Abstract

This study presents an attempt to solve two serious environmental problems: the generation of toxic effluents and solid waste disposal. The work proposes recycling cigarette filters with the purpose of degrading reactive dyes, which are used in the textile industry. Filters of smuggled cigarettes were recycled through Fe3+ immobilization on their surface. The material obtained was characterized through Fourier transform infrared spectroscopy (FTIR), atomic absorption spectroscopy (AAS), scanning electron microscopy–energy-dispersive spectroscopy (SEM-EDS), and ultraviolet–visible spectroscopy (UV–vis). The factorial design revealed that the most suitable conditions for the degradation of Reactive Black 5 dye were obtained by using 1 g of material at pH 3.0 in a 100 mg L−1 hydrogen peroxide solution. The material showed excellent performance in the Reactive Black 5 dye degradation process; in 60 min, 99.09 % dye was removed. At pH 7.0, the dye degradation was 72.67 %, indicating that the material prepared can be used at pH values greater than 3.0 without the occurrence of hydrated Fe3+ oxide precipitation. Furthermore, the material showed no loss of catalytic activity after three degradation studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The accelerated population growth has resulted in increased industrial activity, generating environmental problems of great dimensions such as the generation of toxic effluents and solid waste disposal. Among the toxic effluents, one that outstands is the effluent from the textile industry (Tian et al. 2013).

The textile effluents present high concentration of dyes, which are colored and extremely difficult to degrade through conventional processes; these characteristics decrease water transparency preventing penetration of solar radiation required for photosynthetic processes; thus, some disturbance to the ecosystem occurs (Rangabhashiyam et al. 2013; Liu et al. 2007).

Effluent treatments used by textile industries are based on conventional processes which can be physicochemical (adsorption, coagulation, sedimentation, and filtration) or biological (activated sludge). Unfortunately, these processes have disadvantages, because they produce a large amount of sludge and the dye molecule is not effectively destroyed during the process (Tehrani-Bagha et al. 2010; Pereira and Freire 2005).

Due to the disadvantages of the conventional processes, the advanced oxidation processes (AOPs) become attractive for the treatment of effluents. AOPs are based on the generation of the hydroxyl radical (HO·), which possesses a high potential of oxidation (2.8 V vs. SHE) and allows total or partial elimination of the compounds resistant to conventional processes (Machulek et al. 2013; Ribeiro et al. 2015).

The hydroxyl radical (HO·) may be generated via homogeneous systems: for example, ozonation processes, UV- and/or peroxide-based processes, and Fenton and photo-Fenton processes (Ayodele et al. 2012; Zeng et al. 2013).

Heterogeneous systems, which use catalysts in solid form, can also form HO·, for example, heterogeneous photocatalysis using semiconductors such as TiO2 (Cervantes et al. 2009) and immobilized Fenton or photo-Fenton process; these processes consist in the immobilization of Fe3+ in organic or inorganic matrices (Machulek et al. 2013; Nogueira et al. 2007).

Among AOPs, the Fenton process has attracted much attention in the scientific community because it is fast, presents low cost, and is easily handled at room temperature. In the Fenton process, Fe2+ reacts with hydrogen peroxide to produce hydroxyl radical (HO·) (Eq. 1) (Nogueira et al. 2007, Li et al. 2015).

The Fenton process can be associated to UVB radiation (280 to 320 nm), UVA (320 to 400 nm), and vis (400 to 800 nm); this process is called photo-Fenton process. The photo-Fenton process consists in the hydrolysis of Fe3+ forming Fe(OH)2+ (Eq. 2). When the Fe3+ complexes are irradiated, the promotion of an electron from the ligand to the metal occurs, resulting in the Fe3+ reduction into Fe 2+ and oxidation of the ligand, forming the HO· (Eq. 3) (Nogueira et al. 2007, Wang et al. 2016).

