Abstract

In this study, mesoporous glycidyl methacrylate-divinylbenzene-based chelating resin was synthesized and grafted with diethylenetriamine through epoxy ring-opening reaction. The synthesized resin was characterized by elemental analysis, infrared spectroscopy, surface area and pore size analysis, scanning electron microscopy, energy-dispersive spectroscopy, and thermogravimetry. The resin was used for the first time as an effective sorbent for the preconcentration of nickel in electroplating wastewater samples. The analytical variables like pH, flow rate for sorption/desorption, and eluate selection were systematically investigated and optimized. The uniform and monolayer sorption behavior of resin for nickel was proved by an evident fit of the equilibrium data to a Langmuir isotherm model. Under optimized conditions, the resin was observed to show a good sorption capacity of 20.25 mg g−1 and >96 % recovery of nickel even in the presence of a large number of competitive matrix ions. Its ability to extract trace amount of nickel was exhibited by low preconcentration limit (5.9 μg L−1). The calibration curve was found to be linear (R 2 = 0.998) in the concentration range of 6.0–400.0 μg L−1. Coefficient of variation of less than 5 for all the analysis indicated good reproducibility. The reliability was evaluated by the analysis of standard reference material (SRM) and recovery experiments. The applicability of the resin for the systematic preconcentration of nickel is substantiated by the analysis of electroplating wastewater and river water samples.

ᅟ

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Present-day urbanization and uncontrolled industrial expansion are the major contributors to the globally concerned ecosystem damage, especially the aquatic environment through the generation of metal toxic waste. The resulting contaminated water is an affront to human dignity as it jeopardizes both the environment and human health. Water scarcity is one of the most critically acclaimed environmental and public health problems of the present world. Mandatory stringent control is therefore required (Atkinson et al. 1998; McKay 1995). The electroplating industry is one of the major industries which pose a significant threat to the present ecosystem as it discharges toxic heavy metals into the environment. The electroplating process has a number of applications, but simultaneously, it is also among “red” category industries, identified by the Ministry of Environment & Forests, Government of India, as heavily polluting and covered under Central Action Plan. Nickel is one of the persistent, bioaccumulative, and toxic metals present in electroplating wastewater (EPW) laden with potentially dangerous heavy metals. Exposure to highly nickel-polluted environments from air, food, and water (Cempel and Nikel 2006) can substantially cause a variety of pathological effects in humans varying from contact dermatitis to lung fibrosis, cardiovascular and kidney diseases, and even cancer (Arain et al. 2014; Denkhaus and Salnikow 2002; Kasprzak et al. 2003). Though the removal of metal toxic waste from EPW is obligatory before discharging into aquatic environment, even down the drain, the rest in the effluent will still cause serious environmental impact.

The determination of heavy metals at trace level in various samples has received special attention of researchers as a way to assess the early impact on humans and the environment (Islam et al. 2010, 2012a, 2014). This determination by sophisticated analytical techniques like inductively coupled plasma (ICP)-MS, ICP-AES, ETAAS, and GFAAS is limited due to matrix interference. Hence, it is an essential requisite to apply preconcentration step as an adjunct to such sophisticated analytical techniques. Flame atomic absorption spectrometer (FAAS) has been widely used for its advantages of less spectral interference by concomitants and relatively less running costs instead of expensive flameless techniques which are usually much more sensitive to interference.

Solid-phase extraction (SPE) has been demonstrated in various procedures to be a very effective preconcentration technique in combination with atomic absorption spectrometry (Islam et al. 2011a, 2013a; Yavuz et al. 2013). Several commercially available chelating materials like Amberlite series resins (Islam et al. 2011b), chelex-100 (Freire and Santelli 2012), silica-based resins (Zhang et al. 2009a, b), chitosan (Mladenova et al. 2011), etc. are being used in SPE as metal ion extractants. Still, the ongoing quest of scientists for materials that would combine all the properties of rigidity, hydrophilicity, and a wealth of chemistry is the driving force behind the development of polymers based on glycidyl methacrylate (GMA). Along with the controlled porous properties, hydrophilicity, and high mechanical and chemical stability, GMA-based polymers are amenable to a large number of chemical modifications owing to the presence of pendent-strained epoxide group. This high reactivity of the epoxide group has been exploited in various applications like ionic exchangers in metal recovery (Anirudhan and Jalajamony 2010), polymer monoliths (Wang et al. 2014), enzyme immobilization agents (Karagoz et al. 2010), polymer resins in metal ion separation (Yu et al. 2010; Arslan 2010; Baba et al. 2006; Donia et al. 2006), and many more. Owing to its excellent metal ion chelation, diethylenetriamine (DETA) has been used in SPE (Zhang et al. 2009a, b; Bakircioglu et al. 2001, 2003; Li et al. 2011; Ashgar 2008; Liu et al. 2006; Khanchi et al. 2013). Here, we propose the use of synthesized GMA-divinylbenzene (GMA-DVB) polymer functionalized by DETA as a column packing material for detailed nickel ion preconcentration/separation studies in real environmental water samples and its subsequent determination by FAAS.

