Abstract

Nitrous oxide (N2O), a strong greenhouse gas, can be produced by ammonium-oxidizing bacteria (AOB) as a by-product of ammonium oxidation and can potentially be formed in all types of nitrification processes. However, partial nitritation has been reported to cause significantly higher N2O emissions than complete nitrification. In the study presented here, the mechanisms and factors that drive N2O formation by AOB were investigated with respect to different operational strategies to achieve nitrite accumulation base on combined evaluation of oxygen uptake rate (OUR) and N2O formation rate. On the one hand, N2O formation during partial nitritation and nitrification in a continuously stirred tank reactor (CSTR) with continuous aerobic conditions was observed. On the other hand, the effect of intermittent aeration on N2O formation during nitrification was investigated. The presence of nitrite, the extend of sludge-specific ammonium loading, low oxygen concentration, and transition from aerobic to anoxic conditions significantly increased N2O formation in this reactor independently from each other, indicating that different formation pathways, supposedly via nitrite or hydroxylamine, were active.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrification (oxidation of ammonium to nitrate) and nitritation (oxidation of ammonium to nitrite) are basic biological processes for nitrogen removal from wastewater. While nitrification–mostly combined with denitrification–has become the worldwide state of the art in treatment of municipal wastewater, nitritation–coupled to denitritation or anaerobic ammonium oxidation (anammox)–is mainly applied for treatment of high-loaded, ammonium-rich part streams. Ammonium oxidation via hydroxylamine to nitrite by ammonium-oxidizing bacteria (AOB) is mandatory for all types of nitrification and nitritation processes. To achieve nitritation, the activity of nitrite-oxidizing bacteria (NOB) has to be suppressed. Apart from nitrite, AOB can produce nitric oxide (NO), an ozone-depleting substance and forming acid rain, and nitrous oxide (N2O), a strong greenhouse gas as a by-product of ammonium oxidation (Kampschreur et al. 2009a). Although N2O formation has been a major focus of recent research and it is considered an important part of increasing our understanding of ammonium oxidation processes as a requirement for optimized process design, the detailed mechanisms and influencing factors remain uncertain.

Based on lab- and full-scale observations as well as microbiological investigations, two different pathways of biological N2O formation by AOB have been proposed. One is termed “nitrifier denitrification” and relates to the enzymatic reduction of nitrite to N2O via NO (Remde and Conrad 1990), assumedly making use of electrons from ammonium oxidation. The second route that appears to be directly connected the oxidation of ammonium to hydroxylamine still needs further unraveling. N2O formation could occur via oxidation of hydroxylamine (catalyzed by hydroxylamine oxidoreductase, HAO) to NO (catalyzed by nitric oxide reductase, NOR) followed by reduction to N2O as a direct side reaction of the main ammonia oxidation pathway. Another hypothesis states that N2O formation might result from a chemical breakdown of hydroxyl radicals (NOH) which are formed from hydroxylamine by HAO (Kim et al. 2010; Yu et al. 2010; Ni et al. 2013; Wunderlin et al. 2013). Due to the complex interactions of these pathways and diverse boundary conditions, it is difficult to distinguish these two pathways and correctly allocate the respective influencing factors and thus literature reports are not completely consistent.

The main influencing factors that have been proposed to influence which route dominates N2O formation and how much N2O is produced are oxygen availability, nitrite accumulation, and ammonium load. Chandran et al. (2011) described that limitation of oxygen supply and nitrite concentrations would support N2O formation via nitrifier denitrification, while a sudden increase of substrate supply (return to aerobic conditions, increased ammonium load) would be followed by N2O production from hydroxylamine. Generally, occurrence of the nitrifier denitrification pathway is related to low dissolved oxygen (DO) concentrations below 1 mg O2/L (Sutka et al. 2006; Kampschreur et al. 2007, 2008; Desloover et al. 2011). However, as the reduction of nitrite via this pathway seems to require electrons gained from ammonia oxidation during aerobic conditions, nitrite reduction under completely anoxic conditions is only possible in presence of hydrogen or other electron donators (Bock et al. 1995). Pijuan et al. (2014) reported that an increase of DO (1.5 to 4.5 mg O2/L) was followed by a decrease of N2O emissions down to an unalterable minimum value in a pilot-plant nitritation reactor operated with granular activated sludge. Pan et al. (2014) reported that total N2O generation increased with increasing DO concentration from 0.56 to 1.85 mg O2/L in an intermittently aerated sequencing batch reactor (SBR). However, these authors also emphasized the observed correlation between ammonium conversion rates and N2O formation, hereby supporting findings by Law et al. (2012) and Schneider et al. (2013). While the presence of nitrite is obviously a prerequisite for nitrifier denitrification only, ammonium oxidation activity is linked to both proposed pathways. Wunderlin et al. (2013) found that both pathways are active at the same time with a ratio depending on the availability of ammonia, hydroxylamine, and nitrite in batch tests making use of isotope ratio analyses. The parallel occurrence of both pathways in continuously operated lab-scale/pilot-scale systems for reject water treatment was also uncovered by Schneider et al. (2013) and Pijuan et al. (2014). In both cases, N2O formation was not affected by changes of the nitrite concentration at high concentrations levels (>220 and 368 mg NO2–N/L, respectively), although at lower concentration levels (>2 mg NO2–N/L), nitrite is an important influencing factor (Colliver and Stephenson 2000).