The homogeneous photo-Fenton process has some disadvantages: (a) the need to work at pH below 3.0 to avoid precipitation of Fe(OH)3 and subsequent termination of the reaction, (b) necessity of recovering large amounts of precipitated iron sludge after treatment, and (c) further treatment of the resulting sludge (Li et al. 2015).

The disadvantages presented by the photo-Fenton process motivated the development of the heterogeneous photo-Fenton process, which consists in the immobilization of Fe3+ in organic or inorganic matrices; this process has advantages, such as avoiding the precipitation of hydrated Fe3+ oxide up to pH 3.0 and the reuse of the material containing immobilized iron ions (Machulek et al. 2013; Nogueira et al. 2007).

Several materials have been used as support to the immobilization of Fe3+and applied to the degradation of the recalcitrant organic compounds through Fenton-like reactions. In general, there is absorption of organic compounds on the material surface, followed by photoreduction of Fe3+ into Fe2+ species. The Fe2+ reacts with hydrogen peroxide to produce hydroxyl radical, which promotes oxidative degradation of the previously adsorbed organic compound (Ignacheswki et al. 2010; Taketa et al. 2015; Lan et al. 2015; Dias et al. 2016).

In a study carried out by Souza et al., Fe2+ immobilized in alginate beads was used in the dye degradation through the photo-Fenton process. The beads allowed 80 % degradation of the dye in 45 min of the reaction using solar radiation (Souza et al. 2008). Another polysaccharide that can be used as a support for the immobilization of Fe3+ is cellulose acetate. This material is the main component of cigarette filters.

At the global level, there are around 1 billion smokers. In Brazil, about 27.9 million people are smokers and 110 billion cigarettes are consumed per year out of which 48 billion are smuggled cigarettes (World Health Organization 2015). The smuggled cigarettes are often seized by the Internal Revenue Service (IRS); it is estimated that, in 2014, 3.64 billion illegal cigarettes were seized. These cigarettes do not have a correct destination and are often incinerated, releasing 4700 toxic substances and causing damages to the environment.

Studies regarding the utilization of waste from the destruction of smuggled cigarettes are recent and focus on the composting process from tobacco (Silva et al. 2014). The problem is the elimination of cigarette filters, because they are basically made of cellulose acetate which is difficult to decompose in the environment and cannot be used in the composting process (Czayka and Fisch 2012; Soltani et al. 2014).

Cellulose acetate is an inert polymer, non-toxic, and inodorous (Cerqueira et al. 2010); therefore, the reuse of smuggled cigarette filters as a support for Fe3+ and their application to the degradation of dye through the photo-Fenton process are extremely attractive.

Experimental

The filters used in this study were filters of smuggled cigarette (FSC) seized by the Internal Revenue Service, provided through a partnership between the Internal Revenue Service and the State University of Ponta Grossa.

The reason for using seized FSC was that they have no toxic substances from combustion of tar and nicotine, while the use of used cigarette filters would involve the development of a method of treatment to remove toxic substances before modification with Fe3+.

Reactive Black 5 dye (C.I. 20505, Sigma-Aldrich) was used in 50 mg L−1 aqueous solution. Hydrogen peroxide (H2O2, nuclear, 10 % m/m) and ferric nitrate (Fe(NO3)3, nuclear) and the remaining reagents were used as received.

Preparation of the catalysts

Initially, the filters were separated from the cigarettes and then washed with distilled water and dried at 80 °C for 3 h.

The method adopted for the immobilization of Fe3+ on the surface of the filters is the result of several methods tested with the aim to obtain the best Fe3+ adsorption. The procedure used was that in which a lower amount of Fe3+ was leached during the degradation process.

The procedure consisted of heating the FSC in a NaOH 0.1 mol L−1 solution, followed by washing with H2SO4 0.01 mol L−1 and distilled water until neutral pH was obtained. Then, FSC were kept in a Fe(NO3)3·9H2O (0.1 mol L−1) solution for 4 days; after this time, they were washed and dried at 80 °C. The material obtained will be referred to as modified cigarette filter (MCF).