Experimental details

Chemicals and instrumentation

Glycidyl methacrylate was procured from Fluka (Buchs, St. Gallen, Switzerland). Divinylbenzene was obtained from Sigma-Aldrich (St. Louis, MO, USA). 2, 2′-Azobisisobutyronitrile (AIBN) and polyvinyl alcohol (PVA) were purchased from Otto Chemie (Mumbai, Maharashtra, India). DETA was obtained from Merck (Mumbai, Maharashtra, India). All these reagents were used as purchased. Standard solutions of metal ions (1000 mg L−1) were obtained from Merck (Darmstadt, Hesse, Germany). The pH adjustments for the presented procedure were made by using HCl/glycine (pH 1.2–3.6), CH3COOH/CH3COONa (pH 4.0–6.0), Na2HPO4/C6H8O7 (pH 7.0−7.8), and NH4Cl/NH3 (pH 8–10) buffer solutions. For elution studies, hydrochloric acid and nitric acid were prepared by dilution from concentrated acid solutions obtained from Fisher Scientific (Waltham, MA, USA). All other reagents used were of the highest available purity or at least analytical reagent grade and procured from Merck (Darmstadt, Hesse, Germany). Triply distilled water (TDW) was used for the preparation of all the solutions. All glasswares and columns were treated with 1 % HNO3 for 24 h and then rinsed well with distilled water before use.

An automatic flame control GBC 932+ FAAS (Dandenong, Victoria, Australia) with deuterium background correction was used for the determination of nickel at wavelength of 232.0 nm and slit width of 0.2 nm, on an air/acetylene flame (flow rate 10:2 L min−1). For measuring pH values, an Orion 2 star model pH meter from Thermo Scientific (Waltham, MA, USA) was used. A column (1 × 10 cm), for dynamic studies, was obtained from J-SIL Scientific Industries (Agra, UP, India). Elemental (CHNO) analysis was done on Flash EA 1112 Organic Elemental Analyzer, Thermo Fischer Scientific (Waltham, MA, USA). The FT-IR spectral studies were performed on a PerkinElmer Spectrum Two spectrometer (Waltham, MA, USA), using a KBr disk method in the range between 500 and 4000 cm−1 with resolution of 2.0 cm−1, while the FIR measurements were obtained on a PerkinElmer spectrometer, Frontier (Waltham, MA, USA), in polyethylene pellet under nitrogen atmosphere at room temperature (27 °C). Surface area analysis and pore size measurements were done on an Autosorb iQ Station 1 gas sorption analyzer, Quantachrome Instruments (Boynton Beach, FL, USA). Thermal gravimetric analysis/differential thermal analysis (TGA/DTA) was run on the Shimadzu TGA/DTA simultaneous measuring instrument, DTG-60/60H (Kyoto, Honshu, Japan). SEM images for microstructural observations and energy-dispersive X-ray analysis (EDS) spectra for microcompositional analysis of the resin were examined with a Jeol JSM-6510LV (Tokyo, Japan) after coated being with gold overlayer to avoid charging during electron irradiation.

