Abstract

Oxidation of anthraquinonic dye Acid Blue 62 by electrolysis with conductive-diamond electrodes is studied in this work. COD, TOC, and color have been selected to monitor the degradation of the molecule as a function of several operating inputs (current density, pH, temperature, and NaCl concentration). Results show that the electrochemical oxidation of this model of large molecules follows a first order kinetics in all the conditions assessed, and it does not depend on the pH and temperature. The occurrence of chloride ions in wastewaters increases the rate of color and COD removal as a consequence of the mediated oxidation promoted by the chlorinated oxidizing species. However, chloride occurrence does not have an influence on the mineralization rate. First-order kinetic-constants for color depletion (attack to chromophores groups), oxidation (COD removal), and mineralization (TOC removal) were found to depend on the current density and to increase significantly with its value. A single model was proposed to explain these changes in terms of the mediated oxidation processes. Rate of mineralization remained very close to that expected for a purely mass transfer-controlled process. This was explained assuming that mediated oxidation does not have a significant influence on the mineralization in spite it has some effect on intermediate oxidation stages. The efficiency of the oxidation was found to depend mainly on the concentration of COD being negligible the effect of the other inputs assessed except for the occurrence of chloride ions. Opposite, the efficiency of mineralization depends on concentration of TOC and current density and it did not depend on the chloride occurrence. This observation was found to have an important influence on the power required to remove a given percentage of the initial TOC or COD. To decrease COD efficiently, the occurrence of chloride in the solution is very important, while to remove TOC efficiently, it is more important to work at low current densities and chloride effect is negligible. Energy consumption could be decreased by folds using the proper conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Boron-doped diamond (BDD) has been extensively used as an anode material to promote the electrochemical oxidation of a series of organic pollutants, due to its ability to produce quasi-free hydroxyl radicals (•OH) (Kapałka et al. 2009). As the concentration of these radicals exponentially decays from the BDD surface into the Nernst diffusion layer, the oxidation depends on the mass transport of organics from the bulk to a region close to the anode surface, if the reaction between •OH radicals and the organic pollutants is fast. Thus, a kinetic model was developed by Comninellis’ group (Panizza et al. 2001a, b; Comninellis 1994; Simond et al. 1997; Kapałka et al. 2008) relating a commonly measured parameter, such as the chemical oxygen demand (COD), to the processes that occur close to the anode (reaction cage), independently of the nature of the organic pollutant. The adjustable parameters of that model, which also dictate the efficiency of the electrochemical oxidation, are the current density and the mass-transfer coefficient (that depends on the hydrodynamic conditions). Besides the reaction with organic compounds, the quasi-free •OH radicals may oxidize inorganic ions to yield strong oxidants (Panizza and Cerisola 2009), such as persulfate, percarbonate, perphosphate, or the chloro oxidant species (Cl2, HOCl and OCl−, or undesired ClO3 − and ClO4 −) that can indirectly oxidize organic pollutants (mediated oxidation), as previously shown by Panizza et al. (2001a). The contribution of mediated oxidation was taken into account by Cañizares et al. (2004a, b) through a simplified kinetic model, in which the electrochemical reactor was divided into three stirred tank reactors corresponding to the electrochemical zones (one close to the anode and the other to the cathode) and the chemical zone. Subsequently, in another work, Cañizares’ group (2005) took into account the effect of the chemical reaction to successfully model the electrochemical oxidation of phenolic wastes on a BDD anode.

To model a mass transport-controlled wastewater treatment process, two kinetic expressions should be used: one to define the mass-transport process and another for the mediated oxidation. The kinetics of mass transfer and the electron transfer rate can be defined by Eq. 1. Under mass transport-controlled reaction conditions, the concentration of the pollutant on the electrode surface ([C]s) should be negligible because every molecule that reaches the electrode surface is immediately oxidized. Then, Eq. 1 can be simplified to Eq. 2, which is typical of a first-order kinetic process.

where r m.t. and r d.e.p. are the mass transfer rate and direct electrochemical process rate (mol s−1), respectively, k L is the mass-transfer coefficient (m s−1), A the electrode area (m2), [C]b the concentration of the pollutant in the solution bulk (mol m−3), I L is the electrical current (A), n the number of transferred electrons, and F the Faraday constant (96485 C mol−1).

Mediated electrooxidation processes (med.e.p.) can be modeled by a second-order kinetic equation, according to Eq. 3:

where r med.e.p. is the rate of the mediated electrooxidation process (mol s−1), k ox its rate constant (mol−1 m6 s−1), and [Ox] the concentration of oxidants produced during the electrolytic process (mol m−3).