Characterization of catalyst

The iron concentration in the MCF was determined by atomic absorption spectroscopy (AAS) using a Varian Spectra AA-240FS. Diffuse reflectance electronic spectra were obtained using a Varian Cary 50 spectrophotometer, and an accessory with optical fiber multiple beam pointed to the composite surface was employed. The Fourier transform infrared spectroscopy (FTIR) spectra were obtained with a spectrophotometer Shimadzu Prestige-21 with 4-cm−1 resolution, in the range 4000–400 cm−1. Scanning electron microscopy–energy-dispersive spectroscopy (SEM-EDS) images were taken by a Shimadzu model SSX-550; the samples were coated with a thin gold layer. The measurements were performed at the Complex Multiuser Laboratories–CLABMU/UEPG.

Factorial design

The degradation of reactive dyes through the photo-Fenton process can be influenced by several factors. The hydrogen peroxide concentration and Fe3+concentration are decisive for the occurrence of photo-Fenton reactions (Eqs. 1, 2, and 3) and, therefore, the efficacy of the degradation process (Nogueira et al. 2007; Souza et al. 2008). The pH is an important factor for the photo-Fenton process; at low pH values, the radical formation and organic compound oxidation are improved. At pH 3.0, the formation of Fe(OH)2+ (the most photoactive Fe3+-hydroxyl complex) is favored under UVA and visible radiation (Dias et al. 2016; Wang et al. 2016). Furthermore, the pH influences the dye adsorption on the catalyst surface, an important step for the heterogeneous processes. Therefore, optimization of variables such as the reaction medium pH, hydrogen peroxide concentration, and Fe3+concentration in the films was evaluated using a 23 factorial design, which was increased by a central point assayed in triplicate. The time used to carry out the evaluation was 10 min.

Evaluation of photocatalytic activity

The photo-Fenton reaction was developed inside a discontinuous reactor, containing 100 mL of Reactive Black 5 dye (50 mg L−1) aqueous solutions and 1-g MCF. The substrate was irradiated using a 125-W mercury vapor lamp (without the original glass bulb), inserted into the solution through a glass bulb (UVA and vis radiation), and the reaction temperature was controlled at 25 °C by circulating water. The solution was continuously stirred with an electromagnetic stirrer. The pH was adjusted to the desired value by using 1.0 mol L−1 H2SO4 or 1.0 mol L−1 NaOH. The reaction was initiated by adding a predetermined amount of H2O2 solution.

The material reuse study was developed by evaluating the performance of the proposed material as a catalyst in successive processes of Reactive Black 5 dye degradation. The catalyst utilized in the degradation process was washed with distilled water, dried at 80 °C for 30 min, and used again in another experiment under the same conditions of pH and concentration as the hydrogen peroxide.

Adsorption studies

The adsorption of the dye on the MCF surface is a process that can hinder the interpretation of the degradation studies. The adsorption study was carried out in the refrigerated discontinuous reactor containing 100 mL of Reactive Black 5 dye (50 mg L−1) aqueous solutions and 1-g MCF, without radiation and with an electromagnetic stirrer. The studies were carried out at pH 3.0, 5.0, and 7.0.

Analytical methods

Residual hydrogen peroxide was determined spectrophotometrically, using the methodology based on the ammonium vanadate reaction (Oliveira et al. 2001). All spectroscopic analyses were performed on UV–vis, Varian 3000 spectrophotometer using quartz cuvettes with a 1-cm optical path. Iron concentration in the solution was determined by atomic absorption spectroscopy (AAS) using a Varian Spectra AA-240FS.

