Abstract

This study verifies textile wastewater reuse treated by the conventional activated sludge process and subjected to further treatment by advanced oxidation processes. Three alternative processes are discussed: Fenton, photo-Fenton, and UV/H2O2. Evaluation of treatments effects was based on factorial experiment design in which the response variables were the maximum removal of COD and the minimum concentration of residual H2O2 in treated wastewater. Results indicated Fenton’s reagent, COD/[H2O2]/[Fe2+] mass ratio of 1:2:2, as the best alternative. The selected technique was applied to real wastewater collected from a conventional treatment plant of a textile mill. The quality of the wastewater before and after the additional treatment was monitored in terms of 16 physicochemical parameters defined as suitable for the characterization of waters subjected to industrial textile use. The degradation of the wastewater was also evaluated by determining the distribution of its molecular weight along with the organic matter fractionation by ultrafiltration, measured in terms of COD. Finally, a sample of the wastewater after additional treatment was tested for reuse at pilot scale in order to evaluate the impact on the quality of dyed fabrics. Results show partial compliance of treated wastewater with the physicochemical quality guidelines for reuse. Removal and conversion of high and medium molecular weight substances into low molecular weight substances was observed, as well as the degradation of most of the organic matter originally present in the wastewater. Reuse tests indicated positive results, confirming the applicability of wastewater reuse after the suggested additional treatment.

Textile wastewater samples after additional treatment by Fenton’s reagent, photo-Fenton and H2O2/UV tested in different conditions

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As fresh water becomes an increasingly scarce resource, industries have been challenged to develop economically feasible reuse technologies (Garcia and Pargament 2015). The concept of industrial wastewater reuse was first introduced in the 1980s as a new concept within water resource management (UN 1992). This practice allowed industry to “close the loop” and also prevented discharge of heavy loads of toxic pollution into water bodies (Piadeh et al. 2014). Moreover, water has become an item of heavy taxation for local and national authorities (Vajnhandl and Valh 2014) and if a cost-effective water reuse technology is established, the industry may save resources once spent on water supply.

The textile industry is widely known to employ some of the most water-intensive industrial processes (Blanco et al. 2014). It is estimated that the textile process consumes over 100 L of water per kilogram of processed fabric (Vajnhandl and Valh 2014). The wet-processing of the fibers, in which they are dyed and repeatedly rinsed, applies dyes, surfactants, salts, and other recalcitrant and toxic chemicals resulting in highly toxic and variable textile wastewaters (Hasanbeigi and Price 2015). Textile wastewater characteristics may vary seasonally or even daily and are highly inconsistent depending on the kind of fabric and on the type of dye applied. pH values may vary from 2 to 13, while chemical oxygen demand (COD) values may range from 300 to 60,000,000 mg L−1 (Vajnhandl and Valh 2014). The high variability and toxicity of textile wastewaters may preclude the use of conventional biological treatment, which is often the only treatment available in textile mills (Rodrigues et al. 2013).

Some advanced wastewater treatment technologies have been tested and are currently applied to enable textile wastewater reuse, thus leading to closed water cycles (Vajnhandl and Valh 2014). Various technologies such as membrane filtration (Ellouze et al. 2012), adsorption (Ergas et al. 2006; Weng et al. 2013), ozonation (Constapel et al. 2009), and advanced oxidation processes (AOPs) have already been tested for the treatment of textile wastewater and/or textile dye removal from synthetic solutions. Only a few of the published works related to textile wastewater treatment by AOPs propose treated wastewater reuse (Blanco et al. 2012, 2014), probably due to the challenge of optimizing AOP treatment for a highly variable wastewater which must attend severe quality requirements for reuse purposes.

Homogeneous Fenton (Fe2+/H2O2) (Eq. 1), photo-Fenton (Fe2+/UV/H2O2) (Eq. 2), and Photo-peroxidation (UV/H2O2) (Eq. 3) (Tarr 2003) have been suggested as very efficient technologies for color removal (Gogate and Pandit 2004; Weng et al. 2014; Weng and Huang 2015; Weng and Tsai 2016) which is one of the requirements when aiming at water reuse. Application of artificial light in UV/H2O2 (Eq. 3) and Fe2+/UV/H2O2 may increase costs related to these treatment techniques when compared to Fenton’s reagent.

Some of the drawbacks related to the application of the homogeneous Fenton reagent and photo-Fenton processes are as follows: (i) they must be operated under acidic pH, once Fe must be in its soluble form, requiring the use of chemical reagents to adjust wastewater pH before and after treatment; (ii) reagent concentrations must be optimized to avoid reagent excess and scavenger effects (Amorim et al. 2013); (iii) Fenton systems generate sludge as a by-product which must be properly disposed of (dos Santos et al. 2007); (iv) the use of iron salts as reagents in these systems may culminate in the presence of Fe in the treated wastewater which can contribute to tissue quality damage, as previously reported (Vajnhandl and Valh 2014); and (v) textile wastewaters usually contain high concentrations of ions, such as chloride (Cl−), and some of them may react with HO● leading to a decrease in process efficiency (Manenti et al. 2015).

