Abstract

A new method for the degradation of bisphenol A (BPA) in aqueous solution was developed. The oxidative degradation characteristics of BPA in a heterogeneous Fenton reaction catalyzed by Fe3O4/graphite oxide (GO) were studied. Transmission electron microscopic images showed that the Fe3O4 nanoparticles were evenly distributed and were ∼6 nm in diameter. Experimental results suggested that BPA conversion was affected by several factors, such as the loading amount of Fe3O4/GO, pH, and initial H2O2 concentration. In the system with 1.0 g L−1 of Fe3O4/GO and 20 mmol L−1 of H2O2, almost 90 % of BPA (20 mg L−1) was degraded within 6 h at pH 6.0. Based on the degradation products identified by GC–MS, the degradation pathways of BPA were proposed. In addition, the reused catalyst Fe3O4/GO still retained its catalytic activity after three cycles, indicating that Fe3O4/GO had good stability and reusability. These results demonstrated that the heterogeneous Fenton reaction catalyzed by Fe3O4/GO is a promising advanced oxidation technology for the treatment of wastewater containing BPA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bisphenol A (BPA; 2,2-bis-(4-hydroxy phenyl)-propane) is a representative estrogen and an important industrial chemical widely used as the monomer for producing polycarbonate plastics (Staples et al. 1998). As an additive or contaminant, BPA can be detected in food (Noonan et al. 2011), water (Klečka et al. 2009), paper (Liao and Kannan 2011), and plastic products (Oehlmann et al. 2008). BPA shows the effects of estrogen on gene imprinting and sexual differentiation when accumulated in the human body (Vandenberg et al. 2009). BPA degradation naturally requires more than 90 years, which means that the pollution resulting from BPA or other chemicals with a similar structure can last for several decades once released into water or soil (Vandenberg et al. 2009). Therefore, effective techniques of removing BPA from the environment must be developed.

Several methods have been developed for the removal of BPA from aqueous solution, and the most common approaches are biodegradation and adsorption. Biodegradation, which is widely used in the industrial scale, takes several weeks or more to complete. Meanwhile, adsorption has the advantages of high removal efficiency and short cycle of the adsorption process, but this method is accompanied by complex desorption. Thus, rapid and efficient treatment processes must be developed for BPA removal.

Advanced oxidation processes (AOPs) can be used to effectively degrade recalcitrant and toxic compounds found in air, water, and wastewater (Gültekin and Ince 2007). The Fenton process is an AOP that has the unique advantages of high degradation efficiency, simple operation, mild reaction conditions, environmental friendliness, and low cost (Arnold et al. 1995; Zhao and Hu 2008). This process has been proven to be one of the most effective methods of degrading organic pollutants in wastewater. The classical Fenton reagent consists of a homogeneous solution of iron ions and hydrogen peroxide (H2O2). Studies on BPA degradation by the traditional Fenton reaction are shown in Table 1 (Ioan et al. 2007; Kim et al. 2008; Mohapatra et al. 2011). Despite the advantage of the Fenton reaction, it is efficient only at low pH (pH < 4) and rather inefficient within the pH range of most natural waters (pH 5–9). Another drawback of the homogeneous Fenton process is that it easily produces iron sludge (pH 5–9), which is difficult to remove after treatment. To overcome these problems, heterogeneous catalysts including zero-valent iron (Stieber et al. 2011), iron-based clays (Navalon et al. 2010), iron-containing materials (Luo et al. 2010), and iron oxide minerals (Ortiz de la Plata et al. 2010) have been increasingly developed.

