Abstract

A comparative evaluation of paperboard mill sludge (PMS) versus mixed culture bacteria (MCB) as inoculum for hydrogen production from paperboard mill wastewater (PMW) was investigated. The experiments were conducted at different initial cultivation pHs, inoculums to substrate ratios (ISRs gVS/gCOD), and hydraulic retention times (HRTs). The peak hydrogen yield (HY) of 5.29 ± 0.16 and 1.22 ± 0.11 mmol/gCODinitial was occurred at pH = 5 for MCB and PMS, respectively. At pH of 5, the HY and COD removal achieved the highest values of 2.26 ± 0.14 mmol/gCODinitial and 86 ± 1.6 % at ISR = 6 for MCB, and 2.38 ± 0.25 mmol/gCODinitial and 60.4 ± 2.5 % at ISRs = 3 for PMS. The maximum hydrogen production rate was 93.75 ± 8.9 mmol/day at HRT = 9.6 h from continuous upflow anaerobic reactor inoculated with MCB. Meanwhile, the 16S ribosomal RNA (rRNA) gene fragments indicated a dominance of a novel hydrogen-producing bacterium of Stenotrophomonas maltophilia for PMS microbial community. On the other hand, Escherichia fergusonii and Enterobacter hormaechei were the predominant species for MCB.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The increasing global demand of biofuels for energy security and reduction in climate change problems lead to explore new biomass sources (Gianico et al. 2014). Minimal use of hydrocarbons with only water as a combustion product and high energy yield, 2.75 times greater than that of hydrocarbon fuel, render hydrogen as one of the promising sustainable energy resources (Zhou et al. 2013). Besides, hydrogen can be valorized as transport biofuel or further converted into heat and electricity through a cogeneration heat and power system (Monlau et al. 2015).

Paperboard mills are one of the main water and energy-intensive industries and are considered the sixth largest water polluting sector (Kumar et al. 2014). Where, paperboard mill wastewater (PMW) depends on recycled materials from post-consumer sources in order to reduce wastes. Unfortunately, this technique results in high concentrations of organic and inorganic pollutants in wastewater streams. Negative impacts on product quality, accelerated scaling and corrosion problems of equipment, odor in water, and product, and increasing the biological activity could be the consequences of this behavior (Lerner et al. 2007). Another serious challenge facing the paperboard industry is the generation of large quantity of paperboard mill sludge. This sludge is usually dewatered and disposed by landfilling or incineration by which the value of the raw materials is lost. Also, it may result in gaseous emissions and water pollution rather than numerous problems, and physiological impairment have been posed (Braguglia et al. 2015). Using paperboard mill sludge (PMS) as a biomass to produce renewable energy in the form of hydrogen by anaerobic digestion is a promising approach (Passero et al. 2015). Where, the use of anaerobic digestion is currently expanded from waste treatment concept to energy production (Djelal et al. 2013). Given that, the anaerobic digestion is able to reduce chemical oxygen demand (COD), biochemical oxygen demand (BOD), and toxic low molecular weight chlorinated lignin derivatives present in PMW (Kumar et al. 2014). In addition, as reported by Chairattanamanokorn et al. (2012), the plentiful cellulosic substrate contained in PMS could be feasibly utilized for H2 production by anaerobic digestion process. Furthermore, the cellulose and hemicellulose part of PMS can be hydrolyzed into carbohydrates which are further biologically converted to organic acids and hydrogen in dark fermentation process (Ghimire et al. 2015). Therefore, recovery of paperboard wastes (PMW and PMS) for hydrogen production addresses three of today’s major concerns: reducing dependency on fossil fuel, minimizing greenhouse gas emissions, and reduce waste disposal that can contaminate the environment.

However, the anaerobic digestion is mainly affected by several factors such as pH, inoculum to substrate ratio (ISR), and hydraulic retention time (HRT). In this approach, the initial cultivation pH is one of the most important parameters that influence on H2 production from wastewater and stability of anaerobic digestion process (Zhen et al. 2015). Significantly, pH affects the process efficiency for substrate utilization, hydrogen producers’ activity, distribution of liquid product, or microbial community (Lin et al. 2006). The optimal pH differs from one study to another. Hernández and Rodríguez (2013) reported that the initial pH between 5 and 6 is a preferable range for hydrogen production. Pakarinen et al. (2008) reviewed that initial pH level between 5 and 7 is usually favored for H2 production, where at lower pH, both cell growth and H2 production were inhibited (Ratanatamskul and Saleart 2015). In addition, the results obtained from (Zhang et al. 2003) study showed that no hydrogen would be produced at pH of 4, indicating that H2 production was inhibited at low pH level. While at higher pH, cell growth is more efficient than H2 production. Although, other studies showed that low initial pH (4.5) achieved high specific hydrogen potentials, while the lowest specific H2 production rate has been yielded (Lin et al. 2006; Lee et al. 2008).

ISR directly affects the growth patterns of microorganisms and reflects the initial energy level of batch cultivation. Where, inoculum addition to the substrate aimed at bringing the natural microflora of fermentation microorganisms (Grübel and Suschka 2014). Sun et al. (2011a, b) found that higher concentration of inoculum causes nutrient consumption that eventually inhibits the hydrogen production as a result of the substrate biodegradation inhibition. In another study, it is revealed that high ISR leads to an inadequate food for the population of microorganisms which leads to enhanced growth of filamentous microorganisms (Kumar et al. 2014). On the other hand, low ISR leads to inhibition of methanogens within the consortia due to the acetate production which is favor for H2 generation (Dechrugsa et al. 2013). However, Hafez et al. (2010) found that, at low ISR, a microbial shift occur leading to an increase in the biomass yield which is not related to hydrogen producers. Accordingly, the ideal balance of ISR is essential to overcome the biomass limitation and avoid organic matter overloading for enhanced H2 generation.

Since the HRT for hydrogen production depends strongly on the type of wastewater and inoculum source, the effect of this parameter should be taken into consideration. Where, HRT plays a crucial role in affecting cell bacterial growth and H2 production efficiency. Even more, the inhibition of hydrogen consumers related to methanogenesis is pursued through the variation of HRTs. Thanwised et al. (2012) found that the optimum volumetric hydrogen production rate (HPR) of 883.19 ± 7.89 ml H2/L day from tapioca wastewater treatment was generated at HRT of 6 h using anaerobic baffled reactor (ABR). Other studies revealed that lower HRTs presented a better performance in terms of H2 production (4–6 h) (Masset et al. 2012). Nevertheless, operating the continuous stirred tank reactor (CSRT) at HRT <8 h has a potential problem of cell washout due to the suspended nature of the biomass within the reactor (Julian et al. 2012). Thus, controlling the HRT during continuous hydrogen production under anaerobic digestion is necessary.

