Abstract

Red mud storage facility (RM-SF) pollution remains a serious problem in China mainly due to the RM’s huge quantity, little recyclability, and high alkalinity. And, there is also a risk of dam failure because almost all RM-SFs are processed by damming. In order to address this challenge and improve the level of risk management, it is necessary to evaluate the environmental risk of RM-SFs systematically. So, this paper firstly designs a comprehensive evaluation index system with a three-level evaluation index in the terms of RM characteristics, RM-SF characteristics, ambient environment of RM-SF, the management of RM-SF, and the application aspect of RM by the analytic hierarchy process (AHP) method. Then, a case of RM-SF from a typical alumina production enterprise is studied according to this system, as is assisted by several experts from different fields when determining the weights of all indicators. The results show that the risk of selected RM-SF primarily depends on the former factors, that is, RM and RM-SF characteristics, while the contributions of the other factors are quite smaller.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Red mud (RM), named for its color due to its iron oxide content, is a by-product from alumina production. In the recent decade, alumina industry in the world has expanded sharply, especially in China. China’s alumina industry has increased its output to 47.77 Mt in 2014 (National Bureau of Statistics of the People’s Republic of China 2014), accounting for about one-third of the world output. Depending on the type of bauxite used in the refining process, a typical plant produces one to two times as much RM as alumina (Nan et al. 2009). China’s total amount of RM was estimated to be about 70 Mt in 2014. However, because the utilization ratio of RM is as low as 4 % in China, it is estimated that the storage of RM has achieved about 300 Mt in China so far (National Development and Reform Commission 2013).

RM is considered as an industrial waste with high environmental risks, containing many different toxic substances and chemicals (e.g., Cd, Hg, As, F) (Hind et al. 1999; Akinci and Artir 2008), and it can cause many environment problems. RM also holds highly alkaline wastewater with several poisonous chemicals, which pose a serious threat on the ambient environmental quality. Moreover, RM storage occupies large areas of potentially arable lands. The RM is stored mainly by damming in China, and there are two main methods of RM storage, namely the dry storage and the wet storage. Most of alumina plants adopt the dry process to store RM, disposing the RM through dehydration drying and evaporation before the transport of RM. A small number of alumina plants adopt the wet storage method, transporting the RM to the storage facilities directly, recycling part of the alkali liquor of RM by natural sedimentation separation. Although the storage costs increase, dry storage method reduces the amount of RM and increases the height of RM storage. The storage location of most of RM-SFs in China is in low areas of the coves, with dams on both ends. In general, severe dam failure accident is rare to happen, like that in Hungary. However, geological hazards or bad weather, such as landslides and continuous heavy rain, will cause overflow of RM-SF, contaminating the environment and endangering the residents’ safety. More seriously, if the dam failure of the RM-SF happened, it may cause tremendous impacts on the environment and people. The dam failure accident of October 4, 2010, in Ajka (Hungary) led to a sudden release of 600,000–700,000 m3 of a highly caustic red mud suspension, which engulfed the downstream villages of Kolontár, Devecser, and Somlóvásàrhely in western Hungary (Gruiz 2010; Mayes et al. 2011; Renforth et al. 2012). In addition, it is difficult to avoid the ecological sensitive area or densely populated area, when selecting the storage location of RM-SFs in China and some RM-SFs are close to the communities, only a few thousand meters away. And, another problem is that there is limited supervision to some closed RM-SFs. Therefore, as a kind of typical large amount of solid waste in China, it is quite necessary to conduct the risk evaluation of RM-SFs so as to make proper risk prevention measures.

In fact, many attentions have been paid on evaluating environmental risks caused by RM-SFs in recent years. For example, some scholars focused on the impacts on water quality with the method of single factor pollution index (Liu and Hao 2000; Cao 2006; Yuan et al. 2009). Fontanier et al. (2012) assessed the environmental impact of RM disposal on deep-sea Foraminifera from the Cassidaigne Canyon (NW Mediterranean Sea), using the comparative analysis method. Considering the dam failure risks of RM-SF, Li, et al. studied the RM dam risk with the methods of fault tree analysis (FTA) and fuzzy comprehensive analysis (Li 2006; Li et al. 2008). In Hungary, after the severe accident of dam failure, many researches were carried out to assess the soil pollution, actual radiological risks, and residents’ health and community structure of collembolan by the comparative analysis method (Ruyters et al. 2011; Gundy et al. 2012; Kovács et al. 2013; Winkler 2014).

