Abstract

The production of chlorinated solvents such as tetrachloroethylene and tetrachloromethane has resulted in large stockpiles of unintentionally produced persistent organic pollutants (POPs) including high content of hexachlorobenzene (HCB waste). HCB waste of 15,000 t arising from the production of chlorinated solvents at the Kalush factory in Ukraine was landfilled. In 2008, it was discovered that HCB and other pollutants were escaping from the landfill into local environment including the Sapogi–Limnytsia Rivers, tributaries of the Dniester River. This showed that the HCB waste was not appropriately contained and represented a threat to the Dniester River basin. A Presidential Decree of Ukraine was therefore issued requiring remediation of the site and excavation of the waste. Between 2010 and 2013, approximately 29,445 t of HCB waste and associated contaminated soil was excavated and exported to various EU countries for incineration. This excavation revealed that these wastes can corrode through their drums within a few decades with release of pollutants. Other sites at which chlorinated solvents were produced should therefore be assessed for possible similar pollution. Despite the remediation efforts and the excavation of the landfill, the Kalush area remains a POP-contaminated site requiring further assessment. A part of the waste was exported to Poland and is stored close to the Baltic Sea and is treated in an incinerator with small capacity over a time frame of years. This case and recent similar cases reveal that the control of POP waste for destruction even in EU countries needs to be improved.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The production and release of persistent organic pollutants (POPs) have resulted in global contamination of the environment, wildlife and humans (UNEP 2001; Weinberg 2008; http://chm.pops.int/default.aspx). The protection of human health and the environment from POPs is the principal aim of the Stockholm Convention (Stockholm Convention 2001). High levels of POP contamination, including hexachlorocyclohexane (HCH), polychlorinated biphenyls (PCBs), or perfluorooctanesulfonic acid (PFOS), have been documented at production sites and related landfills (Amirova and Weber 2015; Fernández et al. 2013; Jit et al. 2010; Oliaei et al. 2013; Torres et al. 2013a; Torres et al. 2013b; Wimmerová et al. 2015; Vijgen et al. 2011; Wycisk et al. 2013). Furthermore, the production of certain organochlorine chemicals has resulted in the formation and release of unintentional POPs and associated pollution (UNEP 2012, 2013a; Verta et al. 2009; Weber et al. 2008; Weber and Varbelow 2013). Article 6 of the Stockholm Convention requires that countries shall endeavour to develop appropriate strategies for identifying sites contaminated by POPs. The UNEP Toolkit for Identification and Quantification of Releases of Dioxins, Furans and Other Unintentional POPs (UNEP 2013b) consequently contains a chapter dedicated to POP-contaminated sites and highlights the production of organochlorine compounds as a major source of unintentional POP contamination.

Ukraine ratified the Stockholm Convention on 17.05.2004. Article 6 is therefore particularly relevant to the large-scale organochlorine production which has been operated in Kalush in western Ukraine. The largest operator was the Kalush Chemical and Metallurgical Complex (KChMC) which was founded in 1968 close to the large Kalush-Golinskaya potassium salt deposit. The KChMC consisted of 12 factories specializing in the production of potassium fertilizers, magnesium fertilizers and related compounds, as well as the production of chlorinated solvents. The production was later expanded and reorganized into the chemical company “Vinil chloride” within the “Oriana-Galev” and this operated until October 2001 when the factory was closed.

It is well known that the production of tetrachloroethylene (perchloroethylene) and tetrachloromethane (carbon tetrachloride) can generate high volumes of unintentional POP waste containing hexachlorobenzene (HCB) and pentachlorobenzene (PeCBz) (Jacoff et al. 1986; James 2009; Jones et al. 2005; URS Australia 2011; Weber et al. 2011), both listed in the Stockholm Convention. Furthermore, these wastes contain high levels of hexachlorobutadiene (HCBD) which has been listed as a POP in the Stockholm Convention (UNEP 2015a; International Institute for Sustainable Development 2015). This waste is normally referred to as “HCB waste” which is also used in this review. Large HCB waste stockpiles and associated pollution have been reported at similar sites such as the Spolchemie organochlorine factory at Ústí nad Labem in the Czech Republic. Approximately 80,000 drums of HCB waste along with approximately 4 million tonnes of other wastes were dumped from this production site in a landfill adjacent to the River Elbe (Heinisch et al. 2007; CH2M Hill International Corp 1991; Randak et al. 2009). Subsequent leaching from these wastes into the river resulted in high levels of HCB and PeCBz accumulating in sediments and fish downstream of the production and landfill area (Heinisch et al. 2006, 2007; Randak et al. 2009). HCBD contamination has also been reported around other waste deposits associated with production and use of chlorinated solvents (Austrian Federal Environment Agency 2004; Barnes et al. 2002; RIVM 2001; USEPA 2004; UNEP 2012, 2013a). These historic deposits probably now contain the majority of the world’s inventory of HCB, PeCB and HCBD (UNEP 2010, 2012, 2013a; Weber et al. 2011). A recent Chinese study demonstrated that waste from chlorinated solvent (chloromethane) production also contained high levels of polychlorinated biphenyl (PCB), polychlorinated naphthalene (PCN) and lower levels of polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/F) (Zhang et al. 2015).

It has been established in 2001 that large volumes of HCB waste were produced and landfilled at the Kalush factory (LLC Oriana-Galev 2001). In 2008, it was discovered that HCB, PeCBz and other pollutants were released from the deposits to soil and groundwater including an impact in the Sapogi–Limnytsia Rivers, which are a tributary of the Dniester River (Joint UNEP/OCHA Environment Unit 2010). This suggested that some of the packaging of the HCB waste has corroded and released pollutants in an uncontrolled manner into the environment. These wastes therefore represented an imminent threat to the Dniester River basin which supplies the drinking water to millions of people. As a result, it was decided to remediate the toxic legacy and to excavate the HCB waste from the Polygon, and a Presidential Decree and relevant decree of the Cabinet of Ministers of Ukraine in 2010 was issued (President of Ukraine 2010).