Therefore, the aims of this comparative investigation are to (1) assess the efficiency of using PMS versus mixed culture bacteria (MCB) as consortium for hydrogen production from PMW, (2) study the effect of pH variation and ISRs on the hydrogen yield and volatile fatty acid (VFA) generation, (3) evaluate the effect of HRT on continuous hydrogen production via upflow anaerobic reactor based on the optimum conditions obtained in the last assay, (4) investigate the economic outlays from continuous anaerobic digestion, and (5) identify and detect the microbial consortium responsible for hydrogen production including the phenotypic character and 16S ribosomal RNA (rRNA) sequences.

Materials and methods

Paperboard mill wastewater characteristics

The PMW was collected from Aldar Albydaa paperboard manufacturing company (New Borg Al-Arab City, Egypt). The raw materials used for industrial processes are the waste of printing facilities. The mill capacity is approximately 60 t/day of paperboard and generates about 350 m3 of wastewater per day which is mainly discharged into sewerage network without any treatment. The end of pipe effluent was sampled in clean and plastic containers and transferred to the environmental lab for conducting the batch and continuous experiments. The mean physicochemical characteristics of PMW are presented in Table 1. BOD5/COD ratio of 0.61 ± 0.03 indicates that the organic pollutants existing in PMW are readily biodegradable (Rodrigues et al. 2008).

Sources of inoculum sludge

Two different sources of inoculum were used: (1) MCB that is received from the thickener of the activated sludge treatment plant (Al-Agmy, Egypt) and (2) PMS that is collected from the same mill. Both inocula were concentrated by settling for 24 h, where the supernatant was withdrawn. The inocula was pretreated at 100 °C for 15 min to disrupt the sludge flocs, disintegrate the bacteria, and transfer the intracellular organic matters into the liquid phase (Feki et al. 2015). The total and volatile solids amounted to 25.7 ± 1.5 and 13.6 ± 1.1 g/l for MCB and 34.5 ± 2.9 and 16.2 ± 1.3 g/l for PMS. The sludge volume index (SVI) was 35.8 ± 3.4 and 28.9 ± 2.6 ml/g total solids (TS) for MCB and PMS, respectively.

Experimental setup

pH value and ISR effect

Two assays of batch experiments were conducted. The first assay of experiments focused on studying the effect of pH values on hydrogen production from PMW using MCB and PMS as inoculum, individually. Five hundred milliliters of serum bottles were filled with 200 ml PMW + 100 ml MCB/PMS. The pH of the batches was adjusted to 5, 5.5, 6, 7, and 9 using 1 N NaOH and 1 N HCL since the normal range of pH for bacterial survival in wastewater is 5–9. Moreover, pH lower than 5 can induce bacterial sporulation or shift metabolic activity to solvent formation (Lay et al. 2013). The bottles was initially flushed with nitrogen gas and incubated at a temperature of 35 °C. The second set of the experiments was designed to investigate the effect of ISR on hydrogen production. Different ISRs of 1, 3, 6, and 12 gVS/gCOD were applied as depicted in Table 2. The inoculum concentration of MCB and PMS was kept constant at values of 13.6 ± 1.1 and 16.2 ± 1.3 gVS/l, respectively, and varying the substrate volume (Table 2). The experiments were conducted at pH value of 5, temperature 35 °C.

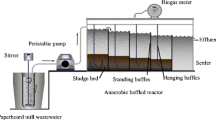

Continuous H2 production at different HRTs

Four laboratory scale upflow anaerobic reactors fabricated from Perspex glass with working volume of 6 l were used. The continuous experiments were conducted for a period of 95 days based on the optimum conditions obtained from the batch experiments, i.e., pH, ISR, and inoculum type. The fresh PMW was continuously fed into the reactors from the feed tank using peristaltic pumps and operated at different HRTs of 4.8, 9.6, 14.4, and 19.2 h. Moreover, the volume of evolved biogas was measured using the displacement method and corrected to the standard conditions (25 °C and 1 atm) as described earlier (Lee et al. 2008). Physicochemical analysis of the influent and the treated effluents were determined twice a week at each HRT. All the experiments were carried out in triplicates, and the depicted results represent the average of three independent operations ± standard deviation.

Calculations and kinetic studies

The tested ISRs and hydrogen yield (HY) were calculated as reported by González-Fernández and García-Encina (2009) and Zhou et al. (2013) (Eqs. 1 and 2), respectively. On the other hand, the Gompertz equation model (Eq. 3) was used for calculating the hydrogen potential from PMW (Farghaly et al. 2015).

where HP is the hydrogen production (mmol), H is the cumulative hydrogen production at time (t), P is the H2 potential (mmol), R m is the maximum hydrogen production rate (mmol/h), \( \uplambda \) is the lag phase required to commence H2 evolution, and e is the Euler’s number.

Analytical methods

The biogas composition was analyzed using a gas chromatograph (GC-2014, Shimadzu, Japan) equipped with a thermal conductivity detector (TCD) and a 0.2 m, 3-mm diameter stainless column packed with ShinCarbon (50/80 mesh). The operational temperatures of the injection port, the column oven, and the detector were 100, 120, and 150 °C, respectively. Helium was used as the carrier gas at a flow rate of 25 ml/min. VFA concentrations in terms of acetate (HAc), butyrate (HBu), propionate (HPr), and lactate (HLa) were analyzed by high-performance liquid chromatography (HPLC) (LC-10AD, Shimadzu, Japan) with ultraviolet detector using a Shim-pack HPLC column (4.6 × 250 mm, VP-ODS, Vertical). The temperature of column oven was 40 °C. H2SO4 (4 mM) was used as a mobile phase at a flow rate of 0.5 ml/min for 22 min followed by 0.4 ml/min for 8 min. Total suspended solids (TSS), volatile suspended solids (VSS), COD, BOD5, total Kjeldahl nitrogen (TKN), and ammonium nitrogen NH4-N were determined according to APHA (2005). Soluble COD was determined using filter paper (0.45-μm Whatman, 7141-104, Japan). The carbohydrate was measured according to the phenol-sulfuric acid method, using glucose as the standard.