However, these studies focused on one certain aspect of risk evaluation, while the risks of RM-SFs are multifaceted. The risks of RM-SFs not only depend on the RM and RM-SFs themselves but also the RM-SFs’ ambient environmental carrying capacity and their management. So, an attempt to combine the above indicators together to establish a comprehensive risk evaluation system is of significance. Compared with the above methods, the comprehensive evaluation of multiple indicator methods is expected to be a more appropriate method in dealing with regional environmental risk, rather than the single indicator risk evaluation, which will effectively play a crucial role in improving evaluation quality and, therefore, effectively control the whole environmental risk of RM-SFs.

Analytic hierarchy process (AHP) is a multi-criteria decision-making method developed by Saaty (1977, 1980). It is based on the hierarchical analysis of a certain problem in indicator of hierarchy that is structured in levels (Radivojević and Gajović 2014). The AHP provides an effective way to deal with complex decision-making, and it has been widely used in multi-criteria decision-making. It is designed to facilitate decision-making by using both empirical data and subjective judgments of the decision makers. It can be helpful to identify and weigh indicators, analyze the collected datum, and expedite the decision-making process (Şener et al. 2011). So, the AHP is an appropriate method in the risk evaluation index system. A large number of authors have applied the AHP method in risk assessment, and it is proved to be an effective method. Saaty applied the AHP method for assessment of uncertainty and risk (Saaty 2006, 2008). Sun and Kong (2008) applied AHP for risk degree calculation in civil engineering construction. Bochao (2010) and Radivojević and Gajović (2014) gave the AHP and fuzzy comprehensive evaluation for supply chain risk assessment. Aminbakhsh et al. (2013) proposed a safety risk assessment in construction projects based on the AHP method. Kant Sharma et al. (2012) used the fuzzy logic and the AHP method for forest fire risk modeling. A detailed description and the mathematical formulation of the AHP method are given in the paper (Saaty 1977, 1980, 1990).

This paper firstly introduces the process for designing the expected comprehensive evaluation index system with the AHP method. After determining the weights of all the indicators by expert marking, the risk index can be calculated and the risk grade of RM-SFs will be judged. Then, a case study based on a typical RM-SF by the comprehensive evaluation method is conducted, subsequently several suggestions on risk prevention and risk management are proposed.

The process for designing the evaluation index system

To design the scientific and reasonable evaluation index system, it is necessary to establish a representative decision-making process when designing the evaluation index system. In this paper, the construction of the evaluation index system mainly includes the hierarchical structure of the evaluation index system and the selection of indicators. The proposed framework consists of the following aspects.

Hierarchical structure of the evaluation index system

Hierarchy is an important feature of the evaluation index system. The evaluation index system generally includes target level, system level, state level, and indicator level. Target level is the highest level, which is often set to be one indicator; system level reflects the situations of target level from several aspects; state level is the further detailed system levels; indicator level is the last level, which is more specific and quantitative. Thus, a hierarchical structure combines the identified indicators and sub-indicators specific to the research objective. To improve the evaluation level, it is very important to select right indicators. So, this paper will then introduce the principles and process of selecting indicators.

Principles on indicator selection for the evaluation index system

In order to serve well the aims of establishing right and rational regulations or laws to control the environmental risks of RM-SFs, several principles must be obeyed when selecting evaluation indicators, such as comprehensiveness, non-overlapping, easy acquisition, and scientificity. Comprehensiveness requires that the scientific indicators should reflect all aspects of evaluation objects in line with evaluation purpose as much as possible. Non-overlapping refers to the independence of the indicators from each other; that is, the indicators of the index system cannot overlap each other; otherwise, they may lead to distortion of the evaluation results. Easy acquisition means that the required data of indicators are easy to be collected and calculated. Scientificity is that the collected data are true and the obtained research results can reflect the intrinsic of the subject investigated.