This research focuses on the treatment and reuse of real textile wastewater collected after the biological treatment available in a textile mill. Three different AOPs were tested: UV/H2O2, homogeneous Fenton, and photo-Fenton. The best treatment option was chosen, and its optimized condition was validated. Finally, dyeing tests were performed in order to evaluate the performance of treated wastewater in the dyeing process.

Materials and methods

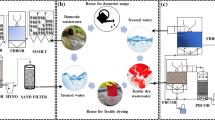

Water and wastewater in the textile industry

Textile wastewater used in this study was collected from a large textile factory located within the Metropolitan Region of Belo Horizonte, Minas Gerais, Brazil. This factory produces 400 t of finished fabric per month. The company consumes an average of 48,300 m3of water per month, supplied from two main sources. In this factory, different types of fabrics (cotton, viscose, polyester, and polyamide) are dyed daily. Therefore, a wide variety of dyes are applied with auxiliaries, such as azo, reactive, disperse, sulfur, acid, and basic, among others; thus, color and physicochemical properties of wastewater commonly fluctuate on a daily basis in this industry. Percentage contribution of different water sources in the total consumption of the textile industry is shared by fresh water (46 %), reclaimed water (48 %), and other sources (6 %) as described in the Supplementary Material (Fig. S1) where a simplified flowchart of the water used in this textile industry is shown. More details of the water flow in this industry were described by Starling et al. (2016).

Textile wastewater used in this study was collected in the output of the wastewater treatment plant (WWTP), which treats wastewaters from the dyeing and washing stages of production through activated sludge biological system.

Definition of the best treatment option

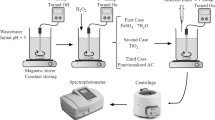

In this first stage, three samples were collected in the output of the WWTP, each one consisting of five fractions of 5 L per day within 1 week (25 L each and 75 L in total). Each one of the three samples was assigned to a different batch process: (i) homogeneous Fenton (Fe2+/H2O2), (ii) photo-Fenton (Fe2+/UV/H2O2), and (iii) photo-peroxidation (UV/H2O2). A bench scale reactor used in all of these experiments, represented in Fig. 1, has an interior glass container with a total volume of 0.9 Land is attached to a cooling system for temperature control (25 °C). UV irradiation (254 nm) is emitted by a mercury vapor lamp (12 W) which is covered by a quartz tube.

Scheme of the reactor used in the presented study (adapted from Amorim et al. (2013)

Operating conditions were kept constant in all of the experiments (temperature = 25 °C, stirring = 100 rpm, reaction time = 2 h), and all tests were carried out in duplicate. Reagents applied in the tests were FeSO4·7H2O (Merck) and H2O2 30 % w/w (Merck). Also, sulfuric acid 0.1 M (Synth) and sodium hydroxide 0.1 M (Merck) were used for acidification and neutralization of the samples. COD was measured before and after all of the performed reactions by the closed reflux colorimetric method in accordance with the standard methodology (APHA 2005). In the end of each reaction, system was neutralized (pH = 7) and catalase enzyme (Sigma-Aldrich catalase from bovine liver, CAS number 9001-05-2, C9322) was added (solution: 460 mg L−1 in phosphate buffer 0.04 M) in a ratio of 0.1:1.9 mL (catalase/sample) for residual H2O2 consumption (Poole 2004). COD final values for the samples to which catalase was added were obtained by subtracting the COD value corresponding to catalase. Also, H2O2 consumption was determined at the end of each reaction by titration method using the iodometric method (USP 2015).

Factorial design of experiments was applied in order to define the optimal conditions for each one of the treatment processes. The experimental planning was performed using the wastewater initial chemical oxygen demand (COD0) as a reference. Relations for [H2O2]/COD and [Fe2+]/[H2O2] varied in three concentration levels: low (0.5 and 0.25), medium (1.0 and 0.5), and high (2.0 and 1.0). Thus, a total of nine Fenton and nine photo-Fenton experiments were carried out, as summarized in Table 1. Control tests were also carried out using the mass ratio of the central experiment (no. 5), without Fe2+ (Control_1) and without H2O2 (Control_2). For Fenton and photo-Fenton reactions, which were conducted at pH 3, wastewater was acidified prior to the addition of Fe2+ and H2O2. After Fe2+ was added, solution was stirred and pH assessed again to assure conditions were acidic, then H2O2 was introduced to the system, and reaction was conducted for the following 2 h.