In order to achieve partial nitritation, different strategies can be applied to suppress or wash-out nitrite-oxidizing bacteria. One possibility is the use of intermittent aeration that can be applied when maintenance of short sludge retention time (SRT) (leading to wash-out of NOB) is not possible or not desired. Several recent studies have investigated the formation of N2O in aerobic and anoxic phases of partial nitritation reactors, but did not specifically focus on the influence of the alternating oxygen concentration on N2O formation by AOB. Rather, N2O formation during anoxic phases was related to incomplete heterotrophic denitrification (Chen et al. 2014; Gabarró et al. 2014) due to availability of biodegradable chemical oxygen demand (COD) in the influent wastewater.

Investigations of the effect of the aeration on N2O formation by AOB is often difficult due to the additional influence of N2O stripping, leading to the transfer of N2O into the gas phase (Kampschreur et al. 2009b). Correct determination of ammonia conversion dynamics in lab-scale reactors is restricted by frequency of sampling and accuracy of measurements. The combined application of online measurements for dissolved N2O and DO following a previously reported procedure (Schneider et al. 2013) allows to determine oxygen uptake rates (OUR) as a measure of ammonium conversion activity as well as N2O formation rates frequently during reactor operation.

The aim of this study was to investigate the influence of varying operational conditions with respect to alternating DO concentration due to intermittent aeration, nitrite concentration, and ammonia load on the ratio between N2O formation and ammonia conversion by AOB. A lab-scale reactor treating reject water was operated with the processes of nitritation and nitrification while almost completely excluding heterotrophic conversion. Subsequent changes of operational conditions supported by determination of N2O formation rates and oxygen uptake rates from online concentration profiles were used to evaluate the respective effects independently from each other and to relate them to different potential mechanisms of N2O formation.

Materials and methods

In this study, a nitritation/nitrification continuously stirred tank reactor (CSTR) with sludge retention was operated and the nitrogen conversion performance and N2O formation was determined. In this study, the influences of nitrite concentration, dissolved oxygen concentration, and transient aerobic-anoxic conditions on the formation of N2O during nitritation and nitrification processes were investigated in the same reactor. For this purpose, N2O formation rates were determined for three different operational phases with varying operational settings and conversion performance:

-

1)

Continuous aerobic conditions

-

a)

Nitrite accumulation (nitritation)

-

b)

Nitrate formation (nitrification)

-

a)

-

2)

Transient aerobic/anoxic conditions (nitrification)

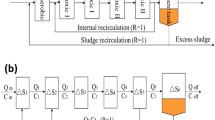

Description of lab-scale CSTR and operational phases

The reactor was a column-shaped CSTR reactor (V = 42 L) as described previously (Schneider et al. 2013). The effluent of the reactor was discharged into a cylindrical clarifier. The settled sludge was returned to the reactor using a peristaltic pump for 15 min every 2 h. The CSTR was operated with temperature of 29 °C, hydraulic retention time (HRT) of 3 days and sludge retention time (SRT) of approximately 6 days. Higher SRT could not be achieved due to poor settleability of the autotrophic sludge. Likewise, the biomass concentration could not be increased to more than 0.1 g VSS/L, due to the low yield of nitrifying bacteria and sludge loss with the effluent, reactor operation was started without seeding.