Microbial community analysis

Isolation of the bacterial strains

The MCB and PMS at the end of experiments were diluted with sterile medium (nutrient broth) in 150-ml serum bottle and agitated in a shaking incubator at 37 °C. The bottles were flushed with nitrogen gas, sealed with rubber septum, and coated by par film to maintain the required anaerobic condition. After incubation at 37 °C for 2 days, 1 ml of the culture broth was inoculated in 50 ml of the same medium. The hydrogen-producing bacterial strains were isolated using the method of anaerobic plate. The enriched culture broth was spread onto nutrient agar plates where 1.5 % (w/v) agar solution (<40 °C) has been poured on the plate till the broth was completely absorbed by the medium. The paraffin wax was overlaid in order to maintain the anaerobic condition. Following the development of colonies at 37 °ͦC, the overlaying has been gently removed with a scalpel. Single colonies were removed from the medium and sub-cultured, where this step has been repeated more than three times to ensure the purity of the strains. Fourteen strains were isolated from the MCB and PMS inocula. Four strains were detected for hydrogen production. Morphological examination was carried out by a light microscope. Biochemical and physiological determinations were carried out according to the methods described in Bergey’s Manual (Bergey and Krieg NR 1984; Brenner Don et al. 2005) where isolates were phenotypically examined (gram stain, motility, morphological and biochemical characteristics).

16S rDNA sequencing and phylogenetic analysis

Total genomic DNA was extracted and purified from the samples. The primer set of F (5′-AGA GTT TGA TCC TGG CTC AG-3′) with a GC clamp and R (5′-GGT TAC CTT GTT ACG ACT T-3′) at the annealing temperature of 65 °C were used for the PCR amplification of the variable region of 16S ribosomal DNA (rDNA) from the purified genomic DNA. PCR has been cleaned up using GeneJET™ PCR Purification Kit (Thermo), where 4 μl from the PCR mixture was loaded to examine the PCR product on 1 % agarose gel against 1 Kb plus ladder (Fermentas). Finally, sequencing to the PCR product has been made at GATC Company by ABI 3730xl DNA sequencer using forward and reverse primers. Sequence analysis was conducted based on the online databases using BLAST where MEGA 3.1 software has been used for the phylogenetic analysis. The phylogenetic tree was constructed by the neighbor-joining method. All the obtained sequences were compared with available database sequences using a BLAST search.

Results and discussion

Effect of pH value

The cumulative HP from PMW at different pH values using MCB and PMS are depicted in Fig. 1a, b (coefficients of variation < 10 %). The obtained results indicated that the initial cultivation pH markedly affect the HP. The maximum HP using MCB and PMS were 11.74 ± 0.12 and 2.7 ± 0.07 mmol at pH of 5, respectively. The HP was significantly (p < 0.001) deteriorated at pH exceeding 5 resulting in a drop by values of 44 and 57 % for MCB and PMS at pH of 9, respectively. These results are in accordance to Mohan (2008) where pH of 5–5.5 was considered to be ideal for efficient hydrogen production due to its positive influence on stimulating H2-producing bacteria within the anaerobic digestion process. At pH of 5, the H2 content in the evolved biogas composition were 70 ± 2.5 and 46 ± 2.5 % using MCB and PMS, respectively. The relatively higher H2 content in MCB than PMS is likely due to the fact that the natural MCB has highly selective population of hydrogen-producing bacteria and tolerance to indigenous microbes present in the PMW (Sivagurunathan et al. 2014), as well as capability for producing a wide range of hydrolytic enzymes (Laothanachareon et al. 2014).

The kinetic effect of pH value on the H2 potential P and the maximum H2 production rate R m were determined using a modified Gompertz bacterial growth model as shown in Table 3. The results showed that the modified Gompertz equation parameter values were pH-dependent with average correlation coefficient of (R 2 ˃ 0.992) and (R 2 ˃ 0.979) using MCB and PMS, respectively. The estimated P and R m were negatively affected by increasing pH value from 5 to 9, i.e., the P and R m were decreased from 11.74 ± 0.12 to 6.6 ± 0.13 mmol and from 0.17 ± 0.013 to 0.07 ± 0.001 mmol/h for MCB. Similarly, P and R m were 2.72 ± 0.07 mmol and 0.08 ± 0.02 mmol/h at pH of 5, which were decreased to 1.16 ± 0.03 mmol and 0.04 ± 0.001 mmol/h with increasing pH to 9. The lower H2 production with higher pH levels was likely due to the decreased number of hydrogen-producing bacteria as a result of lower levels of ATP in the cells (Mohd Yasin et al. 2011). These results indicated that the initial pH plays an important role in H2 production.

Likewise, the HY using MCB decreased from 5.29 ± 0.16 to 2.97 ± 0.09 mmol/gCODinitial and from 28.97 ± 0.25 to 16.28 ± 0.13 mmol/gVSSadded with increasing pH value from 5 to 9, respectively. Similar results were observed for PMS where the HY decreased from 1.22 ± 0.11 to 0.53 ± 0.08 mmol/gCODinitial and from 6.69 ± 0.16 to 2.93 ± 0.09 mmol/gVSSadded at increasing pH values from 5 to 9, respectively. Meanwhile, the COD removal efficiencies were 70.3 ± 2 and 63.5 ± 2.5 % for MCB and PMS at pH of 5. While at pH of 9, the COD removal efficiency dropped to 10 ± 1.9 and 11.5 ± 1.5 %. These observations are comparable to those obtained by De Gioannis et al. (2013), where the higher initial pH (>6) lead to lower H2 production due to promoting the propionate production. The COD removal efficiency and stability of hydrogen production were mainly dependent on which route paperboard mill was degraded, i.e., at low pH values; the COD conversion was quite high where the hydrogen-producing bacteria are dominated. This was not the case at high pH values, where the degradation of COD is quite low as the activity of the anaerobic consortium bacteria is depressed resulting in low removal efficiency of COD and subsequently low hydrogen yield and hydrogen production. In addition, the lower COD removal efficiency at higher pH of 9 was attributed to that the pH range for optimal anaerobic digestion is from 6.8 to 7.2 (Khalid et al. 2011). The highly alkaline pH (>8.3) results in disintegration of microbial granules and subsequent process failure (Ward et al. 2008). Moreover, changing in the physical characteristics of the granules size, density, and volatile solid content were reported at pH > 8 (Sandberg and Ahring 1992).

The experimental results showed that as the initial pH increased from 5 to 9, the total VFAs decreased from 136 ± 3 to 104 ± 2.4 mg/l and from 635 ± 2.9 to 384 ± 2.1 mg/l using MCB and PMS, respectively. Moreover, HAc and HBu were the major VFA products which represented 41.3 and 30.8 % and 33.2 and 27.3 % of the total VFAs for MCB and PMS at pH of 5, respectively. The acidogenesis pathways for HAc and HBu are preferable for hydrogen production. Nevertheless, as pH increased from 5 to 9, the HPr concentration increased from 25 ± 1.8 to 37 ± 3.15 mg/l which has a negative effect on the HP. These results are in accordance to De Gioannis et al. (2013) who reported that the metabolic pathways involving HAc and HBu production appear to be favored at pH of 5, while higher or neutral pHs are believed to promote HPr production. Zhang et al. (2003) found similar observation, where increase of pH from 5 to 9 resulted in increase in HPr production from 2.8 to 8.1 %. Moreover, it was found that the HAc/HBu ratio is significantly initial pH-independent, where with changing pH from 5 to 9, HAc/HBu ratio was about 1.2 ± 0.09 at all pHs. These results are in agreement to those reported by (Khanal 2003).