This second-order kinetic equation can also be simplified to a first-order kinetic equation assuming that oxidants produced and consumed during the electrochemical processes reach a constant pseudo-steady-state (pss) concentration in every electrolysis:

where a new kinetic constant k med is defined as

A mass balance of this discontinuous process leads to Eq. 6, which is a model of the process dynamics.

where V is the electrolyzed solution volume (m3).

Integration of Eq. 6 results in Eq. 7, in which it can be observed that both kinetic constants are contained in the slope (k exp) of the semi-logarithmic linear plot (ln [C b] vs. t); once the value of k L is determined, that of k med can be easily determined.

This model can be used with total organic carbon (TOC), COD, or with the raw pollutant concentration ([C]b). However, it will have different values for each parameter because, despite the mass transfer contribution being the same for every parameter, the mediated oxidation kinetics is not the same for oxidizing functional groups (color) or mineralizing the molecule (TOC).

Moreover, recently many works have been focused on the removal of dyes looking for possible industrial applications; however, this manuscript is focused on the kinetic mechanisms of the oxidation of large molecules using a BDD anode. As a consequence of steric effects, dyes can be used as models of molecules whose size is large enough to hinder their direct oxidation on an electrode surface. On the other hand, chromophore groups are easily oxidized by chemical oxidants in the bulk. This means that mediated oxidation processes are expected to have a significant role in the overall oxidation process. Consequently, the typical control of the oxidation rate by diffusion-controlled processes should be explained in terms of the hard oxidation conditions near the electrode surface (reaction cage) and not of direct electrochemical oxidation processes.

Thus, the electrochemical degradation of an anthraquinonic dye (Acid Blue 62—AB 62) will be investigated with respect to some operational inputs (current density, pH, NaCl concentration, and temperature). Then, the analytical parameters (COD, TOC, and absorbance) commonly used to follow the removal of this pollutant will be compared to the ones of a kinetic model theoretically developed for oxidation on a BDD anode using simple molecules, under mass transport control.

Materials and methods

Chemicals

All chemicals, including NaCl (a.r., Panreac), Na2SO4 (a.r., Panreac), H2SO4 (a.r. Sigma-Aldrich), NaOH (a.r. Panreac), and Acid Blue 62 (Quimanil, industrial grade), were used as received. The dye content in the Acid Blue 62 sample was estimated at about 70 % using TOC measurements. Doubly deionized water (Millipore Milli-Q system, resistivity ≥18.2 MΩ cm) was used for the preparation of all solutions.

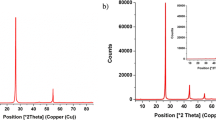

Electrochemical degradation experiments

The electrochemical experiments were carried out in a single-compartment filter-press flow cell operating in batch mode. Boron-doped diamond (BDD) and stainless steel (AISI 304) circular plates were used as anode and cathode, respectively. The BDD anode was assembled on a circular stainless steel plate using a silver paste for electric contact. The geometric area and interelectrode distance were 78 cm2 and 9 mm, respectively. The BDD film (Adamant Technologies, Switzerland) was deposited on a monocrystalline p-doped silicon substrate by the hot filament chemical vapor deposition (HFCVD) technique, with specified boron content of 500 ppm.

The investigated variables and their values were current density (10, 30, and 50 mA cm−2), pH (3, 7, and 11), NaCl concentration (0, 20, and 40 mmol dm−3), and temperature (15, 35, and 55 °C). All the experiments were carried out using 0.6 dm3 of a 100 mg dm−3 (0.25 mmol dm−3) aqueous solution of AB 62 in 0.1 mol dm−3 Na2SO4, at a flow rate of 400 dm3 h−1. The solution pH was continuously monitored and fixed at the desired value by additions of concentrated or diluted solutions of H2SO4 or NaOH.

Analyses

The specific attack to the chromophore was followed through the color abatement of the dye solution; thus, UV–Vis spectra were obtained at certain time intervals from 200 to 800 nm using an UV-1603 spectrophotometer from Shimadzu, until complete decolorization was attained. The COD value (determined by the colorimetric method), which indicates the progress of the organics oxidation, was continuously monitored until its complete removal by sampling 2 cm3 of the electrolyzed solution at certain time intervals. The TOC value (determined by the high-temperature combustion method), which provides information about the conversion of organic pollutants to CO2, was similarly monitored (5 cm3samples). The complete analytical procedures used in the COD and TOC determinations are described elsewhere (Aquino et al. 2013).