UV/H2O2 experiments were performed in the same bench scale reactor (Fig. 1) at pH 3 and sample original pH (≈7.0). Temperature, reaction time, and stirring conditions were kept as detailed for Fenton and photo-Fenton reactions. The same [H2O2]/COD high, medium, and low levels were considered, in a total of six experiments, presented in Table 2. At the end of each reaction, catalase was also used as described earlier.

The evaluation of the efficiency of each treatment process was done by analyzing fitting regression models and response surfaces through the method of least squares, with the support of Matlab® and StatSoft® Statistic softwares.

Validation of best treatment alternative

Statistical analysis of the COD monitoring data, collected for a period of 3 years in the same textile industry (50 samples), showed a coefficient of variation (CV) of 34 % and 182 ± 61.4 mg L−1 of COD median, with a maximum value of 299 mg L−1 of COD and a minimum value of 61.2 mg L−1 of COD. This is a key factor for defining the optimal number of samples in order to ensure a representative number of tests and results of the investigated system. The COD coefficient of variation was used in order to estimate the number of samples (Eq. 4), considering a confidence level of 90 % and an acceptable error, E, of 20 %.

where n is the number of samples; CV is the coefficient of variation (in %); E is the permissible error of the mean estimated by n results (in %); and t α;DOF is the t value for the Student’s t test for a confidence level (1 − α) and degree of freedom (DOF = n − 1).

Since the DOF is not known, the equation must be solved by iteration. A provisional sample size n 0 was randomly chosen (n 0 = 30), and the DOF was calculated using the previously determined values of n 0 and an α. The t α;DOF was obtained from Student’s t distribution table. Using this information in Eq. 6, a new n was obtained and a new value of t α;DOF was established. Calculations were performed iteratively until a convergence value of n was found. Table S1 (Supplementary Data) demonstrates the calculations. A total of 10 single samples was estimated as an adequate sample size, which were collected (4 L) in both dry and wet seasons. All the sampling, preservation, storage, and transportation of samples were carried out according to US Environmental Protection Agency (USEPA 1982) standards.

For all of these 10 samples, physicochemical characterization was performed for 16 parameters, before and after additional treatment by Fenton’s reagent: COD, pH, alkalinity, hardness, conductivity, total dissolved solids (TDS), total suspended solids (TSS), turbidity, nitrate (NO3 −), nitrite (NO2 −), chloride (Cl−), sulfate (SO4 2−), iron (Fe), manganese (Mn), and copper (Cu) were analyzed according to APHA methods (2005) and Rodier and Rodi (1981). In addition, absorbance was determined using the method described by de Mio and Campos (1998). These parameters were selected on the basis of guidelines for water quality use in textile processing, as shown in the Supplementary Data section (Table S2). In order to evaluate if there was significant difference among samples before and after additional treatment, values obtained for each of these 16 physicochemical parameters were statistically compared by Mann-Whitney test (α = 0.05) using the Software Statistica®; p values below 0.05 indicate significant difference between samples.

Also, textile wastewater molecular weight distribution (MWD) was examined before and after treatment to evaluate the impact of AOPs on the wastewater composition. Characterization of dissolved organic matter (DOM) present in wastewater through MWD is a helpful tool for the design of water and wastewater treatment systems (Leiviskä et al. 2008). MWD of the textile wastewater was assessed by filtration through an ultrafiltration cell (Amicon, Model 8400) using membranes with porosity of 1, 10, and 100 kDa (Millipore, PL series). The samples were previously filtered using a glass fiber membrane (porosity of 1.5 μm, Whatman 934-AH).

For the MWD determination, the following procedure was repeated for each membrane. First, 200 mL of the sample was measured and transferred to the ultrafiltration cell to be pressurized with industrial N2 gas (Air Products) for each membrane pressure (1 kDa = 200 kPa; 10 kDa = 200 kPa, and 100 kDa = 50 kPa). During the filtration process, the sample was kept under magnetic stirring (752 Fisatom). When the cell volume reached 50 mL, the system was depressurized and the stirring was continued for a further 10 min. Then, the cell was opened and the volume was brought to 200 mL by adding deionized water. The system was pressurized again and subjected to magnetic stirring, which continued throughout the ultrafiltration process. Once the volume in the cell achieved the mark below 50 mL, the cell was depressurized and the magnetic stirring continued for the next 10 min. Finally, the contents were transferred to a volumetric flask of 50 mL, and its volume was filled with deionized water. The ultrafiltration procedure was performed before and after treatment by selected AOP and is illustrated in Fig. 2.