Initially, the reactor was operated with continuously aerobic conditions. Aeration was based on a two-point control, resulting in continuously aerobic conditions with DO concentration between 2 and 4 mg O2/L. This approach enabled the integration of OUR and N2O formation rate determination methods into continuous reactor operation. After 44 days, the aeration strategy was changed into alternating aerobic and anoxic periods to promote nitrite accumulation. The control strategy described above for aerobic conditions was used for 30 min to establish aerobic phases and combined with a nonaerated period. After the aeration was switched off, the DO was allowed to decrease below 0.5 mg O2/L (aerobic-anoxic transition) and remain at this low level for 30 min, before aeration was switched back to two-point controlled aeration. The different periods and the resulting DO concentration profile are depicted in Fig. 1.

The reactor was continuously fed (inflow 13 L/day) with diluted reject water (50 % dilution with tap water) from the municipal wastewater treatment plant (WWTP) Hannover-Gümmerwald, Germany with average ammonium concentration of 377 mg NH4 +–N/L (350–450) and average COD concentration of 155 mg/L (120–220). The resulting average ammonium load was 4.85 g NH4 +–N/day. The pH was monitored, but not controlled and was only dependent on the alkalinity provided by the wastewater. This approach is typical for reject water treatment (i.e., part-stream treatment with discharge to the mainstream treatment line), where partial nitritation (efficiency of ammonium conversion <60 %) is required for a subsequent anammox stage or when partial nitrification is sufficient to meet effluent criteria in the mainstream.

Analytical methods and calculations

Ammonium (NH4 +–N), nitrite (NO2 −–N), nitrate (NO3 −–N), and COD were determined in filtered samples using photometrical test kits (Hach-Lange, Germany). Alkalinity (KS4.3) was measured according to German Standard Methods (DIN 38409-7). Temperature and pH were continuously monitored using a single rod measuring cell (EGA 142/Pt1000, Sensortechnik Meinsberg GmbH, Germany). The biomass content in terms of volatile suspended solids (g VSS/L) was determined according to European Standard Methods (DIN EN 12879).

Determination of OUR and N2O formation rates was performed as described previously (Schneider et al. 2013) based on online measurements of DO and N2O concentrations. During aerobic periods, the aeration was controlled between 2 and 4 mg O2/L using DASYLab® Software, with aeration being started at the lower set point and stopped at the upper set point. During these phases, the OUR was calculated from the slope of the oxygen concentration curve (linear regression) during the drop of DO concentration from 4 to 2 mg O2/L. As COD removal was very low, it was assumed that all oxygen was used for ammonium oxidation. During anoxic periods, OUR was calculated as the average oxygen uptake from the beginning of the anoxic period (DO = 0.5 mg O2/L) until the restart of aeration. In both cases, calculation followed Eq. 1 (see also Fig. 1):

where ∆c—DO concentration difference (mg O2/L) and ∆t—duration of the respective phase (h)

A clark-type microsensor (N2OR; Unisense A/S, Denmark) was used for online measurement of the dissolved N2O concentration. Analogously to the determination of the OUR, the N2O formation rate (N2O_R) in aerobic periods was determined from the slope of the N2O concentration curve (linear regression) during the drop of DO concentration from 4 to 2 mg O2/L (i.e., when aeration was turned off). The calculation is based on the assumption that N2O transfer to the gas phase is neglectable during these periods (actual measured volumetric mass transfer coefficient very low: k La = 0.065 h−1). During anoxic periods, N2O_R was calculated as the average N2O formation rate from the beginning of the anoxic period (DO = 0.5 mg O2/L) until the restart of aeration.

Average daily ammonium oxidation rates (AOR) calculated from the daily converted ammonium load according to Eq. 2 were used for normalization of N2O formation rates (yielding formation factor N2O_F [%]) and oxygen uptake rates.

where c(NH4 + –N)in–inflow concentration (mg NH4 +–N/L); c(NH4 +–N)out–effluent concentration (mg NH4 +–N/L); and Q–volumetric inflow rate (L/day)

Results

Throughout the study, the efficiency of ammonium oxidation was limited to a maximum of about 44 % by availability of alkalinity in the reject water. Since day 6 of reactor operation (one sludge age), alkalinity in the reactor effluent was used up almost completely (effluent concentration 1 mmol/L) and the maximum ammonium conversion efficiency was achieved. Accordingly, this date was defined as the end of the start-up period. As maximum utilization of alkalinity was constantly achieved throughout reactor operation, the pH was almost stable with an average of 5.84 ± 0.36. Due to the low biodegradable fraction of COD, there was little reduction of about 10 % of the inflow COD.

