption (Bi), KOH-treated activated carbon after adsorption (Bii), un-treated activated carbon before adsorption (Ci) and un-treated activated carbon after adsorption (Cii)

In this study, result from BET surface area and pore structure analysis gave the estimation of specific characteristics of the activated carbons. BET total surface areas for AC-H3PO4, AC-KOH and the untreated leaf biomass of V. vinifera were presented in the (supplementary information). Quantity of analytes adsorbed increased drastically at initial stage with relatively low pressure, and continued to increase slowly before 1.0 (P/P 0) value was attained, indicating that adsorption was favourable at low pressure (Xin-hui et al. 2012). Continuous increase in adsorption capacity of the adsorbents beyond 0.1 (P/P 0) mark of relative pressure clearly indicated that adsorption was type II isotherm according to IUPAC classification; this observation represents a deviation from Langmuir isotherm. Cumulative pore volume distribution chart is presented in supplementary information. This suggests that available pores on the activated carbons mostly occurred in the microporous region. The average pore widths were 19.90 and 38.19 nm for AC-KOH and AC-H3PO4, respectively. Also, the percentage abundance of microspore volumes available on pore surfaces of AC-H3PO4 and AC-KOH were 63.7 and 62.4%, respectively. This result was similar to study by Sethia and Sayari. KOH was used to activate adsorbents prepared from sucrose spherical carbons and reported well-developed surface characteristics—BET total surface area of 1534 cm2/g and 82.6% of micropores (Sethia and Sayari 2016).

FTIR spectra of AC-KOH and AC-H3PO4 before and after adsorption experiment are presented in Fig. 2, showing spectra bands of functional groups available on the surface activated carbons. The FTIR spectra graphs at the region of 3448.1, 3840.04 and 3649.98/cm were assigned to OH free alcohol and interlayered water present in the untreated precursor, and disappeared after carbonization and activation process; this observation was similar to study elsewhere (Xu et al. 2015). Sharp absorption spectrum at 2921.24/cm band was assigned to as C–H in unmodified carbons. This band slightly shifted to 2922.09 and 2921.68/cm bands after chemical treatment, which were assigned to the presence of chelate compounds band of CH2 symmetric stretching (Bedin et al. 2016). Spectrum band (1654.10/cm) represents alkenyl C=C stretching slightly shifted towards 1616.60 and 1604.31/cm after chemical activation with H3PO4 and KOH, respectively; this indicated the presence of double bond C=O, C=C, N=N and COO– asymmetric stretching. Also, 1384.15/cm bands that significantly shifted to 1317.07 and 1317.45/cm indicates the presence of CH3 band (Socrates 2004). The presences of 781.95, 781.94, 873.90 and 1107.07/cm bands were observed on FTIR spectra for AC-H3PO4 and AC-KOH activated carbons, and untreated precursor clearly suggested the presence of C=CH2 (Ahmad et al. 2013). Overall results obtained from physicochemical characterization of the produced activated carbons (AC-H3PO4 and AC-KOH) show that they could explore for possible removal of contaminants.

Effect of pH

In this study, activated carbons were studied under acidic and basic conditions. Figure 3 shows that adsorption was favourable in acidic medium (pH 4) in contrast to studies in the alkaline medium (pH 9). This observation is consistent with previous studies reported by Wang and Shih et al., who reported that sorption of PFOS in aqueous solution was favourable at pH 3 (Wang and Shih 2011). Levels of analytes adsorbed in acid media were significantly higher relative to the sorption of PFOA and PFOS in the alkaline media. A possible explanation of sorption difference at lower pH suggests that there is greater tendency that enhances the electrostatic attraction between adsorbate and adsorbent (Johnson et al. 2007). It was also deduced that abundance of OH− ions in the alkaline media could hinder the diffusion of organic molecules onto the active sites present on the surface of activated carbons, thus reducing the chances of adsorption (Kobya 2004). A similar trend was also reported Moreno-Castilla (2004), who reported that the rate of adsorption at pH 2 was favourable when compared to adsorption at pH 10. The result from this study was also in agreement with another study by Johnson et al. (2007). It was demonstrated that adsorption of PFOS onto carbonaceous surfaces was driven by non-electrostatic attraction (Johnson et al. 2007). It was established that electrostatic interaction played a significant role in the adsorption mechanism when pH values in the aqueous solution were low. This is due to the repulsiveness of negatively charged component present, which reduced the surface electrostatic force in the solution (Ghasemian and Palizban 2016). Other workers showed that pH is an important factor that influences adsorption process of organic pollutants onto a solid phase (Moreno-Castilla 2004). Meanwhile, adsorptive removal of PFOA and PFOS is favourable using AC-H3PO4 and this could be attributed to the limited activities hydroxyl ion (OH–) in the aqueous solution, enhanced electrostatic interaction and surface morphology of the adsorbents (Ochoa-Herrera and Sierra-Alvarez 2008).