The instantaneous current efficiency (ICE) for the electrochemical degradation of the AB 62 dye was calculated for the COD and TOC variations, according to:

where COD t and COD t+∆t or TOC t and TOC t+∆t are the COD or TOC values (g dm−3) at times t and t + Δt, respectively, 2.67 is the conversion factor between COD and TOC, as described by Gray and Becker (2002), F the Faraday constant (96485 C mol−1), and I the applied electrical current (A).

The electric energy consumption per unit volume of electrolyzed solution (w) was calculated using the following equation:

where U is the cell voltage (V).

Results and discussion

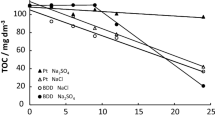

Figures 1 and 2 show the changes in the COD, TOC, and color as a function of the applied electrical charge per unit volume of electrolyzed solution (Q ap), during several electrolyses of a 0.25 mmol dm−3 AB 62 solution, carried out at different current densities and with different compositions in terms of chloride ions. Before discussing the figures, it is worthwhile to clarify that each of these characterization parameters accounts for a different oxidation concept and that unfortunately they are frequently confused in the literature, suggesting that they are equivalent. Color is directly related to the concentration of the dye and its removal means an initial oxidation stage in the mineralization of the molecule in which a chromophore group is attacked (it is simply a transformation of the dye molecule into intermediates). Consequently, color is the parameter that changes faster during the first stage of the electrolysis, being rapidly depleted. On the contrary, TOC indicates the complete mineralization of the dye molecule, i.e., the transformation of the organic carbon into carbon dioxide, a process that in the case of a large molecule will occur via the formation of intermediates due to the large number of electrons that need to be transferred. From TOC, it is not possible to differentiate between the raw dye and its intermediates (it does not inform about the progress of the oxidation) and its change only quantifies the fraction of the dye molecules that has been completely mineralized. This explains why it behaves as the slowest parameter to be depleted and should be considered as the main pollution indicator in the treatment of a dye. COD is an in-between parameter, which indicates the progress of the oxidation process not only based on the direct attack to a particular group or on the total oxidation of the molecule, but actually accounting for every oxidation undergone by the dye molecule or its oxidation intermediates. At the final stages of the electrolysis of a dye, commonly COD has a very small value while TOC is still significant, because of the large oxidation state of the intermediates formed. This means that although the three parameters account for the pollution of a wastewater, color, or TOC are good parameters to follow the initial stage in the treatment of a large molecule or to assess the total depletion caused by the treatment, respectively, whereas COD is the best parameter to follow the course of the degradation itself.

Relative COD decay as a function of the applied electrical charge per unit volume of electrolyzed solution (Q ap). All the experiments were carried out using 0.6 dm3 of a 100 mg dm−3 (0.25 mmol dm−3) aqueous solution of AB 62 in 0.1 mol dm−3 Na2SO4, pH 7, 35 °C, at a flow rate of 400 dm3 h−1. Specific conditions: (white diamond) 30 mA cm−2 and 0 mmol dm−3 NaCl; (black-filled square) 10 mA cm−2 and 20 mmol dm−3 NaCl; (asterisk) 30 mA cm−2 and 20 mmol dm−3 NaCl; (triangle) 30 mA cm−2 and 40 mmol dm−3 NaCl; (black-filled diamond) 50 mA cm−2 and 20 mmol dm−3 NaCl; (dash-dots-dash) expected CODrel changes for 100 % current efficiency. Lines refer to the values calculated using the model—see text: (en dash) 10 mA cm−2, (broken line) 30 mA cm−2, and (ellipsis) 50 mA cm−2

Relative a absorbance (at 596 nm) and b TOC decay as a function of the applied electrical charge per unit volume of electrolyzed solution (Q ap) for the experiments and specific conditions of Fig. 1. (dash-dots-dash) expected TOCrel changes for 100 % current efficiency. Lines refer to the values calculated using the model—see text: (en dash) 10 mA cm−2, (broken line) 30 mA cm−2, and (ellipsis) 50 mA cm−2