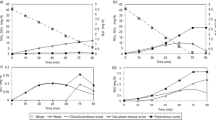

Reactor performance and N2O formation rates during continuously aerobic conditions

During the start-up period (days 0–12), nitrite was the main product of ammonium oxidation (45–157 mg NO2 ––N/L) (Fig. 2). After 6 days (one sludge age), the maximum nitrite concentration was achieved and alkalinity was completely used, indicating that sufficient AOB had been enriched for ammonium conversion. On days 11/12, average NH4 +–N conversion rates of 1.9 mg NH4–N/L/h were observed, with an average OUR of 4.9 mg O2/L/h. The specific oxygen demand for ammonium oxidation to nitrite was 2.5 g O2/g NH4 +–Nox, which only slightly higher than the theoretical stoichiometric value (2.23 g O2/g NH4 +–Nox). The average N2O formation rate on these days (based on 460 calculated rates from repeated measurement during a total of 96 h) was 0.018 mg N2O–N/L/h, which is about 0.94 % of the converted NH4 +–N.

Between days 13 and 38, nitrate formation became dominant and stabilized until day 44. At this time, the aeration strategy was changed to transient aerobic/anoxic conditions in order to promote a backshift to nitrite accumulation. However, with intermittent aerobic and anoxic phases of 30 and 30 min, respectively, nitrate remained the main product for five more weeks of reactor operation (i.e., 7 times SRT).

From days 38 to 44, when nitrate formation had stabilized, slightly higher average NH4–N conversion rates were observed (2.0 mg NH4 +–N/L/h), with an average OUR of 9.7 mg O2/L/h. The specific oxygen demand for ammonium oxidation to nitrate was 4.8 g O2/g NH4–Nox, which is in the range of the theoretical stoichiometric value (4.6 g O2/g NH4 +–Nox). During this phase (days 38/39 and 41/42), the average N2O formation rate (based on 460 calculated rates from repeated measurement during a total of 96 h) was 0.0047 mg N2O–N/L/h, which is about 0.23 % of the converted NH4 +–N.

Despite constant wastewater flow rate and substrate concentrations, the transition phase from nitrite accumulation to nitrate formation was characterized by periodic fluctuations of OUR and the dissolved N2O concentration. As depicted in Fig. 3, both parameters followed the same temporal trend–the concentration of dissolved N2O increased with increasing OUR.

Reactor performance and N2O formation rates during transient aerobic/anoxic conditions

After changing the oxygen supply to a transient aerobic/anoxic pattern, the average ammonium conversion rate was 2.4 mg NH4 +–N/L/h referring to aerobic HRT with an average OUR of 12.3 mg O2/L/h during the aerobic time. The resulting specific oxygen demand for ammonium conversion to nitrate was 5.3 g O2/g NH4–Nox and thus significantly higher than the theoretical value (4.6 g O2/g NH4 +–Nox) (Fig. 4). This difference is analyzed in the “Discussion” section.

During operation with transient aerobic/anoxic conditions, N2O formation was observed during aerobic phases as well as during anoxic phases. The average N2O formation rate was 0.032 mg N2O–N/L/h, which equals 1.33 % of the converted NH4 +–N (based on a total of 288 calculated rates from repeated measurement during a total of 96 h on days 46/47 and days 77/78). There was no statistically significant difference (Welch test, α = 0.05) between N2O formation rates measured shortly after the change of operational conditions and the rates after 1 month of intermittent aeration. Furthermore, there was no statistically significant difference between values measured directly after the restart of aeration and the rates measured about 15 and 30 min after the restart of aeration (Fig. 5). Interestingly, in most cases, the increase of N2O during the anoxic phase was linear, i.e., the formation rate was constant, despite the drop of DO concentration from 4 mg O2/L to less than 0.5 mg O2/L (Fig. 5). But discrete measurements revealed a sharp increase of N2O formation rates when DO concentration dropped below 0.5 mg O2/L (Fig. 5). The maximum N2O formation rate determined from these instances was 0.12 mg N2O–N/L/h.