Effect adsorbent dosage

Adsorbent dosage plays an important role in the determination of the sorption capacity of activated carbon at a given initial concentration of contaminants in aqueous solutions. Effect of adsorption dosage was investigated for removal efficiency of AC-H3PO4 at 0.02 and 0.05 g dosages of activated carbons. Percentage removal for PFOA and PFOS in aqueous solution at 0.05 g adsorbent dosage had greater percentage removal for both compounds as shown in Fig. 4. A similar trend was reported in the study carried out elsewhere (Xu et al. 2015) which indicated that adsorption was favourable at higher dose of adsorbents. Percentage removal efficiency at the higher adsorbent dose (0.05 g) showed remarkable percentage removal (˃90%) for both PFOA and PFOS which gave maximum removal. In contrast, adsorbate dosage of 0.02 g gave lesser percentage removal (˂90%) for both compounds. Furthermore, concentration of the analytes at different dosages also contributed immensely to the adsorption. Saturation is easily achieved for 0.02 g when compared to 0.05 g adsorbent dose. In the light of this, removal of PFOA and PFOS was favourable at the higher adsorbent dosage at constant solution concentration.

Effect of concentration

Concentration of PFOA and PFOS in the aqueous solutions (adsorbate) ranged between 0.125 and 1.0 mg/L. This range represents environmentally relevant levels of PFOS and PFOA in the environment. Higher concentrations represent unusual pollution scenario that could occur in nature. Similar concentration of PFCs within this range (0.1 and 2.0 mg/L) has been reported in studies by Johnson et al. (2007). Equilibrium data showed that 0.125 mg/L had the highest percentage removal for using 0.02 and 0.05 g adsorbent dosages for both PFOS and PFOA. At increasing concentrations of PFOA and PFOS, removal efficiency decreased especially with the 0.02 g adsorbent dosage (Table 1). This observation suggested that higher concentration of PFOA and PFOS in aqueous solution could enhance the formation of semi-micelles and micelles in solution, and this could possibly accumulate on the surface of the adsorbents, which could enhance adsorption of the analytes (Wang and Shih 2011).

Adsorption equilibrium isotherm

Adsorption isotherms are important models, which describe equilibrium and adsorption behaviour of analytes (solutes) onto the surface of solid phase (adsorbents) at optimized temperature and pH. Adsorption equilibrium isotherm was presented in Fig. 4. The amount of adsorbates and removal efficiency of adsorbents could be deduced from the adsorption isotherm models. Experimental equilibrium data obtained from this study were subjected to four adsorption equilibrium isotherms (Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherm) models expressed in Eqs. (4) to (14). Results are presented in Table 2. Relevant information on how the models are applied can be found in the supporting information. Langmuir model was represented in Eq. (4) and linearized as shown in Eq. (5).

C o and C e represent the initial and equilibrium concentrations of adsorbate at equilibrium (mg/L), respectively, q e represents the amount of adsorbate adsorbed per gramme of the adsorbent at equilibrium (mg/g), q m represent the maximum monolayer coverage capacity (mg/g) and K L is Langmuir isotherm constant (L/mg). Values of q m and K L were deduced from the slope and intercept by plotting 1/q e against 1/C e. An important dimensionless feature of Langmuir isotherm parameters which is also called separation factor R L was estimated from the equation. The value of R L obtained was used to predict the nature of the adsorption process. In this regard, adsorption is considered unfavourable if R L > 1, while R L = 1 indicates that linearity and adsorption are considered favourable if R L ˂ 0.