In recent years, different iron oxides and iron hydroxides such as hematite, α-FeOOH, and β-FeOOH have been studied as heterogeneous catalysts for the Fenton reaction (Chou and Huang 1999; Feng et al. 2003; Zhao and Hu 2008). The heterogeneous Fenton catalyst can efficiently destroy organic pollutants within a wider pH range with much less iron loss than the homogeneous Fenton reaction. For heterogeneous processes, the main oxidation reactions occur at the solid–liquid interface, where the iron substantially remains in the solid phase either as a mineral or as an adsorbed ion. However, many of these systems do not show favorable catalytic activity (Kwan and Voelker 2003), particularly due to the inefficiency of Fe3+ in catalyzing the generation of ·OH from H2O2. In this regard, an inverse spinel Fe3O4 has been used as a catalyst in the heterogeneous Fenton process because Fe2+ in Fe3O4 plays an important role in the initiation of the Fenton reaction according to the classical Haber–Weiss mechanism (Costa et al. 2006). Moreover, the octahedral site in the magnetite structure can easily accommodate both Fe2+ and Fe3+, allowing the Fe species to be reversibly oxidized and reduced while maintaining the same structure (Costa et al. 2006). Thus, Fe3O4 can continuously function as a heterogeneous catalyst without substantial loss of its mass. Magnetite can also be easily separated from the reaction medium using an external magnetic field.

Fe3O4 immobilized on solid supports is another type of promising heterogeneous catalysts that is recently gaining attention. The supports can be organic or inorganic materials, such as activated carbon (Nguyen et al. 2011), multiwalled carbon nanotubes (Hu et al. 2011), hydroxyapatite (Yang et al. 2010), mesostructured silica (Aliyan et al. 2013), etc. Nguyen et al. (2011) used Fe3O4-activated carbons as catalysts for degrading the methyl orange. The catalyst showed good catalytic performance with degradation as high as 90 %. However, considerable iron leaching from the support leads to a progressive deactivation in consecutive reaction cycles. Notably, organic supports cannot withstand the attack of ·OH and lack sufficient mechanical strength in general.

Graphene oxide (GO) is attracting attention because of its unique properties, such as large specific surface area, chemical stability, and superior mechanical strength. The hydrophobic surfaces of GO enable it to have strong interactions with organic chemicals. GO is also an effective adsorbent for organic chemicals in water treatment compared with octadecyl adsorbent (C18) and activated carbon (Pan and Xing 2008). Thus, the stability and adsorption property of GO make it a better support than other kinds of materials.

In the present study, GO-supported Fe3O4 catalysts were prepared by in situ growth. For the first time, Fe3O4/GO catalyst was used in a Fenton reaction to adsorb and degrade trace amounts of the environmental hormone BPA in water. Fe3O4/GO was found to be highly effective for BPA degradation within a wide pH range and exhibited excellent long-term stability in the presence of H2O2. The possible catalytic mechanism was also discussed.

Experimental

Chemicals

GO was prepared from natural graphite using a modified Hummers’ method (Hummers and Offeman 1958). Fe(acac)3 (99.9 % purity), octylamine (99 %), and BPA (99 %) were purchased from Sigma–Aldrich. Octanol and H2O2 (>30 wt%) were obtained from Nanjing Chemical Reagent Co., Ltd. (Nanjing, China). Methanol was obtained from Tedia (USA). The water employed was deionized. All reagents were analytical grade and used without further purification. Stock solution was prepared by dissolving desired amount of BPA into methanol (10 %) in brown volumetric flask and stored at 4 °C. Working solutions were followed by diluting a stock solution with methanol (10 %) to desired concentrations.

Synthesis and characterization of Fe3O4/GO nanocomposites

In a typical synthesis of Fe3O4 nanoparticles anchored onto GO, Fe(acac)3 (0.3532 g) and GO (0.1766 g) were dissolved in a mixture of octylamine (10.0 mL) and octanol (24.0 mL). The solution was transferred into a Teflon-lined autoclave, which was sealed and heated to 110 °C for 1 h to remove trace oxygen and moisture. The temperature was increased and maintained at 240 °C for 2 h in an atmosphere furnace. After the reaction, the autoclave was cooled to room temperature, and 30 mL of ethanol was added to the resulting black mixture. A black material was precipitated and separated using a commercial magnet, washed with ethanol several times, and dried to finally obtain Fe3O4/GO nanocomposites.