Taking this into account, the oxidation of large molecules with conductive-diamond electrolyses follows first-order kinetics (linear trend in the semi-logarithmic plot) in all the conditions assessed and with the three parameters monitored, as can be observed in Figs. 1 and 2. For COD and absorbance, there is a huge difference between results obtained in the treatment of the AB 62 dye in the absence or presence of chloride ions, the process being more efficient in the latter case. This is a surprising result because the production of powerful oxidation species during the electrolysis of organics with conductive-diamond anodes is known to be attained with both chloride (active chlorine, chlorate, and perchlorate) and sulfate media (peroxodisulfate); indeed larger efficiencies for electrolyses in sulfate media compared to the chloride media were reported in several papers (Cañizares et al. 2006a; Murugananthan et al. 2008, 2010; Aquino et al. 2011; Solano et al. 2013). Those results had been explained in terms of the slow oxidation kinetics of organics by chlorate and perchlorate at room temperature (Cañizares et al. 2006a). The larger efficiencies observed in this work clearly indicate that the formation of these oxoanions should not be promoted in the presence of sulfate and that these negative effects are not very important. The effect of the presence of NaCl in the electrochemical oxidation of different organics has been reported in the literature, and it seems to also depend on the nature of the organics, concentration, pH, and applied current density. For instance, Scialdone et al. (2009) compared the electrochemical oxidation of oxalic acid (OA) at BDD and DSA® anodes in the presence and absence of NaCl. As it is known, the use of DSA® electrodes promotes the formation of large amounts of active chlorine that seems to successfully attack the OA molecule. This can explain the higher removal percentages obtained in the presence of NaCl. Wu et al. (2009) also observed an increase in the COD removal during the electrolysis of 1,000 mg dm−3 of the methylene blue dye in a conventional electrochemical cell using both BDD and DSA® anodes in the presence of NaCl. On the other hand, Cabeza et al. (2007) did not observe significant differences between the experimental and theoretical (based on a mass transfer model) values of COD removal during the electrochemical degradation of a landfill leachate effluent in the presence of NaCl. Aquino et al. (2011) even observed a superior COD removal in the absence of NaCl during the electrochemical treatment of a real textile effluent using a BDD anode. The expected lower efficiency of the BDD anode towards organic pollutant removal in the presence of chloride ions can be occasioned by a low availability of •OH radicals (Polcaro et al. 2009; Mascia et al. 2010), due to their reaction with chloride ions to produce ClO3 − or ClO4 − (Sánchez-Carretero et al. 2011) and even form chloro radicals (Grebel et al. 2010).

Once the role of NaCl is clarified, although an influence of the current density on the COD removals values is observed, the results are far from those expected. Thus, in every case (sulfate and chloride), the efficiencies are much greater than expected according to a simple mass-transfer electrolytic model (plotted in Fig. 1). Naturally, this model indicates that the process should be more efficient working under low current densities (and also high flow rates); however, the results account for the importance of mediated electrochemical processes in the removal of large molecules and not for direct electrochemical processes. At this point, it is worthwhile to point out that the initial concentration of the AB 62 dye (100 mg dm−3 COD) is below the mass-transfer limit concentration for the used current densities in this type of cell. Thus, a standard mass-transport characterization test with the Fe(CN)6 3− / Fe(CN)6 4− redox couple (Cañizares et al. 2006b) gives a k L value of the electrochemical cell within the fluid dynamic conditions used (400 dm3 h−1, 298 K) of 1.28 × 10−5 m s−1 (Aquino et al. 2012). The value of the limiting current density for the initial concentration (this value decreases linearly with the concentration) is about 1.5 mA cm−2, which is significantly below the range of current densities applied in this work (10–50 mA cm−2).

Changes in the TOC and color removals also follow a first-order kinetics, with a linear trend in the semi-logarithmic plot (just some points at the end of the electrolyses differ from this trend), as can be seen in Fig. 2b. In the case of color removal, the marked difference between the results obtained in the presence or absence of chloride ions is also noticed, but in the case of TOC removal these differences are smaller and the current density starts to play a more significant role. In addition, as expected for a direct electrochemical oxidation process, the most efficient mineralization conditions are those in which the current density values were low. This confirms that although the contribution of mediated oxidation is very important, direct electrolysis (or at least processes occurring close to the anode surface) is essential for mineralization. As expected, the removal of color (transformation of the initial dye molecule into an intermediate) is significantly faster, since the chloro oxidant species (HOCl and OCl−) can easily attack electron rich groups of the dye molecule through addition, substitution or oxidation reactions (Deborde and Gunten 2008). This promotes the rapid formation of intermediates than can be further oxidized as the process proceeds.