Selecting process of indicators in the evaluation index system

To comply with the above principles, selecting indicators for the evaluation index system involves three stages in this paper: the primary selection, the optimal selection, and the final selection. During the primary selection process, qualitative analysis method is adopted. In the paper, the authors propose characteristics of RM, characteristics of RM-SFs, ambient environment of RM-SFs, management of RM-SFs, and respect of RM utilization as the first level indicators in consideration of some relative factors which may help decide the indicators above. Specifically speaking, the first factor is RM, since it is of high alkalinity, high radioactively, even high content of hazardous elements. The second factor is RM-SFs, which are characterized with huge volume, improper dam design, loose supervision, and location close to residential district. The third factor is low degree of RM reuse. The fourth factor is systematical analysis on the domestic- and foreign-related statistical data. The selection processes of the other level indicators’ are similar to the first level.

In order to ensure the scientificity of evaluation system, the primary indicators are then optimized after the primary election. In this paper, the optimal selection uses the quantitative analysis method and correlation coefficient method to determine the degree of correlations between any two indicators. As you know, the greater the correlation degree of the two indicators is, the worse the independence of the two indicators is. Therefore, one of the two should be deleted. Through this process, it is found that first level indicators on the above are non-overlapping, and the other level indicators are optimized again.

After the optimal selection process, the indicators of the evaluation index system are further selected through expert consultation method and principal component analysis method. Thus, the ultimate indicators, which are expected to be with abundant connotation and relative independence, form a specific evaluation index system.

Establishment of the evaluation index system

Based on the above three steps, this paper finally established an evaluation index system, which includes three levels of indicators—5 first level indicators, 11 second level indicators, and 37 third level indicators, as are shown in Table 1.

Characteristics of RM generally refers to “physical characteristics” and “chemical characteristics” of RM, which are the possible potential risk resource of RM-SFs. Due to different bauxite sources and different leaching processes of bauxite, the physical characteristics and chemical characteristics of RM are different distinctly. So, the physical characteristics (e.g., water content, sizes of particulate matter, radioactivity of RM), and chemical characteristics (e.g., chemical substances) of RM have different impacts on the environment and, therefore, perform different environment risks. The physical characteristics usually include particle size of RM, volume weight, water content, radioactivity, etc. In this paper, we choose these four indicators. Take the particle size of RM as an example. It has important influence on atmospheric environment quality and human health. The chemical characteristics mainly are the chemical compositions of RM. RM leachate is a potential contamination to surface water and even groundwater. So, in this paper we choose the concentrations of the anion and cation of RM leachate as the main indicators at the third level. In addition, its extraction toxicity could pollute groundwater and soil, and we also choose extraction toxicity of RM leachate as the main indicator at the third level.

Characteristics of RM-SFs refers to “dam body characteristics” and “dam around characteristics”. Dam body characteristics include dam height, storage capacity, storage facility type, downstream slope of the dam, etc. Obviously, the two most important characteristics of dam body are dam height and storage capacity. When one of them exceeds the critical values, it has the potential risk of dam failure. In addition, the other indicators also play important roles. For example, the smaller the downstream slope of the dam is, the safer the dam is. In addition, a good construction of dam around will effectively prevent the occurrence of the dam failure. Take the construction of slope protection as an example. Strengthening the dam slope protection can eliminate potential dangers.

Environment of RM-SFs includes “natural environment” and “social environment.” The investigation of natural environment and social environment is an important part of environmental risk assessment. On the one hand, the risk affects the environment, and the environmental risk tolerance of different environment is not the same. On the other hand, the environment affects the risk adversely, and the abominable environment can worsen risk. The natural environment usually includes geology, landform, geological disaster, climate, meteorological condition, water loss and soil erosion, flora and fauna, ecology, etc. Based on local circumstances, this paper chooses geology, landform, meteorological condition, water loss and soil erosion, and flora and fauna as the main indicators at the third level, and specific indicators are shown in Table 1. The social environment usually includes population, environmental sensitive area, agriculture and land use, etc. In this paper, we choose two main indicators, distance between RM-SF and environmental sensitive area and population density downstream of RM-SF, which reflect the risk to the security of people’s properties and lives.

Management of RM-SFs refers to reducing the environmental risk by management system, including “risk precaution” and “risk emergency response.” Generally, to reduce the environmental risk, both the risk precaution and risk emergency response have to be considered. The risk precaution usually contains a series of safety precautions and this paper chooses staff training and daily safety precautions. The risk emergency response in this paper refers to four aspects—emergency execution plan, rescue support equipment, rescue channel, and emergency drill. Effective management of RM-SFs may reduce or eliminate the risk.