Maximum adsorption capacities for monolayer coverage q m of Langmuir isotherm for both adsorbents (AC-KOH and AC-H3PO4) were 57.9 and 78.6 mg/g, respectively, for the removal of PFOA from aqueous solutions. Corresponding values for PFOS were 51.8 and 75 mg/g for AC-KOH and AC-H3PO4, respectively. Separation factor R L for both adsorbents is 0.6906 and 0.9856 for AC-KOH and AC-H3PO4, respectively, indicating that adsorption was favourable with both adsorbents. The adsorption data fitted well into Langmuir isotherm model with correlation coefficients (R 2) ranging between 0.9246 and 0.9998 for PFOS and PFOA, respectively.

Freundlich adsorption isotherm was applied to describe the multi-layer adsorption of PFOS and PFOA onto the activated carbons. The empirical equation for Freundlich’s isotherm model is represented in Eq. (7).

K f represents the Freundlich isotherm constant, n is the adsorption intensity, C e is the equilibrium concentration of adsorbate at equilibrium (mg/L) and q e represents the amount of adsorbate that is adsorbed per gramme of adsorbent at equilibrium (mg/g). Summary of the Freundlich’s equation was linearized and expressed in Eq. (8)

Values of K f and 1/n were estimated from the intercept and slope of the plot of log q e against log C e, K f is the indicator of adsorption onto the heterogeneous surface. The value of 1/n indicates the strength of adsorption process, which depends on the adsorption intensity, and could be used to give the estimate of adsorption capacity of the adsorbent (Wang and Shih 2011). If the value of 1/n is <1 that adsorption process is favourable, while a value of 1/n >1 indicates that adsorption process shows an agreement between liquid and solid phases in the system. If n = 1, this shows that partitioning between liquid and solid phases is independent on adsorbate concentration (Xu et al. 2015). Also, the value of k and n as represented in Eq. 8 depends on changes in temperature of the aqueous medium, which may lead to considerable changes in the quantity of the adsorbed analytes (Hameed et al. 2008). The lower the value of the heterogeneity parameter (1/n), the greater the expected heterogeneity and this expression are linear if 1/n is equal to 1. The expression of (1 ˂ n ˂ 10) indicates favourable sorption process (Dada et al. 2012; Hameed et al. 2008). Freundlich’s isotherm model showed that adsorption onto activated carbons was multi-layered on adsorbents’ surfaces with correlation coefficients (R 2) >0.99 (Table 2). In addition, values of 1/n were 0.6683 and 0.9717 for AC-KOH and AC-H3PO4, respectively, for PFOA. Corresponding values for PFOS were 0.1404 and 0.8539, respectively. The n-values that were >1 and <10 indicated that the adsorption of PFOS and PFOA onto AC-KOH and AC-H3PO4 was favourable.

Temkin isotherm model was used to describe adsorption parameters that would express adsorbent–adsorbate interactions, with less emphasis on extremely low and large concentrations of the analytes. Temkin equation represented in Eq. 9 and the linearized form illustrated in Eq. 11 were used by plotting q e against In C e, this was use to determine the adsorption constant, K T from the slope and intercept to derive and b T, respectively (Hameed et al. 2008).

K T (L/g) represent Temkin isotherm equilibrium binding constant, b T (kJ/mol) is the Temkin isotherm constant, R stands for universal gas constant (8.314 J/mol/K), T (K) is the temperature (ideal gas constant 298 K) and B represents the constant related to heat of sorption (J/mol) in Eqs. 9–11. From Temkin isotherm plots, values for K T and b T were obtained. In AC-H3PO4, K T (L/g) values were 176.23 and 208.43 L/g for PFOS and PFOA, respectively. The values using AC-KOH were 14.27 and 67.90 L/g for PFOS and PFOA, respectively. Similarly, Temkin isotherm constant (bT) values for AC-H3PO4 were 40.37 kJ/mol (PFOS) and 48.41 kJ/mol (PFOA) and AC-KOH values were 1.380 and 14.72 kJ/mol for PFOS and PFOA, respectively. Correlation coefficient (R 2) indicated that adsorption data also fitted well into Temkin isotherm model.