Results and discussion

The method adopted for the Fe3+ immobilization on the surface of the filters is the result of several methods tested in order to get the best Fe3+ absorption. The filter treatment with a NaOH solution, through heating, was necessary to remove lignin and impurities. Furthermore, this process promotes the activation of the cellulose acetate surface (Muxel et al. 2011). The methodology used to immobilize the Fe3+ on the filters was obtained after several studies carried out in laboratory (results not shown). The procedure used was that in which a lower amount of Fe3+ was leached during the degradation process.

Characterization of catalyst

Iron concentration in materials was verified through AAS, the MCF was completely dissolved in concentrated nitric acid at 100 °C on a hot plate, and then, the solution was diluted with distilled water. Iron concentration in the MCF was 4.2 ± 0.1 % (w/w).

Figure 1 shows the diffuse reflectance electronic spectra of the smuggled cigarette filters (FSC) and MCF, revealing that the FSC spectrum did not show defined bands. The MCF spectrum, in turn, revealed a broad band in the visible region between 400 and 600 nm, with maximum absorbance at 500 nm, which can be ascribed to d-d transitions of Fe3+ (Sherman and Waite 1985).

The FTIR spectra of filters of national cigarette (FNC), FSC, and MCF are shown in Fig. 2, before and after use in the degradation process. The bands observed are characteristics of the cellulose acetate. The region between 3500 and 3400 cm−1 can be ascribed to the OH stretching present on the cellulose surface. The bands between 3000 and 2900 cm−1 correspond to the CH3 symmetrical stretching. Bands at 1760 and 1240 cm−1 are ascribed to C═O and CO stretching of the ester. The band at 1040 cm−1 is ascribed to C–O–C ether axial deformation, and the band at 604 cm−1 is assigned to C–O stretch of the acetyl groups (Lee et al. 2003; Xiao et al. 2004).

By analyzing Fig. 2, one can see that the characteristic bands of ester decreased in intensity in the filters containing the Fe3+ (Fig. 2c, d); this fact may indicate that the Fe3+ links the surface of the cellulose acetate through the ester, hindering the C═O and C–O ester stretching vibration.

The FNC spectrum (Fig. 2a) and the FSC spectrum (Fig. 2b) showed no differences, indicating that the smuggled cigarette filters contain basically cellulose acetate in their composition. Few differences were also observed between the MCF spectra before (Fig. 2c) and after (Fig. 2d) use in the degradation process, indicating that the degradation process did not promote the destruction of the cellulose acetate fibers.

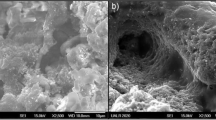

The SEM images (Fig. 3) show that the morphologies of the cellulose acetate fibers did not present degradation after the three photo-Fenton processes, according to the results obtained by FTIR. The SEM-EDS images (Fig. 4) revealed homogeneous iron distribution all over the surface of cellulose acetate fibers, before and after three photo-Fenton processes, without the formation of element agglomerates.

Reactive Black 5 dye degradation studies

The Reactive Black 5 dye is a diazo dye, which is considered recalcitrant and presents low photosensitivity; consequently, its degradation through conventional methods is very difficult (Vasconcelos et al. 2015). Furthermore, it is widely used in the textile industry. Such features make the Reactive Black 5 dye a good substrate to evaluate the efficiency of MCF application in the photo-Fenton process.

Factorial design

The variables’ (concentration of hydrogen peroxide, pH, and mass filters) influence on the Reactive Black 5 dye degradation was studied using a 23 factorial design (study of three variables at two levels) resulting in eight different degradation conditions. The levels of the parameters studied were chosen from preliminary degradation studies carried out in laboratory (results not shown). Table 1 shows the parameters and the value of the levels measured in the factorial design. The Reactive Black 5 dye solution discoloration was monitored spectrophotometrically, using reduction in the signal registered at the absorption maximum (597 nm) for a 10-min reaction as a response. The standard deviation of the experiments was obtained from the triplicate of the central point.

Table 2 shows the conditions used in each experiment as well as the percentage of discoloration obtained in each condition. The results indicate that the highest percentages of discoloration were obtained using higher levels of hydrogen peroxide and MCF mass.