Synthesis of copolymer followed by DETA functionalization

The DETA-functionalized GMA-DVB polymer was synthesized by one-pot free radical suspension polymerization: a modification of the procedure reported by Yan and Sun (2010). Briefly, a 24 mL of monomer phase containing GMA/DVB (5:1) and reaction initiator AIBN (<1 wt% with respect to the monomers) was suspended as droplets in the continuous aqueous phase consisting of 112.5 mL of water, 5.6 g of NaCl, and 0.11 g of PVA as suspension stabilizer. To produce polymer beads, 35 mL of solvating diluents, toluene and heptane 4:1, is added to the components of the suspended monomer phase. The reaction temperature was maintained at 65 °C for 5 h and then at 75 °C for 1 h so that the system is below the boiling point of components while still enabling decomposition of AIBN at an enough rate. The reaction system was continuously stirred to balance the simultaneous coalescence and division of droplets. The polymer beads obtained were filtered and sequentially washed with TDW and ethanol to remove unreacted and inert components. The obtained beads were oven-dried at 50 ° C for 24 h. The dried beads were immersed in minimum amount of reaction solvent for an hour to swell completely before putting to amination by refluxing polymer beads with DETA (4 mL) in dioxane/toluene 4:1 solvents for 10 h. The resin beads were thoroughly washed with water followed by ethanol, then kept in ethanol for 24 h and oven-dried at 50 °C for next 24 h before its further use. The synthesized chelating resin is abbreviated as GDN. The scheme is depicted in Fig. 1.

Procedure for sorption and desorption of analyte

Batch equilibrium procedure was chosen to inspect the effect of pH and effect of analyte ion concentration for sorption isotherms. GDN (100 mg) was stirred with 50 mL of buffered metal ion solution at 27 ± 0.2 °C for 45 min. The resin was filtered, and the sorbed metal ion was stripped off by shaking the metal-loaded resin with 5 mL of eluent acid. The analyte concentration in the filtrate as well as in the eluate was subsequently measured by FAAS. For the rest of the experiments dealing with trace concentration of analyte, fixed bed column dynamic method was preferred. The column was slurry-packed with water-soaked GDN (200 mg) with a bed height of 1.0 cm. Prior to extraction, the column was conditioned to the desired pH with 5.0 mL of corresponding buffer solution. Depending on the experiment concerned, suitable aliquot of buffered metal ion solutions was passed through the column at the optimized conditions. The sorbed metal ion was stripped off from the column with 5 mL of eluent acid. The concentration of the metal ion in the eluate was determined by FAAS.

Sample collection

In order to evaluate different degrees of potential nickel pollution, EPW samples were collected at four different spots (A, B, C, and D) dependent on varying distance from the main industrial area (Aligarh, UP, India). The difference in distance is an inverse measure of the vulnerability of the nearby residents to the potential nickel hazards: spot A, located at the mouth of the EPW source; spot B, in the vicinity of the main source; spot C, approximately 7 km away from spot B; and spot D was the enclosed water pond, in the residential area 3 km away from spot C. However, river water sample was also investigated apart from the EPW samples. The river water collected from the Ganga (Narora, UP, India) is exposed mainly to the local residents. The water samples, immediately after collection, were filtered through a Millipore cellulose membrane filter (0.45-μm pore size), acidified to pH 2 with nitric acid and stored in precleaned polyethylene bottles.