Equation 12 represents Dubinin–Radushkevich isotherm model, and the values for q DRB and K ad were derived from the linearized Eq. 13, by plotting ln q e against 퓔 2.

q e represents the amount of adsorbate adsorbed at equilibrium (mg/g), q DRB is the theoretical isotherm saturation capacity (mg/g), K ad (mol2/kJ2) represents Dubinin–Radushkevich isotherm constant and 퓔 stands for the derived Dubinin–Radushkevich isotherm constant. This model is mostly applicable to distinguish between adsorption mechanisms, which is due to chemisorption and physisorption processes with respect to the mean of free energy. From adsorption data obtained, the values of q DRB for AC-H3PO4 were 21.6 and 94.5 mg/g for PFOS and PFOA, respectively. And values of q DRB obtained for AC-KOH were −2.078 and −0.16 mg/g, respectively.

AC-H3PO4 adsorbent showed the dominance for the removal of PFOA and PFOS in aqueous solution at 236.38 and 184.33 mg/g adsorption capacity, respectively. This was established by Freundlich isotherm model as shown in Table 2. Adsorption efficiency of the produced activated carbons was deduced from correlation coefficient (R 2) values obtained in the study. Maximum (R 2) were 0.9998 (PFOA) and 0.9958 (PFOS) for AC-H3PO4 and AC-KOH, respectively. This result agrees with Freundlich isotherm model which assumes that adsorption behaviour relates to strong heterogeneous and multi-layer surface layers. Also, there is an indication of adsorption onto the monolayer coverage on the surface of adsorbents, as revealed in values obtained from Langmuir isotherm model presented in Table 2.

Kinetic studies

Adsorption mechanism of PFOS and PFOA onto AC-KOH and AC-H3PO4 adsorbents was analysed by four kinetic models (pseudo-first-order kinetics, pseudo-second-order kinetics, Elovich rate equation and Weber–Morris intra-particle diffusion rate) and are expressed in Eqs. 15–18, respectively. There was an initial rapid adsorption rate from 30 min up to 60 min for both PFCs using the two activated carbons as presented in Fig. 5. Similar studies by Yu et al. (2009), with commercial activated carbons, reported that equilibrium was attained at an average of 48 h for the removal of some selected PFCs from aqueous solutions. Relevant information on how the kinetic models are applied can be found in the supporting information.

Pseudo-first-order kinetics K 1 values obtained for AC-KOH were 0.0293 and 0.0224/min for PFOS and PFOA, respectively. And, the correlation coefficients (R 2) for the model using AC-KOH were 0.9044 and 0.4942 for PFOS and PFOA, respectively. Also, K 1 values for AC-H3PO4 were 0.532 and 0.0369/min for PFOS and PFOA, respectively. And the corresponding R 2 values were 0.5881 and 0.5029 for PFOS and PFOA, respectively. Adsorption capacities, q e using AC-H3PO4 were 3.83 and 1.69 mg/g for PFOS and PFOA, respectively. The values obtained with AC-H3PO4 were 0.552 and 2.091 mg/g for PFOS and PFOA, respectively. Results suggested that pseudo-first-order kinetics model did not fitted well into the adsorption data obtained due to poor linearity.

Pseudo-second-order kinetics values obtained in this study revealed coefficient of correlation (R 2) values of 0.995 (PFOS) and 0.4779 (PFOA) for AC-KOH and (R 2) values of 0.9736 (PFOS) and 0.9936 (PFOA) for AC-H3PO4. These values suggested that kinetic rate is in agreement with chemisorption mechanism being a major controlling step with AC-H3PO4 for removal of PFOS and PFOA. Adsorption capacities of the activated carbon gave maximum value of 119.12 mg/g for removal of PFOA using AC-KOH, which implies that pseudo-second-order kinetics favours the removal of PFOA in aqueous solution. Other parameters responsible for adsorption kinetic rate could be attributed to surface characteristics such as the degree of porosity of the adsorbents.