Analysis of the main factor effects and their interactions in the discoloration process indicated that the process is highly influenced by the pH. The dye solution discoloration was most effective at pH 3.0; this result is consistent with the literature, because the Fenton and photo-Fenton processes have a better catalytic efficiency between pH 2.5 and 3.0. This operational limit is due to the precipitation of hydrated Fe3+ oxide at pH values higher than 3.0, which drastically reduces the interaction between the Fe3+ and hydrogen peroxide and, consequently, the production of HO·. A decrease in the pH values also reduces the catalytic activity, because high concentrations of H+ can scavenge hydroxyl radicals and the oxidative process is impaired (Zanella et al. 2010).

The highest percentage of discoloration obtained at the end of 10 min in the factorial design was observed in experiment number 6 (Table 2), in which 1000 mg of MCF and 100 mg L−1 H2O2 were used at pH 3.0. These levels were chosen as the working condition to continue the degradation process studies.

Degradation study

Dye adsorption on the surface of materials may hamper the interpretation of results obtained in the degradation process. The adsorption study (figure not shown) showed that at pH 3.0, the dye adsorption was 8.8 %, while at pH 5.0 and 7.0, the dye adsorption was 4.5 and 2.1 %, respectively. The cellulose acetate point of zero charge (PZC) is less than 4.0 (Kosmulski 2011; Hall et al. 1997); therefore, at higher pH than 4.0, the cellulose acetate surface is negatively charged and repels the Reactive Black 5 dye (anionic species), justifying the fact that low dye adsorption occurs at pH >4.0. Chong et al. observed the same behavior as that of the Reactive Black 5 dye working with TiO2, and the highest dye adsorption occurred at pH below the PZC of TiO2 (pH range of 4.5–7.0); in this condition, the catalyst surface was positively charged and the electrostatic attraction promoted the adsorption of the anionic dye (Chong et al. 2015). The dye adsorption on the catalyst surface is an important step for the heterogeneous processes.

The best conditions obtained in the factorial design (1000-mg MCF, 100 mg L−1 of H2O2, pH 3.0) were used in the degradation of 100 mL of Reactive Black 5 dye (50 mg L−1) aqueous solutions. In the first 10 min of reaction, a large decrease in the chromophore group was observed through spectroscopic monitoring (Fig. 5). After 60 min of reaction, the bands referring to chromophore group (599 nm) and aromatic region (310 nm) practically disappeared. The dye degradation was approximately 99.09 % after 60 min.

The stability of immobilized forms of iron can be checked by successive studies using the material prepared; aiming at checking the MCF stability, three degradation studies were performed with the same sample recovered by drying after each cycle. The MCF proved to be efficient in dye degradation because it was reused in three degradation processes maintaining the degradation percentage above 90 % (Fig. 6). The iron leached was less than 3 mg L−1, a value well below the one allowed by the Brazilian law. This amount of dissolved iron promotes only little dye degradation in Fenton-like processes (homogeneous processes), around 9 % (Ribeiro et al. 2016). Therefore, the process studied in this work using immobilized Fe3+ forms in MCF was essentially heterogeneous. However, the contribution of the homogeneous Fenton reaction from Fe2+ released into the solution cannot be ignored (Li et al. 2015).

The pH limitation is the main difficulty for the photo-Fenton process development, because the pH affects the nature of the iron species present in the solution and, consequently, the generation of HO·. The necessity of acidification and subsequent neutralization in the process is one of the main inconveniences and difficulties to apply such processes at industrial scale (Doumic et al. 2015). The acidification step can be bypassed using immobilized forms of iron, as in the material proposed. Due to this fact, the degradation study at pH 7.0 was carried out (Fig. 7).