This study summarizes the extent of deposited waste from the chlorinated solvent production and the related pollution and details the remediation activities conducted at the site between 2010 and 2013. The current situation of the site is also reviewed. HCBD and PCN were added to the Stockholm Convention in May 2015 (UNEP 2015a, b; International Institute for Sustainable Development 2015), and it will therefore be necessary for parties to assess the contamination and releases in their countries to assess the needs for securing and remediating any contaminated sites and stockpiles. It is hoped that this report of the assessment and remediation of the HCB waste in Kalush will assist in those assessments and the remediation of other sites where HCB waste from solvent production has been landfilled. Finally, some conclusions and recommendations are made—including consideration of the import of POP waste to the European Union for treatment and destruction.

Materials and methods

Sampling

The sampling and analysis of soil, water and excavated HCB waste were carried out in three stages. In the first stage (before the work on HCB waste disposal started), eight wells were drilled at the disposal site (Polygon) to depths of 8 and 12 m. Six of these wells were equipped for hydrochemical monitoring. During the drilling operations, soil samples were taken for analysis of their HCB content (see below). On the Polygon disposal site, excavator pits were dredged down to 2 to 2.5 m. During excavation, four samples (each of 100 g) were taken at between 0.5 and 1.5 m along with two samples from the bottom of the pit. The samples of the individual pits were mixed.

Soil samples were dried in an oven at 110 °С and were then ground in a jasper mortar to fine particle size. These samples were used for extraction and other measurements.

After pumping and restoration, water was sampled from the observation wells using special pre-cleaned sampling devices designed by Simonov.

During the second stage, waste was excavated from the Polygon and sampled using the following method: Daily composite samples were taken from Big-Bags loaded with the excavated wastes for export. For this, 1 kg of wastes was taken from each Big-Bag. These were mixed and 1 kg of the composite sample was removed and stored. Analysis of the samples for HCB and chlorine was undertaken by the Laboratory of the State Institution (SI) “Institute of Environmental Geochemistry of the NAS of Ukraine”, and control samples were analyzed at the Scientific Research Institute of Ecological Problems of the Ministry of Ecology of Ukraine using gas chromatography and mass spectrometry (GC/MS). The results were in reasonably close agreement for HCB concentrations (less than a factor of 2), and the HCB monitoring method was therefore considered appropriate for screening purposes.

In the third stage, the soil surface of the Polygon was analyzed after the HCB waste had been removed and the site had been backfilled. Samples were taken by an envelope method (4 × 100 g samples from each side and 1 point in the centre) over an area 5 × 5 m. These samples were also analyzed as described above.

Water samples were also taken from boreholes around the site and analyzed.

Extraction and analysis

The water samples were extracted with hexane by shaking for 10 min in an automated shaking device.

The screening and monitoring in this study focused on HCB as an indicator substance. Other pollutants were not assessed at this stage because other organochlorine impurities had previously been identified in studies by the Central Epidemiological Station of water transport (at Illichivs’k City), by the laboratory of the SI “Research Institute of Hygiene and Medical Ecology named after Marzeiev” and by the UNEP/OCHA mission (Joint UNEP/OCHA Environment Unit 2010). There was a higher variability in these other pollutants, and they were therefore not suitable for monitoring purposes in this work.

Samples (10 g) of wastes and soil were extracted with benzeneFootnote 1 by Soxhlet extraction for 8 h for the measurement/screening of HCB.

The determination and quantification were performed using gas chromatography (GC) electron capture detector (ECD). A “Carlo Erba” gas chromatograph equipped with a capillary column and Rt-5 (30 m; diameter 0.32 mm; film thickness 0.5 μm) was used for the measurements of HCB in water and soil. The following instrumental settings were chosen for the rapid analysis:

-

Temperature of the injector: 230 °С

-

Isothermal column: 230 °С

-

ECD detector: 270 °С

The retention time of hexachlorobenzene on the column was 2.88 min with these settings (Supporting Information Fig. SI 1). HCB was characterized by retention time and mass spectra (Supporting information Fig. SI 2) and quantified by external standard calibration. Some screenings were also performed by thin-layer chromatography after extraction.

Soil samples were randomly screened using an “Element 02” X-ray fluorescence (XRF) spectrometer to determine the elemental composition. XRF measurements meet the requirements of Category III precision analysis, which is used for mass analysis of geological samples in exploration, reserve calculation and control analyses.

Geophysical studies by resonant acoustic profiling

Geophysical studies were undertaken in early October 2012 using resonant acoustic profiling (RAP; Fig. 1) to establish the structural heterogeneity of soils and to obtain information about groundwater levels. The RAP method has recently been introduced and used in domestic geophysics and showed good performance for solving some practical search and exploration problems in geophysics, hydrogeology, engineering geology, geoscience, glaciology and mining (Zuykov and Olejnik 2001; Zuykov 2001). A RAP assessment together with a metal detector survey of the site was undertaken, and the geodetic coordinates of designated zones (Fig. 4) were collected.

The RAP method uses portable equipment with good performance with a measurement cycle of less than 30 s and provides information of the measured geological section to a depth of 300 m.

All the data is transformed into 3-D model view, and the “RAP-Plus” hardware provides an opportunity to work in “real time” thus allowing direct observation of the spectral characteristics of the signal and allowing rapid changes to the parameters observed.

Results and discussion

The overall environmental situation and threats from former mining activities in the area

Potassium salts were open-cast mined from Dombrivski quarry which is one of the few sites where this technique was used. The Dombrivski quarry operated between 1967 and 2000, during which time 52.5 million m3 of material was excavated. Approximately 14.6 million tonnes of ore was extracted from the northern part of the quarry which was mined to 63 whilst 17.3 million tonnes of ore and 20 million tonnes of rock were recovered from the southern part of the quarry with a depth of up to 127 m. The quarry is currently flooded by a combination of rainfall and groundwater inflow, and more than 16 million m3 of brine has accumulated in the void. The estimated salt concentration is approximately 80 g/l in the upper layers of brines. The groundwater gradient is towards the south-southeast and the contaminated waters will spread towards the River Limnitsa.

The dumps and the pit itself are affected by karstification, and according to expert assessment, the largest threats in the area are the spent Dombrivski mine, the tailings of Mine Waste Dump No. 1 and No. 2, the salt dumps on the sides of the former mine, sludge depository, potash mines “Kalush”, “Holyn”, “Khotyn” and “Novo-Holyn” and the HCB waste landfill near Kalush (the Polygon) (Joint UNEP/OCHA Environment Unit 2010).