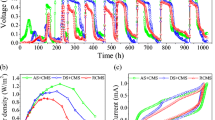

Effect of inoculum to substrate ratio

The results presented in Fig. 2a, b show the effect of ISR on the cumulative HP from PMW cultivated with MCB and PMS at pH value of 5. The results revealed that increasing ISR from 1 to 6 gVS/gCOD increased the HP from 3.93 ± 0.22 to 5 ± 0.16 mmol, respectively. However, HP was decreased to 3.79 ± 0.16 mmol at increasing the ISR up to 12 gVS/gCOD. This was not the case for PMS as inoculum, where the highest HP of 5.22 ± 0.21 mmol was recorded at ISR of 3 gVS/gCOD and the lowest HP of 2.36 ± 0.14 mmol was at ISR of 1 gVS/gCOD (Fig. 2b). In particular, by using inadequate inoculum concentration (low ISR), the hydrogen-producing bacteria in the consortium might not be capable of competing with indigenous microflora in the substrate resulted in decreased H2 production (Sreela-or et al. 2011). In addition, according to Sun et al. (2011a, b), the increase in substrate concentration could improve the hydrogen productivity, however, the higher substrate concentrations might lead to excess substrate inhibition. The gas composition analysis amounted H2 contents to 81.2 ± 5.3 and 54.5 ± 2.7 % using MCB and PMS, respectively. The superiority of MCB than PMS in H2 production may be attributed to the abundant nutrients contained in MCB that are essential for the growth of microorganisms (Zhang et al. 2014).

The average overall magnitude of regression obtained for MCB and PMS using Gompertz model was 0.985 (Table 4). The hydrogen production appeared to be kinetically favorable at ISR of 6 gVS/gCOD for MCB resulting in the highest hydrogen potential (P) and the maximum hydrogen production rate (R m) of 5 ± 0.16 mmol and 0.19 ± 0.013 mmol H2/h, respectively. P and R m reduced by values of 24 and 61 %, respectively, at increasing the ISR up to 12 gVS/gCOD. The data obtained for the PMS inoculation emphasize that ISR value of 3 gVS/gCOD achieved the highest P of 5.22 ± 0.21 mmol. This trend has been declined by a value of 50 % at increasing ISR from 3 to 12 gVS/gCOD. The lower P and R m at low ISR could be resulted from the excess in substrate inhibition (Sun et al. 2011a, b). However, at higher ISRs, the reactions that were operated under substrate-limiting conditions resulted in lower H2 productivity (Elsamadony et al. 2015b).

The respective highest H2 yield (HY) using MCB of 2.27 ± 0.14 mmol/gCODinitial and 13.22 ± 0.13 mmol/gVSSadded have been observed at ISR of 6 gVS/gCOD resulted in removal efficiencies of 86 ± 1.6 % for COD and 71 ± 5.2 % for VSS, respectively. However, the HY dropped below 1.79 ± 0.19 mmol/gCODinitial and 10.48 ± 0.18 mmol/gVSSadded with decreasing the ISR to 1 gVS/gCOD. On the other hand, the highest HY were 2.38 ± 0.25 mmol/gCODinitial and 13.88 ± 0.16 mmol/gVSSadded at ISR of 3 gVS/gCOD using PMS, which deteriorated to 1.08 ± 0.09 mmol/gCODinitial and 6.32 ± 0.43 mmol/gVSSadded at ISR of 1 gVS/gCOD. The highest HY results for PMS coincided to the peak removal efficiencies of 60.4 ± 2.5 % for COD and 63.2 ± 3.6 % for VSS. An explanation was introduced by Sreela-or et al. (2011), where the lower HY at lower ISR might be attributed to that the indigenous microflora might become dominant and produce the products that do not relate to H2 production. Moreover, the low conversion efficiencies were mainly due to the complex polymer structure of PMW which includes polysaccharides and lignin (Farghaly et al. 2015).

As shown in Fig. 2c, the production of VFAs was affected by the ISR. In case of MCB inoculation, the highest HAc (78 ± 1.6 mg/l) and HBu (31.3 ± 0.7 mg/l) concentrations were obtained at ISR of 6 gVS/gCOD, which were corresponded to the highest HP and HY. Nevertheless, the HAc and HBu concentrations amounted to 138 ± 3.5 and 45 ± 1.5 mg/l, respectively, at ISR value of 3 gVS/gCOD using PMS indicating superior H2 production (Eqs. 4 and 5). In addition, HAc/HBu ratio was peaked at ISR ratios of 3 and 6 gVS/gCOD as shown in Fig. 2c, where the increase of HAc/HBu is accompanied by H2 production (Sun et al. 2011a, b).

The results showed that HLa were detected only at ISR of 1 gVS/gCOD with corresponding lower H2 production using MCB. The formation of HLa has a negative effect on the hydrogen production as shown in Eq. 6 (De Gioannis et al. 2013). On the other hand, the lower H2 production at ISRs of 6 and 12 gVS/gCOD using PMS are likely due to the generation of HPr since production of 1 mol of HPr requires 2 mol of hydrogen (Eq. 7).

Effect of hydraulic retention time

The effect of HRT on hydrogen production was studied using upflow anaerobic reactors that were operated at different HRTs of 4.8, 9.6, 14.4, and 19.2 h as shown in Fig. 3. The continuous experiments were conducted under the optimum conditions obtained from batch experiments, i.e., using MCB at pH of 5 and ISR of 6 gVS/gCOD. It was found that hydrogen production was mainly influenced by the time available for microbial communities for substrate degradation (i.e., HRT). The results revealed that increasing the HRT from 4.8 to 9.6 h resulted in increase of HPR and H2 content from 49.8 ± 9.1 mmol/day (28.4 ± 1.7 %) to 94.4 ± 10.3 mmol/day (69.3 ± 5.2 %), respectively. However, further increase of HRT up to 19.2 h decreased HPR and H2 content below 17.2 ± 2.5 mmol/day (11.3 ± 1.2 %), indicating that acidogenesis were dominant at shorter HRTs (Liu et al. 2006). Likely, the observed increase in HPR as a result of shortening HRT might be attributed to the efficient immobilized cells with better ability to sustain high organic loading rate (OLR) (Sivagurunathan et al. 2015). Nevertheless, the relatively lower HPR at HRT of 4.8 h may be due to the washout of microorganisms with low adhesion capabilities (Hawkes et al. 2007). In addition, the reduction in retention time could limit the hydrolytic stage and acid formation decreasing hydrogen production (Hernández and Rodríguez 2013). According to Camilli and Pedroni (2005), the highest volumetric HPR (4.76 mmol/l h) was obtained at HRT of 6.7 h and washout of bacterial cells was observed at HRTs below 5.8 h. Conversely, extending HRTs affected negatively on HPR which mainly due to a decrease of OLR which is not favored for H2 productivity (Dos Reis and Silva 2011). These trends are similar to Hernández and Rodríguez (2013) results where extending HRT from 12 to 36 h decreased the HPR by 71.6 %.