Utilization prospect of RM reflects reducing the storage of RM to debase the potential environmental risk. Resource utilization is an effective way to reduce the RM storage. The RM has been applied in building materials, metal recovery, and water treatment, etc. Unfortunately, so far, the resource utilization rate of RM has been very low, about 4 %.

The letters of A, B, C, D, and E are used to represent the first level indicators “Characteristics of RM”, “Characteristics of RM-SFs”, “Environment of RM-SFs”, “Management of RM-SFs”, and “Utilization prospect of RM”, respectively in Table 1. The second level indicators and third level indicators are used in the same form. For interpretations of the third level indicators, see Appendix A.

Risk evaluation by AHP

Determination of weights based on the AHP

Determining the weights is related to the multiple-criteria decision-making. As mentioned above, AHP is a practical decision-making method and it has been chosen for the determination weights of indicators in this paper. The AHP method takes into account the different preferences between two indicators, and it is therefore possible to detect even slight differences in preferences between the indicators, which are taken into account then in the process of setting the weights (Hruška et al. 2014).

In typical analytic hierarchy studies, there are 9-point scales, ranging from 1 to 9, as shown in Table 2. Each pair comparison enables the decision maker to evaluate the contribution of each indicator to the objective, thereby simplifying the decision-making process (Rezaei-Moghaddam and Karami 2008). Each pair of factors in a particular factor group is examined at a time, in terms of their relative importance.

According to Saaty’s matrix, each pair of comparison matrix is formed in which A ii = 1 and A ij = 1/A ji . The weights of indicators are calculated using the right eigenvector, which are calculated from the maximum absolute eigenvalue (λ max).

Where W is the corresponding eigenvector of λ max, w i is the weight for ranking.

The consistency of the judgment matrix should be tested with calculation of the consistency index (CI), which was proposed by Saaty (1980). And CI is defined as

Where CI is the consistency index, λmax is the largest eigenvalue of the matrix, n is order of matrix.

The consistency ratio (CR) is a global measure for the consistency of pairwise comparisons, which is calculated according to the methodology proposed by Saaty (1980). On the basis of numerous empirical studies, Saaty (1980) concluded that CR less than 0.1 is acceptable, indicating the overall consistency of the pairwise comparison matrix. CR is defined as

Where RI is the average of the resulting consistency index depending on the matrix (Xu 2002; Ying et al. 2007).

Take the first level indicators as an example. First of all, this paper constructed the comparison matrix for between every two first-level indicators, as shown in Tables 3, 4, 5, 6, 7, 8, 9, and 10. And the comparison matrix was then graded by eight experts, who came from three fields: two experts from the tailing security industry, three experts from relevant research institutes of safety evaluation, and another three experts from government professional managing divisions.

Because the weakness of AHP is comparison matrix inconsistency (Li et al. 2013), in order to solve this problem, after finishing the expert scores, the score results were required for the consistency check. When the score results did not satisfy the consistency check, we asked the expert to make an adjustment until meeting the consistency check. Finally, each indicator weight was derived by examining the information given by the experts after several consultation, feedback, and adjustment sessions; averages were derived, and in order to reduce human error and further ensure the rationality of the weights, each indicator weight was confirmed again by experts. The weights of second level indicators and third level indicators were obtained by taking the same approach. The weights were showed in Table 11. From Table 11, it can be seen that the weight of utilization prospect of RM is small, as a result of the low utilization rate of RM. Although substantial researches of utilization technologies of RM have developed in China, such as producing building and construction material and filler, recovery of iron and rare earth elements, adsorption of heavy metal from contaminated water and acid from gas; these processes are not yet commercially applicable until now because of economic or engineering reasons (Liu et al. 2014). RM utilization is still a challenge for China.

Calculation of comprehensive risk index

The size of the environmental risk is characterized by the calculation of comprehensive risk index (CRI). The formula is as follows:

Where:

- CRI:

-

is the comprehensive risk index

- W, W i , and W ij :

-

are the weights of first level indicators, the weights of second level indicators and the weights of third level indicators, respectively

- RRI:

-

is the relative risk index of third level indicators. And the evaluation criteria of RRI of the third level indictors are shown in Appendix A.