The mass balance to obtain the COD fractions is determined by the following Eqs. 5, 6, 7, and 8:

where COD UF100 is the COD of the sample retained on the 100-kDa membrane, in milligrams per liter; COD UF10 is the COD of the sample retained on the 10-kDa membrane, in milligrams per liter; COD UF1 is the COD of the sample retained on the 1-kDa membrane, in milligrams per liter; CODMF1.5 is the COD of the sample permeated on the 1.5-μm filter, in milligrams per liter; and Cf is the correction factor (concentration = V/v = 200 mL/50 mL = 4).

Treated wastewater reuse tests

Reuse of wastewater treated by the selected process was tested in a pilot-scale dyeing machine (Aponus and Rapid Eletrotex). The operation of the machine is such that it is loaded with water or glycerin and is adapted to fit small metallic cylinders which are filled with fabric, water, dyes, and other chemicals used in the process. These machines are able to achieve the temperatures used in fabric dyeing operations. After dyeing, the fabric quality was evaluated through a dyeing standard procedure commonly performed by the factory in order to check the occurrence of discoloration, stains, or color contrasts between the fabrics dyed by conventional and reuse procedures. Samples dyed with treated wastewater were photographed (Sony 7.2 megapixels camera) using fixed light exposure and fixed focal length.

Dyeing tests were performed with a raw fabric consisting of viscose and cotton, which corresponds to 42 % of the selected textile mill total production. The dyeing process uses polyfunctional reactive dyes, besides other chemicals, such as alkalis, salts, bleaches, detergents, stabilizers, sequestrants, dispersants, and complexing agents. Three different colored fabrics from the company catalog were reproduced: white, pink 514, and gray 68. For the white fabric, tests were conducted with fresh water and compared to the Fenton treated wastewater. For the pink and grey products, the reclaimed water was used and compared to Fenton treated wastewater. After dyeing, samples were washed, dried, and submitted to quality control tests.

Results and discussion

Preliminary AOP tests using factorial design

Results showed remarkable reductions of COD (Fig. 3) for the wastewater treated by the homogeneous Fenton (45–66 %) and photo-Fenton (37–68 %) processes (performed at 25 °C). COD removal efficiencies were very similar for both of these systems. The UV/H2O2 process achieved lower COD degradation (1–28 %). This may be explained by lower H2O2 consumption (Fig. 4) in this system, in which hydroxyl radicals are produced only through the cleavage of H2O2 by UV irradiation, when compared to Fenton and photo-Fenton processes. Results obtained for the UV/H2O2process are unacceptable from an economic and technical perspective since there is no consumption of most of the applied peroxide (49–69 %) and also because excessive H2O2 damages fabrics. Low decomposition of H2O2 may be due to the presence of suspended solids and dissolved dye, which absorb UV radiation, damaging the formation of HO●. Wastewater dilution would probably improve DOC removal through UV/H2O2, as observed by other authors (Blanco et al. 2012; Rosa et al. 2015). Also, an increase in reaction temperature would probably be able to increase COD removal in both Fenton and photo-Fenton systems (Blanco et al. 2014).

Hydrogen peroxide consumption was higher in the photo-Fenton process when compared to Fenton process as shown in Fig. 4. This is predictable considering that in irradiated processes, the decomposition of peroxide to hydroxyl radicals is caused not only by reactions with ferrous ions but also by ultraviolet radiation, which provides the photolysis of H2O2. Despite this fact, Fig. 3 shows that the experiments with the photo-Fenton process generally did not achieve COD degradation indexes higher than those obtained by Fenton contradicting expectations, since systems irradiated by UV or visible light generally show enhanced COD degradation when compared to non-irradiated systems, due the occurrence of additional routes for HO● radical formation (Gernjak et al. 2003; Anjaneyulu et al. 2005). This trend can be explained by the possible consumption of hydroxyl radicals by iron in solution.

Fenton experiment no. 9 (1:2:2) showed total hydrogen peroxide consumption. This indicates that this may be the best treatment option among all of the tests performed, since it leads to a COD removal rate which is similar to that of the corresponding photo-Fenton. Furthermore, it is less costly because no ultraviolet radiation is needed.

Visual aspect

Figure 5 shows wastewater samples before and after each applied treatment. Changes promoted by AOP were visible suggesting that, although visible discoloration is perceived, organic matter degradation is not necessarily as effective. This is because the oxidation of dye chromophores by HO● radicals usually takes place in the beginning of reaction, leading to the transformation of dyes into non-colored smaller organic compounds, yet not complete mineralization (Rodrigues et al. 2013). Thus, while aiming at reuse, in order to identify the best treatment alternative, color should be monitored together with other physicochemical parameters (Vajnhandl and Valh 2014).

Regarding Fenton control samples, it is clear that, for the Fenton process, the sample Control_1 (C1, 2:2:0) showed little change in color, while sample Control_2 (C2, 2:0:1) changed colors (Fig. 5), probably due the occurrence of coagulation promoted by iron in this system, especially in the presence of sulfate (Soon and Hameed 2011).