The general lack of rehabilitation, sediment control structures and maintenance, together with the unstable slopes of Mine Waste Dump No. 1, has led to erosion, filling up of drains and uncontrolled runoff of wastes including brines into surrounding waterways and into the Dombrovski Open-Cast Mine. The waste dumps are also a major, and possibly the principal, source of brine polluting the groundwater aquifer towards the River Limnitsya (Joint UNEP/OCHA Environment Unit 2010).

In parts of Kalush City and the villages Kropivnik and Sivka Kalushska, the population is threatened by the unstable earth surface and salinization and pollution of the drinking water. There has been only very limited backfilling of the mines with solid materials. The openings have mainly been filled with brine but, in some cases, also with freshwater, but this does not necessarily guarantee the stability of the inter-chamber pillars. As a result of the degradation of these pillars, the ground above the mine is subsiding (Joint UNEP/OCHA Environment Unit 2010) and a number of subsidence-related sinkholes have been formed varying in size from several metres to over 100 m in diameter. The impact of the sinkholes is localized but would have a direct impact in causing casualties if houses or apartment blocks were affected (Joint UNEP/OCHA Environment Unit 2010). About 1300 of residential units and 23 industrial facilities are located in the area of intensive mining (Fig. 3). According to data and the calculations of the Kalush authorities, 4328 people are at risk in the subsidence zones and in need of resettlement (Joint UNEP/OCHA Environment Unit 2010), and an area for resettlement has been identified in the city which could house over 6000 people, a school and two kindergartens.

Solvent production, HCB waste generation and volumes landfilled

Solvent production started at Kalush in 1973 with an estimated production capacity of 30,000 t per year mainly of carbon tetrachloride, tetrachloroethylene and dichloroethene (ethylenedichloride or ‘EDC’) for PVC production. The tetrachloroethylene was produced by low-pressure chlorinolysis of light hydrocarbons at temperatures above 300 °C. During the process, some tetrachloroethylene is condensed to HCBD and further to HCB and other unintentional POPs in a condensation reaction of radicals (Fig. 2; Zhang et al. 2015). Other by-products include carbon tetrachloride and hydrogen chloride. Company records show that the HCB waste originally consisted of a yellow crystalline substance composed largely of the POPs HCB and HCBD with the following: tetrachloroethylene (С2Сl4), 2–3 %; hexachloroethane (C2Cl6), 7–11 %; hexachlorobutadiene (HCBD; C4Cl6), 20–27 %; and HCB (C6Cl6), 53–67 % (LLC Oriana-Galev 2001).

A recent Chinese study demonstrated that the production of chlorinated methanes involves some further condensation which generates octachlorostyrene (OCS), chlorinated naphthalenes (PCNs) and polychlorinated biphenyls (PCBs) as well as small quantities of polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs) (Zhang et al. 2015) (Fig. 2). This study also raised concerns about polychlorinated naphthalenes due to their high contribution of dioxin-like toxicity (Zhang et al. 2015). Also the PCN levels in PCB revealed the relevance of PCN in another organochlorine production (Huang et al. 2014). Unintentional produced PCNs, PCBs or PCDD/Fs were not measured in this study.

All HCB waste from solvent production as well as wastes from the EDC production was landfilled in the Polygon site due to the lack of any destruction technologies and the limited recycling efforts at the Oriana-Galev organochlorine production (LLC Oriana-Galev 2001, 2002; Tsygulieva-Kharkov 2001) (Figs. 3 and 4). Approximately 540 t/year of HCB waste was landfilled between 1973 and 2001 with a total of approximately 15,000 t. No dedicated storage site was available between 1973 and 1976, yet HCB waste was reported to be dumped in the Kalush area and possibly in Mine Waste Dump No. 1 and/or No. 4, east of the Dombrovski Open-Mine Pit. The major HCB landfill site is located 6 km southwest of the city of Kalush (Fig. 3). This site was visited by a UNEP/OCHA scoping mission in 2010 which confirmed the environmental release and pollution of POPs from the site (Joint UNEP/OCHA Environment Unit 2010). Pentachlorobenzene was also detected in surface water. The UNEP/OCHA scoping mission also assessed Mine Waste Dump No. 1 and/or No. 4, east of the Dombrovski Open-Mine Pit, and found indications that these areas might be impacted from former uncontrolled dumping (Joint UNEP/OCHA Environment Unit 2010).

The HCB wastes had been packed into 200-l steel drums which were tipped at the Polygon in 4-m-deep trenches which subsequently were covered with plastic sheeting and backfilled with soil. Company records from the “Polygon passport” (LLC Oriana-Galev 2002) indicate that a total of 11,087.6 t of HCB waste (hazard class 1) had been deposited when the site was decommissioned in October 2001 (Table 1) along with 265 t of solid residues from equipment (hazard class 3).

Before the remediation work started, several inspections of the site were undertaken on the initiative of the Ivano-Frankivsk Regional Administration to assess the quantity and quality of the waste mixtures and to improve the inventory. Corrosion of the barrels (see Fig. 5) at the time of examination and the partial migration of the contents meant that these assessments differed significantly from the volume of waste originally disposed at the site (Table 1).

Assessment of waste composition and toxicity considerations

The qualitative composition of the waste in the Polygon area along with the associated pollution of the surroundings was investigated in December 2011 by the Central Toxicology Laboratory on water transport. Their studies showed that the waste could contain up to 90 % HCB waste. Releases from the site were screened, and this showed that the vapour phase in the samples of soil contained 1,1-dichloroethene; 1,1-dichloroethane; chloroform; carbon tetrachloride; trichlorethylene; 1,2,3-trichloroethane; tetrachlorethylene; 1-bromo-1,2,2-trichlorethylene; hexachloroethane; and 1,3-butadiene-1,1,2,3,4,4-hexachloro (HCBD).

On the other hand, the associated water samples contained HCB; chloroform; 1,2-dichloroethane; carbon tetrachloride; tetrachlorethylene; hexachloroethane; and 1,3-butadiene-1,1,2,3,4,4-hexachloro (HCBD).