A transmission electron microscope (TEM, H-800) was used to observe the morphological characteristics of the Fe3O4/GO nanocomposites. The X-ray diffraction (XRD, Rigaku D/MAX-2400) was used to analyze the crystal structure of the Fe3O4/GO nanocomposites with Ni-filtered Cu Kα radiation operated at 40 kV and 100 mA in the range of 2θ = 20–80°. The vibrating sample magnetometry (VSM, LAKESHORE-7304) was used to assess the magnetic property at room temperature.

Degradation of BPA by heterogeneous Fenton experiments

A BPA of 50 mL (20 mg L−1) aqueous solution was prepared as above with the addition of required amount of Fe3O4/GO nanocomposites (1 g L−1) and H2O2 (10 mmol L−1). The mixture was mechanically stirred at 150 rpm and 25 °C.

For each oxidation reaction, the suspension solution was clarified quickly by an outer strong permanent magnet at the selected reaction time. The aqueous phase was sampled for analysis. In addition, control experiments and the effects of pH, initial H2O2 concentration, and Fe3O4/GO nanocomposites loading on BPA degradation were carried out according to the same steps as above.

Analyses

The samples were analyzed by high-performance liquid chromatography (HPLC; Agilent, USA 1220) with a C18 reversed phase column (Eclipse Plus C18 4.6 mm × 150 mm, 5-μm particles, Agilent, USA) and a UV detector. The measurement was performed in a methanol/water (=70:30, v/v) as a mobile phase with a flow rate of 1 mL min−1 and a detection wavelength of 278 nm. A GC–MS (Agilent 5975) was used for separation and detection of the intermediate products. The GC was equipped with an HP-5 capillary column (30 m × 0.25 mm i.d.) in helium carrier gas. Total organic content (TOC) present in the samples was determined using a Multi N/C 2100 analyzer (Analytik Jena, Germany). To measure the content of iron, Fe3O4/GO was treated with concentrated nitric acid, and the resulting solution was subject to ICP-AES analysis (Thermo iCAP 6300).

Results and discussion

Characterization of Fe3O4/GO nanocomposites

The morphology of Fe3O4 nanoparticles on GO was examined by TEM under different magnifications (Fig. 1). The Fe3O4 nanoparticles adhering on Fe3O4/GO was homogeneously dispersed on the surface of GO. The Fe3O4 nanoparticles were highly uniform and ∼6 nm in diameter.

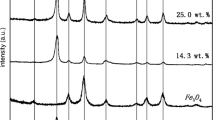

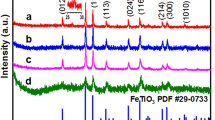

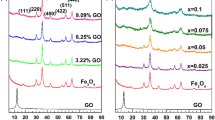

XRD was used to identify the specific nanoparticles anchored onto the surface of GO. Compared with pure Fe3O4 nanoparticles, the reflections of (220), (311), (400), (511), and (440) by both Fe3O4/GO nanocomposites were exactly the same as that of pure Fe3O4 nanoparticles (JCPDS card no. 19–0629). Therefore, Fe3O4 nanoparticles were successfully deposited onto the surface of GO.

The magnetic property of the Fe3O4/GO nanocomposites is in Fig. 2. The saturation magnetization was found to be 17.54 emu g−1, and the samples exhibited supraparamagnetic behavior at room temperature with no coercivity and remanence. As shown in the inset of Fig. 2, vial (a) contained Fe3O4/GO nanocomposites dispersed in ethanol, and vial (b) contained the same content of vial (a) but was closely approached by a commercial magnet. Thus, the Fe3O4/GO nanocomposites were effectively separated from the ethanol solution. Therefore, Fe3O4 nanoparticles were successfully attached onto the GO, and the iron content of Fe3O4/GO was 22.6 % (w/w).