Figure 4 shows the HY in terms of initial COD and VSS and COD removal efficiency at different HRTs. The results showed that the highest values of HY of 53.57 ± 8.48 mmol/gCODinitial and 136.61 ± 23.21 mmol/gVSSinitial were recorded at HRT of 9.6 h. Nonetheless, increasing the HRT up to 19.2 h resulted in deterioration in the HY to become 10.26 ± 1.79 mmol/gCODinitial and 29.46 ± 12.05 mmol/gVSSinitial as shown in Fig. 4. Thanwised et al. (2012) found that with increasing HRT from 3 to 12 h, the HY increased from 5.72 ± 0.11 to 18.7 ± 0.67 mmol/gCODinitial which further dropped to 10.18 ± 0.26 mmol/gCODinitial at longer HRT of 24 h. These results indicate that at short HRTs (9.6 h), the fast growing bacteria (acidogenesis) that are capable of growth at high substrate concentration were dominated and resulted in higher H2 production. The low HY at HRT of 4.8 h may be due to the bacterial washout from the reactor. However, the inverse relationship between HY at HRTs exceeding 9.6 h may be attributed to the inadequate food for microbial population resulting from the low substrate concentration (Kumar et al. 2014). Accordingly, the long HRT is critical to maintain the slow and stable growth of methanogenic microorganisms in the reactor leading to lower HY (Zuo et al. 2015).

Furthermore, the total COD and VSS removal efficiencies increased from 25.7 ± 8.5 to 81.3 ± 2.5 % and from 33.6 ± 10.4 to 71.5 ± 10.7 % at increasing the HRT from 4.8 to 19.2 h, respectively. Where, the lower efficiency at lower HRTs is due to the complex state of PMW, which further hydrolyzed to monomers at higher HRTs (SenthilKumar et al. 2011). This trend is in accordance to previous study in which the COD removal efficiency increased from 16 to 31.1 % with increasing the HRT from 4 to 24 h, respectively, treating starch wastewater using expanded granular sludge bed reactor (Guo et al. 2008). This indicates that prolonging HRT up to 19.2 h in continuous upflow anaerobic reactor led to more biological degradation of the organic matter in PMW and better adaption of the microorganisms.

Figure 5 shows the VFA concentrations exerted through the operation time and the average HPR. The results showed that the main metabolic product was HAc where it is considered as adequate for H2 production. The HAc production was increased from 181.6 ± 7.8 to 204.2 ± 18.3 mg/l at increasing the HRT from 4.8 to 9.6 h, respectively. However, the HAc production decreased to 143.3 ± 60.4 mg/l at increasing the HRT up to 19.2. This is mainly due to the acclimatization of MCB that increases the amounts of metabolites which related to hydrogen production (Hernández and Rodríguez 2013). The same trend was observed by Thanwised et al. (2012), where the HAc increased from 1390.75 to 1726.85 mg/l with decreasing HRT from 18 to 12 h and decreased to 1017.72 mg/l at HRT of 3 h. Lin et al. (2008) reported that the highest HAc concentration (1775 ± 100 mg/l) produced from the anaerobic digestion of starch was occurred at HRT of 8 h. Similar trends were observed for HBu where its concentration was increased from 23.9 ± 12.4 to 30.1 ± 11.7 mg/l at increasing the HRT from 4.8 to 9.6 h. Nevertheless, the HBu was significantly decreased to 10.4 ± 9.7 mg/l at increasing the HRT to 19.2 h. These observations are in accordance to Julian et al. (2012), where the second more produced metabolite at the short HRTs (6 h) is HBu indicating that a mixed fermentation HAc-HBu pathway occurred that is favorable for H2 production. Below pH 6, mainly butyrate and acetate was produced. While at higher pH values, the concentration of butyric acid decreased (Marang et al. 2013).

It was observed that the highest HPr production was occurred at HRT of 19.2 h resulting 21.4 ± 3.1 mg/l which dropped to 16.9 ± 1.7 and 18.6 ± 1.7 mg/l at HRTs of 9.6 and 4.8 h, respectively. Guo et al. (2008) found comparable observations, where HPr concentration was 0.64 ± 0.03 mg/l at HRT of 16 h which deteriorated to 0.25 ± 0.01 mg/l at HRTs of 4. Moreover, HLa increased from 17.1 ± 4.3 to 38.7 ± 3.3 mg/l with increasing HRT from 4.8 to 19.2 h, respectively. Likely, the low production of HBu, HPr, and HLa compared to HAc production at different HRTs indicates such consumption of H2 by homoacetogenic bacteria (Eq. 8) (Julian et al. 2012).

Economic analysis

In order to investigate the benefits behind anaerobic digestion of PMW, an economic analysis was carried out. A full scale upflow anaerobic reactor was designed to treat 350 m3 PMW per day at HRT of 12 h. It has been considered the most appropriate reactor type for providing a low-cost treatment solution since no mechanical mixing is required. Given that the flow regime via the reactor conveyed PMW into intimate contact with the MCB. Moreover, it has the advantage of simplicity in mechanical design and in situ installations.

At the proposed design, it has been assumed that the PMW is pumped to the reactor from an equalization tank. The main periodic expenses of the system are operation, maintenance, and electricity consumption by the pumps (Elsamadony et al. 2015a). The energy consumption required for reactor heating could not be taken into consideration where the effluent temperature of mill is about 40 °C. Thermal energy loss through the surface of reactor can be considered negligible compared to the energy required for pumps, given that it depends on the reactor design (particularly reactor volume) (Motte et al. 2015). The economic analysis based on all the aforementioned conditions and experimental results in addition to the assumptions are summarized in Table 5.

Revenues were calculated based on reuse of the treated PMW as a part of the fresh water used in manufacturing process. The cost analysis showed that the mill could compensate about $51,100/year (82 %) by reusing the treated PMW. In addition, the proposed technology will be paid back after 2 years as shown in Table 5. Accordingly, the anaerobic digestion of PMW inoculated by mixed culture bacteria is recommended from economic point of view.