Result and discussion

Physiochemical characterization

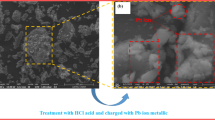

The synthesized resin and subsequent metal ion complexation was characterized and confirmed by delineate examination of a series of techniques and their interpretations. From the FT-IR spectrum of GDN (Online Resource 1 and 2 (poly(GMA-co-DVB)), the opening of the epoxy ring by amine is established by the absence of two characteristic peaks of epoxide, at 915 cm−1 due to –C–O deformation of epoxide and at 3050 cm−1 attributed to –C–H tension of –CH2 of epoxide, and by the presence of the peaks at 1550 and 656 cm−1 due to N–H bending and wagging, respectively. The bands at 3355 and 3487 cm−1 correspond to structural –O–H and –N–H stretching vibrations, respectively, and the peak at 1161 cm−1 is due to –C–N– stretching vibration. The peak at 1264 cm−1 is associated with –C–O– stretching vibrations, while the bands at 1650 and 1467 cm−1 may be assigned to the stretching of –C=O– double bond and –C=C– double bond, respectively. The peak observed at 2946 cm−1 may be assigned to sp2–C–H stretching vibration. In order to calculate the hydrogen ion capacity (Islam et al. 2013b), 0.5 g of dry resin in protonated form was equilibrated by shaking 50.0 mL of 0.1 mol L−1 NaOH solution for 6 h at room temperature, and then, the remaining alkali was titrated volumetrically with 0.1 mol L−1 hydrochloric acid solution. The overall H+ ion capacity was calculated to be 5.0 mM g−1 resin, which may be attributed to the hydrogen ions of the hydroxyl and the amine functionalities constituting the molecule. The amino group was estimated by shaking 0.5 g of resin with 50 mL of 0.05 M HCl for 24 h (Donia et al. 2006). The residual millimole of HCl was measured titrimetrically against 0.05 M NaOH. The number of moles of HCl that interacted with the amino groups and consequently the amine content were calculated to be 3.08 mM g−1 resin. This accounts for the good sorption capacity for Ni by the resin. Elemental analysis of GDN resulted in C, H, N, and O as 60.4, 7.7, 6.2, and 24.7 %, respectively. Considering the opening of one epoxy ring by one DETA molecule, the reaction efficiency was supported to be 100 % by amine content and overall H+ ion content data. However, under this structural consideration, from the elemental analysis, it was interpreted that the synthetic efficiency is lesser than 100 % as the theoretical nitrogen wt% (11.1) is more than the experimental nitrogen wt% (7.7). The multipoint BET analysis resulted in a good surface area of 188.965 m2 g−1. The mesoporous nature of the synthesized chelating resin was characterized by the BJH desorption data, resulting in pore radius of 16.29 nm. The SEM micrograph (Fig. 2) shows a spongy image of GDN bead at high resolution imparting larger surface area attributed to enhanced porosity. The grafting efficiency of copoly (GMA-DVB grafted-PEHA) chelating polymer synthesized earlier is merely 19.0 %, even after the fact that it is supposed to contain more number of nitrogen atoms than the present synthesis (Wang and Wang 2006). Even the surface area of almost similar matrices reported earlier was found to be only 0.02–2.94 m2 g−1 (Wang and Wang 2006), 48 m2 g−1 (Baba et al. 2006), and 129.4 m2 g−1 (Liu et al. 2010), all being comparatively much lesser than the present value. Thus, the presented procedure has synthetic advantages over previously reported synthetic route for similar matrices. On the basis of TGA/DTA curve (Online Resource 3), the thermal stability of GDN was established up to 240 °C. From the TGA curve, a weight loss of 0.48 mg after 55 °C was observed, which may be attributed to the dehydration of sorbed water molecules from GDN. The degradation of resin commences above 240 °C, which may be due to the decomposition of amine and hydroxyl moieties. The complexation of GDN with Ni was supported by far IR exhibiting a metal nitrogen stretching vibration at 469 cm−1 (Online Resource 4). The chelation of analyte with the resin is further validated by the absence and presence of Ni in the elemental mapping obtained from EDS spectra of Ni uncomplexed and Ni-complexed GDN, respectively (Fig. 3).

Method optimization

The ultimate aim of the present article is to propose an optimized solid-phase extraction methodology for the preconcentration/determination of Ni in environmental water samples. Various analytical parameters were studied for their optimization in order to improve the performance of the method.

Among all the experimental variables, pH is a critical parameter for effective sorption of analyte. From Fig. 4a, it was observed that the maximum uptake of Ni was obtained in the acidic pH range and highest at pH 2. On the contrary, the non-aminated GMA-DVB beads did not sorb any Ni ions in the studied pH range of 1.2–9.0. In order to establish the preference of GDN for Ni at pH 2, some other first-row transition metal ions along with lead were also studied. Ni was found to have the highest uptake compared to other metal ions, and hence, suppression of the interference due to the presence of these metal ions in the determination of Ni in real samples is expected at pH 2 (Fig. 4b). In conclusion, pH 2 was selected for all further experiments. In the column SPE system, the quintessential time of analysis is dependent on the flow rate of sample as well as eluent which affects the quantitative sorption and recovery of the analyte, respectively. The influence of Ni sorption by GDN was investigated by varying the flow rate of the sample and eluent in the range of 1.0–5.0 and 1.0–3.0 mL min−1, under the optimum conditions, respectively. The sorption of the analyte was independent up to the flow rate of 4.0 mL min−1 as the metal ions were sufficiently retained by the sorbent. This faster sample flow rate compared to 2.5 mL min−1 for DETA polymer reported earlier (Bakircioglu et al. 2003) is attributed to the hydrophilicity brought in by GMA moiety. The elution flow rate was unaffected up to 2 mL min−1. Thus, the optimum flow rates of 4 mL min−1 for sample and 2 mL min−1 for eluent were selected. A resin amount of 200 mg was found sufficient for the optimized column studies above which the Ni uptake per gram of resin became constant. The complete stripping off analyte ion from the chelating resin is a vital parameter for the optimization of the preconcentration system. HCl and HNO3 acids in various concentrations (1.0–3.0 M) and volumes (2–8 mL) were examined as the eluent for the present method. The recovery of 100.2 % was observed when 5 mL of 2 M HCl was used. All other volume concentration combinations studied offered lesser recovery of Ni. Henceforth, for all further studies, 5 mL of 2 M HCl was optimized.