As a Stockholm Convention listed POP and a major component in the waste, HCB is of highest concern. HCB has a high level of toxicity, is resistant to degradation and has the ability to bioaccumulate in terrestrial and aquatic ecosystems. It is considered to be a probable human carcinogen and a proven animal carcinogen and is highly toxic to aquatic organisms. The long-term effects of HCB and accompanying organic pollutants on humans and the environment represented extremely high environmental risks and required emergency measures to reduce their harmful effects.

Ukraine has developed several standards for HCB, and these include the following (Ministry of Ecology and Natural resources of Ukraine 2010):

-

For surface water: 0.001 μg/l (=1 ng/l) (risk category I)

-

For soil: 0.03 mg/kg dry matter (=30 ng/g)

-

For air: 0.9 μg/m3

These standards are comparable to standards in other countries. For example, HCB background concentrations in Dutch soils are 0.0085 mg/kg dry matter (Joint UNEP/OCHA Environment Unit 2010).

Other compounds of concern in the HCB waste are PeCBz and HCBD which are both POPs and have a higher water solubility than HCB. PeCBz were detected at higher concentrations than HCB in one of the UNEP/OCHA water samples (Joint UNEP/OCHA Environment Unit 2010), and these two POPs need to be taken into account as part of the overall assessment of releases and the associated toxicological risk.

Risks associated with the waste deposits and the decision to remediate

Because of the low standards of disposal and the lack of suitable site engineering, the Polygon site is a hazard to adjacent groundwater—especially as infiltration of the site and the aggressiveness of the salty leachates to metal rapidly corroded the storage drums (Fig. 5). As a result, HCB and other toxic compounds have been released into the soil and groundwater and have contaminated the surrounding. The 2008 monitoring data documented the pollution of air, soil and groundwater in the vicinity of the Polygon including a stream in the Sapogi–Limnytsia River basin (which is a tributary of the Dniester river). A Presidential Decree and relevant decree of the Cabinet of Ministers of Ukraine in 2010 was therefore issued in order to remove the toxic waste and to close the Polygon (President of Ukraine 2010; Cabinet of Ministers of Ukraine 2010). The HCB waste was then excavated in stages between 2010 and 2013 (see Fig. 4), and the waste and contaminated soil were shipped to EU states (UK, France and Poland) for destruction by incineration.

The 2012 and 2013 assessment of the HCB waste deposit (Polygon area)

In 2012 and 2013, the Ukrainian authors of this publication were invited to provide scientific support for the removal of HCB waste from the Polygon. They also conducted a study on the release of pollutants in the Polygon area and an assessment of the migration of HCB into the environment (see below). Data on the geological conditions of HCB waste disposal within the Polygon area is given in Table 2. Another task was the investigation and, where possible, the identification of areas where waste had been deposited but not previously recorded.

The groundwater levels within the HCB waste deposit had previously been estimated to be at a depth of 1.5–2.0 m below the surface. In a more comprehensive recent assessment, it was established that the ground water level was actually at just 1 m below the surface or less, meaning that the majority of the waste was saturated by groundwater (see below and Fig. 5).

In early October 2012, to determine the structural heterogeneity of soils and to obtain information about the levels of groundwater, geophysical studies by resonant acoustic profiling (RAP) with a metal detector survey of the territory were conducted at the site. This method was established by geophysicists in Ukraine and has worked well for solving a range of practical challenges in exploration in geophysics, hydrogeology, engineering geology, glaciology and mining (Zuykov 2001; Zuykov and Olejnik 2001). By this approach, geodetic coordinates referenced designated zones could be established for the site. Finally, a refined scheme of the Polygon with outline maps of the HCB waste storage sites was produced based on the RAP monitoring (Fig. 4) showing that the HCB in the landfill consists of four sections.

According to the archival documents, the base layer was filled with clay to about 0.3 m, which was covered with a 2-mm polyethylene film. The 200-l drums were then placed on the foil in two to three rows, covered by more plastic sheet and backfilled with clay to 0.5 m. During remediation, however, it was discovered that no protective measures were in place to secure the long-term integrity of the drums containing the HCB waste (Fig. 5). It was found that the groundwater level in the polygon was only between 0.15 and 1.7 m below the surface, and thus, virtually all the waste drums were situated below the groundwater level which resulted in their corrosion and failure within the 15 to 40 years of being deposited (Fig. 5).

The Polygon remediation scheme (Fig. 4) includes information on the HCB waste and related contaminated soil removal steps over the years: 8514 t was removed in 2010 with another 9500 t in 2011 and then 3430 t in 2012 (Institute of Environmental Geochemistry of the National Academy of Sciences of Ukraine 2012). The Polygon scheme was used in 2013 as the working document for the removal and additional 8001 t of HCB waste (Institute of Environmental Geochemistry of the National Academy of Sciences of Ukraine 2014). Therefore, during the period between 2010 and 2013, a total of 29,445 t of HCB waste and contaminated soils was removed from the site.

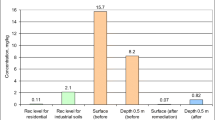

The aim of the removal was the decontamination of the area by removal and destruction of the HCB waste. However, control geochemical soil sampling conducted after the removal of most of the HCB waste from the landfill (as for 20.12.2013) still showed high levels of contamination of HCB in the surface soil layer (Fig. 6).

The analysis of the results for determination of HCB in the control surface soils samples leads to the conclusion that in spite of the removal of waste from the polygon and the backfilling with clean soil, the polygon is still contaminated with HCB levels of up to 0.5 % (5 g/kg). This means that the HCB residues in soil at the Polygon is still 170,000 times higher than the Ukraine LAC limit for dry soil (0.03 mg/kg dry matter) (Ministry of Ecology and Natural resources of Ukraine 2010). Significant levels of HCB were also detected in the topsoil removed from the site. The remediation procedures required these soils to be stored and, then, after the removal of the HCB wastes, to be backfilled into the site.

This contamination of the topsoil shows that the feasibility study for the HCB waste remediation project (Ministry of Ecology and Natural resources of Ukraine 2010) had not taken into account the long-term migration of HCB into the upper soil layers and their subsequent contamination. This migration was probably a result of seasonal changes in groundwater levels and due to capillary effects. Some of the contamination could also have occurred during remediation operations and the associated re-cultivation.