Color removal also took place in the photo-Fenton system. However (Fig. 5), the green/brown aspect of photo-Fenton-treated wastewater is even more noticeable in these samples, indicating that ferrous ions remain in solution at the end of the reaction. This probably occurs due to the excess of Fe, since UV irradiation was acting and promoting its catalytic role in this system.

Regarding the photo-Fenton process control sample C1 (2:2:0), which is similar to the UV/H2O2 system, high decolorization was achieved, probably due to the formation of hydroxyl radicals by the UV cleavage of H2O2 (Malato et al. 2009).

Regression models and response surfaces

Regression models of experimental data adjusted for Fenton and photo-Fenton processes are expressed, respectively, by Eqs. 9 and 10:

where Y = COD reduction, in percentage; A = [H2O2]/COD mass ratio, and B = [Fe2+]/[H2O2] mass ratio, in decimal numbers.

The calculated coefficients of determination are R 2 = 0.916 and R 2 = 0.967 for the Fenton and photo-Fenton processes, respectively, indicating acceptable adjustments of both models.

These equations allow the study of the optimization of the COD/[H2O2]/[Fe2+] ratio, by replacing factors A and B in appropriate levels to give the percentage of COD reduction. However, there are limitations, both in relation to variation ranges of factors A and B and for the COD reduction indexes, which may be estimated using these models. Since these are adjustments to the experimental data, it does not suggest that any new data can be inserted into the models or that they could be extrapolated.

Thus, these models permit the prediction of wastewater COD reduction, using Fenton or photo-Fenton processes for any [H2O2]/COD mass ratio ranging from 0.5 to 2 and [Fe2+]/[H2O2] mass ratio in the range of 0.25 to 1. The contour surfaces shown in Figs. 6 and 7 allow the visualization of the results and the identification of optimal points (red areas). Points highlighted in the graphs refer to the experiments performed according to the factorial design. This work does not aim to optimize the COD/[H2O2]/[Fe2+] ratio, but to verify what is the best of the tested treatment options. According to these graphs, best conditions for both of these systems are those in which medium and higher concentrations of reagents were applied. This is because higher concentrations of reagents (Fe2+ and H2O2) lead to increased formation of hydroxyl radicals and higher COD degradation. However, there may be limitations to maximum concentration levels due to the occurrence of the scavenger effect (Amorim et al. 2013).

Validation of selected AOP

Physicochemical characterization

Table 3 shows median values obtained for analyzed physicochemical parameters before and after additional Fenton’s treatment along with p values (Mann-Whitney test). Figures S2, S3, S4, S5, S6, S7, S8, S9, S10, S11, S12, S13, S14, S15, S16, and S17 present the box-plot graphs made with these results, besides the determination of the absorbance of wastewater samples. In general, the wastewater quality improved after application of the treatment with Fenton’s reagent. Initial concentrations were reduced for almost all parameters, except for sulfate, which promoted an increase in TDS and conductivity.

WWTP wastewater shows higher variance in analyzed parameters if compared to wastewater obtained after the application of Fenton’s reagent. This variation is characteristic of biological treatment systems since its performance fluctuates according to incoming wastewater variability, which is remarkable when it comes to real textile wastewater (Alinsafi et al. 2006; Vajnhandl and Valh 2014). Meanwhile, AOPs show higher stability since hydroxyl radicals are non-selective and highly reactive.

Fenton’s reagent additional treatment was able to degrade most of the organic matter refractory to biological treatment (68 % of COD removal) by combining the oxidant and coagulant features of this process. Blanco et al. (2012; 2014) also achieved best results after applying Fenton and photo-Fenton as biological polishing steps for textile wastewater treatment when aiming at industrial wastewater reuse.

The proposed treatment was able to reduce 80 % of initial wastewater alkalinity, while hardness was reduced by approximately 26 %. These results are not related to oxidation by Fenton’s reagent. They are, instead, due to the neutralization stage, since wastewater originally contains alkalinity and hardness, and the addition of hydroxide provides the simultaneous precipitation of Mg (OH)2 and CaCO3 (Sawyer et al. 1994). In fact, alkalinity may be directly related to the presence of carbonate ions (HCO3 −; CO3 2−) in this wastewater, which may promote dye aggregates, slowing degradation rate and reducing Fenton’s effectiveness. Influence of carbonate ions was proved to be higher in systems where coagulation overcomes oxidation (Merayo et al. 2016).

Conductivity and TDS raised by 20 and 27 %, respectively, mainly due to an increase of sulfate ion concentrations. These parameters have also been raised by the addition of Na+ ions during the neutralization of the wastewater. A correlation between these parameters is used to verify the validity of measured results. It is expected that TDS/conductivity should be between 0.55 and 0.7 (APHA 2005) before and after Fenton’s reagent application. Relations were found to be within these limits, indicating the consistency of presented results.