Effect of initial Ni concentration and sorption isotherms

In batch sorption, the initial concentration of sorbate is the driving force to overcome the mass transfer resistance between the aqueous and solid phases. In this study, the sorption of analyte was investigated by increasing Ni concentration from 150 to 350 mg L−1. The obtained equilibrium data were treated with Langmuir and Freundlich isotherm models. These models relate the amount of solute sorbed at equilibrium per unit weight of sorbent, qe (mg g−1), to the sorbate concentration at equilibrium, Ce (mg L−1). The following linearized equations were applied in order to obtain the isotherm constants for each type of model:

The data gave correlation coefficient values >0.9 but resulted in a better fit to the Langmuir model, as was evidenced from the higher value of R 2 for Langmuir model (0.999) than for Freundlich model (0.9799). The experimentally obtained sorption capacity for Ni (20.25 mg g−1) was also found in close agreement with the capacity determined by the Langmuir model (22.68 mg g−1) rather than the one by the Freundlich model (8.93 mg g−1). It further confirms the Langmuir fit to the present data. Hence, the applicability of the Langmuir isotherm model was confirmed, which assumes the uniform and monolayer sorption of sorbate ions onto the sorbent surface. The essential characteristic of the Langmuir isotherm was further described using a separation factor R L, which is defined as

where C 0 is the initial concentration (mg L−1). The fact that for all the initial concentration values, 0 < R L > 1 (Table 1) indicates the favorable sorption of Ni by GDN. The synthesized resin has comparative advantage of higher Ni sorption capacity over other methacrylic DVB-based chelating resins reported previously for Ni sorption (Turan et al. 2012).

Effect of interferences

To establish the analytical utility of the synthesized chelating resin in the preconcentration/determination of Ni from real environmental samples, the effect of various concomitant ions was studied. To verify this, the possible interference of cations and anions on the recovery of Ni ion was investigated, under the optimized conditions. At the tested level, no significant interference was noted in the determination of Ni after preconcentration (Table 2). Though the presence of alkali, alkaline earth metals, and certain anions exhibits interferences in the FAAS determination of metals, in the proposed method, they have been found to be non-interfering up to 4–40 × 104 μg. The first-row transition metal cations are more susceptible to offer a competition to Ni sorption because of their similar properties and extended possibility of concomitance in EPW samples. To detail the possible interference, these cations were studied at a high ratio of 10:1 (foreign ion/analyte). Table 2 delineates that none of them can be considered as an interferent to the present system, not even Cu which has been reported to well chelate with DETA (Liu et al. 2006).

Preconcentration studies

As defined by IUPAC, preconcentration is an operation as a result of which the ratio of the concentration or the amount of trace components and macrocomponents (matrix) increases (Jackwerth et al. 1979); this not only improves the analytical detection limit but also reduces matrix effects and thereby enhances the accuracy of the results and facilitates calibration (Mizuike 1983; Pyrzynska and Trojanowicz 1999). Further, it improves the representative nature of the results by allowing the trace component in sample of larger volume into a smaller volume. The preconcentration limit of the synthesized resin was investigated by preparing the test solutions such that the total amount of loaded nickel is constant at 5 μg. Table 3 reflects the preconcentration ability of GDN to extract nickel quantitatively up to a limit of 5.9 μg L−1. In order to establish preconcentration in lesser experimental time, further research has been made to explore the effect on preconcentration limit by decreasing both volumes as well as amount of analyte (Table 4). The same preconcentration limit of 5.9 μg L−1 could be achieved even by passing 200 mL of test solution indicating that a reasonable amount of time could be saved.