The rate of ammonium oxidation during anoxic periods was determined based on the calculated OUR. From the oxygen profiles an average OUR of 0.4 mg O2/L/h was calculated. Assuming a specific oxygen demand for ammonium oxidation to nitrate of 4.8 g O2/g NH4 +–Nox (s. above), the average ammonium conversion during anoxic periods was 0.8 mg NH4 +–N/L/h. Based on this value, the average specific N2O formation factor for anoxic periods was 4 % of the converted NH4 +–N in cases of average constant N2O formation rates and 15 % in cases of increased N2O formation rates during low oxygen concentrations.

Discussion

Influence of nitrite accumulation on N2O production

Due to the lower growth rate of nitrite oxidizers, nitrite accumulated during the startup of the CSTR reactor, although the boundary conditions (especially SRT) would theoretically allow for full nitrification. This circumstance allows for a comparison of nitritation and nitrification in the same reactor with equal operational settings. The N2O formation factor during nitrite accumulation was about 4.1 times higher than during nitrate formation. It might be argued that the system was not yet in a steady state during the nitrite accumulation phase, but actually there was no significant deviation of boundary conditions (ammonium load, SRT) or system performance (ammonium oxidation rates) from later reactor operation. Given the fact that maximum ammonium conversion rates to nitrite were already reached after 6 days and due to the relatively short doubling time of AOB of about 1.2 days at the chosen boundary conditions, it is reasonable to use data of this first period. It is only the presence or absence of NOB that makes the difference here and leads to absence or presence of nitrite in the bulk phase, respectively. Therefore, it is supposedly the nitrite concentration that has a strong influence on the N2O formation factor. It is known that an imbalance between the population of AOB and NOB due to delayed growth of NOB and the resulting accumulation of nitrite can lead to an increase of N2O emissions (Fukumoto and Inubushi 2009).

The influence of nitrite on N2O formation by AOB has already been reported in a CSTR without sludge retention (Schneider et al. 2013), yielding a positive correlation of N2O formation and nitrite concentrations below 220 mg NO2 ––N/L. The ratio of N2O formation factors during nitritation and nitrification in that reactor was 4 and thus equaled the results reported here (Table 1). In literature, there is a strong consensus that accumulation of nitrite yields higher N2O emissions than complete nitrification (Ahn et al. 2011; Rodriguez-Caballero et al. 2013). This effect of nitrite is usually explained by the process of nitrifier denitrification, including reduction of nitrite to NO and further reduction to N2O (Chandran et al. 2011; Rodriguez-Caballero and Pijuan 2013). The fact that Pijuan et al. (2014) observed no influence in N2O emissions from changes in the nitrite concentration at high level (>386 mg NO2 ––N/L) supports the idea that these concentrations might be far above the saturation concentration of nitrifier denitrification. It has been previously suggested that–in contrast to earlier findings–nitrifier denitrification might not be limited to oxygen deficient conditions but can occur during fully aerobic conditions as well (Schneider et al. 2013). This hypothesis is supported by the results presented in this paper.

Influence of low oxygen concentration and transient aerobic/anoxic conditions on N2O formation

Low dissolved oxygen concentration and transient aerobic/anoxic conditions have been reported as triggers for increased N2O formation by AOB. On the one hand, nitrifier denitrification is supposed to be enhanced by limitation of oxygen as an electron acceptor, leading to higher N2O formation. On the other hand, transition from anoxic to aerobic conditions with a sudden increase of AOB metabolic activity (and temporal imbalance between produced and consumed electrons) has been described as a mechanism for increased formation of N2O (acting as an electron sink) (Chandran et al. 2011). Due to the repeated aerobic/anoxic transition including a 30-min period with DO <0.5 mg O2/L implemented in this study, both effects could be investigated.

The N2O formation factor during aerobic periods after anoxic periods were higher than during continuous aerobic conditions, which is in agreement with Chandran et al. (2011). The situation after the anoxic or low DO period is often compared to the beginning of an SBR cycle, when higher N2O formation is observed probably due to the sudden increase in bacterial activity when substrate and oxygen is supplied (Lotito et al. 2012; Rathnayake et al. 2013). However, due to the continuous inflow during aerobic and anoxic conditions, ammonium additionally accumulated slightly during the anoxic periods, leading to higher bacterial activity at the beginning of aerobic periods. As there was no online ammonium measurement, this could only be quantified by the few data points of the OUR, but it can be assumed that N2O formation factors for these periods are slightly overestimated. High OUR values at the time of the first measurement after the transition to aerobic conditions (Fig. 4) were observed. In contrast, NH4–N conversion rates were calculated as the average conversion rate over the whole aerobic period, which is an underestimation for the first half of the aerobic period. This is the reason for an apparently higher oxygen demand during this operational period (confirmed by predictions of a fitted mathematical model for two-step nitrification).