Figure 3 shows the influence of current density and NaCl concentration on the fitting first-order kinetic constants for color, COD, and TOC removal. These kinetic constants were calculated from the slope of semi-logarithmic vs. time plots. For the case of COD and TOC, the complete set of data was used to fit the constant, whereas for the case of color only the points corresponding to the first oxidation stage (which fit well to this trend) were used. In this latter case, a change in the slope is commonly found for large values of Q ap, as apparent in Fig. 2, due to competing oxidation reactions of the dye and other intermediate compounds, when differences in oxidizability might become important. These kinetic constants should be interpreted in terms of the following equation, obtained by combining Eqs. 5 and 7:

First order kinetic constants as a function of a current density (for 20 mmol dm−3 NaCl) and b NaCl concentration (at 30 mA cm−2). Parameters: (black-filled diamond) absorbance at 596 nm, (white square) COD, and (white diamond) TOC; (multiplication symbol) refers to data for a purely mass transport-controlled kinetic constant. All the experiments were carried out using 0.6 dm3 of a 100 mg dm−3 (0.25 mmol dm−3) aqueous solution of AB 62 in 0.1 mol dm−3 Na2SO4, pH 7, 35 °C, at a flow rate of 400 dm3 h−1

As can be observed in Fig. 3a, very different values of the kinetic constants were obtained for the color, COD, and TOC removals; however, in every case a slight increase is observed with the current density. Taking into account Eq. 11, this trend can be easily explained in terms of promotion of the formation of higher concentrations of intermediates as the current density increases, because the mass-transfer coefficient, the electrode surface, and the reaction volume do not change. To understand these differences, the different meanings of the three parameters (COD, TOC, and color) have to be taken into account. The slope of the linear trend is similar for COD and TOC, suggesting that mineralization might be considered as the main oxidation process. On the contrary, the color removal does not seem to be strongly influenced by the current density, possibly because of the great value of k ox for this process, which helps to rapidly deplete the color during the treatment, or because of the equivalent effect on the depletion of color brought on by the larger number and the higher concentration of oxidants (quantified as [Ox]) that can attack the chromophore groups.

The expected kinetic constant for a purely mass transport-controlled process is also plotted in Fig. 3. As can be observed, the values of the kinetic constants are mostly greater than the expected values for a purely mass transport-controlled process. Differences are greater for color removal and smaller for TOC removal, suggesting that (according to Eq. 11) k med (k ox[Ox]pss) is very significant for the initial oxidation, but not much for the mineralization process. This means that mediated oxidants play an important role in the oxidation of chromophore groups and a lesser, but still important, role in the mineralization process.

Figure 3b shows the effect of NaCl concentration on the kinetic constants. As discussed above, the influence of mediated oxidation is higher for color and COD removal, whose kinetics is significantly improved in the presence of small concentrations of NaCl. The kinetic constant for color removal in the absence of NaCl is slightly higher than those for COD and TOC removal. This fact could be related to the role of peroxodisulfate ions in the mediated oxidation (Martínez-Huitle et al. 2012). On the other hand, mineralization does not seem to be significantly influenced by the NaCl concentration, as the electrogenerated chloro oxidant species are incapable of converting the intermediate compounds to CO2. Thus, the kinetic constant for TOC removal remained close to the one theoretically calculated for a direct process under mass-transfer control. The possible loss of TOC removal efficiency in the presence of chloride ions, due to the generation of organochlorine byproducts was not observed.

Figure 4 shows the effect of temperature and pH on the kinetic constants of the electrochemical oxidation process. Initially, it could be expected that mediated oxidation carried out by the chlorinated oxoanions or by peroxodisulfate ions should be influenced by both parameters; similarly, a higher mineralization rate with temperature and at acidic pH could also be expected because of the greater effects of both oxidants at these conditions. However, the small influence observed (almost null and negligible in every case), in particular if the effect is compared to that of the current density, indicates that this is not the case and that both parameters have no significant influence on the oxidation rate. Similar results have been reported in the literature (Deborde and Gunten 2008; Martínez-Huitle et al. 2012; Pereira et al. 2012) for the removal of different organics. Pereira et al. (2012), who reported on the electrochemical degradation of bisphenol A in a flow reactor with a BDD anode, also observed that pH does not influence markedly the COD removal, which is slightly improved by changes in the temperature from 25 to 40 °C. On the contrary, Panizza et al. (2001a) observed that an increase in temperature promotes the decomposition of peroxodisulfate ions, thus negatively affecting the BDD-electrochemical oxidation of the Acid Blue 22 dye. In addition, Bensalah et al. (2009) also observed a negligible increase in the oxidation rate of the Alphazurine A dye, when its electrooxidation was carried out in the range of 25 to 60 °C.