BPA degradation in different catalytic systems

To investigate the catalytic activity of Fe3O4/GO nanocomposites for the heterogeneous Fenton degradation of BPA, a series of contrast experiments was carried out. As shown in Fig. 3, the concentration of BPA did not obviously decrease in the presence of Fe3O4 alone. This finding indicated that BPA hardly adsorbed on the Fe3O4 surface because the removal of BPA from the Fe3O4 system mainly depended on the adsorption on Fe3O4. The low adsorption may be ascribed to the fact that BPA is a hydrophobic compound, whereas the Fe3O4 surface is hydrophilic. Similarly, no significant decrease in the BPA concentration was observed in the H2O2 system, which can be ascribed to the weaker oxidation potential of H2O2 than those of hydroxyl and perhydroxyl radicals (Hu et al. 2011). Less than 10 % degradation of BPA was observed in the Fe3O4/H2O2 system, which can be attributed to the slow reaction between Fe(II) on the Fe3O4 surface and H2O2 under near neutral pH condition, as well as to the insufficient ·OH radical generation. The high generation rate of ·OH radicals shown in Eq. 1 was obtained only under an acidic pH condition (De Laat and Gallard 1999). Moreover, the insufficient ·OH radicals were easily scavenged by H2O2 (Eq. 2) (Perez et al. 2002); consequently, the generated ·OH radicals were insufficient to diffuse into the bulk solution to degrade BPA. The low BPA adsorption onto the Fe3O4 surface also led to its difficult degradation.

Compared with the Fe3O4/H2O2 system, the Fe3O4/GO system showed more effective BPA degradation. Approximately 50 % of BPA was degraded after 12 h in the Fe3O4/GO system because of adsorption onto the Fe3O4/GO surface, i.e., the removal of BPA in the Fe3O4/GO system mainly depended on the adsorption on Fe3O4/GO. However, rapid degradation of BPA (>85 % BPA in 12 h) was achieved in the Fe3O4/GO/H2O2 system catalyzed by Fe3O4/GO with initial parameters of pH 6.0, 1.0 g/L catalyst, and 10 mmol L−1 H2O2.

To demonstrate that the degradation of BPA by Fe3O4/GO and Fe3O4/GO/H2O2 was due to adsorption onto the Fe3O4/GO surface, a BPA-desorption experiment was performed in the Fe3O4/GO and Fe3O4/GO/H2O2 catalytic systems. As shown in Fig. 4, about 85 and 55 % BPA were desorbed in the Fe3O4/GO and Fe3O4/GO/H2O2 systems, respectively. This finding demonstrated that the degradation of BPA by Fe3O4/GO occurred because of adsorption on the Fe3O4/GO surface. However, only 55 % of BPA was desorbed in the Fe3O4/GO/H2O2 system, indicating that some BPA molecules were degraded into other products. This enhancement can be attributed to the fact that the performance of Fe3O4/GO was due to the small diameter and regular size of the particles. As shown in Fig. 3, Fe3O4/GO reached equilibrium in about 2 h. To better understand the degradation process, the factors affecting degradation in the aspect of adsorption for 2 h were determined through degradation experiments.

Experimental factors affecting Fenton catalysis

Effect of pH

Figure 5 shows that pH crucially influenced the removal of BPA with Fe3O4/GO by the Fenton reaction. Experiments were conducted at pH 2.0, 4.0, 6.0, and 8.0. Results showed that the degradation of BPA was >85 % in 4 h at pH 2.0. The reaction efficiency of the heterogeneous Fenton process reached the highest at around pH 2.0 and decreased with increased pH. In homogenous systems, pH ≈ 3 is known to be the optimum value for organic pollutant degradation by H2O2/Fe2+ (Arnold et al. 1995). The Harber–Weiss circle indicates that the generation of ·OH from H2O2 is the key step in the entire degradation process. The production of ·OH on the surface of Fe3O4/GO was gradually restricted with increased pH, which resulted in a slow degradation rate of BPA.