The migration of HCB in the soil over time is demonstrated by the analysis of soils from the eight boreholes (wells, Fig. 7). For the two boreholes (wells #2 and #3) with high HCB contamination (3.5 to 20 g/kg soil), the HCB levels were also elevated in the upper layer (0.5 m) and down to 6 and 12 m indicating that the HCB had migrated over time (Fig. 7). For three boreholes (wells #1, #4 and #8) with relatively low contamination, the top layer had the highest HCB levels. This indicates that the HCBs have been transported from areas of high HCB contamination via surface water during heavy rain when the areas have been flooded.

The levels of HCB in the groundwater exceed Ukraine limits (0.001 μg/l) by 10 to 100 times or more. The monitoring of HCB in the water of the Sapogov river at a distance of 200 m from the Polygon shows that the HCB content in water exceeded the Ukrainian standard for surface water (0.001 μg/l) by three to five times.

Fate of exported waste and challenges of destruction of POP waste even in industrial countries

The HCB waste was exported to hazardous waste incinerators in France and UK which were appropriately permitted for the destruction of POPs. The rest of the HCB waste was exported to a Polish hazardous waste incinerator. Here the HCB waste was stored in partly damaged (torn) Big-Bags in the open. The storage site at the incinerator was within ∼50 m of the Baltic Sea with obvious hazards associated with releases to the environment.Footnote 2 Furthermore, the capacity of the Polish incinerator is relatively small, and the destruction of the approximately 10,000 t of HCB waste stored at the plant was estimated to take around 2 years and is still ongoing after more than 3 years. Overall, this incineration facility was not suitable to be used for the destruction of the POP waste, and legal investigations have been initiated. The poor quality of the storage on the site and the inadequate processing of the HCB waste demonstrate that the assessment and the permit given by the authorities in Poland were not appropriate.Footnote 3

In 2011, there had been a similar case in Germany in which the company ENVIO imported and processed equipment containing PCBs and contaminated the factory area and the surrounding (Prognos AG 2011a, b). The ENVIO staff were also heavily contaminated with PCBs, and a court case is ongoing. It is clear that the local authority had not supervised the company appropriately (Prognos AG 2011a, b).

Furthermore, in 2014/2015, the excavation of a HCB waste deposit from an organochlorine producer in Austria has resulted in ongoing large-scale HCB contamination of the environment surrounding including cattle, milk and humans from the release of the Austrian cement kiln used to treat the waste. The case demonstrates that the incorrect loading of HCB waste into state of the art cement kilns at too low temperature can result in high levels of HCB emission with associated widespread and serious pollution (Martinz 2015; Funk et al. 2015). Also, in this case, the competent authority did not appropriately supervise the POP destruction project (Funk et al. 2015).

These examples demonstrate that a more rigorous monitoring framework is needed even in European Union countries when POPs are imported for destruction or wastes are excavated (Weber et al. 2015). Either the regulatory authorities need specific capacity building for the assessment and management of these sensitive wastes or they should ensure that other authorities with appropriate skills and experience should regulate the storage and treatment processes.

Furthermore, the emission from thermal destruction of the cement kiln demonstrates the need of continuous monitoring of emissions of POP destruction projects (Reinmann et al. 2010; Weber 2007).

Lessons to be learned from the Kalush case for other HCB waste deposits

Chlorinated solvents have been produced at a large industrial scale for more than 70 years (Mohr 2010; Rasmussen 1997 Footnote 4). There are many factories around the world which have produced, and continue to produce, chlorinated solvents. In developing and transition countries, these wastes have probably been landfilled until recently due to the lack of destruction capacity (Weber et al. 2013), and some sites may still rely on landfills. Even in industrial countries, organochlorine wastes were largely been landfilled until at least the 1970s (Fernández et al. 2013; Götz et al. 2013; Forter 2006, 2010; Heinisch et al. 2007; Vijgen et al. 2011; Weber et al. 2008, 2011).

HCBD and PCN are now listed in the Stockholm Convention as POPs requiring global control and elimination (UNEP 2015a, b; International Institute for Sustainable Development 2015), and landfilled wastes from solvent production represent the major HCBD stockpiles. The implementation of the Stockholm Convention therefore requires that the countries hosting the (former) chlorinated solvent production and related HCB, HCBD and PCN contamination will need to be assessed, secured and, where appropriate, remediated. Lessons from the remediation in Kalush and in Austria (Funk et al. 2015; Weber et al. 2015) and challenges this has revealed might therefore be useful to help guide remediation at other sites.

The metal drums containing the HCB waste in the Kalush landfill were heavily corroded due to the corrosive environment and the high groundwater level in the site. Corrosion of drums has also been reported for the Australian HCB waste storage at Orica where the drums have been stored indoor (Independent Review Panel 2006). In 2007, Orica commenced a (semi-)automated repackaging of the HCB waste into UN-approved containers for possible shipment as a result of this corrosion (Independent Review Panel 2006). This shows that even the contents of the drums alone can cause corrosion. Therefore, at other sites, metal drums will most likely be corroded resulting in the release of the POPs into the landfill and groundwater. Site remediation will almost certainly require repackaging into appropriate containment.

HCB, HCBD, and other pollutants readily migrate through the soil over a period of years and contaminate the soil and other wastes surrounding the HCB waste. This can impact soil layers both above and below the deposit including capping soil. Migration is likely to depend on the groundwater (or leachateFootnote 5) level in the deposits, but migration, particularly of HCBD, might also take place by desorption and even contaminate landfill gases and the atmosphere around the site as demonstrated at a site in the UK (ENDS 2000). The topsoil and soils in the deposit and the surrounding therefore have to be monitored for HCB, HCBD and possibly other contaminants to decide what proportion of the soil and other wastes might need treatment and which soil, if any, might safely be used for backfilling.

At Kalush, the total volume of contaminated material needing remediation and destruction was more than two times the amount originally estimated for the total remediation of the HCB waste due to the migration of contamination into neighbouring waste and soil. This resulted in the extension of the project and a considerable increase in the original budget.

Conclusions

Ukraine has dedicated considerable effort into the remediation of their largest unintentional POP stockpiles and excavated 29,445 t of HCB waste and contaminated soil between 2010 and 2013 and exported them to three EU states for destruction.

Despite the excavation and the remediation efforts, the Polygon area remains a contaminated site and will need further assessment and remediation including the following:

-

A detailed assessment to establish whether all the HCB waste has been removed from the Polygon area and, potentially, other former dump sites.