Microbial community analysis

The isolated heterotrophic hydrogen-producing bacteria have been purified, characterized, and taken for further experiments. The identification of the microbial species using phenotypic character and 16S rRNA sequences of each strain were determined by comparing with the GenBank database. In these sequences, four bacterial colonies belonged to α-proteobacteria have been detected.

Interestingly, according to bacterial colonies’ morphology, biochemistry, and DNA analysis, a novel hydrogen-producing bacterium of Stenotrophomonas maltophilia has been detected for the batches inoculated by PMS bacterial community with similarity 90 % (Fig. 6a). It is aligned to the order Xanthomonadales, family Xanthomonadaceae. In addition, other three species have been detected (one for PMS batches and two for MCB). They were belonged to the order Enterobacteriales, family Enterobacteriaceae that belonged to the genus Enterobacter which are recorded as hydrogen producer (Shin et al. 2007). The 16S rRNA sequencing and the phylogenetic tree indicated that these isolates strongly could be related to the genus Enterobacter asburiae, Enterobacter hormaechei, and Escherichia fergusonii with similarities 98, 97, and 97 %, respectively (Fig. 6a, b).

According to previous work of Shin et al. (2007), it is reported that E. asburiae SNU-1 was able to produce hydrogen of 0.43 mol H2/mol formate. Also, Tanisho (1998) reported that Enterobacter aerogenes yielded H2 of 1.0 mol/1.0 mol glucose and 2.5 mol/1.0 mol sucrose. In addition, Kumar and Das (2000) found that Enterobacter cloacae IIT-BT 08 could produce about 2.2 mol H2/mol glucose, 6 mol H2/mol sucrose, and 5.4 mol H2/mol cellobiose. According to Nath (2008), E. cloacae DM11 achieved 6.61–6.75 mol H2/mol glucose. Besides, the engineered Escherichia coli strains ZF1 and ZF3 were reported to produce 14.9 and 14.4 μmol H2/mg of dry cell weight, respectively, compared to 9.8 μmol H2/mg of dry cell weight generated by wild-type E. coli strain W3110 (Fan et al. 2009).

Conclusions

A comparative study of the performance of paperboard mill sludge versus mixed culture bacteria on hydrogen production from paperboard mill wastewater was assessed. The mixed culture bacteria exhibited better performance in terms of hydrogen production and yield as compared to paperboard mill sludge. However, the hydrogen production and yield from paper board mill wastewater is pH, ISRs, and HRT dependent. At optimum pH of 5, no significant difference was observed between MCB and PMS for H2 production. However, using MCB at ISR of 6 gVS/gCOD resulted in higher COD removal efficiency of 86 ± 1.6 % than PMS (60.4 ± 2.5 %). Continuous experiments yielded 53.57 ± 8.48 mmol/gCODinitial and 136.61 ± 23.21 mmol/gVSSinitial of H2 at an HRT of 9.6 h. The 16S rRNA sequences confirmed the dominance of a novel H2-producing bacterium of S. maltophilia with similarity 90 % for PMS batches. On the other hand, E. fergusonii and E. hormaechei were the predominant species in batches of MCB bacterial community with similarity 97 %. Based on these results, it is recommended to use mixed culture bacteria as an inoculum for hydrogen production from paperboard mill wastewater at pH, ISRs, and HRT of 5, 3 gVS/gCOD, and 9.6 h, respectively.

Abbreviations

- COD:

-

Chemical oxygen demand

- HRT:

-

Hydraulic retention time

- HAc:

-

Acetate

- HBu:

-

Butyrate

- HPr:

-

Propionate

- HLa:

-

Lactate

- HP:

-

Hydrogen production

- HPR:

-

Hydrogen production rate

- HY:

-

Hydrogen yield

- ISR:

-

Inoculum to substrate ratio

- MCB:

-

Mixed culture bacteria

- PMS:

-

Paperboard mill sludge

- TS:

-

Total solids

- TSS:

-

Total suspended solids

- VS:

-

Volatile solids

- VSS:

-

Volatile suspended solids

- VFAs:

-

Volatile fatty acids

References

APHA (2005) Standard Methods for the Examination of Water and Wastewater, 25th ed. American Public Health Association, Washington, DC, USA

Bergey DH, Krieg NR HJ (1984) Endospore-forming bacteria, Bergey’s Manual of Systematic Bacteriology. Williams & Wilkins, Baltimore

Braguglia CM, Coors A, Gallipoli A, Gianico A (2015) Quality assessment of digested sludges produced by advanced stabilization processes. Environ Sci Pollut Res 22:7216–7235. doi:10.1007/s11356-014-3090-6

Brenner Don J, Krieg Noel R, Staley JT (2005) The proteobacteria (part C). In: Bergey’s Manual® of Systematic Bacteriology. Springer: USA

Camilli M, Pedroni PM (2005) Comparison of the performance of three different reactors for biohydrogen production via dark anaerobic fermentations. Proc Int Hydrog Energy Congr Exhib IHEC 1–12

Chairattanamanokorn P, Tapananont S, Detjaroen S et al (2012) Additional paper waste in pulping sludge for biohydrogen production by heat-shocked sludge. Appl Biochem Biotechnol 166:389–401. doi:10.1007/s12010-011-9434-5

De Gioannis G, Muntoni A, Polettini A, Pomi R (2013) A review of dark fermentative hydrogen production from biodegradable municipal waste fractions. Waste Manag 33:1345–1361. doi:10.1016/j.wasman.2013.02.019

Dechrugsa S, Kantachote D, Chaiprapat S (2013) Effects of inoculum to substrate ratio, substrate mix ratio and inoculum source on batch co-digestion of grass and pig manure. Bioresour Technol 146:101–8. doi:10.1016/j.biortech.2013.07.051

Djelal H, Tahrani L, Fathallah S et al (2013) Treatment process and toxicities assessment of wastewater issued from anaerobic digestion of household wastes. Environ Sci Pollut Res 21:2437–2447. doi:10.1007/s11356-013-2158-z

Dos Reis CM, Silva EL (2011) Effect of upflow velocity and hydraulic retention time in anaerobic fluidized-bed reactors used for hydrogen production. Chem Eng J 172:28–36. doi:10.1016/j.cej.2011.05.009

Elsamadony M, Tawfik A, Suzuki M (2015a) Surfactant-enhanced biohydrogen production from organic fraction of municipal solid waste (OFMSW) via dry anaerobic digestion. Appl Energy 149:272–282. doi:10.1016/j.apenergy.2015.03.127