First order kinetic constants as a function of a temperature (at pH 7) and b pH (at 35 °C), at 30 mA cm−2, in the presence of 20 mmol dm−3 NaCl. Parameters: (black-filled diamond) absorbance at 596 nm, (white square) COD, (white diamond) TOC; (multiplication symbol) refers to a purely mass transport-controlled kinetic constant. All the experiments were carried out using 0.6 dm3 of a 100 mg dm−3 (0.25 mmol dm−3) aqueous solution of AB 62 in 0.1 mol dm−3 Na2SO4, at a flow rate of 400 dm3 h−1

Figure 5 shows the effect of the concentration of organics (TOC or COD), temperature or sodium chloride concentration, and current density on the instantaneous current efficiency (ICE). As can be observed, concentration is the most relevant parameter: the ICE values diminish as the concentration decreases. This effect is especially important for very small concentrations (in which a small decrease of 10 % leads to more than one order of magnitude drop in the efficiency) and less significant but still appreciable at higher concentrations of organics (logarithmic scale). On the other hand, the effect of the current density, temperature or sodium chloride concentration is less significant and a cloud of points is observed without a clear trend. Just the points corresponding to a nil content of chloride show a significantly less efficient behavior for the oxidation (COD), although there is no significant influence on the efficiency of mineralization (TOC), indicating that chlorine, as explained before, has a significant role in the oxidation of the dye to intermediates but has no influence on its conversion to carbon dioxide, which does not depend on the concentration of chloride in the supporting media. The expected ICE behaviors according to a mass transport model for the three applied current densities are also depicted in Fig. 5. As can be observed, an effect of current density on ICE is expected for a purely mass transfer-controlled process, contrary to obtained results. In addition, most ICE values are greater than the ones expected for a purely mass transport-controlled process in terms of COD (even for the condition in the absence of NaCl), but not in terms of TOC in which points lay over the lines proposed by the mass transfer model. This means that many of the oxidation processes are occurring in the bulk but the mineralization is attained near the electrode surface by direct oxidation or by the action of strong oxidants such as hydroxyl radicals.

Instantaneous current efficiency (ICE) as a function of the a relative COD and b relative TOC decay. Conditions: (black-filled square) 10 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 7; (asterisk) 30 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 7; (black-filled diamond) 50 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 7; (white diamond) 30 mA cm−2, 0 mmol dm−3 NaCl, 35 °C, and pH 7; (white triangle) 30 mA cm−2, 40 mmol dm−3 NaCl, 35 °C, and pH 7; (white circle) 30 mA cm−2, 20 mmol dm−3 NaCl, 15 °C, and pH 7; (plus symbol) 30 mA cm−2, 20 mmol dm−3 NaCl, 55 °C, and pH 7; (en dash) 30 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 3, (multiplication symbol) 30 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 11. All the experiments were carried out using 0.6 dm3 of a 100 mg dm−3 (0.25 mmol dm−3) aqueous solution of AB 62 in 0.1 mol dm−3 Na2SO4, at a flow rate of 400 dm3 h−1. Lines refer to the values calculated from model: (en dash) 10 mA cm−2, (broken line) 30 mA cm−2, and (ellipsis) 50 mA cm−2

These changes in the efficiency have an important influence on the power required to remove a percentage of the initial TOC or COD, although it is also important to take into account the cell voltage. Figure 6 shows the variation of energy consumption (w) with the percentage removal of COD and TOC. In chloride media energy consumptions as low as 10 kW h m−3 are required to attain the complete COD removal, independently of the operating conditions. However, in the absence of NaCl, this value increases abruptly (around ten times). On the other hand, energy consumptions around 100 kW h m−3 are required for complete mineralization of the organics both in the presence or absence of chloride ions. The difference between both values should be explained in terms of the accumulation of carboxylic acids at the latter stages of the electrolytic process because these species have an almost nil theoretical COD and still a significant TOC value. As observed, cost can significantly decrease if the right conditions are used. Finally, it should be noted that to efficiently remove COD, the presence of chloride ions is very important to promote mediated oxidation processes, whereas to efficiently remove TOC, the use of low current densities is very important to promote oxidation near the anode surface.