-

Establishing the extent of the residual soil contamination on the Polygon site and then determining the appropriate remediation and securing measures needed.

-

Determination of the HCB and HCBD pollution from the Polygon in the surroundings including the river sediments and fish

The feasibility study for the decommissioning of the site should also take into account the long-term migration of POP waste and associated pollutants into the soil, groundwater and the wider environment. Further, groundwater assessment requires consideration of chlorinated compounds with higher water solubility (tetrachloroetylene, trichloroethylene, vinylchloride) as these compounds are critical for off-site migration risk (see, e.g. supporting information in Wycisk et al. 2013).

Very recently, it has been shown that PCN is a major pollutant with the highest dioxin-like activity in waste from organochlorine solvent production (Zhang et al. 2015). The assessment of waste deposits from solvent production must therefore also consider PCN listed in the Stockholm Convention in May 2015. The Stockholm Convention inventories are an important part of the process and when they are developed for PCN, HCBD, HCB any past and present residues from chlorinated solvent production need to be considered comprehensively.

The HCB waste from Kalush and experience from other solvent production sites highlight that a systematic assessment of stockpiles is needed in combination with securing and any necessary remediation measures. The excavation of the HCB waste in Kalush demonstrated that metal drums containing these waste are largely corroded after a few decades, and this results in the release of the POPs into groundwater and soil and the wider environment when the waste has been dumped in badly engineered sites. This needs to be considered and evaluated for other sites where wastes from chlorinated solvent productions have been stored or landfilled. The more water soluble HCBD (4 mg/l) included in the EU environmental quality standards for fish might be a good indicator for releases from landfills and other storage areas.

Finally, the import of Kalush/Ukraine HCB waste to Poland3 (and in another case of PCB waste import to Germany (Prognos AG 2011a, b) or treatment in an Austrian cement kiln (Funk et al. 2015) revealed that the control by the authorities for the importation and/or management of POP waste for destruction and the related monitoring of facilities and companies can be ineffective and inadequate even in EU countries (Weber et al. 2015). The control relating to waste imports and their subsequent storage and treatment need to be significantly improved with better supervision and monitoring. The final destruction of POP waste should only be carried out in well-regulated and ‘state-of-the-art’ incinerators or by other technologies proven to be capable of effectively destroying POPs, and the emissions should be continuously monitored.

Notes

The extraction procedure will be changed from the carcinogen benzene to toluene in future.

See documentary film at http://uwaga.tvn.pl/reportaze,2671,n/the-carcinogenic-hcb-by-the-baltic-sea,135689.html

The permit to import the HCB waste into Poland was given by Andrzej Jagusiewicz who was until recently the president of the Conference of the Parties of the Basel Convention for controlling transboundary movements of hazardous waste and their disposal http://uwaga.tvn.pl/reportaze,2671,n/the-carcinogenic-hcb-by-the-baltic-sea,135689.html.

Small quantities of chlorinated solvents had been produced earlier. The production of chloroform for use as an anaesthetic, for example, started in the mid-nineteenth century, and carbon tetrachloride was produced from the 1890s to extract fats from vegetables (Rasmussen 1997).

If, for example, the site has engineered containment but has not been adequately pumped to de-water it, then the leachate levels might be very high in the landfill and can cause corrosion of drums as well as transporting contamination.

References

Amirova Z, Weber R (2015) Massive PCDD/F contamination at the Khimprom organochlorine plant in Ufa—a review and recommendations for future management. Environ Sci Pollut Res Int. doi:10.1007/s11356-015-5048-8

Austrian Federal Environment Agency (2004) Medienübergreifende Umweltkontrolle in ausgewählten Gebieten – Brückl. Monographien M-168, pp. 119–142, Wien 2004

Barnes G, Baxter J, Litva A, Staples B (2002) The social and psychological impact of the chemical contamination incident in Weston Village, UK: a qualitative analysis. Soc Sci Med 55:2227–2241

Cabinet of Ministers of Ukraine (2010) Regulation of the № 381-p “On some measures related the liquidation of consequences of an ecological situation in the town Kalush and villages Kropyvnyk and Sivka-Kalush of Kalush district, Ivano-Frankivsk region. 02. March 2010. (in Ukrainian)

Central Toxicology Laboratory on Water Transport (2011) Act of inspection of hexachlorobenzene waste disposal at the polygon of toxic wastes of LLC “Oriana-Galev” in Kalush, Ivano-Frankivsk region dated 23.05.2011. (in Ukrainian)

CH2M Hill International Corp (1991) Feasibility study: hazardous-waste remediation at the Chabarovice site. Volume 1. Export trade information Report No: PB-92-216027/XAB, in Other Information: This document was provided to NTIS by the U.S. Trade and Development Program, Rosslyn, VA. 1991. p. Medium: X; Size: Pages: (230 p)

ENDS (2000) Village blighted by pollution from ICI Runcorn’s old waste tip, vol 301. Environmental Data Services (ENDS) Ltd, London, pp 4–5

Fernández J, Arjol MA, Cacho C (2013) POP-contaminated sites from HCH production in Sabiñánigo, Spain. Environ Sci Pollut Res Int 20:1937–1950

Forter M (2006) Dioxin and dioxin-like compounds in chemical landfills of the Basel chemical industry. Organohalogen Compd 68:886–889

Forter M (2010) Falsches Spiel – Die Umweltsu¨nden der Basler Chemie vor und nach ‘Schweizerhalle’. ChronosVerlag, Zürich

Funk B-C, Hutter H-P, Neubacher F, Raschauer B (2015) HCB-Belastung Görtschitztal / Kärnten Verfahrenstechnische – juristische – medizinische Beurteilung. May 2015

Götz R, Sokollek V, Weber R (2013) The Dioxin/POPs legacy of pesticide production in Hamburg: Part 2: Waste deposits and remediation of Georgswerder landfill. Env Sci Pollut Res 20:1925–1936

Heinisch E, Kettrup A, Bergheim W, Martens D, Wenzel S (2006) Persistent chlorinated hydrocarbons, source-oriented monitoring in aquatic media. 4. The chlorobenzenes. Fresenius Environ Bull 15(3):148–169