Grade of risk level

The risk level is characterized with CRI, which is obtained as the product of the weights and the relative risk index. This paper divides the CRI into four risk classes, which are translated into a qualitative classification of “high–secondary high–medium–low”. The grade division of risk level is shown in Table 12. In addition, considering the risk of dam failure when the CRI of characteristics of RM-SF ≥ 4, this paper defines the risk as the high risk level, no matter what the CRI is.

Case Study

Background of study area

The area studied in this paper, located in Shandong province, east of China, is one of the typical alumina production areas in China (Fig. 1). It is a semi-arid and sub-humid continental climate with an average annual temperature of 12.9 °C, annual precipitation of 621.8 mm, and annual evaporation of 1030.8 mm. The dominant wind direction is main northwest in winter and southwest in summer with an average annual wind speed 3.0 m/s. There is no geological hazard of debris flow and landslide in the area of the RM-SF in history and the seismic basic intensity is VII. The extreme rainfall is 225.5 mm in a day and the annual mean precipitation is 621.8 mm. Vegetation coverage around the RM-SF is high and vegetation coverage could effectively slow down the occurrence of soil erosion. There are three small villages in the northeast of the RM-SF, and the distance between the RM-SF and villages is very close, about 0.5 km. The population density downstream of the RM-SF is large.

Characteristics of the RM-SF and management of the RM-SF

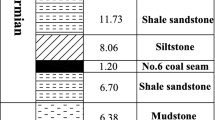

The RM-SF was built in 2007, whose design capacity is 12.5 million m3. It is irregularly rectangular, with ∼600-m long north–south and 400-m wide east–west. The height of the dam is ∼108 m. The RM-SF is built on flat ground, belonged to the flat ground type. Degree of seepage control mainly depends on the soil property and anti-seepage material. The bottom of the RM-SF laid cushion of RM and lime with the thickness of 6 m and then on top of the cushion laid PVC impervious membrane with the thickness of 0.5 mm, the permeability coefficient of 1.2 × 10−11 cm/s.

Because it is made by the state-owned enterprise, the RM-SF is better than those of private-owned enterprises in terms of management. Firstly, the enterprise has strict daily management specification and has operable and scientific contingency plans. Secondly, the enterprise has plenty of emergency relief supplies and good supply ability, which can meet the demand of emergency. Thirdly, the enterprise had installed the monitoring system to implement 24-h online monitoring of the RM-SF. In addition, the enterprise has good abilities in alarm, emergency disposal, and emergency evacuation.

Sample analysis of RM

The particle size distribution of the RM samples of the enterprise is analyzed in this paper. The particle sizes are between 0.330 ∼ 133.180 μm, and the peaks appeared at 5.334 μm. The specific radioactivity of Th-232 and K-40 is 437.2 (Bq/kg) and 270.9 (Bq/kg), respectively, and the related risk is low. For the major metal concentrations of RM leachate and leaching toxicity, see Appendix B.

Evaluation results

After the calculation using the formula of CRI, we finally get that the CRI is 5.44 points and the CRI of characteristics of RM-SF is 2.01 points, as shown in Table 13. And then according to the grade of risk level, the risk level of RM-SF is the secondary high risk.

The risks of RM-SF are mainly shown in the following aspects: the concentrations of harmful substances in leachate are high and they will pollute the surface water and groundwater; there are risks of dam overtopping and dam failure, due to the high height of the dam and large capacity of the dam, not in conformity with the relevant requirements of the minimum beach width and minimum free height. In addition, the distance between RM-SF and environmental sensitive area is so close that there is a huge risk to the surrounding environment and the lives and properties of the residents.

Conclusions and managerial implications

In this paper, a risk evaluation framework of RM-SF is developed and the risk evaluation index system of RM-SF is established based on the AHP method. A typical RM-SF is chosen as a case. The case application shows the applicability of this framework in providing a valuable tool in the risk evaluation process. The CRI is proposed in the evaluation of RM-SF’s environmental risk. And in the case study, the CRI is 5.44 points and the CRI of RM-SF characteristic is 2.01 points. According to grade of risk level, the risk levels reached the secondary high risk. There is a large risk to the surrounding environment because of the harmful substances in the leachate of RM, the high height, and large capacity of the dam and the close distance between RM-SF and environmental sensitive area.