TSS and turbidity showed similar behavior, however with larger reductions (94 and 88 %, respectively). Probably, particulate and colloidal matter, both responsible for turbidity, were removed by coagulation promoted by ferrous sulfate, which is a very effective coagulant in the pH range of 7–8. Concentrations of nitrate showed no remarkable reduction after the proposed treatment. On the other hand, nitrite was reduced by 86 %, due to its conversion to NO3 − after oxidation.

Non-treated textile wastewater presented high concentration of Cl−, due to the use of salt (NaCl) as an auxiliary in the dyeing process, and SO4 −, which could have limited Fenton’s efficiency since these ions may react with HO● or even inhibit its production in the system (Machulek et al. 2007). After treatment, there was a small reduction of Cl−, as further treatment is not able to remove this ion (Vilar et al. 2011). Meanwhile, sulfate concentration was increased by about five times, when compared to its initial concentration. This is due to the addition of ferrous sulfate from Fenton’s reagent and also from the sulfuric acid used for pH adjustment (from 7 to 3) prior to additional treatment.

Regarding metals, Fe, Mn, and Cu concentrations were reduced by precipitation. Fe concentrations showed great variety in the WWTP output, yet became homogeneous after the application of Fenton’s reagent. It is noteworthy that the Fe originally present in the wastewater is favorable for the proposed treatment, acting as a catalyst in the formation of oxygen radicals. Similarly, Mn and Cu in the presence of H2O2 can act as catalysts in the Fenton process (Britto and Rangel 2008).

The scanning of spectrum absorption curves showed significant absorbance reduction due to oxidation and coagulation promoted by Fenton’s reagent (Fig. 8). Also, in terms of visible color, wastewater treated by Fenton’s reagent is similar to fresh water and, therefore, probably appropriate for reuse.

After further treatment, the wastewater showed compliance with the following parameters: pH, alkalinity, hardness, TSS, turbidity, and Mn, as shown in the Supplementary Data section (Table S2). Although samples treated with Fenton’s reagent did not comply with the limits proposed for COD, nitrite, Fe, and Cu, they did show significant reductions. In addition, it shows compliance with all of the parameters for water reuse in the dyeing stage listed by (Vajnhandl and Valh 2014) and reported on Table S2.

When compared to the reclaimed water (Table S3), Fenton-treated wastewater shows lower COD, alkalinity, hardness, TSS, turbidity, and Fe concentrations. Both of these waters are similar for pH, NO3 −, NO2 −, and Cu concentration. Also, Cl− and sulfate contents are higher in Fenton-treated wastewater, leading to high conductivity and TDS. In fact, dissolved solids may act positively, since electrolytes are usually added during the dyeing process to transport the dye from the aqueous medium to the fabric fibers. Therefore, in order to confirm reuse feasibility, it is important to perform reuse tests.

Determination of the molecular weight distribution

Fractionation of COD is presented by Fig. 9, which compares the MWD profiles before and after the proposed treatment and shows that most of the organic matter (68 %) was effectively degraded by Fenton’s reagent. Results show a predominance of dissolved substances (<2 nm) responsible for the organic load of textile wastewaters, before and after further treatment.

Figure 9 shows that there was a reduction in the concentration of MWD in the intermediate ranges (2–1500 nm) and an increase in the low molecular weight range (<2 nm). Leiviska et al. (2007) performed this analysis with a pulp mill effluent treated only by biological treatment, and MWD was similar before and after treatment. Therefore, in this study, Fenton additional treatment was probably the stage responsible for partial degradation of intermediate molecular weight substances, resulting in lower mass substances. Although TSS was reduced by 94 %, the COD related to suspended solids decreased only from 27 to 21 %, indicating that the remaining COD of the suspended material exhibits a very refractory characteristic.

After further treatment, the wastewater presents a very plain profile showing two major peaks related to suspended solids (>1500 nm), which correspond to 21 % of COD, and, predominantly, dissolved substances (<2 nm) responsible for 70 % of the organic load of wastewater treated by Fenton’s reagent. Remaining 9 % of textile wastewater initial COD are well distributed in the colloidal range.

Reuse tests

Fabrics dyed, using wastewater treated by Fenton’s reagent (reuse water), were very similar to those dyed by the traditional dyeing procedure (production waters). For pink and gray fabric samples, results obtained using Fenton’s treated wastewater were better than those obtained by fabrics dyed using reclaimed water since reclaimed water added a slightly darker tone to the fabrics, which is due to the color of the reclaimed water. All fabric samples have been approved by industrial quality control and presented fully satisfactory results. There were no stains, discoloration, opacity, or any other undesirable effects in the fabrics produced using wastewater treated by Fenton’s reagent. These results indicate that post-treated wastewater is suitable for reuse in the textile dyeing process. Figure S18 (Supplementary Data) shows the picture of fabrics produced in the textile industry laboratory, following the procedure used for dyeing on an industrial scale.