a COD and b TOC removals as a function of the electrical energy consumption per unit volume of electrolyzed solution. Conditions: (black-filled square) 10 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 7; (asterisk) 30 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 7; (black-filled diamond) 50 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 7; (white diamond) 30 mA cm−2, 0 mmol dm−3 NaCl, 35 °C, and pH 7; (white triangle) 30 mA cm−2, 40 mmol dm−3 NaCl, 35 °C, and pH 7; (white circle) 30 mA cm−2, 20 mmol dm−3 NaCl, 15 °C, and pH 7; (plus symbol) 30 mA cm−2, 20 mmol dm−3 NaCl, 55 °C, and pH 7; (en dash) 30 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, pH 3, (multiplication symbol) 30 mA cm−2, 20 mmol dm−3 NaCl, 35 °C, and pH 11. All the experiments were carried out using 0.6 dm3 of a 100 mg dm−3 (0.25 mmol dm−3) aqueous solution of AB 62 in 0.1 mol dm−3 Na2SO4, at a flow rate of 400 dm3 h−1

Conclusions

From this work, the following conclusions can be drawn:

-

1.

The electrochemical degradation of the Acid Blue 62 dye was successfully attained using a BDD anode in the presence and absence of chloride ions. Chloride ions present in solution lead to increased rates of color and COD removal as a consequence of the mediated oxidation promoted by the chlorinated oxidizing species. However, this has no influence on the mineralization rate.

-

2.

Contrary to what it could be expected for a process in which mediated oxidation plays a significant role, a very small influence of pH and temperature on the reaction rate and efficiencies was observed during the oxidation of AB 62.

-

3.

The obtained first-order kinetic constants for color removal (attack on the chromophores groups), oxidation (COD removal), and mineralization (TOC removal) depend on the current density and increase significantly with its value.

-

4.

The obtained first-order kinetic constants for mineralization remained very close to that of a purely mass transfer-controlled process, indicating that most mineralization processes should occur not in the bulk but near the electrode surface, in accordance with the reaction cage model proposed by the group of Comninellis group.

-

5.

The efficiencies for color and COD removal depend mainly on the organics concentration and the presence of chloride ions in solution. For the mineralization process, these efficiencies do not depend on the presence of chloride ions, but they depend significantly on the current density; thus, the process is more efficient when carried at low current densities. The energy consumption can be significantly decreased if adequate conditions are chosen.

References

Aquino JM, Pereira GF, Rocha-Filho RC, Bocchi N, Biaggio SR (2011) Electrochemical degradation of a real textile effluent using boron-doped diamond or β-PbO2 as anode. J Hazard Mater 192:1275–1282

Aquino JM, Rodrigo MA, Rocha-Filho RC, Sáez C, Cañizares P (2012) Influence of the supporting electrolyte on the electrolyses of dyes with conductive-diamond anodes. Chem Eng J 184:221–227

Aquino JM, Rocha-Filho RC, Rodrigo MA, Sáez C, Cañizares P (2013) Electrochemical degradation of the reactive red 141 dye using a boron-doped diamond anode. Water Air Soil Pollut 224:1397

Bensalah N, Alfaro MAQ, Martínez-Huitle CA (2009) Electrochemical treatment of synthetic wastewaters containing Alphazurine A dye. Chem Eng J 149:348–352

Cabeza A, Urtiaga AM, Ortiz I (2007) Electrochemical treatment of landfill leachates using a boron-doped diamond anode. Ind Eng Chem Res 46:1439–1446

Cañizares P, García-Gómez J, Lobato J, Rodrigo MA (2004a) Modeling of wastewater electro-oxidation processes part II. Application to active electrodes. Ind Eng Chem Res 43:1923–1931

Cañizares P, García-Gómez J, Lobato J, Rodrigo MA (2004b) Modeling of wastewater electro-oxidation processes part I. General description and application to inactive electrodes. Ind Eng Chem Res 43:1915–1922

Cañizares P, Lobato J, Paz R, Rodrigo MA, Sáez C (2005) Electrochemical oxidation of phenolic wastes with boron-doped diamond anodes. Water Res 39:2687–2703

Cañizares P, Martínez L, Paz R, Sáez C, Lobato J, Rodrigo MA (2006a) Treatment of Fenton-refractory olive oil mill wastes by electrochemical oxidation with boron-doped diamond anodes. J Chem Technol Biotechnol 81:1331–1337

Cañizares P, García-Gómez J, Marcos IFD, Rodrigo MA, Lobato J (2006b) Measurement of mass-transfer coefficients by an electrochemical technique. J Chem Educ 83:1204–1207

Comninellis C (1994) Electrocatalysis in the electrochemical conversion/combustion of organic pollutants for waste water treatment. Electrochim Acta 39:1857–1862

Deborde M, Gunten UV (2008) Reactions of chlorine with inorganic and organic compounds during water treatment—kinetics and mechanisms: a critical review. Water Res 42:13–51