Analytical figures of merit

At optimal instrumental parameters and method conditions, the calibration curve for Ni was plotted by least squares method after preconcentrating a series of standards in the range of 6.0–400.0 μg L−1. The linear plot was observed with the correlation coefficient and regression equation of R 2 = 0.998 and A = 0.0013C + 0.0111, respectively. The values of 2.29 μg L−1 for limit of detection (LOD) and 7.63 μg L−1 for limit of quantification (LOQ) are calculated as three times (3s) and ten times (10s) the standard deviation of the blank signal (mean absorbance = 0.0013) for 20 replicate measurements, respectively. The precision of the method was determined as the coefficient of variation was found to be 2.92 % for five replicate determinations of Ni at 50 μg L−1. JSS 513-4 Cr steel standard reference material (19.23 mg) (SRM) (Iron and Steel Institute of Japan, Tokyo, Japan) was accurately weighed and analyzed to inspect the bias of the outlined method. It was digested as per the procedure reported in previous literature (Islam et al. 2012b). Considering the presence of many diverse concomitant ions in the analyzed SRM (composition C 0.16, Si 0.25, Mn 0.79, P 0.012, S 0.01, Ni 0.13, Cr 1.15, Mo 0.01, Cu 0.074, V 0.005, Al 0.025, and N 0.0121 %), it is critical to highlight that none of the potential interferents will deviate the quantitative recovery of Ni. The standard deviation of 1.81 was observed in the mean concentration value of Ni obtained by the proposed method. For the observed results t cal (3.31) < t tab (4.303) calculated by using Students’ t test at 95 % confidence limit (n = 3). The statistical insignificance for the observed value of 0.1296 % (1296 μg g−1) from the certified value of 0.1300 % (1300 μg g−1) clearly indicates the complete absence of systematic errors. To rule out the presence of constant errors in the outlined preconcentration procedure, the recovery test for environmental water samples was carried out. Two different amounts of nickel were spiked to 250 mL of each tested water sample (Table 5). A good agreement was obtained between the spiked and measured nickel amounts. The recovery of greater than 97 % proves the reliable applicability of the presented method for preconcentration of nickel.

Application to real environmental water samples

To demonstrate the utility of the proposed method, it was applied for the preconcentration/determination of nickel with confidence limits in river water and EPW samples collected from different spots. The nickel concentration in the EPW samples was found to decrease (138.36–10.95 μg L−1) on moving away from the main industrial source and least in the river water (7.25 μg L−1) with relative standard deviation (RSD) not more than 3.06 %. This trend suggests that even down the drain, the potential nickel pollution is present, and it may risk the interacting biota. Determination of Ni by FAAS in electroplating industrial effluents usually containing many possible interfering metallic constituents would not have been possible without such preconcentration step.

Conclusion

The present research systematically investigates the preconcentrating ability of synthesized GDN mesoporous resin beads for Ni in environmental water samples. The DETA-functionalized GMA-DVB resin resulted in good accessibility for analyte ion leading to good sorption capacity for Ni. Also, low preconcentration limit combined with low detection limit allows an excellent trace extraction and determination of Ni. Furthermore, the operational advantages of fast synthesis, simplicity, low cost, optimization at pH 2 which is also the storage pH for various environmental samples, and no organic solvent usage make it environmentally innocuous and simultaneously suitable for routine trace Ni analysis. At the optimized conditions, the proposed sorbent did not exhibit any affinity for the major concomitant first-row transition metal cations, alkali or alkaline-earth metals, and their associated counter ions, efficiently reducing the matrix effect of diverse environmental samples. The accuracy and precision of the presented method were established, by the analysis of SRM, recovery experiments, and a good RSD value (<5 %, N = 5). As yet, several aspects of the method, which were revealed with regard to its potential analytical utility, render the great analytical potential of the proposed method in efficient preconcentration of nickel and its subsequent determination with FAAS.