Elovich’s kinetic model was also applied to determine the adsorption and desorption processes involved in the adsorption process. And, this was used to deduce the feasibility of application of produced activated carbons to real-life scenario. Calculated values for α was 0.1892 mg/g/min, β = 0.4806 mg/g and correlation coefficient (R 2) was 0.8891 for sorption of PFOA onto AC-H3PO4. Corresponding values for PFOS using AC-H3PO4 were α = 0.0927 mg/g/min, β = 0.0268 g/mg and R 2 value of 0.9408. Result from this model suggested that higher rate of adsorption (α) than desorption rate (β) supported fast uptake of PFOS and PFOA at the initial stage. And, adsorption rate decreases with time as shown in agreement with chemisorption mechanism being the controlling step.

Weber–Morris intra-particle diffusion kinetic plot showed multi-linearity indicating that two or more stages took place in the process (Fig. 6 (Di, Dii)). Equilibrium was attained before 60 min. However, adsorption mechanism for the removal of PFOA involved two stages. The initial stage with a steady increase in adsorption up to 40 min and the second stage of intra-particle diffusion proceeded slowly due to low concentration of analytes available in aqueous solution. Graphical presentation of the kinetics model is illustrated in Fig. 6. Adsorption kinetics models presented in this study are presented in Table 3 and show that equilibrium data interpretation fitted well onto more than one models. Correlation coefficient (R 2) values obtained were greater than (>0.9) for AC-H3PO4 as illustrated by Elovich rate equation, intra-particle diffusivity equation and pseudo-second-order kinetic models. From this result, pseudo-second-order kinetics and Elovich rate equation models gave the maximum correlation coefficient values with (R 2) values 0.9408 and 0.9736 for PFOA and PFOS, respectively. However, this study establishes that both Elovich rate equation and pseudo-second-order kinetics models agreement with chemisorption mechanisms (Bäuerlein et al. 2012) being the controlling step for adsorption processes in this study.

Thermodynamic studies

From the thermodynamic study, it was observed that changes in temperature affected the quantity of adsorbate on the surface of the adsorbents. Levels of PFOS and PFOA in solution did not decrease with increase in temperature. At increased temperature, the mobility of adsorbates increased in solution, thereby enhancing the adsorption process. Whereas, at reducing temperature, mobility of adsorbates were evidently reduced. Observation from this study suggested that adsorption process was exothermic and that the condition favoured the sorption process. The summary of thermodynamics parameters is presented in Table 4. All the values obtained for ΔG° were negative. This indicates that reaction was spontaneous during the adsorption processes. It was also observed that ΔG° value decrease with rise in temperature (at −11.03 kJ/mol (298.15 K) > −10.86 kJ/mol (303.15 K) > −10.801 kJ/mol (308.15 K), suggesting that sorption of PFOA onto the activated carbons was favourable at low temperature. In addition, AC-H3PO4 gave maximum adsorption q m (78.90 mg/g) with K L values of 0.0146 at the minimum temperature 298.15 K when compared to other investigated temperatures (303.15 and 308.15 K), while AC-KOH that gave q e (57.90 mg/g) with K L values of 0.0142 at the chemisorption was favourable and ΔH° value of −21.66 kJ/mol obtained for AC-KOH was attributed to both physisorption and chemisorption. Large positive value obtained for (ΔS°) entropy is a clear indication of increasing mobility in the system, due to availability of unused energy during adsorption process (Ali and Asim 2012) (Table 5).

Desorption studies

Desorption studies were conducted to examine the regeneration capacity of the developed activated carbon and also to establish their reusability potentials. Three solvents (acetonitrile, methanol and hydrochloric acid solution) of different ratios with distilled water were optimized for desorption of PFOS and PFOA from the surface of activated carbons after the adsorption process. Desorption was 99% for the removal of PFOS and PFOA with 100% methanol, 96% using 100% acetonitrile and 85% with 0.1 M HCl. Regenerated activated carbons (AC-H3PO4 and AC-KOH) were reused successfully for uptake of PFOA and PFOS from aqueous solutions. During adsorption experiments, ˃90% was achieved for both activated carbons.

Adsorption capacities of the produced activated carbons in this study were compared with previously reported values (Table 6), although commercially available synthetic activated carbons have been reported to have higher adsorption capacities when compared with agro-based activated carbons (Senevirathna et al. 2010). However, environmental and health risks associated with most of the available synthetic activated carbons have not been fully investigated. Agro-based activated carbons sourced from V vinifera leaf litter are a clear alternative adsorbent for the removal of contaminants in the water system.