The environmental pollution and environmental risk towards RM-SFs have increasingly become prominent. Therefore, it is urgent for the government and the alumina enterprises to implement effective management and take relevant measures to reduce the environmental risk caused by RM-SFs. First of all, design of new RM-SF should follow the design standard. All of the procedures of designing new RM-SF must be normalized from site selection, designing, damming, seepage proofing, flood drainage, management to safety monitoring to avoid the accidents of environmental pollution and dam failure, and ensuring the sustainable development of RM-SFs. Secondly, governments should strengthen environmental quality monitoring around the RM-SF and daily management and supervision of the RM-SF. Governments should strengthen the environmental quality monitoring, especially the monitoring of groundwater and surface water, to ensure getting the environmental pollution signal timely and take appropriate measures. At the same time, governments should supervise and urge enterprises to strengthen the daily management of RM-SF and risk prevention to ensure the safety of RM-SF surrounding environment. Finally, relative enterprises ought to facilitate the construction of demonstration projects of low cost treatment technology and comprehensive utilization technology. In the meantime, governments should strengthen the financial and technology support and promote comprehensive utilization of RM, so as to solve the fundamental problem of environmental pollution. At the end of this paper, it is expected that this comprehensive evaluation method may help provide effective scientific measures to evaluate the risk of RM-SF.

References

Akinci A, Artir R (2008) Characterization of trace elements and radionuclides and their risk assessment in red mud. Mater Charact 59(4):417–421

Aminbakhsh S, Gunduz M, Sonmez R (2013) Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J Saf Res 46:99–105

Bochao, L., 2010. Supply Chain Risk Assessment Based on AHP and Fuzzy Comprehensive Evaluation. In International Conference on Management of e-Commerce and e-Government (ICMeCG), Changzhou Institution of Mechatron. Technol., Changzhou, China, October (pp. 23–24).

Cao XH (2006) The influence of the red mud piled field in Shanxi aluminum industry on the groundwater. Groundwater 28(1):53–55 (in Chinese)

Fontanier C, Fabri MC, Buscail R, Biscara L, Koho K, Reichart GJ, Pigot L (2012) Deep-sea foraminifera from the Cassidaigne Canyon (NW Mediterranean): assessing the environmental impact of bauxite red mud disposal. Mar Pollut Bull 64(9):1895–1910

Gruiz K. 2010. Environmental information: the red mud catastrophe in Hungary. http://enfo.agt.bme.hu/drupal/en/gallery/808120102010

Gundy, S., Farkas, G., Székely, G., & Kásler, M., 2012. No short-term cytogenetic consequences of Hungarian red mud catastrophe. Mutagenesis, ges042.

Haridasan PP (2013) (IAEA Vienna),2013. Managing exposure to natural sources: international standards and new challenges. Proceedings of an International Symposium Beijing, China, 31–47

Hind AR, Bhargava SK, Grocott SC (1999) The surface chemistry of Bayer process solids: a review. Colloids Surf A Physicochem Eng Asp 146(1):359–374

Hruška R, Průša P, Babić D (2014) The use of AHP method for selection of supplier. Transport 29(2):195–203

Kant Sharma L, Kanga S, Singh Nathawat M, Sinha S, Chandra Pandey P (2012) Fuzzy AHP for forest fire risk modeling. Disaster Prev Manag: Int J 21(2):160–171

Kovács T, Sas Z, Jobbágy V, Csordás A, Szeiler G, Somlai J (2013) Radiological aspects of red mud disaster in Hungary. Acta Geophysica 61(4):1026–1037

Li M (2006) The Stability Analysis and Safety Precautions Research of Red Mud Embankment for Shandong Aluminium Corporation: [D]. University of Science & Technology Beijing, Beijing

Li QM, Chen X, Wang YH, Wang Q (2008) Research on the evaluation model of dam failing risk of tailing reservoir based on fuzzy theory. J Safety Sci Technol 4(6):57–61 (in Chinese)

Li F, Phoon KK, Du X, Zhang M (2013) Improved AHP method and its application in risk identification. J Constr Eng Manag 139(3):312–320

Liu GA, Hao JJ (2000) Appraisement of No 2 red-mud-heap field effect on underground water environment. Shandong Geol 16(3):30–35 (in Chinese)

Liu W, Chen X, Li W, Yu Y, Yan K (2014) Environmental assessment, management and utilization of red mud in China. J Clean Prod 84:606–610