It is noteworthy that the water produced by the proposed method will not reach the quality of fresh water, given the limitations of the process and the accumulation of dissolved ions, as previously discussed. Thus, the wastewater treated by Fenton’s reagent is presented here as an additional water source

Conclusions

Fenton’s reagent in the COD/[H2O2]/[Fe2+] mass ratio of 1:2:2 represents the best alternative, reaching the quality guidelines for textile industrial (re)use. There was significant difference in the wastewater before and after additional Fenton treatment for COD (68 % removal), turbidity (88 % removal), and other important parameters required for water reuse. In addition, visual color was comparable to that of fresh water after additional treatment. The wastewater samples presented different MWD profiles before and after the intervention of additional treatment, although predominantly soluble substances responsible for the COD were found in both cases, indicating that organic matter was effectively degraded.

The reuse of textile wastewater after further treatment by AOPs is evaluated as applicable. The functional reuse of wastewater treated by the suggested AOP seems to be valid in textile production and did not damage the quality of dyed fabrics in the studied conditions. Regression models and response surfaces obtained by factorial design may allow the optimization of the Fenton and photo-Fenton processes in reducing wastewater COD.

References

Alinsafi A, da Motta M, Le Bonté S, Pons MN, Benhammou A (2006) Effect of variability on the treatment of textile dyeing wastewater by activated sludge. Dyes Pigments 69:31–39

Amorim CC, Leão MMD, Moreira RFPM, Fabris JD, Henriques AB (2013) Performance of blast furnace waste for azo dye degradation through photo-Fenton-like processes. Chem Eng J 224:59–66

Anjaneyulu Y, Sreedhara Chary N, Samuel Suman Raj D (2005) Decolourization of industrial effluents—available methods and emerging technologies—a review. Rev Environ Sci Bio/Technol 4:245–273

APHA, AWWA, WEF (2005) Standard methods for examination of water and wastewater. American Public Health Association WWA, Washington DC

Blanco J, Torrades F, De la Varga M, García-Montaño J (2012) Fenton and biological-Fenton coupled processes for textile wastewater treatment and reuse. Desalination 286:394–399

Blanco J, Torrades F, Morón M, Brouta-Agnésa M, García-Montaño J (2014) Photo-Fenton and sequencing batch reactor coupled to photo-Fenton processes for textile wastewater reclamation: feasibility of reuse in dyeing processes. Chem Eng J 240:469–475

Britto JM, Rangel MC (2008) Advanced oxidation process of phenolic compounds in industrial wasterwater. Quim Nov. 31:114–122

Constapel M, Schellenträger M, Marzinkowski JM, Gäb S (2009) Degradation of reactive dyes in wastewater from the textile industry by ozone: analysis of the products by accurate masses. Water Res 43:733–743

de Mio GP, Campos JR (1998) Proposition of method for evaluation of color removal in wastewater of textile industry. Proceedings of the XXVI CongresoLatinoamericano de IngenieriaSanitária y Ambiental-CD-ROM, Lima

dos Santos AB, Cervantes FJ, van Lier JB (2007) Review paper on current technologies for decolourisation of textile wastewaters: perspectives for anaerobic biotechnology. Bioresour Technol 98:2369–2385

Ellouze E, Tahri N, Amar RB (2012) Enhancement of textile wastewater treatment process using nanofiltration. Desalination 286:16–23

Ergas SJ, Therriault BM, Reckhow DA (2006) Evaluation of water reuse technologies for the textile industry. J Environ Eng 132:315–323

Garcia X, Pargament D (2015) Reusing wastewater to cope with water scarcity: economic, social and environmental considerations for decision-making. Resour Conserv Recycl 101:154–166

Gernjak W, Krutzler T, Glaser A, Malato S, Caceres J, Bauer R, Fernández-Alba AR (2003) Photo-Fenton treatment of water containing natural phenolic pollutants. Chemosphere 50:71–78

Gogate PR, Pandit AB (2004) A review of imperative technologies for wastewater treatment I: oxidation technologies at ambient conditions. Adv Environ Res 8:501–551

Hasanbeigi A, Price L (2015) A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. J Clean Prod 95:30–44

Leiviskä T, Nurmesniemi H, Pöykiö R, Rämö J, Kuokkanen T, Pellinen J (2008) Effect of biological wastewater treatment on the molecular weight distribution of soluble organic compounds and on the reduction of BOD, COD and P in pulp and paper mill effluent. Water Res 42:3952–3960