However, the elevated N2O formation factor was not limited to a short period of time after aeration resumed, but this effect lasted for at least 30 min, when the ammonium effluent concentration had already decreased to average levels. This might be a hint on a more substantial influence of aerobic/anoxic transition on AOB.

Low DO concentrations (<0.5 mg O2/L) always remained in the reactor, which allowed the determination of ammonium conversion rates from the oxygen uptake during oxygen-limited periods and subsequently the calculation of N2O formation factors. The results reveal a significant increase of the N2O formation factor during these periods. A significant change of N2O formation rates upon a decrease of DO below 0.5 mg O2/L was observed repeatedly, but only for approximately every third of the observed transition phases. In most cases, the formation rate remained constant, which still resulted in a rising formation factor due to the reduced ammonium oxidation activity at oxygen-limiting conditions. No definite reason for the occasional increases of the N2O formation rate could be determined in this study. Eventually, incomplete mixing leading to local differences in DO, ammonia, and N2O concentrations could have played a role. This aspect will have to be further investigated in future studies.

During the period discussed here, nitrite concentration was below detection level, which means that nitrifier denitrification was not induced by high nitrite concentration. Furthermore, it has been assumed that nitrifier denitrification requires electrons from the ammonium oxidation pathway, which would be less available during anoxic conditions. Considering these two issues, it is more probable that N2O production via the so-called hydroxylamine route (either chemically or biochemically) was intensified by low oxygen concentrations yielding a higher fraction of N2O as the end product of ammonium conversion. These observations are different from the findings of Rodriguez-Caballero and Pijuan (2013) who observed significant N2O accumulation during the anoxic settling period of a nitritation SBR only when remaining nitrite was present.

Influence of SRT and sludge-specific load on N2O formation

In contrast to the most recent studies which were performed in SBRs (e.g., Law et al. 2012; Kong et al. 2013; Rodriguez-Caballero et al. 2013), the reactor described in this study was continuously fed with ammonium-containing wastewater. This results in equal distribution of the ammonium load over time and in almost steady ammonium effluent concentration. Such stable conditions are expected to lead to a reduction of N2O formation compared to SBR operation. At the same time, the sludge-specific ammonium load (1.2 g N/g VSS/day) was similar to these reported studies (1.6–10 g N/g VSS/day), but here, the biomass concentration and SRT were significantly lower (0.1 g VSS/L and 6 days) than in typical lab-scale SBRs (0.8 g VSS/L and >20 days). Only a small effect was actually observed in this study: the N2O formation factor for both partial nitritation and nitrification was slightly lower than recently reported for SBRs (>1 % of oxidized NH4–N). However, comparison to a chemostat-type reactor without sludge retention—with the main operational difference being the sludge-specific loading rate (chemostat: 8-fold higher during nitritation, 3-fold higher during nitrification) and the SRT (7.5-fold lower during nitritation, 3-fold lower during nitrification)—demonstrated that the CSTR with sludge retention yielded three times lower N2O formation factors than the chemostat with high sludge loading rate and minimum SRT required for AOB/NOB (Table 1). Apparently, the excess amount of biomass in reactors with sludge retention and low-resulting ammonium loading rate is potentially favorable for minimization of N2O formation. A similar effect has been described by Lotito et al. (2012) for the oxidation tank of a pilot-activated sludge system. In their study, ammonium peak loads applied to the steady-state system lead to immediate increase of the N2O emissions and was related to the sudden overload of the existing biomass. This effect might be connected to the lower specific ammonium conversion rate as discussed below.