Heinisch E, Kettrup A, Bergheim W, Wenzel S (2007) Persistent chlorinated hydrocarbons, source-oriented monitoring in aquatic media. 6. Strikingly high contaminated sites. Fresenius Environ Bull 16:1248–1273

Huang J, Yu G, Yamauchi M, Matsumura T, Yamazaki N, Weber R (2014) Congener-specific analysis of polychlorinated naphthalenes (PCNs) in the major Chinese technical PCB formulation from a stored Chinese electrical capacitor. Environ Sci Pollut Res Int. doi:10.1007/s11356-014-3677-y

International Institute for Sustainable Development (IISD) Reporting Service (2014) Summary of the tenth meeting of the Stockholm convention’s persistent organic pollutants review committee: 27–30 October 2014. Earth Negotiation Bulletin Vol. 15 No. 214

Independent Review Panel (2006) Further independent review Orica HCB waste stockpile safe interim storage and destruction independent review. Report to the Australian minister of planning

Institute of Environmental Geochemistry of the National Academy of Sciences of Ukraine (2012) Research and methodological support in the implementation of environmental protection measures of the customer on disposal of hazardous waste of hexachlorobenzene, which are at the Polygon in the area of conservation of Dombrowski career in Kalush district, Ivano-Frankivsk region, (3 volumes) № of state registration 0112U007273. (in Ukrainian)

Institute of Environmental Geochemistry of the National Academy of Sciences of Ukraine (2014) Research and methodological support of the disposal of hazardous waste of hexachlorobenzene, which are at the Polygon in the area of conservation of Dombrivskii career in Kalush district, Ivano-Frankivsk region in 2013. (in Ukrainian)

International Institute for Sustainable Development (IISD) (2015) Summary of the meetings of the conference of the parties to the Basel, Rotterdam and Stockholm convention, 4-15 May 2015. Earth Negotiations Bulletin 15 No. 230

Jacoff F, Scarberry R, Rosa D (1986) Source assessment of hexachlorobenzene from the organic chemical manufacturing industry, In Morris CR, Cabral JRP. Hexachlorobenzene: Proceedings of an International Symposium pp. 31–37.

James P (2009) The supervision of environmental risk: the case of HCB waste or Botany/Randwick? J Environ Manag 90:1576–1582

Jit S, Dadhwal M, Kumari H, Jindal S, Kaur J, Lata P, Niharika N, Lal D, Garg N, Gupta SK, Sharma P, Bala K, Singh A, Vijgen J, Weber R, Lal R (2010) Evaluation of hexachlorocyclohexane contamination from the last Lindane production plant operating in India. Environ Sci Pollut Res 18:586–597

Joint UNEP/OCHA Environment Unit (2010) A joint united nations – European commission environmental emergency response mission: technical scoping mission Kalush area, Ukraine March 2010

Jones K, Barber J, Sweetman A (2005) Hexachlorobenzene - sources, environmental fate and risk characterisation - Eurochlor Science Dossier. 2005

LLC Oriana-Galev (2001) Passport of potentially dangerous object. Kalush (in Ukrainian) Паспорт потенційно небезпечного об’єкта ТОВ “Оріана-Галев”, м. Калуш-2001 р. - 19 с

LLC Oriana-Galev (2002) Passport of the waste disposal site “Polygon of solid toxic waste” Kalush, Ivano-Frankivsk region. Registration number 8. 19.08.2002. (in Ukrainian)

Martinz T (2015) HCB-Skandal sprengt Landesbudget. Kurier 24.03.2015 http://kurier.at/themen/HCB

Ministry of Ecology and Natural resources of Ukraine (2010) The feasibility study of the project on waste management of hexachlorobenzene located in Dombrivsii quarry and polygon of solid toxic wastes that are in the zone of ecological emergency in the town Kalush and villages Kropyvnyk and Sivka-Kalush of Kalush district, Ivano-Frankivsk region. Developer: State Enterprise “National Center on hazardous waste management” (in Ukrainian).

Mohr TKM (2010) Historical use of chlorinated solvents and their stabilizing compounds. In: Mohr TKG, Stickney JA, DiGuiseppi WH (eds) Environmental investigation and remediation - 1,4-dioxane and other solvent stabilizers. CRC Press, Boca Raton, pp 1–73

Oliaei F, Kriens D, Weber R, Watson A (2013) PFOS and PFC releases and associated pollution from a PFC production plant in Minnesota (USA). Environ Sci Pollut Res Int 20:1977–1992

President of Ukraine (2010) Decree of the President of Ukraine № 145 “On the announcement of Kalush areas and villages Kropyvnyk and Sivka-Kalush of Kalush district, Ivano-Frankivsk region of the zone of ecological emergency. 10. February 2010. (in Ukrainian)

Prognos AG (2011) Abschlussbericht Der Fall ENVIO/Dortmunder Hafen -Klärung weiterer Fragestellungen mit immissionsschutzrechtlichem und abfallwirtschaftlichem Hintergrund

Prognos AG (2011) Gutachten über die Untersuchung möglicher Schwachstellen in der Behördenstruktur und Organisation der Arbeitsschutz-, Gesundheits-, und Umweltverwaltung im Fall ENVIO/Dortmunder Hafen

Randak T, Zlabek V, Pulkrabova J, Randák T, Žlábek V, Pulkrabová J, Kolářová J, Kroupová H, Sirotka Z, Velíšek J, Svobodová Z, Hajšlová J (2009) Effects of pollution on chub in the River Elbe, Czech Republic. Ecotoxicol Environ Saf 72:737–746

Rasmussen K (1997) Chlorinated solvents - health effects after long-term exposure. Public Health Perspectives. PhD Thesis Institute of Epidemiology and Social Medicine University of Aarhus, Denmark

Reinmann J, Weber R, Haag R (2010) Long-term monitoring of PCDD/PCDF and other unintentionally produced POPs – Concepts and case studies from Europe. Sci China: Chem 53:1017–1024

RIVM (2001) Environmental risk limits for hexachlorobenzene and hexachlorobutadiene in water. Using bioaccumulation data to convert biota standards into water risk limits. RIVM letter report 601714015/2011. National Institut for Public Health and the Environment, Netherlands

Torres JPM, Fróes-Asmus CIR, Weber R, Vijgen JMH (2013a) Status of HCH contamination from former pesticide production and formulation in Brazil – a task for Stockholm Convention Implementation. Environ Sci Pollut Res 20:1951–1957