Machulek A, Moraes JEF, Vautier-Giongo C, Silverio CA, Friedrich LC, Nascimento CAO, Gonzalez MC, Quina FH (2007) Abatement of the inhibitory effect of chloride anions on the photo-Fenton process. Environ Sci Technol 41:8459–8463

Malato S, Fernández-Ibáñez P, Maldonado MI, Blanco J, Gernjak W (2009) Decontamination and disinfection of water by solar photocatalysis: recent overview and trends. Catal Today 147:1–59

Manenti D, Soares P, Silva TCV, Módenes A, Espinoza-Quiñones F, Bergamasco R, Boaventura RR, Vilar VP (2015) Performance evaluation of different solar advanced oxidation processes applied to the treatment of a real textile dyeing wastewater. Environ Sci Pollut Res 22:833–845

Merayo N, Hermosilla D, Jefferson B, Blanco Á (2016) Influence of alkalinity on the efficiency and catalyst behavior of photo-assisted processes. Chem Eng Technol 39:158–165

Piadeh F, AlaviMoghaddam MR, Mardan S (2014) Present situation of wastewater treatment in the Iranian industrial estates: recycle and reuse as a solution for achieving goals of eco-industrial parks. Resour Conserv Recycl 92:172–178

Poole AJ (2004) Treatment of biorefractory organic compounds in wool scour effluent by hydroxyl radical oxidation. Water Res 38:3458–3464

Rodier J, Rodi L (1981) Análisis de las aguas: aguasnaturales, aguasresiduales, aguas de mar. Omega, Barcelona

Rodrigues CSD, Madeira LM, Boaventura RAR (2013) Optimization and economic analysis of textile wastewater treatment by photo-Fenton process under artificial and simulated solar radiation. Ind Eng Chem Res 52:13313–13324

Rosa JM, Fileti AMF, Tambourgi EB, Santana JCC (2015) Dyeing of cotton with reactive dyestuffs: the continuous reuse of textile wastewater effluent treated by ultraviolet/hydrogen peroxide homogeneous photocatalysis. J Clean Prod 90:60–65

Sawyer CN, McCarty PL, Parkin GF (1994) Chemistry for environmental engineering. McGraw-Hill, New York

Soon AN, Hameed BH (2011) Heterogeneous catalytic treatment of synthetic dyes in aqueous media using Fenton and photo-assisted Fenton process. Desalination 269:1–16

Starling MCVM, Castro LAS, Marcelino RBP, Leão MMD, Amorim CC (2016) Optimized treatment conditions for textile wastewater reuse using photocatalytic processes under UV and visible light sources. Environmental Science and Pollution Research, 1–11

Tarr MA (2003) Chemical degradation methods for wastes and pollutants—environmental and industrial applications, New York, NY

UN (1992) Report of the United Nations Conference on the environment and development

USEPA –US Environmental Protection Agency (1982) Handbook for sampling and sample preservation of water and wastewater. Office of Research and Development, Environmental Monitoring and Support Laboratory, Cincinnati

USP (2015) Methods for residual peroxide determination iodometric titration. USP Technologies. http://www.h2o2.com/technical-library/analytical-methods/default.aspx?pid=70&name=Iodometric-Titration. Accessed 17 Sep 2015

Vajnhandl S, Valh JV (2014) The status of water reuse in European textile sector. J Environ Manag 141:29–35

Vilar VJP, Pinho LX, Pintor AMA, Boaventura RAR (2011) Treatment of textile wastewaters by solar-driven advanced oxidation processes. Sol Energy 85:1927–1934

Weng C-H, Huang V (2015) Application of Fe0 aggregate in ultrasound enhanced advanced Fenton process for decolorization of methylene blue. J Ind Eng Chem 28:153–160

Weng C-H, Tsai K-L (2016) Ultrasound and heat enhanced persulfate oxidation activated with Fe0 aggregate for the decolorization of C.I. Direct Red 23. Ultrason Sonochem 29:11–18

Weng C-H, Lin Y-T, Chen Y-J, Sharma YC (2013) Spent green tea leaves for decolourisation of raw textile industry wastewater. Color Technol 129:298–304

Weng C-H, Lin Y-T, Liu N, Yang H-Y (2014) Enhancement of the advanced Fenton process by ultrasound for decolorisation of real textile wastewater. Color Technol 130:133–139

Acknowledgments

The authors acknowledge the support of FAPEMIG, CNPQ, and CAPES.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 2529 kb)

Rights and permissions

About this article

Cite this article

Ribeiro, M.C.M., Starling, M.C.V.M., Leão, M.M.D. et al. Textile wastewater reuse after additional treatment by Fenton’s reagent. Environ Sci Pollut Res 24, 6165–6175 (2017). https://doi.org/10.1007/s11356-016-6921-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-6921-9