Correlation of N2O formation and ammonium conversion

A strong relation between OUR and the dissolved N2O concentration was observed. Due to the low content of degradable COD, the OUR reflects very well the ammonium oxidation rate in this study. The concentration of N2O depends on the relation between N2O formation rates during periods without aeration (no stripping) and the transfer to the atmosphere during periods with aeration. If the aeration pattern remains the same and N2O formation rates are constant, stable minimum and maximum concentrations of N2O are achieved and the average N2O concentration is constant over time. In contrast, fluctuations of the dissolved N2O concentration are a sign of changes in the N2O formation rate: increasing concentrations indicate increasing formation rates and vice versa. Accordingly, the observed relation between fluctuations of OUR and dissolved N2O concentration prove a strong relation between ammonium oxidation rates and N2O formation rates. The N2O formation factor (N2O–N/NH4 +–N) remains almost constant despite changing AOR. This observation is consistent with findings reported by Law et al. (2012) that a linear relation (linear section of an exponential function) between AOR and N2O_R exists in an AOR range of about 0–150 mg NH4–N/(g VSS/h) in a nitritation SBR. Similar results were obtained for a CSTR without sludge retention (Schneider et al. 2013), where AOR and biomass concentration are directly coupled. In the reactor reported here, more biomass was retained in the system than is actually needed to achieve the maximum conversion efficiency. Comparatively, this results in lower cell-specific AOR with reduced N2O formation factor.

Conclusions

The formation of N2O during nitritation/nitrification of reject water in a CSTR with sludge retention and different aeration strategies was studied. The combination of online measurement of oxygen uptake rates and N2O formation rates made detailed analyses of short-term effects, like transition from anoxic to aerobic conditions, possible. The highest N2O formation factor (up to 15 %) was measured during nitrification with oxygen-limited conditions (DO <0.5 mg O2/L). Nitritation with continuously aerobic conditions yielded a four times higher N2O formation factor (0.94 %) than nitrification at the same conditions (0.23 %). The results provide indications that nitrite rather than low oxygen concentration might be the trigger for nitrifier denitrification and that oxygen availability and the specific ammonium load strongly influence N2O formation via the hydroxylamine route.

References

Ahn JH, Kwan T, Chandran K (2011) Comparison of partial and full nitrification processes applied for treating high-strength nitrogen wastewaters: microbial ecology through nitrous oxide production. Environ Sci Technol 45(7):2734–2740

Bock E, Schmidt I, Stüven R, Zart D (1995) Nitrogen loss caused by denitrifying Nitrosomonas cells using ammonium or hydrogen as electron donors and nitrite as electron acceptor. Arch Microbiol 163:16–20

Chandran K, Stein LY, Klotz MG, Van Loosdrecht MCM (2011) Nitrous oxide production by lithotrophic ammonia-oxidizing bacteria and implications for engineered nitrogen-removal systems. Biochem Soc Trans 39(6):1832–1837

Chen Y, Wang D, Zheng X, Li X, Feng L, Chen H (2014) Biological nutrient removal with low nitrous oxide generation by cancelling the anaerobic phase and extending the idle phase in a sequencing batch reactor. Chemosphere 109:56–63

Colliver BB, Stephenson T (2000) Production of nitrogen oxide and dinitrogen oxide by autotrophic nitrifiers. Biotechnol Adv 18(3):219–232

Desloover J, Clippeleir HED, Boeckx P, Laing GD, Colsen J, Verstraete W, Vlaeminck SE (2011) Floc-based sequential partial nitritation and anammox at full scale with contrasting N2O emissions. Water Res 45(9):2811–2821

Fukumoto Y, Inubushi K (2009) Effect of nitrite accumulation on nitrous oxide emission and total nitrogen loss during swine manure composting. Soil Sci Plant Nutr 55(3):428–434

Gabarró J, González-Cárcamo P, Ruscalleda M, Ganigué R, Gich F, Balaguer MD, Colprim J (2014) Anoxic phases are the main N2O contributor in partial nitritation reactors treating high nitrogen loads with alternate aeration. Bioresour Technol 163:92–99

Kampschreur MJ, Picioreanu C, Tan NCG, Kleerebezem R, Jetten MSM, van Loosdrecht MCM (2007) Unraveling the source of nitric oxide emission during nitrification. Water Environ Res 79(13):2499–2509

Kampschreur MJ, Tan NCG, Kleerebezem R, Picioreanu C, Jetten MSM, van Loosdrecht MCM (2008) Effect of Dynamic process conditions on nitrogen oxides emission from a nitrifying culture. Environ Sci Technol 42(2):429–435

Kampschreur MJ, Temmink H, Kleerebezem R, Jetten MSM, van Loosdrecht MCM (2009a) Nitrous oxide emission during wastewater treatment (review). Water Res 43:4093–4103