Gray SR, Becker NSC (2002) Contaminant flows in urban residential water systems. Urban Water 4:331–346

Grebel JE, Pignatello JJ, Mitch WA (2010) Effect of halide ions and carbonates on organic contaminant degradation by hydroxyl radical-based advanced oxidation processes in saline waters. Environ Sci Technol 44:6822–6828

Kapałka A, Fóti G, Comninellis C (2008) Kinetic modelling of the electrochemical mineralization of organic pollutants for wastewater treatment. J Appl Electrochem 38:7–16

Kapałka A, Fóti G, Comninellis C (2009) The importance of electrode material in environmental electrochemistry. Formation and reactivity of free hydroxyl radicals on boron-doped diamond electrodes. Electrochim Acta 54:2018–2023

Martínez-Huitle CA, dos Santos EV, de Araújo DM, Panizza M (2012) Applicability of diamond electrode/anode to the electrochemical treatment of a real textile effluent. J Electroanal Chem 674:103–107

Mascia M, Vacca A, Polcaro AM, Palmas S, Ruiz JR, Pozzo AD (2010) Electrochemical treatment of phenolic waters in presence of chloride with boron-doped diamond (BDD) anodes: experimental study and mathematical model. J Hazard Mater 174:314–322

Murugananthan M, Yoshihara S, Rakuma T, Shirakashi T (2008) Mineralization of bisphenol A (BPA) by anodic oxidation with boron-doped diamond (BDD) electrode. J Hazard Mater 154:213–220

Murugananthan M, Latha SS, Raju GB, Yoshihara S (2010) Anodic oxidation of ketoprofen—an anti-inflammatory drug using boron doped diamond and platinum electrodes. J Hazard Mater 180:753–758

Panizza M, Cerisola G (2009) Direct and mediated anodic oxidation of organic pollutants. Chem Rev 109:6541–6569

Panizza M, Michaud PA, Cerisola G, Comninellis C (2001a) Anodic oxidation of 2-naphthol at boron-doped diamond electrodes. J Electroanal Chem 507:206–214

Panizza M, Michaud PA, Cerisola G, Comninellis C (2001b) Electrochemical treatment of wastewaters containing organic pollutants on boron-doped diamond electrodes: prediction of specific energy consumption and required electrode area. Electrochem Commun 3:336–339

Pereira GF, Rocha-Filho RC, Bocchi N, Biaggio SR (2012) Electrochemical degradation of bisphenol A using a flow reactor with a boron-doped diamond anode. Chem Eng J 198–199:282–288

Polcaro AM, Vacca A, Mascia M, Palmas S, Ruiz JR (2009) Electrochemical treatment of waters with BDD anodes: kinetics of the reactions involving chlorides. J Appl Electrochem 39:2083–2092

Sánchez-Carretero A, Sáez C, Cañizares P, Rodrigo MA (2011) Electrochemical production of perchlorates using conductive diamond electrolyses. Chem Eng J 166:710–714

Scialdone O, Randazzo S, Galia A, Silvestri G (2009) Electrochemical oxidation of organics in water: role of operative parameters in the absence and in the presence of NaCl. Water Res 43:2260–2272

Simond O, Schaller V, Comninellis C (1997) Theoretical model for the anodic oxidation of organics on metal oxide electrodes. Electrochim Acta 42:2009–2012

Solano AMS, de Araújo CKC, de Melo JV, Peralta-Hernandez JM, da Silva DR, Martínez-Huitle CA (2013) Decontamination of real textile industrial effluent by strong oxidant species electrogenerated on diamond electrode: viability and disadvantages of this electrochemical technology. Appl Catal B 130–131:112–120

Wu M, Zhao G, Li M, Liu L, Li D (2009) Applicability of boron-doped diamond electrode to the degradation of chloride-mediated and chloride-free wastewaters. J Hazard Mater 163:26–31

Acknowledgments

This work was supported by the MCT (Ministerio de Ciencia y Tecnología, Spain) through the projects CTM2010-18833/TECNO and CTM2013-45612-R. The Brazilian funding agencies CNPq and CAPES (for the scholarship awarded to J.M. Aquino) and the company Quimanil (for supplying the dye samples) are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Aquino, J.M., Rocha-Filho, R.C., Sáez, C. et al. High efficiencies in the electrochemical oxidation of an anthraquinonic dye with conductive-diamond anodes. Environ Sci Pollut Res 21, 8442–8450 (2014). https://doi.org/10.1007/s11356-014-2784-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-2784-0