References

Anirudhan TS, Jalajamony S (2010) Cellulose-based anion exchanger with tertiary amine functionality for the extraction of arsenic(V) from aqueous media. J Environ Manage 91:2201–2207

Arain SS, Kazi TG, Arain JB et al (2014) Determination of nickel in blood and serum samples of oropharyngeal cancer patients consumed smokeless tobacco products by cloud point extraction coupled with flame atomic absorption spectrometry. Environ Sci Pollut Res Int. doi:10.1007/s11356-014-3091-5

Arslan M (2010) Preparation and use of amine-functionalized glycidyl methacrylate-g-poly(ethylene terephthalate) fibers for removal of chromium(VI) from aqueous solution. Fibers Polym 11:325–330

Ashgar NM (2008) Column extraction and separation of some metal ions by diethylenetriamine polysiloxane immobilized ligand system. E-J Chem 5:107–113

Atkinson BW, Bux F, Kasan HC (1998) Considerations for application of biosorption technology to remediate metal-contaminated industrial effluents. Water SA 24:129–135

Baba Y, Ohe K, Kawasaki Y et al (2006) Adsorption of mercury(II) from hydrochloric acid solutions on glycidylmethacrylate–divinylbenzene microspheres containing amino groups. React Funct Polym 66:1158–1164

Bakircioglu Y, Seren G, Akman S (2001) Determination of cadmium, copper, and zinc by flame atomic absorption spectrometry after preconcentration using a deta (diethylenetriamine) polymer. Anal Lett 34:439–447

Bakircioglu Y, Akman S, Bicak N et al (2003) Determination of some trace heavy metals in some water samples by FAAS after their preconcentration using deta. J Trace Microprobe Tech 21:239–248

Cempel M, Nikel G (2006) Ni: a review of its sources and environmental toxicology. Pol J Environ Stud 15:375–382

Denkhaus E, Salnikow K (2002) Nickel essentiality, toxicity, and carcinogenicity. Crit Rev Oncol Hematol 42:35–56

Donia AM, Atia AA, El-Boraey H et al (2006) Uptake studies of copper(II) on glycidyl methacrylate chelating resin containing Fe2O3 particles. Sep Purif Technol 49:64–70

Freire AS, Santelli RE (2012) Trace elements determination in high salinity petroleum produced formation water by high-resolution continuum source graphite furnace atomic absorption spectrometry after matrix separation using Chelex-100® resin. Spectrochim Acta B 71–72:92–97

Islam A, Laskar MA, Ahmad A (2010) Characterization of a novel chelating resin of enhanced hydrophilicity and its 568 analytical utility for preconcentration of trace metal ions. Talanta 81:1772–1780

Islam A, Laskar MA, Ahmad A (2011a) The efficiency of Amberlite XAD-4 resin loaded with 1-(2-pyridylazo)-2-naphthol in preconcentration and separation of some toxic metal ions by flame atomic absorption spectrometry. Environ Monit Assess 175:201–212

Islam A, Ahmad A, Laskar MA (2011b) A newly developed salicylanilide functionalized Amberlite XAD-16 chelating resin for use in preconcentration and determination of trace metal ions from environmental and biological samples. Anal Methods 3:2041–2048

Islam A, Ahmad A, Laskar MA (2012a) Characterization of a chelating resin functionalized via azo spacer and its analytical applicability for the determination of trace metal ions in real matrices. J Appl Polym Sci 123:3448–3458

Islam A, Ahmad A, Laskar MA (2012b) Preparation, characterization of a novel chelating resin functionalized with o-hydroxybenzamide and its application for preconcentration of trace metal ions. Clean Soil Air Water 40:54–65

Islam A, Ahmad H, Zaidi N et al (2013a) Selective separation of aluminum from biological and environmental samples using glyoxal-bis(2-hydroxyanil) functionalized Amberlite XAD-16 resin: kinetics and equilibrium studies. Ind Eng Chem Res 52:5213–5220

Islam A, Laskar MA, Ahmad A (2013b) Preconcentration of metal ions through chelation on a synthesized resin containing O, O donor atoms for quantitative analysis of environmental and biological samples. Environ Monit Assess 185:2691–2704

Islam A, Zaidi N, Ahmad H et al (2014) Synthesis, characterization, and systematic studies of a novel aluminum selective chelating resin. Environ Monit Assess. doi:10.1007/s10661-014-3823-5

Jackwerth E, Mizuike A, Zolotov YA et al (1979) Separation and preconcentration of trace substances. I. Preconcentration for inorganic trace analysis. Pure Appl Chem 51:1195–1211