Elsamadony M, Tawfik A, Danial A, Suzuki M (2015b) Optimization of hydrogen production from organic fraction of municipal solid waste (OFMSW) dry anaerobic digestion with analysis of microbial community. Int J Energy Res. doi:10.1002/er.3297

Fan Z, Yuan L, Chatterjee R (2009) Increased hydrogen production by genetic engineering of Escherichia coli. In: Herman C (ed) Genetic engineering, recent developments in applications, PLoS ONE 4. Apple academic press Inc., USA

Farghaly A, Tawfik A, Mona G (2015) Surfactant-supplemented mixed bacterial cultures to produce hydrogen from paperboard mill wastewater. Eng Life Sci 15:525–532. doi:10.1002/elsc.201400099

Feki E, Khoufi S, Loukil S, Sayadi S (2015) Improvement of anaerobic digestion of waste-activated sludge by using H2O2 oxidation, electrolysis, electro-oxidation and thermo-alkaline pretreatments. Environ Sci Pollut Res. doi:10.1007/s11356-015-4677-2

Ghimire A, Frunzo L, Pirozzi F et al (2015) A review on dark fermentative biohydrogen production from organic biomass: process parameters and use of by-products. Appl Energy 144:73–95. doi:10.1016/j.apenergy.2015.01.045

Gianico A, Braguglia CM, Gallipoli A, Mininni G (2014) Innovative two-stage mesophilic/thermophilic anaerobic degradation of sonicated sludge: performances and energy balance. Environ Sci Pollut Res. doi:10.1007/s11356-014-3123-1

González-Fernández C, García-Encina PA (2009) Impact of substrate to inoculum ratio in anaerobic digestion of swine slurry. Biomass Bioenergy 33:1065–1069. doi:10.1016/j.biombioe.2009.03.008

Grübel K, Suschka J (2014) Hybrid alkali-hydrodynamic disintegration of waste-activated sludge before two-stage anaerobic digestion process. Environ Sci Pollut Res 7258–7270. doi: 10.1007/s11356-014-3705-y

Guo WQ, Ren NQ, Chen ZB et al (2008) Simultaneous biohydrogen production and starch wastewater treatment in an acidogenic expanded granular sludge bed reactor by mixed culture for long-term operation. Int J Hydrogen Energy 33:7397–7404. doi:10.1016/j.ijhydene.2008.09.039

Hafez H, Nakhla G, El Naggar MH et al (2010) Effect of organic loading on a novel hydrogen bioreactor. Int J Hydrogen Energy 35:81–92. doi:10.1016/j.ijhydene.2009.10.051

Hawkes F, Hussy I, Kyazze G et al (2007) Continuous dark fermentative hydrogen production by mesophilic microflora: principles and progress. Int J Hydrogen Energy 32:172–184. doi:10.1016/j.ijhydene.2006.08.014

Hernández M, Rodríguez M (2013) Hydrogen production by anaerobic digestion of pig manure: effect of operating conditions. Renew Energy 53:187–192. doi:10.1016/j.renene.2012.11.024

Julian C-R, Lourades BC, Felipe A-M, Elias R-F (2012) Different start-up strategies to enhance biohydrogen production from cheese whey in UASB reactors. Int J Hydrogen Energy 37:5591–5601. doi:10.1016/j.ijhydene.2012.01.004

Khalid A, Arshad M, Anjum M et al (2011) The anaerobic digestion of solid organic waste. Waste Manag 31:1737–1744. doi:10.1016/j.wasman.2011.03.021

Khanal S (2003) Biological hydrogen production: effects of pH and intermediate products. Int J Hydrogen Energy 29:1123–1131. doi:10.1016/j.ijhydene.2003.11.002

Kumar N, Das D (2000) Enhancement of hydrogen production by Enterobacter cloacae IIT-BT 08. Process Biochem 35:589–593. doi:10.1016/S0032-9592(99)00109-0

Kumar V, Dhall P, Naithani S et al (2014) Biological approach for the treatment of pulp and paper industry effluent in sequence batch reactor. J Biorem Biodegrad 05:1–10. doi:10.4172/2155-6199.1000218

Laothanachareon T, Kanchanasuta S, Mhuanthong W et al (2014) Analysis of microbial community adaptation in mesophilic hydrogen fermentation from food waste by tagged 16S rRNA gene pyrosequencing. J Environ Manage 144:143–51. doi:10.1016/j.jenvman.2014.05.019

Lay C, Sen B, Huang S et al (2013) Sustainable bioenergy production from tofu-processing wastewater by anaerobic hydrogen fermentation for onsite energy recovery. Renew Energy 58:60–67. doi:10.1016/j.renene.2013.03.011

Lee K, Hsu Y, Lo Y et al (2008) Exploring optimal environmental factors for fermentative hydrogen production from starch using mixed anaerobic microflora. Int J Hydrogen Energy 33:1565–1572. doi:10.1016/j.ijhydene.2007.10.019

Lerner M, Stahl N, Galil N (2007) Aerobic vs. anaerobic-aerobic biotreatment: paper mill wastewater. Environ Eng Sci 24:277–285. doi:10.1089/ees.2005.0046

Lin C-Y, Hung C-H, Chen C-H et al (2006) Effects of initial cultivation pH on fermentative hydrogen production from xylose using natural mixed cultures. Process Biochem 41:1383–1390. doi:10.1016/j.procbio.2006.01.021

Lin C, Chang C, Hung C (2008) Fermentative hydrogen production from starch using natural mixed cultures. Int J Hydrogen Energy 33:2445–2453. doi:10.1016/j.ijhydene.2008.02.069

Liu D, Liu D, Zeng RJ, Angelidaki I (2006) Hydrogen and methane production from household solid waste in the two-stage fermentation process. Water Res 40:2230–6. doi:10.1016/j.watres.2006.03.029

Marang L, Jiang Y, Van Loosdrecht MCM, Kleerebezem R (2013) Butyrate as preferred substrate for polyhydroxybutyrate production. Bioresour Technol 142:232–239. doi:10.1016/j.biortech.2013.05.031

Masset J, Calusinska M, Hamilton C et al (2012) Fermentative hydrogen production from glucose and starch using pure strains and artificial co-cultures of Clostridium spp. Biotechnol Biofuels 5:1–15. doi:10.1186/1754-6834-5-35

Mohan SV (2008) Fermentative hydrogen production with simultaneous wastewater treatment: influence of pretreatment and system operating conditions. J Sci Ind Res 67:950–961

Mohd Yasin NH, Rahman NA, Man HC et al (2011) Microbial characterization of hydrogen-producing bacteria in fermented food waste at different pH values. Int J Hydrogen Energy 36:9571–9580. doi:10.1016/j.ijhydene.2011.05.048