The formation of radicals from H2O2 and iron oxides has been previously proposed (Lin and Gurol 1998). The mechanism underlying H2O2 activation by Fe3O4/GO may involve the initial formation of a complex by ligand displacement between the hydrous surface of Fe(II)·H2O and H2O2, being assigned as Fe(II)·H2O2 (Eq. 3), where Fe(II)·H2O stands for Fe(α) sites on the hydrous catalyst surface. The initially generated Fe(II)·H2O2 species can produce ·OH by intramolecular electron transfer, and ·OH can readily degrade and mineralize BPA (Eqs. 4 and 5).

The generated Fe(II) subsequently produces ·OH (Eqs. 3, 4, and 5). Although ·OH can be produced from H2O2 when either Fe(II) or Fe(III) is present, the generation rates are much slower in the latter case (De Laat and Gallard 1999; Kwan and Voelker 2002). Compared with the other iron oxides, magnetite (Fe3O4) remained as the most effective catalyst (Kong et al. 1998) possibly because it was the only one with Fe(II) in its structure, which may enhance the production rate of ·OH (Kwan and Voelker 2002).

Effect of H2O2 dosage on BPA degradation

The oxidation of BPA over 1.0 g L−1 Fe3O4/GO at pH 6.0 and different H2O2 concentrations was also investigated, and the results are shown in Fig. 6. The degradation percentage of BPA increased from 82.7 to 88.4 % with increased H2O2 concentration from 5.0 to 30.0 mmol L−1. Given that BPA degradation is directly related to the concentration of the ·OH produced by the catalytic decomposition of H2O2, more BPA decomposition is expected with a higher increase in H2O2 concentration. However, a significant improvement was not observed at higher H2O2 concentrations (20.0 mmol L−1) after 6 h. Moreover, BPA degradation significantly decreased at an excessive H2O2 concentration of 30.0 mmol L−1.

The maximum H2O2 concentration for the effective degradation of BPA can be explained by the scavenging effect of ·OH by H2O2 (Xue et al. 2009). At a much higher H2O2 concentration, a competitive reaction existed between BPA and H2O2. ·OH reacted with H2O2 to produce hydroperoxy (·OOH) and superoxide anion (O2·−) according to the following equations (Eqs. 6 and 7):

Effect of catalyst loading on BPA degradation

The influence of catalyst loading on the heterogeneous Fenton degradation of BPA by Fe3O4/GO was investigated at different catalyst loadings (0.5, 1.0, and 2.0 g L−1). As shown in Fig. 7, the degradation efficiency of BPA increased from 81.7 to 85.0 % with increased Fe3O4/GO loading from 0.5 to 1.0 g L−1 at 10 mmol L−1 H2O2 after 10 h of reaction. This finding was due to the increased amount of active sites for the formation of ·OH and may be equally important for BPA adsorption. However, with increased catalyst dosage of up to 2.0 g L−1, the BPA degradation efficiency did not obviously increase because the excessive catalysts were hydroxyl radical scavengers (Eq. 8) that reduced the amount of generated ·OH (Malik 2004; Neyens and Baeyens 2003).

Mineralization of BPA

The results displayed in Fig. 8 show the removal efficiencies of TOC and BPA. In the initial stage of 15 min, the TOCremoval yield presented a very similar behavior to the degradation of BPA. The rate of TOCremoval was then lower than that of BPA degradation after 15 min, the maximum of TOCremoval was 64.7 % while that of BPA removal was nearly 85 %.

Reusability of Fe3O4/GO nanocomposites

Reusability is an important factor affecting catalyst application from an economic perspective. Figure 9 shows BPA degradation in a heterogeneous Fenton reaction catalyzed by Fe3O4/GO nanocomposites after three recycles. The reused catalyst Fe3O4/GO nanocomposites were found to retain their catalytic activity as efficiently as in the first cycle, and >80 % BPA was degraded in the third run. These results demonstrated that Fe3O4/GO nanocomposites as a catalyst had good stability and reusability.