Mayes WM, Jarvis AP, Burke IT, Walton M, Feigl V, Klebercz O et al (2011) Dispersal and attenuation of trace contaminants downstream of the Ajka bauxite residue (red mud) depository failure, Hungary. Environ Sci Technol 45:5147–55

Nan XL, Zhang TA, Liu Y, Dou ZH, Zhao QY, Jiang XL (2009) Main categories of red mud and its environmental impacts. Chin J Process Eng 9(1):459–464, in Chinese

National Bureau of Statistics of the People’s Republic of China, 2014. National economic operation data in 2014. Available from: http://www.chinairn.com/print/4232689.html

National Development and Reform Commission, 2013. Report of comprehensive utilization of waste non-ferrous metal resources. Available from: http://www.sdpc.gov.cn/gzdt/201410/t20141009_628795.html

Radivojević G, Gajović V (2014) Supply chain risk modeling by AHP and Fuzzy AHP methods. J Risk Res 17(3):337–352

Renforth P, Mayes WM, Jarvis P et al (2012) Contaminant mobility and carbon sequestration downstream of the Ajka (Hungary) red mud spill: the effects of gypsum dosing [J]. Science of the Total Environment, s 421–422(3):253–259

Rezaei-Moghaddam K, Karami E (2008) A multiple criteria evaluation of sustainable agricultural development models using AHP. Environ Dev Sustain 10(4):407–426

Ruyters S, Mertens J, Vassilieva E, Dehandschutter B, Poffijn A, Smolders E (2011) The red mud accident in Ajka (Hungary): plant toxicity and trace metal bioavailability in red mud contaminated soil. Environ Sci Technol 45(4):1616–1622

Saaty TL (1977) A scaling method for priorities in hierarchical structures. J Math Psychol 15:234–281

Saaty TL (1980) The Analytic Hierarchy Process. McGraw-Hill, New York

Saaty TL (1990) How to make decisions: the analytical hierarchy process. Eur J Oper Res 48:9–26

Saaty TL (2006) Risk—its priority and probability: the analytic hierarchy process. Risk Anal Int J 7(2):125–275

Saaty TL (2008) The analytic hierarchy and analytic network measurement processes: applications to decisions under risk. Eur J Pure Appl Math 1(1):122–196

Şener Ş, Sener E, Karagüzel R (2011) Solid waste disposal site selection with GIS and AHP methodology: a case study in Senirkent–Uluborlu (Isparta) Basin, Turkey. Environ Monit Assess 173(1–4):533–554

Sun HC, Kong LY (2008) “Study on the risk management mode of civil engineering construction by WBS-RBS & AHP methods”. Proc. In: 2nd Int. Conf. on Risk Management & Engineering Management, IEEE Computer Society, Los Alamitos, CA., pp 272–276

Winkler D (2014) Collembolan response to red mud pollution in Western Hungary. Appl Soil Ecol 83:219–229

Xu JH (2002) Mathematical methods in contemporary geography. China Higher Education Press, Beijing

Ying X, Zeng GM, Chen GQ, Tang L, Wang KL, Huang DY (2007) Combining ahp with gis in synthetic evaluation of eco-environment quality—a case study of hunan province, China. Ecol Modelling 209(s 2–4):97–109

Yuan XM, Peng Q, Li G (2009) The influence of the red mud piled field in Zhongzhou aluminum manufacturer on the underground water in the neighborhood. J Luoyang Inst Sci Technol, Nat Sci Ed 19(3):4–7 (in Chinese)

Acknowledgments

The authors gratefully acknowledge the financial supports from Public Welfare Scientific Research Special Project established by the Ministry of Environmental Protection of the People’s Republic of China (No. 201109034).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Appendices

Appendix A: Evaluation criterias of the third level indictors

Appendix B: Sample analysis result of RM for case study

Major metal concentrations of RM leachate and extraction toxicity of RM are shown in Tables 15 and 16, respectively.

Rights and permissions

About this article

Cite this article

Wen, Zc., Ma, Sh., Zheng, Sl. et al. Assessment of environmental risk for red mud storage facility in China: a case study in Shandong Province. Environ Sci Pollut Res 23, 11193–11208 (2016). https://doi.org/10.1007/s11356-016-6243-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-6243-y