Torres JPM, Leite C, Krauss T, Weber R (2013b) Landfill mining from a deposit of the chlorine/ organochlorine industry as source of dioxin contamination of animal feed and assessment of the responsible processes. Environ Sci Pollut Res 20:1958–1965

Tsygulieva-Kharkov O (2001) Persistent organic pollutants: a review of the situation in Ukraine. International POPs Elimination Project. Accessible at: http://www.ecoaccord.org/pop/ipep/ukr-review.htm (in Ukrainian) Стойкие органические загрязнители: обзор ситуации в Украине. Международный проект по ликвидации СОЗ / О. Цыгулева, И. Корсунская – Харьков

UNEP (2001) Stockholm convention on persistent organic pollutants (POPs). Text and Annexes

UNEP (2010) Additional consideration of new persistent organic pollutants: pentachlorobenzene. 6th POP Review Committee meeting Geneva 10/2010 (UNEP/POPRC/6/INF/21)

UNEP (2012) Draft risk profile: hexachlorobutadiene. UNEP/POPS/POPRC.8/3

UNEP (2013) Addendum. Risk management evaluation on hexachlorobutadiene. UNEP/POPS/POPRC.9/13/Add.2

UNEP (2013) Toolkit for identification and quantification of releases of dioxins, furans and other unintentional POPs under article 5 of the Stockholm convention on persistent organic pollutants. Geneva, Switzerland, January 2013

UNEP (2015) Recommendation by the persistent organic pollutants review committee to list hexachlorobutadiene in annexes A and C to the convention and draft text of the proposed amendment. Document for the seventh meeting of the Conference of Parties, Geneva 4–15 May 2015. UNEP/POPS/COP.7/19

UNEP (2015) Recommendation by the persistent organic pollutants review committee to list chlorinated naphthalenes in annexes A and C to the convention and draft text of the proposed amendment. Document for the seventh meeting of the Conference of Parties, Geneva 4–15 May 2015. UNEP/POPS/COP.7/18

URS Australia (2011) Human health and environmental risk assessment orica villawood. Final report. Prepared for Orica Australia Pty Ltd. 9. February 2011

USEPA (2004) Hazard ranking system documentation record for devil’s swamp lake. Superfund site assessment section, EPA Region 6. March 15, 2004

Verta M, Kiviranta H, Salo S, Malve O, Korhonen M, Verkasalo PK, Ruokojärvi P, Rossi E, Hanski A, Päätalo K, Vartiainen T (2009) A decision framework for possible remediation of contaminated sediments in the River Kymijoki, Finland. Environ Sci Pollut Res Int 16:95–105

Vijgen J, Abhilash PC, Li Y-F, Lal R, Forter M, Torres J, Singh N, Yunus M, Tian C, Schäffer A, Weber R (2011) HCH as new Stockholm convention POPs—a global perspective on the management of Lindane and its waste isomers. Environ Sci Pollut Res 18:152–162

Weber R (2007) Relevance of PCDD/PCDF formation for the evaluation of POPs destruction technologies – review on current status and assessment gaps. Chemosphere 67:109–117

Weber R, Varbelow G (2013) The dioxin/POPs legacy of pesticide production in Hamburg: part 1 securing of the production area. Environ Sci Pollut Res 20:1918–1924

Weber R, Gaus C, Tysklind M, Johnston P, Forter M, Hollert H, Heinisch H, Holoubek I, Lloyd-Smith M, Masunaga S, Moccarelli P, Santillo D, Seike N, Symons R, Torres JPM, Verta M, Varbelow G, Vijgen J, Watson A, Costner P, Wölz J, Wycisk P, Zennegg M (2008) Dioxin- and POP-contaminated sites—contemporary and future relevance and challenges. Environ Sci Pollut Res 15:363–393

Weber R, Watson A, Forter M, Oliaei F (2011) Persistent organic pollutants and landfills—a review of past experiences and future challenges. Waste Manag Res 29:107–121

Weber R, Aliyeva G, Vijgen J (2013) The need for an integrated approach to the global challenge of POPs management. Environ Sci Pollut Res Int 20:1901–1906

Weber R, Schlumpf M, Vijgen J (2015) The need for better management and control of POPs stockpiles. Environ Sci Pollut Res Int. doi:10.1007/s11356-015-5162-7

Weinberg J (2008) An NGO guide to persistent organic pollutants. A framework for action to protect human health and the environment from persistent organic pollutants (POPs). http://ipen.org/sites/default/files/documents/ngo_guide_pops-en.pdf

Wimmerová S, Watson A, Drobná B, Šovčíková E, Weber R, Lancz K, Patayová H, Jurečková D, Jusko TA. Murínová L, Hertz-Picciotto I, Trnovec T (2015) The spatial distribution of human exposure to PCBs around a former production site in Slovakia. Environ Sci Pollut Res. doi:10.1007/s11356-015-5047-9

Wycisk P, Stollberg R, Neumann C, Gossel W, Weiss H, Weber R (2013) Integrated methodology for assessing the HCH groundwater pollution at the multi-source contaminated mega-site Bitterfeld/Wolfen. Environ Sci Pollut Res 20:1907–1917

Zhang L, Yanga W, Zhanga L, Lib X (2015) Highly chlorinated unintentionally produced persistent organic pollutants generated during the methanol-based production of chlorinated methanes: a case study in China. Chemosphere 133:1–5

Zuykov I (2001) Resonance acoustical profiling system and methods of using same/US Patent № 6199016 B1, March 6, 2001

Zuykov I, Olejnik W (2001) Novel subsurface imaging system—subsurface sensors and applications. Proc SPIE 3752:174–181

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Philippe Garrigues

This article is part of the series “Dioxin and POP contaminated sites” edited by Roland Weber, Mats Tysklind and Caroline Gaus (Weber et al. 2008).

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 119 kb)

Rights and permissions

About this article

Cite this article

Lysychenko, G., Weber, R., Kovach, V. et al. Threats to water resources from hexachlorobenzene waste at Kalush City (Ukraine)—a review of the risks and the remediation options. Environ Sci Pollut Res 22, 14391–14404 (2015). https://doi.org/10.1007/s11356-015-5184-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5184-1