GC–MS chromatograms of sample solution after degradation. Peak numbers correspond to those listed in Table 2. Other peaks are unidentified compounds and contaminants

Some catalysts with high efficiency in BPA degradation have been previously reported, including Au/carbon (Yang et al. 2013) and Fe3O4 magnetic nanoparticles (Huang et al. 2012). However, these catalysts are often expensive and immediately lose catalytic activity. Fe3O4/GO nanocomposites can overcome these drawbacks and, as heterogeneous catalysts, exhibit higher catalytic activity in BPA degradation than the Fe3O4, H2O2, Fe3O4/H2O2, and Fe3O4/GO reactions (Fig. 3). Therefore, Fe3O4/GO nanocomposites may be a promising heterogeneous catalyst that can be used to remove BPA from wastewater because of their high efficiency and reusability.

Identification of products and reaction mechanism

Six products were identified by GC–MS and assigned as products 1–6 (Fig. 10). Except for product 3, the other products were tentatively identified by comparing with identified products from the degradation reported in the literature because of the lack of authentic standards. The mass spectrum of BPA was used as a reference to interpret the fragmentation pattern of the products. Table 2 exhibits the mass spectra data of all products, including the molecular structures and characteristic fragment ions. Products 1–6 were identified as p-hydroquinone, 2-hexene,2,5,5-trimethyl, 2-methoxy,1,4-benzenediol, 4-isopropenylphenol, 4′-hydroxyacetophenone, and BPA, respectively. The percentage of the sum of the five intermediate products and remaining BPA concentrations to the initial BPA one was lower for the heterogeneous Fenton process after 10 h. The remaining percentage can be attributed to the presence of unidentified intermediates, analytical error, and/or loss of intermediates during the analytical process.

Based on the intermediate products listed in Table 2 and the results obtained by other researchers (Guo et al. 2009), the possible degradation pathway for BPA is proposed in Scheme 1. In the initial oxidation reaction, 4-isopropylphenol and p-hydroquinone were formed in the cleavage of phenyl groups in BPA by the attack of ·OH radicals. An oxidative ring-opening reaction at the level of C–C bonds between adjacent hydroxyl or ketone groups led to the formation of aliphatic compounds (Hong and Zeng 2002; Wu et al. 2001), followed by the evolution of CO2 gas.

Proposed reaction pathways of BPA degradation; 1–6* correspond to those in Table 2

Conclusions

A novel heterogeneous Fenton catalyst, Fe3O4/GO, was successfully prepared by the in situ growth of Fe3O4 nanoparticles on GO surface. The adsorption of BPA onto Fe3O4/GO was studied, and Fe3O4/GO was found to have a high ability for the adsorption of trace BPA in aqueous solution. Fe3O4/GO can be used as an efficient heterogeneous catalyst to adsorb and degrade trace BPA in aqueous solution by a heterogeneous Fenton reaction. The degradation process mainly occurred on the catalyst surface. The enhanced catalytic activity of Fe3O4/GO in the heterogeneous Fenton system caused by the positive effect of GO through the adsorption of trace pollutant molecules facilitated degradation. Five kinds of intermediate products of BPA were also identified during the heterogeneous Fenton process. The degradation pathway of BPA was proposed based on the identified by-products. The novel catalyst has many potential applications because of its good structural stability, simple separation, stable catalytic activity in a repetitive reaction cycle, and reusability.

References

Aliyan H, Fazaeli R, Jalilian R (2013) Fe3O4@ mesoporous SBA-15: a magnetically recoverable catalyst for photodegradation of malachite green. Appl Surf Sci 276:147–153

Arnold SM, Hickey WJ, Harris RF (1995) Degradation of atrazine by Fenton’s reagent: condition optimization and product quantification. Environ Sci Technol 29:2083–2089

Chou S, Huang C (1999) Application of a supported iron oxyhydroxide catalyst in oxidation of benzoic acid by hydrogen peroxide. Chemosphere 38:2719–2731

Costa RC, Lelis M, Oliveira L, Fabris J, Ardisson J, Rios R, Silva C, Lago R (2006) Novel active heterogeneous Fenton system based on Fe3-xMxO4 (Fe, Co, Mn, Ni): the role of M2+ species on the reactivity towards H2O2 reactions. J Hazard Mater 129:171–178