Conclusion

This study presents the use of V. vinifera leaf biomass, an agro-based material sourced locally in Stellenbosch South Africa, to generate activated carbons. Produced activated carbons were modified in both acidic (H3PO4) and basic (KOH) media. They were both found to be effective for the removal PFOA and PFOS in aqueous solution using adsorption techniques; however, AC-H3PO4 gave maximum adsorption capacity of 78.90 and 75.13 mg/g for PFOA and PFOS, respectively. The influence of lower solution pH, increase in available cations concentration, low temperature and physicochemical characteristics of the adsorbents contributed to the remarkable removal capacity of AC-H3PO4. Produced activated carbons proved to be a promising alternative adsorbent for commercially available adsorbents. Adsorption kinetic model suggested that physisorption is a major controlling mechanism for removal of PFOA and PFOS from aqueous solutions. Adsorption process was exothermic and spontaneous. The well-developed surface morphology, abundance of microspores and large surface areas of the activated carbons contributed to removal efficiencies of the activated carbons. V. vinifera leaf biomass is an eco-friendly, cost-effective, regenerated potential and accessible alternative adsorbent that may be explored for the removal of other environmental contaminants in water.

References

Agarwal S, Tyagi I, Gupta VK, Ghasemi N, Shahivand M, Ghasemi M (2016) Kinetics, equilibrium studies and thermodynamics of methylene blue adsorption on Ephedra strobilacea saw dust and modified using phosphoric acid and zinc chloride. J Mol Liq 218:208–218

Ahmad F, Daud WMAW, Ahmad MA, Radzi R (2013) The effects of acid leaching on porosity and surface functional groups of cocoa (Theobroma cacao)-shell based activated carbon. Chem Eng Res Des 91:1028–1038

Ali I, Asim M, Khan TA (2012) Low cost adsorbents for the removal of organic pollutants from wastewater. J Environ Manag 113:170–183

Bäuerlein PS, Mansell JE, ter Laak TL, de Voogt P (2012) Sorption behavior of charged and neutral polar organic compounds on solid phase extraction materials: which functional group governs sorption? Environ Sci Technol 46:954–961

Bedin KC, Martins AC, Cazetta AL, Pezoti O, Almeida VC (2016) KOH-activated carbon prepared from sucrose spherical carbon: adsorption equilibrium, kinetic and thermodynamic studies for methylene blue removal. Chem Eng J 286:476–484

Benford D et al. (2008) Opinion of the scientific panel on contaminants in the food chain on perfluorooctane sulfonate (PFOS), perfluorooctanoic acid (PFOA) and their salts EFSA Journal:1–131

Castiglioni S et al (2015) Sources and fate of perfluorinated compounds in the aqueous environment and in drinking water of a highly urbanized and industrialized area in Italy. J Hazard Mater 282:51–60

Cui L, Zhou QF, Liao CY, Fu JJ, Jiang GB (2009) Studies on the toxicological effects of PFOA and PFOS on rats using histological observation and chemical analysis. Arch Environ Contam Toxicol 56:338–349

Dada A, Olalekan A, Olatunya A, Dada O (2012) Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. J Appl Chem 3:38–45

Ericson I, Domingo JL, Nadal M, Bigas E, Llebaria X, van Bavel B, Lindström G (2009) Levels of perfluorinated chemicals in municipal drinking water from Catalonia, Spain: public health implications. Arch Environ Contam Toxicol 57:631–638

Ghasemian E, Palizban Z (2016) Comparisons of azo dye adsorptions onto activated carbon and silicon carbide nanoparticles loaded on activated carbon. Int J Environ Sci Technol 13:501–512

Giesy JP, Kannan K (2002) Peer reviewed: perfluorochemical surfactants in the environment. Environ Sci Technol 36:146A–152A

Hameed B, Tan I, Ahmad A (2008) Adsorption isotherm, kinetic modeling and mechanism of 2,4,6-trichlorophenol on coconut husk-based activated carbon. Chem Eng J 144:235–244

Izquierdo MT, Rubio B, Mayoral C, Andrés JM (2003) Low cost coal-based carbons for combined SO2 and NO removal from exhaust gas. Fuel 82:147–151