Karagoz B, Bayramoglu G, Altintas B et al (2010) Poly(glycidyl methacrylate)-polystyrene diblocks copolymer grafted nanocomposite microspheres from surface-initiated atom transfer radical polymerization for lipase immobilization: application in flavor ester synthesis. Ind Eng Chem Res 49:9655–9665

Kasprzak KS, Sunderman FW Jr, Salnikow K (2003) Nickel carcinogenesis. Mutat Res Fundam Mol Mech Mutagen 533:67–97

Khanchi AR, Kalal HS, Mashhadizadeh MH et al (2013) Synthesis and characterization of Amberlite XAD-4 functionalized with diethylenetriamine: its uses for preconcentration and determination of rhodium (III) in aqueous solutions. Stud Chem Process Technol 1:44–54

Li H, Bi S, Liu L et al (2011) Separation and accumulation of Cu(II), Zn(II) and Cr(VI) from aqueous solution by magnetic chitosan modified with diethylenetriamine. Desalination 278:397–404

Liu C, Bai R, Hong L (2006) Diethylenetriamine-grafted poly (glycidyl methacrylate) adsorbent for effective copper ion adsorption. J Colloid Interface Sci 303:99–108

Liu C, Bai R, Hong L et al (2010) Functionalization of adsorbent with different aliphatic polyamines for heavy metal ion removal: characteristics and performance. J Colloid Interface Sci 345:454–460

McKay G (1995) Use of adsorbents for the removal of pollutants from wastewater. CRC Press, Boca Raton

Mizuike A (1983) Enrichment techniques for inorganic trace analysis. Springer, Berlin

Mladenova EK, Dakova IG, Karadjova IB et al (2011) Chitosan membranes as sorbents for trace elements determination in surface waters. Environ Sci Pollut Res 18:1633–1643

Pyrzynska K, Trojanowicz M (1999) Functionalized cellulose sorbents for preconcentration of trace metals in environmental analysis. Crit Rev Anal Chem 29:313–321

Turan S, Tokalioglu S, Sahan A, Soykan C (2012) Synthesis, characterization and application of a chelating resin for solid phase extraction of some trace metal ions from water, sediment and tea samples. React Funct Polym 72:722–728

Wang CC, Wang CC (2006) Adsorption characteristics of metal complexes by chelated copolymers with amino group. React Funct Polym 66:343–356

Wang H, Zhang H, Lv Y et al (2014) Polymer monoliths with chelating functionalities for solid phase extraction of metal ions from water. J Chromatogr A 1343:128–134

Yan X, Sun W (2010) Synthesis and metal ion adsorption studies of chelating resins derived from macroporous glycidyl methacrylate-divinylbenzene copolymer beads anchored schiff bases. J Appl Polym Sci 117:953–959

Yavuz E, Tokalioglu S, Sahan H et al (2013) Ultralayered Co3O4 as a new adsorbent for preconcentration of Pb(II) from water, food, sediment and tobacco samples. Talanta 115:724–729

Yu Z, Wu R, Wu M et al (2010) Preparation of polyamine-functionalized copper specific adsorbents for selective adsorption of copper. Colloids Surf B 78:222–228

Zhang Y, Qu R, Sun C et al (2009a) Comparison of synthesis of chelating resin silica-gel-supported diethylenetriamine and its removal properties for transition metal ions. J Hazard Mater 163:127–135

Zhang Y, Qu R, Sun C et al (2009b) Chemical modification of silica-gel with diethylenetriamine via an end-group protection approach for adsorption to Hg(II). Appl Surf Sci 255:5818–5826

Acknowledgments

The authors are grateful to the University Grant Commission (UGC) India, for providing research fellowship to Noushi Zaidi (UGC-SRF) and Hilal Ahmad (UGC-BSR). The authors acknowledge the support provided by UGC-SAP program and DST (FIST and PURSE), New Delhi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 422 kb)

Rights and permissions

About this article

Cite this article

Islam, A., Zaidi, N., Ahmad, H. et al. Amine-functionalized mesoporous polymer as potential sorbent for nickel preconcentration from electroplating wastewater. Environ Sci Pollut Res 22, 7716–7725 (2015). https://doi.org/10.1007/s11356-014-4011-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-4011-4