Monlau F, Sambusiti C, Antoniou N et al (2015) A new concept for enhancing energy recovery from agricultural residues by coupling anaerobic digestion and pyrolysis process. Appl Energy 148:32–38. doi:10.1016/j.apenergy.2015.03.024

Motte J-C, Sambusiti C, Dumas C, Barakat A (2015) Combination of dry dark fermentation and mechanical pretreatment for lignocellulosic deconstruction: an innovative strategy for biofuels and volatile fatty acids recovery. Appl Energy 147:67–73. doi:10.1016/j.apenergy.2015.02.042

Nath K (2008) Kinetics of two-stage fermentation process for the production of hydrogen. Int J Hydrogen Energy 33:1195–1203. doi:10.1016/j.ijhydene.2007.12.011

Pakarinen O, Lehtomaki A, Rintala J (2008) Batch dark fermentative hydrogen production from grass silage: the effect of inoculum, pH, temperature and VS ratio. Int J Hydrogen Energy 33:594–601. doi:10.1016/j.ijhydene.2007.10.008

Passero M, Cragin B, Coats ER et al (2015) Dairy Wastewaters for Algae Cultivation Polyhydroxyalkanote Reactor Effluent Versus Anaerobic Digester Effluent. BioEnergy Res. doi:10.1007/s12155-015-9619-9

Ratanatamskul C, Saleart T (2015) Effects of sludge recirculation rate and mixing time on performance of a prototype single-stage anaerobic digester for conversion of food wastes to biogas and energy recovery. Environ Sci Pollut Res. doi:10.1007/s11356-015-4448-0

Rodrigues AC, Boroski M, Shimada NS et al (2008) Treatment of paper pulp and paper mill wastewater by coagulation—flocculation followed by heterogeneous photocatalysis. J Photochem Photobiol Chem 194:1–10. doi:10.1016/j.jphotochem.2007.07.007

Sandberg M, Ahring BK (1992) Anaerobic treatment of fish meal process waste-water in a UASB reactor at high pH. Appl Microbiol Biotechnol 36:800–804. doi:10.1007/BF00172198

SenthilKumar M, Gnanapragasam G, Arutchelvan V, Nagarajan S (2011) Influence of hydraulic retention time in a two-phase upflow anaerobic sludge blanket reactor treating textile dyeing effluent using sago effluent as the co-substrate. Environ Sci Pollut Res 18:649–654. doi:10.1007/s11356-010-0409-9

Shin J, Hyunyoon J, Kim M et al (2007) Fermentative hydrogen production by the newly isolated Enterobacter asburiae SNU-1. Int J Hydrogen Energy 32:192–199. doi:10.1016/j.ijhydene.2006.08.013

Sivagurunathan P, Sen B, Lin C-Y (2014) Batch fermentative hydrogen production by enriched mixed culture: combination strategy and their microbial composition. J Biosci Bioeng 117:222–8. doi:10.1016/j.jbiosc.2013.07.015

Sivagurunathan P, Sen B, Lin C-Y (2015) High-rate fermentative hydrogen production from beverage wastewater. Appl Energy 147:1–9. doi:10.1016/j.apenergy.2015.01.136

Sreela-or C, Plangklang P, Imai T, Reungsang A (2011) Co-digestion of food waste and sludge for hydrogen production by anaerobic mixed cultures: statistical key factors optimization. Int J Hydrogen Energy 36:14227–14237. doi:10.1016/j.ijhydene.2011.05.145

Sun J, Yuan X, Shi X et al (2011a) Fermentation of Chlorella sp. for anaerobic bio-hydrogen production: influences of inoculum-substrate ratio, volatile fatty acids and NADH. Bioresour Technol 102:10480–5. doi:10.1016/j.biortech.2011.09.016

Sun J, Yuan X, Shi X et al (2011b) Fermentation of Chlorella sp. for anaerobic bio-hydrogen production: influences of inoculum-substrate ratio, volatile fatty acids and NADH. Bioresour Technol 102:10480–5. doi:10.1016/j.biortech.2011.09.016

Tanisho S (1998) Hydrogen Production by Facultative Anaerobe Enterobacter aerogenes. In: Zaborsky OR, Benemann JR, Matsunaga T, et al. (eds) Biohydrogen. Springer US, Plenum Press, New York, pp 273–279

Thanwised P, Wirojanagud W, Reungsang A (2012) Effect of hydraulic retention time on hydrogen production and chemical oxygen demand removal from tapioca wastewater using anaerobic mixed cultures in anaerobic baffled reactor (ABR). Int J Hydrogen Energy 37:15503–15510. doi:10.1016/j.ijhydene.2012.02.068

Ward AJ, Hobbs PJ, Holliman PJ, Jones DL (2008) Optimisation of the anaerobic digestion of agricultural resources. Bioresour Technol 99:7928–40. doi:10.1016/j.biortech.2008.02.044

Zhang T, Liu H, Fang HHP (2003) Biohydrogen production from starch in wastewater under thermophilic condition. J Environ Manag 69:149–156. doi:10.1016/S0301-4797(03)00141-5

Zhang X, Yan S, Tyagi RD et al (2014) Wastewater sludge as raw material for microbial oils production. Appl Energy 135:192–201. doi:10.1016/j.apenergy.2014.08.078

Zhen G, Lu X, Kobayashi T et al (2015) Mesophilic anaerobic co-digestion of waste activated sludge and Egeria densa: performance assessment and kinetic analysis. Appl Energy 148:78–86. doi:10.1016/j.apenergy.2015.03.038

Zhou P, Elbeshbishy E, Nakhla G (2013) Optimization of biological hydrogen production for anaerobic co-digestion of food waste and wastewater biosolids. Bioresour Technol 130:710–8. doi:10.1016/j.biortech.2012.12.069

Zuo Z, Wu S, Qi X, Dong R (2015) Performance enhancement of leaf vegetable waste in two-stage anaerobic systems under high organic loading rate: role of recirculation and hydraulic retention time. Appl Energy 147:279–286. doi:10.1016/j.apenergy.2015.03.001

Acknowledgments

The first author is very grateful for Ministry of Higher Education (MOHE) of Egypt and Egypt-Japan University of Science and Technology (E-JUST) for providing him financial and technical support (PhD scholarship) for this research. This research is partially funded from STDF, project no. 3665.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Farghaly, A., Tawfik, A. & Danial, A. Inoculation of paperboard mill sludge versus mixed culture bacteria for hydrogen production from paperboard mill wastewater. Environ Sci Pollut Res 23, 3834–3846 (2016). https://doi.org/10.1007/s11356-015-5652-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5652-7