Kampschreur MJ, Poldermans R, Kleerebezem R, van der Star WRL, Haarhuis R, Abma WR, Jetten MSM, van Loosdrecht MCM (2009b) Emission of nitrous oxide and nitric oxide from a full-scale single-stage nitritation-anammox reactor. Water Sci Technol 60(12):3211–3217

Kim S-W, Miyahara M, Fushinobu S, Wakagi T, Shoun H (2010) Nitrous oxide emission from nitrifying activated sludge dependent on denitrification by ammonia-oxidizing bacteria. Bioresour Technol 101:3958–3963

Kong Q, Liang S, Zhang J, Xie H, Miao M, Tian L (2013) N2O emission in a partial nitrification system: dynamic emission characteristics and the ammonium-oxidizing bacteria community. Bioresour Technol 127:400–406

Law Y, Ni B-J, Lant P, Yuan Z (2012) N2O production rate of an enriched ammonia-oxidizing bacteria culture exponentially correlates to its ammonia oxidation rate. Water Res 46(10):3409–3419

Lotito AM, Wunderlin P, Joss A, Kipf M, Siegrist H (2012) Nitrous oxide emissions from the oxidation tank of a pilot activated sludge plant. Water Res 46:3563–3573

Ni BJ, Yuan Z, Chandran K, Vanrolleghem PA, Murthy S (2013) Evaluating four mathematical models for nitrous oxide production by autotrophic ammonia-oxidizing bacteria. Biotechnol Bioeng 110(1):153–163

Pan M, Wen X, Wu G, Zhang M, Zhan X (2014) Characteristics of nitrous oxide (N2O) emission from intermittently aerated sequencing batch reactors (IASBRs) treating slaughterhouse wastewater at low temperature. Biochem Eng J 86:62–68

Pijuan M, Torà J, Rodríguez-Caballero A, César E, Carrera J, Pérez J (2014) Effect of process parameters and operational mode on nitrous oxide emissions from a nitritation reactor treating reject wastewater. Water Res 49(1):23–33

Rathnayake RMLD, Song Y, Tumendelger A, Oshiki M, Ishii S, Satoh H, Toyoda S, Yoshida N, Okabe S (2013) Source identification of nitrous oxide on autotrophic partial nitrification in a granular sludge reactor. Water Res 47(19):7078–7086

Remde A, Conrad R (1990) Production of nitric oxide in Nitrosomonas europaea by reduction of nitrite. Arch Microbiol 154(2):187–191

Rodriguez-Caballero A, Pijuan M (2013) N2O and NO emissions from a partial nitrification sequencing batch reactor: exploring dynamics, sources and minimization mechanisms. Water Res 47:3131–3140

Rodriguez-Caballero A, Ribera A, Balcázar JL, Pijuan M (2013) Nitritation versus full nitrification of ammonium-rich wastewater: comparison in terms of nitrous and nitric oxides. Bioresour Technol 139:195–202

Schneider Y, Beier M, Rosenwinkel K-H (2013) Nitrous oxide formation during nitritation and nitrification of high-strength wastewater. Water Sci Technol 67(11):2494–2502

Sutka RL, Ostrom NE, Ostrom PH, Breznak JA, Gandhi H, Pitt AJ, Li F (2006) Distinguishing nitrous oxide production from nitrification and denitrification on the basis of isotopomer abundances. Appl Environ Microbiol 72(1):638–644

Wunderlin P, Lehmann MF, Siegrist H, Tuzson B, Joss A, Emmenegger L, Mohn J (2013) Isotope signatures of N2O in a mixed microbial population system: constraints on N2O producing pathways in wastewater treatment. Environ Sci Technol 47(3):1339–1348

Yu R, van Loosdrecht MCM, Chandran K (2010) Mechanisms and Specific directionality of autotrophic nitrous oxide and nitric oxide generation during transient anoxia. Environ Sci Technol 44:1313–1319

Acknowledgments

This work was supported by Deutsche Forschungsgemeinschaft (DFG) (Research Grant RO 1221/13-2). The authors wish to thank Celso da Silva and Ellen Bonna for their contributions to experimental planning, reactor operation, and data processing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Schneider, Y., Beier, M. & Rosenwinkel, KH. Influence of operating conditions on nitrous oxide formation during nitritation and nitrification. Environ Sci Pollut Res 21, 12099–12108 (2014). https://doi.org/10.1007/s11356-014-3148-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-3148-5