De Laat J, Gallard H (1999) Catalytic decomposition of hydrogen peroxide by Fe(III) in homogeneous aqueous solution: mechanism and kinetic modeling. Environ Sci Technol 33:2726–2732

Feng J, Hu X, Yue PL, Zhu HY, Lu GQ (2003) Discoloration and mineralization of Reactive Red HE-3B by heterogeneous photo-Fenton reaction. Water Res 37:3776–3784

Gültekin I, Ince NH (2007) Synthetic endocrine disruptors in the environment and water remediation by advanced oxidation processes. J Environ Manag 85:816–832

Guo C, Ge M, Liu L, Gao G, Feng Y, Wang Y (2009) Directed synthesis of mesoporous TiO2 microspheres: catalysts and their photocatalysis for bisphenol A degradation. Environ Sci Technol 44:419–425

Hong P, Zeng Y (2002) Degradation of pentachlorophenol by ozonation and biodegradability of intermediates. Water Res 36:4243–4254

Hu X, Liu B, Deng Y, Chen H, Luo S, Sun C, Yang P, Yang S (2011) Adsorption and heterogeneous Fenton degradation of 17α-methyltestosterone on nano Fe3O4/MWCNTs in aqueous solution. Appl Catal B Environ 107:274–283

Huang R, Fang Z, Yan X, Cheng W (2012) Heterogeneous sono-Fenton catalytic degradation of bisphenol A by Fe3O4 magnetic nanoparticles under neutral condition. Chem Eng J 197:242–249

Hummers WS Jr, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339–1339

Ioan I, Wilson S, Lundanes E, Neculai A (2007) Comparison of Fenton and sono-Fenton bisphenol A degradation. J Hazard Mater 142:559–563

Kim J-H, Park P-K, Lee C-H, Kwon H-H, Lee S (2008) A novel hybrid system for the removal of endocrine disrupting chemicals: nanofiltration and homogeneous catalytic oxidation. J Membr Sci 312:66–75

Klečka GM, Staples CA, Clark KE, van der Hoeven N, Thomas DE, Hentges SG (2009) Exposure analysis of bisphenol A in surface water systems in North America and Europe. Environ Sci Technol 43:6145–6150

Kong S-H, Watts RJ, Choi J-H (1998) Treatment of petroleum-contaminated soils using iron mineral catalyzed hydrogen peroxide. Chemosphere 37:1473–1482

Kwan WP, Voelker BM (2002) Decomposition of hydrogen peroxide and organic compounds in the presence of dissolved iron and ferrihydrite. Environ Sci Technol 36:1467–1476

Kwan WP, Voelker BM (2003) Rates of hydroxyl radical generation and organic compound oxidation in mineral-catalyzed Fenton-like systems. Environ Sci Technol 37:1150–1158

Liao C, Kannan K (2011) High levels of bisphenol A in paper currencies from several countries, and implications for dermal exposure. Environ Sci Technol 45:6761–6768

Lin S-S, Gurol MD (1998) Catalytic decomposition of hydrogen peroxide on iron oxide: kinetics, mechanism, and implications. Environ Sci Technol 32:1417–1423

Luo W, Zhu L, Wang N, Tang H, Cao M, She Y (2010) Efficient removal of organic pollutants with magnetic nanoscaled BiFeO3 as a reusable heterogeneous Fenton-like catalyst. Environ Sci Technol 44:1786–1791

Malik P (2004) Oxidation of safranine T in aqueous solution using Fenton’s reagent: involvement of an Fe(III) chelate in the catalytic hydrogen peroxide oxidation of safranine T. J Phys Chem A 108:2675–2681

Mohapatra D, Brar S, Tyagi R, Surampalli R (2011) Concomitant degradation of bisphenol A during ultrasonication and Fenton oxidation and production of biofertilizer from wastewater sludge. Ultrason Sonochem 18:1018–1027