The MCF was shown to be effective for the degradation of Reactive Black 5 dye at pH 7.0. The dye degradation was approximately 72.67 % after 60 min, but its efficiency was lower when compared to the degradation performed at pH 3.0. The lower efficiency occurs due to lesser dye adsorption on the MCF surface at pH 7.0. As previously reported, the dye adsorption on the catalyst surface is an important step for the heterogeneous processes.

An important fact was observed; the precipitation of hydrated Fe3+ oxide at pH 7.0 did not occur, showing that the use of MCF allows the application of photo-Fenton process over a wider pH range.

Conclusions

Filters of smuggled cigarettes with immobilized Fe3+ (MCF) demonstrated great potential to the degradation of Reactive Black 5 dye through the photo-Fenton process. Through the factorial design, it was found that the most suitable dye degradation conditions were obtained using 1-g MCF, at pH 3.0, and with 100 mg L−1 hydrogen peroxide. After 60 min of reaction, bands referring to the chromophore group (599 nm) and aromatic region (310 nm) practically disappeared. Dye degradation was approximately 99.09 % after 60 min. Reuse studies showed that the MCF can be used three consecutive times. This indicates that the catalyst can be used for extended periods of reaction; therefore, the material is promising to be used in continuous systems of waste degradation. Based on the proposal that the supported catalyst avoids iron precipitation over pH 4.0, the degradation at pH 7.0 registered was also good and the dye degradation was approximately 72.67 % after 60 min. An important fact was observed; the precipitation of hydrated Fe3+ oxide at pH 7.0 did not occur, showing that the use of MCF allows the application of photo-Fenton process over a wider pH range. We conclude that the recycling of cigarette filters with Fe3+ to be used in the degradation of reactive dyes has been achieved. A problematic solid waste was used in the degradation of another problematic substance (dye in the textile industry), so the results are very promising for the solution of two serious environmental problems: the generation of toxic effluents and solid waste disposal.

References

Ayodele OB, Lim JK, Hameed BH (2012) Degradation of phenol in photo-Fenton process by phosphoric acid modified kaolin supported ferric-oxalate catalyst: optimization and kinetic modeling. Chem Eng J 197:181–192. doi:10.1016/j.cej.2012.04.053

Cerqueira DA, Filho GR, Carvalho RA, Valente AJM (2010) Characterization of cellulose acetate obtained from the bagasse of cane sugar by 1 H-NMR.). Polim: Cienc Tecnol 20:85–91. doi:10.1590/S0104-14282010005000017

Cervantes TNM, Zaia DAM, Santana HS (2009) Study on heterogeneous photocatalysis Ti/TiO2 in colours synthetic discoloration. Quim Nov. 32:2423–2428. doi:10.1590/S0100-40422009000900035

Chong MN, Cho YJ, Poh PE, Jin B (2015) Evaluation of Titanium dioxide photocatalytic technology for the treatment of reactive Black 5 dye in synthetic and real greywater. J Cleaner Prod 89:196–202. doi:10.1016/j.jclepro.2014.11.014

Czayka M, Fisch M (2012) Effects of electron beam irradiation of cellulose acetate cigarette filters. Radiat Phys Chem 81:874–878. doi:10.1016/j.radphyschem.2012.03.003

Dias FF, Oliveira AAS, Arcanjo AP, Moura FCC (2016) Residue-based iron catalyst for the degradation of textile dye via heterogeneous photo-Fenton. Appl Catal B: Environ 186:136–142. doi:10.1016/j.apcatb.2015.12.049

Doumic LL, Soares PA, Ayude MA, Cassanello M, Boaventura RAR, Vilar VJP (2015) Enhancement of a solar photo-Fenton reaction by using ferrioxalate complexes for the treatment of a synthetic cotton-textile dyeing wastewater. Chem Eng J 277:86–96. doi:10.1016/j.cej.2015.04.074

Hall MS, Strarov VM, Lloyd DR (1997) Reverse osmosis of multicomponent electrolyte solutions. Part 1: theoretical development. J Mem Sci 128:23–37