Jiang W, Zhang Y, Yang L, Chu X, Zhu L (2015) Perfluoroalkyl acids (PFAAs) with isomer analysis in the commercial PFOS and PFOA products in China. Chemosphere 127:180–187

Johnson RL, Anschutz AJ, Smolen JM, Simcik MF, Penn RL (2007) The adsorption of perfluorooctane sulfonate onto sand, clay, and iron oxide surfaces. J Chem Eng Data 52:1165–1170

Kobya M (2004) Removal of Cr (VI) from aqueous solutions by adsorption onto hazelnut shell activated carbon: kinetic and equilibrium studies. Bioresour Technol 91:317–321

Komkiene J, Baltrenaite E (2016) Biochar as adsorbent for removal of heavy metal ions [Cadmium (II), Copper (II), Lead (II), Zinc (II)] from aqueous phase. Int J Environ Sci Technol 13:471–482

Moreno-Castilla C (2004) Adsorption of organic molecules from aqueous solutions on carbon materials. Carbon 42:83–94

Ochoa-Herrera V, Sierra-Alvarez R (2008) Removal of perfluorinated surfactants by sorption onto granular activated carbon, zeolite and sludge. Chemosphere 72:1588–1593

Paul AG, Jones KC, Sweetman AJ (2008) A first global production, emission, and environmental inventory for perfluorooctane sulfonate. Environ Sci Technol 43:386–392

Rattanaoudom R, Visvanathan C, Boontanon SK (2012) Removal of concentrated PFOS and PFOA in synthetic industrial wastewater by powder activated carbon and hydrotalcite. Journal of Water Sustainability 2:245–258

Senevirathna S, Tanaka S, Fujii S, Kunacheva C, Harada H, Ariyadasa B, Shivakoti B (2010) Adsorption of perfluorooctane sulfonate (n-PFOS) onto non ion-exchange polymers and granular activated carbon: batch and column test. Desalination 260:29–33

Sethia G, Sayari A (2016) Activated carbon with optimum pore size distribution for hydrogen storage. Carbon 99:289–294

So M et al (2007) Perfluorinated compounds in the Pearl river and Yangtze river of China. Chemosphere 68:2085–2095

Socrates G (2004) Infrared and Raman characteristic group frequencies: tables and charts: John Wiley & Sons

Strynar MJ, Lindstrom AB, Nakayama SF, Egeghy PP, Helfant LJ (2012) Pilot scale application of a method for the analysis of perfluorinated compounds in surface soils. Chemosphere 86:252–257

Wang F, Shih K (2011) Adsorption of perfluorooctanesulfonate (PFOS) and perfluorooctanoate (PFOA) on alumina: influence of solution pH and cations. Water Res 45:2925–2930

Xin-hui D, Srinivasakannan C, Qu W-W, Xin W, Jin-hui P, Li-bo Z (2012) Regeneration of microwave assisted spent activated carbon: process optimization, adsorption isotherms and kinetics. Chem Eng Process Process Intensif 53:53–62

Xu C, Chen H, Jiang F (2015) Adsorption of perflourooctane sulfonate (PFOS) and perfluorooctanoate (PFOA) on polyaniline nanotubes. Colloids Surf A Physicochem Eng Asp 479:60–67

Yu Q, Zhang R, Deng S, Huang J, Yu G (2009) Sorption of perfluorooctane sulfonate and perfluorooctanoate on activated carbons and resin: kinetic and isotherm study. Water Res 43:1150–1158

Zhang P, Wang T, Qian G, Wu D, Frost RL (2014) Removal of methyl orange from aqueous solutions through adsorption by calcium aluminate hydrates. J Colloid Interface Sci 426:44–47

Acknowledgement

The authors wish to acknowledge the financial support of the National Research Foundation (NRF), South Africa, for the Thuthuka Research Grant No. 84185 awarded to Prof B.O. Opeolu.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(DOCX 113 kb)

Rights and permissions

About this article

Cite this article

Fagbayigbo, B.O., Opeolu, B.O., Fatoki, O.S. et al. Removal of PFOA and PFOS from aqueous solutions using activated carbon produced from Vitis vinifera leaf litter. Environ Sci Pollut Res 24, 13107–13120 (2017). https://doi.org/10.1007/s11356-017-8912-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-8912-x