Navalon S, Alvaro M, Garcia H (2010) Heterogeneous Fenton catalysts based on clays, silicas and zeolites. Appl Catal B Environ 99:1–26

Neyens E, Baeyens J (2003) A review of classic Fenton’s peroxidation as an advanced oxidation technique. J Hazard Mater 98:33–50

Nguyen TD, Phan NH, Do MH, Ngo KT (2011) Magnetic Fe2MO4 (M: Fe, Mn) activated carbons: fabrication, characterization and heterogeneous Fenton oxidation of methyl orange. J Hazard Mater 185:653–661

Noonan GO, Ackerman LK, Begley TH (2011) Concentration of bisphenol A in highly consumed canned foods on the US market. J Agric Food Chem 59:7178–7185

Oehlmann J, Oetken M, Schulte-Oehlmann U (2008) A critical evaluation of the environmental risk assessment for plasticizers in the freshwater environment in Europe, with special emphasis on bisphenol A and endocrine disruption. Environ Res 108:140–149

Ortiz de la Plata GB, Alfano OM, Cassano AE (2010) Decomposition of 2-chlorophenol employing goethite as Fenton catalyst II: reaction kinetics of the heterogeneous Fenton and photo-Fenton mechanisms. Appl Catal B Environ 95:14–25

Pan B, Xing B (2008) Adsorption mechanisms of organic chemicals on carbon nanotubes. Environ Sci Technol 42:9005–9013

Perez M, Torrades F, Domenech X, Peral J (2002) Fenton and photo-Fenton oxidation of textile effluents. Water Res 36:2703–2710

Staples CA, Dome PB, Klecka GM, Oblock ST, Harris LR (1998) A review of the environmental fate, effects, and exposures of bisphenol A. Chemosphere 36:2149–2173

Stieber M, Putschew A, Jekel M (2011) Treatment of pharmaceuticals and diagnostic agents using zero-valent iron–Kinetic studies and assessment of transformation products assay. Environ Sci Technol 45:4944–4950

Vandenberg LN, Maffini MV, Sonnenschein C, Rubin BS, Soto AM (2009) Bisphenol-A and the great divide: a review of controversies in the field of endocrine disruption. Endocr Rev 30:75–95

Wu C, Liu X, Wei D, Fan J, Wang L (2001) Photosonochemical degradation of phenol in water. Water Res 35:3927–3933

Xue X, Hanna K, Abdelmoula M, Deng N (2009) Adsorption and oxidation of PCP on the surface of magnetite: kinetic experiments and spectroscopic investigations. Appl Catal B Environ 89:432–440

Yang X, Tian P-F, Zhang C, Xu J, Deng Y-Q, Gong J, Han Y-F (2013) Au/carbon as Fenton-like catalysts for the oxidative degradation of bisphenol A. Appl Catal B Environ 134:145–152

Yang Z-P, Gong X-Y, Zhang C-J (2010) Recyclable Fe3O4/hydroxyapatite composite nanoparticles for photocatalytic applications. Chem Eng J 165:117–121

Zhao Y, Hu H (2008) Photo-Fenton degradation of 17 beta-estradiol in presence of alpha-FeOOHR and H2O2. Appl Catal B Environ 78:250–258

Acknowledgments

We are grateful for the grants from the National Natural Science Foundation of China (Grant no. 51308183, 51379060), Natural Science Foundation of Jiangsu Province of China (Grant no. BK20130828), Special Fund of Specialized Research Fund for the Doctoral Program of Higher Education (20130094120009), National Key Technologies R&D Program of China (2012BAB03B04), and Major Science and Technology Program for Water Pollution Control and Treatment (2012ZX07103-005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Hua, Z., Ma, W., Bai, X. et al. Heterogeneous Fenton degradation of bisphenol A catalyzed by efficient adsorptive Fe3O4/GO nanocomposites. Environ Sci Pollut Res 21, 7737–7745 (2014). https://doi.org/10.1007/s11356-014-2728-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-2728-8