Ignachewski F, Fujiwara ST, Cótica LF, Carneiro LM, Tauchert E, Peralta-Zamora P (2010) Degradation of reactive dyes by photo-Fenton process using Fe3+ immobilized in molecular sieve 4A. Quim Nov. 33:1640–1645. doi:10.1590/S0100-40422010000800004

Kosmulski M (2011) The pH-dependent surface charging and points of zero charge: V. Update. J Colloid Interface Sci 353:1–15. doi:10.1016/j.jcis.2010.08.023

Lan H, Wang A, Liu R, Liu H, Qu J (2015) Heterogeneous photo-Fenton degradation of acid red B over Fe2O3 supported on activated carbon fiber. J Hazard Mater 285:167–172. doi:10.1016/j.jhazmat.2014.10.057

Lee SJ, Altaner C, Puls J, Saake B (2003) Determination of the substituent distribution along cellulose acetate chains as revealed by enzymatic and chemical methods. Carbohydr Polym 54:353–362. doi:10.1016/S0144-8617(03)00189-9

Li H, Li Y, Xianga L, Huanga Q, Qiua J, Zhanga H, Sivaiah MV, Baronb F, Barrault J, Petit S, Valange S (2015) Heterogeneous photo-Fenton decolorization of Orange II over Al-pillared Fe-smectite: response surface approach, degradation pathway, and toxicity evaluation. J Hazard Mater 287:32–41. doi:10.1016/j.jhazmat.2015.01.023

Liu R, Chiu HM, Shiau C, Yeh RY, Hung Y (2007) Degradation and sludge production of textile dyes by Fenton and photo-Fenton processes. Dyes Pigm 73:1–6. doi:10.1016/j.dyepig.2005.10.002

Machulek A, Oliveira SC, Osugi ME et al (2013) Application of different advanced oxidation processes for the degradation of organic pollutants. Environmental Sciences Organic Pollutants - Monitoring, Risk and Treatment 6:141–166. doi:10.5772/53188

Muxel AA, Gimenez SMN, ALMEIDA FAS, Alfaya RVS, Alfaya AAS (2011) Cotton fiber/ZrO2, a new material for adsorption of Cr(VI) ions in water. Clean: Soil, Air, Water 39:289–295. doi:10.1002/clen.201000165

Nogueira RFP, Trovó AG, Silva MRA, Villa RD (2007) Fundamentals and environmental applications of Fenton and photo-Fenton process. Quim Nov. 30:400–408. doi:10.1590/S0100-40422007000200030

Oliveira MC, Nogueira RFP, Neto JAG, Jardim WF, Rohwedder JJR (2001) Flow injection spectrophotometric system for hydrogen peroxide monitoring in photo-Fenton degradation processes. Quim Nov. 24:188–190. doi:10.1590/S0100-40422001000200007

Pereira WS, Freire RS (2005) Ferro zero: iron zero: a new approach for the treatment of waters contaminated with organic pollutants compounds. Quim Nov. 28:130–136. doi:10.1590/S0100-40422005000100022

Rangabhashiyam S, Anu N, Selvaraju N (2013) Sequestration of dye from textile industry wastewater using agricultural waste products as adsorbents. J Environ Chem Eng 1:629–641. doi:10.1016/j.jece.2013.07.014

Ribeiro AR, Nunes OC, Pereira MF, Silva AF (2015) An overview on the advanced oxidation processes applied for the treatment of water pollutants defined in the recently launched Directive. Environ Int 75:33–51. doi:10.1016/j.envint.2014.10.027

Ribeiro K, Andrade TM, Fujiwara ST (2016) Preparation and application of cellulose acetate/Fe films in the degradation of Reactive Black 5 dye through photo-Fenton reaction. Environ. Technol. In press. doi:10.1080/09593330.2015.1127290

Sherman DM, Waite TD (1985) Electronic spectra of Fe3+ oxides and oxide hydroxides in the near IR to near UV. Am Min 70:1262–1269

Silva CP, Voigt CL, Campos SX (2014) Determination of metal ions in contraband cigarettes in Brazil. Rev Virtual Quim 6:1249–1259. doi:10.5935/1984-6835.20140082

Soltani SM, Yazdi SK, Hosseini S, Gargari MK (2014) Effect of nitric acid modification on porous characteristics of mesoporous char synthesized from the pyrolysis of used cigarette filters. J Environ Chem Eng 2:1301–1308. doi:10.1016/j.jece.2014.04.005

Souza KV, Peralta-Zamora P, Zawadzki SF (2008) Immobilization of iron (II) in alginate matrix and its use in textile dye degradation by Fenton processes. Quim Nov. 31:1145–1149. doi:10.1590/S0100-40422008000500041

Taketa LY, Ignachewski I, Villalba JC, Anaissi FJ, Fujiwara ST (2015) Phenol degradation using the mixed material clay/Fe immobilized on glass slides. Environ Sci Pollut Res Int 22:894–902. doi:10.1007/s11356-014-3239-3

Tehrani-Bagha AR, Menger FM (2010) Degradation of a persistent organic dye from colored textile wastewater by ozonation. Desalination 260:34–38. doi:10.1016/j.desal.2010.05.004

Tian H, Gao J, Hao J, Lu L, Zhu C, Qiu P (2013) Atmospheric pollution problems and control proposals associated with solid waste management in China: a review. J Hazard Mater 252–253:142–154. doi:10.1016/j.jhazmat.2013.02.013

Vasconcelos VM, Ribeiro FL, Migliorini FL, Alves SA, Steter JR, Baldan MR, Ferreira NG, Lanza MRV (2015) Electrochemical removal of Reactive Black 5 azo dye using non-commercial boron-doped diamond film anodes. Electrochim Acta 178:484–493. doi:10.1016/j.electacta.2015.07.133

Wang N, Zheng T, Zhang G, Wang P (2016) A review on Fenton-like processes for organic wastewater treatment. J Environ Chem Eng 4:762–787. doi:10.1016/j.jece.2015.12.016

World Health Organization (2015) Tobacco. Publishing who.int. http://www.who.int/mediacentre/factsheets/fs339/en/. Accessed 27 Nov 2015 and http://www.who.int/tobacco/surveillance/gats_factsheet_brazil.pdf. Accessed 27 Nov 2015.

Xiao D, Hu J, Zhang M, Li M, Wang G, Yao H (2004) Synthesis and characterization of camphorsulfonyl acetate of cellulose. Carbohydr Res 339:1925–1931. doi:10.1016/j.carres.2004.06.009

Zanella G, Sharf M, Vieira GA, Peralta-Zamora P (2010) Treatment of textile dyeing baths by photo-Fenton processes and evaluation of the reuse potentiality. Quim Nov. 33:1039–1043. doi:10.1590/S0100-40422010000500006

Zeng Z, Zou H, Li X, Arowo M, Sun B, Chen J, Chu G (2013) Degradation of phenol by ozone in the presence of Fenton reagent. Chem Eng J 229:404–411. doi:10.1016/j.cej.2013.06.018

Acknowledgments

LPG is indebted to CAPES for the fellowship and PJC is indebted to PET Química/UEPG–CAPES for the fellowship. STF is indebted to CAPES, Fundação Araucária, and CNPq for financial support. The authors are also indebted to CLABMU/UEPG for AAS, FTIR, SEM-EDS analysis and the Internal Revenue Service for providing of smuggled cigarettes.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Glugoski, L.P., de Jesus Cubas, P. & Fujiwara, S.T. Reactive Black 5 dye degradation using filters of smuggled cigarette modified with Fe3+ . Environ Sci Pollut Res 24, 6143–6150 (2017). https://doi.org/10.1007/s11356-016-6820-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-6820-0